- DL manuals

- Yamaha

- Motorcycle

- 2004 WR250FS

- Owner's Service Manual

Yamaha 2004 WR250FS Owner's Service Manual

Summary of 2004 WR250FS

Page 1

Lit-11626-17-51 wr250fs 5um-28199-11 owner’s service manual.

Page 3

Wr250fs owner’s service manual ©2003 by yamaha motor corporation, u.S.A. 1st edition, september 2003 all rights reserved. Any reprinting or unauthorized use without the written permission of yamaha motor corporation u.S.A. Is expressly prohibited. Printed in japan p/n. Lit-11626-17-51.

Page 4: Introduction

Ec020000 introduction congratulations on your purchase of a yamaha wr series. This model is the culmina- tion of yamaha’s vast experience in the pro- duction of pacesetting racing machines. It represents the highest grade of craftsmanship and reliability that have made yamaha a leader. This manual e...

Page 6: Important Notice

Important notice this machine is designed strictly for competition use, only on a closed course. It is illegal for this machine to be operated on any public street, road, or highway. Off-road use on public lands may also be illegal. Please check local regula- tions before riding. 1. This machine is ...

Page 7

6. Gasoline can cause injury. If you should swallow some gasoline, inhale excess gasoline vapors, or allow any gasoline to get into your eyes, contact a doctor immediately. If any gasoline spills onto your skin or clothing, immediately wash skin areas with soap and water, and change your clothes. 7....

Page 8: To The New Owner

Ec050000 to the new owner this manual will provide you with a good basic understanding of features, operation, and basic maintenance and inspection items of this machine. Please read this manual carefully and completely before operating your new machine. If you have any questions regarding the opera...

Page 9: How To Use

Ec080000 how to use this manual ec081000 particularly important information the safety alert symbol means attention! Become alert! Your safety is involved! Failure to follow warning instructions could result in severe injury or death to the machine operator, a bystander, or a person inspecting or re...

Page 10

Ec083000 manual format all of the procedures in this manual are organized in a sequential, step-by-step format. The informa- tion has been complied to provide the mechanic with an easy to read, handy reference that contains comprehensive explanations of all disassembly, repair, assembly, and inspect...

Page 11: Gen

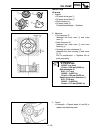

Illustrated symbols (refer to the illustration) illustrated symbols 1 to 7 are designed as thumb tabs to indicate the chapter’s number and content. 1 general information 2 specifications 3 regular inspection and adjustments 4 engine 5 chassis 6 electrical 7 tuning illustrated symbols 8 to d are used...

Page 12: Memo

Memo.

Page 13: Index

Ec090000 index general information 1 specifications spec 2 regular inspection and adjustments 3 engine eng 4 chassis chas 5 electrical elec 6 tuning tun 7 gen info insp adj – +.

Page 14: Contents

Ec0a0000 contents chapter 1 general information description .......................................... 1-1 machine identification .................... 1-2 important information ................... 1-3 checking of connection ................ 1-6 special tools ...................................... 1-...

Page 15: Chapter 4

Chapter 4 engine seat, fuel tank and side covers .......................................... 4-1 exhaust pipe and silencer ............ 4-3 radiator ................................................ 4-5 carburetor ......................................... 4-8 camshafts ...................................

Page 16: Chapter 6

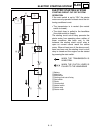

Chapter 6 electrical electrical components and wiring diagram ................................... 6-1 map-controlled cdi unit ................ 6-2 ignition system ................................... 6-3 electric starting system .............. 6-8 charging system ............................. 6-17 th...

Page 17: Gen

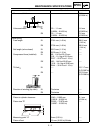

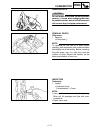

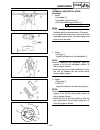

Gen info 1 - 1 description ec100000 general information ec110000 description 1 clutch lever 2 hot starter lever 3 engine stop switch 4 trip meter 5 main switch 6 start switch 7 front brake lever 8 throttle grip 9 radiator cap 0 fuel tank cap a taillight b kickstarter crank c fuel tank d headlight e ...

Page 18: Gen

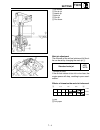

1 - 2 gen info machine identification ec120001 machine identification there are two significant reasons for knowing the serial number of your machine: 1. When ordering parts, you can give the number to your yamaha dealer for positive identification of the model you own. 2. If your machine is stolen,...

Page 19: Gen

1 - 3 gen info important information ec130000 important information ec131010 preparation for removal and disassembly 1. Remove all dirt, mud, dust, and foreign material before removal and disassembly. When washing the machine with high pres- sured water, cover the parts follows. • silencer exhaust p...

Page 20: Gen

1 - 4 gen info important information ec132000 all replacement parts 1. We recommend to use yamaha genuine parts for all replacements. Use oil and/or grease recommended by yamaha for assembly and adjustment. Ec133000 gaskets, oil seals and o-rings 1. All gaskets, oil seals, and o-rings should be repl...

Page 21: Gen

1 - 5 gen info important information ec136000 circlips 1. All circlips should be inspected carefully before reassembly. Always replace piston pin clips after one use. Replace distorted circlips. When installing a circlip 1, make sure that the sharp-edged corner 2 is posi- tioned opposite to the thru...

Page 22: Gen

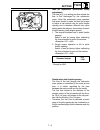

1 - 6 gen info checking of connection ec1c0001 checking of connection dealing with stains, rust, moisture, etc. On the connector. 1. Disconnect: • connector 2. Dry each terminal with an air blower. 3. Connect and disconnect the connector two or three times. 4. Pull the lead to check that it will not...

Page 23: Gen

Gen info 1 - 7 special tools special tools the proper special tools are necessary for complete and accurate tune-up and assembly. Using the correct special tool will help prevent damage caused by the use of improper tools or improvised techniques. The shape and part number used for the special tool ...

Page 24: Gen

Gen info 1 - 8 special tools ym-01442, 90890-01442 fork seal driver this tool is used when install the fork oil seal. Ys-1880-a, 90890-01701 sheave holder this tool is used for when loosening or tightening the flywheel magneto securing nut yu-3112-c, 90890-03112 pocket tester use this tool to inspec...

Page 25: Gen

Gen info 1 - 9 special tools ym-04141, 90890-04141 rotor puller this tool is used to remove the flywheel magneto. Ym-34487 90890-06754 dynamic spark tester ignition checker this instrument is necessary for checking the ignition system components. Acc-quick-gs-kt 90890-85505 quick gasket yamaha bond ...

Page 26: Gen

1 - 10 gen info control functions ec150000 control functions main switch functions of the respective switch positions are as follows: on: the engine can be started only at this position. Off: all electrical circuits are switched off. Main switch indicator light the main switch 1 is equipped with an ...

Page 27: Gen

1 - 11 gen info control functions ec152000 clutch lever the clutch lever 1 is located on the left han- dlebar; it disengages or engages the clutch. Pull the clutch lever to the handlebar to disen- gage the clutch, and release the lever to engage the clutch. The lever should be pulled rapidly and rel...

Page 28: Gen

1 - 12 gen info control functions ec157000 rear brake pedal the rear brake pedal 1 is located on the right side of the machine. Press down on the brake pedal to activate the rear brake. Fuel cock the fuel cock supplies fuel from the tank to carburetor and also filters the fuel. The fuel cock has thr...

Page 29: Gen

1 - 13 gen info sidestand this sidestand 1 is used to support only the machine when standing or transporting it. Warning • never apply additional force to the side- stand. • hold up the sidestand before starting out. 1 ec15f000 valve joint this valve joint 1 prevents fuel from flowing out and is ins...

Page 30: Gen

1 - 14 gen info fuel always use the recommended fuel as stated below. Also, be sure to use new gasoline the day of a race. Caution: use only unleaded gasoline. The use of leaded gasoline will cause severe damage to the engine internal parts such as valves, piston rings, and exhaust system, etc. Note...

Page 31: Gen

1 - 15 gen info starting and break-in starting and break-in warning never start or run the engine in a closed area. The exhaust fumes are poisonous; they can cause loss of consciousness and death in a very short time. Always operate the machine in a well-ventilated area. Caution: • the carburetor on...

Page 32: Gen

1 - 16 gen info starting and break-in note: if the engine fails to start by pushing the start switch, release the switch, wait a few seconds, and then try again. Each starting attempt should be as short as possible to preserve the battery. Do not crank the engine more than 10 seconds on any one atte...

Page 33: Gen

1 - 17 gen info starting and break-in starting a warm engine do not operate the cold starter knob and throt- tle. Pull the hot starter lever 1 and start the engine by pushing the start switch or by kick- ing the kickstarter crank forcefully with a firm stroke. As soon as the engine starts, release t...

Page 34: Gen

1 - 18 gen info break-in procedures 1. Before starting the engine, fill the fuel tank with the fuel. 2. Perform the pre-operation checks on the machine. 3. Start and warm up the engine. Check the idle speed, and check the operation of the controls and the engine stop switch. Then, restart the engine...

Page 35: Gen

Gen info 1 - 19 torque-check points torque-check points frame construction combined seat and fuel tank exhaust system engine mounting steering steering stem to handlebar suspension front steering stem to front fork rear for link type rear installation of rear shock absorber rear installation of swin...

Page 36: Gen

1 - 20 gen info cleaning and storage ec1b0000 cleaning and storage ec1b1000 cleaning frequent cleaning of your machine will enhance its appearance, maintain good overall performance, and extend the life of many com- ponents. 1. Before washing the machine, block off the end of the exhaust pipe to pre...

Page 37: Gen

1 - 21 gen info cleaning and storage ec1b2001 storage if your machine is to be stored for 60 days or more, some preventive measures must be taken to avoid deterioration. After cleaning the machine thoroughly, prepare it for storage as follows: 1. Drain the fuel tank, fuel lines, and the car- buretor...

Page 38: Spec

Spec 2 - 1 general specifications ec200000 specifications ec211000 general specifications model name: wr250fs (usa) wr250f (europe) wr250f(s) (cdn, aus, nz, za) model code number: 5um5 (usa) 5um6 (europe) 5um7 (cdn, aus, nz, za) dimensions: overall length 2,165 mm (85.2 in) overall width 827 mm (32....

Page 39: Spec

Spec 2 - 2 general specifications oil capacity: engine oil periodic oil change 1.2 l (1.06 imp qt, 1.27 us qt) with oil filter replacement 1.3 l (1.14 imp qt, 1.37 us qt) total amount 1.4 l (1.23 imp qt, 1.48 us qt) coolant capacity (including all routes): 1.3 l (1.14 imp qt, 1.37 us qt) air filter:...

Page 40: Spec

Spec 2 - 3 general specifications brake: front brake type single disc brake operation right hand operation rear brake type single disc brake operation right foot operation suspension: front suspension telescopic fork rear suspension swingarm (link type monocross suspension) shock absorber: front sho...

Page 41: Spec

Spec 2 - 4 maintenance specifications maintenance specifications engine item standard limit cylinder head: warp limit ---- 0.05 mm (0.002 in) cylinder: bore size 77.00 ~ 77.01 mm (3.0315 ~ 3.0319 in) ---- out of round limit ---- 0.05 mm (0.002 in) camshaft: drive method chain drive (left) ---- camsh...

Page 42: Spec

Spec 2 - 5 maintenance specifications timing chain: timing chain type/no. Of links 92rh2010-114m/114 ---- timing chain adjustment method automatic ---- valve, valve seat, valve guide: valve clearance (cold) in 0.10 ~ 0.15 mm (0.0039 ~ 0.0059 in) ---- ex 0.17 ~ 0.22 mm (0.0067 ~ 0.0087 in) ---- valve...

Page 43: Spec

Spec 2 - 6 maintenance specifications stem runout limit ---- 0.01 mm (0.0004 in) valve seat width in 0.9 ~ 1.1 mm (0.0354 ~ 0.0433 in) 1.6 mm (0.0630 in) ex 0.9 ~ 1.1 mm (0.0354 ~ 0.0433 in) 1.6 mm (0.0630 in) valve spring: free length in 37.81 mm (1.49 in) 36.81 mm (1.45 in) ex 37.54 mm (1.48 in) 3...

Page 44: Spec

Spec 2 - 7 maintenance specifications piston pin bore inside diameter 16.002 ~ 16.013 mm (0.6300 ~ 0.6304 in) 16.043 mm (0.6316 in) piston pin outside diameter 15.991 ~ 16.000 mm (0.6296 ~ 0.6299 in) 15.971 mm (0.6288 in) piston rings: top ring: type barrel ---- dimensions (b × t) 0.90 × 2.75 mm (0....

Page 45: Spec

Spec 2 - 8 maintenance specifications clutch: friction plate thickness 2.9 ~ 3.1 mm (0.114 ~ 0.122 in) 2.7 mm (0.106 in) quantity 9 ---- clutch plate thickness 1.1 ~ 1.3 mm (0.043 ~ 0.051 in) ---- quantity 8 ---- warp limit ---- 0.1 mm (0.004 in) clutch spring free length 37.0 mm (1.46 in) 36.0 mm (...

Page 46: Spec

Spec 2 - 9 maintenance specifications lubrication system: oil filter type paper type ---- oil pump type trochoid type ---- tip clearance 0.12 mm or less (0.0047 in or less) 0.20 mm (0.008 in) side clearance 0.09 ~ 0.17 mm (0.0035 ~ 0.0067 in) 0.24 mm (0.009 in) housing and rotor clearance 0.03 ~ 0.1...

Page 47: Spec

Spec 2 - 10 maintenance specifications part to be tightened thread size q’ty tightening torque nm m·kg ft·lb spark plug m10s × 1.0 1 13 1.3 9.4 camshaft cap m6 × 1.0 10 10 1.0 7.2 cylinder head blind plug screw m12 × 1.0 1 28 2.8 20 cylinder head (stud bolt) m6 × 1.0 2 7 0.7 5.1 (stud bolt) m8 × 1.2...

Page 48: Spec

Spec 2 - 11 maintenance specifications note: - marked portion shall be checked for torque tightening after break-in or before each race. Silencer m8 × 1.25 2 35 3.5 25 silencer clamp m8 × 1.25 1 16 1.6 11 spark arrester (for usa) m6 × 1.0 3 10 1.0 7.2 silencer end pipe (for usa) m6 × 1.0 1 10 1.0 7....

Page 49: Spec

Spec 2 - 12 maintenance specifications chassis item standard limit steering system: steering bearing type taper roller bearing ---- front suspension: usa, cdn europe aus, nz, za front fork travel 300 mm (11.8 in) ← ← fork spring free length 460 mm (18.1 in) ← ← spring rate, std k = 4.31 n/mm (0.44 k...

Page 50: Spec

Spec 2 - 13 maintenance specifications wheel: usa, cdn, za europe, aus, nz front wheel type spoke wheel ← ---- rear wheel type spoke wheel ← ---- front rim size/material 21 × 1.60/aluminum ← ---- rear rim size/material 18 × 1.85/aluminum 18 × 2.15/aluminum ---- rim runout limit: radial ---- ---- 2.0...

Page 51: Spec

Spec 2 - 14 maintenance specifications note: 1. First, tighten the steering nut approximately 38 nm (3.8 m • kg, 27 ft • lb) by using the steering nut wrench, then loosen the steering nut one turn. 2. Retighten the steering nut 7 nm (0.7 m • kg, 5.1 ft • lb). Part to be tightened thread size q’ty ti...

Page 52: Spec

Spec 2 - 15 maintenance specifications part to be tightened thread size q’ty tightening torque nm m·kg ft·lb nipple (spoke) — 72 3 0.3 2.2 rear wheel sprocket m8 × 1.25 6 50 5.0 36 rear brake disc cover m6 × 1.0 2 7 0.7 5.1 rear brake caliper protector m6 × 1.0 2 7 0.7 5.1 drive chain puller adjust ...

Page 53: Spec

Spec 2 - 16 maintenance specifications note: - marked portion shall be checked for torque tightening after break-in or before each race. Headlight body and headlight unit m6 × 1.0 2 7 0.7 5.1 headlight (left and right) m6 × 1.0 2 10 1.0 7.2 headlight (lower) m6 × 1.0 1 7 0.7 5.1 taillight m6 × 1.0 3...

Page 54: Spec

Spec 2 - 17 maintenance specifications ec212300 electrical item standard limit ignition system: advancer type electrical ---- cdi: pickup coil resistance (color) 248 ~ 372 Ω at 20 °c (68 °f) (white – red) ---- cdi unit-model/manufacturer 5um-50/yamaha (for usa) ---- 5um-60/yamaha (except for usa) --...

Page 55: Spec

Spec 2 - 18 maintenance specifications note: tighten the rotor nut to 65 nm (6.5 m · kg, 47 ft · lb), loosen and retighten the rotor nut to 65 nm (6.5 m · kg, 47 ft · lb). Starter relay: model/manufacturer 2768090-a/jideco ---- amperage rating 180 a ---- coil winding resistance 4.2 ~ 4.6 Ω at 20 °c ...

Page 56: Spec

Spec 2 - 19 ec220001 general torque specifications this chart specifies torque for standard fasten- ers with standard i.S.O. Pitch threads. Torque specifications for special components or assemblies are included in the applicable sec- tions of this book. To avoid warpage, tighten multi-fastener asse...

Page 57: Spec

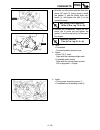

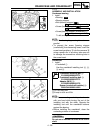

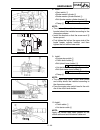

2 - 20 spec cable routing diagram ec240000 cable routing diagram 1 fuel tank breather hose 2 oil tank breather hose 3 clamp 4 diode 5 wire harness 6 hot starter cable 7 throttle position sensor lead 8 neutral switch lead 9 oil hose 0 hose guide a ac magneto lead b cylinder head breather hose c start...

Page 58: Spec

2 - 21 spec cable routing diagram È insert the fuel tank breather hose into the hole in the steering stem cap. É pass the oil tank breather hose on the outside of the ac magneto lead, neutral switch lead, wire harness, starter motor lead, negative battery lead and cylinder head breather hose. Ê fast...

Page 59: Spec

2 - 22 spec Î fasten the wire harness at its white tape. Ï fasten the wire harness, throttle position sensor lead (in the wire harness), starter motor lead and negative battery lead. Ð make sure that the throttle position sensor coupler does not go outside the chassis. Ñ fasten the throttle position...

Page 60: Spec

2 - 23 spec cable routing diagram × pass the cylinder head breather hose on the inside of the radiator hose 1 and on the outside of the radiator pipe (radiator hose 4). Make sure that the cylinder head breather hose does not go for- ward of the chassis. Ø pass the starter motor lead in front of the ...

Page 61: Spec

2 - 24 spec cable routing diagram 1 hot starter cable 2 cable guide 3 throttle cable (return) 4 throttle cable (pull) 5 ignition coil 6 coolant reservoir breather hose 7 rectifier/regulator 8 coolant reservoir hose 9 rectifier/regulator lead 0 clamp a cdi unit lead b cdi unit c cdi unit band d cdi u...

Page 62: Spec

2 - 25 spec cable routing diagram Ì fasten the coolant reservoir breather hose and carburetor breather hoses together. Í fasten the rectifier/regulator lead. Î fasten the cdi unit lead. Ï insert the cdi unit band over the cdi unit stay as far as possible. Ð do not allow the rectifier/regulator lead ...

Page 63: Spec

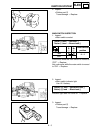

2 - 26 spec cable routing diagram 1 brake master cylinder 2 brake hose holder 3 brake hose È install the brake hose so that its pipe portion directs as shown and lightly touches the projection on the brake caliper. É pass the brake hose into the brake hose holders. Ê if the brake hose contacts the s...

Page 64: Spec

2 - 27 spec cable routing diagram 1 starter motor lead 2 negative battery lead 3 wire harness 4 clamp 5 taillight lead 6 coolant reservoir breather hose 7 coolant reservoir hose 8 positive battery lead 9 starting circuit cut-off relay 0 battery È position the starter motor lead, negative battery lea...

Page 65: Spec

2 - 28 spec cable routing diagram 1 throttle cable 2 clamp 3 brake hose 4 hot starter cable 5 clutch cable 6 hose guide 7 clutch switch lead 8 engine stop switch lead 9 trip meter cable 0 main switch lead a trip meter b main switch c start switch lead È fasten the start switch lead. É fasten the eng...

Page 66: Insp

3 - 1 insp adj maintenance intervals ec300000 regular inspection and adjustments maintenance intervals the following schedule is intended as a general guide to maintenance and lubrication. Bear in mind that such factors as weather, terrain, geographical location, and individual usage will alter the ...

Page 67: Insp

3 - 2 insp adj maintenance intervals shift fork, shift cam, guide bar inspect inspect wear rotor nut retighten exhaust pipe, silencer, protector inspect and retighten clean replace * whichever comes first *spark arrester clean (every six months) crank inspect and clean carburetor inspect, adjust and...

Page 68: Insp

3 - 3 insp adj maintenance intervals *marked: for usa front forks inspect and adjust replace oil suspension oil “01” replace oil seal front fork oil seal and dust seal clean and lube lithium base grease rear shock absorber inspect and adjust lube (after rain ride) molybdenum disulfide grease retight...

Page 69: Insp

3 - 4 insp adj pre-operation inspection and maintenance ec320000 pre-operation inspection and maintenance before riding for break-in operation, practice or a race, make sure the machine is in good operating condition. Before using this machine, check the following points. General inspection and main...

Page 70: Insp

3 - 5 insp adj ec350000 engine coolant level inspection warning do not remove the radiator cap 1, drain bolt and hoses when the engine and radia- tor are hot. Scalding hot fluid and steam may be blown out under pressure, which could cause serious injury. When the engine has cooled, place a thick tow...

Page 71: Insp

3 - 6 insp adj coolant replacement caution: take care so that coolant does not splash on painted surfaces. If it splashes, wash it away with water. 1. Place a container under the engine. 2. Remove: • seat refer to “seat, fuel tank and side covers” section in the chapter 4. 3. Disconnect: • coolant r...

Page 72: Insp

3 - 7 insp adj coolant replacement 9. Fill: • radiator • engine to specified level. Caution: • do not mix more than one type of ethyl- ene glycol antifreeze containing corro- sion inhibitors for aluminum engine. • do not use water containing impurities or oil. Recommended coolant: high quality ethyl...

Page 73: Insp

3 - 8 insp adj radiator cap inspection/ radiator cap opening pressure inspection 12. Install: • coolant reservoir cap 13. Start the engine and let it warm up for sev- eral minutes. 14. Turn off the engine and inspect the coolant level. Refer to “coolant level inspection” section. Note: before checki...

Page 74: Insp

3 - 9 insp adj cooling system inspection/ clutch adjustment 2. Apply the specified pressure. 3. Inspect: • pressure impossible to maintain the specified pres- sure for 10 seconds → replace. Radiator cap opening pressure: 110 kpa (1.1 kg/cm 2 , 15.6 psi) cooling system inspection 1. Inspect: • coolan...

Page 75: Insp

3 - 10 insp adj throttle cable adjustment 2. Adjust: • clutch lever free play note: • make minute adjustment on the lever side using the adjuster 2. • after adjustment, check proper operation of clutch lever. Clutch lever free play adjustment steps: • loosen the locknuts 1. • adjust the free play by...

Page 76: Insp

3 - 11 insp adj throttle lubrication/ hot starter lever adjustment throttle lubrication 1. Remove: • cover (throttle cable cap) 1 • cover (grip cap) 2 • throttle grip cap 3 2. Apply: • lithium soap base grease on the throttle cable end a. 3. Install: • throttle grip cap • screw (throttle grip cap) •...

Page 77: Insp

3 - 12 insp adj air filter cleaning air filter cleaning note: proper air filter maintenance is the biggest key to preventing premature engine wear and damage. Caution: never run the engine without the air filter element in place; this would allow dirt and dust to enter the engine and cause rapid wea...

Page 78: Insp

3 - 13 insp adj caution: • do not twist the element when squeezing the element. • leaving too much of solvent in the ele- ment may result in poor starting. 5. Inspect: • air filter element damage → replace. 6. Apply: • foam-air-filter oil or equivalent oil to the element note: • squeeze out the exce...

Page 79: Insp

3 - 14 insp adj engine oil level inspection engine oil level inspection 1. Start the engine, warm it up for several minutes, and then turn off the engine and wait for five minutes. 2. Place the machine on a level place and hold it up on upright position by placing the suitable stand under the engine...

Page 80: Insp

3 - 15 insp adj engine oil replacement (except for usa and cdn) caution: • do not add any chemical additives or use oils with a grade of cd a or higher. • do not use oils labeled “energy con- serving ii” b or higher. Engine oil also lubricates the clutch and additives could cause clutch slippage. • ...

Page 81: Insp

3 - 16 insp adj engine oil replacement 4. Remove: • oil tank cap 1 • oil filler cap 2 • frame oil drain bolt 3 • crankcase oil drain bolt 4 • oil filter element drain bolt 5 drain the crankcase and oil tank (frame) of its oil. 5. Remove: • lower engine bracket • oil hose clamp 1 • bolt (oil hose) 2 ...

Page 82: Insp

3 - 17 insp adj 8. Install: • copper washer 1 • oil strainer (frame) 2 • oil hose 3 • bolt (oil hose) 4 • oil hose clamp 5 • lower engine bracket 9. Install: • copper washer • oil filter element drain bolt • crankcase oil drain bolt • frame oil drain bolt 10. Fill: • engine oil 11. Check: • oil leak...

Page 83: Insp

3 - 18 insp adj oil pressure inspection 1. Check: • oil pressure checking steps: • slightly loosen the oil pressure check bolt 1. • start the engine and keep it idling until oil starts to seep from the oil pressure check bolt. If no oil comes out after one minute, turn the engine off so it will not ...

Page 84: Insp

3 - 19 insp adj engine idling speed adjustment/ valve clearance inspection and adjustment engine idling speed adjustment 1. Start the engine and thoroughly warm it up. 2. Adjust: • engine idling speed adjustment steps: • adjust the pilot screw. Refer to “pilot screw adjustment” section. • turn the t...

Page 85: Insp

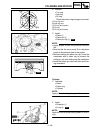

3 - 20 insp adj valve clearance inspection and adjustment 3. Remove: • right radiator refer to “radiator” section in the chapter 4. • carburetor refer to “carburetor” section in the chapter 4. • spark plug • upper engine bracket • cylinder head cover refer to “camshafts” section in the chapter 4. 4....

Page 86: Insp

3 - 21 insp adj valve clearance inspection and adjustment • measure the valve clearance e using a feeler gauge 1. Note: record the measured reading if the clear- ance is incorrect. 6. Adjust: • valve clearance adjustment steps: • remove the camshaft (intake and exhaust). Refer to “camshafts” section...

Page 87: Insp

3 - 22 insp adj valve clearance inspection and adjustment note: the thickness a of each pad is indicated in hundredths of millimeters on the pad upper surface. • round off the last digit of the installed pad number to the nearest increment. Last digit of pad number rounded value 0, 1 or 2 0 4, 5 or ...

Page 88: Insp

3 - 23 insp adj intake exhaust measured clearance installed pad number 120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240 0.00 ~ 0.04 120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 0.05 ~ 0.09 120 125 130 1...

Page 89: Insp

3 - 24 insp adj spark arrester cleaning (for usa) warning • be sure the exhaust pipe and muffler are cool before cleaning the spark arrester. • do not start the engine when cleaning the exhaust system. 1. Remove: • bolt (spark arrester) 1 1 1 2. Remove: • spark arrester 1 pull the spark arrester out...

Page 90: Insp

3 - 25 insp adj ec360000 chassis ec361012 brake system air bleeding warning bleed the brake system if: • the system has been disassembled. • a brake hose has been loosened or removed. • the brake fluid is very low. • the brake operation is faulty. A dangerous loss of braking performance may occur if...

Page 91: Insp

3 - 26 insp adj front brake adjustment 3. Install: • protector (rear brake) • reservoir float (front brake) • diaphragm • brake master cylinder cap note: if bleeding is difficult, it may be necessary to let the brake fluid system stabilize for a few hours. Repeat the bleeding procedure when the tiny...

Page 92: Insp

3 - 27 insp adj rear brake adjustment/ front brake pad inspection and replacement ec364002 rear brake adjustment 1. Check: • brake pedal height a out of specification → adjust. Brake pedal height a: 5 mm (0.20 in) 2. Adjust: • brake pedal height pedal height adjustment steps: • loosen the locknut 1....

Page 93: Insp

3 - 28 insp adj front brake pad inspection and replacement • loosen the pad pin 2. • remove the brake hose holder 3 and brake caliper 4 from the front fork. • remove the pad pin and brake pads 5. • connect the transparent hose 6 to the bleed screw 7 and place the suitable con- tainer under its end. ...

Page 94: Insp

3 - 29 insp adj rear brake pad inspection and replacement 3. Inspect: • brake fluid level refer to “brake fluid level inspec- tion” section. • install the pad pin plug b. T r . . Pad pin plug: 3 nm (0.3 m • kg, 2.2 ft • lb) 4. Check: • brake lever operation a softy or spongy feeling → bleed brake sy...

Page 95: Insp

3 - 30 insp adj rear brake pad inspection and replacement • remove the pad pin 6 and brake pads 7. • connect the transparent hose 8 to the bleed screw 9 and place the suitable con- tainer under its end. • loosen the bleed screw and push the brake caliper piston in. Caution: do not reuse the drained ...

Page 96: Insp

3 - 31 insp adj rear brake pad insulator inspection/ brake fluid level inspection 3. Inspect: • brake fluid level refer to “brake fluid level inspec- tion” section. 4. Check: • brake pedal operation a softy or spongy feeling → bleed brake system. Refer to “brake system air bleed- ing” section. Ec36b...

Page 97: Insp

3 - 32 insp adj sprockets inspection/drive chain inspection sprockets inspection 1. Inspect: • sprocket teeth a excessive wear → replace. Note: replace the drive sprocket, rear wheel sprocket and drive chain as a set. Drive chain inspection 1. Remove: • drive chain 1 note: remove the drive chain usi...

Page 98: Insp

3 - 33 insp adj drive chain inspection 5. Check: • drive chain stiffness a clean and oil the drive chain and hold as illustrated. Stiff → replace the drive chain. 6. Install: • chain joint 1 • o-ring 2 • drive chain 3 note: when installing the drive chain, apply the lith- ium soap base grease on the...

Page 99: Insp

3 - 34 insp adj drive chain slack adjustment drive chain slack adjustment 1. Elevate the rear wheel by placing the suit- able stand under the engine. 2. Check: • drive chain slack a above the seal guard installation bolt. Out of specification → adjust. Note: before checking and/or adjusting, rotate ...

Page 100: Insp

3 - 35 insp adj drive chain stopper inspection/front fork inspection/ front fork oil seal and dust seal cleaning • tighten the axle nut while pushing down the drive chain. T r . . Axle nut: 125 nm (12.5 m • kg, 90 ft • lb) • tighten the locknuts. T r . . Locknut: 16 nm (1.6 m • kg, 11 ft • lb) drive...

Page 101: Insp

3 - 36 insp adj front fork internal pressure relieving/front fork rebound damping force adjustment front fork internal pressure relieving note: if the front fork initial movement feels stiff dur- ing a run, relieve the front fork internal pres- sure. 1. Elevate the front wheel by placing a suit- abl...

Page 102: Insp

3 - 37 insp adj front fork compression damping force adjustment • standard position: this is the position which is back by the spe- cific number of clicks from the fully turned-in position. * for aus, nz and za caution: do not force the adjuster past the minimum or maximum extent of adjustment. The ...

Page 103: Insp

3 - 38 insp adj rear shock absorber inspection • standard position: this is the position which is back by the spe- cific number of clicks from the fully turned-in position. * for europe, aus, nz and za caution: do not force the adjuster past the minimum or maximum extent of adjustment. The adjuster ...

Page 104: Insp

3 - 39 insp adj rear shock absorber spring preload adjustment rear shock absorber spring preload adjustment 1. Elevate the rear wheel by placing the suit- able stand under the engine. 2. Remove: • rear frame 3. Loosen: • locknut 1 4. Adjust: • spring preload by turning the adjuster 2. * for europe n...

Page 105: Insp

3 - 40 insp adj rear shock absorber rebound damping force adjustment ec36n014 rear shock absorber rebound damping force adjustment 1. Adjust: • rebound damping force by turning the adjuster 1. Stiffer a→ increase the rebound damp- ing force. (turn the adjuster 1 in.) softer b→ decrease the rebound d...

Page 106: Insp

3 - 41 insp adj ec36c000 rear shock absorber low compression damping force adjustment 1. Adjust: • low compression damping force by turning the adjuster 1. Stiffer a→ increase the low compres- sion damping force. (turn the adjuster 1 in.) softer b→ decrease the low compres- sion damping force. (turn...

Page 107: Insp

3 - 42 insp adj rear shock absorber high compression damping force adjustment ec36d000 rear shock absorber high compression damping force adjustment 1. Adjust: • high compression damping force by turning the adjuster 1. Stiffer a→ increase the high compres- sion damping force. (turn the adjuster 1 i...

Page 108: Insp

3 - 43 insp adj tire pressure check/spokes inspection and tightening/wheel inspection ec36q000 tire pressure check 1. Measure: • tire pressure out of specification → adjust. Note: • check the tire while it is cold. • loose bead stoppers allow the tire to slip off its position on the rim when the tir...

Page 109: Insp

3 - 44 insp adj steering head inspection and adjustment 2. Inspect: • bearing free play exist play → replace. Ec36u013 steering head inspection and adjustment 1. Elevate the front wheel by placing a suit- able stand under the engine. 2. Check: • steering stem grasp the bottom of the forks and gently...

Page 110: Insp

3 - 45 insp adj • tighten the steering ring nut 3 using steering nut wrench 4. Note: set the torque wrench to the steering nut wrench so that they form a right angle. Steering nut wrench: yu-33975/90890-01403 t r . . Steering ring nut (initial tightening): 38 nm (3.8 m • kg, 27 ft • lb) • loosen the...

Page 111: Insp

3 - 46 insp adj lubrication lubrication to ensure smooth operation of all components, lubricate your machine during setup, after break-in, and after every race. 1 all control cable 2 clutch lever pivot 3 shift pedal pivot 4 footrest pivot 5 throttle-to-handlebar contact 6 drive chain 7 tube guide ca...

Page 112: Insp

3 - 47 insp adj electrical/spark plug inspection/ ignition timing check ec370000 electrical ec371001 spark plug inspection 1. Remove: • spark plug 2. Inspect: • electrode 1 wear/damage → replace. • insulator color 2 normal condition is a medium to light tan color. Distinctly different color → check ...

Page 113: Insp

3 - 48 insp adj ignition timing check 2. Attach: • timing light • inductive tachometer to the ignition coil lead (orange lead 1). Timing light: ym-33277-a/90890-03141 1 3. Adjust: • engine idling speed refer to “engine idling speed adjustment” section. 4. Check: • ignition timing visually check the ...

Page 114: Insp

3 - 49 insp adj battery inspection and charging warning batteries generate explosive hydrogen gas and contain electrolyte which is made of poisonous and highly caustic sulfuric acid. Therefore, always follow these preventive measures: • wear protective eye gear when handling or working near batterie...

Page 115: Insp

3 - 50 insp adj battery inspection and charging note: since mf batteries are sealed, it is not possi- ble to check the charge state of the battery by measuring the specific gravity of the electro- lyte. Therefore, the charge of the battery has to be checked by measuring the voltage at the battery te...

Page 116: Insp

3 - 51 insp adj battery inspection and charging 4. Measure: • battery charge È relationship between the open-circuit voltage and the charging time at 20 °c (68 °f) (these values vary with the temperature, the condition of the battery plates, and the electro- lyte level.) É open-circuit voltage Ê cha...

Page 117: Insp

3 - 52 insp adj battery inspection and charging 5. Charge: • battery (refer to the appropriate charging method illustration) warning do not quick charge a battery. Caution: • never remove the mf battery sealing caps. • do not use a high-rate battery charger since it forces a high-amperage current in...

Page 118: Insp

3 - 53 insp adj battery inspection and charging charging method using a variable voltage charger.

Page 119: Insp

3 - 54 insp adj battery inspection and charging charging method using a constant voltage charger.

Page 120: Insp

3 - 55 insp adj battery replacement/fuse inspection 6. Install: • battery • battery band 7. Connect: • battery leads (to the battery terminals) caution: first, connect the positive lead 1, then the negative lead 2. 8. Check: • battery terminals dirt → clean with a wire brush. Loose connection → conn...

Page 121: Insp

3 - 56 insp adj fuse inspection 2. Check: • continuity 2 reserve fuse checking steps: • remove the fuse 1. • connect the pocket tester to the fuse and check the continuity. Note: set the pocket tester selector to “ Ω × 1”. Pocket tester: yu-3112-c/90890-03112 • if the pocket tester indicates “ ∞”, r...

Page 122: Insp

3 - 57 insp adj replacing the headlight bulbs/ adjusting the headlight beams replacing the headlight bulbs 1. Remove: • headlight refer to “seat, fuel tank and side covers” section in the chapter 4. 2. Remove: • headlight bulb holder cover 1 3. Detach: • headlight bulb holder 1 4. Remove: • headligh...

Page 123: Eng

4 - 1 eng ec400000 engine seat, fuel tank and side covers extent of removal: 1 seat removal 2 fuel tank removal 3 side covers removal 4 headlight removal extent of removal order part name q’ty remarks seat, fuel tank and side covers removal preparation for removal turn the fuel cock to “off”. Discon...

Page 124: Eng

4 - 2 eng removal points side cover 1. Remove: • bolt (side cover) • left side cover 1 • right side cover 2 note: draw the side cover downward to remove it because its claws a are inserted in the air fil- ter case. Seat, fuel tank and side covers.

Page 125: Eng

4 - 3 eng exhaust pipe and silencer ec4s0000 exhaust pipe and silencer È except for usa extent of removal: 1 silencer removal 2 exhaust pipe removal extent of removal order part name q’ty remarks exhaust pipe and silencer removal preparation for removal right side cover refer to “seat, fuel tank and...

Page 126: Eng

4 - 4 eng exhaust pipe and silencer inspection silencer and exhaust pipe 1. Inspect: • gasket 1 damage → replace. 1 assembly and installation silencer and exhaust pipe 1. Install: • gasket • exhaust pipe 1 • nut (exhaust pipe) 2 • bolt (exhaust pipe) 3 note: first, temporarily tighten the nut (exhau...

Page 127: Eng

4 - 5 eng radiator ec450001 radiator extent of removal: 1 radiator removal extent of removal order part name q’ty remarks radiator removal preparation for removal drain the coolant. Refer to “coolant replacement” section in the chapter 3. Seat, fuel tank and left side cover refer to “seat, fuel tank...

Page 128: Eng

4 - 6 eng radiator ec456000 handling note warning do not remove the radiator cap when the engine and radiator are hot. Scalding hot fluid and steam may be blown out under pressure, which could cause serious injury. When the engine has cooled, open the radi- ator cap by the following procedure: place...

Page 129: Eng

4 - 7 eng radiator 3. Install: • right radiator 1 • bolt (right radiator) 2 • radiator hose 3 3 refer to “cable routing diagram” section in the chapter 2. T r . . 10 nm (1.0 m · kg, 7.2 ft · lb) 4. Install: • left radiator 1 • bolt (left radiator) 2 • radiator hose 1 3 refer to “cable routing diagra...

Page 130: Eng

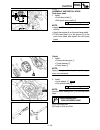

4 - 8 eng carburetor carburetor 9 6 t r . . 4 nm (0.4 m • kg, 2.9 ft • ib) t r . . 2 nm (0.2 m • kg, 1.4 ft • ib) t r . . 11 nm (1.1 m • kg, 8.0 ft • ib) t r . . 4 nm (0.4 m • kg, 2.9 ft • ib) t r . . 3 nm (0.3 m • kg, 2.2 ft • ib) t r . . 3 nm (0.3 m • kg, 2.2 ft • ib) 7 8 5 1 2 6 4 4 1 3 extent of...

Page 131: Eng

4 - 9 eng carburetor ec468000 carburetor disassembly extent of removal: 1 carburetor disassembly extent of removal order part name q’ty remarks carburetor disassembly 1 carburetor breather hose 4 2 valve lever housing cover 1 3 screw (throttle shaft) 1 4 throttle valve 1 5 needle holder 1 6 jet need...

Page 132: Eng

4 - 10 eng carburetor extent of removal order part name q’ty remarks f float pin 1 g float 1 h needle valve 1 i main jet 1 j needle jet 1 k spacer 1 l pilot jet 1 m starter jet 1 n push rod 1 pull the push rod. O throttle shaft assembly 1 p push rod link lever assembly 1 q pilot air jet 1 r cold sta...

Page 133: Eng

4 - 11 eng carburetor handling note caution: do not loosen the screws (throttle position sensor) 1 except when changing the throt- tle position sensor due to failure because it will cause a drop in engine performance. 1 removal points pilot screw 1. Remove: • pilot screw 1 note: to optimize the fuel...

Page 134: Eng

4 - 12 eng carburetor 2. Inspect: • main jet 1 • pilot jet 2 • needle jet 3 • starter jet 4 • pilot air jet 5 • leak jet 6 damage → replace. Contamination → clean. Note: • use a petroleum based solvent for cleaning. Blow out all passages and jets with com- pressed air. • never use a wire. Needle val...

Page 135: Eng

4 - 13 eng carburetor float height 1. Measure: • float height a out of specification → adjust. Float height: 8.0 mm (0.31 in) measurement and adjustment steps: • hold the carburetor in an upside down position. Note: • slowly tilt the carburetor in the opposite direction, then take the measurement wh...

Page 136: Eng

4 - 14 eng starter plunger 1. Inspect: • cold starter plunger 1 • hot starter plunger 2 wear/damage → replace. Accelerator pump 1. Inspect: • diaphragm (accelerator pump) 1 • spring (accelerator pump) 2 • accelerator pump cover 3 • o-ring 4 • push rod 5 tears (diaphragm)/damage → replace. Dirt → cle...

Page 137: Eng

4 - 15 eng carburetor 2. Install: • pilot air jet 1 1 3. Install: • spring 1 1 • lever 1 2 to lever 2 3. Note: make sure the spring 1 fits on the stopper a of the lever 2. A 3 1 2 4. Install: • spring 2 1 to lever 2 2. 1 2 5. Install: • push rod link lever assembly 1 note: make sure the stopper a of...

Page 138: Eng

4 - 16 eng carburetor 7. Install: • spring 1 to throttle shaft 2. Note: install the bigger hook a of the spring fits on the stopper b of the throttle shaft pulley. 8. Install: • throttle shaft assembly 1 • washer (metal) 2 • washer (resin) 3 • valve lever 4 note: • apply the fluorochemical grease on...

Page 139: Eng

4 - 17 eng carburetor 10. Install: • starter jet 1 • pilot jet 2 • spacer 3 • needle jet 4 • main jet 5 11. Install: • needle valve 1 • float 2 • float pin 3 note: • after installing the needle valve to the float, install them to the carburetor. • check the float for smooth movement. 12. Install: • ...

Page 140: Eng

4 - 18 eng carburetor 14. Install: • diaphragm (air cut valve) 1 • spring (air cut valve) 2 • o-ring 3 • air cut valve cover 4 • screw (air cut valve cover) 5 15. Install: • diaphragm (accelerator pump) 1 • spring 2 • o-ring 3 • accelerator pump cover 4 • hose holder (drain hose) 5 • screw (accelera...

Page 141: Eng

4 - 19 eng carburetor 19. Install: • carburetor breather hose 1 note: install the carburetor breather hoses to the carburetor so that the hoses do not bend near where they are installed. Accelerator pump timing adjustment adjustment steps: note: in order for the throttle valve height a to achieve th...

Page 142: Eng

4 - 20 eng 3. Install: • hot starter plunger 1 t r . . 2 nm (0.2 m · kg, 1.4 ft · lb) 1 4. Tighten: • screw (air filter joint) 1 • screw (carburetor joint) 2 t r . . 3 nm (0.3 m · kg, 2.2 ft · lb) t r . . 3 nm (0.3 m · kg, 2.2 ft · lb) 5. Install: • throttle cable (pull) 1 • throttle cable (return) ...

Page 143: Eng

4 - 21 eng 9. Install: • clamp 1 refer to “cable routing diagram” section in the chapter 2. 1 carburetor.

Page 144: Eng

4 - 22 eng camshafts camshafts cylinder head cover extent of removal: 1 cylinder head cover removal extent of removal order part name q’ty remarks cylinder head cover removal preparation for removal seat and fuel tank refer to “seat, fuel tank and side covers” section. Carburetor refer to “carbureto...

Page 145: Eng

4 - 23 eng camshafts camshafts extent of removal: 1 camshaft removal extent of removal order part name q’ty remarks camshafts removal 1 timing mark accessing screw 1 refer to “removal points”. 2 crankshaft end accessing screw 1 3 timing chain tensioner cap bolt 1 4 timing chain tensioner 1 5 camshaf...

Page 146: Eng

4 - 24 eng camshafts removal points camshaft 1. Remove: • timing mark accessing screw 1 • crankshaft end accessing screw 2 2. Align: • t.D.C. Mark with align mark. Checking steps: • turn the crankshaft counterclockwise with a wrench. • align the t.D.C. Mark a on the rotor with the align mark b on th...

Page 147: Eng

4 - 25 eng camshafts 5. Remove: • exhaust camshaft 1 • intake camshaft 2 note: attach a wire 3 to the timing chain to prevent it from falling into the crankcase. 1 2 3 inspection camshaft 1. Inspect: • cam lobe pitting/scratches/blue discoloration → replace. 2. Measure: • cam lobe length a and b out...

Page 148: Eng

4 - 26 eng camshafts 4. Measure: • camshaft-to-cap clearance out of specification → measure camshaft outside diameter. Camshaft-to-cap clearance: 0.020 ~ 0.054 mm (0.0008 ~ 0.0021 in) : 0.08 mm (0.003 in) measurement steps: • install the camshaft onto the cylinder head. • position a strip of plastig...

Page 149: Eng

4 - 27 eng camshafts decompression system 1. Check: • decompression system checking steps: • check that the decompression mecha- nism cam 1 moves smoothly. • check that the decompression mechanism cam lever pin 2 projects from the camshaft. Timing chain tensioner 1. Check: • while pressing the tensi...

Page 150: Eng

4 - 28 eng camshafts • fit the timing chain 3 onto both camshaft sprockets and install the camshafts on the cylinder head. Note: the camshafts should be installed onto the cylinder head so that the punch mark c on the exhaust camshaft and the punch mark d on the intake camshaft must align with the c...

Page 151: Eng

4 - 29 eng 3. Turn: • crankshaft counterclockwise several turns. 4. Check: • rotor t.D.C. Mark align with the crankcase align mark. • camshaft match marks align with the cylinder head surface. Out of alignment → adjust. • with the rod fully wound and the chain ten- sioner up mark a facing upward, in...

Page 152: Eng

4 - 30 eng 6. Install: • timing chain guide (top side) 1 • cylinder head cover gasket 2 • cylinder head cover 3 • bolt (cylinder head cover) 4 note: apply the sealant on the cylinder head cover gasket. 7. Install: • oil tank breather hose • cylinder head breather hose • spark plug t r . . 10 nm (1.0...

Page 153: Eng

4 - 31 eng cylinder head cylinder head extent of removal: 1 cylinder head removal extent of removal order part name q’ty remarks cylinder head removal preparation for removal seat and fuel tank refer to “seat, fuel tank and side covers” section. Exhaust pipe and silencer refer to “exhaust pipe and s...

Page 154: Eng

4 - 32 eng cylinder head inspection cylinder head 1. Eliminate: • carbon deposits (from the combustion chambers) use a rounded scraper. Note: do not use a sharp instrument to avoid damag- ing or scratching: • spark plug threads • valve seats 2. Inspect: • cylinder head scratches/damage → replace. 3....

Page 155: Eng

4 - 33 eng cylinder head assembly and installation cylinder head 1. Install: • dowel pin 1 • cylinder head gasket 2 • timing chain guide (exhaust side) 3 • cylinder head 4 note: while pulling up the timing chain, install the timing chain guide (exhaust side) and cylinder head. 2. Install: • washer 1...

Page 156: Eng

4 - 34 eng valves and valve springs valves and valve springs extent of removal: 1 valve removal extent of removal order part name q’ty remarks valves and valve springs removal preparation for removal cylinder head refer to “cylinder head” section. 1 valve lifter 5 use special tool. Refer to “removal...

Page 157: Eng

4 - 35 eng valves and valve springs removal points valve lifter and valve cotter 1. Remove: • valve lifter 1 • pad 2 note: identify each lifter 1 and pad 2 position very carefully so that they can be reinstalled in their original place. 2. Check: • valve sealing leakage at the valve seat → inspect t...

Page 158: Eng

4 - 36 eng valves and valve springs inspection valve 1. Measure: • stem-to-guide clearance out of specification → replace the valve guide. Stem-to-guide clearance = valve guide inside diameter a – valve stem diameter b clearance (stem to guide): intake: 0.010 ~ 0.037 mm (0.0004 ~ 0.0015 in) : 0.08 m...

Page 159: Eng

4 - 37 eng valves and valve springs valve guide remover: intake: 4.0 mm (0.16 in) ym-4111/90890-04111 exhaust: 4.5 mm (0.18 in) ym-4116/90890-04116 valve guide installer: intake: 4.0 mm (0.16 in) ym-4112/90890-04112 exhaust: 4.5 mm (0.18 in) ym-4117/90890-04117 valve guide reamer: intake: 4.0 mm (0....

Page 160: Eng

4 - 38 eng valves and valve springs 5. Measure: • runout (valve stem) out of specification → replace. Note: • when installing a new valve always replace the guide. • if the valve is removed or replaced always replace the oil seal. 6. Eliminate: • carbon deposits (from the valve face and valve seat) ...

Page 161: Eng

4 - 39 eng valves and valve springs 9. Lap: • valve face • valve seat note: after refacing the valve seat or replacing the valve and valve guide, the valve seat and valve face should be lapped. Lapping steps: • apply a coarse lapping compound to the valve face. Caution: do not let the compound enter...

Page 162: Eng

4 - 40 eng valves and valve springs valve spring 1. Measure: • valve spring free length a out of specification → replace. 2. Measure: • compressed spring force a out of specification → replace. B installed length free length (valve spring): intake: 37.81 mm (1.49 in) : 36.81 mm (1.45 in) exhaust: 37...

Page 163: Eng

4 - 41 eng valves and valve springs assembly and installation valve and valve spring 1. Apply: • molybdenum disulfide oil onto the valve stem and valve stem seal. 2. Install: • valve 1 • valve spring seat 2 • valve stem seal 3 • valve spring 4 • valve spring retainer 5 to cylinder head. Note: • make...

Page 164: Eng

4 - 42 eng valves and valve springs 5. Install: • adjusting pad 1 • valve lifter 2 note: • apply the molybdenum disulfide oil on the valve stem end. • apply the engine oil on the valve lifters. • valve lifter must turn smoothly when rotated with a finger. • be careful to reinstall valve lifters and ...

Page 165: Eng

4 - 43 eng cylinder and piston cylinder and piston extent of removal: 1 cylinder removal 2 piston removal extent of removal order part name q’ty remarks cylinder and piston removal preparation for removal cylinder head refer to “cylinder head” section. 1 bolt (cylinder) 1 2 cylinder 1 3 piston pin c...

Page 166: Eng

4 - 44 eng cylinder and piston removal points piston and piston ring 1. Remove: • piston pin clip 1 • piston pin 2 • piston 3 note: • put identification marks on each piston head for reference during reinstallation. • before removing each piston pin, deburr the clip groove and pin hole area. If the ...

Page 167: Eng

4 - 45 eng cylinder and piston cylinder bore “c” 77.00 ~ 77.01 mm (3.0315 ~ 3.0319 in) taper limit “t” 0.05 mm (0.002 in) out of round “r” 0.05 mm (0.002 in) “c” = maximum d “t” = (maximum d 1 or d 2 ) – (maximum d 5 or d 6 ) “r” = (maximum d 1 , d 3 or d 5 ) – (minimum d 2 , d 4 or d 6 ) • if out o...

Page 168: Eng

4 - 46 eng cylinder and piston piston ring 1. Measure: • ring side clearance use a feeler gauge 1. Out of specification → replace the piston and rings as a set. Note: clean carbon from the piston ring grooves and rings before measuring the side clearance. 2. Position: • piston ring (in cylinder) not...

Page 169: Eng

4 - 47 eng cylinder and piston piston pin 1. Inspect: • piston pin blue discoloration/grooves → replace, then inspect the lubrication system. 2. Measure: • piston pin-to-piston clearance assembly and installation piston ring and piston 1. Install: • piston ring onto the piston. Note: • be sure to in...

Page 170: Eng

4 - 48 eng cylinder and piston 2. Position: • top ring • 2nd ring • oil ring offset the piston ring end gaps as shown. A top ring end b 2nd ring end c oil ring end (upper) d oil ring e oil ring end (lower) 45˚ 135˚ 135˚ a b c e d 3. Install: • piston 1 • piston pin 2 • piston pin clip 3 note: • appl...

Page 171: Eng

4 - 49 eng 3. Install: • cylinder gasket 1 • cylinder 2 note: install the cylinder with one hand while com- pressing the piston rings with the other hand. Caution: • pass the timing chain 3 through the tim- ing chain cavity. • be careful not to damage the timing chain guide 4 during installation. 4....

Page 172: Eng

4 - 50 eng clutch ec4a0000 clutch extent of removal: 1 push rod 1, 2 and push lever shaft removal 2 push pod 1 disassembly 3 friction plate and clutch plate removal 4 primary driven gear removal extent of removal order part name q’ty remarks clutch removal preparation for removal drain the engine oi...

Page 173: Eng

4 - 51 eng clutch extent of removal order part name q’ty remarks 10 friction plate 9 11 clutch plate 8 12 cushion spring 1 13 seat plate 1 14 nut (clutch boss) 1 use special tool. Refer to “removal points”. 15 look washer 1 16 clutch boss 1 17 thrust washer 1 18 primary driven gear 1 19 push lever s...

Page 174: Eng

4 - 52 eng clutch ec4a3000 removal points clutch boss 1. Remove: • nut 1 • lock washer 2 • clutch boss 3 note: straighten the lock washer tab and use the clutch holding tool 4 to hold the clutch boss. È for usa and cdn É except for usa and cdn clutch holding tool: ym-91042/90890-04086 È É ec4a4000 i...

Page 175: Eng

4 - 53 eng clutch friction plate 1. Measure: • friction plate thickness out of specification → replace friction plate as a set. Measure at all four points. Ec484600 clutch plate 1. Measure: • clutch plate warpage out of specification → replace clutch plate as a set. Use a surface plate 1 and thickne...

Page 176: Eng

4 - 54 eng clutch ec4a5000 assembly and installation push lever shaft 1. Install: • push lever shaft 1 • bolt (push lever shaft) 2 note: • apply the lithium soap base grease on the oil seal lip. • apply the engine oil on the push lever shaft. • fit the seat plate 3 in the groove a of the push lever ...

Page 177: Eng

4 - 55 eng 3. Bend the lock washer 1 tab. 4. Install: • seat plate 1 • cushion spring 2 note: • install the seat plate with its chamfered por- tion a facing the clutch boss 3. • install the seat plate so that it is not caught on the step b. • install the cushion spring with the paint c facing out. 1...

Page 178: Eng

4 - 56 eng clutch 7. Install: • push rod 2 1 • ball 2 • push rod 1 3 note: apply the engine oil on the push rod 1, 2 and ball. 8. Install: • pressure plate 1 9. Install: • clutch spring 1 • bolt (clutch spring) 2 note: tighten the bolts in stage, using a crisscross pattern. T r . . 8 nm (0.8 m · kg,...

Page 179: Eng

4 - 57 eng oil filter element, water pump and right crankcase cover oil filter element, water pump and right crankcase cover extent of removal: 1 oil filter element removal 2 water pump removal 3 right crankcase cover removal extent of removal order part name q’ty remarks oil filter element, water p...

Page 180: Eng

4 - 58 eng oil filter element, water pump and right crankcase cover extent of removal order part name q’ty remarks 3 water pump housing 1 4 oil delivery pipe 1 5 bolt (oil hose) 1 6 kickstarter crank 1 7 right crankcase cover 1 8 impeller 1 refer to “removal points”. 9 washer 1 10 impeller shaft 1 1...

Page 181: Eng

4 - 59 eng oil filter element, water pump and right crankcase cover removal points impeller shaft 1. Remove: • impeller 1 • washer 2 • impeller shaft 3 note: hold the impeller shaft on its width across the flats a with spanners, etc. And remove the impeller. Ec4g3210 oil seal note: it is not necessa...

Page 182: Eng

4 - 60 eng oil filter element, water pump and right crankcase cover ec444200 impeller shaft 1. Inspect: • impeller shaft 1 bend/wear/damage → replace. Fur deposits → clean. Ec444300 impeller shaft gear 1. Inspect: • gear teeth a wear/damage → replace. Ec4h4600 bearing 1. Inspect: • bearing rotate in...

Page 183: Eng

4 - 61 eng oil filter element, water pump and right crankcase cover 2. Install: • bearing 1 note: install the bearing by pressing its outer race parallel. Impeller shaft 1. Install: • impeller shaft 1 • washer 2 • impeller 3 note: • take care so that the oil seal lip is not dam- aged or the spring d...

Page 184: Eng

4 - 62 eng oil filter element, water pump and right crankcase cover 2. Install: • right crankcase cover 1 • bolt (right crankcase cover) 2 note: • apply the engine oil on the impeller shaft end. • mesh the impeller shaft gear 3 with primary drive gear 4. • tighten the bolts in stage, using a crisscr...

Page 185: Eng

4 - 63 eng oil filter element, water pump and right crankcase cover water pump housing 1. Install: • dowel pin 1 • o-ring 2 note: apply the lithium soap base grease on the o- ring. New 2. Install: • water pump housing 1 • bolt (water pump housing) 2 t r . . 10 nm (1.0 m · kg, 7.2 ft · lb) oil filter...

Page 186: Eng

4 - 64 eng balancer balancer extent of removal: 1 balancer shaft drive gear 2 balancer shaft extent of removal order part name q’ty remarks balancer removal preparation for removal primary driven gear refer to “clutch” section. Right crankcase cover refer to “oil filter element, water pump and right...

Page 187: Eng

4 - 65 eng balancer removal points balancer shaft drive gear and balancer shaft driven gear 1. Straighten the lock washer tab. 2. Loosen: • nut (primary drive gear) 1 • nut (balancer shaft driven gear) 2 note: place an aluminum plate a between the teeth of the balancer shaft drive gear 3 and driven ...

Page 188: Eng

4 - 66 eng balancer assembly and installation balancer shaft, balancer shaft drive gear and balancer shaft driven gear 1. Install: • balancer shaft 1 note: • apply the engine oil on the bearing. • when installing the balancer shaft, align the center a of the balancer shaft weight along the line conn...

Page 189: Eng

4 - 67 eng oil pump oil pump extent of removal: 1 oil pump removal 2 oil pump disassembly extent of removal order part name q’ty remarks oil pump removal and dis- assembly preparation for removal primary driven gear refer to “clutch” section. Right crankcase cover refer to “oil filter element, water...

Page 190: Eng

4 - 68 eng oil pump extent of removal order part name q’ty remarks 12 dowel pin 1 13 washer 1 14 oil pump drive shaft 1 15 rotor housing 1 2.

Page 191: Eng

4 - 69 eng oil pump inspection oil pump 1. Inspect: • oil pump drive gear 1 • oil pump drive shaft 2 • rotor housing 3 • oil pump cover 4 cracks/wear/damage → replace. 1 3 2 4 2. Measure: • tip clearance a (between the inner rotor 1 and outer rotor 2) • side clearance b (between the outer rotor 2 an...

Page 192: Eng

4 - 70 eng oil pump assembly and installation oil pump 1. Install: • oil pump drive shaft 1 • washer 2 • dowel pin 3 • inner rotor 1 4 note: • apply the engine oil on the oil pump drive shaft and inner rotor 1. • fit the dowel pin into the groove in the inner rotor 1. 2. Install: • outer rotor 1 1 n...

Page 193: Eng

4 - 71 eng 4. Install: • outer rotor 2 1 • dowel pin 2 • oil pump assembly 3 • bolt (oil pump assembly) [l = 25 mm (0.94 in)] 4 • bolt (oil pump assembly) [l = 30 mm (1.18 in)] 5 note: apply the engine oil on the outer rotor 2. T r . . 10 nm (1.0 m · kg, 7.2 ft · lb) t r . . 10 nm (1.0 m · kg, 7.2 f...

Page 194: Eng

4 - 72 eng kick shaft and shift shaft kick shaft and shift shaft extent of removal: 1 kick shaft removal 2 kick shaft disassembly 3 shift shaft removal 4 segment removal extent of removal order part name q’ty remarks kick shaft and shift shaft removal preparation for removal oil pump refer to “oil p...

Page 195: Eng

4 - 73 eng kick shaft and shift shaft extent of removal order part name q’ty remarks 12 torsion spring 1 13 roller 1 14 shift guide 1 refer to “removal points”. 15 shift lever assembly 1 16 shift lever 1 17 pawl 2 18 pawl pin 2 19 spring 2 20 bolt (stopper lever) 1 21 stopper lever 1 22 torsion spri...

Page 196: Eng

4 - 74 eng kick shaft and shift shaft removal points kick shaft assembly 1. Remove: • kick shaft assembly 1 note: unhook the torsion spring 2 from the hole a in the crankcase. Ec4c3101 shift guide and shift lever assembly 1. Remove: • bolt (shift guide) • shift guide 1 • shift lever assembly 2 note:...

Page 197: Eng

4 - 75 eng kick shaft and shift shaft ec4b4400 shift shaft 1. Inspect: • shift shaft 1 bend/damage → replace. • spring 2 broken → replace. Ec4c4100 shift guide and shift lever assembly 1. Inspect: • shift guide 1 • shift lever 2 • pawl 3 • pawl pin 4 • spring 5 wear/damage → replace. Ec4b4500 stoppe...

Page 198: Eng

4 - 76 eng kick shaft and shift shaft ec4b5111 stopper lever 1. Install: • torsion spring 1 • stopper lever 2 • bolt (stopper lever) 3 note: align the stopper lever roller with the slot on segment. Shift guide and shift lever assembly 1. Install: • spring 1 • pawl pin 2 • pawl 3 to shift lever 4. No...

Page 199: Eng

4 - 77 eng kick shaft and shift shaft shift shaft 1. Install: • roller 1 • collar 2 • torsion spring 3 • shift shaft 4 note: apply the engine oil on the roller and shift shaft. 2. Install: • shift pedal refer to “ac magneto and starter clutch” section. Kick shaft assembly 1. Install: • kick gear 1 •...

Page 200: Eng

4 - 78 eng kick shaft and shift shaft 3. Install: • spring guide 1 note: slide the spring guide into the kick shaft, make sure the groove a in the spring guide fits on the stopper of the torsion spring. 4. Install: • kick shaft assembly 1 • washer 2 note: • apply the molybdenum disulfide grease on t...

Page 201: Eng

4 - 79 eng ac magneto and starter clutch ac magneto and starter clutch extent of removal: 1 starter clutch/wheel gear removal 2 rotor removal 3 pickup coil/stator removal extent of removal order part name q’ty remarks ac magneto and stator removal preparation for removal drain the engine oil. Refer ...

Page 202: Eng

4 - 80 eng ac magneto and starter clutch note: tighten the rotor nut to 65 nm (6.5 m · kg, 47 ft · lb), loosen and retighten the rotor nut to 65 nm (6.5 m · kg, 47 ft · lb). Extent of removal order part name q’ty remarks 8* nut (rotor) 1 refer to note. 9 rotor 1 use special tool. Refer to “removal p...

Page 203: Eng

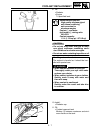

4 - 81 eng ac magneto and starter clutch ec4l3000 removal points rotor 1. Remove: • nut (rotor) 1 • washer use the sheave holder 2. Sheave holder: ys-1880-a/90890-01701 2 1 2. Remove: • rotor 1 use the rotor puller 2. Rotor puller: ym-04141/90890-04141 starter clutch 1. Remove: • starter clutch asse...

Page 204: Eng

4 - 82 eng ac magneto and starter clutch ec4l4200 woodruff key 1. Inspect: • woodruff key 1 damage → replace. Starter clutch 1. Check: • starter clutch damage/wear → replace. 2. Check: • idle gear • starter clutch drive gear pitting/burrs/chips/roughness/wear → replace the defective parts. 3. Check:...

Page 205: Eng

4 - 83 eng ac magneto and starter clutch ec4l5000 assembly and installation ac magneto and starter clutch 1. Install: • stator 1 • bolt (stator) 2 • pickup coil 3 • bolt (pickup coil) 4 t r . . 7 nm (0.7 m · kg, 5.1 ft · lb) t r . . 10 nm (1.0 m · kg, 7.2 ft · lb) 2. Install: • holder 1 • bolt 2 cau...

Page 206: Eng

4 - 84 eng ac magneto and starter clutch 5. Install: • washer 1 • bearing 2 • starter clutch drive gear 3 note: apply the engine oil on the washer, bearing and starter clutch drive gear inner circumfer- ence. E 1 2 3 6. Install: • starter clutch 1 to rotor 2. Note: • install the starter clutch with ...

Page 207: Eng

4 - 85 eng ac magneto and starter clutch 9. Install: • washer (rotor) • nut (rotor) 1 use the sheave holder 2. Note: tighten the rotor nut to 65 nm (6.5 m · kg, 47 ft · lb), loosen and retighten the rotor nut to 65 nm (6.5 m · kg, 47 ft · lb). T r . . 65 nm (6.5 m · kg, 47 ft · lb) sheave holder: ys...

Page 208: Eng

4 - 86 eng 12. Install: • cover (idle gear 1) 1 • bolt 2 note: install the cover (idle gear 1) with its mark a facing upward. T r . . 10 nm (1.0 m · kg, 7.2 ft · lb) a 2 1 2 13. Install: • engine guard 1 • clamp 2 • washer 3 • bolt [engine guard (front)] 4 • bolt [engine guard (rear)] 5 • cylinder h...

Page 209: Eng

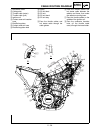

4 - 87 eng engine removal ec4m0000 engine removal extent of removal order part name q’ty remarks engine removal preparation for removal hold the machine by placing the suitable stand under the frame. Warning support the machine securely so there is no danger of it falling over. Drain the engine oil....

Page 210: Eng

4 - 88 eng engine removal extent of removal: 1 engine removal extent of removal order part name q’ty remarks ignition coil disconnect the ac magneto lead. Starter motor lead disconnect at the starter motor side. Negative battery lead disconnect at the engine side. Right engine guard 1 neutral switch...

Page 211: Eng

4 - 89 eng engine removal ec4m3000 removal points ec4f3100 drive sprocket 1. Remove: • nut (drive sprocket) 1 • lock washer 2 note: • straighten the lock washer tab. • loosen the nut while applying the rear brake. 2. Remove: • drive sprocket 1 • drive chain 2 note: remove the drive sprocket together...

Page 212: Eng

4 - 90 eng engine removal ec4m5000 assembly and installation engine installation 1. Install: • engine 1 install the engine from right side. • pivot shaft 2 • engine mounting bolt (lower) 3 • lower engine bracket 4 • bolt (engine bracket) 5 • engine mounting bolt (front) 6 • upper engine bracket 7 • ...

Page 213: Eng

4 - 91 eng engine removal drive sprocket 1. Install: • drive sprocket 1 • drive chain 2 note: install the drive sprocket together with the drive chain. 2. Install: • lock washer 1 • nut (drive sprocket) 2 note: tighten the nut while applying the rear brake. T r . . 75 nm (7.5 m · kg, 54 ft · lb) new...

Page 214: Eng

4 - 92 eng engine removal 2. Install: • spring 1 • pin 2 • o-ring 3 • neutral switch 4 • screw (neutral switch) 5 note: apply the lithium soap base grease on the o- ring. T r . . 4 nm (0.4 m · kg, 2.9 ft · lb) new.

Page 215: Eng

4 - 93 eng crankcase and crankshaft crankcase and crankshaft extent of removal: 1 crankcase separation 2 crankshaft removal extent of removal order part name q’ty remarks crankcase and crank- shaft removal preparation for removal engine refer to “engine removal” section. Piston refer to “cylinder an...

Page 216: Eng

4 - 94 eng crankcase and crankshaft extent of removal order part name q’ty remarks 4 bolt [l = 45 mm (1.77 in)] 6 refer to “removal points”. 5 bolt [l = 55 mm (2.17 in)] 1 6 bolt [l = 70 mm (2.76 in)] 4 7 hose guide 1 8 clutch cable holder 1 9 right crankcase 1 10 left crankcase 1 11 oil strainer 1 ...

Page 217: Eng

4 - 95 eng crankcase and crankshaft crankcase bearing extent of removal: 1 crankcase bearing removal extent of removal order part name q’ty remarks crankcase bearing removal preparation for removal transmission shift cam and shift fork refer to “transmission, shift cam and shift fork” section. 1 oil...

Page 218: Eng

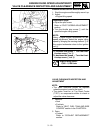

4 - 96 eng crankcase and crankshaft removal points crankcase 1. Separate: • right crankcase • left crankcase separation steps: • remove the crankcase bolts 1, hose guide 2 and clutch cable holder 3. Note: loosen each bolt 1/4 of a turn at a time and after all the bolts are loosened, remove them. • r...

Page 219: Eng

4 - 97 eng crankcase and crankshaft crankshaft 1. Remove: • crankshaft 1 use the crankcase separating tool 2. Caution: do not use a hammer to drive out the crankshaft. Crankcase bearing 1. Remove: • bearing 1 note: • remove the bearing from the crankcase by pressing its inner race. • do not use the ...

Page 220: Eng

4 - 98 eng crankcase and crankshaft ec4n4201 crankshaft 1. Measure: • runout limit a • small end free play limit b • connecting rod big end side clearance c • crank width d out of specification → replace. Use the dial gauge and a thickness gauge. Dial gauge and stand: yu-3097/90890-01252 standard ru...

Page 221: Eng

4 - 99 eng crankcase and crankshaft ec4n5000 assembly and installation crankcase bearing 1. Install: • bearing • bearing stopper • bolt (bearing stopper) • screw (bearing stopper) • screw [bearing stopper (crankshaft)] 1 to left and right crankcase. Note: • install the bearing by pressing its outer ...

Page 222: Eng

4 - 100 eng crankcase and crankshaft 2. Check: • shifter operation • transmission operation unsmooth operation → repair. 3. Install: • oil strainer 1 • bolt (oil strainer) 2 t r . . 10 nm (1.0 m · kg, 7.2 ft · lb) 4. Apply: • sealant on the right crankcase 1. Note: clean the contacting surface of le...

Page 223: Eng

4 - 101 eng crankcase and crankshaft 6. Tighten: • hose guide 1 • clutch cable holder 2 • bolt (crankcase) 3 note: tighten the crankcase tightening bolts in stage, using a crisscross pattern. T r . . 12 nm (1.2 m · kg, 8.7 ft · lb) 7. Install: • oil delivery pipe 2 1 • o-ring 2 • bolt (oil delivery ...

Page 224: Eng

4 - 102 eng transmission, shift cam and shift fork ec4h0000 transmission, shift cam and shift fork extent of removal: 1 shift fork, shift cam, main axle and drive axle removal extent of removal order part name q’ty remarks transmission, shift cam and shift fork removal preparation for removal engine...

Page 225: Eng

4 - 103 eng transmission, shift cam and shift fork ec4h3000 removal points ec4h3230 transmission 1. Remove: • main axle 1 • drive axle 2 • shift cam • shift fork 3 • shift fork 2 • shift fork 1 note: • remove assembly with the collar 3 installed to the crankcase. • remove assembly carefully. Note th...

Page 226: Eng

4 - 104 eng transmission, shift cam and shift fork ec4h4810 shift fork, shift cam and segment 1. Inspect: • shift fork 1 wear/damage/scratches → replace. 2. Inspect: • shift cam 1 • segment 2 wear/damage → replace. 3. Check: • shift fork movement unsmooth operation → replace shift fork. Note: for a ...

Page 227: Eng

4 - 105 eng transmission, shift cam and shift fork 2. Install: • 2nd wheel gear (28t) 1 • 4th wheel gear (25t) 2 • 3rd wheel gear (28t) 3 • 5th wheel gear (22t) 4 • 1st wheel gear (31t) 5 • o-ring 6 to drive axle 7. Note: • apply the molybdenum disulfide oil on the 1st, 2nd and 3rd wheel gears inner...

Page 228: Eng

4 - 106 eng transmission, shift cam and shift fork 5. Install: • shift fork 1 (l) 1 • shift fork 2 (c) 2 • shift fork 3 (r) 3 • shift cam 4 to main axle and drive axle. Note: • apply the molybdenum disulfide oil on the shift fork grooves. • mesh the shift fork #1 (l) with the 4th wheel gear 5 and #3...

Page 229: Chas

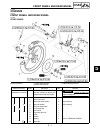

5 - 1 chas ec500000 chassis ec590000 front wheel and rear wheel ec598000 front wheel front wheel and rear wheel extent of removal: 1 front wheel removal 2 wheel bearing removal 3 brake disc removal extent of removal order part name q’ty remarks preparation for removal front wheel removal hold the ma...

Page 230: Chas

5 - 2 chas ec598100 rear wheel extent of removal: 1 rear wheel removal 2 wheel bearing removal 3 brake disc removal extent of removal order part name q’ty remarks preparation for removal rear wheel removal hold the machine by placing the suitable stand under the engine. Warning support the machine s...

Page 231: Chas

5 - 3 chas front wheel and rear wheel ec593000 removal points ec523101 rear wheel 1. Remove: • wheel 1 note: push the wheel forward and remove the drive chain 2. Ec513201 wheel bearing (if necessary) 1. Remove: • bearing 1 note: remove the bearing using a general bearing puller 2. Ec594000 inspectio...

Page 232: Chas

5 - 4 chas front wheel and rear wheel ec514200 wheel axle 1. Measure: • wheel axle bends out of specification → replace. Use the dial gauge 1. Note: the bending value is shown by one half of the dial gauge reading. Warning do not attempt to straighten a bent axle. Wheel axle bending limit: 0.5 mm (0...

Page 233: Chas

5 - 5 chas front wheel and rear wheel ec595000 assembly and installation front wheel 1. Install: • bearing (left) 1 • spacer 2 • bearing (right) 3 • oil seal 4 note: • apply the lithium soap base grease on the bearing and oil seal lip when installing. • use a socket that matches the outside diam- et...

Page 234: Chas

5 - 6 chas front wheel and rear wheel 5. Install: • wheel note: • install the brake disc 1 between the brake pads 2 correctly. • make sure that the projections a in the trip meter gear unit fits over the stopper b on the front fork outer tube. 6. Install: • wheel axle 1 note: apply the lithium soap ...

Page 235: Chas

5 - 7 chas front wheel and rear wheel 8. Tighten: • bolt (axle holder) 1 note: before tightening the bolt, fit the wheel axle to the axle holder by stroking the front fork sev- eral times with the front brake applied. T r . . 23 nm (2.3 m · kg, 17 ft · lb) 9. Install: • brake hose 1 to brake hose ho...

Page 236: Chas

5 - 8 chas 11. Install: • trip meter cable 1 1 rear wheel 1. Install: • bearing (right) 1 • circlip 2 • spacer 3 • bearing (left) 4 • oil seal 5 note: • apply the lithium soap base grease on the bearing and oil seal lip when installing. • install the bearing with seal facing outward. • use a socket ...

Page 237: Chas

5 - 9 chas front wheel and rear wheel 3. Install: • rear wheel sprocket 1 • bolt (rear wheel sprocket) 2 • washer (rear wheel sprocket) 3 • nut (rear wheel sprocket) 4 note: tighten the nuts in stage, using a crisscross pattern. T r . . 50 nm (5.0 m · kg, 36 ft · lb) 4. Install: • collar 1 note: app...

Page 238: Chas

5 - 10 chas front wheel and rear wheel 8. Install: • right drive chain puller 1 • washer 2 • nut (wheel axle) 3 note: temporarily tighten the nut (wheel axle) at this point. 9. Adjust: • drive chain slack a refer to “drive chain slack adjustment” section in the chapter 3. Drive chain slack: 40 ~ 50 ...

Page 239: Chas

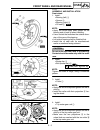

5 - 11 chas front brake and rear brake ec5a0000 front brake and rear brake ec5a8000 front brake extent of removal: 1 brake hose removal 2 brake caliper removal 3 brake master cylinder removal extent of removal order part name q’ty remarks preparation for removal front brake removal hold the machine ...

Page 240: Chas

5 - 12 chas ec5a8100 rear brake extent of removal: 1 brake master cylinder removal 2 brake hose removal 3 brake caliper removal extent of removal order part name q’ty remarks preparation for removal rear brake removal hold the machine by placing the suitable stand under the engine. Warning support t...

Page 241: Chas

5 - 13 chas brake caliper disassembly È front É rear extent of removal: 1 front brake caliper disassembly 2 rear brake caliper disassembly extent of removal order part name q’ty remarks brake caliper disassem- bly a b 1 pad pin 1 1 2 brake pad 2 2 3 pad support 1 1 4 brake caliper piston 2 1 refer t...

Page 242: Chas

5 - 14 chas front brake and rear brake brake master cylinder disassembly È front É rear extent of removal: 1 front brake master cylinder disassembly 2 rear brake master cylinder disassembly extent of removal order part name q’ty remarks brake master cylinder disassembly 1 brake master cylinder cap 1...

Page 243: Chas

5 - 15 chas front brake and rear brake ec5a3000 removal points brake fluid 1. Remove: [front] • brake master cylinder cap 1 [rear] • brake master cylinder cap 1 • protector note: do not remove the diaphragm. È front É rear 2. Connect the transparent hose 2 to the bleed screw 1 and place a suitable c...

Page 244: Chas

5 - 16 chas front brake and rear brake brake caliper piston seal kit 1. Remove: • dust seal 1 • piston seal 2 note: remove the piston seals and dust seals by pushing them with a finger. Caution: never attempt to pry out piston seals and dust seals. Warning replace the piston seals and dust seals whe...

Page 245: Chas

5 - 17 chas 4. Inspect: • brake master cylinder piston 1 • brake master cylinder cup 2 wear/damage/score marks → replace brake master cylinder kit. È front É rear È É brake caliper 1. Inspect: • brake caliper cylinder inner surface a wear/score marks → replace brake cali- per assembly. È front É rea...

Page 246: Chas

5 - 18 chas brake caliper piston 1. Clean: • brake caliper • piston seal • dust seal • brake caliper piston clean them with brake fluid. 2. Install: • piston seal 1 • dust seal 2 warning always use new piston seals and dust seals. Note: fit the piston seals and dust seals onto the slot on brake cali...

Page 247: Chas

5 - 19 chas front brake and rear brake 2. Install: • copper washer 1 • union bolt 2 warning always use new copper washers. Caution: install the brake hose so that its pipe por- tion a directs as shown and lightly touches the projection b on the brake cali- per. T r . . 30 nm (3.0 m · kg, 22 ft · lb)...

Page 248: Chas

5 - 20 chas front brake and rear brake 2. Install: • brake disc cover 1 • bolt (brake disc cover) 2 t r . . 7 nm (0.7 m · kg, 5.1 ft · lb) 3. Install: • brake caliper 1 • rear wheel 2 refer to “front wheel and rear wheel” section. 4. Tighten: • pad pin 3 5. Install: • pad pin plug 4 t r . . 18 nm (1...

Page 249: Chas