- DL manuals

- Yamaha

- Motorcycle

- 2003 FJR1300

- Service Manual

Yamaha 2003 FJR1300 Service Manual

Summary of 2003 FJR1300

Page 1

2003 fjr1300(r) fjr1300a(r) 5jw1-ae4 supplementary service manual.

Page 3: Foreword

Foreword this supplementary service manual has been prepared to introduce new service and data for the fjr1300(r)/fjr1300a(r) 2003. For complete service information procedures it is necessary to use this supplementary service manual together with the following manuals. Fjr1300(n) 2001 service manual...

Page 4: Notice

Eas00002 notice this manual was produced by the yamaha motor company, ltd. Primarily for use by yamaha deal- ers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manual. Therefore, anyone who uses this book to perform maintenance and repairs on yama...

Page 5: How to Use This Manual

Eas00007 how to use this manual this manual is intended as a handy, easy-to-read reference book for the mechanic. Comprehensive explanations of all installation, removal, disassembly, assembly, repair and check procedures are laid out with the individual steps in sequential order. 1 the manual is di...

Page 6: Symbols

Eas00008 symbols the following symbols are not relevant to every vehicle. Symbols 1 to 9 indicate the subject of each chapter. 1 general information 2 specifications 3 periodic checks and adjustments 4 chassis 5 engine 6 cooling system 7 fuel injection system 8 electrical system 9 troubleshooting sy...

Page 7: Contents

Contents general information ..............................................................................1 special tools ......................................................................................1 specifications .............................................................................

Page 8

Electrical ...............................................................................................131 electrical components .............................................................131 checking the switches ...............................................................133 immobilizer sy...

Page 9: – 1 –

– 1 – gen info special tools general information eb104000 special tools the following special tool is necessary for complete and accurate tune-up and assembly. Use only the appropriate special tool as this will help prevent damage caused by the use of inappro- priate tools or improvised techniques. ...

Page 10: – 2 –

– 2 – spec specifications general specifications item standard limit model code fjr1300: 5jwa (for europe) 5jwb (for f) 5jwc (for oceania) fjr1300a: 5vs1 (for europe) 5vs2 (for f) 5vs3 (for oceania) ---- ---- ---- ---- ---- ---- dimensions overall length 2,195 mm ---- overall width 760 mm ---- overa...

Page 11: – 3 –

– 3 – spec engine specifications engine specifications item standard limit engine engine type liquid-cooled, 4-stroke, dohc ---- displacement 1,298 cm 3 ---- cylinder arrangement forward-inclined parallel 4-cylinder ---- bore × stroke 79.0 × 66.2 mm ---- compression ratio 10.8 : 1 ---- engine idling...

Page 12: – 4 –

– 4 – spec engine specifications cooling system radiator capacity (including all routes) 3.2 l ---- radiator capacity 1.03 l ---- radiator cap opening pressure 93.3 ~ 122.7 kpa (0.93 ~ 1.23 kg/cm 2 , 0.93 ~ 1.23 bar) ---- valve relief pressure 4.9 kpa (0.05 kg/cm 2 , 0.05 bar) ---- radiator core wid...

Page 13: – 5 –

– 5 – spec chassis specifications chassis specifications item standard limit front tire tire type tubeless ---- size 120/70 zr17 m/c (58w) ---- model (manufacturer) mez4j front (metzeler)/ bt020f n (bridgestone) ---- tire pressure (cold) 0 ~ 90 kg 250 kpa (2.5 kgf/cm 2 , 2.5 bar) ---- 90 ~ 201 kg (f...

Page 14: – 6 –

– 6 – spec chassis specifications front suspension suspension type telescopic fork ---- front fork type coil spring/oil damper ---- front fork travel 135 mm ---- spring free length 264 mm 259 mm spacer length 149.5 mm ---- installed length 249 mm ---- spring rate (k1) 7.84 n/mm (0.8 kgf/mm) ---- spr...

Page 15: – 7 –

– 7 – spec chassis specifications rear suspension suspension type swingarm (link suspension) ---- rear shock absorber assembly type coil spring/gas-oil damper ---- rear shock absorber assembly travel 60 mm ---- upper spring free length 156 mm 152.88 mm installed length 138.1 mm ---- lower spring fre...

Page 16: – 8 –

– 8 – spec electrical specifications item standard limit system voltage 12 v ---- ignition system ignition system type transistorized coil ignition (digital) ---- ignition timing 5° btdc at 1,050 r/min ---- advancer type electric ---- pickup coil resistance/color 420.8 ~ 569.3 Ω/gy–b ---- transistor...

Page 17: – 9 –

– 9 – spec coolant temperature sensor model (manufacturer) 8cc (mitsubishi) ---- resistance 5.21 ~ 6.37 k Ω at 0 °c 0.290 ~ 0.354 k Ω at 80 °c ---- ---- fuses (amperage × quantity) main fuse 50 a × 1 ---- fuel injection system fuse 15 a ---- headlight fuse 25 a × 1 ---- signaling system fuse 15 a × ...

Page 18: – 10 –

– 10 – spec tightening torques chassis tightening torques part to be tightened thread size tightening torque remarks nm m·kg fuel tank and frame m6 10 1.0 fuel tank and fuel tank bracket m8 15 1.5 front wheel sensor and sensor housing m8 30 3.0 fjr1300a front brake pipe (hydraulic unit to front brak...

Page 19: – 11 –

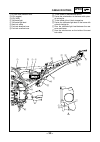

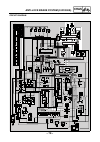

– 11 – spec cable routing fjr1300 1 throttle cable 2 brake hose 3 clutch hose 4 main switch lead/immobilizer lead 5 headlight lead 6 fuse box 7 thermostat assembly breather hose 8 coolant reservoir hose 9 hazard switch 0 rectifier/regulator a plate b plunger control unit hose 2 c radiator d radiator...

Page 20: – 12 –

– 12 – spec È pass the right handlebar switch lead under the handlebar. É pass the left handlebar switch lead under the handlebar. Ê pass the wire harness, stator coil lead, coolant reservoir hose, and thermostat assembly breather hose through the left slit of the plate. Ë to the thermostat housing ...

Page 21: – 13 –

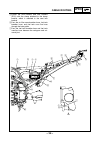

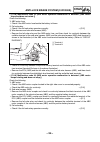

– 13 – spec 1 brake hose 2 right handlebar switch lead 3 throttle cable 4 starter relay lead 5 battery 6 positive battery lead 7 main fuse 8 front turn signal lead 9 spark plug lead #4 0 spark plug lead #1 a ignition coil leads #1 and #4 b front turn signal extension-lead c ignition coils #1 and #4 ...

Page 22: – 14 –

– 14 – spec È fasten the positive battery lead to the battery stay with a plastic locking tie. É fasten the positive battery lead and main fuse lead with a plastic locking tie to the battery stay. Ê insert the front turn signal leads into the inner panel. Ë install the connector so that the ignition...

Page 23: – 15 –

– 15 – spec Ñ support the coolant reservoir hose and coolant reservoir breather hose with the hose holder located under the coolant reservoir. Ò pass the coolant reservoir breather hose through the hole of the coolant reservoir breather hose holder. Ó fasten spark plug leads #1 and #4 at the num- be...

Page 24: – 16 –

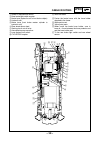

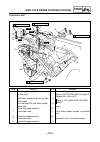

– 16 – spec 1 immobilizer lead 2 main switch lead 3 left handlebar switch lead 4 hazard switch 5 rectifier/regulator 6 clutch hose 7 fuel tank breather hose 8 fuel tank overflow hose 9 stator coil lead 0 sidestand switch a sidestand switch lead b oil level switch lead c brake hose d coolant reservoi...

Page 25: – 17 –

– 17 – spec È to the radiator fan É pass the wire harness, stator coil lead, coolant reservoir hose, and thermostat assembly breather hose through the left slit of the plate. Ê to the right side of the frame Ë fasten the wire harness with the plastic band attached to the frame. Ì to the fuel tank Í ...

Page 26: – 18 –

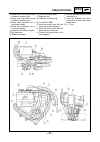

– 18 – spec 1 ecu 2 tail/brake light 3 tail/brake light lead 4 seat lock cable 5 fuel tank breather hose 6 fuel tank overflow hose 7 air filter case breather hose È to the intake air temperature sensor É fasten the wire harness to the frame with a plastic locking tie. Ê to the inside of the u-lock s...

Page 27: – 19 –

– 19 – spec 1 air cut-off valve 2 clutch hose 3 left handlebar switch lead 4 headlight lead 5 main switch lead 6 immobilizer lead 7 throttle cable 8 right handlebar switch lead 9 t-bar 0 spark plug lead #3 a spark plug lead #2 b spark plug lead #1 c spark plug lead #4 d cable guide e throttle positi...

Page 28: – 20 –

– 20 – spec È connect the wire harness and right handlebar switch lead. É pass the left handlebar switch lead, immobilizer lead, main switch lead, headlight lead, and clutch hose through the hole on the left side of the frame. Ê pass the right handlebar switch lead and throttle cables through the ho...

Page 29: – 21 –

– 21 – spec Ò support the throttle cables with the t-bar located behind the cable guide. Ó pass the throttle cables under spark plug leads #1, #2, #3, and #4, and the wire harness, head- light lead, main switch lead, immobilizer lead, right handlebar switch lead, and left handlebar switch lead. Inst...

Page 30: – 22 –

– 22 – spec 1 intake air temperature sensor 2 lean angle circuit cut-off relay 3 starting circuit cut-off relay 4 atmospheric pressure sensor 5 cyclelock coupler 6 seat lock cable È to the rear brake light switch É pass the rear brake light switch through the lead guide attached to the frame. Ê pass...

Page 31: – 23 –

– 23 – spec cable routing fjr1300a 1 throttle cable 2 brake hose (front brake master cylinder to hydraulic unit) 3 clutch hose 4 main switch/immobilizer lead 5 front wheel sensor lead 6 headlight lead 7 brake hose (hydraulic unit to front brake caliper) 8 right handlebar switch lead 9 fuse box 0 the...

Page 32: – 24 –

– 24 – spec È pass the right handlebar switch lead under the handlebar. É pass the left handlebar switch lead under the handlebar. Ê pass the clutch hose and left handlebar switch lead through the guide. Ë install the front wheel sensor lead grommet into the holder. Ì pass the brake hose (front brak...

Page 33: – 25 –

– 25 – spec Ò pass the radiator fan lead on the outside of the plate. Ó fasten the brake hoses to the frame. Ô tighten the brake hose joint bolt, union bolt, and brake hose holder bolt in the proper tightening sequence as shown. Õ when replacing the brake hoses, remove the engine from the frame. A a...

Page 34: – 26 –

– 26 – spec 1 brake hose (front brake master cylinder to hydraulic unit) 2 right handlebar switch lead 3 throttle cable 4 starter relay lead 5 battery 6 horn lead 7 positive battery lead 8 main fuse 9 spark plug lead #4 0 front turn signal lead a spark plug lead #1 b ignition coils #1 and #4 c front...

Page 35: – 27 –

– 27 – spec È fasten the positive battery lead to the battery stay with a plastic locking tie. É fasten the positive battery lead and main fuse lead to the bat- tery stay with a plastic locking tie. Ê insert the front turn signal leads into the inner panel. Ë install the connector so that ignition c...

Page 36: – 28 –

– 28 – spec Ñ support the coolant reservoir hose and coolant reservoir breather hose with the hose holder located under the coolant reservoir. Ò pass the coolant reservoir breather hose through the hole of the coolant reservoir breather hose holder. The coolant reservoir hose end must extend at leas...

Page 37: – 29 –

– 29 – spec 1 tail/brake light lead 2 hydraulic unit 3 brake hose (front brake master cylinder to hydraulic unit) 4 brake hose (hydraulic unit to rear brake caliper) 5 brake hose (hydraulic unit to front brake caliper) 6 brake hose (rear brake master cylinder to hydraulic unit) 7 rear wheel sensor l...

Page 38: – 30 –

– 30 – spec 1 immobilizer lead 2 main switch lead 3 left handlebar switch lead 4 hazard switch 5 rectifier/regulator 6 clutch hose 7 stator coil lead 8 fuel tank breather hose 9 fuel tank overflow hose 0 sidestand switch a sidestand switch lead b oil level switch lead c front wheel sensor d brake ho...

Page 39: – 31 –

– 31 – spec È pass the wire harness, stator coil lead, coolant reservoir hose, and thermostat assembly breather hose through the left slit of the plate. É to the right side of the frame Ê fasten the wire harness with the plastic band attached to the frame. Ë to the fuel tank Ì pass the stator coil l...

Page 40: – 32 –

– 32 – spec Ò pass the brake hose (hydraulic unit to front brake caliper) and front wheel sensor through the brake hose holder. Ó 60 ~ 70 mm Ô 43 ~ 53 mm Õ to the radiator fan Ö fasten the clutch hose with the hose holder attached to the frame. × fasten the headlight lead and the front wheel sensor ...

Page 41: – 33 –

– 33 – spec 1 air filter case breather hose 2 ecu (engine) 3 ecu (abs) 4 tail/brake light 5 tail/brake light lead 6 seat lock cable 7 fuel tank breather hose 8 fuel tank overflow hose È to the intake air temperature sensor É fasten the wire harness to the frame with a plas- tic locking tie. Ê to the...

Page 42: – 34 –

– 34 – spec Î fasten the wire harness and wire harness (ecu) with the clamp attached to the clamp bracket, which is attached to the seat lock bracket. Ï pass the air filter case breather hose, fuel tank breather hose, and fuel tank over flow hose through the hose guide. Ð pass the fuel tank breather...

Page 43: – 35 –

– 35 – spec 1 ecu (engine) 2 wire harness 3 ecu (abs) 4 sub-wire harness (abs) 5 rear wheel sensor lead 6 brake hose (rear brake master cylinder to hydraulic unit) 7 brake hose (hydraulic unit to rear brake caliper) 8 brake hose (hydraulic unit to front brake caliper) 9 brake hose (front brake maste...

Page 44: – 36 –

– 36 – spec 1 air cut-off valve 2 clutch hose 3 front wheel sensor lead 4 left handlebar switch lead 5 headlight lead 6 main switch lead 7 immobilizer lead 8 throttle cable 9 right handlebar switch lead 0 brake hose (front brake master cylinder to hydraulic unit) a t-bar b spark plug lead #3 c spark...

Page 45: – 37 –

– 37 – spec È connect the wire harness and right handlebar switch lead. É pass the left handlebar switch lead, front wheel sensor lead, immobilizer lead, main switch lead, headlight lead, and clutch hose through the hole on the left side of the frame. Ê pass the brake hoses, right handlebar switch l...

Page 46: – 38 –

– 38 – spec Ò support the throttle cables with the t-bar located behind the cable guide. Ó pass the throttle cables under spark plug leads #1, #2, #3, and #4, and the wire harness, head- light lead, main switch lead, immobilizer lead, right handlebar switch lead, and left handlebar switch lead. Inst...

Page 47: – 39 –

– 39 – spec 1 intake air temperature sensor 2 rear brake light switch coupler 3 brake hose (hydraulic unit to front brake caliper) 4 hydraulic unit 5 brake hose (front brake master cylinder to hydraulic unit) 6 rear wheel sensor lead 7 starting circuit cut-off relay 8 atmospheric pressure sensor 9 l...

Page 48: – 40 –

– 40 – spec Í pass the cyclelock coupler through the inside of the storage box of the u-lock. Î pass the cyclelock coupler through the lead guide. Ï pass the wire harnesses under the tray bracket. 1 Ì 2 3 4 6 7 8 9 a 0 È É Ê È Ë Í Î Ï 5 cable routing.

Page 49: – 41 –

– 41 – spec 1 brake hose (front brake master cylinder to hydraulic unit) 2 brake hose (rear brake master cylinder to hydraulic unit) 3 brake hose (hydraulic unit to rear brake caliper) 4 brake hose (hydraulic unit to front brake caliper) 5 hydraulic unit solenoid coupler 6 fail-safe relay 7 abs moto...

Page 50: – 42 –

– 42 – chk adj introduction/periodic maintenance and lubrication chart eas00036 periodic checks and adjustments introduction this chapter includes all information necessary to perform recommended checks and adjustments. If followed, these preventive maintenance procedures will ensure more reliable v...

Page 51: – 43 –

– 43 – chk adj periodic maintenance and lubrication chart note: • the air filter needs more frequent service if you are riding in unusually wet or dusty areas. • hydraulic brake and clutch service • regularly check and, if necessary, correct the brake and clutch fluid levels. • every two years repla...

Page 52: – 44 –

– 44 – chk adj seats and fuel tank seats and fuel tank eas00040 fuel tank order job/part q’ty remarks removing the fuel tank remove the parts in the order listed. Rider seat refer to “seats and fuel tank” in chapter 3. (manual no.: 5jw1-ae1) fuel drain. 1 fuel tank side panel (left and right) 1/1 2 ...

Page 53: – 45 –

– 45 – chk adj seats and fuel tank order job/part q’ty remarks 12 bolt 1 13 fuel tank 1 refer to “removing the fuel tank” in chapter 3. (manual no.: 5jw1-ae1) for installation, reverse the removal procedure..

Page 54: – 46 –

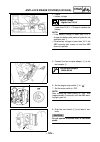

– 46 – chk adj installing the fuel pump 1. Install: • fuel pump note: • do not damage the installation surfaces of the fuel tank when installing the fuel pump. • always use a new fuel pump gasket. • install the fuel pump as shown in the illustra- tion. • tighten the fuel pump bolts in stages in a cr...

Page 55: – 47 –

– 47 – chk adj cowlings and covers eas00041 cowlings and covers cowlings 1 3 5 12 4 8 9 10 6 7 11 14 15 t r . . 10 nm (1.0 m • kg) 2 13 order job/part q’ty remarks removing the cowlings remove the parts in the order listed. Rider seat refer to “seats and fuel tank” in chapter 3. (manual no.: 5jw1-ae...

Page 56: – 48 –

– 48 – chk adj 1 3 5 12 4 8 9 10 6 7 11 14 15 t r . . 10 nm (1.0 m • kg) 2 13 order job/part q’ty remarks 11 front left inner panel (front cowling) 1 12 accessory box solenoid coupler 1 13 clamp 1 14 sub-wire harness coupler 3 15 front cowling assembly 1 for installation, reverse the removal procedu...

Page 57: – 49 –

– 49 – chk adj (7) 1 2 3 4 5 0 0 a a 5 6 7 9 8 order job/part q’ty remarks disassembling the front cowling assembly remove the parts in the order listed. 1 windshield outer bracket 1 2 windshield 1 3 grommet 7 4 windshield inner bracket 1 5 rear view mirror (left and right) 2 6 panel 1 7 front cowli...

Page 58: – 50 –

– 50 – chk adj electrical system eas00185 adjusting the headlight beams the following procedure applies to both of the headlights. 1. Adjust: • headlight beam (vertically) ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ a. Turn the adjusting knob 1 in direction a or b. ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ...

Page 59: – 51 –

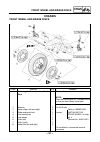

– 51 – chas front wheel and brake discs eas00514 chassis front wheel and brake discs order job/part q’ty remarks removing the front wheel and brake discs remove the parts in the order listed. Note: place the motorcycle on a suitable stand so that the front wheel is elevated. 1 reflector 2 for aus on...

Page 60: – 52 –

– 52 – chas rear wheel and brake disc rear wheel and brake disc eas00560 order job/part q’ty remarks disassembling the rear wheel remove the parts in the order listed. 1 dust cover 1 2 rear wheel drive hub 1 3 dust seal 1 4 wheel bearing 1 5 rear wheel drive hub damper 6 6 oil seal 1 7 circlip 1 8 w...

Page 61: – 53 –

– 53 – chas installing the bearing 1. Install: • bearing 1 a 3.5 ~ 4.5 mm b rear wheel a b 1 rear wheel and brake disc.

Page 62: – 54 –

– 54 – chas front and rear brakes front and rear brakes eas00586 rear brake master cylinder È fjr1300a order job/part q’ty remarks removing the rear brake master cyl- inder remove the parts in the order listed. Side cover (right) refer to “cowlings and covers” in chapter 3. (manual no.: 5jw1-ae1) br...

Page 63: – 55 –

– 55 – chas front and rear brakes È fjr1300a order job/part q’ty remarks 8 union bolt 1 refer to “disassembling/ assembling the rear brake master cylinder” in chapter 4. (manual no.: 5jw1-ae1) 9 copper washer 2 10 brake hose 1 disconnect. 11 cotter pin 1 12 pin 1 13 brake master cylinder 1 for insta...

Page 64: – 56 –

– 56 – chas eas00587 order job/part q’ty remarks disassembling the rear brake mas- ter cylinder remove the parts in the order listed. 1 dust boot 1 2 circlip 1 3 push rod 1 4 brake master cylinder kit 1 5 brake master cylinder 1 for assembly, reverse the disassembly procedure. Front and rear brakes.

Page 65: – 57 –

– 57 – chas handlebars right handlebar order job/part q’ty remarks removing the right handlebar remove the parts in the order listed. 1 front brake light switch connector 2 disconnect. 2 brake master cylinder holder 1 refer to “removing/ installing the handlebars” in chapter 4. (manual no.: 5jw1-ae1...

Page 66: – 58 –

– 58 – chas anti-lock brake system (fjr1300a) abs outline yamaha abs features 1. The yamaha abs (anti-lock brake system) features a dual electronic control system, which acts on the front and rear brakes independently. 2. The abs features a compact and lightweight design to help maintain the basic m...

Page 67: – 59 –

– 59 – chas anti-lock brake system (fjr1300a) eas00872 abs the operation of the yamaha abs brakes is the same as conventional motorcycles, with a brake lever for operating the front wheel brake and a brake pedal for operating the rear wheel brake. When wheel lockup is detected during emer- gency bra...

Page 68: – 60 –

– 60 – chas anti-lock brake system (fjr1300a) • slip ratio: when the brakes are applied, slipping occurs between the tires and the road sur- face. This causes a difference between the wheel speed and the chassis speed. Slip ratio is the value that shows the rate of wheel slippage and is defined by t...

Page 69: – 61 –

– 61 – chas eas00875 wheel slip and hydraulic control the ecu (abs) calculates the wheel speed of each wheel according to the rotation signal received from the front and rear wheel sen- sors. In addition, the ecu (abs) calculates the motorcycle chassis speed and the rate of speed reduction based on ...

Page 70: – 62 –

– 62 – chas the higher the cornering force on a tire, the less traction there is available for braking. This is true whether the motorcycle is equipped with an abs or not. Therefore, sudden braking while cornering is not recommended. Exces- sive cornering force, which an abs cannot pre- vent, could ...

Page 71: – 63 –

– 63 – chas eas00877 electronic abs features the yamaha abs (anti-lock brake system) has been developed with the most advanced electronic technology. The abs control is processed with good response providing various travel conditions for motorcy- cles. The abs also includes a highly developed self-d...

Page 72: – 64 –

– 64 – chas eas00878 abs component functions • wheel sensors and sensor rotors wheel sensors 1 detect the wheel rotation speed and transmit the wheel rotation signal to the ecu (abs). Each wheel sensor is composed of a perma- nent magnet and a coil. The wheel sensors are installed in the sensor hous...

Page 73: – 65 –

– 65 – chas eas00879 • hydraulic unit the hydraulic unit 1 is composed of a hydrau- lic control valve (solenoid valve, flow control valve), a buffer chamber, and a hydraulic pump for each brake and an abs motor. The hydraulic unit adjusts the front and rear wheel brake fluid pressure to control the ...

Page 74: – 66 –

– 66 – chas • hydraulic control valve the hydraulic control valve is composed of a flow control valve and solenoid valve. When the abs is activated, the flow control valve regulates the flow of brake fluid to each brake and the solenoid valve decreases and increases the brake fluid pressure. 1) when...

Page 75: – 67 –

– 67 – chas • buffer chamber the buffer chamber accumulates the brake fluid that is depressurized while the abs is operating. 1 buffer chamber (pressurized) 2 buffer chamber (depressurized) 3 raised piston • electronic control unit (ecu) the ecu (abs) 1 controls the abs and is installed under the tr...

Page 76: – 68 –

– 68 – chas as shown in the block diagram below, the ecu (abs) receives wheel sensor signals from the front and rear wheels and also receives signals from other monitor circuits. Both a main microcomputer and a sub microcomputer are installed in the ecu (abs) to provide mutual monitoring. 1 battery ...

Page 77: – 69 –

– 69 – chas • abs control operation the abs control operation performed in the ecu (abs) is divided into the following two parts. • hydraulic control • self-diagnosis these operations are performed once every 8/1,000 of a second. When a failure is detected in the abs, a malfunction code is stored in...

Page 78: – 70 –

– 70 – chas anti-lock brake system (fjr1300a) • fail-safe relay the fail-safe relay controls the power supply of the hydraulic unit and is located beside the hydraulic unit. 1 fail-safe relay composition and operation the fail-safe relay is composed of the solenoid relay 1 and abs motor relay 2. The...

Page 79: – 71 –

– 71 – chas anti-lock brake system (fjr1300a) abs operation the abs hydraulic circuit consists of two systems: the front wheel and rear wheel. The following describes the front system only. • normal braking (abs not activated) when the abs is not activated port d a of the solenoid valve is closed be...

Page 80: – 72 –

– 72 – chas • emergency braking (abs activated) 1) depressurized state when the front wheel is about to lockup, port d a of the solenoid valve is opened by the “depres- surization” signal transmitted from the ecu (abs). When this occurs, the spool of the flow control valve compresses the return spri...

Page 81: – 73 –

– 73 – chas anti-lock brake system (fjr1300a) 2) pressurized state port d a is closed by the “pressurization” signal transmitted from the ecu (abs). Before this occurs, the spool of the flow control valve has compressed the return spring to close port b 9. Brake fluid that has entered through port a...

Page 82: – 74 –

– 74 – chas anti-lock brake system (fjr1300a) eas00880 self-diagnosis function • abs warning light the abs warning light 1 comes on when a malfunction is detected by the abs self-diag- nosis. It is located in the meter assembly. • instances when the abs warning light comes on 1) the abs warning ligh...

Page 83: – 75 –

– 75 – chas anti-lock brake system (fjr1300a) 4) the abs warning light 4 flashes and mal- function code 3 is indicated on the multi- function display when a test coupler adaptor 2 is connected to the 4-pin test coupler 1 for troubleshooting the abs. The 4-pin test coupler can be accessed by removing...

Page 84: – 76 –

– 76 – chas anti-lock brake system (fjr1300a) cautions for operation * wheel lock: a condition that occurs when the rotation of one or both of the wheels has stopped but the motorcycle continues to travel. Abs warning light: • when the main switch is set to “on”, the abs warning light comes on for 2...

Page 85: – 77 –

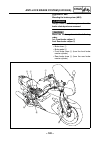

– 77 – chas anti-lock brake system (fjr1300a) eas00882 abs components 1 front brake hose (front brake master cylinder to hydraulic unit) 2 abs warning light 3 fuse box 4 front brake hose (hydraulic unit to front brake caliper) 5 front wheel sensor 6 front wheel sensor rotor 7 abs test coupler 8 elec...

Page 86: – 78 –

– 78 – chas anti-lock brake system (fjr1300a) eas00883 abs couplers w1 b1 gy w gy w gy w b/w r/l b r/l y br/w l/w b1 lg sb b2 w1 g/r lg sb b1 b2 w1 g/r l/w y br/w w2 b3 r b b r/w (black) (green) (green) r/g b2 br/r r/w g/w y/l g/l g/r lg y l ch w dg b sb w/r lg w w r r r g r w b r/w br/w r p/w g/r w...

Page 87: – 79 –

– 79 – chas anti-lock brake system (fjr1300a) eas00884 circuit diagram on off p r r r br /l br /r bb1 bb2 bb4 bb3 g /y br bl y ch dg y dg b l /r ch dg ch br/w br/w ch dg br /w br /g b /r r /b b /r r /b r /b b /r b b l /y b /y b /y l /y (black) (black) r r r r br /l br /l b b /w r r /l b b /w r r /l ...

Page 88: – 80 –

– 80 – chas anti-lock brake system (fjr1300a) 2 main switch 5 abs fuse 7 main fuse 8 abs motor fuse 9 battery [ sub-wire harness (abs) \ ecu (abs) ] rear wheel sensor _ fail-safe relay a hydraulic unit b abs test coupler c front wheel sensor k abs warning light l multifunction meter ß rear brake lig...

Page 89: – 81 –

– 81 – chas anti-lock brake system (fjr1300a) troubleshooting eas00881 abs troubleshooting outline use this section to troubleshoot the abs. Read this service manual carefully and make sure you understand the information provided before repairing any malfunctions or performing service. The electroni...

Page 90: – 82 –

– 82 – chas anti-lock brake system (fjr1300a) 3. Handling and service caution: handling the abs components with care since they have been accurately adjusted. Keep them away from dirt and do not subject them to shocks. • the ecu (abs), hydraulic unit, wheel sensors, and fail-safe relay cannot be dis...

Page 91: – 83 –

– 83 – chas eas00886 basic troubleshooting process note: _ do not delete the malfunction codes during troubleshooting. Delete the malfunction codes only after service has been completed. Warning _ when maintenance or checks have been performed on components related to the abs, be sure to per- form a...

Page 92: – 84 –

– 84 – chas eas00887 abs troubleshooting • [a] abs malfunction check using the abs warning light set the main switch to “on”. (do not start the engine.) 1) warning light does not come on. → [b-1] 2) warning light remains on. → [b-2] 3) warning light flashes. → [b-3] 4) warning light comes on for 2 s...

Page 93: – 85 –

– 85 – chas • [b-4] abs malfunction check using the abs self-diagnosis (past malfunction) remove the right inner panel (front cowling) and the front right inner panel (front cowling) to access the test coupler 1. Remove the protective cap and connect the test coupler adaptor 2 to the test coupler. T...

Page 94: – 86 –

– 86 – chas • [b-5] abs malfunction check using the abs self-diagnosis (present malfunction) note: _ before proceeding, read [b-3], “function of the test coupler terminals”. Remove the right inner panel (front cowling) and the front right inner panel to access the test cou- pler. Remove the protecti...

Page 95: – 87 –

– 87 – chas • [c] determining the cause and location of the malfunction • [c-1] only the abs warning light does not come on when the main switch is set to “on” note: _ check following the steps in sequence. 1. Visual check 1) check the abs fuse. Determine the cause of the blown fuse and repair. Repl...

Page 96: – 88 –

– 88 – chas • [c-3] abs warning light flashes with the engine off, check the front and rear brake switches. Check if the brake light comes on when the front or rear brake is applied. 1) the light does not come on for only one brake. → the corresponding brake switch connector is disconnected. (refer ...

Page 97: – 89 –

– 89 – chas • [c-5] diagnosis by the malfunction code malfunction codes are used to determine the malfunctions that have occurred. (refer to “[b-4] abs malfunction check using the abs self-diagnosis (past malfunction)” and “[b-5] abs malfunction check using the abs self-diagnosis (present malfunctio...

Page 98: – 90 –

– 90 – chas *1 malfunction code 11 is indicated if the rear wheel rotates for more than 20 seconds with the front wheel stopped. Note: _ malfunction code 15 (front wheel sensor) or 16 (rear wheel sensor) is displayed if a defective con- nection to either the front or rear sensor is detected whether ...

Page 99: – 91 –

– 91 – chas • [c-5-1] malfunction code 11 (front wheel sensor signal is not received correctly.) set the main switch to “off”, then back to “on” after removing the test coupler adaptor. 1) abs warning light remains on. → defective connection in the front wheel sensor circuit. • front wheel sensor co...

Page 100: – 92 –

– 92 – chas • [c-5-3] malfunction codes 13 (front wheel) and 14 (rear wheel) (incorrect signal is detected from either the front or rear wheel.) 1) the wheel sensors or sensor rotors are not properly installed. 1 installation of the front or rear wheel sensor • check that the wheel sensor is properl...

Page 101: – 93 –

– 93 – chas • [c-5-6] malfunction code 31 (disconnection is detected between the fail-safe relay and the hydraulic unit solenoid.) check the following: 1) abs motor fuse • check if the abs motor fuse beside the battery is blown. 2) hydraulic unit solenoid coupler • check if the hydraulic unit soleno...

Page 102: – 94 –

– 94 – chas • [c-5-8] malfunction code 33 (abs motor operation malfunction is detected. [abs motor stops and does not rotate.]) check the following: 1) abs motor fuse • check if the abs motor fuse beside the battery is blown. 2) fail-safe relay • check if the fail-safe relay operates correctly. → [d...

Page 103: – 95 –

– 95 – chas • [c-5-10] malfunction code 41 (front wheel does not recover from the locking tendency even though the signal is continuously transmitted from the ecu (abs) to release the hydraulic pressure [when the battery voltage is normal].) check the following: 1) rotation of the front wheel • chec...

Page 104: – 96 –

– 96 – chas 5) hydraulic unit solenoid coupler terminal • check if the front and rear hydraulic unit solenoid coupler terminals (hydraulic unit and sub-wire harness [abs]) are reversed. 6) hydraulic unit if the malfunction is not corrected after performing steps 1) to 5), replace the hydraulic unit....

Page 105: – 97 –

– 97 – chas • check that the connections of the brake hose lines from the brake master cylinder to the hydrau- lic unit and to the rear brake caliper from the hydraulic unit are correct. Warning _ the rear brake will not function properly if the connections are reversed. • rear brake hose 1 inlet: f...

Page 106: – 98 –

– 98 – chas • [c-5-12] malfunction code 51 (front wheel does not recover from the locking tendency even though the signal is continuously transmitted from the ecu (abs) to release the hydraulic pressure [when the battery voltage is low].) check the following: 1) rotation of the front wheel refer to ...

Page 107: – 99 –

– 99 – chas • [c-5-13] malfunction code 52 (rear wheel does not recover from the locking tendency even though the signal is continuously transmitted from the ecu (abs) to release the hydraulic pressure [when the battery voltage is low].) check the following: 1) rotation of the rear wheel refer to “[...

Page 108: – 100 –

– 100 – chas eas00888 ecu (abs) and fail-safe relay 3 4 7 6 1 2 5 order job/part q’ty remarks removing the ecu (abs) and fail- safe relay remove the parts in the order listed. Air filter case refer to “air filter case” in chapter 3. (manual no.: 5jw1-ae1) 1 abs motor coupler 1 disconnect. 2 hydrauli...

Page 109: – 101 –

– 101 – chas [d-1] maintenance of the ecu (abs) • removing the ecu (abs) 1. Remove: • ecu (abs) 1 note: _ when removing the ecu (abs), take care not to damage the ecu (abs) or ecu (abs) cou- plers. 2. Remove: • ecu (abs) coupler 1 • ecu (abs) coupler 2 note: _ do not pull the ecu (abs) leads to remo...

Page 110: – 102 –

– 102 – chas • checking the fail-safe relay 1. Check: • solenoid relay for continuity connect the pocket tester ( Ω × 1) to the ter- minals. Check for continuity between terminals 3 and 4 of the solenoid relay. Tester positive probe → terminal 3 tester negative probe → terminal 4 tester reading is “...

Page 111: – 103 –

– 103 – chas 2. Check: • abs motor relay for continuity connect the pocket tester ( Ω × 1) to the ter- minals of the abs motor relay. Check for continuity between terminals 1 and 6 of the abs motor relay. Tester positive probe → terminal 1 tester negative probe → terminal 6 tester reading is “ ∞”. →...

Page 112: – 104 –

– 104 – chas eas00889 front wheel sensor and sensor rotor 1 3 2 1 3 6 5 9 10 7 10 8 t r . . 7 nm (0.7 m • kg) t r . . 40 nm (4.0 m • kg) t r . . 30 nm (3.0 m • kg) t r . . 23 nm (2.3 m • kg) t r . . 72 nm (7.2 m • kg) ls lt lt (6) (6) 4 . Order job/part q’ty remarks removing the front wheel sensor a...

Page 113: – 105 –

– 105 – chas 1 3 2 1 3 6 5 9 10 7 10 8 t r . . 7 nm (0.7 m • kg) t r . . 40 nm (4.0 m • kg) t r . . 30 nm (3.0 m • kg) t r . . 23 nm (2.3 m • kg) t r . . 72 nm (7.2 m • kg) ls lt lt (6) (6) 4 . Order job/part q’ty remarks 9 collar (right) 1 10 brake disc (left and right) 2 for installation, reverse ...

Page 114: – 106 –

– 106 – chas anti-lock brake system (fjr1300a) [d-3] maintenance of the front wheel sensor and sensor rotor • abs wheel sensor and sensor rotor caution: _ • handle the abs components with care since they have been accurately adjusted. Keep them away from dirt and do not sub- ject them to shocks. • t...

Page 115: – 107 –

– 107 – chas anti-lock brake system (fjr1300a) 2. Measure: • front wheel sensor resistance connect the pocket tester ( Ω × 1k) to the terminals of the front wheel sensor coupler. Tester positive probe → terminal 1 tester negative probe → terminal 2 out of specification → replace. 3. Check: • front w...

Page 116: – 108 –

– 108 – chas anti-lock brake system (fjr1300a) 2. Install: • front wheel sensor 1 • front wheel sensor lead holder 2 • brake caliper 3 • brake hose holder 4 note: _ when installing the front wheel sensor, check the wheel sensor lead for twists and the sensor electrode for foreign materials. Caution:...

Page 117: – 109 –

– 109 – chas anti-lock brake system (fjr1300a) eas00890 rear wheel sensor and sensor rotor . Order job/part q’ty remarks removing the rear wheel sensor and sensor rotor remove the parts in the order listed. Note: place the motorcycle on a suitable stand so that the rear wheel is elevated. Ecu (abs) ...

Page 118: – 110 –

– 110 – chas anti-lock brake system (fjr1300a) . Order job/part q’ty remarks 9 sensor housing 1 10 brake disc 1 for installation, reverse the removal procedure..

Page 119: – 111 –

– 111 – chas anti-lock brake system (fjr1300a) [d-4] maintenance of the rear wheel sensor and sensor rotor caution: • be sure not to contact the sensor elec- trode to any metal part when removing the front wheel sensor from the sensor housing. • do not operate the brake lever when removing the brake...

Page 120: – 112 –

– 112 – chas anti-lock brake system (fjr1300a) • installing the rear wheel sensor 1. Install: • rear wheel note: • align the slot a of the sensor housing 1 with the projection b of the rear brake cali- per assembly 2, and then assemble them. • after installation, check that the projection c of the r...

Page 121: – 113 –

– 113 – chas anti-lock brake system (fjr1300a) eas00891 hydraulic unit t r . . 30 nm (3.0 m • kg) t r . . 30 nm (3.0 m • kg) t r . . 16 nm (1.6 m • kg) 3 4 3 1 2 1 5 6 5 7 8 7 12 9 13 11 t r . . 16 nm (1.6 m • kg) 10 new new new new order job/part q’ty remarks removing the hydraulic unit remove the ...

Page 122: – 114 –

– 114 – chas anti-lock brake system (fjr1300a) t r . . 30 nm (3.0 m • kg) t r . . 30 nm (3.0 m • kg) t r . . 16 nm (1.6 m • kg) 3 4 3 1 2 1 5 6 5 7 8 7 12 9 13 11 t r . . 16 nm (1.6 m • kg) 10 new new new new order job/part q’ty remarks 6 rear brake hose 1 (rear brake master cylinder to hydraulic un...

Page 123: – 115 –

– 115 – chas anti-lock brake system (fjr1300a) [d-5] maintenance of the hydraulic unit caution: _ do not remove the hydraulic unit to check the resistance of the solenoid valves and the abs motor for continuity. Warning _ refill with the same type of brake fluid that is already in the system. Mixing...

Page 124: – 116 –

– 116 – chas anti-lock brake system (fjr1300a) • checking the resistance of the solenoid valves and abs motor for continuity caution: when check the hydraulic unit solenoid relay and abs motor, do not remove the brake hoses. 1. Measure: • resistance of the solenoid valve (front) connect a pocket tes...

Page 125: – 117 –

– 117 – chas anti-lock brake system (fjr1300a) • removing the hydraulic unit 1. Remove: • brake hose 1 (from the front brake master cylinder) • brake hose 2 (to the front brake caliper) • brake hose 3 (from the rear brake master cylinder) • brake hose 4 (to the rear brake caliper) note: _ do not ope...

Page 126: – 118 –

– 118 – chas anti-lock brake system (fjr1300a) • installing the hydraulic unit proceed in the reverse order of disassembly. Pay attention to the following items. 1. Install: • hydraulic unit bracket 1 1 note: tighten the nuts in the proper sequence. T r . . 16 nm (1.6 m · kg) 2. Install: • hydraulic...

Page 127: – 119 –

– 119 – chas anti-lock brake system (fjr1300a) 5. Fill: • brake master cylinder reservoirs 6. Bleed the brake system. 7. Check the operation of the hydraulic unit according to the brake lever and the brake pedal response. (refer to “[d-6-3-1] hydraulic unit operation test 1”.) caution: _ always chec...

Page 128: – 120 –

– 120 – chas anti-lock brake system (fjr1300a) hydraulic abs eas00892 bleeding the brake system (abs) warning _ always bleed the brake system when the brake related parts are removed. Caution: _ bleed the brake system in the following order. 1st: front brake caliper a 2nd: rear brake caliper b • bra...

Page 129: – 121 –

– 121 – chas anti-lock brake system (fjr1300a) bleeding the abs for fjr1300a 1 hydraulic unit 2 brake caliper 3 solenoid valve 4 buffer chamber 5 hydraulic pump 6 brake master cylinder pressure 7 hydraulic pump pressure eas00134 bleeding the abs brake warning bleed the abs whenever: • the system is ...

Page 130: – 122 –

– 122 – chas anti-lock brake system (fjr1300a) 1. Remove: • right side cover refer to “cowlings and covers” in chapter 3. (manual no.: 5jw1-ae1) 2. Bleed: • abs ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ a. Fill the brake fluid reservoir to the proper level with the recommended brake fluid. B...

Page 131: – 123 –

– 123 – chas anti-lock brake system (fjr1300a) l. Tighten the bleed screw to the specified torque. M. Fill the brake fluid reservoir to the proper level with the recommended brake fluid. Refer to “checking the brake fluid level” in chapter 3. (manual no.: 5jw1-ae1) warning after bleeding the abs, ch...

Page 132: – 124 –

– 124 – chas anti-lock brake system (fjr1300a) 2. Check: • installation of the wheel sensors to the sen- sor housings (refer to “[d-3] maintenance of the front wheel sensor and sensor rotor” and “[d-4] maintenance of the rear wheel sensor and sensor rotor”.) t r . . Wheel sensor 30 nm (3.0 m·kg) hyd...

Page 133: – 125 –

– 125 – chas anti-lock brake system (fjr1300a) 4. Check: • battery voltage lower than 12.8 v → charge or replace the battery. Note: _ • if the battery voltage is lower than 12.8 v, charge the battery and perform hydraulic unit operation test 1. • if the battery voltage is lower than 10 v, the abs wa...

Page 134: – 126 –

– 126 – chas anti-lock brake system (fjr1300a) 9. After releasing the start switch, operate the brake lever and the brake pedal simulta- neously. Note: • a reaction-force pulsating action is gener- ated in the brake lever 1 0.5 second after the brake lever and the brake pedal are oper- ated simultan...

Page 135: – 127 –

– 127 – chas anti-lock brake system (fjr1300a) 12.Set the main switch to “off”. 13.Remove the test coupler adaptor from the test coupler. 14.Set the main switch to “on”. 15.Set the engine stop switch to “ ”. • [d-6-3-2] hydraulic unit operation test 2 warning _ securely support the motorcycle so tha...

Page 136: – 128 –

– 128 – chas anti-lock brake system (fjr1300a) 6. Set the main switch to “on” while operating the brake lever and the brake pedal simulta- neously. Caution: _ when the main switch is set to “on”, be sure to operate both the brake levers and the brake pedal simultaneously. If only the brake levers or...

Page 137: – 129 –

– 129 – chas anti-lock brake system (fjr1300a) 3. Set the engine stop switch 1 to “ ”. Caution: _ be sure to set the engine stop switch to “ ”. If the start switch is pushed without setting the engine stop switch to “ ”, the starter motor gears or other parts may be damaged. 4. Push the start switch...

Page 138: – 130 –

– 130 – chas anti-lock brake system (fjr1300a) • [d-6-6] delete function test 1. Place the motorcycle on the centerstand. 2. Set the main switch to “off”. 3. Connect the test coupler adapter to the test coupler. 4. Set the main switch to “on”. 5. Check: • ecu voltage connect the pocket tester (dc 20...

Page 139: – 131 –

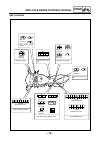

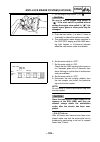

– 131 – – + elec electrical components eas00729 electrical electrical components 1 windshield drive unit 2 battery 3 starter relay 4 fuel injection system fuse 5 front brake switch 6 clutch switch 7 fuse box 8 radiator fan motor 9 wire harness 0 neutral switch a sidestand switch b oil level switch c...

Page 140: – 132 –

– 132 – – + elec electrical components 1 coolant temperature sensor 2 intake air pressure sensor 3 intake air temperature sensor 4 atmospheric pressure sensor 5 lean angle cut-off switch 6 hydraulic unit (fjr1300a) 7 fail-safe relay (fjr1300a) 8 ecu (engine) 9 ecu (abs) (fjr1300a) 0 starting circuit...

Page 141: – 133 –

– 133 – – + elec checking the switches eas00731 checking the switches check each switch for damage or wear, proper connections, and also for continuity between the ter- minals. Refer to “checking switch continuity” in chapter 8. (manual no.: 5jw1-ae1) damage/wear → repair or replace. Improperly conn...

Page 142: – 134 –

– 134 – – + elec 1 main fuse 2 main switch 3 clutch switch 4 pass switch 5 dimmer switch 6 horn switch 7 windshield position switch 8 turn signal switch 9 front brake light switch 0 engine stop switch a start switch b rear brake light switch c neutral switch d sidestand switch e oil level switch f h...

Page 143: – 135 –

– 135 – – + elec immobilizer system eb805000 immobilizer system circuit diagram on off p r r r br /l br /r bb1 bb2 bb4 bb3 g /y br bl y ch dg y dg b l /r ch dg ch br/w br/w ch dg br /w br /g b /r r /b b /r r /b r /b b /r b b l /y b /y b /y l /y (black) (black) r r r r br /l br /l b b /w r r /l b b /...

Page 144: – 136 –

– 136 – – + elec immobilizer system general information this vehicle is equipped with an immobilizer system to help prevent theft by re-registering codes in the standard keys. This system consists of the following. • a code re-registering key (with a red bow) • two standard keys (with a black bow) t...

Page 145: – 137 –

– 137 – – + elec immobilizer system key codes registration method in the course of use, you may encounter the following case where replace these parts and registra- tion of code re-registering/standard key is required. Note: each standard key is registered during production, therefore re-registering...

Page 146: – 138 –

– 138 – – + elec immobilizer system standard key registration: when you lose a standard key and need a new one. Or when the code re-registering key is re-reg- istered after the immobilizer unit or ecu, are replaced. Note: it is prohibited to start the engine with the standard key that is not registe...

Page 147: – 139 –

– 139 – – + elec immobilizer system 6. Check that the engine can be started with the two registered standard keys. Note: the flashing stops when 5 seconds elapse and the registration mode is finished. In this case, the second standard key cannot be registered and only the first standard key is regis...

Page 148: – 140 –

– 140 – – + elec self-diagnosis error code indication when the system failure occurred, the error code number is indicated in the immobilizer system indicator light blinks at the same time. The pattern of blinking also shows the error code. Immobilizer system indicator light error code indication di...

Page 149: – 141 –

– 141 – – + elec immobilizer system eas00781 troubleshooting check: 1. Main, ignition and backup fuses 2. Battery 3. Main switch 4. Wiring (of the entire immobilizer system) note: • before troubleshooting, remove the following part(s). 1) rider seat 2) fuel tank 3) right inner panel (front cowling) ...

Page 150: – 142 –

– 142 – – + elec immobilizer system checking the immobilizer system 1. Immobilizer system indicator light does not go on when the main switch is set to “on”. Yes no yes no yes no 1. Voltage • connect the pocket tester (dc 20 v) to the meter assembly coupler as shown. Tester positive probe → green/bl...

Page 151: – 143 –

– 143 – – + elec immobilizer system yes no 4. Voltage • connect the pocket tester (dc 20 v) to the immobilizer unit coupler as shown. Tester positive probe → green/blue 1 tester negative probe → black 2 • set the main switch to “on”. • measure the voltage (12 v) between green/blue and black on the i...

Page 152: – 144 –

– 144 – – + elec immobilizer system 2. When the main switch is set to “on”, the immobilizer system indicator light flashes after 1 sec- ond. • check if metal or other immobilizer system keys exists near the immobilizer unit. If found, remove the metal or keys, and then check the condition again. Set...

Page 153: – 145 –

– 145 – – + elec accessory box system accessory box system circuit diagram r r on off p r r r br /l br /r bb1 bb2 bb4 bb3 g /y br bl y ch dg y dg b l /r ch dg ch br/w br/w ch dg br /w br /g b /r r /b b /r r /b r /b b /r b b l /y b /y b /y l /y (black) (black) r r r r br /l br /l b b /w r r /l b b /w...

Page 154: – 146 –

– 146 – – + elec accessory box system eas00781 troubleshooting caution: before troubleshooting, make sure that the transmission is in neutral. Check: 1. Main and signaling system fuses 2. Battery 3. Main switch 4. Neutral switch 5. Accessory box relay 6. Accessory box solenoid 7. Wiring (of the enti...

Page 155: – 147 –

– 147 – – + elec accessory box system eas00759 yes no yes no eas00818 yes no 5. Accessory box relay • disconnect the accessory box relay from the wire harness. • connect the pocket tester ( Ω × 1) and bat- tery (12 v) to the accessory box relay termi- nals as shown. Battery positive terminal → brown...

Page 156: – 148 –

– 148 – trbl shtg troubleshooting with the abs warning light troubleshooting troubleshooting with the abs warning light when the main switch is set to “on”. (engine does not start.) only the abs warning light does not come on • blown, damaged, or incorrect fuse (abs fuse) • defective connection of t...

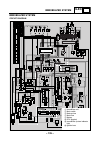

Page 157: Fjr1300A Wiring Diagram

Fjr1300a wiring diagram 1 immobilizer unit 2 main switch 3 rectifier/regulator 4 generator 5 abs fuse 6 backup fuse (odometer, clock and windshield) 7 main fuse 8 abs motor fuse 9 battery 0 fuel injection system fuse a starter relay b starter motor c relay unit d starting circuit cut-off relay e fue...

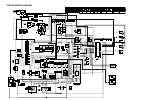

Page 158: Fjr1300 Wiring Diagram

Fjr1300 wiring diagram 1 immobilizer unit 2 main switch 3 rectifier/regulator 4 generator 5 backup fuse (odometer, clock and windshield) 6 main fuse 7 battery 8 fuel injection system fuse 9 starter relay 0 starter motor a relay unit b starting circuit cut-off relay c fuel injection system relay d ne...

Page 160

Yamaha motor co., ltd. 2500 shingai iwata shizuoka japan.

Page 161: Fjr1300A Wiring Diagram

Fjr1300a wiring diagram on off p r r r br/l br/r bb1 bb2 bb4 bb3 g/y br b l y ch dg y dg b l/r ch dg ch br/w br/w ch dg br/w br/g b/r r/b b/r r/b r/b b/r b b l/y b/y b/y l/y (black) (black) r r r r br/l br/l b b/w r r/l b b/w r r/l br/r br/r (black) (gray) w w w b g/w b r/l r b b b r r r r r br/l br...

Page 162: Fjr1300 Wiring Diagram

Fjr1300 wiring diagram on off p r r r br/l br/r bb1 bb2 bb4 bb3 g/y br b l y ch dg y dg b l/r ch dg ch br/w br/w ch dg br/w br/g b/r r/b b/r r/b r/b b/r b b l/y b/y b/y l/y (black) (black) r r r r br/l br/l br/r br/r (black) (gray) w w w b g/w b r/l r b b b r r r r r br/l br/y b b b r r r b l/w r/g ...