- DL manuals

- Yamaha

- Motorcycle

- 2008 YW50X

- Service Manual

Yamaha 2008 YW50X Service Manual

Summary of 2008 YW50X

Page 1

2008 motorcycle service manual model : yw50x_ 5pnf81972100 *5pnf81972100*.

Page 2: Forword

Eas00000 yw50x 2007 supplementary service manual ©2007 by yamaha motor taiwan co., ltd. First edition, june 2007 all rights reserved. Any reproduction or unauthorized use without the written permission of yamaha motor taiwan co., ltd. Is expressly prohibited. Printed in canada forword this supplemen...

Page 3: Notice

Eas00002 notice this manual was produced by the yamaha motor taiwan company, ltd. Primarily for use by yamaha dealers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manual. Therefore, anyone who uses this book to perform maintenance and repairs on...

Page 4: How To Use This Manual

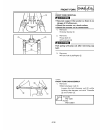

4-3 eng cylinder head, cylinder and piston cylinder head, cylinder and piston job name/part name cylinder head, cylinder and piston removal engine muffler/gasket air shroud 2 spark plug cylinder head/cylinder head gasket cylinder piston pin clip piston pin/ bearing piston piston ring set cylinder ga...

Page 5: Gen

Gen info spec chk adj eng trbl shtg chas - + elec 4 m b ls new m g cool 1 2 3 4 5 6 7 8 9 0 q w e r i s h j eas00008 symbols the following symbols are not relevant to every vehicle. Symbols 1 to 9 indicate the subject of each chapter. 1 general information 2 specifications 3 periodic checks and adju...

Page 6: Table of Contents

Eas00010 table of contents general information specifications periodic checks and adjustments carburetor gen info spec chk adj carb 1 2 3 4 5 6 5 7 8 9.

Page 7: Gen

1-8 gen info chapter 1 general information scooter identification ................................................................... 1-1 vehicle identification number ............................................. 1-1 model label .........................................................................

Page 8: Gen

1-1 gen info 1 1 scooter identification eas00015 general information scooter identification eas00017 vehicle identification number the vehicle identification number 1 is stamped into the frame. Eas00018 model label the model label 1 is affixed to the seat. This information will be needed to order sp...

Page 9: Gen

1-2 gen info important information eas00020 important information preparation for removal and disas- sembly 1. Before removal and disassembly, remove all dirt, mud, dust and foreign material. 2. Use only the proper tools and cleaning equipment. Refer to the “special tools”. 3. When disassembling, al...

Page 10: Gen

1-3 gen info important information eas00023 lock washers/plates and cotter pins after removal, replace all lock washers/plates 1 and cotter pins. After the bolt or nut has been tightened to specification, bend the lock tabs along a flat of the bolt or nut. Eas00024 bearings and oil seals install bea...

Page 11: Gen

1-4 gen info checking the connections eas00026 checking the connections check the leads, couplers, and connectors for stains, rust, moisture, etc. 1. Disconnect: 8 lead 8 coupler 8 connector 2. Check: 8 lead 8 coupler 8 connector moisture i dry with an air blower. Rust/stains i connect and disconnec...

Page 12: Gen

1-5 gen info tool no. Tool name / function illustration special tools eas00027 special tools the following special tools are necessary for complete and accurate tune-up and assembly. Use only the appropriate special tools as this will help prevent damage caused by the use of inappropri- ate tools or...

Page 13: Gen

1-6 gen info tool no. Tool name / function illustration special tools 90890-06760 90890-03112 yu-03112-c 90890-01409 ym-01409 90890-01410 ym-01410 90890-06754 ym-34487 90890-85505 acc-11001-05-01 90890-01348 ym-01348 90890-01268 yu-01268 90890-01367 ym-a9409-7 90890-01400 ym-a9409-3 90890-01326 ym-0...

Page 14: Gen

1-7 gen info tool no. Tool name / function illustration special tools 90890-01312 ym-01312-a fuel level gauge this gauge is used to measure the fuel le- ver in the float chamber..

Page 15: Spec

2-23 spec chapter 2 specifications general specifications ................................................................. 2-1 engine specifications ..................................................................... 2-2 chassis specifications ........................................................

Page 16: Spec

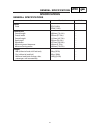

2-1 spec specifications general specifications item standard limit general specifications model code 5pj5 (usa) … 5pn6 (can) … dimensions overall length 1890mm (74.41in) … overall width 705mm (27.76in) … overall height 1110mm (43.70in) … seat height 765mm (30.12in) … wheelbase 1275mm (50.20in) … min...

Page 17: Spec

2-2 spec engine engine type air-cooled 2-stroke reed valve … displacement 0.049l (49cm³, 2.99cu-in) … cylinder arrangement forward inclined single cylinder … bore × stroke 40.0 × 39.2mm (1.57 × 1.54in) … compression ratio 7.01:1 … engine idle speed 1800 ~ 1900r/min … fuel recommended fuel unleaded g...

Page 18: Spec

2-3 spec item standard limit engine specifications cylinder bore 40.000 ~ 40.014mm … (1.5748 ~ 1.5754in) maximum taper … 0.05mm (0.0020in) maximum out-of-round … 0.05mm (0.0020in) piston piston-to-cylinder clearance 0.035 ~ 0.040mm 0.10mm (0.0014 ~ 0.0016in) (0.0039in) diameter d 39.960 ~ 39.979mm …...

Page 19: Spec

2-4 spec item standard limit crankshaft width “a” 37.90 ~ 37.95mm … (1.4921 ~ 1.4941in) maximum runout “c” … 0.03mm (0.0012in) big end side clearance “d” 0.20 ~ 0.50mm 1.00mm (0.0079 ~ 0.0197in) (0.0394in) big end radial clearance 0.004 ~ 0.017mm … (0.0002 ~ 0.0007in) small end free play “f” 0.40 ~ ...

Page 20: Spec

2-5 spec item standard limit engine specifications carburetor id mark 5pj5 00 … main jet (m.J.) # 80 … needle jet (n.J.) 2.085 … jet needle-clip position (j.N.) 3n24-1/1 … main air jet (m.A.J.) 2.0 … cutaway (c.A.) 3.0 … pilot jet (p.J.) # 44 … bypass 0.8 … valve seat size (v.S.) 1.8 … starter jet (...

Page 21: Spec

2-6 spec chassis specifications chassis specifications item standard limit frame frame type steel tube underbone … caster angle 26.5° … trail 93mm (3.66in) … front wheel wheel type cast wheel … rim size j10 × mt3.50 … material aluminum … wheel travel 61mm (2.40in) … wheel runout maximum radial wheel...

Page 22: Spec

2-7 spec item standard limit chassis specifications rear tire tire type tubeless … size 130/90-10 59j … model (manufacturer) c-924 (cheng shin) … tire pressure (cold) up to 90kg (198lb) load 200kpa (2.00kgf/cm², 29psi) … 90kg (198lb) load ~ maximum load* 200kpa (2.00kgf/cm², 29psi) … minimum tire tr...

Page 23: Spec

2-8 spec chassis specifications item standard limit front suspension suspension type telescopic fork … front fork type coil spring/oil damper … front fork travel 70mm (2.76in) … spring free length 217.1mm (8.55in) 212.8mm (8.38in) installed length 212.1mm (8.35in) … spring rate (k1) 15.69n/mm … (1.6...

Page 24: Spec

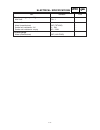

2-9 spec item standard limit electrical specifications electrical specifications system voltage 12v … ignition system ignition system type c.D.I. … ignition timing 14° btdc at 5000r/min … advancer type fixed … pick coil resistance/color 400 ~ 600Ωat 20°c (68°f)/ … black - white/red c.D.I. Unit model...

Page 25: Spec

2-10 spec electrical specifications item standard limit headlight type halogen bulb … indicator light (voltage/wattage × quantity) turn signal indicator light 12v 1.7w × 1 … high beam indicator light 12v 1.7w × 1 … oil level indicator light 12v 1.7w × 1 … bulbs (voltage/wattage × quantity) headlight...

Page 26: Spec

2-11 spec item standard limit electrical specifications fuse (amperage × quantity) main fuse 7a × 1 … fuel sender model (manufacturer) 4vp (tatung) … sender unit resistance - full 4 ~ 10Ω … sender unit resistance - empty 90 ~ 100Ω … oil lever gauge model (manufacturer) 4vp (lun ping) ….

Page 27: Spec

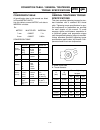

2-12 spec eas00028 conversion table all specification data in this manual are listed in si and metric units. Use this table to convert metric unit data to imperial unit data. Conversion table eas00030 general tightening torque specifications this chart specifies tightening torques for stan- dard fas...

Page 28: Spec

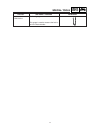

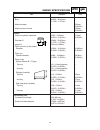

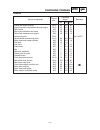

2-13 spec part to be tightened part name thread size q ’ ty tightening torque nm m•kg ft•lb remarks tightening torques tightening torques engine 2.0 1.4 1.0 0.7 0.2 0.7 0.4 1.1 0.9 0.2 0.9 2.6 1.1 0.9 1.2 1.2 1.2 0.7 0.7 1.8 0.3 0.8 0.9 1.3 4.0 3.0 0.8 3.8 spark plug cylinder head and cylinder cylin...

Page 29: Spec

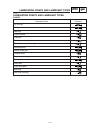

2-14 spec part to be tightened thread size tightening torque nm m•kg ft•lb remarks tightening torques chassis 8.4 4.5 1.3 3.0 1.6 6.0 2.0 1.0 0.7 0.4 0.7 0.7 0.2 0.7 7.0 12.0 1.0 2.3 2.0 2.3 0.6 frame and engine bracket engine bracket, compression rod and engine rear carrier rear shock absorber and ...

Page 30: Spec

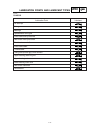

2-15 spec tightening torques 1 lower ring nut 2 rubber washer 3 center ring nut 4 lock washer 5 upper ring nut note : 1. First, tighten the ring nut(lower) approximately 38nm(3.8m•kg, 27.5ft•lb) by using the torque wrench, then loosen the ring nut 1/4 turn. 2. Second, tighten the ring nut(lower) app...

Page 31: Spec

2-16 spec lubrication point lubricant lubrication points and lubricant types eas00031 lubrication points and lubricant types engine ls ls e g g g m oil seal lips o-rings bearings piston surface piston pin cylinder transmission case (bearing) autolube pump starter wheel gear idle gear plate secondary...

Page 32: Spec

2-17 spec lubrication points and lubricant types lubrication point lubricant eas00032 chassis oil seal lips o-rings bearings speedometer drive gear front brake lever pivot shaft rear brake lever pivot shaft front brake camshaft front brake cable throttle cable tube guide (throttle grip) inner surfac...

Page 33: Spec

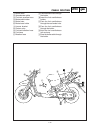

2-18 spec cable routing eas00035 cable routing 1 horn 2 rectifier regulator 3 main switch 4 headlight leads 5 speedometer cable 6 ignition coil 7 throttle cable 1 8 throttle cable 3 9 battery negative lead 0 wire brake q fuel sender lead w seat lock cable e oil tank hose r c.D.I. Unit t wire harness...

Page 34: Spec

2-19 spec cable routing 1 brake cable 2 speedometer cable 3 fuel tank overflow hose 4 brake cable holder 5 brake hose 6 brake hose holder 7 license bracket 8 flasher relay 9 fuel tank breather hose 0 fuel hose q breather hose a pass the brake hose through the holder. B insert the fuel overflowhose b...

Page 35: Spec

2-20 spec cable routing 1 brake hose 2 front fender 3 front fork assembly 4 nut 5 plate washer 6 brake hose holder 1 7 flange bolt 8 brake hose holder 2 9 bolt 0 grommet q flange bolt w brake hose holder e brake hose holder 3 a tighting torque:3.5 ~ 5.5nm. B assemble the brake hose holder 3 hang hoo...

Page 36: Spec

2-21 spec cable routing 1 ignition coil 2 spark plug lead 3 starter relay leads 4 auto choke leads 5 starter relay 6 band 7 c.D.I. Unit 8 autolube hose 9 seat lock cable 0 bracket q fuel tank breather hose w band 2 e battery - lead r battery + lead a pass battery leads through the slot of footrestbo...

Page 37: Spec

2-22 spec cable routing 1 grip assembly 2 handlebar switch(right) 3 front brake light switch 4 speedometer 5 rear brake cable 6 handlebar switch(left) 7 grip 8 handlebar assembly 9 wire harness 0 throttle cable 1 q throttle cable 3 w speedometer cable e brake hose a route the front brake light switc...

Page 38: Chk

3-10 chk adj chapter 3 periodic checks and adjustments introduction ....................................................................................... 3-1 periodic maintenance and minor repair ................................ 3-1 periodic maintenance chart for the emission control system .........

Page 39: Chk

3-1 chk adj introduction/periodic maintenance and minor repair eas00036 periodic checks and adjustments introduction this chapter includes all information necessary to perform recommended checks and adjustments. If followed, these preventive maintenance procedures will ensure more reliable vehicle o...

Page 40: Chk

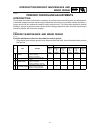

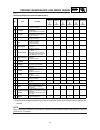

3-2 chk adj periodic maintenance and minor repair eau32115 general maintenance and lubrication chart * since these items require special tools, data and technical skills, have a yamaha dealer perform the service. Note: from 19000 km (12000 mi) or 36 months, repeat the maintenance intervals starting ...

Page 41: Chk

3-3 chk adj periodic maintenance and minor repair eau17620 note: ● the air filter needs more frequent service if you are riding in unusually wet or dusty areas. ● hydraulic brake system • when disassembling the master cylinder or caliper cylinder, always replace the brake fluid. Check the brake flui...

Page 42: Chk

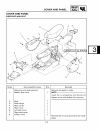

3-4 chk adj remarks order job/part q’ty 1 2 3 4 5 6 7 8 1 1 1 1 1 1 1 1 cover and panel eas00038 cover and panel seat and side covers removing the seat and side covers battery box cover seat seat hanger rear carrier rear cover side cover(left) side cover(right) center cover remove the parts in the o...

Page 43: Chk

3-5 chk adj 1 2 3 5 4 remarks order job/part q’ty 1 2 3 4 5 1 1 1 1 1 cover and panel lower cowling, upper cover and leg shield 1 removing the lower cowling, upper cover, and leg shield 1 lower cowling head light lead coupler(low) head light lead coupler(high) upper cover leg shield 1 remove the par...

Page 44: Chk

3-6 chk adj 1 2 3 4 5 6 7 8 7nm (0.7 m•kg, 5.1 ft•lb) remarks order job/part q’ty 1 2 3 4 5 6 7 8 1 1 1 1 1 1 1 1 cover and panel leg shield 2 and footrest board removing the leg shield 2 and foot- rest board leg shield 1 main switch cover leg shield 2 footrest(left) footrest(right) battery negative...

Page 45: Chk

3-7 chk adj remarks order job/part q’ty 1 2 3 1 1 1 cover and panel handlebar cover(front and rear) removing the handlebar cover(front and rear) handlebar cover(front) speedometer cable handlebar cover(rear) remove the parts in the order listed. Disconnect. For installation, reverse the removal pro-...

Page 46: Chk

3-8 chk adj 1 adjusting the engine idling speed eas00054 adjusting the engine idling speed note: prior to adjusting the engine idling speed, the air filter element should be clean, and the engine should have adequate compression. 1. Start the engine and let it warm up for sev- eral minutes. W before...

Page 47: Chk

3-9 chk adj adjusting the engine idling speed 5. Adjust: 8engine idling speed ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Turn the throttle stop screw 1 in direction a or b until the specified engine idling speed is obtained. Direction a engine idling speed is increased. Direction b engine idling speed is decreased....

Page 48: Carb

4-4 carb chapter 4 carburetor air induction system ....................................................................... 4-1 air filter case assembly ......................................................... 4-1 checking the air induction system ................................... 4-3.

Page 49: Carb

4-1 carb air induction system remarks order job/part q’ty 1 2 3 1 1 1 remove the parts in the order listed. Disconnect. Disconnect. For installation, reverse the removal pro- cedure. Air induction system air filter case assembly removing the air filter case assem- bly hose(to air filter) pipe(to exh...

Page 50: Carb

4-2 carb 8 9 0 q w 2 1 3 7 4 5 6 air induction system remarks order job/part q’ty 1 2 3 4 5 6 7 8 9 0 q w 1 1 1 1 1 1 1 1 1 1 1 remove the parts in the order listed. For assembly, reverse the disassembly procedure. Disassembling the air filter case as- sembly cap damper air filter case cap reed valv...

Page 51: Carb

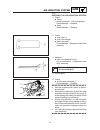

4-3 carb air induction system eas00510 checking the air induction system 1. Check: 8 hoses loose connection i connect properly. Cracks/damage i replace. 8 pipes cracks/damage i replace. 2. Check: 8 reed valve 1 8 reed valve stopper 8 reed valve seat cracks/damage i replace the reed valve assembly. 3...

Page 52: Yw50X Wiring Diagram

A, b, c, lock open off check on off start off push b 1 3 2 4 n b g l k 6 5 s 7 9 8 q a o i e w d , m h z x c v 0 f j 12v 7a 12v 1.7w oil 12v 3.4w ilumi 12v 1.7w beam 12v 1.7w turn p y t r u ; 8 (green) (black)(black) (black) (red) (red) (red) (red) (black) (black) (brown) (brown) (green) (green) (re...

Page 264

Yamaha motor canada ltd. 480 gordon baker road toronto, on m2h 3b4.