Yfm350xp supplementary service manual lit-11616-15-09 3gd-28197-16.

Foreword this supplementary service manual has been prepared to introduce new service and new data for the yfm350xp. For complete information on service procedures, it is necessary to use this supple- mentary service manual together with the following manual. Yfm350xa service manual: 3gd-28197-12 yf...

Eb001000 notice this manual was produced by the yamaha motor company primarily for use by yamaha dealers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manual, so it is assumed that anyone who uses this book to perform maintenance and repairs on y...

How to use this manual construction of this manual this manual consists of chapters for the main categories of subjects. (see “illustrated symbols”) 1st title 1: this is a chapter with its symbol on the upper right of each page. 2nd title 2: this title appears on the upper of each page on the left o...

Eb003000 illustrated symbols illustrated symbols 1 to 9 are printed on the top right of each page and indicate the subject of each chapter. 1 general information 2 specifications 3 periodic checks and adjustments 4 engine 5 carburetion 6 drive train 7 chassis 8 electrical 9 troubleshooting illustrat...

Contents specifications ........................................................................................... 1 general specifications ................................................................. 1 maintenance specifications ........................................................ 2 engin...

– 1 – spec general specifications specifications general specifications model yfm350xp model code number: 5nf4 (except for california) 5nf5 (for california) spark plug: type/manufacturer dr8ea (ngk) gap 0.6 ~ 0.7 mm (0.024 ~ 0.028 in) electrical: ignition system dc. C.D.I. Charging system a.C. Magne...

– 2 – spec maintenance specifications maintenance specifications engine model yfm350xp cylinder: bore size 82.97 ~ 83.02 mm (3.267 ~ 3.269 in) taper limit piston: piston size “d” 82.92 ~ 82.97 mm (3.265 ~ 3.267 in) measuring point “h” 5.5 mm (0.22 in) (from bottom line of piston skirts) piston clear...

– 3 – spec maintenance specifications carburetor: i. D. Mark 3gd 00 (except for california) 3gd 10 (for california) main jet (m.J) #145 main air jet (m.A.J) 0.6 jet needle (j.N) 5j18-3 (except for california) 5j31-1 (except for california) needle jet (n.J) o-6 (except for california) o-6m (for calif...

– 4 – spec maintenance specifications chassis electrical model yfm350xp brake lever and brake pedal: brake lever free play 0 mm (0 in) at lever end brake pedal position 10 mm (0.4 in) brake pedal free play 8 mm (0.315 in) model yfm350xp c.D.I.: magneto model/manufacturer f4t466/mitsubishi pickup coi...

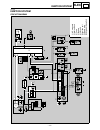

– 5 – spec cable routing 1 clutch switch 2 rear brake cable 3 clutch cable 4 front brake hose 5 front brake light switch 6 throttle cable 7 band È install the fuel tank breather hose into the hole of the handlebar cover. Cable routing.

– 6 – spec 1 main switch lead 2 handlebar switch lead 3 clutch switch lead 4 park switch lead 5 front brake light switch lead 6 fuel tank breather hose cable routing.

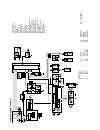

– 7 – spec 1 starter relay 2 neutral relay 3 tail/brake light 4 cdi unit 5 rectifier/regulator 6 fuse 7 battery breather hose È pass the battery breather hose through the inside of the frame bracket. É pass the battery breather hose through the guide. Cable routing.

– 8 – spec 1 battery negative lead 2 rear brake light switch 3 drive select lever switch 4 rear brake cable 5 rear brake hose 6 rectifier/regulator 7 cdi unit 8 carburetor overflow hose 9 rear brake light switch lead È pass the wire harness and starter motor lead through the holder. É fasten the wir...

– 9 – chk adj introduction/ periodic maintenance/lubrication intervals eb300000 periodic checks and adjustments introduction this chapter includes all information necessary to perform recommended inspections and adjust- ments. These preventive maintenance procedures, if followed, will ensure more re...

– 10 – chk adj periodic maintenance/lubrication intervals note: ● recommended brake fluid: dot4 ● brake fluid replacement: 1.When disassembling the master cylinder or caliper, replace the brake fluid. Normally check the brake fluid level and add fluid as required. 2.On the inner parts of the master ...

– 11 – chk adj adjusting the front brake/ adjusting the rear brake light switch chassis adjusting the front brake 1.Check: ● brake lever free play a out of specification → bleed the front brake system. Refer to “air bleeding (hydraulic brake system)” in chapter 3. (manual no.: 3gd-28197-12) adjustin...

– 12 – chas front suspension chassis front suspension 1 thrust cover 2 bushing 3 front upper arm 4 collar 5 front lower arm 6 shock absorber 7 steering knuckle.

– 13 – – + elec checking the switch electrical checking the switch checking the switch use a pocket tester to check the terminals for continuity. If the continuity is faulty at any point, replace the switch. Note: ● set the pocket tester to “0” before starting the test. ● the pocket tester should be...

– 14 – – + elec ignition system eb802000 ignition system circuit diagram off lo hi off on off push on off w /g w /g w /r r w /g w /r r o o w w w w r br br r /b r /w b w w r w /gr w /rw /g rw /g w /lw /r lr /b r /wb r g /yb bb rb r w ww r /bl br r /w w ww b (gra y) rb www (green) g /ws b br w /b (gra...

– 15 – – + elec ignition system eb802010 troubleshooting procedure check: 1.Fuse 2.Battery 3.Spark plug 4.Ignition spark gap 5.Spark plug cap resistance 6.Ignition coil resistance if the ignition system fails to operate (no spark or intermittent spark): 7.Engine stop switch 8.Main switch 9.Pickup co...

– 16 – – + elec ignition system correct spark plug gap: 0.8 ~ 0.9 mm (0.031 ~ 0.035 in) incorrect repair or replace the spark plug. For usa and cdn 4.Ignition spark gap ● disconnect the spark plug cap from the spark plug. ● connect the dynamic spark tester 1 as shown. 2 spark plug cap 3 spark plug ●...

– 17 – – + elec ignition system 5.Spark plug cap resistance ● remove the spark plug cap. ● connect the pocket tester ( Ω × 1k) to the spark plug cap. * meets specification ● check that the spark plug cap has the specified resistance. Spark plug cap resistance: 10 k Ω at 20 °c (68 °f) out of specific...

– 18 – – + elec ignition system both meet specification ● connect the pocket tester ( Ω × 1k) to the ignition coil. Tester (+) lead → orange lead terminal tester (–) lead → spark plug lead ● check that the secondary coil has the specified resistance. Secondary coil resistance: 6.32 ~ 9.48 k Ω at 20 ...

– 19 – – + elec ignition system c0ntinuity meets specification 10.Charging/rotor rotation direction detec- tion coil resistance ● disconnect the ac magneto coupler from the wire harness. ● connect the pocket tester ( Ω × 100) to the charging/rotor rotation direction detection coil terminal. Tester (...

– 20 – – + elec signal system eb806000 signal system circuit diagram off lo hi off on off push on off w /g w /g w /r r w /g w /r r o o w w w w r br br r /b r /w b w w r w /gr w /rw /g rw /g w /lw /r lr /b r /wb r g /yb bb rb r w ww r /bl br r /w w ww b (gra y) rb www (green) g /ws b br w /b (gra y) ...

– 21 – – + elec signal system checking the signal system 1.If the tail/brake light fails to come on: continuity 1.Bulb and bulb socket ● check the bulb and bulb socket for continu- ity. No continuity replace the bulb and/or bulb socket. Continuity 2.Brake light switches refer to “checking the switch...

Yamaha motor co., ltd. 2500 shingai iwata shizuoka japan printed in u.S.A..

Yfm350xp wiring diagram off lo hi off on off push on off w /g w /g w /r r w /g w /r r o o w w w w r br br r /b r /w b w w r w /gr w /rw /g rw /g w /lw /r lr /b r /wb r g /yb bb rb r w ww r /bl br r /w w ww b (gra y) rb www (green) g /ws b br w /b (gra y) (gra y) yb r (bla ck) bb (bla ck) br www b b ...