- DL manuals

- Yamaha

- Motorcycle

- 2006 YSF-R1(V)

- Supplementary Service Manual

Yamaha 2006 YSF-R1(V) Supplementary Service Manual

Summary of 2006 YSF-R1(V)

Page 1

2006 yzf-r1(v) 5vy-28197-e2 supplementary service manual yzf-r1s(v).

Page 3: Foreword

Yzf-r1 (v) / yzf-r1s (v) 2006 supplementary service manual ©2005 by yamaha motor co., ltd. First edition, october 2005 all rights reserved. Any reproduction or unauthorized use without the written permission of yamaha motor co., ltd. Is expressly prohibited. Foreword this supplementary service manua...

Page 4: Notice

Eas00002 notice this manual was produced by the yamaha motor company, ltd. Primarily for use by yamaha deal- ers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manual. Therefore, anyone who uses this book to perform maintenance and repairs on yama...

Page 5: How To Use This Manual

Eas00007 how to use this manual this manual is intended as a handy, easy-to-read reference book for the mechanic. Comprehensive explanations of all installation, removal, disassembly, assembly, repair and check procedures are laid out with the individual steps in sequential order. The manual is divi...

Page 6: Symbols

Eas00008 symbols the following symbols are not relevant to every vehicle. Symbols to indicate the subject of each chapter. General information specifications periodic checks and adjustments chassis engine cooling system fuel injection system electrical system troubleshooting symbols to indicate the ...

Page 7: Contents

Contents general information special tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 specifications general specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 engine specifications . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 8

Engine engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57 installing the engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59 camshafts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61 clutch . . . ...

Page 9: Gen

Gen info 1 eas00027 general information special tools the following special tools are necessary for complete and accurate tune-up and assembly. Use only the appropriate special tools as this will help prevent damage caused by the use of inappropri- ate tools or improvised techniques. Special tools, ...

Page 10: Spec

Spec 2 specifications general specifications item standard limit model code yzf-r1 5vye (eur), 5vyr (eur), 5vyf (fra), 5vys (fra), 5vyg (aus), 5vyp (aus) • • • yzf-r1s 4b11 (eur), 4b12 (fra), 4b13 (aus) • • • dimensions overall length 2,085 mm (82.1 in) • • • wheelbase 1,415 mm (55.7 in) • • • weigh...

Page 11: Spec

Spec 3 engine specifications item standard limit engine oil recommended oil sae10w30se or sae10w40se or sae15w40se or sae20w40se or sae20w50se api service se, sf, sg type or higher oil pump oil-pump-housing-to-inner-and-outer- rotor clearance 0.06 ~ 0.13 mm (0.0024 ~ 0.0051 in) 0.20 mm (0.0079 in) c...

Page 12: Spec

Spec 4 item standard limit clutch friction plates color code red • • • thickness 2.9 ~ 3.1 mm (0.114 ~ 0.122 in) 2.8 mm (0.110 in) plate quantity 7 • • • color code red • • • thickness 2.9 ~ 3.1 mm (0.114~ 0.122 in) 2.8 mm (0.110 in) plate quantity 1 • • • color code red • • • thickness 2.9 ~ 3.1 mm...

Page 13: Spec

Spec 5 chassis specifications item standard limit front wheel wheel type forged wheel (yzf-r1s) • • • rear wheel wheel type forged wheel (yzf-r1s) • • • front tire model(manufacturer) pilot power (michelin) (yzf-r1) • • • d218fg (dunlop) (yzf-r1) • • • diablo corsa h (pirelli) (yzf-r1s) • • • tire p...

Page 14: Spec

Spec 6 item standard limit front suspension (yzf-r1) fork oil quantity (each front fork leg) 0.52 l (0.46 imp qt, 0.55 us qt) • • • level (from the top of the outer tube, with the outer tube fully compressed, and without the fork spring) 90 mm (3.54 in) • • • spring preload adjusting positions minim...

Page 15: Spec

Spec 7 item standard limit rear suspension (yzf-r1) spring preload adjusting positions minimum 1 • • • standard 5 • • • maximum 9 • • • (yzf-r1s) spring free length 150.0 mm (5.91 in) • • • installed length 139.0 mm (5.47 in) • • • spring rate (k1) 95.0 n/mm (9.68 kg/mm, 542.18 lb/in) • • • spring p...

Page 16: Spec

Spec 8 electrical specifications tightening torques engine tightening torques item standard limit ignition system t.C.I. Unit model (manufacturer) f8t82073 (mitsubishi) (eur, aus) • • • f8t82074 (mitsubishi) (fra) • • • battery manufacturer gs-yuasa • • • ten hour rate amperage 0.9 a • • • item fast...

Page 17: Spec

Spec 9 chassis tightening torques item thread size tightening remarks nm m•kg ft•lb horn bracket and under bracket m6 7 0.7 5.1 connecting rod (yzf-r1s) m6 8 0.8 5.8 side cover and fuel tank m5 4 0.4 2.9 front fork and stay (yzf-r1s) m5 6 0.6 4.3 front fork and bracket (yzf-r1s) m5 6 0.6 4.3 rear br...

Page 18: Spec

Spec 10 eas00031 lubrication points and lubricant types engine eas00032 chassis lubrication point lubricant valve lifter surfaces (intake and exhaust) valve stem ends (intake and exhaust) lubrication point lubricant pivot shaft lubrication points and lubricant types.

Page 19: Spec

Spec 11 lubrication diagrams main axle oil delivery pipe drive axle lubrication diagrams.

Page 20: Spec

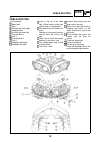

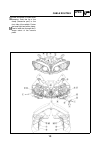

Spec 12 eas00035 cable routing ground lead meter lead stay 1 auxiliary light lead (right) headlight lead auxiliary light lead (left) console panel 1 duct 1 console panel 2 duct 2 headlight lead (right) headlight lead (left) insert to the rib of the head light. (either location of the right and left ...

Page 21: Spec

Spec 13 there should be no slack when clamping. Point the tip of the clamp (excessive part) to the front side of the vehicle. Fasten the head light lead with a clamp. Feed a lead wire through the u shape cutout of the console panel. Cable routing.

Page 22: Spec

Spec 14 right handlebar switch lead clutch cable main switch lead left handlebar switch lead horn lead horn throttle cables brake hose throttle cable (return side) throttle cable (pull side) route the clutch cable so as to get along the front side of the main switch after passing it through the guid...

Page 23: Spec

Spec 15 contact the wire guide to the top face of the under bracket boss. The throttle cable should not be caught between the wire guide and under bracket. The throttle cable (pull side) should be positioned above the vehicle wen the wire guide is installed. Clamp should be positioned at the protect...

Page 24: Spec

Spec 16 wire harness crankshaft position sensor lead heat protector right handlebar switch lead positioning guide rear brake light switch lead coolant reservoir tank speed sensor lead clutch cable radiator oil cooler outlet hose coolant reservoir tank drain hose clamp it after passing between the fr...

Page 25: Spec

Spec 17 the coupler for the air induction solenoid lead and camshaft sensor lead should be con- nected above the ignition coil sub wire harness and it should not drop on the cylinder head cover behind the ignition coil. Pass the right handlebar switch lead between the frame and heat protector. Coola...

Page 26: Spec

Spec 18 heat protector main switch lead left handlebar switch lead immobilizer lead exup servo motor lead coolant reservoir tank drain hose fuel tank drain hose coolant outlet pipe sidestand switch lead oil level switch lead a.C.Magneto lead fuse box stay water hose stay 1 chain case cover clamp the...

Page 27: Spec

Spec 19 pass the coolant reservoir tank drain hose and fuel tank drain hose through the clamp from the outer side of the water pump inlet pipe after routing it behind the water pump breather hose. The lengths of two hose ends are allowed to be random. Any direction of cut edges can be accepted. (onl...

Page 28: Spec

Spec 20 routing of the fuel tank drain hose. Exup servo motor, oil level switch and sidestand switch leads are omitted in this draw- ing. Cable routing.

Page 29: Spec

Spec 21 heat protector crankshaft position sensor lead neutral switch lead ground lead coolant reservoir tank battery positive lead starter relay turn signal relay main fuse lean angle sensor atmospheric pressure sensor tail /brake light lead rear fender seat lock cable anti safety alarm coupler sta...

Page 30: Spec

Spec 22 main fuse lead (to the battery positive lead) right handlebar switch lead pass the wire harness through the clamp inserted to the radia- tor stay. To the headlight lead clamp the lead between three protrusions of the pipe (the first and second parts from the vehi- cle front). Point the tip o...

Page 31: Spec

Spec 23 pass the water hose lower side of the thermostat, and between the ground lead and the neutral switch. Install the leads so that the engine ground lead is posi- tioned lower and the battery negative lead to be upper. Install the protrusion of each lead to be above the vehicle. Route the crank...

Page 32: Spec

Spec 24 point the tip of the clamp (excessive part) to the rear side of the vehicle. Fasten the starter relay lead, turn signal relay lead, main fuse lead, main fuse lead (from the battery positive lead) and starting circuit cut-off relay lead with a clamp. Route each lead upper side the wire harnes...

Page 33: Spec

Spec 25 insert the wire harness wrap- ping clamp to the hole of the frame. Make sure that the lead is fas- tened with the guide of the radiator stay. To the right handlebar switch battery negative lead should not run on the swingarm bracket. The hoses should not be located higher than the throt- tle...

Page 34: Spec

Spec 26 fuel tank o-ring fuel tank drain hose fuel tank breather hose clip air filter stay fuel hose 2 3 way connector pipe fuel tank bracket fuel hose clamp fuel hose 1 fuel pump assembly install the lip of o-ring facing upward. Install the part pointing the white paint part of the hose to the left...

Page 35: Spec

Spec 27 2. After item 1 mentioned above is finished, check that the clamp is inserted from the down side, and , and -sections are perfectly equipped. Cable routing.

Page 36: Chk

Chk adj 28 eas00036 periodic checks and adjustments introduction this chapter includes all information necessary to perform recommended checks and adjustments. If followed, these preventive maintenance procedures will ensure more reliable vehicle operation, a longer service life and reduce the need ...

Page 37: Chk

Chk adj 29 note: • air filter • this model’s air filter is equipped with a disposable oil-coated paper element, which must not be cleaned with compressed air to avoid damaging it. • the air filter element needs to be replaced more frequently when riding in unusually wet dusty areas. • hydraulic brak...

Page 38: Chk

Chk adj 30 eas00155 chassis adjusting the front fork legs (yzf-r1s) the following procedure applies to both of the front fork legs. Warning • always adjust both front fork legs evenly. Uneven adjustment can result in poor han- dling and loss of stability. • securely support the vehicle so that there...

Page 39: Chk

Chk adj 31 note: note: to find the standard position, turn the adjusting bolt in direction until it stop. 1. If the alignment mark on the adjusting bolt is positioned past the alignment mark on the front fork cap, turn the adjusting bolt in direction until the alignment marks match. Turn the adjusti...

Page 40: Chk

Chk adj 32 compression damping caution: never go beyond the maximum or minimum adjustment positions. 1. Adjust: • compression damping a. Turn the adjusting screw in direction or . Direction compression damping is increased (suspension is harder). Direction compression damping is decreased (suspensio...

Page 41: Chk

Chk adj 33 eas00158 adjusting the rear shock absorber assembly (yzf-r1s) warning securely support the vehicle so that there is no danger of it falling over. Spring preload caution: never go beyond the maximum or minimum adjustment positions. 1. Adjust: • spring preload a. Turn the adjusting knob in ...

Page 42: Chk

Chk adj 34 1. Adjust: • rebound damping a. Turn the adjusting screw in direction or . Compression damping (fast compression damping) caution: never go beyond the maximum or minimum adjustment positions. 1. Adjust: • fast compression damping a. Turn the adjusting bolt in direction or . Direction rebo...

Page 43: Chk

Chk adj 35 compression damping (slow compression damping) caution: never go beyond the maximum or minimum adjustment positions. 1. Adjust: • slow compression damping a. Turn the adjusting screw in direction or . Direction compression damping is increased (suspension is harder). Direct ion compressio...

Page 44: Chas

Chas 36 eas00514 chassis front wheel and brake discs order job / part q’ty remarks removing the front wheel and brake discs remove the parts in the order listed. Note: note: place the vehicle on a suitable stand so that the front wheel is elevated. 1 brake hose holder (left and right) 2 2 front brak...

Page 45: Chas

Chas 37 eas00560 rear wheel and brake discs rear brake disc and rear wheel sprocket order job / part q’ty remarks removing the rear brake disc and rear wheel sprocket remove the parts in the order listed. 1 rear brake disc 1 2 rear wheel sprocket 1 3 collar 2 4 oil seal 1 5 bearing 1 6 rear wheel dr...

Page 46: Chas

Chas 38 order job / part q’ty remarks disassembling the rear wheel disassemble the parts in the order listed. Collar 1 bearing 1 spacer 1 oil seal 1 bearing 1 for assembly, reverse the disassembly procedure. (yzf-r1s) rear wheel and brake discs.

Page 47: Chas

Chas 39 eas00648 front fork front fork legs order job / part q’ty remarks disassembling the front fork legs disassemble the parts in the order listed. Note: note: the following the procedure applies to both of the front fork legs. Fork stay 1 fork bracket 1 cap bolt 1 o-ring 1 damper adjusting rod 1...

Page 48: Chas

Chas 40 order job / part q’ty remarks spring guide 1 spring seat 1 dust seal 1 oil seal clip 1 oil seal 1 washer 1 damper rod assembly 1 inner tube 1 outer tube 1 for assembly, reverse the disassembly procedure. (yzf-r1s) 20 nm (2.0 m•kg, 14 ft•lb) 25 nm (2.5 m•kg, 18 ft•lb) 6 nm (0.6 m•kg, 4.3 ft•l...

Page 49: Chas

Chas 41 eas00652 disassembling the front fork legs (yzf-r1s) the following procedure applies to both of the front fork legs. 1. Remove: • fork stay • fork bracket • cap bolt (from the damper adjusting rod) a. Press down on the spacer with the fork spring compressor . B. Install the spanner between t...

Page 50: Chas

Chas 42 4. Remove: • dust seal • oil seal clip • oil seal • washer (with a flat-head screwdriver) caution: do not scratch the inner tube. 5. Remove: • spring seat note: note: use a wire or the like and bend the end in l- letter shape for about 10 mm (0.39 in) and hook this part to the spring seat en...

Page 51: Chas

Chas 43 eas00656 checking the front fork legs (yzf-r1s) the following procedure applies to both of the front fork legs. 1. Check: • inner tube • outer tube bends / damage / scratches → replace. Warning do not attempt to straighten a bent inner tube as this may dangerously weaken it. 2. Measure: • sp...

Page 52: Chas

Chas 44 eas00659 assembling the front fork legs (yzf-r1s) the following procedure applies to both of the front fork legs. Warning • make sure the oil levels in both front fork legs are equal. • uneven oil levels can result in poor han- dling and a loss of stability. Note: note: • when assembling the...

Page 53: Chas

Chas 45 4. Install: • dust seal • oil seal clip • oil seal • washer caution: make sure the numbered side of the oil seal faces up. Note: note: • before installing the oil seal, lubricate its lips with lithium-soap-based grease. • lubricate the outer surface of the inner tube with fork oil. • before ...

Page 54: Chas

Chas 46 7. Install: • dust seal (with the fork seal driver weight ) 8. Install: • rod puller • rod puller attachment (onto the damper rod ) 9. Fill: • front fork leg (with the specified amount of the recom- mended fork oil) note: note: • while filling the front fork leg, keep it upright. • after fil...

Page 55: Chas

Chas 47 10.Install: • spring seat • spring guide • spacer • clip • fork spring • spring seat (upper) • nut • damper adjusting rod • cap bolt • fork bracket • fork stay a. Install the spring seat, spring guide, spacer and circlip. B. Install the fork spring, spring seat (upper) and nut. C. Press down...

Page 56: Chas

Chas 48 eas00685 rear shock absorber assembly order job/part q’ty remarks removing the rear shock absorber assembly remove the parts in the order listed. Rider seat and passenger seat refer to “seats” in chapter 3. Fuel tank refer to “fuel tank” in chapter 3. Bottom cowling and rear cowling (upper) ...

Page 57: Chas

Chas 49 order job / part q’ty remarks 10 relay arm 1 for installation, reverse the removal procedure. (yzf-r1s) 92 nm (9.2 m•kg, 67 ft•lb) 44 nm (4.4 m•kg, 32 ft•lb) 44 nm (4.4 m•kg, 32 ft•lb) 44 nm (4.4 m•kg, 32 ft•lb) rear shock absorber assembly.

Page 58: Chas

Chas 50 eas00690 removing the rear shock absorber assembly (yzf-r1s) 1. Stand the vehicle on a level surface. Warning becurely support the vehicle so that there is no danger of it falling over. Note: note: place the vehicle on a suitable stand so that the rear wheel is elevated. 2. Remove: • rider s...

Page 59: Chas

Chas 51 eas00698 installing the rear shock absorber assembly (yzf-r1s) 1. Lubricate: • spacers • bearings 2. Check: • connecting rod assembly refer to “checking the connecting rod assembly” 3. Install: • rear shock absorber assembly note: note: • when installing the rear shock absorber assembly, lif...

Page 60: Chas

Chas 52 eas00703 swingarm and drive chain removing the swingarm (yzf-r1s) 1. Stand the vehicle on a level surface. Warning securely support the vehicle so that there is no danger of it falling over. Note: note: place the vehicle on a suitable stand so that the rear wheel is elevated. 2. Remove: • re...

Page 61: Chas

Chas 53 eas00707 checking the swingarm (yzf-r1s) 1. Check: • swingarm bends / cracks / damage → replace. 2. Check: • pivot shaft roll the pivot shaft on a flat surface. Bends → replace. Warning do not attempt to straighten a bent pivot shaft. 3. Wash: • pivot shaft • dust covers • spacer • washers •...

Page 62: Chas

Chas 54 checking the connecting rod assembly 1. Check: • connecting rod assembly bends / damage → replace the connecting rod assembly • oil seal damage/wear → replace • bearing damage/wear → replace 2. Measure: • connecting rod assembly length . Out of specification → adjust note: note: when the con...

Page 63: Chas

Chas 55 eas00709 checking the drive chain 1. Measure: • measure the dimension between 15-links on the inner side and outer side of the roller and calculate the dimension between pin centers. • dimension between pin centers = (inner dimension + outer dimension ) / 2 • 15-link section of the drive cha...

Page 64: Chas

Chas 56 caution: this vehicle has a drive chain with small rubber o-rings between the drive chain side plates. Never use high-pressure water or air, steam, gasoline, certain solvents (e.G., benzine), or a coarse brush to clean the drive chain. High-pressure methods could force dirt or water into the...

Page 65: Eng

Eng 57 engine engine order job / part q’ty remarks removing the engine remove the parts in the order listed. Note: note: place a suitable stand under the frame and engine. 1 right front engine mounting bolt 1 2 engine mount collar (inside) (yzf-r1) 1 engine mount collar (inside, outside) (yzf-r1s) 2...

Page 66: Eng

Eng 58 order job / part q’ty remarks 8 upper engine mounting bolt 1 9 engine mounting adjust bolt 2 note: note: use the pivot shaft wrench and adapter to loosen the engine mounting adjust bolts. 10 engine 1 for installation, reverse the removal procedure. 51 nm (5.1 m•kg, 37 ft•lb) 45 nm (4.5 m•kg, ...

Page 67: Eng

Eng 59 installing the engine 1. Install: • engine mounting adjust bolts (temporary tighten) 2. Install: • engine 3. Install: • lower engine mounting bolt • upper engine mounting bolt • self locking nuts note: note: lubricate the lower and upper engine mount- ing bolts threads with lithium-soap-based...

Page 68: Eng

Eng 60 7. Tighten: • upper self-locking nut • lower self-locking nut note: note: first tighten the lower self-locking nut, and then tighten the upper self-locking nut. 8. Tighten: • left front engine mounting bolt 9. Tighten: • right front engine mounting bolt pivot shaft wrench 90890-01471, ym-0147...

Page 69: Eng

Eng 61 eas00196 camshafts order job / part q’ty remarks removing the camshafts remove the parts in the order listed. Pickup rotor cover refer to “crankshaft position sensor and pickup rotor”. 1 camshaft sprocket bolt 4 loosen. 2 timing chain tensioner 1 3 timing chain tensioner gasket 1 4 intake cam...

Page 70: Eng

Eng 62 clutch clutch cover order job / part q’ty remarks removing the clutch cover remove the parts in the order listed. Right side cowling right frame side cover right frame side panel bottom cowling engine oil drain. Refer to “changing the engine oil” in chapter 3. 1 cover 1 2 clutch cable 1 disco...

Page 71: Eng

Eng 63 clutch order job / part q’ty remarks removing the clutch remove the parts in the order listed. 1 compression spring 6 2 pressure plate 1 3 pull rod 1 4 bearing 1 5 friction plate 1 1 6 clutch plate 1 7 7 friction plate 2 7 8 wire clip 1 9 clutch plate 2 1 10 friction plate 3 1 11 clutch dampe...

Page 72: Eng

Eng 64 order job / part q’ty remarks 13 clutch boss nut 1 14 washer 1 15 thrust plate 1 1 16 clutch boss 1 17 thrust plate 2 1 18 clutch housing 1 19 bearing 1 for installation, reverse the removal procedure. 95 nm (9.5 m•kg, 69 ft•lb) (yzf-r1) 10 nm (1.0 m•kg, 7.2 ft•lb) clutch.

Page 73: Eng

Eng 65 order job / part q’ty remarks removing the clutch remove the parts in the order listed. 1 compression spring 6 2 pressure plate 1 1 3 pull rod 1 4 bearing 1 5 friction plate 1 1 6 clutch plate 1 1 7 friction plate 2 7 8 clutch plate 2 1 9 clutch plate 3 6 10 friction plate 3 1 11 clutch dampe...

Page 74: Eng

Eng 66 order job / part q’ty remarks 14 spring 3 15 clutch boss 1 16 pressure plate 2 1 17 conical spring washer 1 18 thrust plate 2 1 19 clutch housing 1 20 bearing 1 for installation, reverse the removal procedure. 10 nm (1.0 m•kg, 7.2 ft•lb) 95 nm (9.5 m•kg, 69 ft•lb) (yzf-r1s) clutch.

Page 75: Eng

Eng 67 eas00276 removing the clutch (yzf-r1s) 1. Remove: • clutch cover • gasket note: note: loosen each bolt 1 / 4 of a turn at a time, in stages and in a crisscross pattern. After all of the bolts are fully loosened, remove them. 2. Remove: • compression spring bolts • compression springs • pressu...

Page 76: Eng

Eng 68 6. Loosen: • clutch boss nut note: note: while holding the clutch boss with the uni- versal clutch holder , loosen the clutch boss nut. 7. Remove: • clutch boss nut • springs • clutch boss • pressure plate 2 • conical spring washer • thrust plate 2 eas00280 checking the friction plates (yzf-r...

Page 77: Eng

Eng 69 eas00281 checking the clutch plates (yzf-r1s) the following procedure applies to all of the clutch plates. 1. Check: • clutch plate damage → replace the clutch plates as a set. 2. Measure: • clutch plate warpage (with a surface plate and thickness gauge ) out of specification → replace the cl...

Page 78: Eng

Eng 70 note: note: when adjusting the clutch assembly width [by replacing the clutch plate(s)], be sure to replace the clutch plate fast. After replacing the clutch plate , if specifica- tions cannot be met, replace the clutch plate . Eas00282 checking the clutch springs (yzf-r1s) the following proc...

Page 79: Eng

Eng 71 checking the pressur plate 2 (yzf-r1s) 1. Check: • pressure plate 2 cracks / damage → replace. Eas00285 checking the clutch boss (yzf-r1s) 1. Check: • clutch boss splines damage / pitting / wear → replace the clutch boss. Note: note: pitting on the clutch boss splines will cause erratic clutc...

Page 80: Eng

Eng 72 eas00287 checking the pull lever shaft and pull rod (yzf-r1s) 1. Check: • pull lever shaft pinion gear teeth • pull rod teeth damage / wear → replace the pull rod and pull lever shaft pinion gear as a set. 2. Check: • pull rod bearing damage / wear → replace. Installing the clutch (yzf-r1s) 1...

Page 81: Eng

Eng 73 3. Install: • spring • clutch boss nut note: note: • put the spring detent into the groove of the pressure plate 2. Assemble so that each spring detent is positioned in a different groove. • while holding the clutch boss with the clutch holding tool , tighten the clutch boss nut. • lock the t...

Page 82: Eng

Eng 74 6. Install: • friction plate 3 • friction plate 2 • clutch plate 3 • clutch plate 2 • clutch plate 1 note: note: assemble the friction plates and clutch plates according to the installation order. 7. Install: • friction plate 1 note: note: install the last friction plate shifting half phase. ...

Page 83: Eng

Eng 75 10.Install: • pull lever note: note: install the pull lever with the “ ” mark facing toward upper side. 11.Install: • clutch cover • clutch cover gasket note: note: • install the pull rod so that the teeth a face towards the rear of the vehicle. Then, install the clutch cover. • apply oil ont...

Page 84: Yzf-R1 (V)/

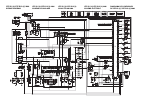

Yzf-r1 (v)/ yzf-r1s (v) 2006 wiring diagram main switch a.C. Magneto rectifier/regulator fuse (main) fuse (back up) immobilizer unit battery fuse (fuel injection) starter relay starter motor starting circuit cut-off relay neutral switch sidestand switch fuel pump ecu ignition coil #1 ignition coil #...

Page 86

Yamaha motor co., ltd. 2500 shingai iwata shizuoka japan.

Page 87: Yzf-R1 (V)/yzf-R1S (V) 2006

O/g r/b o gy/r gy/g l br/r w/b r/w b/l o/g r/b o gy/r gy/g l br/r w/b r/w b/l b b b b b b b b b/y b b/g b l/r b b/y b b/g b l/r b o o c b b y/b b/r y/l lg b/w br r/g sb/w l/w g ch g/w dg b/y l lg lg b r/b b/y y/b y/b b b/g b/y b y dg dg e ch ch e y/l y/l l y b/l g/b g/b b b/l d y/r y/w l g/y b/l b d...