- DL manuals

- Yamaha

- Bicycle

- 2004 TT600RE

- Service Manual

Yamaha 2004 TT600RE Service Manual

Summary of 2004 TT600RE

Page 1

Yamaha ────────── tt600r ────────── m.Y 1997-2007 service manual.

Page 2: How to Use This Manual

Eas00007 how to use this manual this manual is intended as a handy, easy-to-read reference book for the mechanic. Comprehensive ex- planations of all installation, removal, disassembly, assembly, repair and check procedures are laid out with the individual steps in sequential order. 1 the manual is ...

Page 3: Gen

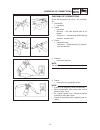

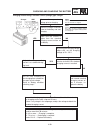

Illustrated symbols the following symbols are not relevant to every vehicle. Illustrated symbols 1 to 8 are printed on the top right of each page and indicate the subject of each chapter. 1 general information 2 specifications 3 periodic inspections and adjustments 4 chassis 5 engine 6 carburetor 7 ...

Page 4: General Information

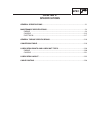

General information table of contents gen info 1 specifications spec 2 periodic inspection and adjustments insp adj 3 engine eng 5 carburetion carb 6 chassis chas 4 electrical elec 7 troubleshooting trbl shtg 8 ? E004000

Page 6: Gen

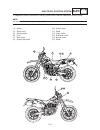

1 gen info.

Page 7: Gen

Gen info chapter 1. General information motorcycle identification ......................................................................................1-1 vehicle identification number..........................................................................1-1 model label ............................

Page 8: Gen

Gen info.

Page 9: Gen

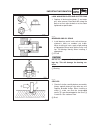

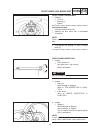

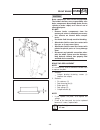

1-1 gen info vehicle identification 1 general information vehicle identification vehicle identification number the vehicle identification number 1 is stamped in- to the frame. Model label the model label 1 is affixed to the frame under the seat. This information will be needed to order spare parts..

Page 10: Gen

Gen info important information 1-2 eb101000 important information preparation for removal procedures 1. Remove all dirt, mud, dust and foreign materi- al before removal and disassembly. 2. Use proper tools and cleaning equipment. Refer to the “special tools” section. 3. When disassembling the machin...

Page 11: Gen

Gen info important information 1-3 eb101030 lock washers/plates and cotter pins 1. Replace all lock washers/plates 1 and cotter pins after removal. Bend lock tabs along the bolt or nut flats after the bolt or nut has been tightened to specification. Eb101040 bearings and oil seals 1. Install bearing...

Page 12: Gen

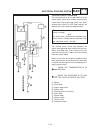

Gen info checking of connections 1-4 eb801000 checking of connections check the connectors for stains, rust, moisture, etc. 1. Disconnect: • connector 2. Check: • connector moisture → dry each terminal with an air blower. Stains/rust → connect and disconnect the terminals several times. 3. Check: • ...

Page 13: Gen

1-5 gen info special tools special tools the following special tools are necessary for complete and accurate tune-up and assembly. Use only the appropriate special tools; this will help prevent damage caused by the use of inappropriate tools or impro- vised techniques. When placing an order, refer t...

Page 14: Gen

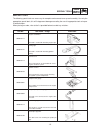

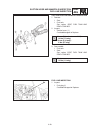

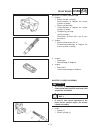

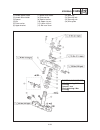

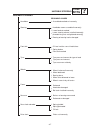

1-6 gen info special tools tool no. 90890-01083 rocker arm shaft puller bolt these tools are used when removing the rocker arm shafts. Tool name / usage illustration 90890-01084 weight these tools are used when removing the rocker arm shafts. 90890-04019 valve spring compressor these tools are used ...

Page 15: Gen

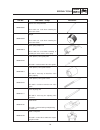

1-7 gen info special tools tool no. Tool name / usage illustration 90890-04086 all-purpose clutch holder this tool is used to lock the clutch, when the clutch boss lock nut is being loosened or tightened. 90890-01135 crankcase separating tool this tool is necessary to disassemble the crankcase. 9089...

Page 16: Gen

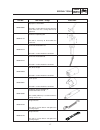

1-8 gen info special tools tool no. Tool name / usage illustration 90890-11043 du bush/oil seal guide this tool is used to install the du bush and the fork oil seal. 90890-01326 t-handle this tool is needed to loosen and tighten the front fork damper rod holding bolt. 90890-01460 front fork damper r...

Page 17: Spec

2 spec.

Page 18: Spec

Spec chapter 2. Specifications general specifications ............................................................................................ 2-1 maintenance specifications ....................................................................................2-4 engine ..............................

Page 19: Spec

Spec.

Page 20: Spec

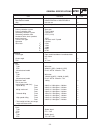

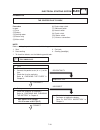

Spec general specifications 2-1 specifications general specifications item standard limit model tt600re: 5ch5 dimensions overall length 2,220 mm ••• overall width 865 mm ••• overall height 1,195 mm ••• seat height 890 mm ••• wheelbase 1,480 mm ••• ground clearance 280 mm ••• minimum turning radius 3...

Page 21: Spec

Spec general specifications 2-2 item standard limit spark plug manufacturer/model ngk/dpr8ea-9 or ngk/dpr9ea-9 gap 0.8–0.9 mm ••• clutch type wet. Multiple-disc transmission primary reduction system spur gear primary reduction ratio 71/34 (2.088) secondary reduction system chain drive secondary redu...

Page 22: Spec

Spec general specifications 2-3 item standard limit brakes front: type single Ø 267 mm disk brake, 2 x 28 mm operation right hand fluid dot 4 rear: type single Ø 220 mm disk brake, 1 x 34 mm caliper operation right foot fluid dot 4 suspension front telescopic fork outside tube dia. 46 mm rear deltab...

Page 23: Spec

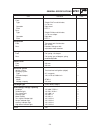

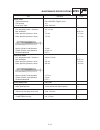

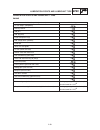

Spec maintenance specifications 2-4 maintenance specifications engine item standard limit cylinder head max. Warpage ••• 0.03 mm cylinder bore 94.970 - 95.020 mm 95.10 mm measuring point 50 mm ••• camshaft drive system chain drive (left) camshaft cap inside diameter 23.000 - 23.021 mm ••• camshaft j...

Page 24: Spec

Spec maintenance specifications 2-5 item standard limit timing chain model/number of links 75-010/126 tensioning system automatic rocker arm/rocker arm shaft arm inside diameter 12.000 - 12.018 mm ••• shaft outside diameter 11.976 - 11.991 mm ••• arm-to-shaft clearance 0.009 - 0.042 mm ••• valve, va...

Page 25: Spec

Spec maintenance specifications 2-6 item standard limit valve spring inner spring: free length intake 40.10 mm 38.10 mm exhaust 40.10 mm 38.10 mm installed length (valve closed) intake 22.70 mm ••• exhaust 22.70 mm ••• compressed spring force (installed) intake 164.80 - 190.20 n ••• 16.80 - 19.39 kg...

Page 26: Spec

Spec maintenance specifications 2-7 item standard limit piston ring top ring: ring type barrel dimensions (b x t) 1.20 x 3.80 mm ••• end gap (installed) 0.30 - 0.45 mm 0.70 mm ring side clearance 0.040 - 0.080 mm 0.130 mm 2 nd ring: ring type plain dimensions (b x t) 1.20 x 3.80 mm ••• end gap (inst...

Page 27: Spec

Spec maintenance specifications 2-8 item standard limit ballancer ballancer drive method gear clutch clutch release method inner push, cam push friction plate thickness 2.72 - 2.88 mm ••• wear limit ••• 2.60 mm plate quantity 6 pcs friction plate thickness 2.94 - 3.06 mm ••• wear limit ••• 2.8 mm pl...

Page 28: Spec

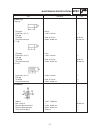

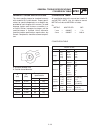

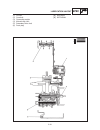

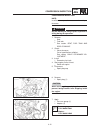

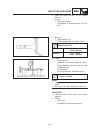

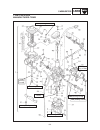

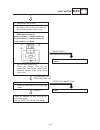

2-9 spec maintenance specifications cylinder head tightening steps: crankcase tightening steps: right crankcase left crankcase engine.

Page 29: Spec

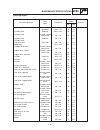

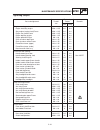

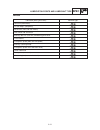

Spec maintenance specifications 2-10 tightening part torque part to be tightened name thread size remarks nm mkg cylinder head washer based bol m8 x 1.25 29 2.9 cylinder head stud bolt m10 x 1.25 20 2.0 cylinder head hexagon socket head screw m6 x 1.0 10 1.0 cylinder head stud bolt m6 x 1.0 7 0.7 cy...

Page 30: Spec

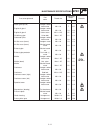

Spec maintenance specifications 2-11 tightening part torque part to be tightened name thread size remarks nm mkg stator (pick-up coil) hexagon socket head screw m6 x 1.0 7 0.7 engine oil pipe 1 hexagon socket head screw m6 x 1.0 10 1.0 engine oil pipe 2 union screw m12 x 1.25 35 3.5 oil delivery pip...

Page 31: Spec

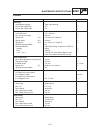

Spec maintenance specifications 2-12 item standard limit steering steering bearing type taper roller bearing lock to lock angle (left) 45° ••• lock to lock angle (right) 45° ••• front suspension front fork travel 277 - 283 mm ••• fork spring free length 530 mm ••• spring rate (k1) 7.0 n/mm (0.71 kgf...

Page 32: Spec

Spec maintenance specifications 2-13 item standard limit drive chain type/manufacturer 520 135orsb / regina chain link quantity 114 drive chain slack 30.0 - 40.0 mm ••• front disc brake disc outside diameter x thickness 267 x 4 mm ••• max. Deflection ••• 0.15 mm brake pad lining thickness-inner 7.5 ...

Page 33: Spec

Spec maintenance specifications 2-14 tightening part to be tightened thread torque remarks size n · m m · kg engine mounting and rear frame: engine front/stay engine m10 x 1.25 64 6.4 stay engine (engine front)/frame m10 x 1.25 64 6.4 engine rear under/frame m10 x 1.25 68 6.8 engine top/stay engine ...

Page 34: Spec

Spec maintenance specifications 2-15 tightening part to be tightened thread torque remarks size n · m m · kg front brake: front hub/disc brake m6 x 1.0 12 1.2 front caliper/front fork m8 x 1.25 25 2.5 front caliper/bleeder tightening m10 x 1.0 14 1.4 union bolt tightening (front) m10 x 1.0 20 2.0 re...

Page 35: Spec

Spec maintenance specifications 2-16 tightening part to be tightened thread torque remarks size n · m m · kg starting motor cord/starting motor m6 x 1.0 11 1.1 wire minus lead (-)/starting motor m6 x 1.0 10 1.0 front flasher lights/stay, headlight m6 x 1.0 1.5 0.15 clutch wire/engine m6 x 1.0 7 0.7 ...

Page 36: Spec

Spec maintenance specifications 2-17 item standard limit ignition system ignition timing (b.T.D.C.) 12° / 1,300 r/min ••• advanced timing (b.T.D.C.) 31° / 7,500 r/min ••• advancer type electrical type transistorized coil ignition pickup coil resistance 230 Ω ± 20% l/y-g/w ••• t.C.I. Unit model/manuf...

Page 37: Spec

Spec maintenance specifications 2-18 item standard limit horn horn type plane quantity 1 pcs manufacturer leonelli max. Amperage 1.5 a ••• flasher relay type semi-transistor ••• model/manufacturer fb222m/nippondenso ••• self cancelling device no ••• flasher frequency 75 - 95 cycle/min ••• wattage 10...

Page 38: Spec

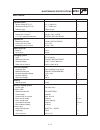

2-19 general torque specifications this chart specifies torque for standard fasteners with standard i.S.O. Pitch threads. Torque specifi- cations for special components or assemblies are provided for each chapter of this manual. To avoid warpage, tighten multi-fastener assemblies in a crisscross fas...

Page 39: Spec

2-20 spec lubrlcatlon points and lubricant type lubrlcatlon points and lubricant types engine lubrication points (part name) lubricant type oil seal edges (completely) bearing retainer rod pins rod (big end) piston and piston rings hub (weight drive sprocket) piston pin valve stim and guide oil seal...

Page 40: Spec

2-21 spec lubrlcatlon points and lubricant type chassis lubrication points (part name) lubricant type gear unit (tachometer) oil seal edges (completely) wheel axle (front and rear wheels) rear wheel hub and clutch bearings brasses (rear arm) and bearing push cover front footrest pivot points (brake ...

Page 41: Spec

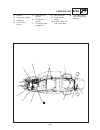

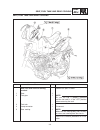

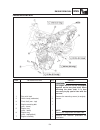

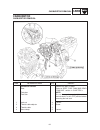

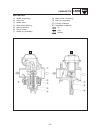

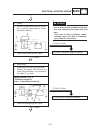

2-22 spec lubrication layout lubrication layout (1) oil tank (2) oil pump (3) oil filter (oil tank) (4) oil strainer (engine) (5) oil vapour retrieval hose (6) oil blow-by retrieval hose [a] delivery [b] retrieval.

Page 42: Spec

Spec lubrication layout 2-23 (1) oil pump (2) oil filter (3) camshaft (4) oil delivery hose (5) main driving shaft (6) drive shaft [a] delivery [b] retrieval a b.

Page 43: Spec

Spec lubrication layout 2-24 (1) oil filter (2) camshaft (3) connecting rod pin (4) main driving shaft (5) secondary drive shaft (6) drain plug [a] delivery [b] retrieval a b.

Page 44: Spec

Spec lubrication layout 2-25 (1) oil pump (2) oil filter (3) oil delivery hose (4) transmission (5) oil strainer [a] delivery [b] retrieval a b.

Page 45: Spec

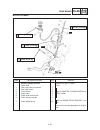

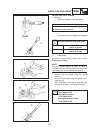

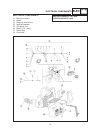

Spec cable routing 2-26 2 22 4 3 4 7 5 5 6 3 17 5 1 6 5 9 8 18 19 16 20 13 14 11 15 12 10 5 21 1 a cable routing (1) clutch cable (2) brake hose holder (3) brake hose (4) throttle cables (5) bands (6) lighting wire harness (7) brake and engine stop switch wire harness (8) tachometer/ odometer cable ...

Page 46: Spec

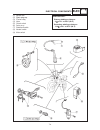

Spec cable routing 2-27 30 27 24 26 25 22 29 23 28 1 2 3 4 5 12 13 15 8 7 18 19 17 11 10 16 14 6 9 20 10 b c d a (1) front brake hose (2) brake hose holder (3) left tube guard (4) plastic plate (5) throttle cables (6) tachometer/ odometer cable (7) clutch cable (8) clutch cable holder (9) throttle c...

Page 47: Spec

Spec cable routing 2-28 (1) tachometer/ odometer cable (2) tachometer/ odometer cable holder (3) tachometer/ odometer cable band (4) right tube guard (5) spark plug cable (6) horn (7) carburetor suction pipe (8) main wire harness band (9) rear brake switch wire harness (10) rear brake fluid tank hos...

Page 48: Spec

Spec cable routing 2-29 (1) rectifier (2) wire harness bands (3) protection (4) left turn wire harness (5) right turn wire harness (6) tail light wire harness (7) air breather pipe (carburetor) (8) wire extension (9) starter power cables (10) engine cables and side stand switch [ a ] screw protectio...

Page 49: Spec

Spec.

Page 50: Insp

3 insp adj.

Page 51: Insp

Insp adj chapter 3. Periodic inspection and adjustments introduction ..........................................................................................................3-1 periodic maintenance/lubrication intervals ........................................3-1 seat, fuel tank and rear cowling ....

Page 52: Insp

Insp adj electrical system ............................................................................................3-47 checking and charging the battery ..................................................3-47 checking the fuses .......................................................................

Page 53: Insp

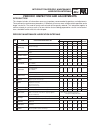

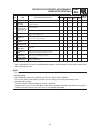

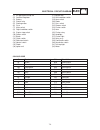

Insp adj introduction/periodic maintenance/ lubrication intervals 3-1 periodic inspection and adjustments introduction this chapter includes all information necessary to perform recommended inspections and adjustments. These preventive maintenance procedures, if followed, will ensure more reliable v...

Page 54: Insp

Introduction/periodic maintenance/ lubrication intervals 3-2 insp adj odometer reading (x 1,000 km) annual n0. Item check or maintenance job 1 10 20 30 40 check 18 * rear brake • check operation, fluid level and vehicle for fluid leakage. ✓ ✓ ✓ ✓ rear shock • check operation and shock absorber for o...

Page 55: Insp

Insp adj seat, fuel tank and rear cowling 3-3 seat, fuel tank and rear cowling order job name/part name q.Ty remarks seat, fuel tank and rear cowling remove the parts in order. Removal 1 seat 1 2 fuel pipe 1 note: be sure the cap is properly tightened and the fuel cock is in the “off” position befor...

Page 56: Insp

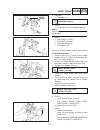

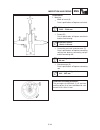

Valve clearance adjustment 3-4 insp adj engine valve clearance adjustment note: • valve clearance must be adjusted when the engine is at ambient temperature. • adjust valve clearance with the piston under compression at top dead centre (t.D.C.). Warning hold the motorcycle firmly in place to prevent...

Page 57: Insp

Insp adj valve clearance adjustment 3-5 6. Align: • reference mark “t” on the flywheel (1) with the fixed reference mark on the crankcase (2). Note: check that the piston is under compression at top dead centre (t.D.C.). (3) ignition timing reference mark 7. Check: • valve clearance out of specifica...

Page 58: Insp

Valve clearance adjustment 3-6 insp adj 9. Reassemble: • caps • tappet cover (intake) • tappet covers (exhaust) • spark plug tappet cover (exhaust): 12 nm (1.2 mkg) bolt (tappet cover - intake): 10 nm (1.0 mkg) spark plug: 18 nm (1.8 mkg) note: the tappet cover (intake) should be mounted with arrow ...

Page 59: Insp

Insp adj drive chain adjustment idle speed adjustment 3-7 drive chain adjustment the drive chain does not need to be adjusted. Idle speed adjustment 1. Start the engine and let it heat. 2. Connect: • the inductive engine speed indicator to the spark plug cable special tool: p/n. 90890-03113 engine i...

Page 60: Insp

Throttle cable free play adjustment 3-8 insp adj throttle cable free play adjustment note: before adjusting the throttle cable free play, adjust the engine idle speed. 1. Remove: • seat • fuel tank see section “seat, fuel tank and rear cowling”. 2. Check: • throttle cable free play (a) out of specif...

Page 61: Insp

Insp adj spark plug inspection 3-9 spark plug inspection 1. Remove: • seat • fuel tank see section “seat, fuel tank and rear cowling”. 2. Disconnect: • spark plug cap 3. Remove: • spark plug (1) before removing the spark plug, use com- pressed air to blow away any dirt accumulat- ed in the spark plu...

Page 62: Insp

Spark plug inspection 3-10 insp adj 8. Lock tighten: • spark plug before installing the spark plug, clean the surface and thread. Spark plug: 18 nm (1.8 mkg) seat screws: 10 nm (1.0 mkg) note: tighten the spark plug by hand before torquing to specification. 9. Connect: • spark plug cap 10. Install: ...

Page 63: Insp

Insp adj 3-11 ignition timing check ignition timing check 1. Start the engine and let it heat. 2. Connect: • inductive rev counter • stroboscopic lamp to spark plug cable inductive engine speed indicator: p/n. 90890-03113 stroboscopic lamp: p/n. 90890-03141 3. Remove: • cap (1) in certain conditions...

Page 64: Insp

3-12 insp adj compression inspection compression inspection note: insufficient compression causes a loss of per- formance. Warning set the motorcycle firmly in place to prevent it falling during the operation. 1. Remove: • seat • fuel tank see section “seat, fuel tank and rear cowling”. 2. Check: • ...

Page 65: Insp

Insp adj 3-13 compression inspection inspection: • turn the main switch to "on". • with the throttle wide open, crank the engine until the reading on the compression gauge stabilized. Warning while operating the starter, disconnect the spark plug cap to avoid sparks. • compare the pressure reading w...

Page 66: Insp

3-14 insp adj compression inspection 9. Remove: • secondary fuel tank • pressure gauge (with adapter) 10. Reassemble: • spark plug see section “spark plug inspec- tion”. Spark plug: 18 nm (1.8 mkg) seat screws: 10 nm (1.0 mkg) 11. Connect: • spark plug cap 12. Reassemble: • fuel tank • seat see sect...

Page 67: Insp

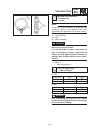

Insp adj 3-15 engine oil level check engine oil level check do not put additives into the engine oil. The latter also lubricates the clutch and additives might cause it to slide. Warning never remove the oil tank cap when the engine is hot. The boiling oil might spill over, causing burns. Wait for t...

Page 68: Insp

3-16 insp adj engine oil level check if the oil level is below minimum ➔ add oil up to maximum level. Recommended oil: sae20w40se or sae10w30se refer to the chart for selection of the oils suited to the atmospheric temperature. Api standard: api se, sf, sg or higher grade • do not put in any chemica...

Page 69: Insp

Insp adj 3-17 engine oil replacement 3 4 engine oil replacement do not put additives into the engine oil. The latter also lubricates the clutch and additives might cause it to slide. Warning never remove the oil tank cap when the engine is hot. The boiling oil might spill over, causing burns. Wait f...

Page 70: Insp

3-18 insp adj engine oil replacement fastening torques: drain plug (engine): 30 nm (3.0 mkg) oil tank hose (flange): 10 nm (1.0 mkg) oil filter cover air bleeder screw: 5 nm (0.5 mkg) 9. Fill: • oil tank recommended oil: sae20w40se or sae10w30se refer to the chart for selection of the oils suited to...

Page 71: Insp

Insp adj 3-19 engine oil replacement 7 6 engine oil replacement (with oil filter replace- ment) 1. Warm up the engine for a few minutes. 2. Stop the engine. Place an oil pan under the engine and remove the oil filler cap. 3. Remove the drain plug (1) and drain the engine oil. 4. Remove two bolts (2)...

Page 72: Insp

3-20 insp adj engine oil replacement recommended oil: sae20w40se or sae10w30se refer to the chart for selection of the oils suited to the atmospheric temperature. Api standard: api se, sf, sg or higher grade oil capacity: total: 3.0 litres periodic oil change: 2.4 litres with oil filter change: 2.5 ...

Page 73: Insp

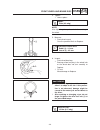

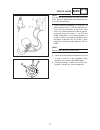

Insp adj 3-21 engine oil pressure check/ clutch adjustment 2 1 a 1 2 engine oil pressure check 1. Remove: • bleeder screw (1) 2. Start the engine and keep it idling until oil flows out of the bleed hole. 3. Inspect: • conditions of oil at bleeder hole. Oil leakage ➔ oil pressure good. No leakage ➔ p...

Page 74: Insp

Clutch adjustment 3-22 insp adj note: after adjustment, recheck lever free play to make sure that it works smoothly and progressively. If it is impossible to obtain the required adjust- ment or if the clutch does not work properly, adjust the internal mechanism. Internal mechanism adjustment 1. Loos...

Page 75: Insp

Insp adj clutch adjustment 3-23 11. Install: • right crankcase cover • right crankcase cover fastening screws • oil delivery hose fastening screw screw (crankcase cover): 10 nm (1.0 mkg) oil delivery hose screw: 18 nm (1.8 mkg) screw (rear master cylinder): 10 nm (1.0 mkg) bolt (footrest): 48 nm (4....

Page 76: Insp

Air filter cleaning 3-24 insp adj 1 2 air filter cleaning 1. Remove: • fast screws (1) • air filter box cap (2) 2. Pull out: • filtering element (3) from its seat 3. Wash: • filtering element (with water and biodegradable liquid soap) note: rinse properly and dry perfectly by squeezing the filtering...

Page 77: Insp

Insp adj air filter cleaning/ fuel filter cleaning 3-25 periodically check wheter the sleeve on the bottom of the air filter case is empty. Remove the plug (5) and clean it if dirt or water accu- mulate. Caution: fuel filter cleaning 1. Turn the fuel cock to "off". 2. Disconnect: • fuel pipe from co...

Page 78: Insp

Engine oil tank filter cleaning 3-26 insp adj engine oil tank filter cleaning warning securely support the motorcycle so there is no danger of it falling over. 1. Drain: • engine oil see section “engine oil replace- ment”. 2. Remove: • seat • rear cowling see section “seat, fuel tank and rear cowlin...

Page 79: Insp

Insp adj engine oil tank filter cleaning 3-27 7. Reassemble: • or gaskets • oil tank filter • oil delivery hose flange fastening screws screw (oil delivery hose flange): 10 nm (1.0 mkg) screw (oil return hose flange): 35 nm (3.5 mkg) • oil return hose • oil return hose flange fastening screws 8. Tig...

Page 80: Insp

Suction hose and manifold inspection/ fuel line inspection 3-28 insp adj suction hose and manifold inspection 1. Remove: • seat • fuel tank see section “seat, fuel tank and rear cowling”. 2. Inspect: • suction hoses (1) cracked/damaged ➔ replace. Screw (2) (carburetor manifold): 10 nm (1.0 mkg) scre...

Page 81: Insp

Insp adj cranckcase ventilation hose inspection/ exhaust system inspection 3-29 cranckcase ventilation hose inspection 1. Inspect: • crankcase ventilation hoses (1) cracked/damaged ➔ replace. Exhaust system inspection 1. Inspect: • exhaust pipe (1) • muffer (2) cracks/damage ➔ replace. • gaskets (3)...

Page 82: Insp

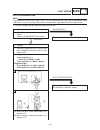

Adjusting the front brake 3-30 insp adj 2 a 1 chassis adjusting the front brake 1. Adjust: • brake lever position (distance a between the brake lever and the handlebar grip) a. Turn the adjusting dial 1 while holding the lever pushed away from the handlebar grip note: align the setting on the adjust...

Page 83: Insp

1 2 insp adj adjusting the rear brake 3-31 adjusting the rear brake 1. Check: • brake pedal position (distance a from the top of the rider footrest to the top of the brake pedal) out of specification ➔ adjust. 2. Adjust: • brake pedal position • tighten lock nut. After adjusting the brake pedal posi...

Page 84: Insp

Checking the brake fluid level 3-32 insp adj checking the brake fluid level 1. Stand the motorcycle on a level surface. Note: • place the motorcycle on a suitable stand. • make sure that the motorcycle is upright. 2. Check: • brake fluid level below the minimum level mark a ➔ add the recommended bra...

Page 85: Insp

Insp adj brake pad wear inspection/ brake hosing inspection 3-33 1. Operate the brake lever or brake pedal. 2. Check: • thickness of frictional material out of specification ➔ replace. Brake hosing inspection 1. Inspect: • brake hosing cracks/damage ➔ replace. To replace hosing, see section “front a...

Page 86: Insp

Brake circuit bleeding 3-34 insp adj 1 1 b brake circuit bleeding warning if the brake lever or brake pedal has a soft or slack feel, this means that there is air in the brake system. It should be bled away before using the motorcycle. Air in the system seri- ously affects the effectiveness of braki...

Page 87: Insp

Insp adj drive chain slack inspection and adjustment 3-35 a note: if bleeing proves difficult, it may be necessary to allow the brake fluid system to stabilise for a few hours. Repeat the bleeding procedure when the tiny bubbles in the system have disappeared. J. Top up fluid to the maximum level. D...

Page 88: Insp

Drive chain slack inspection and adjustment/ drive chain lubrication 3-36 insp adj rear wheel axle nut: 115 nm (11.5 mkg) • turn each adjusting bolt exactly the same amount to maintain correct axle alignment. There are marks on each side of the swingarm. Use these marks to align the rear wheel. Driv...

Page 89: Insp

Insp adj front fork inspection/ front fork adjustment 3-37 a b a b 1 front fork inspection warning when inspecting the front fork, hold the motorcycle firmly to prevent it falling over. 1. Place the motorcycle on a level surface. 2. Check: • inner tube scratches/damage ➔ replace. • oil seal undue oi...

Page 90: Insp

Rear shock absorber adjustment 3-38 insp adj a a b 2 1 rear shock absorber adjustment warning this shock absorber contains highly pressur- ized nitrogen gas. For proper handling, read and understand the following information before handling the shock absorber. The man- ufacturer cannot be held respo...

Page 91: Insp

Insp adj rear shock absorber adjustment 3-39 note: • use the special wrench included in the owner's tool kit to make the adjustment. • the spring preload setting is determined by measuring distance a, shown in the illustra- tion. The longer distance a is, the lower the spring preload; the shorter di...

Page 92: Insp

Steering inspection 3-40 insp adj steering inspection warning hold the motorcycle firmly in place to prevent it falling over. 1. Raise the front wheel and place a support under the engine. 2. Check: • steering bearings grasp the bottoms of the front fork legs and rock back and forward. Free play ➔ a...

Page 93: Insp

Insp adj steering inspection / tyre inspection 3-41 ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ nut (steering axle): 115 nm (11.5 mkg) screws (front fork bracket): 28 nm (2.8 mkg) • tighten the steering axle nut and the front fork bracket screws. • reassemble the fuel tank. See section...

Page 94: Insp

Tyre inspection 3-42 insp adj 1. Check: • tyre pressure out of specification ➔ adjust. Tire air pressure (measured on cold tires) load* front rear 200 kpa 220 kpa up to 90 kg (2.00 kgf/cm 2 , (2.20 kgf/cm 2 , 2.00 bar) 2.20 bar) 210 kpa 240 kpa 90 kg-maximum (2.10 kgf/cm 2 , (2.40 kgf/cm 2 , 2.10 ba...

Page 95: Insp

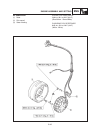

Insp adj tyre inspection 3-43 minimum track thickness: (front and rear) 1,6 mm note: these limits may be different by regulation from country to country. If so, conform to the limits specified by the regulations of your own country. (1) track thickness (2) side (3) wear indicators warning the use of...

Page 96: Insp

Wheel inspection / spoke inspection and tightening 3-44 insp adj wheel inspection 1. Inspect: • wheels damage/deformation ➔ replace. Note: always balance the wheel after the replacement or reassembly of a tyre or rim. Warning never try to repair a rim in any way. Bearing inspection check the front a...

Page 97: Insp

Insp adj cable inspection / lever and pedal lubrication 3-45 cable inspection warning if the cable sheath is damaged, corrosion might ensue or the cable might not run freely. To avoid such drawbacks, replaced damaged cables as quickly as possible. 1. Inspect: • cable sheath damaged ➔ replace the cab...

Page 98: Insp

Sidestand lubrication/ rear suspension lubrication 3-46 insp adj sidestand lubrication lubricate the sidestand pivoting and mating parts. Check to see that the sidestand moves up and down smoothly. Recommended lubricant: sae 10w30 motor oil 1 rear suspension lubrication lubricate the pivoting parts....

Page 99: Insp

Insp adj checking and charging the battery electrical system checking and charging the battery warning batteries generate explosive hydrogen gas and contain electrolyte which is made of poi- sonous and highly caustic sulfuric acid. Therefore, always follow these preventive measures: • wear protectiv...

Page 100: Insp

Checking and charging the battery 3-48 insp adj note: since mf batteries are sealed, it is not possible to check the charge state of the battery by measuring the specific gravity of the electrolyte. Therefore, the charge of the battery has to be checked by meas- uring the voltage at the battery term...

Page 101: Insp

Insp adj checking and charging the battery 3-49 open-circuit voltage (v) warning do not quick charge a battery. • never remove the mf battery sealing caps. • do not use a high-rate battery charger. They force a high-amperage current into the battery quickly and can cause battery overheating and batt...

Page 102: Insp

Checking and charging the battery 3-50 insp adj charging method using a variable-current (voltage) type charger charger note: voltage should be measured 30 minutes after the machine is stopped. Note: set the charging voltage at 16 ~ 17 v (if the setting is lower, charging will be insufficient. If to...

Page 103: Insp

Insp adj checking and charging the battery 3-51 charging method using a constant-voltage type charger measure the open-circuit voltage prior to charging. Connect a charger and amp meter to the battery and start charging. Make sure the current is higher than the standard charging current written on t...

Page 104: Insp

Checking and charging the battery 3-52 insp adj 6. Connect: • battery leads (to the battery terminals) first, connect the positive lead 2, then the negative lead 1. 7. Check: • battery terminals dirt ➔ clean with a wire brush. Loose connection ➔ connect properly. 8. Lubricate: • battery terminals ca...

Page 105: Insp

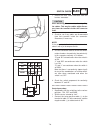

Insp adj checking the fuses 3-53 checking the fuses to avoid a short circuit, always turn the main switch to "off" when checking or replacing a fuse. 1. Remove: • seat • panel 1 2. Check: • fuse caution: a. Connect the pocket tester to the fuse and check it for continuity. Note: set the pocket teste...

Page 106: Insp

Checking the fuses/ replacing the headlight bulbs 3-54 insp adj warning never use a fuse with an amperage rating other than that specified. Improvising or using a fuse with the wrong amperage rating may cause extensive damage to the electrical sys- tem, cause the lighting and ignition systems to mal...

Page 107: Insp

Insp adj replacing the headlight bulbs 3-55 1 3 2 1 auxiliary light bulb 1. Remove: • cowling screws (1) 2. Remove: • cowling (from the meter bracket) note: remove the cowling from the meter bracket by lowering it to disengage it, and then lifting it up. 3. Remove: • headlight (2) • auxiliary light ...

Page 108: Insp

Replacing the turn indicator light bulb 3-56 insp adj 1 2 3 replacing the turn indicator light bulb 1. Remove: • lens screw (1) • lens (2) • bulb (3) note: to remove the bulb press it into place and turn it counterclockwise. 2. Install: • new bulb note: to install the bulb press it into place and tu...

Page 109: Insp

Insp adj replacing the tail/ brake light bulb 3-57 1 2 a b 3 replacing the tail/brake light bulb 1. Remove: • screws (1) (lens fixing) • lens (2) • bulb (3) note: to remove the bulb press it into place and turn it counterclockwise (a). 2. Install: • new bulb note: to install the bulb press it into p...

Page 110: Insp

Insp adj.

Page 111: Chas

4 chas.

Page 112: Chas

Chas chapter 4. Chassis front wheel and brake disc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 front wheel and brake disc removal . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 front wheel disassembly . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 113: Chas

Chas front fork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42 front fork removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42 front fork disassembly . . . . . . . . . . . . . . . . . . ...

Page 114: Chas

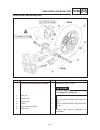

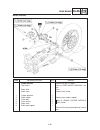

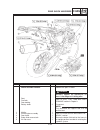

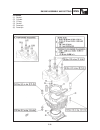

Chas front wheel and brake disc 4-1 chassis - front wheel and brake disc order job name/part name q.Ty remarks front wheel and brake disc remove the parts in order. Removal warning securely support the motorcycle so there is no danger of it falling over. 1 speedometer cable 1 disconnect. 2 pinch bol...

Page 115: Chas

Front wheel and brake disc 4-2 chas order job name/part name q.Ty remarks front wheel disassembly remove the parts in order. 1 oil seal 1 2 bearing 1 3 spacer 1 refer to “front wheel disassembly/ 4 oil seal 1 assembly” section. 5 bearing 1 reverse the removal procedure for instal- lation. 1 2 3 5 4.

Page 116: Chas

Chas front wheel and brake disc 4-3 front wheel disassembly 1. Remove: • oil seal • bearing (1) • spacer removal procedure: • clean the outside of the hub. • remove the dust cover with a flat-headed screwdriver. ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ • disassemble the bearing (1) ...

Page 117: Chas

Front wheel and brake disc 4-4 chas 4. Tighten: • loose spokes 5. Measure: • front wheel runout over the specified limits ➔ replace. Spoke: 2 nm (0.2 mkg) note: after tightening the spokes, check the centring of the wheel. 6. Inspect: • front wheel bearings bearings allow free play in the wheel hub ...

Page 118: Chas

Chas front wheel and brake disc 4-5 brake disc inspection 1. Inspect: • brake disc wear/damage ➔ replace. 2. Measure: • brake disc deflection (a) if over envisaged limits ➔ verify wheel centring. If the wheel centring is correct, replace the brake disc. Misure at 2 mm from disc edge • brake disc thi...

Page 119: Chas

Front wheel and brake disc 4-6 chas front wheel installation 1. Install: • brake disc (1) 2. Install: • speedometer gear unit (1) screw (brake disc): 12 nm (1.2 mkg) note: • apply loctite ® to the threads of brake disc screw. • tighten the screws (brake disc) in stage using a crisscross pattern. 3. ...

Page 120: Chas

Chas front wheel and brake disc 4-7 4. Adjust: • wheel static balance adjusting steps: • install a balancing weight (1) on the rim exact- ly opposite to the heavy spot “x”. ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ • turn the wheel so that the heavy spot is 90° up. • check that the h...

Page 121: Chas

Front brake 4-8 chas front brake brake pad order job name/part name q.Ty remarks brake pad removal remove the parts in order. 1 brake caliper screw 2 2 brake caliper 1 3 pad pin retainer 2 refer to “brake pad replacement” 4 pad pin 1 section. 5 brake pad 2 6 pad spring 2 reverse the removal procedur...

Page 122: Chas

Chas front brake 4-9 brake components must not be disassembled. The builder declines every responsibility after brake components disassembly (brake master cylinder or brake caliper) or in case of use of non original parts. Do not: • remove brake components from the motorcycle unless is absolutely ne...

Page 123: Chas

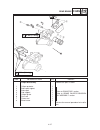

Front brake 4-10 chas 3. Lubricate: • guide pins (1) 4. Install: • pin bracket (2) (on the caliper body (3)) note: fit the rubber protections (4) when installing the caliper body. Lithium-base grease 5. Install: • pad springs (1) (new) • brake pads (2) (new) • pad fastening pin (3) • pin retainers (...

Page 124: Chas

Chas front brake 4-11 master cylinder order job name/part name q.Ty remarks master cylinder removal remove the parts in order. Brake fluid drain. 1 rear view mirror (right)/ master cylinder bracket 1/1 2 brake lever 1 3 brake switch 1 4 union bolt 1 5 plain washer 2 refer to “master cylinder instal-...

Page 125: Chas

Front brake 4-12 chas order job name/part name q.Ty remarks master cylinder disassembly remove the parts in order. 1 reservoir cap 1 2 diaphragm 1 3 master cylinder boot 1 refer to “master cylinder assem- 4 circlip 1 bly” section. 5 master cylinder assembly 1 6 spring 2 reverse the disassembly proce...

Page 126: Chas

Chas front brake 4-13 master cylinder inspection 1. Inspect: • master cylinder assembly wear/scratches ➔ replace the master cylinder assembly. • master cylinder body cracks/damage ➔ replace the master cylinder assembly. • fluid delivery passage (master cylinder) obstruction ➔ clean with a jet of com...

Page 127: Chas

Front brake 4-14 chas 2. Install: • circlip (1) • master cylinder boot (2) master cylinder installation 1. Install: • master cylinder (1) • master cylinder bracket (2) screw (master cylinder bracket): 9 nm (0.9 mkg) 2. Install: • plain washer (1) (new) • brake hose (2) • union bolt (3) union bolt (b...

Page 128: Chas

Chas front brake 4-15 brake fluid may deteriorate painted surfaces or plastic parts. Always clean up spilled fluid immediately. Caution: warning • use only designated quality brake fluid. Otherwise, the rubber seals may deterio- rate, causing leakage and poor brake per- formance. • refill with the s...

Page 129: Chas

Front brake 4-16 chas brake caliper order job name/part name q.Ty remarks caliper removal remove the parts in order. Brake fluid drain. 1 union bolt 1 2 plain washer 2 3 brake hose 1 refer to “caliper installation” sec- 4 caliper support bolt 2 tion 5 caliper assembly 1 reverse the removal procedure...

Page 130: Chas

Chas front brake 4-17 order job name/part name q.Ty remarks caliper disassembly remove the parts in order. Brake pad refer to “brake pad” section. 1 pad spring 2 2 caliper piston 2 3 dust seal 2 refer to “brake caliper disassem- 4 piston seal 2 bly/assembly” section. 5 bleed screw 1 refer the disass...

Page 131: Chas

Front brake 4-18 chas brake caliper disassembly 1. Remove: • brake caliper piston • dust seal (1) • piston seal (2) removal procedure: • blow compressed air into the hose joint open- ing to force out the caliper piston from the brake caliper body. ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ...

Page 132: Chas

Chas front brake 4-19 • fluid delivery passage (caliper) obstruction ➔ clean with compressed air. Caliper assembly warning • all internal brake components should be cleaned and lubricated with new brake fluid only before installation. • in case of non correct operation of the brake caliper, replace ...

Page 133: Chas

Front brake 4-20 chas 2. Fill: • brake fluid reservoir 3. Air bleed: • brake system refer to “air bleeding (hydraulic brake system)” section in chapter 3. Recommended brake fluid: dot 4 brake fluid may deteriorate painted surfaces or plastic parts. Always clean up spilled fluid immediately. Caution:...

Page 134: Chas

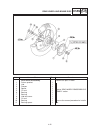

Chas rear wheel and brake disc 4-21 rear wheel and brake disc order job name/part name q.Ty remarks rear wheel and brake disc removal remove the parts in order. Warning securely support the motorcycle so there is no danger of it falling over. 1 axle nut 1 2 wheel axle 1 3 drive chain - 4 collar 2 5 ...

Page 135: Chas

Rear wheel and brake disc 4-22 chas order job name/part name q.Ty remarks rear wheel disassembly remove the parts in order. 1 driven sprocket 1 2 hub 1 3 damper 4 4 spacer 1 refer to “rear wheel disassembly/as- 5 oil seal 1 sembly” section. 6 bearing 1 7 bearing 1 8 hub dust cover 1 9 oil seal 1 10 ...

Page 136: Chas

Chas rear wheel and brake disc 4-23 rear wheel disassembly 1. Remove: • hub and driven sprocket • dampers • hub spacer • oil seal • hub bearing • wheel bearing • wheel spacer • wheel bearing • dust cover • oil seal • wheel bearing • wheel spacer removal procedure: • clean the outside of the hub. • r...

Page 137: Chas

Rear wheel and brake disc 4-24 chas 4. Tighten: • loose spokes 5. Measure: • rear wheel runout over the specified limits ➔ replace. Spoke: 2 nm (0.2 mkg) note: after tightening the spokes, check the centring of the wheel. 6. Inspect: • rear wheel bearings bearings allow free play in the wheel hub or...

Page 138: Chas

Chas rear wheel and brake disc 4-25 rear wheel assembly 1. Install: • wheel spacer • wheel bearing • oil seal • dust cover • wheel bearing • wheel spacer • wheel bearing • hub bearing • oil seal • hub spacer • dampers • hub and driven sprocket assembly procedure: • install the new bearing, the dust ...

Page 139: Chas

Rear wheel and brake disc 4-26 chas lithium-base grease check that the brake caliper support has stayed in the correct position on the rear arm. Caution: 5. Install: • rear wheel assembly (in the rear arm) • bearing • edge of the hub dust cover check that the brake disc is driving through the brake ...

Page 140: Chas

Chas rear wheel and brake disc 4-27 wheel static balance adjustment 1. Remove: • balancing weight 2. Set: • wheel (on a suitable stand) 3. Find: • heavy spot note: • after replacing the tire and/or rim, the wheel static balance should be adjusted. • adjust the rear wheel static balance with the brak...

Page 141: Chas

Rear wheel and brake disc 4-28 chas 5. Check: • wheel static balance checking steps: • turn the wheel so that it comes to each point as shown. • check that the wheel is at rest at each point. If not, readjust the rear wheel static balance. ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▲ ...

Page 142: Chas

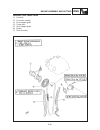

Chas rear brake 4-29 rear brake brake pad order job name/part name q.Ty remarks brake pad removal remove the parts in order. Rear wheel refer to “rear wheel removal” section. Brake hose remove from clamp. 1 caliper protector 1 2 pad pin retainer 1 3 pad pin 1 4 brake pad 1 refer to “brake pad replac...

Page 143: Chas

Rear brake 4-30 chas brake components must not be disassem- bled. The builder declines every responsibility after brake components disassembly (brake master cylinder or brake caliper) or in case of use of non original parts. Do not: • remove brake components from the motorcycle unless is absolutely ...

Page 144: Chas

Chas rear brake 4-31 a b 4. Check: • brake fluid level refer to “brake fluid inspection” section in chapter 3. (a) minimum level mark “min” (b) maximum level mark “max” 5. Check: • brake pedal operation pedal soft and spongy ➔ bleed air from brake circuit. Refer to “air bleeding (hydraulic brake sys...

Page 145: Chas

Rear brake 4-32 chas master cylinder order job name/part name q.Ty remarks master cylinder removal remove the parts in order. Brake fluid drain. 1 rear stop switch connector 1 2 rear stop switch 1 3 plain washer 2 refer to “master cylinder installa- 4 brake hose 1 tion” section. 5 brake fluid reserv...

Page 146: Chas

Chas rear brake 4-33 master cylinder inspection 1. Inspect: • master cylinder assembly wear/scratches ➔ replace the master cylinder assembly. • master cylinder body cracks/damage ➔ replace the master cylinder assembly. • fluid delivery passage (master cylinder) obstruction ➔ clean with a jet of com-...

Page 147: Chas

Rear brake 4-34 chas master cylinder installation 1. Install: • brake pedal (refer to “brake pedal removal” section in this chapter). Note: lubricate the pin of the brake pedal with lithium- base grease. • master cylinder • brake fluid reserve tank • plain washers (1) (new) • brake hose (2) • stop s...

Page 148: Chas

Chas rear brake 4-35 3. Air bleed: • brake system refer to “air bleeding (hydraulic brake system)” in chapter 3. 4. Inspect: • brake fluid level lower than “min” mark (1) ➔ fill. Refer to “brake fluid inspection” section in chapter 3. (1) minimum level mark “min” brake pedal removal 1. Remove: • spl...

Page 149: Chas

Rear brake 4-36 chas brake caliper order job name/part name q.Ty remarks caliper removal remove the parts in order. Rear wheel refer to “rear wheel removal” sec- tion. Brake fluid drain. Brake hose remove from clamp. 1 caliper protector 1 2 brake caliper 1 remove from caliper support. 3 union bolt 1...

Page 150: Chas

Chas rear brake 4-37 order job name/part name q.Ty remarks caliper disassembly remove the parts in order. 1 caliper protector 1 2 brake pad support 1 3 brake pad 2 refer to “brake pad” section. 4 pad support 1 5 caliper piston 1 refer to “brake caliper disassem- 6 dust seal 1 bly/assembly” section. ...

Page 151: Chas

Rear brake 4-38 chas brake caliper disassembly 1. Remove: • brake caliper piston (1) • dust seal (3) • piston seal (2) removal procedure: • blow compressed air into the hose joint open- ing to force out the caliper piston from the brake caliper body. ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼...

Page 152: Chas

Chas rear brake 4-39 • fluid delivery passage (caliper) obstruction ➔ clean with compressed air. Brake caliper assembly warning • all internal brake components should be cleaned and lubricated with new brake fluid only before installation. • in case of non correct operation of the brake caliper, rep...

Page 153: Chas

Rear brake 4-40 chas 2. Fill: • brake fluid reserve tank check that the brake hose has stayed in cor- rect position with the pipe-fitting matching the projection (a) of the caliper. Caution: warning check that the brake hose routing is correct. Refer to “cable routing” section. Recommended brake flu...

Page 154: Chas

Chas rear brake 4-41 4. Inspect: • brake fluid level lower than “min” mark (1) ➔ fill. Refer to “brake fluid inspection” section in chapter 3. (1) minimum level mark “min” 1.

Page 155: Chas

Front fork 4-42 chas front fork front fork removal order job name/part name q.Ty remarks front fork removal remove the parts in order. Front wheel refer to “front wheel” section. 1 inner tube protector 1 2 brake hose guide 1 3 protector guide 2 4 brake caliper assembly 1 5 cowling (displace) 1 6 pin...

Page 156: Chas

Chas front fork 4-43 order job name/part name q.Ty remarks front fork disassembly remove the parts in order. Refer to “front fork removal/instal- lation”. 1 cap bolt 1 2 seat 1 3 spacer 1 refer to “oil replacement” section. 4 seat 1 5 fork spring 1 6 bolt 1 7 o-ring 1 8 damper adjusting cylinder 1 r...

Page 157: Chas

Front fork 4-44 chas order job name/part name q.Ty remarks 12 inner tube 1 13 inner tube bushing 1 14 oil seal 1 refer to “seal and bush replace- 15 washer 1 ment” section. 16 outer tube bushing 1 17 outer tube 1 reverse the removal procedure for instal- lation..

Page 158: Chas

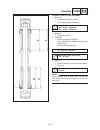

Chas front fork 4-45 oil capacity (in each fork leg): 650 cm 3 recommended oil: liqui moly racing suspension oil sae 7,5 front fork oil level standard 180 mm minimum 190 mm maximum 170 mm from top of inner tube with inner tube fully com- pressed without spring. Minimum fork spring free length: 530 m...

Page 159: Chas

Front fork 4-46 chas oil replacement note: the quality of the fork oil is of fundamental impor- tance for obtaining the maximum performance and functioning. For this reason it needs to be replaced after the first 3÷4 hours to eliminate any residues due to the adaptation of the internal components an...

Page 160: Chas

Chas front fork 4-47 7. Fill: • part of the new oil (with the fork leg in a vertical position) recommended oil: liqui moly racing suspension oil sae 7,5 recommended oil: liqui moly racing suspension oil sae 7,5 8. Using the inner tube pump back and forth until a regular drag is felt on the return st...

Page 161: Chas

Front fork 4-48 chas cap bolt (on inner tube): 20 nm (2.0 mkg) note: always tighten the lower pinch bolt (to the pre- scribed torque) and then the upper one (to the prescribed torque) and then retighten the lower one (to the prescribed torque). 15. Tighten: • cap bolt (on inner tube) 14. Tighten: • ...

Page 162: Chas

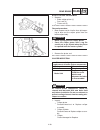

Chas front fork 4-49 cleaning the dust seal note: after using the motorcycle it is necessary to clean the dust seal carefully in order to maintain the fork at maximum efficiency. In fact, if dust infiltrates to the inside of the dust seal it can compromise the smoothness and therefore the sensitivit...

Page 163: Chas

Front fork 4-50 chas 4. Using a small screwdriver take a small amount of silicon grease and insert it under the lip paying attention not to scratch it. Lubricate the dust seal by rotating it in such a manner that the grease is distributed in the inner part of the lip. 5. Remount the dust seal insert...

Page 164: Chas

Chas front fork 4-51 1 2 3 3. Insert an allen key in the bolt (3) at the bottom of the outer tube and the special tool (1) with the holder (2) on the damper cylinder assem- bly and unscrew the bolt completely. Before unscrewing the bolt ensure that the end of the damper rod holder is correctly engag...

Page 165: Chas

Front fork 4-52 chas 6. Tightly clamp the fork leg horizontally fasten- ing it by caliper attachment on the outer tube. 7. Using a screwdriver prise the dust seal (4) from the edge of the oil seal seat (5). Then withdraw the dust seal using force. 5 4 5 4 1 2 8. Remove: • snap ring (1) (using a scre...

Page 166: Chas

Chas front fork 4-53 9. With a few sharp blows withdraw the inner tube (2) from the outer tube (3). Note: the oil seal (4), the washer (5), the outer tube du bush (6) and the inner tube du bush (7) are installed on the inner tube and must be removed and replaced with new one. 10. Install: • outer tu...

Page 167: Chas

Front fork 4-54 chas 12. The vice tightened, grip the outer tube and with a few strong blows hit it against the tool (3) until the du outer tube bush (4) is correct- ly positioned in its seat. 13. Remove the fork leg from the vice and remove the tool (1). Insert the new washer (3) and the new oil se...

Page 168: Chas

Chas front fork 4-55 16. Tightly clamp the fork leg horizontally fasten- ing it by caliper attachment on the outer tube. 17. Install: • snap ring (1) check that the snap ring is correctly seated. Caution: 18. Install: • dust seal (1) (new) note: apply lightweight lithium-soap base grease to the dust...

Page 169: Chas

Front fork 4-56 chas oil leakage from dust seal if there is a leakage of oil from between the dust seal (1) and the inner tube (2) replace the oil seal (refer to “seal and bush replacement” section). Anomalous hydraulic braking if the fork shows an anomalous hydraulic braking effect it is necessary ...

Page 170: Chas

Chas front fork 4-57 front fork inspection the front fork has a very sophisticated inter- nal construction and is particularly sensitive to foreign bodies. Use enough care to prevent foreign bodies entering when replacing oil or disassembling and reassembling the front fork. Caution: 1. Inspect: • c...

Page 171: Chas

Front fork 4-58 chas warning do not attempt to straighten a bent inner tube as this may have dangerous consequences. 4. Inspect : • outer tube (1) score marks/wear/damage ➔ replace. 5. Inspect: • cap bolt • o-ring wear/damage ➔ replace..

Page 172: Chas

Chas front fork 4-59 front fork installation 1. Install: • front fork (1) temporarily tighten the pinch bolts (lower). 2. Tighten: • cap bolt cap bolt: 20 nm (2.0 kgm) note: do not tighten the pinch bolt (upper) yet. 3. Adjust: • front fork top end (a) front fork top end (a) (standard): 0 mm 4. Tigh...

Page 173: Chas

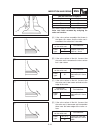

4-60 front fork chas a b a b 1 adjusting the front fork this front fork is equipped with spring pre-load ad- justing bolts. Warning always adjust both fork legs equally, other- wise poor handling and loss of stability may result. Adjust the spring preload as follows. To increase the spring preload a...

Page 174: Chas

Chas 4-61 steering order job name/part name q.Ty remarks steering removal remove the parts in order. Park the motorcycle on a level surface. Warning securely support the motorcycle to pre- vent it falling over. Front wheel refer to “front wheel removal” sec- tion. Fork legs refer to “front fork” sec...

Page 175: Chas

Steering 4-62 chas order job name/part name q.Ty remarks 9 upper ring nut 1 refer to “steering removal/instal- 10 lower ring nut 1 lation” section. 11 ball race cover 1 12 lower bracket/steering axle 1 13 bearing (upper) 1 14 bearing (lower) 1 reverse the removal procedure for instal- lation. Tighte...

Page 176: Chas

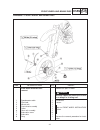

Chas 4-63 steering (1) handle upper holder (2) handle lower holder (3) spacer (4) nut (5) plate washer (6) upper bracket (7) brake hose holder (8) plate washer (9) special washer (10) upper ring nut (11) lower ring nut (12) ball race cover (13) bearings (14) steering lock (15) steering axle (16) wir...

Page 177: Chas

Chas 4-64 steering steering removal 1. Park the motorcycle on a level surface. 2. Raise the front wheel placing a suitable sup- port under the engine. 3. Remove: • front wheel refer to “front wheel-removal” section. • front fork refer to “front fork-removal” sec- tion. 4. Remove: • front fender • co...

Page 178: Chas

Chas 4-65 steering ring nut wrench (2): 90890-01268 7. Remove: • ring nut (lower) (1) • use the ring nut wrench (2) warning support the steering axle to prevent it falling. Steering inspection 1. Wash the bearings in solvent. 2. Inspect: • bearing (upper and lower) (1) corrosion/damage ➔ replace rac...

Page 179: Chas

4-66 chas steering 3. Install: • ring nut (lower) (1) use the ring nut wrench (2). Ring nut wrench: 90890-01268 note: apply the lithium soap-base grease to the steer- ing axle thread. Lower ring nut tightening steps: • tighten the ring nut (1) using the ring nut wrench. Ring nut (lower) (initial tig...

Page 180: Chas

Chas steering 4-67 ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ installation steps: • install the ring nut (upper) (1). • finger tighten the ring nut (upper), then align the slots of both ring nuts. If not aligned, hold the lower...

Page 181: Chas

Steering 4-68 chas 8. After tightening the nut, check the steering for smooth movement. If it is not smooth, adjust by progressively loosening the (lower) ring nut. 9. Tighten: • pinch bolts (upper and lower bracket) pinch bolt (upper bracket): 28 nm (2.8 mkg) pinch bolt (under bracket): 23 nm (2.3 ...

Page 182: Chas

Chas rear shock absorber 4-69 order job name/part name q.Ty remarks shock absorber removal remove the parts in order. Warning securely support the motorcycle so there is no danger of it falling over. Seat refer to “seat, fuel tank and rear fuel tank rear cowling cowling” section in chapter 3. Batter...

Page 183: Chas

Rear shock absorber 4-70 chas order job name/part name q.Ty remarks 6 lower bolt 1 7 upper bolt 1 reverse the removal procedure for instal- lation..

Page 184: Chas

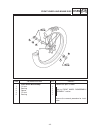

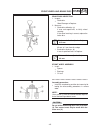

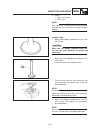

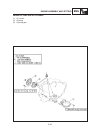

Chas rear shock absorber 4-71 (1) rear shock absorber (2) spring (3) spring adjuster ring nut (4) lock ring nut (5) end of stroke buffer (6) special spanner.

Page 185: Chas

Rear shock absorber 4-72 chas warning this shock absorber contains high-pressure nitrogen gas. Read the following information carefully before handling it. The manufacturer cannot be held responsible for any damage or injury that may result from improper handling. • never tamper with or attempt to o...

Page 186: Chas

Chas rear shock absorber 4-73 shock absorber removal warning support the motorcycle securely to prevent it from falling over. 1. Park the motorcycle on a level surface. 2. Remove: • seat • rear cowling • fuel tank see section “seat, fuel tank and rear cowling” in chapter 3. 3. Disconnect: • battery ...

Page 187: Chas

Rear shock absorber 4-74 chas shock absorber inspection 1. Inspect: • shock absorber oil leak/damaged ➔ replace. Rear shock absorber adjustment this shock absorber is equipped with a spring pre- load adjuster. A a b 2 1 never attempt to turn an adjusting mecha- nism beyond the maximum or minimum set...

Page 188: Chas

Chas rear shock absorber 4-75 2. Tighten the locknut to the specified torque. Locknut: 45 nm (4.5 m·kgf) always tighten the locknut against the adjust- ing nut, and then tighten the locknut to the specified torque. Caution:.

Page 189: Chas

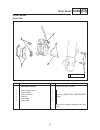

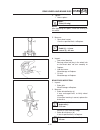

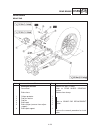

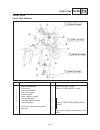

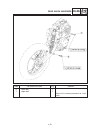

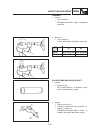

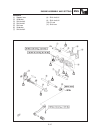

Swingarm 4-76 chas swingarm (1) upper chain case (2) swingarm (3) chain support (4) swingarm guard seal (5) connecting rod (6) relay arm [a] lateral free play (end): 1.0 mm [b] lateral free play: 0.4 ~ 0.7 mm.

Page 190: Chas

Chas swingarm 4-77 swingarm removal note check free play and remove swingarm, if neces- sary, after removing the rear shock absorber. 1 . Remove: • swingarm connecting rod bolt (1) 2 . Check: • swingarm free play ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ inspection procedure: • check...

Page 191: Chas

Swingarm chas 4-78 3. Remove: • upper chain case (1) • chain support (2) 4. Remove: • swingarm pivot shaft • swingarm swingarm inspection 1. Inspect: • swingarm deformation/cracks/damage ➔ replace. 2. Inspect: • connecting rod (1) • relay arm (2) deformation/cracks/damage ➔ replace. 3. Inspect: • oi...

Page 192: Chas

Chas swingarm 4-79 lateral free play adjustment 1. Measure: • length of bushes a1 and a2 out of specification ➔ replace. Length of bushes: a1 = 76.70 ~ 76.85 mm a2 = 74.90 ~ 75.00 mm swing arm lateral free play c: 0.4 ~ 0.7 mm measurement of adjust shim (1): 0.3 mm 2. Measure: • length b1 and b2 3. ...

Page 193: Chas

Swingarm 4-80 chas swingarm installation perform “removal” operations in reverse order. Note the following points. 1. Lubricate: • bearings • bushes • thrust cover (inside) • flange • swingarm pivot shaft • bolt (connecting rod) • bolt (relay arm) • bolt (shock absorber) lithium-base grease 2. Tight...

Page 194: Chas

Chas swingarm 4-81 drive chain slack: 30 ~ 40 mm refer to “drive chain slack adjust- ment” in chapter 3. 5. Install: • fuel tank • rear cowling • seat bolt (seat): 10 nm (1.0 mkg) refer to “seat, fuel tank and rear cowling” section in chapter 3. 4. Adjust: • drive chain slack.

Page 195: Chas

Drive chain, drive sprocket and rear wheel sprocket 4-82 chas drive chain, drive sprocket and rear wheel sprocket note: before removing the drive chain, drive sprocket and rear wheel sprocket, it is necessary to meas- ure the free play and length of the 10 links in the chain. Drive chain removal 1. ...

Page 196: Chas

Chas drive chain, drive sprocket and rear wheel sprocket 4-83 a 6. Remove: • swingarm • drive chain refer to “rear shock absorber removal” and “swingarm removal” sections. Drive chain inspection 1. Measure: • length of 10 links (drive chain) out of specification ➔ replace drive chain. Maximum lenght...

Page 197: Chas

Drive chain, drive sprocket and rear wheel sprocket 4-84 chas 3. Inspect: • seal rings (1) (drive chain) damaged ➔ replace drive chain. • rollers (2) • lateral plates (3) damage/wear ➔ replace drive chain. 4. Lubricate: • drive chain lubricant for drive chain: sae 80w/90 engine oil or special lubric...

Page 198: Chas

Chas drive chain, drive sprocket and rear wheel sprocket 4-85 3. Tighten: • rear wheel sprocket fastening bolts rear wheel sprocket fastening bolts: 48 nm (4.8 mkg) nut (drive sprocket): 110 nm (11.0 mkg) nut (swingarm pivot shaft): 90 nm (9.0 mkg) nut (frame-relay arm): 60 nm (6.0 mkg) ▲ ▲ ▲ ▲ ▲ ▲ ...

Page 199: Chas

Drive chain, drive sprocket and rear wheel sprocket 4-86 chas 5. Tighten: • rear wheel axle nut rear wheel axle nut: 115 nm (11.5 mkg) screws (drive sprocket cover): 10 nm (1.0 mkg) bolt (shift pedal): 10 nm (1.0 mkg) refer to “rear wheel installation” section. 7. Install: • cover (drive sprocket) •...

Page 200: Eng

Eng 5.

Page 201: Eng

Eng chapter 5. Engine engine removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 muffler, exhaust pipe, engine protector, drive sprocket, crankcase cover, drive sprocket and shift pedal . . . . . . . . . . . . . . . 5-1 engine mountin...

Page 202: Eng

Eng engine assembly and setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-41 valves and rocker arms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-41 valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 203: Eng

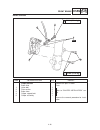

Eng engine removal 5-1 engine engine removal muffler, exhaust pipe, engine protector, drive sprocket crankcase cover, drive sprocket and shift pedal order job name/part name q.Ty remarks muffler, exhaust pipe, engine remove the parts in order. Protector, drive sprocket crankcase cover, drive sprocke...

Page 204: Eng

Engine removal 5-2 eng order job name/part name q.Ty remarks drain the engine oil (refer to “engine oil replacement” section in chapter 3). Remove the seat, the fuel tank and the rear cowling (refer to “seat, fuel tank and rear cowling” section in chapter 3). 1 battery leads connector 1 disconnect. ...

Page 205: Eng

Eng engine removal 5-3 order job name/part name q.Ty remarks – starter leads 2 disconnect. – starter 1 remove. 10 connectors of engine wire harness 2 disconnect. 11 oil delivery hose 1 disconnect. 12 oil return hose 1 disconnect. 13 oil breather pipe (to oil tank) – disconnect. 14 oil breather pipe ...

Page 206: Eng

Engine removal 5-4 eng order job name/part name q.Ty remarks the engine and rear arm are assembled together on the rear pivot shaft. When removing the pivot shaft, it is thus necessary to pay special care with the rear arm. 1 stay of oil tank – remove the mounting screws (to engine). 2 hose clamp (c...

Page 207: Eng

Eng engine disassembly 5-5 engine disassembly cylinder head, cylinder, camshaft and piston note: the cylinder head, cylinder, camshaft and piston can be examined with the engine installed by removing the following parts. • seat • fuel tank • rear cowling • carburetor • exhaust pipe 1. Remove: • spar...

Page 208: Eng

Engine disassembly 5-6 eng 4. Remove: • cam sprocket (1) • camshaft (2) • caps (left crankcase cover) note: fix a safety wire (3) to the timing chain to prevent it falling into the crankcase. 5. Remove: • chain stopper guide (1) 6. Remove: • cylinder head note: loosen all bolts by a 1/4 turn and rem...

Page 209: Eng

Eng engine disassembly 5-7 7. Remove: • gasket (1) (cylinder head) • pins (2) • cylinder (3) • gasket (4) (cylinder) 8. Remove: • pins (1) 9. Remove: • pin ring (1) note: before removing the pin ring, cover the crankcase with a clean cloth to prevent the ring falling into the crankcase cavity. 10. R...

Page 210: Eng

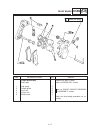

Engine disassembly 5-8 eng avoid using the hammer to pull the pin out. Caution: piston pin puller set: p/n. 90890-01304 3. Remove: • neutral gear switch cable (1) 2. Remove: • intermediate starter gear (1) • bearing (2) • distributor shaft (3) intermediate starter gear, crankcase cover (l) and gener...

Page 211: Eng

Eng engine disassembly 5-9 4. Remove: • crankcase cover gasket (1) (l) • centring pins • seal ring and o-ring • gasket 6. Remove: • cable clamp (1) • coil (2) • stator (3) crankcase cover (r), clutch, primary drive gear and balancer shaft gear note: the clutch, the primary gear and the balance gear ...

Page 212: Eng

Engine disassembly 5-10 eng 2. Remove: • compression spring (1) • pressure plate (2) • ball (3) • friction plate (4) • clutch plate (5) • clutch boss spring (6) • clutch boss (7) • thrust plate (8) • clutch shroud (9) • push rod (10) 1. Remove: • engine oil delivery hose screw • copper washer • oil ...

Page 213: Eng

Eng engine disassembly 5-11 3. Remove • primary drive gear (1) • disc (2) • balancer drive gear (3) • disc (4) • key (5) • disc washer (6) • disc (7) • balancer gear (8) • straight key (9) note: before loosening the nut (9) (primary drive gear) and nut (10) (balancer gear), straighten the wash lock ...

Page 214: Eng

Engine disassembly 5-12 eng oil pump and shift lever note: the oil pump and shift lever may be checked with the engine installed by removing the following parts: • footrest (r) • oil delivery hose screw • crankcase (r) • clutch 1. Remove: • circlip (1) • oil pump gear (2) • oil pump (3) • o-rings (4...

Page 215: Eng

Eng engine disassembly 5-13 ac generator and timing chain note: the ac generator may be inspected with the engine installed by removing the following parts: • crankcase (l) 1. Remove: • nut (1) • washer (2) • rotor (3) (with starter gear) • bearing (4) • shim adjustment washer (5) • key (6) note: to...

Page 216: Eng

Engine disassembly 5-14 eng crankcase (r) 1. Remove: • crankcase (r) note: • loosen nuts starting from the one with the highest number. • loosen all by 1/4 turn and then remove. Removal procedure: • set the crankcase separating tool (1) in place. ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼...

Page 217: Eng

Eng engine disassembly 5-15 • be careful not to damage surfaces in con- tact with the crankcase. • use a soft hammer to hit the engine crankcase. Only hit the reinforced parts. Do not hit the surface in contact with the gasket. Work slowly and carefully. Be care- ful to perform the separation unifor...

Page 218: Eng

Engine disassembly 5-16 eng gearbox and transmission 1. Remove: • guide bar (1) • shift cam (2) • selector fork # 3 (3) • selector fork # 2 (4) • selector fork # 1 (5) 2. Remove: • transmission assembly unit (1) 3. Remove: • shift shaft # 1 (1) • shift shaft # 2 (2).

Page 219: Eng

Eng engine disassembly 5-17 balancer shaft and crankshaft 1. Remove: • balancer shaft (1) 2. Remove: • crankshaft (1) note: • remove the crankshaft by using the crankcase separating tool (2). Crankcase separating tool: p/n. 90890-01135 • tighten the separating tool bolts, making sure that the tool b...

Page 220: Eng

Engine disassembly 5-18 eng rocker arms note: the rocker arms may be examined with the engine installed by removing the following parts. • seat • fuel tank • cylinder head cover 1. Remove: • cap (1) 2. Remove: • bolts (1) (rocker shaft) 3. Remove: • rocker shaft • rocker arms note: remove the rocker...

Page 221: Eng

Eng engine disassembly 5-19 valves note: the valves may be inspected with the engine installed by removing the following parts. • seat • fuel tank • exhaust pipe • carburetor • cylinder head cover • cylinder head 1. Check: • valve seal leakage from valve seats’ inspect the valve surface, the seat an...

Page 222: Eng

Engine disassembly 5-20 eng 2. Remove: • cotters (1) • top spring retainer (2) • internal spring (3) • external spring (4) • lower spring retainer (5) • valve (6) • valve stem seal (7) note: mark each part and its position so that each may reassembled as before. Note: compress the valve spring using...

Page 223: Eng

Eng inspection and repair 5-21 inspection and repair cylinder head 1. Eliminate: • carbon deposits (from combustion chamber) use a rounded scraper (1). Note: do not use a pointed tool to avoid damaging or scratching: • spark plug thread • valve seats • combustion chamber 2. Inspect: • cylinder head ...

Page 224: Eng

Inspection and repair 5-22 eng valves and valve guides 1. Measure: • clearance between stem and guide clearance between stem and guide = internal diameter of valve guide (a) – diameter of valve stem (b) out of specification ➔ replace valve guide. Clearance between stem and guide: intake: 0.010 ~ 0.0...

Page 225: Eng

Eng inspection and repair 5-23 2. Clean the valve surfaces of the carbon deposits. 3. Inspect: • valve seal surface pitting/wear ➔ grind the valve seal sur- face. 4. Measure: • edge thickness (a) out of specification ➔ replace valve. Edge thickness (a): intake: 1.0 ~ 1.4 mm : 0.8 mm exhaust: 0.8 ~ 1...

Page 226: Eng

Inspection and repair 5-24 eng 3. Measure: • valve seat width (a) out of specification ➔ renew valve seat. Valve seat width (a): intake: 1.0 ~ 1.2 mm : 1.8 mm exhaust: 1.0 ~ 1.2 mm : 1.8 mm ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ...

Page 227: Eng

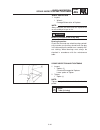

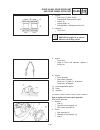

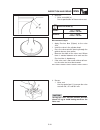

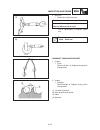

Eng inspection and repair 5-25 mill the valve seat as follows: section cutter a 30° b 45° c 60° ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ valve seat faults recorded by analysing the valve seal surface: [a] if the valve surface resembles that shown in the figure, this means that the v...

Page 228: Eng

Inspection and repair 5-26 eng 5. Emery: • valve seal surface • valve seat note: if the valve seat is renewed or the valve and guide replaced, the valve seat and seal surface must be lapped. ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ lapping steps: • apply rough-lapping compound to th...

Page 229: Eng

Eng inspection and repair 5-27 • apply prussian blue (dykem) to the valve seal surface. • install the valve in the cylinder head. • press the valve onto the housing through the guide to leave a clear outline. • measure the valve seat width once more. If the width of the valve is out of specification...

Page 230: Eng

Inspection and repair 5-28 eng camshaft 1. Inspect: • cam eccentrics pitting/scratches/blue colour ➔ replace camshaft. 2. Measure: • cam eccentrics out of specification ➔ replace camshaft. (a) (b) intake: 36.47~36.57 mm 30.06~30.16 mm exhaust: 36.62~36.72 mm 30.11~30.21 mm rocker arms and rocker sha...

Page 231: Eng

Eng inspection and repair 5-29 3. Measure: • rocker arm-shaft clearance rocker arm-shaft clearance internal diameter (a) of rocker arm – external diameter (b) of shaft out of specification ➔ replace whole unit. Rocker shaft clearance: 0.009 ~ 0.042 mm camshaft chain and sprocket 1. Inspect: • chain ...

Page 232: Eng

Inspection and repair 5-30 eng camshaft chain guide 1. Inspect: • side chain guide (exhaust) (1) • side chain guide (intake) (2) wear/damage ➔ replace. Cylinder and piston 1. Inspect: • piston and cylinder walls vertical scratches ➔ replace cylinder liner and piston. 2. Measure: • piston-cylinder cl...

Page 233: Eng

Eng inspection and repair 5-31 • if the measurements are out of tolerance, replace the piston and circlips all together. • calculate the piston-cylinder free play accord- ing to the following formula. Third step piston-cylinder clearance = cylinder boring “c” – piston skirt diameter “p” piston-cylin...

Page 234: Eng

Inspection and repair 5-32 eng piston rings 1. Measure: • side clearance of rings use a thickness gauge. Out of specification ➔ replace piston. Note: before measuring side clearance, remove carbon deposits from the piston ring seats and from the rings themselves. Piston ring side clearance (installe...

Page 235: Eng

Eng inspection and repair 5-33 piston pin 1. Check: • piston pin blue colour/grooves ➔ replace and check lubrication system. External diameter (pin): 21.991 ~ 22.000 mm clearance between piston pin and pin seat on piston: 0.004 ~ 0.024 mm : 0.07 mm 2. Measure: • external diameter (a) of pin out of s...

Page 236: Eng

Inspection and repair 5-34 eng 2. Inspect: • clutch gear assy bearing damaged ➔ replace. 3. Inspect: • groove in clutch boss. Pitting: moderate ➔ burr. Accentuated ➔ replace clutch boss. Note: pitting of the clutch boss grooves causes irregular functioning. 4. Measure: • thickness of friction plates...

Page 237: Eng

Eng inspection and repair 5-35 7. Measure: • free length of clutch compression springs (a) out of specification ➔ replace all springs. Oil pump 1. Measure: • clearance between rotors (a) (between the internal rotor (1) and the external rotor (2)) • side clearance (b) (between the external rotor (2) ...

Page 238: Eng

Inspection and repair 5-36 eng transmission and gearbox 1. Inspect: • shift fork pin (1) • shift fork pawl (2) lines/creases/wear ➔ replace. 2. Inspect: • shift cam groove • shift cam pins wear/damage ➔ replace. 3. Check: • shift fork movement rough functioning ➔ replace shift forks and/or guide bar...

Page 239: Eng

Eng inspection and repair 5-37 6. Inspect: • gear teeth brown colouring/pitting/wear ➔ replace. • mating clutches rounded edges/cracks/missing frag- ments ➔ replace. 7. Check: • proper mating of each gear (with corre- sponding part) • gear movement roughness ➔ replace. ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ...

Page 240: Eng

• install the starter rim on the gear and hold the gear firm. • when turning the gear rim in a clockwise direction (a), the gear and rim must be meshed. Otherwise, the gear is faulty and must be replaced. • when the gear rim is turned in a anti- clockwise direction (b), it must turn freely. Otherwis...

Page 241: Eng

Eng inspection and repair 5-39 crankshaft 1. Measure: • width of crank (a) out of specification ➔ replace crankshaft. Width of crank: 74.95 ~ 75.00 mm crankshaft runout: : 0.03 mm connecting rod small end clearance: 0.8 mm connecting rod big end clearance: 0.35 ~ 0.65 mm • runout (b) out of specific...

Page 242: Eng

Inspection and repair 5-40 eng balancer shaft drive and driven gears 1. Inspect: • drive gear teeth (1) • driven gear teeth (2) wear/damage ➔ replace both gears. 2. Check: • marks (1) if they are not aligned ➔ align the marks as shown in the figure. Crankcase 1. Inspect: • crankcase • bearing housin...

Page 243: Eng

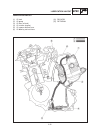

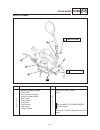

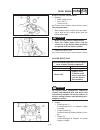

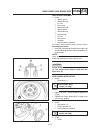

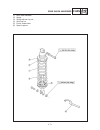

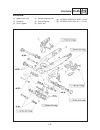

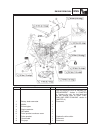

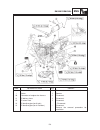

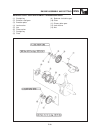

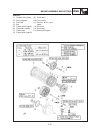

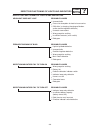

Eng engine assembly and setting 5-41 engine assembly and setting valves and rocker arms (1) rocker arm n. 2 (2) wave washer (3) rocker shaft (intake) (4) rocker arm n. 1 (5) valve cotters (6) upper valve spring retainer (7) oil seal (8) inner valve spring (9) outer valve spring (10) valve (intake) (...

Page 244: Eng

Engine assembly and setting 5-42 eng valves 1. Burrs: • valve stem tip (leave the valve stem tip with an oil stone). 2. Lubricate: • valve stem and oil seal (apply high quality molybdenum disulfide oil) 3. Install: • oil seal (1) • valves (2) • lower valve spring retainer (3) • inner valve spring (4...

Page 245: Eng

Eng engine assembly and setting 5-43 rocker arms 1. Lubricate: • rocker shaft (apply engine oil) 2. Install: • rocker arm • rocker shaft screws (1) (rocker shaft): 10 nm (1.0 kgm) note: each rocker arm is numbered. (1) # 1 (2) # 2 (3) # 3 (4) # 4 3. Install: • cap (1).

Page 246: Eng

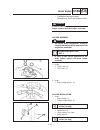

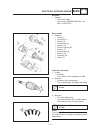

Engine assembly and setting 5-44 eng crankshaft and balancer shaft (1) connecting rod pin (2) crank (left) (3) connecting rod (4) bearing (5) bearing (6) bearing (7) balancer shaft (8) bearing.

Page 247: Eng

Eng engine assembly and setting 5-45 crankshaft and balancer shaft 1. Install: • crankshaft crankshaft installation tool (1): p/n. Y u-90050 crankshaft installation tool spacer (2): p/n. 90890-01274 crankshaft installation tool bolt (3): p/n. 90890-01275 adapter # 10 (ml 4) (4): p/n. Y m-90069 p/n. ...

Page 248: Eng

Engine assembly and setting 5-46 eng transmission (1) sprocket (2) oil seal (3) bearing (4) second wheel gear (5) secondary shaft (6) fifth wheel gear (7) third wheel gear (8) fourth wheel gear (9) first wheel gear (10) bearing (11) bearing (12) second sprocket gear (13) fifth sprocket gear (14) thi...

Page 249: Eng

Eng engine assembly and setting 5-47 gearbox (1) stopper lever (2) guide bar (3) shift fork #3 (4) shift fork #1 (5) shift cam (6) guide bar (7) shift fork #2 (8) shift shaft #1 (9) shift shaft #2 (10) oil seal (11) shift lever.

Page 250: Eng

5-48 eng engine assembly and setting transmission and gearbox 1. Install: • transmission assembly (1) 2. Install: • shift fork #1 (1) • shift fork #2 (2) • shift fork #3 (3) • shift cam (4) • guide bar (5) note: each shift fork is identified by the number stamped on its side. All numbers must face l...

Page 251: Eng

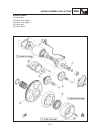

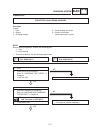

Eng engine assembly and setting 5-49 engine oil pump and oil strainer (1) oil strainer (2) oil pump (3) oil pump gear.

Page 252: Eng

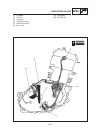

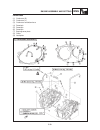

Engine assembly and setting 5-50 eng crankcase (1) crankcase (r) (2) crankcase (l) (3) crankcase ventilation hose (4) dowel pin (5) dowel pin (6) dowel pin (7) bearing cover plate (8) collar (9) lock plate.

Page 253: Eng

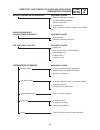

Eng engine assembly and setting 5-51 engine oil strainer 1. Install: • oil strainer (1) • oil passage cover (2) screw (oil strainer): 7 nm (0.7 mkg) screw (oil passage cover): 7 nm (0.7 mkg) warning always use a new gasket. Yamaha bond n° 1215®: p/n. 90890-85505 2 install: • dowel pin (2) 3. Assembl...

Page 254: Eng

Engine assembly and setting 5-52 eng 4. Tighten: • screws (crankcase) (1) ~ (14) note: tighten the screws beginning with the one with the lowest number. Screw (crankcase): 10 nm (1.0 mkg) stopper lever screw (4): 10 nm (1.0 mkg) 5. Apply: • 4-stroke engine oil (to the connecting rod pin, the bearing...

Page 255: Eng

Eng engine assembly and setting 5-53 note: when installing the shift lever, align the mark on the lever with that on the shift shaft. 3. Install: • circlip (1) (to the driving axle) • spacer (2) • circlip (3) 4. Apply: • 4-stroke engine oil (oil pipes in crankcase) to avoid damage to the engine, lub...

Page 256: Eng

Engine assembly and setting 5-54 eng timing chain 1. Install: • timing chain (1) • chain guide (2).

Page 257: Eng

Eng engine assembly and setting 5-55 piston and rings (1) ring (upper) (2) ring (lower) (3) scraper (4) piston (5) piston pin (6) circlip piston size: 94.915 ~ 94.965 mm piston ring end gap: top: 0.30 ~ 0.45 mm 2nd: 0.30 ~ 0.45 mm oil: 0.20 ~ 0.70 mm piston ring side clearance: top: 0.04 ~ 0.08 mm 2...

Page 258: Eng

Engine assembly and setting 5-56 eng cylinder (1) gasket (2) cylinder (3) o-ring (4) gasket (5) dowel pin (6) dowel pin.

Page 259: Eng

Eng engine assembly and setting 5-57 cylinder head (1) cylinder head cover (2) o-ring (3) tappet cover (intake) (4) tappet covers (exhaust) (5) o-ring (6) cap (7) cylinder head (8) valve guide (intake valve) (9) valve guide (exhaust valve) (10) spark plug (11) dowel pin 10 nm (1.0 m • kg 7.2 ft • lb...

Page 260: Eng