- DL manuals

- Yamaha

- Motorcycle

- 2005 BT1100

- Supplementary Service Manual

Yamaha 2005 BT1100 Supplementary Service Manual

Summary of 2005 BT1100

Page 1

Bt1100 supplementary service manual 2005 5jn4-ae1.

Page 3: Foreword

Bt1100 2005 supplementary service manual © 2004 by yamaha motor italia s.P.A. First edition, september 2004 all rights reserved. Any reproduction or unauthorized use without the written permission of yamaha motor italia s.P.A. Is expressly prohibited. Printed in italy foreword this supplementary ser...

Page 4: Notice

Notice this manual was produced by the yamaha motor italia s.P.A. Primarily for use by yamaha dealers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manual, so it is assumed that anyone who uses this book to perform maintenance and repairs on yama...

Page 5: How to Use This Manual

Eas00007 how to use this manual this manual is intended as a handy, easy-to-read reference book for the mechanic. Comprehensive ex- planations of all installation, removal, disassembly, assembly, repair and check procedures are laid out with the individual steps in sequential order. 1 the manual is ...

Page 6: Gen

Illustrated symbols the following symbols are not relevant to every vehicle. Illustrated symbols 1 to 8 are printed on the top right of each page and indicate the subject of each chapter. 1 general information 2 specifications 3 periodic inspections and adjustments 4 engine 5 carburetor 6 chassis 7 ...

Page 7: Contents

Contents specifications general specifications.................................................................................... 1 maintenance specifications – engine ........................................................ 4 lubrication chart .........................................................

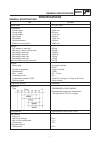

Page 9: Spec

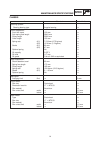

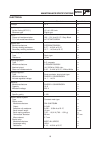

1 spec general specifications item standard model code: bt1100: 5jn4 dimensions: overall length 2,200 mm overall width 800 mm overall height 1,140 mm seat height 812 mm wheelbase 1,530 mm ground clearance 168 mm minimum turning radius 2,980 mm weight: dry (without oil and fuel) 233 kg wet (with oil ...

Page 10: Spec

2 spec general specifications item standard air filter: dry type element fuel: type regular unleaded gasoline fuel tank capacity 20 l fuel reserve amount 5.8 l carburetor: type/quantity bsr37/2 manufacturer mikuni spark plug: type bpr7es/w22epr-u manufacturer ngk/denso spark plug gap 0.7 0.8 mm clut...

Page 11: Spec

3 spec general specifications item standard brake: front brake type dual disc brake operation right hand operation rear brake type single disc brake operation right foot operation suspension: front suspension telescopic fork rear suspension swingarm (link suspension) shock absorber: front shock abso...

Page 12: Spec

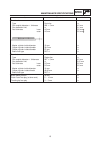

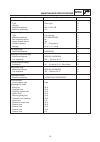

4 spec maintenance specifications item standard limit cylinder head: volume 57.0 58.4 cm 3 ••• warp limit ••• 0.03 mm cylinder: bore size 95.00 95.01 mm 95.1 mm measuring point 40 mm ••• max. Out of round ••• 0.01 mm camshaft: drive method chain drive (left & right) ••• cam cap inside diameter 25.00...

Page 13: Spec

5 spec maintenance specifications item standard limit timing chain: timing chain type/no. Of links silent 98l ••• timing chain adjustment method automatic ••• rocker arm/rocker arm shaft: bearing inside diameter 14.000 mm 14.018 mm 14.036 mm shaft outside diameter 13.985 mm 13.991 mm 13.95 mm arm-to...

Page 14: Spec

6 spec maintenance specifications item standard limit stem runout limit ••• 0.03 mm valve seat width in 1.2 1.4 mm 2.0 mm ex 1.2 1.4 mm 2.0 mm valve spring: free length in 44.6 mm 43.5 mm ex 44.6 mm 43.5 mm set length (valve closed) in 40 mm ••• ex 40 mm ••• compressed pressure (installed) in 160.7 ...

Page 15: Spec

7 spec maintenance specifications item standard limit piston rings: top ring: type plain ••• dimensions (b x t) 1.5 3.8 mm ••• end gap (installed) 0.3 0.5 mm 0.8 mm side clearance (installed) 0.04 0.08 mm 0.1 mm 2 nd ring: type taper ••• dimensions (b x t) 1.2 3.8 mm ••• end gap (installed) 0.30 0.4...

Page 16: Spec

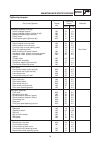

8 spec maintenance specifications item standard limit clutch: friction plate thickness 2.9 3.1 mm 2.8 mm quantity 8 ••• clutch plate thickness 2.5 2.7 mm 0.1 mm quantity 1 ••• clutch plate thickness 1.9 2.1 mm 0.1 mm quantity 7 ••• clutch spring free length 7.2 mm 6.5 mm quantity 1 ••• clutch housin...

Page 17: Spec

9 spec maintenance specifications item standard limit lubrication system: oil filter type paper type ••• oil pump type trochoid type ••• tip clearance “a” or “b” 0.03 0.09 mm 0.15 mm side clearance 0.03 0.08 mm 0.15 mm bypass valve opening pressure 80 120 kpa (0.8 ~ 1.2 kgf/cm 2 ) ••• relief valve o...

Page 18: Spec

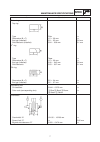

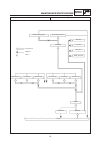

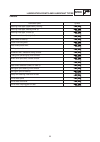

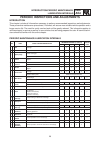

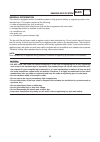

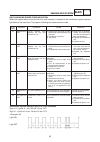

10 spec maintenance specifications item standard lubrication chart: needle bearing (starter) connecting rod big end crankshaft main axle drive axle pinin drive middle driveshaft rocker arm (in) camshaft (in) camshaft (ex) rocker arm (in) rocker arm (ex) rocker arm (ex) oil filter oil pump relief val...

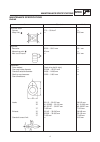

Page 19: Spec

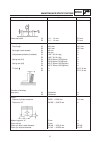

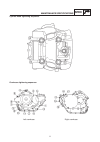

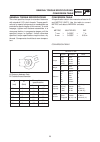

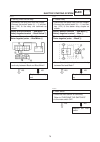

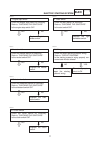

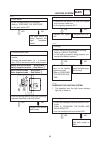

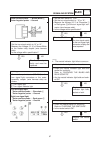

11 spec maintenance specifications cylinder head tightening sequence: crankcase tightening sequence: right crankcase left crankcase.

Page 20: Spec

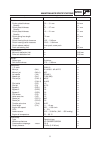

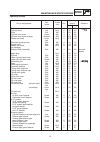

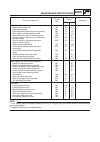

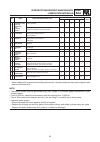

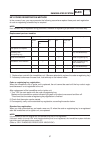

12 spec maintenance specifications part thread tightening part to be tightened name size q’ty torque remarks n · m m · kg cylinder head nut m12 8 50 5.0 cylinder head nut m10 2 35 3.5 plate bolt m8 2 20 2.0 cylinder head cover screw m6 4 4 0.4 cylinder head (exhaust pipe) stud bolt m8 4 12.5 1.25 ro...

Page 21: Spec

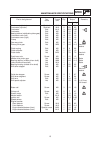

13 spec maintenance specifications part thread tightening part to be tightened name size q’ty torque remarks n · m m · kg crankcase (cylinder) stud bolt m12 8 24 2.4 crankcase (cylinder) stud bolt m10 2 20 2.0 crankcase bolt m10 3 38.5 3.85 crankcase bolt m6 10 10 1.0 bearing retainer (middle drive ...

Page 22: Spec

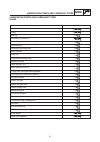

14 spec maintenance specifications item standard limit steering system: steering bearing type angular bearing ••• front suspension: front fork travel 130 mm ••• fork spring free length 364.8 mm ••• fitting length 339.8 mm ••• collar length 150 mm ••• spring rate (k1) 7.5 n/mm (0.75 kg/mm) ••• (k2) 1...

Page 23: Spec

15 spec maintenance specifications item standard limit front brake: type dual disc ••• disc outside diameter thickness 298 5 mm 4.5 mm disc deflection limit ••• 0.1 mm pad thickness inner 4.5 mm 0.5 mm outer 4.5 mm 0.5 mm master cylinder inside diameter 15 mm ••• caliper cylinder inside diameter 30....

Page 24: Spec

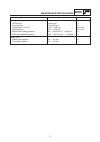

16 spec maintenance specifications tightening part to be tightened thread torque remarks size n · m m · kg headlight assembly/cowling: lower headlight support m6 10 1.0 upper headlight support (right and left) m6 7 0.7 headlight bracket (right and left) m6 10 1.0 plastic cover m5 4 0.4 front flasher...

Page 25: Spec

17 spec maintenance specifications tightening part to be tightened thread torque remarks size n · m m · kg rear brake/footrests: brake caliper torque rod m8 25 2.5 rear brake adjuster m6 10 1.0 rear brake pedal fastening screw (special) m8 16 1.6 rear master cylinder fastening screw m6 10 1.0 rear b...

Page 26: Spec

18 spec maintenance specifications item standard limit voltage: 12 v ••• ignition system: ignition timing (b.T.D.C.) 10° at 1,000 r/min ••• advancer type digital type ••• t.C.I.: pickup coil resistance/color 189 231 Ω at 20 °c / gray–black ••• t.C.I. Unit model/manufacturer j4t157/mitsubishi ••• ign...

Page 27: Spec

19 spec maintenance specifications item standard limit horn: type plane type ••• quantity 1 ••• model/manufacturer k80 l-12v/leb ••• maximum amperage 3 a ••• flasher relay: type full transistor ••• model/manufacturer fe218bh/denso ••• self cancelling device no ••• hazard flasher device yes ••• flash...

Page 28: Spec

20 spec general torque specifications/ conversion table general torque specifications this chart specifies torque for standard fasteners with standard i.S.O. Pitch threads. Torque specifi- cations for special components or assemblies are provided for each chapter of this manual. To avoid warpage, ti...

Page 29: Spec

21 spec lubrication points and lubricant types lubrication points and lubricant types engine lubrication point symbol oil seal lips o-ring bearing connecting rod bolt/nut connecting rod small end and big end crankshaft pin crankshaft journal/big end piston surface piston pin camshaft cam lobe/journa...

Page 30: Spec

22 spec lubrication points and lubricant types chassis lubrication point symbol steering head pipe (upper/lower), bearing steering head pipe, bearing cover lip steering head pipe, oil seal lip front wheel oil seal lip (right/left) rear wheel oil seal lip clutch hub fitting area rear brake pedal shaf...

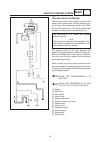

Page 31: Spec

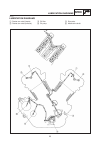

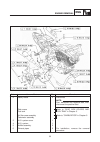

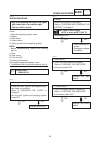

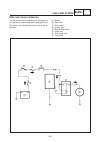

23 spec lubrication diagrams eb205000 lubrication diagrams 1 rocker arm shaft (intake) 2 rocker arm shaft (exhaust) 3 oil filter 4 oil pump 5 drive axle 6 middle drive shaft.

Page 32: Spec

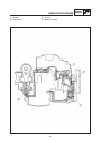

24 spec lubrication diagrams 1 oil pump 2 releaf valve 3 oil filter 4 middle drive shaft.

Page 33: Spec

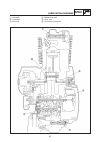

25 spec lubrication diagrams 1 camshaft 2 crankshaft 3 main axle 4 middle drive shaft 5 drive axle 6 connecting rod big end.

Page 34: Spec

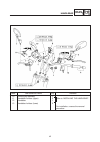

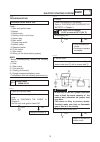

26 spec cable routing cable routing 1 relays group 2 flasher relay 3 speed sensor 4 sidestand switch 5 fuel drain hose 6 engine earth 7 neutral switch 8 carburetor heater 9 filler tank cap fuel drain pipe 0 filler tank cap fuel drain pipe q fuel hose (carburetor-3 way) w handlebar switch leads (left...

Page 35: Spec

27 spec cable routing a rubber cap for front wiring connections s horn d front brake hose (right) f a.I.S. Pipe to the front cylinder g starter motor h starter motor lead j oil level gauge k rear brake hose l brake fluid reservoir hose ; ignition coil (rear cylinder) z starter relay assy x depressio...

Page 36: Spec

28 spec cable routing @ carburetor pipe vent # depression fuel cock $ battery % fuel hose ^ spark plug lead (rear) & battery positive (+) terminal * fuse box ( battery negative (-) terminal ) igniter unit q fuel filter w fuel pump e fuel sender r air intake pipe (a.I.S. System) t anti-theft alarm co...

Page 37: Insp

29 insp adj introduction/periodic maintenance/ lubrication intervals periodic inspections and adjustments introduction this chapter includes all information necessary to perform recommended inspections and adjustments. These preventive maintenance procedures, if followed, will ensure more reliable v...

Page 38: Insp

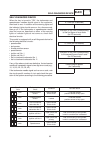

30 insp adj introduction/periodic maintenance/ lubrication intervals * items marked with an asterisk should be performed by a yamaha dealer as they require special tools, data and technical skills. Note: • the annual checks must be performed every year, except if a kilometer-based maintenance is per...

Page 39: Insp

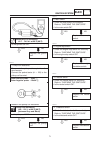

31 eb304001 chassis adjusting the front brake 1. Adjust: • brake lever position (distance a between the brake lever and the handlebar grip) a. Turn the adjusting dial 1 while holding the lever pushed away from the handlebar grip note: align the setting on the adjusting dial with the arrow mark 2 war...

Page 40: Insp

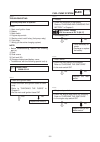

32 insp adj checking the fuses eas00181 checking the fuses the following procedure applies to all of the fuses. To avoid a short circuit, always turn the main switch to "off" when checking or replacing a fuse. 1. Remove: • seat • storage compartment 1 2. Check: • fuse caution: a. Connect the pocket ...

Page 41: Insp

33 fuses amperage quantity rating 1 main fuse 30 a 1 2 carburetor heater fuse 15 a 1 3 headlight fuse 15 a 1 4 signaling system fuse 10 a 1 5 ignition fuse 10 a 1 6 odometer fuse (backup) 10 a 1 7 parking lighting fuse 10 a 1 8 igniter fuse 5 a 1 9 reserve fuse 30 a 1 0 reserve fuse 15 a 1 q reserve...

Page 42: Eng

34 eng engine removal engine engine removal seat, storage compartment, side covers, fuel tank, air filter case assembly, carburetor assembly and exhaust system order job name/part name q’ty remarks removing the seat, storage remove the parts in the order listed. Compartment, side covers, fuel tank, ...

Page 43: Eng

35 engine removal eng order job name/part name q’ty remarks 2 battery leads 2 disconnect side covers fuel tank air filter case assembly carburetor assembly 3 a.I.S. System cover 1 4 a.I.S. System 1 5 muffler assembly 2 6 exhaust pipes 2 for installation, reverse the removal procedure. Refer to "seat...

Page 44: Carb

36 carb carburetor carburetion carburetor order job name/part name q’ty remarks removing the carburetors remove the parts in the order listed. Seat refer to "seat, side covers and fuel tank fuel tank" in chapter 3. 1 air filter case assembly 1 2 air ducts 2 3 cylinder head breather hose 1 disconnect...

Page 45: Chas

37 chas front brake chassis front brake master cylinder order job name/part name q’ty remarks removing the front brake master remove the parts in the order listed. Cylinder drain the brake fluid 1 brake lever 1 2 front brake switch lead 2 3 front brake switch 1 4 union bolt 1 5 copper washers/brake ...

Page 46: Chas

38 chas front brake order job name/part name q’ty remarks disassembling the front brake remove the parts in the order listed. Master cylinder 1 dust boot 1 2 circlip 1 3 master cylinder cup 1 4 spring 1 for assembly, reverse the disassembly procedure..

Page 47: Chas

39 chas front brake front brake calipers order job name/part name q’ty remarks removing the front brake calipers remove the parts in the order listed. Drain the brake fluid 1 union bolt 1 2 copper washers 2 3 brake hose 1 4 brake caliper assembly 1 for installation, reverse the removal procedure. Re...

Page 48: Chas

40 chas front brake order job name/part name q’ty remarks disassembling the front brake remove the parts in the order listed. Calipers 1 pad pin clips 2 2 pad pin 1 3 pad spring 1 4 brake pads 2 5 bleed screw 1 6 brake caliper pistons 4 7 dust seals 4 8 caliper piston seals 4 for assembly, reverse t...

Page 49: Chas

41 chas handlebar handlebar order job name/part name q’ty remarks removing the handlebar remove the parts in the order listed. Stand the motorcycle on a level surface. 1 plastic locking ties 2/2 2 clutch cable 1 3 handlebar switch (left) 1 4 grip (left) 1 5 clutch lever assembly/rear view mirror 1/1...

Page 50: Chas

42 chas handlebar order job name/part name q’ty remarks 10 throttle grip assembly 1 11 handlebar holders (upper) 2 12 handlebar 1 13 handlebar holders (lower) 2 for installation, reverse the removal procedure. Refer to “installing the handlebar”..

Page 51: Chas

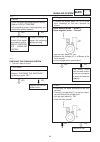

43 easb0025 installing the handlebar 1. Stand the motorcycle on a level surface. Warning securely support the motorcycle so that there is no danger of it falling over. 2. Install: • handlebar • upper handlebar holders • first, tighten the bolts on the front side of the handlebar holder, then on the ...

Page 52: Chas

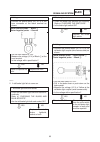

44 5. Install: • master cylinder holder 2 chas handlebar 10 nm (1.0 m•kg) note: install the master cylinder holder 2 with the mark "up" facing up. 6. Install: • clutch lever holder 1 note: align the slit in the clutch lever a holder with the punch mark in the handlebar. 7. Install: • left handlebar ...

Page 53: Chas

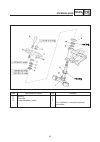

45 chas steering head steering head lower bracket order job name/part name q’ty remarks removing the lower bracket remove the parts in the order listed. Front wheel refer to “front wheel and brake discs”. Front fork legs refer to “front fork”. Handlebar refer to ”handlebar”. 1 crown nut/washer plate...

Page 54: Chas

46 chas steering head order job name/part name q’ty remarks 11 bearing 1 12 dust seal 1 13 lower handlebar holder 2 for installation, reverse the removal procedure..

Page 55: Elec

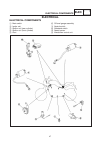

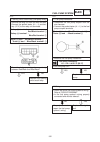

Elec electrical components 47 electrical electrical components 1 main switch 2 igniter unit 3 ignition coil (rear cylinder) 4 ignition coil (front cylinder) 5 horn 6 oil level gauge assembly 7 neutral switch 8 sidestand switch 9 speed sensor 0 immobilizer control unit.

Page 56: Elec

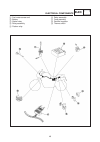

Electrical components 48 elec q fuel meter senser unit w battery e starter relay r relay assembly t flasher relay y relay assembly u fuse assembly i rectifier/regulator o thermo switch.

Page 57: Elec

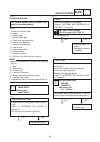

Elec switches 49 eas0010 switches checking switch continuity check each switch for continuity with the pocket tester. If the continuity reading is incorrect, check the wiring connections and if necessary, replace the switch. Never insert the tester probes into the coupler terminal slots 1. Always in...

Page 58: Elec

50 checking the switches elec eas00731 checking the switches check each switch for damage or wear, proper connections, and also for continuity between the termi- nals. Refer to “checking switch continuity”. Damage/wear → repair or replace the switch. Improperly connected → properly connect. Incorrec...

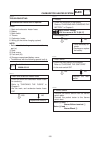

Page 59: Elec

Elec checking the switches 51 1 clutch switch 2 pass switch 3 horn switch 4 dimmer switch 5 turn switch 6 main switch 7 front brake switch 8 hazard switch 9 engine stop switch 0 start switch q fuses w rear brake switch e sidestand switch r neutral switch.

Page 60: Elec

52 elec checking the bulbs and bulb sockets eas00732 checking the bulbs and bulb sockets check each bulb and bulb socket for damage or wear, proper connections, and also for continuity between the terminals. Damage/wear → repair or replace the bulb, bulb socket or both. Improperly connected → proper...

Page 61: Elec

53 checking the bulbs and bulb sockets elec warning since the headlight bulb gets extremely hot, keep flammable products and your hands away from the bulb until it has cooled down. • be sure to hold the socket firmly when removing the bulb. Never pull the lead, oth- erwise it may be pulled out of th...

Page 62: Elec

Elec checking the bulbs and bulb sockets 54 checking the condition of the bulb sockets the following procedure applies to all of the bulb sockets. 1. Check: • bulb socket (for continuity) (with the pocket tester) no continuity → replace. Note: check each bulb socket for continuity in the same manner...

Page 63: Elec

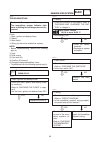

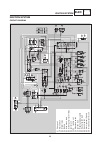

55 immobilizer system elec gy b b br gy br free push st ar t run off e/g stop hazard off on rb gy rw br lw b dg brw ch gy br dg brw ch b rw rb lw gy rb rw br ch brw dg lw b ry ry ry lb lb wb ry lb dg brw ch passing off on dimmer lo ry b p g y by ly lb horn off on by turn l n r ch dg b g y brw brw br...

Page 64: Elec

Elec immobilizer system 56 general information this vehicle is equipped with an immobilizer system to help prevent theft by re-registering codes in the standard keys. This system consists of the following: • a code re-registering key (with a red bow) • two standard keys (with a black bow) that can b...

Page 65: Elec

57 immobilizer system elec key codes registration method in the course of use, you may encounter the following case where replace these parts and registration of code re-registering/ standard key is required. Note: each standard key is registered during production, therefore re-registering at purcha...

Page 66: Elec

Elec immobilizer system 58 1. Check that the immobilizer system indicator light is flashing. It indicates the “standby mode”. To initiate the standby mode, turn “off” the main switch and then it will be the standby mode when it passes 30 seconds. After 24 hours have passed, the indicator light stop ...

Page 67: Elec

59 immobilizer system elec 2. Battery • check the condition of the battery. Refer to “checking and charging the bat- tery” in chapter 3. Open-circuit voltage 12.8 v or more at 20 °c • is the battery ok? 3. Main switch • check the main switch for continuity. Refer to “checking the switches”. • is the...

Page 68: Elec

Elec immobilizer system 60 1. Voltage • connect the pocket tester (dc 20 v) to the multi-function display couplers as shown. Tester positive probe – green/blue 1 tester negative probe – black 2 • set the main switch to “on”. • measure the voltage (12 v) between green/ blue and black on the multi-fun...

Page 69: Elec

61 immobilizer system elec 4. Voltage • connect the pocket tester (dc 20 v) to the immobilizer unit couplers as shown. Tester positive probe – green/blue 1 tester negative probe – black 2 • set the main switch to “on”. • measure the voltage (12 v) between green/ blue and black on the immobilizer uni...

Page 70: Elec

Elec immobilizer system 62 51 error code detection immobilizer unit symptoms cannot transmit code between the key and immobilizer unit. Trouble measures 1) objects that may keep off radio waves exist around the keys and antennas. 2) immobilizer unit failure. 3) key failure. 1) keep clear of magnets,...

Page 71: Elec

63 self-diagnosis device elec self-diagnosis device when the key is turned to "on", the tachometer and speedometer needles should move to the maximum, then back to zero. In addition all the warning lights and the indicator lights should come on for a few seconds, then go off. If the tachometer or sp...

Page 72: Elec

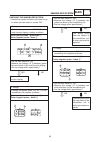

Elec self-diagnosis device 64 pocket tester 90890-03112 eas00836 1. Throttle position sensor circuit diagram 0 ignitor unit e throttle position sensor easb0044 troubleshooting check: 1. Throttle position sensor 2. Speed sensor 3. Ignition coil n. 1 and 2 4. Fuel-cut solenoid n. 1 and 2 note: • befor...

Page 73: Elec

65 self-diagnosis device elec 1. Speed sensor circuit diagram 0 ignitor unit ! Speed sensor brw brw brg rb lg lr lb lb yl rw rb gy2 g b b lb lb lg lr yb y l gy1 ly rb rw b br or rl bl w sb wb yl sbw rb l lb lr lw by sb ly lg b b lg b b b w yb l y bl ly wb rl sb br g ns sl1 sl2 sp rpm gnd g g br br b...

Page 74: Elec

Elec self-diagnosis device 66 3. Ignition coil n. 1 and 2 1. Wiring • check the entire ignition system’s wiring. Refer to “circuit diagram”. • is the ignition system’s wiring properly con- nected and without defects? Repair or replace the wire harness. Yes no 2. Ignition coil resistance the followin...

Page 75: Elec

67 self-diagnosis device elec 4. Fuel-cut solenoid (eur) circuit diagram 0 igniter unit * fuel-cut solenoid 1 ( fuel-cut solenoid 2 yl rw rb gy2 g b lb lb lg lr yb y l gy1 ly rb rw b br or rl bl w sb wb l l lb lr lw by sb b b w yb l y bl ly wb rl sb br g ns sl1 sl2 sp rpm gnd g g br br 10 11 9 12 14...

Page 76: Elec

Elec ignition system 68 gy b b br gy br free push st ar t run off e/g stop hazard off on rb gy rw br lw b dg brw ch gy br dg brw ch b rw rb lw gy rb rw br ch brw dg lw b ry ry ry lb lb wb ry lb dg brw ch passing off on dimmer lo ry b p g y by ly lb horn off on by turn l n r ch dg b g y brw brw brg l...

Page 77: Elec

69 ignition system elec 2. Battery • check the condition of the battery. Refer to “checking and charging the battery” in chapter 3. Min. Open-circuit voltage 12.8 v or more at 20 °c (68 °f) • is the battery ok? 3. Spark plugs the following procedure applies to all of the spark plugs. • check the con...

Page 78: Elec

Elec ignition system 70 4. Ignition spark gap the following procedure applies to all of the spark plugs. • disconnect the spark plug cap from the spark plug. • connect the ignition checker 1 as shown. • spark plug cap 2 . • set the main switch to “on”. • measure the ignition spark gap a . • crank th...

Page 79: Elec

71 ignition system elec secondary coil resistance 10.7 14.5 k at 20°c (68°f) • is the ignition coil ok? Replace the ignition coil. Yes no replace the pickup coil. Yes no 7. Pickup coil resistance • disconnect the pickup coil coupler from the wire harness. • connect the pocket tester ( 100) to the pi...

Page 80: Elec

Elec ignition system 72 ✳ 14. Wiring • check the entire ignition system’s wiring. Refer to “circuit diagram”. • is the ignition system’s wiring properly con- nected and without defects? Replace the ignitor unit. Properly connect or repair the ignition sys- tem’s wiring. No yes eas00754.

Page 81: Elec

73 electric starting system elec gy b b br gy br free push st ar t run off e/g stop hazard off on rb gy rw br lw b dg brw ch gy br dg brw ch b rw rb lw gy rb rw br ch brw dg lw b ry ry ry lb lb wb ry lb dg brw ch passing off on dimmer lo ry b p g y by ly lb horn off on by turn l n r ch dg b g y brw ...

Page 82: Elec

Elec electric starting system 74 eb803010 starting circuit operation the starting circuit on this model consists of the starter motor, starter relay, and the starting circuit cut-off relay. If the engine stop switch is on “run” and the main switch is on “on” (both switches are closed), the starter m...

Page 83: Elec

75 electric starting system elec 2. Battery • check the condition of the battery. Refer to “checking and charging the battery” in chapter 3. Min. Open-circuit voltage: 12.8 v or more at 20 °c (68 °f) • is the battery ok? 3. Starter motor • connect the battery positive terminal 1 and starter motor le...

Page 84: Elec

Elec electric starting system 76 4. Starting circuit cut-off relay • disconnect the relay unit from the coupler. • connect the pocket tester ( 1) and bat- tery (12v) to the relay unit terminals as shown. Battery positive terminal → red/black 1 battery negative terminal → black/yellow 2 tester positi...

Page 85: Elec

77 electric starting system elec 7. Engine stop switch • check the engine stop switch for continuity. Refer to “checking the switches”. • is the engine stop switch ok? Replace the right han- dlebar switch. Eas00750 yes no 8. Neutral switch • check the neutral switch for continuity. Refer to “checkin...

Page 86: Elec

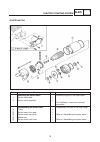

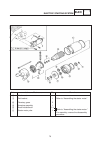

Elec electric starting system 78 order job name/part name q’ty remarks removing the starter motor remove the parts in the order listed. 1 starter motor lead 1 2 starter motor assembly 1 for installation, reverse the removal procedure. Disassembling the starter motor disassembly the pats in the order...

Page 87: Elec

79 electric starting system elec order job name/part name q’ty remarks 6 washer set 1 7 end bracket 1 refer to “assembling the starter motor.” 8 planetary gears 2 9 armature assembly 1 0 brush holder/brush 1/1 q starter motor yoke 1 for assembly, reverse the disassembly procedure. Refer to “assembli...

Page 88: Elec

Elec electric starting system 80 eas00769 checking the starter motor 1. Check: • commutator dirt → clean with 600 grit sandpaper. 2. Measure: • commutator diameter a out of specification → replace the starter motor. 3. Measure: • mica undercut a out of specification → scrape the mica to the proper m...

Page 89: Elec

81 electric starting system elec 5. Measure: • brush length a out of specification → replace the brushes as a set. 6. Measure: • brush spring force out of specification → replace the brush springs as a set. 7. Check: • gear teeth damage/wear → replace the gear. 8. Check: • oil seal damage/wear → rep...

Page 90: Elec

Elec electric starting system 82 3. Install: • starter motor rear cover 1 note: align the match marks a on the rear cover with the match marks b on the front cover..

Page 91: Elec

83 charging system elec run off e/g stop hazard off on rb gy rw br lw b dg brw ch gy br dg brw ch gy rb rw br ch brw dg lw b r b b b b b2 b1 bb3 bb4 bb2 bb1 b2 b1 bb3 bb4 bb2 bb1 b r b w w r gy1 bl gy gy b bl w w w w w w w w w w w w off on p brr brr brl rw b b b r r rw l rw l 4 5 6 7 17 1 b 10a brl ...

Page 92: Elec

Elec charging system 84 2. Battery • check the condition of the battery. Refer to “checking and charging the battery” in chapter 3. Min. Open-circuit voltage 12.8 v or more at 20 °c (68 °f) • is the battery ok? 3. Charging voltage • connect the engine tachometer to the spark plug lead of cylinder #1...

Page 93: Elec

85 charging system elec note: make sure that the battery is fully charged. • is the charging voltage within specification? The charging circuit is ok. No yes replace the stator coil assembly. Yes no 4. Stator coil assembly resistances • remove the left side cover. • connect the pocket tester ( 1) to...

Page 94: Elec

86 elec lighting system gy b b br gy br free push st ar t run off e/g stop hazard off on rb gy rw br lw b dg brw ch gy br dg brw ch b rw rb lw gy rb rw br ch brw dg lw b ry ry ry lb lb wb ry lb dg brw ch passing off on dimmer lo ry b p g y by ly lb horn off on by turn l n r ch dg b g y brw brw brg l...

Page 95: Elec

87 elec lighting system pocket tester 90890-03112 1. Main and headlight fuses • check the main and headlight fuses for con- tinuity. Refer to “checking the fuses” in chapter 3. • are the main and headlight fuses ok? Replace the fuse(-s). Eas00738 easb0033 troubleshooting check: 1. Main and headlight...

Page 96: Elec

88 elec lighting system 5. Pass switch • check the pass switch for continuity. Refer to “checking the switches”. • is the pass switch ok? The pass switch is faulty. Replace the right handlebar switch. Eas00786 yes no yes no 8. Wiring • check the entire lighting system’s wiring. Refer to “circuit dia...

Page 97: Elec

89 2. Voltage • connect the pocket tester (dc 20 v) to the headlight and high beam indicator light cou- plers as shown. å when the dimmer switch is set to “ 2 ” ∫ when the dimmer switch is set to “ 1 ” headlight tester positive probe → yellow 1 or green 2 tester negative probe → black 3 high beam in...

Page 98: Elec

90 elec lighting system the wiring circuit from the main switch to the tail/brake light coupler is faulty and must be repaired. This circuit is ok. Yes no 2. Voltage • connect the pocket tester (dc 20 v) to the tail/brake light coupler (wire harness side) as shown. Tester positive probe → blue/red 1...

Page 99: Elec

91 elec signaling system gy b b br gy br free push st ar t run off e/g stop hazard off on rb gy rw br lw b dg brw ch gy br dg brw ch b rw rb lw gy rb rw br ch brw dg lw b ry ry ry lb lb wb ry lb dg brw ch passing off on dimmer lo ry b p g y by ly lb horn off on by turn l n r ch dg b g y brw brw brg ...

Page 100: Elec

92 elec signaling system 3 main switch 4 starter relay 5 battery 6 wire minus lead t ignition fuse y right handlebar switch u front brake switch o signal fuse s left handlebar switch f horn g flasher relay h multi-function display j neutral switch lead k neutral switch ; front turn signal light (l) ...

Page 101: Elec

93 elec signaling system pocket tester 90890-03112 1. Main, ignition and signaling system fuses • check the main, ignition and signaling sys- tem fuses for continuity. Refer to “checking the fuses” in chapter 3. • are the main, ignition and signaling system fuses ok? Replace the fuse(-s). Eas00738 e...

Page 102: Elec

94 elec signaling system 1. Horn switch • check the horn switch for continuity. Refer to “checking the switches”. • is the horn switch ok? Replace the left han- dlebar switch. Eas00796 checking the signaling system 1. The horn fails to sound. Yes no the wiring circuit from the main switch to the hor...

Page 103: Elec

95 replace the horn. Repair or replace the horn. Yes no 4. Voltage • connect the pocket tester (dc 20 v) to the horn connecter at the black terminal as shown. Tester positive probe → black 1 tester negative probe → ground • set the main switch to “on”. • measure the voltage (12 v) of black 1 at the ...

Page 104: Elec

96 elec signaling system 2. Turn signal switch • check the turn signal for continuity. Refer to “checking the switches”. • is the turn signal switch ok? Replace the left han- dlebar switch. Yes no the wiring circuit from the main switch to the flasher relay coupler (flasher relay side) is faulty and...

Page 105: Elec

97 the flasher relay is faulty and must be replaced. Yes no tester positive probe → brown/white 1 tester negative probe → ground • set the main switch to “on”. • set the turn signal switch to “ Î ” or “ ¥ ”. • measure the voltage (12 v) of brown/white at the flasher relay coupler (wire harness side)...

Page 106: Elec

98 elec signaling system 2. Oil level switch • drain the engine oil and remove the oil level switch from the oil pan. • check the oil level switch for continuity. Refer to “checking the switches”. • is the oil level switch ok? Replace the oil level switch. Yes no 3. Voltage • connect the pocket test...

Page 107: Elec

99 elec fuel pump system gy b b br gy br free push st ar t run off e/g stop hazard off on rb gy rw br lw b dg brw ch gy br dg brw ch b rw rb lw gy rb rw br ch brw dg lw b ry ry ry lb lb wb ry lb brw brw brg brw brg wb br p p by ly ry brl ry br r rl brr brg 5a 10a 15a 10a brl r b r b w w r w w w off ...

Page 108: Elec

100 elec fuel pump system eb808010 fuel pump circuit operation the fuel pump circuit consists of the fuel pump re- lay, fuel pump, engine stop switch and ignitor unit. The ignitor unit includes the control unit for the fu- el pump. 1 battery 2 main fuse 3 main switch 4 ignition fuse 5 engine stop sw...

Page 109: Elec

101 elec fuel pump system pocket tester 90890-03112 1. Main and ignition fuses • check the main and ignition fuses for conti- nuity. Refer to "checking the fuses" in chapter 3. • are the main and ignition fuses ok? Replace the fuse(-s). Eas00738 easb0037 troubleshooting check: 1. Main, and ignition ...

Page 110: Elec

102 elec fuel pump system replace the fuel pump. Yes no 6. Fuel pump resistance • disconnect the fuel pump coupler from the wire harness. • connect the pocket tester ( 1) to the fuel pump coupler terminals. Tester (+) lead → blue/black terminal 1 tester (–) lead → black terminal 2 • measure the fuel...

Page 111: Elec

103 elec fuel pump system easb0038 fuel pump test warning gasoline is extremely flammable and under certain circumstances there can be a danger of an explosion or combustion. Be extremely careful and note the following points: • stop the engine before refuelling. • do not smoke and keep away from op...

Page 112: Elec

104 elec carburetor heater system gy b b br gy br free push st ar t run off e/g stop hazard off on rb gy rw br lw b dg brw ch gy br dg brw ch b rw rb lw gy rb rw br ch brw dg lw b ry ry ry lb lb wb ry lb dg brw ch passing off on dimmer lo ry b p g y by ly lb horn off on by turn l n r ch dg b g y brw...

Page 113: Elec

105 elec carburetor heater system pocket tester 90890-03112 1. Main and carburetor heater fuses • check the main and carburetor heater fuses for continuity. Refer to "checking the fuses" in chapter 3. • are the main, and carburetor heater fuses ok? Replace the fuse(-s). Eas00738 easb0039 troubleshoo...

Page 114: Elec

106 elec carburetor heater system • immerse the thermo switch in the water 3 . • check the thermo switch for continuity. Note the temperatures while heating the water with the temperature gauge 4 . Test step water temperature good condition 1 less than 23 ± 3 °c o 2 more than 23 ± 3 °c 3 more than 1...

Page 115: Trbl

107 trbl shtg starting failure/hard starting ? Troubleshooting note: the following guide for troubleshooting does not cover all the possible causes of problems. It should be helpful, however, as a guide to troubleshooting. Refer to the relative procedure in this manual for inspec- tion, adjustment a...

Page 116

Printed in italy ya m a h a m o t o r i ta l i a s . P. A ..

Page 117: Bt1100 Wiring Diagram

Bt1100 wiring diagram color code b ...........Black br ..........Brown ch .........Chocolate dg .........Dark green g ...........Green gy .........Gray l............Blue lg..........Light green o ...........Orange p ...........Pink r ...........Red sb .........Sky blue w ..........White y .............