- DL manuals

- Yamaha

- Motorcycle

- 2006 FJR1300AS

- Service Manual

Yamaha 2006 FJR1300AS Service Manual

Summary of 2006 FJR1300AS

Page 1

2006 supplementary service manual fjr1300as(v) 3p6-28197-e1.

Page 2: Foreword

Et2d21027 foreword this supplementary service manual has been prepared to introduce new service and data for the fjr1300as(v). For complete service information procedures it is necessary to use this supplementary service manual together with the following manual. Fjr1300a(v) service manual: 3p6-2819...

Page 3: Notice

Eas20070 notice this manual was produced by the yamaha motor company, ltd. Primarily for use by yamaha dealers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one man- ual. Therefore, anyone who uses this book to perform maintenance and repairs on yama...

Page 4: How to Use This Manual

Eas20090 how to use this manual this manual is intended as a handy, easy-to-read reference book for the mechanic. Comprehensive explanations of all installation, removal, disassembly, assembly, repair and check procedures are laid out with the individual steps in sequential order. • the manual is di...

Page 5: Symbols

Eas20100 symbols the following symbols are used in this manual for easier understanding. Note: the following symbols are not relevant to every vehicle. G m e b ls m 9 10 11 12 13 14 15 16 lt new t r . . 1 2 3 4 5 6 7 8 1. Serviceable with engine mounted 2. Filling fluid 3. Lubricant 4. Special tool ...

Page 6: Contents

Eas20110 contents features......................................................................................................... 1 outline of the ycc-s (yamaha chip controlled-shift) system ......... 1 special tools ....................................................................................

Page 7

Shaft drive .................................................................................................. 46 installing the drive shaft and final drive assembly ......... 46 engine removal ......................................................................................... 47 removing the ...

Page 8

Ycc-s (yamaha chip controlled-shift) system......................................... 85 circuit diagram (1/2)........................................................................... 85 circuit diagram (2/2)........................................................................... 87 troubleshoot...

Page 10: Features

Features – 1 – eas20170 features et2d21013 outline of the ycc-s (yamaha chip controlled-shift) system concept ycc-s offers more enjoyable and easy riding by eliminating the need for the user to operate the clutch, which also reduces fatigue during long touring. Ycc-s is not an automatic transmission...

Page 11: Features

Features – 2 – shift pattern this vehicle is equipped with a constant-mesh 5-speed transmission. The gears can be shifted using either the shift pedal “1” or the hand shift switch “2”. The hand shift switch has to be enabled by pressing the hand shift select button “3” prior to being used. The gear ...

Page 12: Features

Features – 3 – attention • do not turn the main switch to “off” while the vehicle is moving, otherwise the electrical systems will be switched off, including the ycc-s system, which may result in loss of control or an accident. Make sure that the vehicle is stopped before turning the main switch to ...

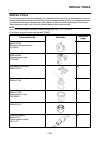

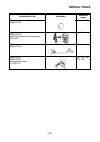

Page 13: Special Tools

Special tools – 4 – eas20260 special tools the following special tools are necessary for complete and accurate tune-up and assembly. Use only the appropriate special tools as this will help prevent damage caused by the use of inappropriate tools or improvised techniques. Special tools, part numbers ...

Page 14: Special Tools

Special tools – 5 – pivot shaft wrench adapter 90890-01476 49 digital circuit tester 90890-03174 model 88 multimeter with tachometer yu-a1927 50, 60 test coupler adapter 90890-03149 95 pocket tester 90890-03112 analog pocket tester yu-03112-c 129, 130, 132, 133, 134 tool name/tool no. Illustration r...

Page 15: General Specifications

General specifications – 6 – eas20280 general specifications model model 2d21(europe except (b)and(f))(za) 2d22(b)(f) 2d23(aus) weight with oil and fuel 295.0 kg (650 lb) maximum load 208 kg (459 lb).

Page 16: Engine Specifications

Engine specifications – 7 – eas20290 engine specifications clutch clutch type wet, multiple-disc clutch release method hydraulic inner push clutch lever free play 1.9–20.7 mm (0.07–0.81 in) friction plate thickness 2.90–3.10 mm (0.114–0.122 in) wear limit 2.80 mm (0.1102 in) plate quantity 9 pcs clu...

Page 17: Chassis Specifications

Chassis specifications – 8 – eas20300 chassis specifications tire air pressure (measured on cold tires) loading condition 0–90 kg (0–198 lb) front 270 kpa (39 psi) (2.70 kgf/cm²) rear 290 kpa (42 psi) (2.90 kgf/cm²) loading condition 90–208 kg (198–459 lb) front 270 kpa (39 psi) (2.70 kgf/cm²) rear ...

Page 18: Electrical Specifications

Electrical specifications – 9 – eas20310 electrical specifications gear position sensor output voltage (at neutral position) 0.71–0.91 v resistance 4.0–6.0 k Ω foot shift switch output voltage 2.4–2.6 v resistance 4.0–6.0 k Ω grip warmer resistance 1.21–1.48 Ω at 20 °c (68 °f) fuses main fuse 50.0 a...

Page 19: Tightening Torques

Tightening torques – 10 – eas20320 tightening torques eas20340 engine tightening torques item thread size q’ty tightening torque remarks clutch fluid reservoir bolt m6 1 7 nm (0.7 m·kg, 5.1 ft·lb) clutch actuator bracket bolt m8 2 19 nm (1.9 m·kg, 13 ft·lb) clutch actuator bracket bolt m6 3 10 nm (1...

Page 20: Tightening Torques

Tightening torques – 11 – eas20350 chassis tightening torques item thread size q’ty tightening torque remarks shift pedal bolt m6 1 7 nm (0.7 m·kg, 5.1 ft·lb) shift pedal pivot bolt m8 1 16 nm (1.6 m·kg, 11 ft·lb) pivot shaft locknut retainer bolt m6 1 10 nm (1.0 m·kg, 7.2 ft·lb) lt lt lt.

Page 21: Tightening Torques

Tightening torques – 12 –.

Page 22: Cable Routing

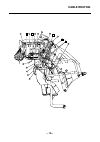

Cable routing – 13 – eas20430 cable routing b-b a a b b a b c d e f f g g h i j k l 1 1 1 2 2 2 2 3 3 3 7 7 6 7 4 8 5 9 6 13 13 14 14 10 13 12 11 14 15 17 16 18 19 20 22 21 23 23 23 24 24 24 1 2 3 m.

Page 23: Cable Routing

Cable routing – 14 – 1. Brake hose (front brake master cylinder to hydraulic unit) 2. Right handlebar switch lead 3. Left handlebar switch lead 4. Left grip warmer lead 5. Hand shift switch lead 6. Right grip warmer lead 7. Main switch lead 8. Immobilizer unit lead 9. Left horn (low) 10. Brake hose ...

Page 24: Cable Routing

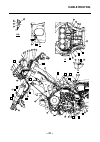

Cable routing – 15 – b c c-c d-d e-e a-a b-b f f a a cb d e d e a b c e i j k l 1 1 2 3 3 4 4 5 5 5 5 5 5 6 7 8 9 10 11 12 13 13 14 15 16 17 18 18 18 18 19 20 21 23 24 25 26 27 27 29 28 30 30 31 32 33 34 35 36 37 38 39 d f g m n s 27 30 30 18 q r h 22 40 41 42 41 o p 11.

Page 25: Cable Routing

Cable routing – 16 – 1. O 2 sensor lead 2. Engine idling speed adjusting cable 3. Starter motor lead 4. Air deflector 5. Wire harness 6. Spark plug lead #4 7. Spark plug lead #1 8. Cylinders-#1/#4 ignition coil 9. Cylinders-#2/#3 ignition coil 10. Starter relay 11. Starter relay lead 12. Fuse box 2 ...

Page 26: Cable Routing

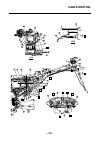

Cable routing – 17 – b c 1 a d e g 1 2 3 4 5 6 7 8 9 14 13 10 11 12 15 f.

Page 27: Cable Routing

Cable routing – 18 – 1. Rear wheel sensor lead 2. Rear brake fluid reservoir 3. Rear brake light switch lead 4. Clutch actuator motor lead 5. Clutch actuator sensor lead 6. Hydraulic unit 7. Brake hose (front brake master cylinder to hydraulic unit) 8. Brake hose (hydraulic unit to proportioning val...

Page 28: Cable Routing

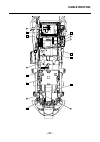

Cable routing – 19 – a b c d e 1 2 3 4 6 5 8 7 9 11 10 12 13.

Page 29: Cable Routing

Cable routing – 20 – 1. Auxiliary dc jack 2. Left radiator fan motor lead 3. Accessory box solenoid 4. Wire harness 5. Front cowling wire harness 6. Radiator inlet hose 7. Grip warmer control unit leads 8. Left radiator fan 9. Coolant reservoir breather hose 10. Left horn (low) 11. Left horn (low) l...

Page 30: Cable Routing

Cable routing – 21 – up a-a b d c c b d a a a b d c f g h i j k l m n o p q t r s 1 3 2 19 19 11 12 13 11 15 14 17 18 20 21 22 23 10 24 25 26 16 27 28 29 30 31 32 33 e 7 9 8 4 6 5 30 34 35 u 16.

Page 31: Cable Routing

Cable routing – 22 – 1. Grip warmer couplers 2. Hand shift switch coupler 3. Handlebar switch couplers 4. Right grip warmer lead 5. Right handlebar switch lead 6. Immobilizer unit lead 7. Main switch lead 8. Hand shift switch lead 9. Left grip warmer lead 10. Left handlebar switch lead 11. Stator co...

Page 32: Cable Routing

Cable routing – 23 – a-a b-b c c b b a a a b e d c g f h i j l k m 2 2 1 1 5 5 5 6 6 6 7 8 9 16 11 12 13 15 10 17 18 19 12 3 3 4 3 20 21 11 22 11 22 23 24 25 26 27 14.

Page 33: Cable Routing

Cable routing – 24 – 1. Wire harness 2. Ecu (engine control unit) 3. Abs ecu (electronic control unit) 4. Mcu (motor control unit) 5. Tail/brake light 6. Rear turn signal light 7. Tail/brake light assembly lead 8. License plate light lead 9. Seat lock cable 10. Shift actuator motor lead 11. Abs wire...

Page 34: Cable Routing

Cable routing – 25 – h a d e b c f g i i j k l m n o p 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 31 30

Page 35: Cable Routing

Cable routing – 26 – 1. Spark plug lead #1 2. Spark plug lead #2 3. Front wheel sensor lead 4. Immobilizer unit lead 5. Main switch lead 6. Throttle cable (accelerator cable) 7. Throttle cable (decelerator cable) 8. Brake hose (hydraulic unit to front brake calipers) 9. Brake hose (metering valve to...

Page 36: Cable Routing

Cable routing – 27 – d b c a e e f i 3 4 5 2 1 6 h g.

Page 37: Cable Routing

Cable routing – 28 – 1. Clutch actuator motor lead 2. Clutch actuator sensor lead 3. License plate light lead 4. Tail/brake light assembly lead 5. Seat lock cable 6. Intake air temperature sensor a. Connect the clutch actuator motor lead and clutch actuator sensor lead, install the rubber cover arou...

Page 38: Periodic Maintenance

Periodic maintenance – 29 – eas20450 periodic maintenance eas20460 introduction this chapter includes all information necessary to perform recommended checks and adjustments. If followed, these preventive maintenance procedures will ensure more reliable vehicle operation, a long- er service life and...

Page 39: Periodic Maintenance

Periodic maintenance – 30 – eau40550 note: • the air filter needs more frequent service if you are riding in unusually wet or dusty areas. • hydraulic brake and ycc-s clutch service • regularly check and, if necessary, correct the brake and ycc-s clutch fluid levels. • every two years replace the in...

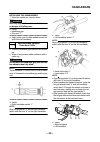

Page 40: Engine

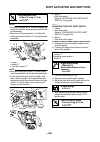

Engine – 31 – eas20470 engine eas20890 checking the clutch fluid level 1. Stand the vehicle on a level surface. Note: place the vehicle on the centerstand. 2. Remove: • left side cover refer to “general chassis” in chapter 4. (manual no.: 3p6-28197-e0) 3. Check: • clutch fluid level below the minimu...

Page 41: Engine

Engine – 32 – b. Turn the main switch to “on” and check that the transmission is in neutral. C. Add the recommended clutch fluid to the proper level. D. Install the clutch fluid reservoir diaphragm. E. Connect the vacuum/pressure pump gauge set “2” tightly to the bleed screw “3”. F. Loosen the bleed...

Page 42: Engine

Engine – 33 – d. Install a suitable bracket “4”, the magnet base b “5”, and the dial gauge & stand set “6”. E. Disengage the clutch by turning the manual clutch operation bolt. F. Measure the clutch pressure plate stroke. G. If the pressure plate stroke is out of specifica- tion, repeat steps (j) to...

Page 43: Engine

Engine – 34 – b. Start the engine. C. Shift the transmission from neutral to 1st gear and back to neutral ten times. D. Shift the transmission into 1st gear, and then apply the rear brake. Note: if the engine stalls, restart the engine, let it idle for at least 90 seconds, and then repeat steps (c) ...

Page 44: Chassis

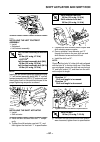

Chassis – 35 – eas21140 chassis et2d21002 adjusting the shift pedal 1. Check: • shift pedal position note: the shift pedal “1” can be adjusted to three po- sitions to suit the rider’s preference as shown. 2. Adjust: • shift pedal position ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ a. Remove t...

Page 45: Electrical System

Electrical system – 36 – eas21750 electrical system eas21790 replacing the headlight bulbs the following procedure applies to both of the headlight bulbs. 1. Remove: • front cowling left inner panel 1 • front cowling left inner panel 2 • front cowling right inner panel 1 • front cowling right inner ...

Page 46: General Chassis

General chassis – 37 – eas21830 general chassis removing the front cowling assembly order job/parts to remove q’ty remarks open the accessory box lid. 1 left side panel 1 2 left side cowling 1 3 front left turn signal light coupler 1 disconnect. 4 right side panel 1 5 right side cowling 1 6 front ri...

Page 47: General Chassis

General chassis – 38 – 16 front cowling left inner panel 2 1 17 plastic band 2 disconnect. 18 plastic holder 1 disconnect. 19 handlebar switch coupler 2 disconnect. 20 hand shift switch coupler 2 disconnect. 21 front cowling wire harness coupler 6 disconnect. 22 horn connector 4 disconnect. 23 grip ...

Page 48: General Chassis

General chassis – 39 – removing the air filter case order job/parts to remove q’ty remarks left side cover refer to “general chassis” on page 37. T-bar refer to “general chassis” in chapter 4. (manual no.: 3p6-28197-e0) fuel tank refer to “fuel tank” in chapter 7. (manual no.: 3p6-28197-e0) shift ac...

Page 49: General Chassis

General chassis – 40 – 13 bypass air unit inlet hose 1 disconnect. 14 crankcase breather hose 1 disconnect. 15 air induction system hose (air filter case joint assembly to 3-way joint) 1 disconnect. 16 air filter case joint clamp screw 4 loosen. 17 air filter case joint assembly 1 18 air filter case...

Page 50: Handlebars

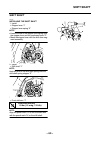

Handlebars – 41 – eas22850 handlebars removing the left handlebar order job/parts to remove q’ty remarks 1 left handlebar 1 2 left grip warmer lead 1 3 hand shift switch lead 1 4 left handlebar switch lead 1 5 lead holder 1 1 6 hand shift switch 1 7 lead holder 2 1 8 left handlebar switch 1 9 grip e...

Page 51: Handlebars

Handlebars – 42 – removing the right handlebar order job/parts to remove q’ty remarks 1 front brake light switch connector 2 disconnect. 2 front brake master cylinder holder 1 3 front brake master cylinder assembly 1 4 grip end 1 5 throttle cable housing 2 6 throttle cable 2 disconnect. 7 throttle g...

Page 52: Handlebars

Handlebars – 43 – eas22900 installing the handlebars 1. Stand the vehicle on a level surface. Warning ewa13120 securely support the vehicle so that there is no danger of it falling over. 2. Install: • handlebar grip • grip end “1” ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ a. Apply a thin coa...

Page 53: Handlebars

Handlebars – 44 – note: fit the projections on each handlebar into the holes in the upper bracket, making sure that the handlebars are installed in the same position. 7. Install: • handlebar bolts “1” (temporarily) • handlebar nuts “2” (temporarily) 8. Tighten: • handlebar bolts • handlebar nuts not...

Page 54: Handlebars

Handlebars – 45 – • first, tighten the upper bolt, then the lower bolt. 11.Adjust: • throttle cable free play refer to “adjusting the throttle ca- ble free play” in chapter 3. (manual no.: 3p6-28197-e0) throttle cable free play 3.0–5.0 mm (0.12–0.20 in) b a 1.

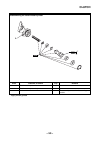

Page 55: Shaft Drive

Shaft drive – 46 – eas23550 shaft drive eas23660 installing the drive shaft and final drive assembly 1. Lubricate: • drive shaft spline (final drive pinion gear side) 2. Lubricate: • drive shaft spline (universal joint side) 3. Install: • oil seal “1” • washer “2” (with the fork seal driver weight “...

Page 56: Engine Removal

Engine removal – 47 – eas23710 engine removal disconnecting the leads and hoses order job/parts to remove q’ty remarks front fender refer to “front wheel” in chapter 4. (manual no.: 3p6-28197-e0) air filter case refer to “general chassis” on page 37. Throttle bodies refer to “throttle bodies” in cha...

Page 57: Engine Removal

Engine removal – 48 – gear position sensor cover refer to “shift actuator and shift rod” on page 57. 1 gear position sensor coupler 1 disconnect. 2 gear position sensor 1 3 clutch release cylinder 1 4 dowel pin 2 5 crankcase breather hose 1 6 stator coil coupler 1 disconnect. 7 oil level switch coup...

Page 58: Engine Removal

Engine removal – 49 – et2d21003 removing the gear position sensor 1. Disconnect: • gear position sensor coupler 2. Remove: • gear position sensor note: remove only the screws “1” when removing the gear position sensor. Do not remove the screws “2”. Et3p61023 removing the engine 1. Loosen: • spacer b...

Page 59: Engine Removal

Engine removal – 50 – et2d21005 adjusting the gear position sensor 1. Check: • gear position sensor refer to “checking the gear position sensor” on page 132. 2. Adjust: • gear position sensor angle ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ a. Connect the gear position sensor coupler to the g...

Page 60: Clutch

Clutch – 51 – eas25060 clutch removing the clutch actuator and clutch master cylinder order job/parts to remove q’ty remarks clutch fluid drain. Refer to “bleeding the hydraulic clutch system” on page 31. Swingarm refer to “swingarm” in chapter 4. (manual no.: 3p6-28197-e0) 1 rear brake hose/rear wh...

Page 61: Clutch

Clutch – 52 – 13 clutch master cylinder 1 14 shim (clutch master cylinder kit) 1 15 o-ring (clutch master cylinder kit) 1 16 clutch actuator 1 for installation, reverse the removal proce- dure. Removing the clutch actuator and clutch master cylinder order job/parts to remove q’ty remarks t r . . 19 ...

Page 62: Clutch

Clutch – 53 – * apply silicon grease disassembling the clutch master cylinder order job/parts to remove q’ty remarks 1 clutch master cylinder kit 1 2 clutch master cylinder body 1 for assembly, reverse the disassembly pro- cedure. 1 2 new ∗.

Page 63: Clutch

Clutch – 54 – removing the clutch release cylinder order job/parts to remove q’ty remarks clutch fluid drain. Refer to “bleeding the hydraulic clutch system” on page 31. 1 clutch hose union bolt 1 2 copper washer 2 3 clutch hose 1 disconnect. 4 clutch release cylinder 1 5 dowel pin 2 6 plate 1 for i...

Page 64: Clutch

Clutch – 55 – et2d21037 breaking in the friction plates after replacement 1. If the friction plates are replaced, perform the following procedure to break them in. ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ a. Start the engine and warm it up until at least three segments appear on the coolant...

Page 65: Clutch

Clutch – 56 – b. If the thickness of the shim installed on the vehicle is 1.5 mm (0.06 in), refer to the follow- ing table. ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲▲▲ 7. Check: • rear wheel drag torque refer to “checking the vehicle after bleeding the hydraulic clutch system” on page 33. 8. C...

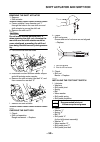

Page 66: Shift Actuator and Shift Rod

Shift actuator and shift rod – 57 – et2d21006 shift actuator and shift rod removing the shift actuator, shift rod and foot shift switch order job/parts to remove q’ty remarks rider seat/left side cover refer to “general chassis” in chapter 4. (manual no.: 3p6-28197-e0) air shroud refer to “general c...

Page 67: Shift Actuator and Shift Rod

Shift actuator and shift rod – 58 – 14 wave washer 1 15 washer 1 16 shift pedal 1 17 ball 1 18 spring 1 19 washer 1 for installation, reverse the removal proce- dure. Removing the shift actuator, shift rod and foot shift switch order job/parts to remove q’ty remarks lt lt t r . . 65 nm (6.5 m • kg, ...

Page 68: Shift Actuator and Shift Rod

Shift actuator and shift rod – 59 – et2d21007 removing the shift actuator 1. Remove: • shift actuator ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ a. Pass a suitable 5 mm diameter rod “1” through the holes in the rear shift arm and shift actuator to secure the shift rod. B. Remove the shift rod...

Page 69: Shift Actuator and Shift Rod

Shift actuator and shift rod – 60 – note: • position the projection “a” on the shift pedal be- tween the ends “b” of the spring on the left foot- rest assembly. • be sure to fit the projections “c” on the shift pedal pivot into the holes “d” in the left footrest assembly. 3. Install: • holder “1” • ...

Page 70: Shift Actuator and Shift Rod

Shift actuator and shift rod – 61 – ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲▲▲ et2d21011 installing the left footrest assembly 1. Install: • sidestand • left footrest assembly note: install the left footrest assembly/sidestand bolts “1”, left footrest assembly bolts (m8) “2” and left footrest...

Page 71: Shift Actuator and Shift Rod

Shift actuator and shift rod – 62 – h. Pull out the rod from the holes. ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲▲▲ t r . . Shift rod front locknut 7 nm (0.7 m·kg, 5.1 ft·lb) shift rod rear locknut 10 nm (1.0 m·kg, 7.2 ft·lb).

Page 72: Shift Shaft

Shift shaft – 63 – eas25410 shift shaft eas25450 installing the shift shaft 1. Install: • stopper lever “1” • stopper lever spring “2” note: • hook the ends of the stopper lever spring onto the stopper lever and the crankcase boss “3”. • mesh the stopper lever with the shift drum seg- ment assembly....

Page 73: Middle Gear

Middle gear – 64 – eas25710 middle gear removing the middle gear order job/parts to remove q’ty remarks engine refer to “engine removal” in chapter 5. (manual no.: 3p6-28197-e0) oil pan/oil pump refer to “oil pump” in chapter 5. (manual no.: 3p6-28197-e0) 1 middle gear case cover 1 2 middle gear cas...

Page 74: Middle Gear

Middle gear – 65 – 14 middle drive shaft assembly 1 15 spacer 1 16 middle driven gear 1 17 bearing retainer 1 18 bearing 1 19 middle drive pinion gear shim 20 bearing 1 for installation, reverse the removal proce- dure. Removing the middle gear order job/parts to remove q’ty remarks.

Page 75: Crankcase

Crankcase – 66 – eas25540 crankcase separating the crankcase order job/parts to remove q’ty remarks engine refer to “engine removal” in chapter 5. (manual no.: 3p6-28197-e0) cylinder head refer to “cylinder head” in chapter 5. (manual no.: 3p6-28197-e0) starter clutch refer to “generator and starter...

Page 76: Crankcase

Crankcase – 67 – 5 spacer 1 6 collar 1 7 spring washer 1 8 neutral switch 1 9 ycc-s speed sensor 1 10 lower crankcase 1 11 dowel pin 3 for installation, reverse the removal proce- dure. Separating the crankcase order job/parts to remove q’ty remarks t r . . 24 nm (2.4 m • kg, 17 ft • ib) t r . . 12 ...

Page 77: Transmission

Transmission – 68 – eas26240 transmission removing the transmission, shift drum assembly, and shift forks order job/parts to remove q’ty remarks crankcase separate. Refer to “crankcase” in chapter 5. (man- ual no.: 3p6-28197-e0) stopper lever refer to “shift shaft” in chapter 5. (man- ual no.: 3p6-2...

Page 78: Transmission

Transmission – 69 – 13 shift drum assembly 1 14 shift fork-c 1 15 main axle assembly 1 for installation, reverse the removal proce- dure. Removing the transmission, shift drum assembly, and shift forks order job/parts to remove q’ty remarks.

Page 79: Transmission

Transmission – 70 –.

Page 80: Electric Starting System

Electric starting system – 71 – eas27160 electric starting system eas27170 circuit diagram (1/2) w /y w /b br b /g on off p g /w b r /lb e e e e e e c b b b c f c c c c b b c b c e e e e e e d a a a a d r l br /r br /l br /l br /w r r r /g r w w w w w w r r br /l br /r br /b br /b br /b l /y r /b l ...

Page 81: Electric Starting System

Electric starting system – 72 – 1. Main switch 7. Main fuse 8. Battery 10.Starter relay 11.Starter motor 12.Diode 1 17.Coupler 2 (wire harness–front cowling wire harness) 18.Neutral switch 25.Rear brake light switch 27.Brake light relay 33.Coupler 3 (wire harness–front cowling wire harness) 34.Sides...

Page 82: Electric Starting System

Electric starting system – 73 – et3p61003 circuit diagram (2/2) front cowling wire harness shift down shift up push up down lg r /b l /rb r/ g br br /lb r/ l r /bb r r br /b b b l /r g /l l /ry y gg bb b br b b /l r /w r /w r /b w /l b br g /y r /y y lg sb /w o /wo /bg /rg /b r /b br /lb b /l dg ch ...

Page 83: Electric Starting System

Electric starting system – 74 – 17.Coupler 2 (front cowling wire harness–wire harness) 33.Coupler 3 (front cowling wire harness–wire harness) 65.Coupler 6 (front cowling wire harness–wire harness) 82.Front brake light switch 83.Engine stop switch 84.Start switch 92.Relay unit 93.Starting circuit cut...

Page 84: Electric Starting System

Electric starting system – 75 – eas27180 starting circuit cut-off system operation if the engine stop switch is set to “ ” (the switch circuit is closed), the main switch is turned “on” (the switch circuit is closed), and the brake lever is squeezed (the front brake light switch circuit is open) or ...

Page 85: Electric Starting System

Electric starting system – 76 – eas27190 troubleshooting the starter motor fails to turn. Note: • before troubleshooting, remove the following part(s): 1. Front cowling assembly 2. Fuel tank 3. T-bar 4. Throttle bodies ng → ok ↓ ng → ok ↓ ok → ng ↓ ng → ok ↓ ng → ok ↓ ng → ok ↓ 1. Check the fuses. (...

Page 86: Electric Starting System

Electric starting system – 77 – ng → ok ↓ ng → ok ↓ ng → ok ↓ ng → ok ↓ ng → ok ↓ ng → ok ↓ ng → ok ↓ ng → ok ↓ ng → ok ↓ ng → ok ↓ 7. Check the starter relay. Refer to “checking the re- lays” on page 130. Replace the starter relay. 8. Check the brake light relay. Refer to “checking the re- lays” on...

Page 87: Electric Starting System

Electric starting system – 78 – ng → ok ↓ 17.Check the entire starting system wiring. Refer to “circuit diagram (1/2)” on page 71 and “circuit dia- gram (2/2)” on page 73. Properly connect or repair the starting sys- tem wiring. Replace the mcu or diode 1..

Page 88: Grip Warmer System

Grip warmer system – 79 – et2d21014 grip warmer system et2d21015 circuit diagram (1/2) l on off p g /w b r /lb e e e e e e c b b b c f c c c c b b c b c e e e e e e d a a a a d br /r br /l br /l br /w r r r /g r w w w w w w r r br /l br /r br /b br /b br /b l /y r /b l l /y l b r b r g /y br /l br /...

Page 89: Grip Warmer System

Grip warmer system – 80 – 1. Main switch 7. Main fuse 8. Battery 43.Ecu (engine control unit) 65.Coupler 6 (wire harness–front cowling wire harness) 66.Headlight (on/off)/grip warmer relay 68.Signaling system fuse 69.Headlight fuse 72.Grip warmer control unit.

Page 90: Grip Warmer System

Grip warmer system – 81 – et2d21016 circuit diagram (2/2) front cowling wire harness up down lg r/b l/r br/g br br/l br/l r/b br r br/b b b l/r g/l l/r y y g g b b b r/w r/b w/l b br g/y r/y y lg sb/w l/b r/g sb sb/w g l/b y b br r/w l/w r/y br/b g/l l/r r/b b/r b r/b b/r r br r/w g/l l/w r/y r/b l/...

Page 91: Grip Warmer System

Grip warmer system – 82 – 65.Coupler 6 (front cowling wire harness–wire harness) 122.Right grip warmer 123.Left grip warmer.

Page 92: Grip Warmer System

Grip warmer system – 83 – et2d21017 troubleshooting • the grip warmers do not become warm at all. • the grip warmers are abnormally hot while the engine is idling. • the grip warmers do not become very warm while the vehicle is traveling. Note: • before troubleshooting, remove the following part(s):...

Page 93: Grip Warmer System

Grip warmer system – 84 – ng → ok ↓ the grip warmers do not become very warm while the vehicle is traveling. Ng → ok ↓ ng → ok ↓ ng → ok ↓ 2. Disconnect the grip warmer control unit coupler (white/yellow and black/green) and check that the temperature does not drop while the engine is running. Repla...

Page 94: – 85 –

Ycc-s (yamaha chip controlled-shift) system – 85 – et2d21018 ycc-s (yamaha chip controlled-shift) system et2d21019 circuit diagram (1/2) on off p g /w b r /lb e e e e e e c b b b c f c c c c b b c b c e e e e e e d a a a a d r l br /r br /l br /l br /w r r r /g r w w w w w w r r br /l br /r br /b br...

Page 95: – 86 –

Ycc-s (yamaha chip controlled-shift) system – 86 – 1. Main switch 7. Main fuse 8. Battery 14.Coupler 1 (wire harness–front cowling wire harness) 17.Coupler 2 (wire harness–front cowling wire harness) 20.Abs ecu (electronic control unit) 25.Rear brake light switch 27.Brake light relay 33.Coupler 3 (w...

Page 96: – 87 –

Ycc-s (yamaha chip controlled-shift) system – 87 – et2d21020 circuit diagram (2/2) front cowling wire harness shift down shift up push up down lg r /b l /rb r/ g br br /lb r/ l r /bb r r br /b b b l /r g /l l /ry y gg bb b br b b /l r /w r /w r /b w /l b br g /y r /y y lg sb /w o /wo /bg /rg /b r /b...

Page 97: – 88 –

Ycc-s (yamaha chip controlled-shift) system – 88 – 14.Coupler 1 (front cowling wire harness–wire harness) 17.Coupler 2 (front cowling wire harness–wire harness) 33.Coupler 3 (front cowling wire harness–wire harness) 58.Coupler 4 (front cowling wire harness–wire harness) 60.Coupler 5 (front cowling w...

Page 98: – 89 –

Ycc-s (yamaha chip controlled-shift) system – 89 – et2d21035 troubleshooting • the hand shift select indicator light fails to come on. • the transmission gear display on the multi-function meter fails to indicate the selected gear. Note: • before troubleshooting, remove the following part(s): 1. Fro...

Page 99: – 90 –

Ycc-s (yamaha chip controlled-shift) system – 90 – the transmission gear display on the multi-function meter fails to indicate the selected gear. Ng → ok ↓ ng → ok ↓ et2d21021 maintenance of the mcu checking the mcu 1. Check: • terminals “1” of the mcu cracks/damages → replace the mcu. • terminals “...

Page 100: – 91 –

Ycc-s (yamaha chip controlled-shift) system – 91 – checking the ycc-s indicator and warning light the ycc-s indicator and warning light come on for 1.4 seconds after the main switch has been turned to “on” and they come on while the start switch is being pushed. If the ycc-s indicator and warning li...

Page 101: – 92 –

Ycc-s (yamaha chip controlled-shift) system – 92 – sh_ _13* overcurrent to clutch actuator motor detected current in clutch actuator motor is too high. Unable unable sh_ _14* overcurrent to shift actuator motor detected current in shift actuator motor is too high. Unable unable sh_ _15* abnormal cur...

Page 102: – 93 –

Ycc-s (yamaha chip controlled-shift) system – 93 – sh_ _31 engine speed signal is abnormal. Engine speed signal from ecu does not match multi-function meter engine speed. Unable unable sh_ _32* ycc-s speed sensor signal is abnormal. Ycc-s speed sensor signal does not match multi-function meter ve- h...

Page 103: – 94 –

Ycc-s (yamaha chip controlled-shift) system – 94 – *if the main switch is turned to “off”, the fault code number will disappear from the display and will not be displayed again when the main switch is turned back to “on”. Therefore, use the engine stop switch to stop the engine, not the main switch....

Page 104: – 95 –

Ycc-s (yamaha chip controlled-shift) system – 95 – 5. Erase the malfunction history in the diagnos- tic mode. Refer to “diagnostic code table (di- agnostic code no. Sh_ _62)”. Note: turning the main switch to “off” will not erase the malfunction history. Et2d21031 diagnostic mode setting the diagnos...

Page 105: – 96 –

Ycc-s (yamaha chip controlled-shift) system – 96 – diagnostic code table diagnos- tic code no. Item data displayed on meter (reference value) checking method sh_ _61 malfunction history code display • no history sh_ _61 — • history exists fault code numbers sh_ _11–sh_ _52 • (first displays sh_ _61 ...

Page 106: – 97 –

Ycc-s (yamaha chip controlled-shift) system – 97 – sh_ _63 clutch actuation op- eration note: the checking meth- od for the diagnostic code (sh_ _63) can- not be performed when any of the fol- lowing fault codes are detected. Sh_ _11, sh_ _12, sh_ _13, sh_ _15, sh_ 16, sh_ _17, sh_ _25, sh_ _26, sh_...

Page 107: – 98 –

Ycc-s (yamaha chip controlled-shift) system – 98 – sh_ _65 gear position setting sh_ _65 the gear position can be set in this mode. 1. Make sure that the transmission is in neutral. 2. Push the start switch. If the gear position sensor output signal is correct for the neutral position, the hand shif...

Page 108: – 99 –

Ycc-s (yamaha chip controlled-shift) system – 99 – et2d21032 troubleshooting details this section describes the measures per fault code number displayed on the meter. Select diagnostic code no. Sh_ _61, and then confirm the fault code numbers in the malfunction history. Check and ser- vice the items...

Page 109: – 100 –

Ycc-s (yamaha chip controlled-shift) system – 100 – fault code no. Sh_ _11 symptom too low or too high voltage is supplied to the ycc-s system. Order item/components and probable cause check or maintenance job reinstatement method 1 connections • wire harness mcu (motor control unit) coupler • check...

Page 110: – 101 –

Ycc-s (yamaha chip controlled-shift) system – 101 – note: if the main switch is turned to “off”, the fault code number will disappear from the display and will not be displayed again when the main switch is turned back to “on”. Therefore, use the engine stop switch to stop the engine, not the main s...

Page 111: – 102 –

Ycc-s (yamaha chip controlled-shift) system – 102 – note: if the main switch is turned to “off”, the fault code number will disappear from the display and will not be displayed again when the main switch is turned back to “on”. Therefore, use the engine stop switch to stop the engine, not the main s...

Page 112: – 103 –

Ycc-s (yamaha chip controlled-shift) system – 103 – note: if the main switch is turned to “off”, the fault code number will disappear from the display and will not be displayed again when the main switch is turned back to “on”. Therefore, use the engine stop switch to stop the engine, not the main s...

Page 113: – 104 –

Ycc-s (yamaha chip controlled-shift) system – 104 – note: if the main switch is turned to “off”, the fault code number will disappear from the display and will not be displayed again when the main switch is turned back to “on”. Therefore, use the engine stop switch to stop the engine, not the main s...

Page 114: – 105 –

Ycc-s (yamaha chip controlled-shift) system – 105 – note: if the main switch is turned to “off”, the fault code number will disappear from the display and will not be displayed again when the main switch is turned back to “on”. Therefore, use the engine stop switch to stop the engine, not the main s...

Page 115: – 106 –

Ycc-s (yamaha chip controlled-shift) system – 106 – note: if the main switch is turned to “off”, the fault code number will disappear from the display and will not be displayed again when the main switch is turned back to “on”. Therefore, use the engine stop switch to stop the engine, not the main s...

Page 116: – 107 –

Ycc-s (yamaha chip controlled-shift) system – 107 – note: if the main switch is turned to “off”, the fault code number will disappear from the display and will not be displayed again when the main switch is turned back to “on”. Therefore, use the engine stop switch to stop the engine, not the main s...

Page 117: – 108 –

Ycc-s (yamaha chip controlled-shift) system – 108 – fault code no. Sh_ _21 symptom output signal of gear position sensor is abnor- mal. Order item/components and probable cause check or maintenance job reinstatement method 1 connections • wire harness mcu (motor control unit) coupler • gear position...

Page 118: – 109 –

Ycc-s (yamaha chip controlled-shift) system – 109 – fault code no. Sh_ _23 symptom no input signal from sidestand switch. Order item/components and probable cause check or maintenance job reinstatement method 1 connections • wire harness mcu (motor control unit) coupler • check the coupler for any p...

Page 119: – 110 –

Ycc-s (yamaha chip controlled-shift) system – 110 – note: if the main switch is turned to “off”, the fault code number will disappear from the display and will not be displayed again when the main switch is turned back to “on”. Therefore, use the engine stop switch to stop the engine, not the main s...

Page 120: – 111 –

Ycc-s (yamaha chip controlled-shift) system – 111 – note: if the main switch is turned to “off”, the fault code number will disappear from the display and will not be displayed again when the main switch is turned back to “on”. Therefore, use the engine stop switch to stop the engine, not the main s...

Page 121: – 112 –

Ycc-s (yamaha chip controlled-shift) system – 112 – fault code no. Sh_ _34 symptom tps (throttle position sensor) signal is abnor- mal. Order item/components and probable cause check or maintenance job reinstatement method 1 connections • wire harness mcu (motor control unit) coupler • wire harness ...

Page 122: – 113 –

Ycc-s (yamaha chip controlled-shift) system – 113 – fault code no. Sh_ _36 symptom output signal of clutch actuator sensor is ab- normal. Order item/components and probable cause check or maintenance job reinstatement method 1 connections • wire harness mcu (motor control unit) coupler • clutch actu...

Page 123: – 114 –

Ycc-s (yamaha chip controlled-shift) system – 114 – note: if the main switch is turned to “off”, the fault code number will disappear from the display and will not be displayed again when the main switch is turned back to “on”. Therefore, use the engine stop switch to stop the engine, not the main s...

Page 124: – 115 –

Ycc-s (yamaha chip controlled-shift) system – 115 – fault code no. Sh_ _38 symptom malfunction of hand shift lever switch (shift up or shift down). Order item/components and probable cause check or maintenance job reinstatement method 1 connections • wire harness mcu (motor control unit) coupler • h...

Page 125: – 116 –

Ycc-s (yamaha chip controlled-shift) system – 116 – fault code no. Sh_ _41 symptom coolant temperature sensor signal is abnormal. Order item/components and probable cause check or maintenance job reinstatement method 1 connections • wire harness mcu (motor control unit) coupler • wire harness ecu co...

Page 126: – 117 –

Ycc-s (yamaha chip controlled-shift) system – 117 – note: if the main switch is turned to “off”, the fault code number will disappear from the display and will not be displayed again when the main switch is turned back to “on”. Therefore, use the engine stop switch to stop the engine, not the main s...

Page 127: – 118 –

Ycc-s (yamaha chip controlled-shift) system – 118 – note: if the main switch is turned to “off”, the fault code number will disappear from the display and will not be displayed again when the main switch is turned back to “on”. Therefore, use the engine stop switch to stop the engine, not the main s...

Page 128: – 119 –

Ycc-s (yamaha chip controlled-shift) system – 119 – note: if the main switch is turned to “off”, the fault code number will disappear from the display and will not be displayed again when the main switch is turned back to “on”. Therefore, use the engine stop switch to stop the engine, not the main s...

Page 129: – 120 –

Ycc-s (yamaha chip controlled-shift) system – 120 – note: if the main switch is turned to “off”, the fault code number will disappear from the display and will not be displayed again when the main switch is turned back to “on”. Therefore, use the engine stop switch to stop the engine, not the main s...

Page 130: – 121 –

Ycc-s (yamaha chip controlled-shift) system – 121 – note: if the main switch is turned to “off”, the fault code number will disappear from the display and will not be displayed again when the main switch is turned back to “on”. Therefore, use the engine stop switch to stop the engine, not the main s...

Page 131: – 122 –

Ycc-s (yamaha chip controlled-shift) system – 122 –.

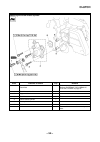

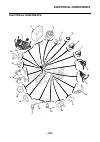

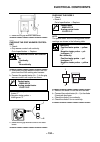

Page 132: Electrical Components

Electrical components – 123 – eas27970 electrical components 1 2 3 4 5 6 7 8 9 10 11 12 13 15 14 16 18 19 20 17.

Page 133: Electrical Components

Electrical components – 124 – 1. Windshield drive unit 2. Battery 3. Starter relay 4. Abs motor fuse 5. Front brake light switch 6. Fuse box 2 7. Fuse box 1 8. Right radiator fan motor 9. Left radiator fan motor 10. Neutral switch 11. Sidestand switch 12. Ycc-s speed sensor 13. Oil level switch 14. ...

Page 134: Electrical Components

Electrical components – 125 – 1 19 18 17 20 21 3 2 4 5 6 8 7 9 10 11 12 13 14 15 16.

Page 135: Electrical Components

Electrical components – 126 – 1. Coolant temperature sensor 2. Throttle position sensor 3. Intake air pressure sensor 4. Intake air temperature sensor 5. Abs motor relay 6. Hydraulic unit 7. Mcu (motor control unit) 8. Ecu (engine control unit) 9. Abs (ecu) 10. Cylinder identification sensor 11. O 2...

Page 136: Electrical Components

Electrical components – 127 – eas27980 checking the switches 1 r br/l br/r on off p br/l br/r r 2 (brown) b b 3 lg b sb up down 15 dg br/w ch 16 b p 12 14 r/y y r/y l/b 13 b br/w ch dg r/b r/w g/y l/w br 7 l/w b r/w r/b 8 ch dg br/w 6 (blue) b b 5 4 g/y br sb 10 shift up shift down g/r g/b b/l 11 o/...

Page 137: Electrical Components

Electrical components – 128 – 1. Front brake light switch 2. Main switch 3. Rear brake light switch 4. Neutral switch 5. Sidestand switch 6. Hazard switch 7. Start switch 8. Engine stop switch 9. Hand shift select button 10. Hand shift lever switch (shift up) 11. Hand shift lever switch (shift down)...

Page 138: Electrical Components

Electrical components – 129 – check each switch for continuity with the pocket tester. If the continuity reading is incorrect, check the wiring connections and if necessary, replace the switch. Caution: eca14370 never insert the tester probes into the coupler terminal slots “a”. Always insert the pr...

Page 139: Electrical Components

Electrical components – 130 – eas28040 checking the relays check each switch for continuity with the pocket tester. If the continuity reading is incorrect, re- place the relay. 1. Disconnect the relay from the wire harness. 2. Connect the pocket tester ( Ω × 1) and battery (12 v) to the relay termin...

Page 140: Electrical Components

Electrical components – 131 – headlight relay (dimmer) first step: second step: brake light relay first step: second step: ycc-s control relay first step: 1. Positive tester probe 2. Negative tester probe 3. Negative tester probe result continuity (between “1” and “2”) no continuity (between “1” and...

Page 141: Electrical Components

Electrical components – 132 – second step: radiator fan motor relay eas28240 checking the ycc-s speed sensor 1. Check: • ycc-s speed sensor output voltage out of specification → replace. ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ a. Connect the pocket tester (dc 20 v) to the ycc-s speed senso...

Page 142: Electrical Components

Electrical components – 133 – ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ a. Connect the pocket tester ( Ω × 1k) to the gear position sensor terminals as shown. B. Measure the gear position sensor maximum resistance. ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲▲▲ 3. Install: • gear position...

Page 143: Electrical Components

Electrical components – 134 – c. Measure the grip warmer resistance. ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲▲▲ et2d21025 checking the grip warmer control unit 1. Check: • grip warmer control unit continuity out of specification → replace. ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ a. ...

Page 144: Electrical Components

Electrical components – 135 –.

Page 145: Wiring Diagram

Eas28740 wiring diagram fjr1300as(v) 2006 1. Main switch 2. Rectifier/regulator 3. Ac magneto 4. Abs ecu fuse 5. Fuel injection system fuse 6. Backup fuse (odometer, clock, immobilizer system, and wind- shield drive system) 7. Main fuse 8. Battery 9. Abs motor fuse 10. Starter relay 11. Starter moto...

Page 146

P/w pink/white r/b red/black r/g red/green r/l red/blue r/w red/white r/y red/yellow sb/w sky blue/white w/b white/black w/g white/green w/l white/blue w/y white/yellow y/b yellow/black y/g yellow/green y/l yellow/blue y/w yellow/white.

Page 148

Yamaha motor co., ltd. 2500 shingai iwata shizuoka japan.

Page 149

Fjr1300as(v) 2006 wiring diagram (1/2) fjr1300as(v) 2006 schÉma de cblage (1/2) fjr1300as(v) 2006 schaltplan (1/2) fjr1300as(v) 2006 schema elettrico (1/2) fjr1300as(v) 2006 diagrama elÉctrico (1/2) on off p g/w b r/l b e e e e e e c b b b c f c c c c b b c b c e e e e e e d a a a a d r l br/r br/l ...

Page 150

Fjr1300as(v) 2006 wiring diagram (2/2) front cowling wire harness fjr1300as(v) 2006 schÉma de cblage (2/2) faisceau de fils au carénage avant fjr1300as(v) 2006 schaltplan (2/2) frontverkleidungs-kabelbaum fjr1300as(v) 2006 schema elettrico (2/2) cablaggio elettrico del cupolino fjr1300as(v) 2006 dia...