- DL manuals

- Yamaha

- Outboard Motor

- 200A

- Service Manual

Yamaha 200A Service Manual

Summary of 200A

Page 1

200a l200a 60h-28197-5e-11 290446 ser vice manual.

Page 2

Notice this manual has been prepared by yamaha primarily for use by yamaha dealers and their trained mechanics when performing maintenance procedures and repairs to yamaha equipment. It has been written to suit the needs of persons who have a basic understanding of the mechanical and electrical conc...

Page 3: Contents

Contents general information gen info specifications spec periodic checks and adjustments chk adj fuel system fuel power unit powr lower unit lowr bracket unit brkt electrical systems elec troubleshooting trbl shtg index – +.

Page 4: General Information

60h5e11 gen info general information general information how to use this manual ................................................................................................ 1-1 manual format ............................................................................................................

Page 5

60h5e11 1 checking the remote control cables ........................................................................ 1-15 checking the steering system ................................................................................. 1-15 checking the gearshift and throttle operation ..................

Page 6

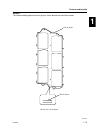

60h5e11 gen info general information 60h5e11 5 a 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 60h50280 1 gasket 2 2 cylinder head 2 3 thermo switch 2 4 gasket 2 5 cylinder head cover 2 6 gasket 2 7 thermostat 2 8 thermostat cover 2 9 bolt 8 m6 x 40 mm 10 bolt 36 m6 x 30 mm 11 bolt 24 m8 x 60 mm 12 clamp 1 13...

Page 7

60h5e11 1 symbols the symbols below are designed to indicate the content of a chapter. General information fuel system bracket unit symbols 1 to 6 indicate specific data. 1 special tool 2 specified oil or fluid 3 specified engine speed symbols 7 to b in an exploded diagram indicate the grade of lubr...

Page 8

60h5e11 gen info general information 1-3 parts, lubricants, and sealants use only genuine yamaha parts, lubricants, and sealants or those recommended by yamaha, when servicing or repairing the outboard motor. Under normal conditions, the lubricants men- tioned in this manual should not harm or be ha...

Page 9

60h5e11 1 safety while working 1-4 disassembly and assembly 1. Use compressed air to remove dust and dirt during disassembly. 2. Apply engine oil to the contact surfaces of moving parts before assembly. 3. Install bearings with the manufacture iden- tification mark in the direction indicated in the ...

Page 10

60h5e11 gen info general information identification applicable models this manual covers the following models. Applicable models 200aet,l200aet serial number the outboard motor serial number is stamped on a label attached to the port clamp bracket. 1 model name 2 approved model code 3 transom height...

Page 11

60h5e11 1 features and benefits hour meter a hour meter is incorporated for easier control of interval time for the periodic maintenance. As the main switch is turned on, all segments light up for 2 seconds to check that the light emitting diode is not failed. Then, the meter indicates the total of ...

Page 12

60h5e11 gen info general information exhaust components (factory option) the cylindrical components have been painted externally and internally after the anodic oxide coating to make a film for additional corrosion-resistance. 60h10030 1-7 for x transom exhaust guide plate exhaust manifold muffler e...

Page 13

60h5e11 1 piston and cylinder following items have been given to improve the durability for the piston and cylinder. A hard anodic oxide coating has been given to the piston pin boss and piston ring groove of the #1 and #2 piston. Multilayer plating has been given to the piston ring. The cylinder sl...

Page 14

60h5e11 gen info general information larger mating face bearing with 18 rollers silver plating identification mark carburizing and quenching connecting rod and bearings connecting rod a process of the carburizing and quenching has been given to the inside of the small end to increase the strength. T...

Page 15

60h5e11 1 silicon bead silicon bead gasket with silicon bead gasket the intake manifold gasket has been given a silicon bead to increase more sealer. 60h10060 1-10 features and benefits.

Page 16

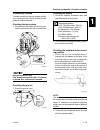

60h5e11 gen info general information reduction gear and clutch the process of the double shot-peening has been given to the surface of the teeth portion of the pinion gear, forward gear and dog clutch to increase the durability. 60h10070 1-11 dog clutch forward gear pinion gear.

Page 17

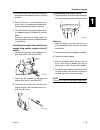

60h5e11 1 coating with a sealing material full threaded bolt bolt hole bolt corroded particles sealing material power unit mount bolt a fully threaded bolt coated with a sealing material to the thread portion has been adopted for mount- ing the power unit. This gives a sealing function to the bolt, ...

Page 18

60h5e11 gen info general information s60c1110 - s60c1125 - selection when the engine speed is at the full throttle operating range (4,500 – 5,500 r/min), the ideal propeller for the boat is one that provides maxi- mum performance in relation to boat speed and fuel consumption. Regular rotation model...

Page 19

60h5e11 1 checking the battery 1. Check the capacity, electrolyte level, and specified gravity of the battery. 2. Check that the red and black battery cables are securely connected. Checking the outboard motor mount- ing position 1. Check that the anti-cavitation plate is aligned with the bottom of ...

Page 20

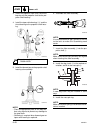

60h5e11 gen info general information f n r checking the steering system 1. Check that the steering operates smoothly. 60h10090 2. Check that there is no interference with wires, hoses, or remote control cable when the outboard motor is steered. Checking the gearshift and throttle operation 1. Check ...

Page 21

60h5e11 1 2. Check that there is no abnormal noise pro- duced when the outboard motor is tilted up or down. 3. Check that there is no interference with wires, hoses, or remote control cable when the tilted-up outboard motor is steered. 4. Check that the trim meter points down when the outboard motor...

Page 22

60h5e11 gen info general information break-in perform the break-in operation in the following four stages. 1. Keep the engine running at idle for the ini- tial ten minutes. 60h10100 2. Fifty minutes at 3,000 r/min. Or less. 60h10110 3. One hour at 4,000 r/min. Or less. 60h10120 4. For another eight ...

Page 23: Specifications

60h5e11 2 specifications genral specifications .................................................................................................... 2-1 maintenance specifications .......................................................................................... 2-3 power unit ..................

Page 24

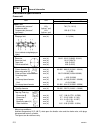

60h5e11 spec general information genral specifications item unit dimension overall length overall width overall height (l) (x) transom height (l) (x) weight(*1) (l) (x) performance maximum output full throttle operating range maximum fuel consumption idle speed power unit type total displacement bor...

Page 25

60h5e11 2 item unit fuel and oil fuel type fuel rating engin oil type engin oil grade gear oil type gear oil grade gear oil quantity bracket unit trim angl (at 12° boat transom) tilt-up angle steering angle drive unit gear shift positions gear ratio reduction gear type clutch type propeller shaft ty...

Page 26

60h5e11 spec general information maintenance specifications power unit item unit kpa (kgf/cm 2 , psi) kpa (kgf/cm 2 , psi) mm (in) mm (in) mm (in) mm (in) mm (in) mm (in) mm (in) mm (in) mm (in) mm (in) mm (in) mm (in) mm (in) mm (in) mm (in) mm (in) mm (in) mm (in) 700 (7.0, 101.5) 520 (5.2, 75.4) ...

Page 27

60h5e11 2 item unit connecting rods small-end inside diameter big-end inside diameter big-end side clearance small-end axial play limit crankshaft crankshaft journal diameter crank pin diameter run-out limit thermostats opening temperature fully open temperature valve open lower limit carburetor id ...

Page 28

60h5e11 spec general information electrical item unit ignition system ignition timing (standard ignition timing) (full advance) piston position (full advance) pulser coil output peak voltage (w/b - w/l, w/br - w/y, w/g - w/r) at cranking 1(*1) at cranking 2(*1) at 1,500 r/min at 3,500 r/min pulser c...

Page 29

60h5e11 2 item unit starter motor type output cranking time limit brushes standard length wear limit commutator standard diameter wear limit mica standard undercut wear limit charging system fuse lighting coil output peak voltage (g - g/w) at cranking(*1) at 1,500 r/min(*1) at 3,500 r/min(*1) lighti...

Page 30

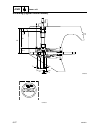

60h5e11 spec general information mm(in) 660(26.0) 35 300(11.8) 426(16.8) 569(22.4) l: 1,032(40.6) x: 1,144(45.0) 543(21.4) 188(7.4) 74(2.9) 788(31.0) l: 946(37.2) x: 1,072(42.2) 631(24.8) l: 516(20.3) x: 642(25.3) 210(8.3) 205(8.1) 26(1.0) 45(1.8) l: 762(30.0) x: 837(33.0) l: 54(2.1) x: 62(2.4) l: 4...

Page 31

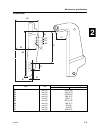

60h5e11 2 b5 b9 b4 c3 d1 d2 b1 b9 b9 b2 b6 d1 b3 item unit b1 b2 b3 b4 b5 b6 b9 c3 d1 d2 mm (in) mm (in) mm (in) mm (in) mm (in) mm (in) mm (in) mm (in) mm (in) mm (in) 125.4 (4.9) 254 (10.0) 163.5 (6.4) 50.8 (2.0) 180 (7.1) 367 (14.5) 18.5 (0.7) 82 (3.2) 13 (0.5) 55.5 (2.2) model 200aet l200aet cla...

Page 32

60h5e11 spec general information tightening torques specified torques power unit flywheel nut m20 160 16 116 1st m10 20 2 15 crankcase bolt 2nd 39 3.9 29 1st m8 10 1 7 2nd 18 1.8 13 intake manifold 1st m6 4 0.4 3 2nd 8 0.8 6 cylinder head 1st m8 15 1.5 11 2nd 29 2.9 21 cylinder head cover 1st m6 4 0...

Page 33

60h5e11 2 bracket unit upper rubber mount nut m12 71 7.1 52 lower rubber mount nut m14 51 5.1 38 through tube nut 7/8'' 15 1.5 11 trim sender cam screw 2 0.2 2 trim rod reciever nut m10 36 3.6 26 ptt reserver cap 0.7 0.07 0.5 reserver mount bolt 1/4'' 5 0.5 4 motor unit mount bolt 1/4'' 5 0.5 4 gear...

Page 34

60h5e11 chk adj periodic checks and adjustments periodic checks and adjustments special service tools ..................................................................................................... 3-1 maintenance interval chart ....................................................................

Page 35

60h5e11 3 lower unit .................................................................................................................... 3-19 checking the gear oil level ...................................................................................... 3-19 changing the gear oil ..................

Page 36

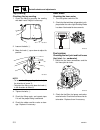

60h5e11 chk adj periodic checks and adjustments 3-1 special service tools timing light 90890-03141 dial gauge set 90890-01252 digital tachometer 90890-06760 leakage tester 90890-06840

Page 37

60h5e11 3 top cowling top cowling fit check/adjust 3-3 fuel system fuel joint and fuel hoses check 3-3 fuel filter check/replace 3-4 fuel tank (*1) clean – power unit ignition timing check 3-6,7 spark plugs clean/adjust/replace 3-4 piston rings check/replace 5-31 thermostat check 3-5 pressure contro...

Page 38

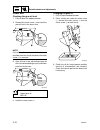

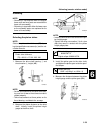

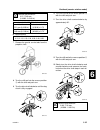

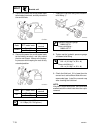

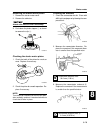

60h5e11 chk adj periodic checks and adjustments 3-3 top cowling checking the top cowling 1. Check the fitting by pushing the cowling with both hands. Adjust if necessary. 60h30010 2. Loosen the bolts 1 . 3. Move the hook 2 up or down to adjust its position. 60h30020 note: • to loosen the fitting, pu...

Page 39

60h5e11 3 note: • be sure not to spill any fuel when removing the fuel filter cup. • apply a thin coat of gasoline to the o-ring 5 before assembly. Top cowling / hour meter / fuel system / power unit 3-4 specified spark plug: b8hs-10 (ngk) br8hs-10 (ngk) spark plug gap a : 1.0 - 1.1 mm (0.039 - 0.04...

Page 40

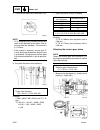

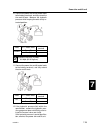

60h5e11 chk adj periodic checks and adjustments 3-5 thermostat cover bolts 1st : 4 n • m (0.4 kgf • m, 3 ft • lb) 2nd : 8 n • m (0.8 kgf • m, 6 ft • lb) t r . . Water valve lift a temperature 0 mm (0 in) – 50°c (122°f) (when the valve begins to open.) above more than 60°c (140°f) 3.0 mm (0.12 in) 5....

Page 41

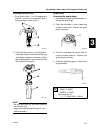

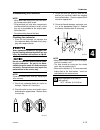

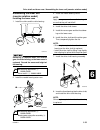

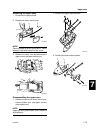

60h5e11 3 power unit / control system 3-6 control system whenever servicing the running engine, take precautions not to touch the rotating parts or the areas carrying the high-volt- age current. The sequence of the services specified below shall be strictly followed and pursued to the end, when adju...

Page 42

60h5e11 chk adj periodic checks and adjustments 3-7 ignition timing at wide open throttle: btdc 18° timing light: 90890-03141 3. Check the ignition timing while engine is running at wide open throttle (i.E. At fully advanced position). 60h30140 ignition timing at idle speed : atdc 7° 2. Check the ig...

Page 43

60h5e11 3 7. Move the magnet control lever 1 until the standard ignition timing adjusting screw 3 touches the fully closed stopper 4 on the cylinder block. 60h30190 standard ignition timing: atdc 7° control system 3-8 5. Check that the mark b on flywheel mag- net is aligned with the mark c on base a...

Page 44

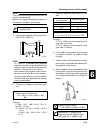

60h5e11 chk adj periodic checks and adjustments dial gauge set: 90890-01252 specified position : 2.05 mm (0.0807 in) full advanced timing : btdc 18° 3-9 5. Mount the dial gauge in the spark plug hole on #1 cylinder. 60h30210 note: secure the dial gauge after retracting it by ap- proximately 3mm (0.1...

Page 45

60h5e11 3 specified length b : 25.0 mm(0.98 in) magnet control link length e : 65mm(2.56in) (reference) control system 3-10 standard ignition timing : atdc 7° 10. Secure the timing plate 5 at the adjusted position and mark the position with paint. 11. Adjust the fully advanced stop screw 2 so that t...

Page 46

60h5e11 chk adj periodic checks and adjustments ignition timing at idle speed : atdc 7° ignition timing at wide open throttle : btdc 18° standard ignition timing adjusting screw length f : 16mm(0.63in) (reference) spark plug: 25 n • m (2.5 kgf • m, 18 ft • lb) t r . . Engine idle speed: 675-725 r/mi...

Page 47

60h5e11 3 digital tachometer : 90890-06760 engine idle speed : 675-725 r/min control system 3-12 5. Visually check that the throttle valves are all closed. Note: move the throttle lever slightly to help the vi- sual check. 6. Tighten the throttle lever tightening screw 1 counterclockwise, to make th...

Page 48

60h5e11 chk adj periodic checks and adjustments 3-13 adjusting the carburetor synchroniza- tion note: make sure the ignition timing is properly ad- justed before synchronizing the carburetor. 1. Disconnect the throttle cable . 2. Remove the intake silencer and flywheel cover. 3. Loosen the throttle ...

Page 49

60h5e11 3 engine idle speed : 675-725 r/min control system 3-14 7. On the central carburetor, tighten the throttle lever tightening screw 1 counter- clockwise to make the accelerator cam 6 aligned with the centerline of the roller 7 . 60h30335 8. Install the intake silencer and flywheel cover. 9. St...

Page 50

60h5e11 chk adj periodic checks and adjustments engine idle speed : 675-725 r/min 3-15 digital tachometer : 90890-06760 5. Install the tachometer onto the spark plug wire of #1 cylinder, and start the engine. 60h30350 6. Adjust the engine idle speed by turning the idle adjusting screw 5 . 60h30360 n...

Page 51

60h5e11 3 engine idle speed : 675-725 r/min control system 3-16 3. Check that the accelerator cam 3 is aligned with the centerline of the roller 4 . 60h30390 4. Loosen the throttle lever tightening screw 5 clockwise to make the accelerator cam aligned with the centerline of the roller 4 . 5. Tighten...

Page 52

60h5e11 chk adj periodic checks and adjustments 3-17 3. Connect the cable joint, install the clip 2, and tighten the locknut 1. 4. Check the throttle cable for smooth opera- tion, and repeat steps 1-3 if necessary. Checking the gearshift operation 1. Check that the gearshift operates smoothly when i...

Page 53

60h5e11 3 3. If the fluid level is low, add sufficient fluid of the recommended type until it overflows out of the filler hole. 4. Install the reservoir cap 2 , and tighten it to the specified torque. Control system / power trim and tilt unit / lower unit checking the power trim and tilt fluid level...

Page 54

60h5e11 chk adj periodic checks and adjustments 3-19 changing the gear oil 1. Fully tilt up the outboard motor. 2. Place a drain pan under the drain screw 1 , remove the drain screw 1 and the check screw 2 to drain the oil. 60h30460 3. Check the oil for metal powder possibly mixed in it, discolorati...

Page 55

60h5e11 3 leakage tester : 90890-06840 lower unit holding pressure: 100 kpa (1.0 kgf/cm 2 , 14 psi) lower unit / general 3-20 oil quantity: regular rotation model: 980 cm 3 (34.5 imp qt) counter rotation model: 870 cm 3 (30.6 imp qt) recommended gear oil: hypoid gear oil sae: 90 4. Insert the gear o...

Page 56

60h5e11 chk adj periodic checks and adjustments 3-21 checking the battery 1. Check the battery electrolyte level. If the level is at or below the minimum level mark a , add distilled water until it reaches to the level between the maximum and minimum level marks. 60h30510 2. Check the specific gravi...

Page 57

60h5e11 3 general 3-22 electrolyte specific gravity: 1.280 at 20°c (68°f) note: batteries vary per manufacturer. The proce- dures mentioned in this manual may not al- ways apply, therefore, consult the instruction manual of the battery. Disconnect the black (–) battery cable first, then the red (+) ...

Page 58

60h5e11 chk adj periodic checks and adjustments 3-23 3. Apply yamaha grease d to the areas shown. 60h30610 c 60h30590 note: apply grease to the grease nipples until it over- flows from the bushings a . 2. Apply yamaha grease c to the areas shown. 60h30600 60h30605 c.

Page 59: Fuel System

60h5e11 4 fuel system special service tools ..................................................................................................... 4-1 hose routing .................................................................................................................. 4-2 fuel hoses ..........

Page 60

60h5e11 fuel system fuel 4-1 special service tools vacuum/pressure pump gauge set 90890-06756.

Page 61

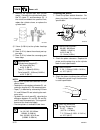

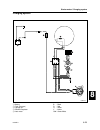

60h5e11 4 hose routing fuel hoses 60h40010 4-2 special service tools / hose routing 1 fuel hose(fuel joint-to-fuel filter) 2 fuel hose(fuel filter-to-fuel pump) 3 fuel hose(fuel pump-to-carburetor).

Page 62

60h5e11 fuel system fuel fuel filter, fuel pump, fuel joint 60h40020 4-3 1 bolt 1 m6 x 28 mm 2 fuel joint 1 3 bolt 4 m6 x 50 mm 4 fuel pump 2 5 gasket 2 6 fuel filter bracket 1 7 fuel filter 1 8 bolt 2 m6 x 16mm 9 fuel hose 1 fuel joint-to-fuel filter 10 fuel hose 1 fuel filter-to-joint 11 fuel hose...

Page 63

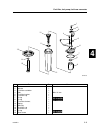

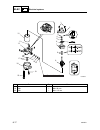

60h5e11 4 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 60h40030 4-4 fuel filter, fuel pump, fuel hose connector no. Part name q’ty remarks 1 bolt 1 m6 x 16 mm 2 washer 1 3 fuel filter nut holder 1 4 bolt 1 m6 x 14 mm 5 fuel filter bracket 1 6 fuel filter cap 1 7 o-ring 1 8 o-ring 1 9 fuel filter element 1 10...

Page 64

60h5e11 fuel system fuel 60h40070 4-5 no. Part name q’ty remarks 1 fuel pump base 2 2 diaphragm 2 3 spring seat 2 4 spring 2 5 nut 8 6 fuel pump body 2 7 fuel pump valve 8 8 screw 8 m5 x 6 mm 9 gasket 2 10 diaphragm 2 11 diaphragm body 2 12 screw 6 m5 x 35 mm 1 2 3 4 5 6 7 8 9 10 11 12 5 7 8 7 8.

Page 65

60h5e11 4 vacuum/pressure pump gauge set : 90890-06756 fuel hose connector holding pressure: 50 kpa(0.5kgf/cm 2 ) 4-6 fuel filter, fuel pump, fuel hose connector checking the fuel joint 1. Visually check the fuel hose connector for cracks or damage. 2. Connect the special service tool at the out- le...

Page 66

60h5e11 fuel system fuel specified pressure: 30 kpa(0.3kgf/cm 2 ) vacuum/pressure pump gauge set: 90890-06756 4-7 checking the fuel pump 1. Disconnect the fuel hoses. Note: to disconnect the fuel hoses, place a drain pan below the pump-hose connection so as not to spill any fuel. 2. Mount the specia...

Page 67

60h5e11 4 4-8 fuel filter, fuel pump, fuel hose connector disassembling the fuel pump 1. Remove and disassemble the fuel pump to check the diaphragm for damage or break- age. 2. Check the seat valve for bending or dam- age. Also check the fuel pump body and the spring for damage. 60h40110 3. Clean o...

Page 68

60h5e11 fuel system fuel 60h40130 4-9 1 gasket 3 2 nut 12 3 carburetor 1 1 4 carburetor 2 1 5 carburetor 3 1 6 accelerator lever rod 1 7 choke rod 2 8 joint 5 9 choke nob 1 10 gasket 3 11 intake silencer 1 12 screw 12 m5 x 55 mm 13 hose 1 14 bolt 2 m6 x 15 mm 15 choke solenoid 1 16 o-ring 1 17 gromm...

Page 69

60h5e11 4 60h40140 4-10 carburetor 1 plug 6 2 gasket 6 3 screw 3 4 plate 3 5 pilot screw 6 6 spring 6 7 screw 3 8 gasket 3 9 air bleed plug 6 10 slow air jet 6 11 carburetor body 3 12 needle valve 6 13 clip 6 14 pin 6 15 float 6 16 gasket 3 17 screw drain 6 no. Part name q’ty remarks 1 2 3 4 5 6 7 8...

Page 70

60h5e11 fuel system fuel 60h40140 4-11 18 gasket 6 19 main jet 6 no. 1,3 : 150 / no. 2,4 : 154 / no. 5 : 152 / no. 6 : 158 20 plug 6 21 gasket 6 22 slow jet 6 23 screw 12 m5 x 16 mm 24 idle adjusting screw 1 25 spring 1 26 carburetor 2 1 27 carburetor 3 1 28 choke joint 1 no. Part name q’ty remarks ...

Page 71

60h5e11 4 4-12 carburetor disassembling the carburetor note: • write down how many turns you have actu- ally turned out the pilot screw. • disassembled jets and other components shall be sorted out and kept in order, so that they are re-assembled to the original posi- tion without fail. • do not ben...

Page 72

60h5e11 fuel system fuel 4-13 assembling the carburetor • do not apply the excessive force to push- in the needle valve. • do not apply the excessive force to screw- in the pilot screw. Note: install the pilot screw 1 , turn-in until it is lightly seated, and then turn out by the specified num- ber ...

Page 73: Power Unit

60h5e11 5 power unit special service tools ..................................................................................................... 5-1 power unit ...................................................................................................................... 5-2 checking the comp...

Page 74

60h5e11 power unit powr 5-1 special service tools compression gauge 90890-03160 flywheel holder 90890-06522 flywheel puller 90890-06521 ball bearing attachment 90890-06663, 90890-06637 driver rod ls 90890-06606 bearing inner race attachment 90890-06661, 90890-06662 needl bearing attachment 90890-066...

Page 75

60h5e11 5 power unit checking the compression pressure 1. Start the engine, warm it up for 5 minutes, and then turn it off. 2. Remove the lock plate for the engine stop switch on the remote control box. 3. Remove all spark plugs, and mount the compression gauge on spark plug hole. Clear out the area...

Page 76

60h5e11 power unit powr 60h50020 5-3 1 flywheel cover 1 2 intake silencer 1 3 screw 12 m5 x 55 mm 4 bolt 2 m6 x 20 mm 5 retaining plate 1 6 grommet 1 7 air vent hose 1 8 dowel pin 2 9 gasket 1 10 bolt 2 m6 x 30 mm 11 bolt 6 m8 x 135 mm 12 bolt 2 m6 x 20 mm 13 apron 1 14 bolt 2 m6 x 20 mm 15 bolt 2 m...

Page 77

60h5e11 5 18 nut 2 19 grommet 2 20 collar 2 21 grommet 2 22 washer 2 23 washer 2 24 washer 2 no. Part name q’ty remarks power unit 60h50020 5-4 11 12 9 10 1 4 5 6 8 3 2 7 19 20 13 14 15 16 17 17 18 21 22 23 24.

Page 78

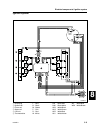

60h5e11 power unit powr 60h50030 1 nut 1 : 30 mm 2 washer 1 3 flywheel magnet assembly 1 4 bolt 3 m6 x 60 mm 5 stator assembly 1 6 pulser coil assembly 1 7 screw 4 m6 x 18 mm 8 stopper 4 9 base 1 10 timing plate 1 11 screw 1 m6 x 10 mm 12 woodruff key 1 no. Part name q’ty remarks c 572 lt e 1 2 3 4 ...

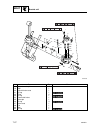

Page 79

60h5e11 5 a 1 8 17 19 27 9 21 22 23 24 25 10 29 7 6 5 4 18 9 14 26 15 16 1 28 2 2 20 13 10 11 3 a a a a power unit 5-6 60h50035 1 joint 2 2 nut 2 3 magnet control rod 1 4 accelerator link 1 5 bolt 1 m6 x 25 mm 6 collar 1 7 wave washer 1 8 accelerator cam 1 9 cap 2 10 nut 2 11 fully advanced stop scr...

Page 80

60h5e11 power unit powr 5-7 60h50035 18 bush 1 19 spring 1 20 magnet control lever 1 21 washer 1 22 washer 1 23 shift bracket 1 24 bolt 2 m8 x 30 mm 25 bush 1 26 clamp 1 27 cable joint 1 28 clip 1 29 magnet control lever 1 no. Part name q’ty remarks a 1 8 17 19 27 9 21 22 23 24 25 10 29 7 6 5 4 18 9...

Page 81

60h5e11 5 1 2 3 4 5 6 7 8 8 9 10 11 12 12 13 13 14 15 16 17 18 19 20 21 21 22 24 25 26 27 28 22 23 572 lt 572 lt 1 60h50040 1 bolt 2 m8 x 45 mm 2 starter motor 1 3 shim 1 4 washer 1 5 bolt 1 m8 x 35 mm 6 wire lead 1 7 nut 1 8 washer 2 9 bolt 1 m8 x 16 mm 10 negative battery lead 1 11 wiring harness ...

Page 82

60h5e11 power unit powr 1 2 3 4 5 6 7 8 8 9 10 11 12 12 13 13 14 15 16 17 18 19 20 21 21 22 24 25 26 27 28 22 23 572 lt 572 lt 1 60h50040 18 holder 1 19 wire lead 1 20 connector 1 21 washer 6 22 nut 6 23 cover 2 24 positive battery lead 1 25 fuse 1 26 fuse holder 1 27 plastic tie 1 28 tube 1 no. Par...

Page 83

60h5e11 5 1 2 3 4 5 6 7 8 9 10 11 12 13 15 14 17 16 18 19 20 60h50050 power unit 5-10 1 bracket 1 2 grommet 3 3 washer 3 4 bolt 3 m6 x 30 mm 5 bolt 2 m6 x 12 mm 6 screw 4 m6 x 19 mm 7 cdi unit cover 1 8 screw 4 m6 x 15 mm 9 ignition coil 6 10 bolt 6 m6 x 20 mm 11 bolt 2 m6 x 12 mm 12 cdi unit 1 13 w...

Page 84

60h5e11 power unit powr 5-11 60h50050 18 grommet 1 19 collar 3 20 plug cap 6 no. Part name q’ty remarks 1 2 3 4 5 6 7 8 9 10 11 12 13 15 14 17 16 18 19 20

Page 85

60h5e11 5 1 wiring harness 1 b 2 wiring harness 1 b 3 wiring harness 1 r 4 wiring harness 1 g 5 bolt 1 m6 x 12 mm 6 wire lead 1 rectifier regulator (g/w) 7 wire lead 1 rectifier regulator (g) 8 rectifier regulator 1 9 bolt 2 m6 x 20 mm 10 nut 3 11 spring washer 3 12 washer 3 13 nut 1 14 spring washe...

Page 86

60h5e11 power unit powr 18 hour meter 1 19 screw 2 20 bolt 2 m6 x 25 mm 21 collar 2 22 grommet 2 23 bracket 1 24 bolt 1 m6 x 12 mm 25 clamp 1 26 plastic tie 1 27 choke solenoid 1 28 o-ring 1 29 bolt 2 m6 x 15 mm no. Part name q’ty remarks 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 2...

Page 87

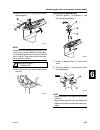

60h5e11 5 5. Disconnect the wiring for power trim and tilt system, the pilot jet hose, and water pressure control valve hose. Remove the mounting bracket bolts 5 for shift rod as- sembly. 60h50085 6. Remove the upper case cover 6 and the apron 7 . 60h50090 7. Lift up the power unit after removing th...

Page 88

60h5e11 power unit powr note: screw-in the flywheel puller set bolt until the flywheel magnet comes off completely. 3. Remove the woodruff key. Removing the electrical components 1. Remove the stator assembly. 2. Remove the pulser coil assembly. 60h50140 3. Remove the starter motor. 60h50150 flywhee...

Page 89

60h5e11 5 7. Remove the cdi unit. 60h50183 8. Remove the bracket. 60h50184 removing the power unit 5-16 4. Remove the starter relay, and the power trim and tilt relay assembly. 60h50160 5. Remove the rectifier regulator, hour meter, and magnet control lever. 60h50170 6. Remove the cdi unit cover. 60...

Page 90

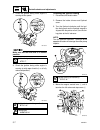

60h5e11 power unit powr 1 2 3 4 5 6 8 4 5 7 12 11 11 9 10 2 3 13 14 15 13 14 15 60h50185 intake manifold 1 gasket 1 2 reed valve 6 3 gasket 6 4 clamp 2 5 bolt 16 m6 x 25mm 6 bolt 12 m5 x 15mm 7 hose 3 8 hose 1 9 hose 1 10 hose 1 11 clamp 2 12 hose 6 13 bolt 4 m6 x 20 mm 14 bushing 2 15 damper bracke...

Page 91

60h5e11 5 intake manifold 5-18 removing the intake manifold 1. Remove the carburetor and the fuel hoses. 60h50190 2. Remove the intake manifold, and the reed valve plate assembly. 60h50200 60h50215 note: loosen the bolts in the sequence shown. 3. Remove the reed valve assembly. 60h50210 4. Check the...

Page 92

60h5e11 power unit powr valve bending limit : 0.2 mm(0.08in) valve stopper height : 6.5 mm (0.26in) 5-19 5. Check the reed valves for bending. Replace them if the bending exceeds the specified limit. 60h50220 6. Measure the valve stopper height. Replace the stopper if the height exceeds the speci- f...

Page 93

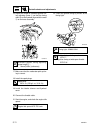

60h5e11 5 1 2 3 4 5 6 7 8 9 10 11 12 13 4 14 15 16 exhaust 60h50255 1 bolt 7 m6 x 20mm 2 cylinder cover 1 3 gasket 1 4 gasket 2 5 exhaust inner cover 1 6 exhaust outer cover 1 7 bolt 29 m6 x 35mm 8 gasket 1 9 pressure control valve cover 1 10 bolt 2 m6 x 20mm 11 pressure control valve seat 1 12 pres...

Page 94

60h5e11 power unit powr 5-21 removing the exhaust cover 1. Remove the pressure control valve. 60h50250 2. Remove the exhaust outer cover, and the exhaust inner cover. 60h50260 60h50265 note: loosen the bolts in the sequence shown. 3. Remove the cylinder block exhaust inner cover. 4. Check the pressu...

Page 95

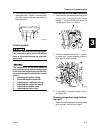

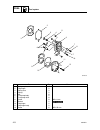

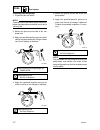

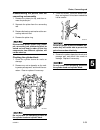

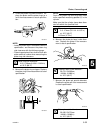

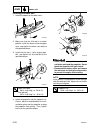

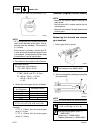

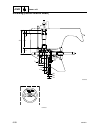

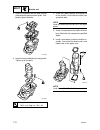

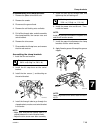

60h5e11 5 a 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 60h50280 1 gasket 2 2 cylinder head 2 3 thermoswitch 2 4 gasket 2 5 cylinder head cover 2 6 gasket 2 7 thermostat 2 8 thermostat cover 2 9 bolt 8 m6 x 40 mm 10 bolt 36 m6 x 30 mm 11 bolt 24 m8 x 60 mm 12 clamp 1 13 bolt 2 m8 x 20 mm 14 engine hanger 1 ...

Page 96

60h5e11 power unit powr 5-23 removing the cylinder head 1. Remove the spark plugs. 2. Remove the thermostat cover and the ther- mostat. 60h50300 note: loosen the bolts in the sequence shown. 3. Remove the cylinder head cover. 60h50310 note: loosen the bolts in the sequence shown. 4. Remove the therm...

Page 97

60h5e11 5 warpage limit: 0.1mm(0.04in) cylinder head 5-24 9. Check the cylinder head warpage. Replace the cylinder head if measured warpage exceeds the specified limit. 60h50340 note: check the warpage in the directious shown, using a straightedge and a thickness gauge..

Page 98

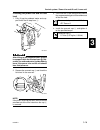

60h5e11 power unit powr 60h50350 1 bolt 4 m6 x 20mm 2 oil seal 1 3 upper bearing housing 1 4 o-ring 2 5 needle bearing 1 6 crankcase 1 7 dowel 2 8 bolt 8 m10 x 60mm 9 bolt 12 m8 x 30mm 10 oil seal housing 1 11 oil seal 1 12 oil seal 1 13 bolt 4 m6 x 20mm 14 gasket 1 15 cover 1 16 bolt 2 m6 x 16 mm 1...

Page 99

60h5e11 5 60h50360 1 crankshaft 1 2 big-end bearing 6 3 connecting rod cap 6 4 connecting rod bolt 12 5 circlip 2 6 main journal bearing 2 7 cylinder block 1 8 anode 8 9 screw 8 10 piston/connecting rod assembly 6 11 gasket 2 12 accessory plug 2 13 seal ring 9 14 bearing 1 15 cir clip 1 no. Part nam...

Page 100

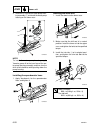

60h5e11 power unit powr removing the crankcase 1. Remove the bearing housing. 2. Remove the o-ring, oil seal, and needle bearing from the bearing housing. 60h50370 note: once removed, oil seal and needle bearing must be replaced with the new one. 3. Install a new needle bearing into the bear- ing ho...

Page 101

60h5e11 5 cylinder block 5-28 8. Remove the crankcase. 60h50420 60h50425 note: loosen the bolts in the sequence shown. 9. Check the crankcase for corrosion. Also check the mating face of the crankcase and the cylinder block for possible distortion. 60h50430 removing the piston, connecting rod assemb...

Page 102

60h5e11 power unit powr e 1 4 5 6 3 2 7 e e 5 3 8 60h50450 1 connecting rod 6 2 piston 3 starboard 3 washer 12 4 needle bearing 6 5 piston pin clip 12 6 piston pin 6 7 piston ring set 6 8 piston 3 port no. Part name q’ty remarks 5-29 piston, connecting rod.

Page 103

60h5e11 5 piston, connecting rod 5-30 disassembling the piston, and the connecting rod assembly 1. Remove the piston pin clip, and then re- move the piston pin. 2. Separate the piston from the connecting rod. 3. Remove the bearing and washer at the con- necting rod small end. 4. Remove the piston ri...

Page 104

60h5e11 power unit powr oversize piston: 1st : 90.145 - 90.165mm (3.5490 - 3.5498 in) 2nd : 90.395 - 90.415 mm (3.5589 - 3.5596 in) piston ring dimensions (top ring, second ring): b:1.97 - 1.99mm (0.0776 - 0.0783 in) t: 2.7-2.9mm (0.1063 - 0.1142 in) at 20°c (68 °f) 5-31 5. Measure the cylinder bore...

Page 105

60h5e11 5 piston, connecting rod 5-32 4. Check the piston ring side clearance. Re- place the piston and the piston rings as a set if the measurement is out of specifica- tion. 60h50515 note: • install the piston rings in accordance with the specification, and measure the piston ring side clearance w...

Page 106

60h5e11 power unit powr 6. Measure the crank pin diameter. Replace the crankshaft if the measurment is out of specification. 60h50610 7. Measure the crankshaft run-out. 60h50620 note: measure the run-out at the crankshaft journals using the v-block and the dial gauge. Bearing separator: 90890-06534 ...

Page 107

60h5e11 5 e axial play limit: 2 mm (0.08 in) t r . . Piston, connecting rod 5-34 connecting rod: 1st : 19n • m (1.9kgf • m, 14 ft • lb) 2nd : 36n • m (3.6kgf • m, 27 ft • lb) 3rd : loosen completely 4th : 19n • m (1.9kgf • m, 14 ft • lb) 5th : 36n • m (3.6kgf • m, 27 ft • lb) 8. Install bearings and...

Page 108

60h5e11 power unit powr 572 lt 572 lt 5-35 e e e assembling the piston and connect- ing rod 1. Install the piston rings 1 , 2 . 60h50660 note: install the piston rings with the recess for the locating pin facing up toward the piston crown. 2. Install the connecting rod, needle bearing, washer, pisto...

Page 109

60h5e11 5 e piston, connecting rod piston ring compressor : 90890-05158 5-36 installing the piston and the connect- ing rod. 1. Insert the piston and connecting rod as- sembly into the cylinder. 60h50675 60h50680 note: • "up"marking shall come to the upper part of the power head. • make sure that th...

Page 110

60h5e11 power unit powr t r . . Crankcase bolt: 1st: m10 bolt: 20 n • m (2.0 kgf • m, 15 ft • lb) m8 bolt: 10 n • m (1.0 kgf • m, 7 ft • lb) 2nd: m10 bolt: 39 n • m (3.9 kgf • m, 29 ft • lb) m8 bolt: 18 n • m (1.8 kgf • m, 13 ft • lb) cylinder head bolt: 1st : 15 n • m (1.5 kgf • m, 11 ft • lb) 2nd ...

Page 111

60h5e11 5 a 5-38 3. Install the cylinder head cover. 60h50750 note: tighten the cylinder head cover bolts to the specified torque in two stages and in the se- quence shown. 4. Install the thermostat and the thermostat cover. 60h50760 note: tighten the thermostat cover bolts to the speci- fied torque...

Page 112

60h5e11 power unit powr pressure control valve cover bolt: 1st : 4 n • m (0.4 kgf • m, 3 ft • lb) 2nd : 8 n • m (0.8 kgf • m, 6 ft • lb) t r . . Intake manifold bolt: 1st : 4 n • m (0.4 kgf • m, 3 ft • in) 2nd : 8 n • m (0.8 kgf • m, 6 ft • in) t r . . Exhaust outer cover bolt: 1st : 4 n • m (0.4 kg...

Page 113

60h5e11 5 piston, connecting rod 5-40 mounting the coils 1. Install the pulser coil assembly, and the sta- tor assembly. 2. Mount the woodruff key, and then install the flywheel magnet. 60h50890 installing the power unit 1. Clean the mating face of the power unit and the upper case, and install dowe...

Page 114

60h5e11 power unit powr 572 lt 572 lt 572 lt 5-41 8. Install the upper case cover and the apron. 60h50930 9. Install the mounting bracket for the shift rod assembly. 60h50935 10. Connect the power trim and tilt motor leads, pilot jet hose, and water pressure control valve hose. 11. Install the carbu...

Page 115

60h5e11 5 piston, connecting rod a 5-42 positive terminal nut 1 : 4 n • m (0.4 kgf • m, 3 ft • lb) negative terminal bolt 2 : 6 n • m (0.6 kgf • m, 5 ft • lb) t r . . 16. Connect the battery cable. 60h50970 12. Connect the fuel hoses. 60h50950 13. Connect the shift cable, and the throttle cable. 60h...

Page 116: Lower Unit

60h5e11 lower unit lowr lower unit special service tools ..................................................................................................... 6-1 lower unit (regular rotation model) ............................................................................. 6-4 removing the lower ...

Page 117

60h5e11 6 lower unit (counter rotation model) .......................................................................... 6-34 removing the lower unit ......................................................................................... 6-37 removing the water pump and shift rod ....................

Page 118

60h5e11 lower unit lowr 6-1 special service tools ring nut wrench 4 90890-06512 ring nut wrench extension 90890-06513 bearing housing puller claw l 90890-06502 stopper guide plate 90890-06501 center bolt 90890-06504 bearing separator 90890-06534 stopper guide stand 90890-06538 bearing puller assembl...

Page 119

60h5e11 6 special service tools 6-2 bearing inner race attachment 90890-06642, 90890-06661, 90890-06639, 90890-06660, 90890-06662 drive shaft holder 6 90890-06520 pinion nut holder 90890-06505 bearing outer race puller assembly 90890-06523 ball bearing attachment 90890-06636, 90890-06633,90890-06629...

Page 120

60h5e11 lower unit lowr 6-3 backlash indicator 90890-06706 magnet base 90890-06705 magnet base plate 90890-07003 dial gauge set 90890-01252 ring nut wrench 90890-06578.

Page 121

60h5e11 6 11 12 13 14 15 9 10 1 5 8 2 7 4 3 6 4 3 16 60h60010 special service tools / lower unit (regular rotation model) 1 lower unit 1 2 check screw 1 3 gasket 2 4 dowel 2 5 bolt 6 m10 x 45mm 6 drain screw 1 7 bolt 1 m10 x 45mm 8 bolt 1 m10 x 70mm 9 spacer 1 10 propeller 1 11 washer 1 12 washer 1 ...

Page 122

60h5e11 lower unit lowr 60h60020 11 12 13 14 15 16 17 18 20 19 10 1 4 5 6 3 2 7 24 23 22 21 4 25 26 27 8 9 22 28 29 30 31 1 bolt 3 m6 x 20mm 2 oil seal 1 3 oil seal housing 1 4 o-ring 1 5 spring 1 6 circlip 1 7 shift rod 1 8 joint 1 9 plastic tie 3 10 hose 1 11 joint 1 12 bolt 4 m8 x 45mm 13 cover 1...

Page 123

60h5e11 6 18 o-ring 1 19 impeller 1 20 outer plate cartridge 1 21 gasket 1 22 dowel 2 23 woodruff key 1 24 seal damper 1 25 guide 1 26 nut 1 27 cooling water inlet cover 1 28 cooling water inlet cover 1 29 bolt 1 m5 x 45 mm 30 washer 3 31 washer 4 no. Part name q’ty remarks 11 12 13 14 15 16 17 18 2...

Page 124

60h5e11 lower unit lowr 6-7 • place a block of wood between the anti- cavitation plate and the propeller. Do not touch the propeller with your hands. • disconnect the battery cable, and remove the lock plate for the engine stop switch to prevent the engine from starting. 7. Disconnect the speedomete...

Page 125

60h5e11 6 lower unit (regular rotation model) 6-8 removing the water pump and shift rod 1. Remove the water pump 1 and the shift rod 2 . 60h60050 note: • remove the woodruff key from the drive shaft, and then the outer plate cartridge. • make sure that the dowels were removed from the lower case. Ch...

Page 126

60h5e11 lower unit lowr 6-9 4. Check the woodruff key 4 and the groove a for wear. Replace if necessary. 60h60090 5. Check the shift rod for deformation or wear. Replace if necessary. 60h60100

Page 127

60h5e11 6 a a 11 12 13 14 15 16 17 18 20 19 9 10 1 4 5 6 8 3 2 7 21 22 4 2 60h60110 1 slide shift 1 2 ball 2 3 slider 1 4 ball 2 5 ball 2 6 spring 1 7 dog clutch 1 8 cross pin 1 9 cross pin ring 1 10 propeller shaft 1 11 washer 1 12 reverse gear 1 13 reverse gear shim * as required 14 thrust washer ...

Page 128

60h5e11 lower unit lowr a a 11 12 13 14 15 16 17 18 20 19 9 10 1 4 5 6 8 3 2 7 21 22 4 2 60h60110 18 key 1 19 needle bearing 1 20 oil seal 2 21 claw washer 1 22 ring nut 1 no. Part name q’ty remarks 6-11.

Page 129

60h5e11 6 ring nut wrench 4: 90890-06512 ring nut wrench extension: 90890-06513 bearing housing puller claw l 1 : 90890-06502 center bolt 2 : 90890-06504 stopper guide plate 3 : 90890-06501 propeller shaft, propeller shaft housing (regular rotation model) 6-12 removing the propeller shaft housing as...

Page 130

60h5e11 lower unit lowr driver rod l3: 90890-06652 needle bearing attachment: 90890-06653 6-13 2. Remove the ball bearing. 60h60150 3. Remove the oil seal. Also remove the needle bearing. 60h60160 note: when the oil seal or the needle bearing is re- moved, always replace them with new ones. Shimming...

Page 131

60h5e11 6 a a e bearing inner race attachment 4 : 90890-06642 bearing inner race attachment 5 : 90890-06661 installation depth a : 24.75 - 25.25mm (0.9744 - 0.9941 in) propeller shaft, propeller shaft housing (regular rotation model) 6-14 note: first, drive-in the inner oil seal halfway into the pro...

Page 132

60h5e11 lower unit lowr 6-15 disassembling the propeller shaft as- sembly 1. Remove the slide shift 1 . 2. Remove the cross pin ring 2 , pull out the cross pin 3 , and remove the dog clutch 4 . Note: mark the dog clutch so that it will be reinstalled in correct orientation. 3. Pull out the slider as...

Page 133

60h5e11 6 propeller shaft, propeller shaft housing (regular rotation model) 6-16 assembling the propeller shaft assem- bly 1. Assemble the slider assembly. 60h60290 note: it is recommended to apply grease or the like to the balls to make the assembling work easier. 2. Insert the slider assembly 1 in...

Page 134

60h5e11 lower unit lowr 11 12 13 14 15 16 17 9 10 1 4 5 6 8 3 2 7 60h60300 1 drive shaft 1 2 drive shaft sleeve 1 3 cover 1 4 oil seal 2 5 bolt 4 8 x 25mm 6 drive shaft housing 1 7 needle bearing 1 8 o-ring 1 9 pinion shim * as required 10 thrust bearing 1 11 needle bearing 1 12 pinion 1 13 nut 1 14...

Page 135

60h5e11 6 6-18 disassembling the lower case 1. Remove the taper roller bearing outer race. 60h60320 2. Remove the needle bearing outer race. 60h60330 drive shaft holder 6 1 : 90890-06520 pinion nut holder 2 : 90890-06505 socket adapter 3 2 : 90890-06508 bearing outer race puller assembly 1 : 90890-0...

Page 136

60h5e11 lower unit lowr 2. First, drive-in the inner oil seal halfway into the drive shaft housing, and then drive-in the outer oil seal to the specified depth. 60h60360 3. Install the cover. 6-19 e a a needle bearing attachment 1 : 90890-06610 driver rod l3 2 : 90890-06652 driver rod ss 1 : 90890-0...

Page 137

60h5e11 6 e bearing separator 1 : 90890-06534 bearing inner race attachment 2 : 90890-06639 needle bearing attachment 1 : 90890-06612 bearing depth plate 2 : 90890-06603 driver rod ss 3 : 90890-06604 installation depth a : 20.95 - 21.45 mm(0.8248 - 0.8445 in) installation depth b : 4.45 - 4.95 mm (0...

Page 138

60h5e11 lower unit lowr e a a bearing outer race attachment 1 : 90890-06619 driver rod ll 2 : 90890-06605 6-21 ball bearing attachment 3 : 90890-06633 bearing outer race puller assembly 4 : 90890-06523 checking the drive shaft 1. Check the drive shaft for bends or wear. Replace the shaft if necessar...

Page 139

60h5e11 6 6-22 pinion nut: 93 n • m(9.3 kgf • m, 69 lb • ft) t r . . 3. Install the needle bearing rollers. Note: apply some grease on the needle bearing roll- ers so that they will not fall off. 4. Install the forward gear assembly. 5. Install the drive shaft, the drive shaft sleeve, and the pinion...

Page 140

60h5e11 lower unit lowr ring nut: 145 n • m (14.5 kgf • m, 105 lb • ft) t r . . 6-23 10. Install the shift rod 7 assembly, and tighten the bolt. 60h60480 11. Install the shim(s), washer, and propeller shaft housing assembly. 60h60490 12. Align the key way, and install the key. 13. Install the claw w...

Page 141

60h5e11 6 a a a a 6-24 installing the water pump 1. Install the gasket 1 , the dowels 2 , and the outer plate cartridge 3 . 60h60520 2. Install the woodruff key 4 into the drive shaft. 3. Install the impeller 5 after aligning it with the woodruff key. 60h60530 note: • align the groove on the impelle...

Page 142

60h5e11 lower unit lowr propeller nut: 54 n • m(5.4 kgf • m, 40 lb • ft) t r . . 6-25 installing the lower unit 1. Install the dowels to the lower case. 60h60560 2. Make sure that the shift rod is in neutral position. Install the lower unit to the upper case, and tighten the lower case bolts to the ...

Page 143

60h5e11 6 6-26 5. Insert the gear oil tube or gear oil pump into the drain hole and fill the gear oil until it flows out of the check hole and no air bubbles are visible. 60h30470 6. Install the check screw, and quickly install the drain screw. Assembling the lower unit (regular rotation model) reco...

Page 144

60h5e11 lower unit lowr 69h60600 a b b3 t3 b4 61.0 t1 b1 37.0 17.2 a1 a3 b2 t2 a2 f r p 69h60605 6-27 shimming (regular rotation model).

Page 145

60h5e11 6 60h60620 note: • install the drive shaft in the center of the pin- ion height gauge. • tighten the wing nuts another 1/4 of a turn after they come in contact with the pinion height gauge plate. 3. Install the pinion gear to the drive shaft, and tighten the pinion gear nut to the specified ...

Page 146

60h5e11 lower unit lowr available shim thickness: 0.10, 0.12, 0.15, 0.18, 0.30, 0.40, 0.50 calculated numeral at 1/100 place rounded numeral 1,2 0 3,4,5 2 6,7,8 5 9,10 8 6-29 shimming plate 2 : 90890-06701 digital caliper 3 : 90890-06704 5. Calculate the lower case standard(p/100). S69j6555 example:...

Page 147

60h5e11 6 t2 shimming plate 1 : 90890-06701 digital caliper 2 : 90890-06704 available shim thickness: 0.10, 0.12, 0.15, 0.18, 0.30, 0.40, 0.50 calculated numeral at 1/100 place rounded numeral 1,2 0 3,4,5 2 6,7,8 5 9,10 8 6-30 example: if "t1" is 0.55 mm, then the forward gear shim is 0.52 mm. If "t...

Page 148

60h5e11 lower unit lowr 6-31 shift rod push arm: 90890-06052 available shim thickness: 0.10, 0.12, 0.15, 0.18, 0.30, 0.40, 0.50 calculated numeral at 1/100 place rounded numeral 1,2 0 3,4,5 2 6,7,8 5 9,10 8 example: if "t2" is 1.16mm, then the reverse gear shim is 1.15 mm. If "t2" is 1.20mm, then th...

Page 149

60h5e11 6 backlash indicator 4 : 90890-06706 forward gear backlash: 0.25 - 0.46 mm (0.0098 - 0.0181 in) 4. Set the dial gauge onto the lower unit, and fix it where the dial gauge plunger contacts the mark b on the backlash indicator a . S69j6655 5. Set the lower unit upside down. Shimming / backlash...

Page 150

60h5e11 lower unit lowr reverse gear backlash m shim thickness(mm) less than to be decreased by 0.74 mm (0.0291 in) (1.02-m) x 0.72 more than to be increased by 1.29 mm (0.0508 in) (m-1.02) x 0.72 6-33 propeller nut: 5 n • m (0.5 kgf • m, 4 ft • lb) t r . . Available shim thickness: 0.10, 0.12, 0.15...

Page 151

60h5e11 6 11 12 13 14 15 9 10 1 5 8 2 7 4 3 6 4 3 16 60h61010 1 lower unit 1 2 check screw 1 3 gasket 2 4 dowel 2 5 bolt 6 m10 x 45mm 6 drain screw 1 7 bolt 1 m10 x 45mm 8 bolt 1 m10 x 70mm 9 spacer 1 10 propeller 1 11 washer 1 12 washer 1 13 propeller nut 1 14 cotter pin 1 15 trim tab 1 16 cap 1 no...

Page 152

60h5e11 lower unit lowr 11 12 13 14 15 16 17 18 20 19 10 1 4 5 6 3 2 7 24 23 22 21 4 25 26 27 8 9 22 28 29 b 30 31 60h61020 1 bolt 3 m6 x 20mm 2 oil seal 1 3 oil seal housing 1 4 o-ring 1 5 spring 1 6 circlip 1 7 shift rod 1 8 joint 1 9 plastic tie 3 10 hose 1 11 joint 1 12 bolt 4 m8 x 45mm 13 cover...

Page 153

60h5e11 6 60h61020 18 o-ring 1 19 impeller 1 20 outer plate cartridge 1 21 gasket 1 22 dowel 2 23 woodruff key 1 24 seal damper 1 25 guide 1 26 nut 1 27 cooling water inlet cover 1 28 cooling water inlet cover 1 29 bolt 1 m5 x 45 mm 30 washer 3 31 washer 4 no. Part name q’ty remarks 6-36 lower unit ...

Page 154

60h5e11 lower unit lowr 6-37 • place a block of wood between the anti- cavitation plate and the propeller. Do not touch the propeller with your hands. • disconnect the battery cable, and remove the lock plate for the engine stop switch to prevent the engine from starting. 7. Disconnect the speedomet...

Page 155

60h5e11 6 6-38 removing the water pump and shift rod 1. Remove the water pump 1 and the shift rod 2 . 60h61050 note: • remove the woodruff key, from the drive shaft and then the outer plate cartridge. • make sure that the dowels were removed from the lower case. Checking the water pump and shift rod...

Page 156

60h5e11 lower unit lowr b 6-39 4. Check the woodruff key 4 and the groove a for wear. Replace if necessary. 60h60090 5. Check the shift rod for deformation or wear. Replace if necessary. 60h61100

Page 157

60h5e11 6 e a a 11 12 13 14 15 16 17 18 20 19 9 10 1 4 5 6 8 3 2 7 21 22 23 4 2 60h61110 1 slide shift 1 2 ball 2 3 slider 1 4 ball 2 5 ball 2 6 spring 1 7 dog clutch 1 8 cross pin 1 9 cross pin ring 1 10 forward gear 1 11 forward gear shim * as required 12 thrust washer 1 13 taper roller bearing 1 ...

Page 158

60h5e11 lower unit lowr e a a 11 12 13 14 15 16 17 18 20 19 9 10 1 4 5 6 8 3 2 7 21 22 23 4 2 60h61110 no. Part name q’ty remarks 18 propeller shaft housing 1 19 key 1 20 needle bearing 1 21 oil seal 2 22 claw washer 1 23 ring nut 1 6-41.

Page 159

60h5e11 6 ring nut wrench 4: 90890-06512 ring nut wrench extension: 90890-06513 6-42 removing the propeller shaft housing assembly and propeller shaft 1. Pull up the claw washer tabs. 2. Remove the ring nut. 60h60120 3. Remove the propeller shaft housing. 60h60130 60h60135 note: make sure that the s...

Page 160

60h5e11 lower unit lowr 6-43 checking the propeller shaft assem- bly shimming is required when forward gear, taper roller bearing, or propeller shaft hous- ing is replaced. 1. Check the propeller shaft for bends or wear. Replace if necessary. 60h61260 2. Measure the propeller shaft run-out. 60h61265...

Page 161

60h5e11 6 a a installation depth a : 24.75 - 25.25mm (0.9744 - 0.9941 in) bearing inner race attachment 4 : 90890-06642 e driver rod ss 1 : 90890-06604 needle bearing attachment 2 : 90890-06610 bearing depth plate 3 : 90890-06603 6-44 assembling the propeller shaft and propeller shaft assembly 1. In...

Page 162

60h5e11 lower unit lowr 6-45 3. Install the propeller shaft shim, the thrust bearing and the propeller shaft to the pro- peller shaft housing. 4. Install the taper roller bearing 56 and the thrust bearing to the propeller shaft hous- ing. 60h61220 5. Install the forward gear to the propeller shaft h...

Page 163

60h5e11 6 60h61300 11 12 13 14 15 16 17 9 10 1 4 5 6 8 3 2 7 6-46 1 drive shaft 1 2 drive shaft sleeve 1 3 cover 1 4 oil seal 2 5 bolt 4 8 x 25mm 6 drive shaft housing 1 7 needle bearing 1 8 o-ring 1 9 pinion shim * as required 10 thrust bearing 1 11 needle bearing 1 12 pinion 1 13 reverse gear shim...

Page 164

60h5e11 lower unit lowr sst bearing puller assembly: 90890-06535 6-47 drive shaft holder 6 1 : 90890-06520 socket adapter 3 2 : 90890-06508 pinion nut holder 2 : 90890-06505 bearing outer race puller assembly 1 : 90890-06523 removing the drive shaft and reverse gear note: shimming is required when t...

Page 165

60h5e11 6 needle bearing attachment 1 : 90890-06610 driver rod l3 2 : 90890-06652 e 6-48 2. Remove the needle bearing outer race. 60h60330 checking the drive shaft housing 1. Check the drive shaft housing for cracks or damage. Also check the needle bearing for run-out and roughness, and the oil seal...

Page 166

60h5e11 lower unit lowr e installation depth a : 20.95 - 21.45 mm(0.8248 - 0.8445 in) installation depth b : 4.45 - 4.95 mm(0.1752 - 0.1949 in) 6-49 checking the reverse gear 1. Check the teeth and dogs of the reverse gear for cracks or wear. Also check the bearing for run-out and roughness. 2. Remo...

Page 167

60h5e11 6 ball bearing attachment 1 : 90890-06629 driver rod ll 2 : 90890-06605 a a ball bearing attachment 3 : 90890-06633 bearing outer race puller assembly 4 : 90890-06523 6-50 assembling the lower unit (counter rotation model) installing the lower case 1. Install the shims and the roller bearing...

Page 168

60h5e11 lower unit lowr pinion nut: 93 n • m(9.3 kgf • m, 69 lb • ft) t r . . Ring nut: 145 n • m (14.5 kgf • m, 105 lb • ft) 6-51 drive shaft holder 6 5 : 90890-06520 pinion nut holder 6 : 90890-06505 socket adapter 3 6 : 90890-06508 ring nut wrench 7 : 90890-06512 ring nut wrench extension 8 : 908...

Page 169

60h5e11 6 a a a a 6-52 15. Make sure that the shifting mechanism works properly. 60h61510 note: change the shift rod position to forward, to re- verse, and to neutral. Make sure that propel- ler shaft rotating direction is correct in forward and in reverse. Also make sure that the posi- tion is corr...

Page 170

60h5e11 lower unit lowr 6-53 4. Install the o-ring into the water pump hous- ing assembly 6 , and install the water pump housing on the lower case. 60h60540 note: to install the water pump housing, apply yamaha grease a to the inner face of the wa- ter pump housing assembly, and then turn the drive ...

Page 171

60h5e11 6 recommended gear oil: hypoid gear oil sae: 90 oil quantity: counter rotation model: 870 cm 3 (30.6 lmp oz) 6-54 5. Insert the gear oil tube or gear oil pump into the drain hole and fill the gear oil until it flows out of the check hole and no air bubbles are visible. 60h31470 6. Install th...

Page 172

60h5e11 lower unit lowr a b b4 t3 b3 61.0 a3 t1 b1 36.5 a1 b7 b5 t4 b6 16.8 b2 t2 a2 a4 a5 60h61600 f r p 60h61607 6-55 shimming (counter rotation model).

Page 173

60h5e11 6 pinion gear nut: 93 n • m(9.3 kgf • m, 69 lb • ft) t r . . 6-56 shimming note: • shimming is not required when the original lower case and inner parts are reused for the lower unit reassembly. • shimming is required if either the lower case or the assembly parts are replaced for the lower ...

Page 174

60h5e11 lower unit lowr available shim thickness: 0.10, 0.12, 0.15, 0.18, 0.30, 0.40, 0.50 calculated numeral at 1/100 place rounded numeral 1,2 0 3,4,5 2 6,7,8 5 9,10 8 6-57 5. Calculate the lower case standard(p/100). S69j6555 note: • "p" a stamped on the trim tab mounting face refers to the devia...

Page 175

60h5e11 6 digital caliper 3 : 90890-06704 shimming plate 1 : 90890-06701 digital caliper 2 : 90890-06704 available shim thickness: 0.10, 0.12, 0.15, 0.18, 0.30, 0.40, 0.50 calculated numeral at 1/100 place rounded numeral 1,2 0 3,4,5 2 6,7,8 5 9,10 8 6-58 note: • set the thrust bearing and the race ...

Page 176

60h5e11 lower unit lowr shimming plate 2 : 90890-06701 digital caliper 3 : 90890-06704 available shim thickness: 0.10, 0.12, 0.15, 0.18, 0.30, 0.40, 0.50 calculated numeral at 1/100 place rounded numeral 1,2 0 3,4,5 2 6,7,8 5 9,10 8 6-59 2. Calculate the lower case standard(r/100). S69j6585 note: • ...

Page 177

60h5e11 6 digital caliper: 90890-06704 propeller shaft end play: 0.25-0.35 mm (0.0098 - 0.0138 in) magnet base 6 : 90890-06705 magnet base plate: 90890-07003 dial gauge set 7 : 90890-01252 available shim thickness: 0.10, 0.12, 0.15, 0.18, 0.30, 0.40, 0.50 calculated numeral at 1/100 place rounded nu...

Page 178

60h5e11 lower unit lowr shit rod push arm : 90890-06052 6-61 backlash (counter rotation model) note: • measure the backlash after removing the wa- ter pump. • set the gear shift in neutral position for the measurement. • measure the backrush for both forward and reverse gears. Measuring the forward ...

Page 179

60h5e11 6 available shim thickness: 0.10, 0.12, 0.15, 0.18, 0.30, 0.40, 0.50 forward gear backlash: 0.21 - 0.43 mm (0.0083 - 0.0169 in) forward gear backlash m shim thickness(mm) less than to be decreased by 0.21 mm (0.0083 in) (0.32-m) x 0.72 more than to be increased by 0.43 mm (0.0169 in) (m-0.32...

Page 180

60h5e11 lower unit lowr note: when measuring the reverse gear backlash, turn the shift rod push arm towards the reverse position c with force. 14. Add or remove shim(s) if out of specifica- tion. 15. Remove the special service tools, and then install the water pump assembly. Available shim thickness...

Page 181: Bracket Unit

60h5e11 7 bracket unit special service tools ..................................................................................................... 7-1 bottom cowling ............................................................................................................. 7-2 upper case ............

Page 182

60h5e11 bracket unit brkt 7-1 special service tools hydraulic pressure gauge: 90890-06776 up-relief fitting: 90890-06773 down-relief fitting: 90890-06774 trim & tilt wrench: 90890-06548.

Page 183

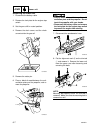

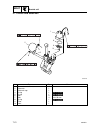

60h5e11 7 60h70010 special service tools / bottom cowling 1 clip 3 2 shift rod 1 3 bush 1 4 washer 1 5 shift rod lever 1 6 washer 1 7 bush 1 8 shift rod bracket 1 9 grease nipple 1 10 washer 1 11 circlip 1 12 rubber seal 1 13 ball 1 14 spring 1 15 bushing 1 16 bolt 2 m8 x 30 mm 17 o-ring 1 no. Part ...

Page 184

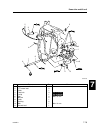

60h5e11 bracket unit brkt 11 12 13 14 15 16 17 17 17 18 18 18 20 19 21 22 24 9 10 11 12 13 14 10 1 4 5 6 8 3 2 7 25 9 11 12 13 14 10 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 23 7 60h70020 1 wire harness clamp 1 2 bolt 1 m6 x 20 mm 3 plate 1 4 bolt 1 m8 x 20 mm 5 bracket 1 6 clamp 2 7 pin 2 8 gro...

Page 185

60h5e11 7 11 12 13 14 15 16 17 17 17 18 18 18 20 19 21 22 24 9 10 11 12 13 14 10 1 4 5 6 8 3 2 7 25 9 11 12 13 14 10 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 23 7 60h70020 18 bushing 3 19 trailer switch holder 1 20 bolt 1 m6 x 28 mm 21 trailer switch 1 22 grommet 1 23 rubber seal 1 24 screw 2 25...

Page 186

60h5e11 bracket unit brkt 11 12 13 14 15 16 17 17 17 18 18 18 20 19 21 22 24 9 10 11 12 13 14 10 1 4 5 6 8 3 2 7 25 9 11 12 13 14 10 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 23 7 7-5 35 grommet 1 36 bolt 2 m6 x 15 mm 37 retaining plate 1 38 clamp 1 no. Part name q’ty remarks 60h70020

Page 187

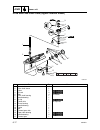

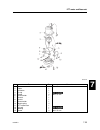

60h5e11 7 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 23 22 27 25 26 25 9 28 upper case 60h70030 1 nut 2 2 washer 2 3 upper mount 2 4 bracket 1 5 washer 2 6 washer 2 7 washer 2 8 bolt 2 m12 x 190 mm 9 bushing 2 10 nut 2 11 washer 2 12 bolt 4 m10 x 45 mm 13 mount housing 2 14 sprin...

Page 188

60h5e11 bracket unit brkt 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 23 22 27 25 26 25 9 28 7-7 60h70040 60h70030 18 washer 2 19 ground lead 1 20 bolt 2 m14 x 180 mm 21 upper case assembly 1 22 ground lead 1 23 hose 1 24 bolt 3 m10 x 45 mm 25 washer 2 26 bolt 1 m6 x 10 mm 27 bolt...

Page 189

60h5e11 7 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 18 19 20 21 22 23 24 25 17 26 28 17 27 60h70040 1 bolt 6 m8 x 45 mm 2 gasket 1 3 union joint 1 4 upper exhaust guide 1 5 gasket 1 6 lower exhaust guide 1 7 bolt 7 m8 x 30 mm 8 gasket 1 9 exhaust manifold 1 10 bolt 4 m8 x 45 mm 11 gasket 1 12 muffler 1...

Page 190

60h5e11 bracket unit brkt 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 18 19 20 21 22 23 24 25 17 26 28 17 27 7-9 60h70040 18 upper case 1 19 rubber seal 1 20 pipe 1 21 rubber seal 1 x transom 22 muffler 2 1 x transom 23 rubber seal 1 x transom 24 bushing 1 x transom 25 circlip 1 x transom 26 cap 1 27 gro...

Page 191

60h5e11 7 removing the upper case 1. Disconnect the ground lead. 2. Remove the lower mount cover. 60h70060 note: cover may pop up by the spring force. Hold it down by hand when loosening the screw. 3. Remove the lower case by loosening the upper mount and lower mount nuts. 60h70065 disassembling the...

Page 192

60h5e11 bracket unit brkt 7. Remove the exhaust manifold. 60h70110 8. Remove the lower exhaust guide. 60h70120 7-11 5. Remove the muffler assembly, the rubber seal and dowels. 60h70090 note: in addition, remove the muffler 2 for x transom model. Muffler 2 is to be removed downward. 5. Remove the muf...

Page 193

60h5e11 7 9. Remove the pressure control valve union joint from the upper exhaust guide. 60h70130 checking the upper case 1. Check the union joint and hose for dam- age. Replace if necessary. 60h70140 2. Check the rubber damper for deterioration. Replace if necessary. 60h70150 3. Check the water tub...

Page 194

60h5e11 bracket unit brkt 7-13 572 lt a 4. Install the rubber damper and spring nut on the muffler. Also install the water seal and water tube. Note: install the water tube so that it fits in the water pump. 5. Install a new gasket on the muffler that has been fitted with the components specified ab...

Page 195

60h5e11 7 572 lt a 572 lt a 9. Install the springs on the lower mount bracket, and attach the lower mount onto the upper case. 60h70250 note: fit the spring in the groove for installation. 10. Install the pressure control valve union joint and hose, exhaust rubber seal, and upper exhaust guide rubbe...

Page 196

60h5e11 bracket unit brkt after tilting up the outboard motor, be sure to support it with the tilt stop lever. Other- wise, the outboard motor could suddenly lower if the power trim and tilt unit should lose fluid pressure. 7. Remove the reservoir cap, and check the fluid level. If the level is low,...

Page 197

60h5e11 7 60h70290 1 power trim and tilt unit 1 2 ptt motor lead 2 3 shaft 1 4 plastic tie 3 5 circlip 1 6 bolt 2 m8 x 16 mm 7 washer 2 8 shaft 1 9 bushing 6 10 bolt 1 m6 x 10 mm 11 ground lead 1 no. Part name q’ty remarks power trim and tilt unit 7-16 1 2 3 4 5 6 6 7 7 8 9 9 9 9 10 11 a a a a a.

Page 198

60h5e11 bracket unit brkt 7-17 manual valve: 3 n • m(0.3kgf • m, 3 ft • lb) t r . . 60h70310 removing the power trim and tilt unit 1. Fully tilt up the outboard motor, and lock it with the tilt stop lever 1 . 60h30430 after tilting up the outboard motor, be sure to support it with the tilt stop leve...

Page 199

60h5e11 7 2. Fully extend the power trim and tilt rods. 3. Remove the circlip 1 and manual valve 2 . Install the hydraulic pressure gauge 4 and up-relief fitting 3 . 60h70370 note: quickly install the hydraulic pressure gauge and up-relief fitting so that the fluid will not flow out of the hole. 4. ...

Page 200

60h5e11 bracket unit brkt 7-19 hydraulic pressure (up): 10-12 mpa(100-120 kgf/cm 2 ) hydraulic pressure gauge: 90890-06776 down-relief fitting : 90890-06774 5. Connect the power trim and tilt motor leads to the battery terminals, and fully retract the trim and tilt rods. 60h70380 6. Connect the powe...

Page 201

60h5e11 7 10. Connect the power trim and tilt motor leads to the battery terminals, and fully retract the trim and tilt rods. Measure the hydraulic pressure while keeping the rods at fully re- tracted position. 60h70380 11. Connect the power trim and tilt motor leads to the battery terminals, and fu...

Page 202

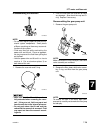

60h5e11 bracket unit brkt 7-21 60h70440 1 2 3 4 5 6 7 8 9 10 1 power trim and tilt motor 1 2 reservoir 1 3 reservoir cap 1 4 o-ring 1 5 o-ring 1 6 bolt 3 1/4 x 35 mm 7 bolt 4 1/4 x 35 mm 8 o-ring 1 9 filter 1 10 joint 1 no. Part name q’ty remarks ptt motor and reservoir.

Page 203

60h5e11 7 13 14 1 screw 1 m4 x 15 mm 2 stator 1 3 armature 1 4 o-ring 1 5 screw 2 m4 x 10 mm 6 brush holder 1 7 brush 2 1 8 brush 1 1 9 brush holder 1 10 brush spring 2 11 ptt motor base 1 12 oil seal 1 13 bearing 1 14 screw 2 m4 x 15 mm no. Part name q’ty remarks 60h70445 ptt motor and reservoir 7-...

Page 204

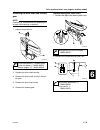

60h5e11 bracket unit brkt 1 2 7-23 60h70480 5 60h70470 4 disassembling the ptt motor 1. Remove the ptt motor, o-ring, filter, and drive pin. 60h70450 make sure that the tilt rod and trim rods are fully extended when removing the ptt motor. If they are not, fluid may spurt out from the unit due to th...

Page 205

60h5e11 7 brush length limit a : 4.8 mm (0.19 in) commutator diameter limit c : 21 mm (0.83 in) armature coil continuity: a b commutator segments e continuity segment e - laminations f no continuity segment e - shaft g no continuity checking the ptt motor 1. Check the blush length a . Replace the bl...

Page 206

60h5e11 bracket unit brkt 3 3 4 7-25 60h70580 note: when the bearings and oil seals are removed, always replace them with new ones. Assembling the ptt motor 1. Connect the leads 1 , and tighten up the screw 2 . 60h70560 2. Push the brush 3 into the brush holder while installing the armature 4 . 60h7...

Page 207

60h5e11 7 60h70590 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 1 bolt 2 m5 x 16 mm 2 pump filter 1 3 gear 2 4 ball 2 5 shuttle piston 2 6 o-ring 2 7 main valve 2 8 ball 2 9 bolt 1 m8 x 85 mm 10 bolt 2 m8 x 24 mm 11 pump housing 1 12 circlip 1 13 manual valve 1 14...

Page 208

60h5e11 bracket unit brkt 7-27 60h70590 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 18 absorber valve pin 1 19 ball 1 20 up-relief valve seat 1 21 o-ring 1 22 filter 2 23 o-ring 1 24 down-relief valve 1 25 valve pin 1 26 o-ring 4 27 valve seat 1 28 pin 1 29 ball ...

Page 209

60h5e11 7 2. Drain the fluid from the reservoir to check any damage. Also check the cap and o- ring. Replace if necessary. Disassembling the gear pump unit 1. Remove the gear pump unit. 60h70620 note: make sure that the o-ring, valve pin, and check valve assembly are removed. 2. Remove the filter, d...

Page 210

60h5e11 bracket unit brkt 7-29 a b 3. Remove the gear pump cover and gear pump. 60h70640 note: make sure that the shuttle piston and ball are removed, since they would be stuck on the gear pump cover. 4. Remove the up-relief valve assembly. 60h70650 5. Remove the main valves. 60h70660 note: to remov...

Page 211

60h5e11 7 checking the reservoir and gear pump unit 1. Clean all the valves, pistons, balls, and fil- ters. Check them for damages or wear. Check the gear pump for damages or wear. Replace them if necessary. 60h70680 assembling the reservoir and gear pump unit reinstall the components and parts in t...

Page 212

60h5e11 bracket unit brkt 7-31 manual valve: 3 n • m(0.3 kgf • m, 3 ft • lb) t r . . Gear pump cover bolts: 6 n • m (0.6 kgf • m, 4 ft • lb) t r . . 5. Install the gear pump cover b on the pump housing, and temporarily tighten the mount- ing bolts. 60h70730 6. Make sure that the gear pump turns smoo...

Page 213

60h5e11 7 1 2 3 4 5 5 6 6 7 7 8 8 9 10 11 11 12 12 13 13 14 15 15 16 16 17 18 18 19 19 20 21 22 23 24 a a 60h70750 1 tilt rod 1 2 trim piston assembly 2 3 cylinder body 1 4 free piston 1 5 backup ring 1 6 o-ring 1 7 dust seal 2 8 seal 2 9 trim cylinder end screw 2 10 o-ring 2 11 backup ring 2 12 o-r...

Page 214

60h5e11 bracket unit brkt 1 2 3 4 5 5 6 6 7 7 8 8 9 10 11 11 12 12 13 13 14 15 15 16 16 17 18 18 19 19 20 21 22 23 24 a a 7-33 60h70750 18 o-ring 1 19 o-ring 1 20 washer 1 21 nut 1 22 ball 1 23 valve 1 24 spring 1 no. Part name q’ty remarks.

Page 215

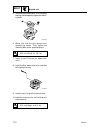

60h5e11 7 60h70760 1 a trim & tilt wrench: 90890-06548 trim & tilt wrench: 90890-06548 60h70770 4 disassembling the tilt cylinder and trim cylinder 1. Loosen the tilt cylinder end cap 1 , and re- move the tilt piston assembly 2 . 60h70760 make sure that the rods are fully extended before removing th...

Page 216

60h5e11 bracket unit brkt 7-35 filter plug: 6 n • m(0.6 kgf • m, 4 ft • lb) t r . . A a 2. Check the tilt piston and free piston for scratches. Replace if necessary. 60h70800 3. Air blow the contamination on the tilt pis- ton absorber valve. Check the valve for wear, and check the spring for deterio...

Page 217

60h5e11 7 60h70900 assembling the power trim and tilt unit 1. Fill the tilt cylinders with the fluid. 60h70920 note: fill the tilt cylinders with the specified quantity of recommended fluid through the hole a . 2. Push-in the free piston 1 to the bottom of tilt cylinder. 60h70930 recommended power t...

Page 218

60h5e11 bracket unit brkt 2 2 reservoir mounting bolts: 5 n • m(0.5 kgf • m, 4 ft • lb) t r . . 7-37 trim rod end cap: 78 n • m(7.8 kgf • m, 57 ft • lb) t r . . Trim & tilt wrench: 90890-06548 gear pump unit mounting bolts: 8 n • m(0.8 kgf • m, 6 ft •lb) t r . . 3. Fill in the trim cylinders with fl...

Page 219

60h5e11 7 12. Install the joint 4 and filter 3 on the gear pump unit. 60h71040 13. Make sure that the gear pump unit is filled out with the fluid to the top. Then turn the gear pump with screwdriver for air bleed- ing. 60h71050 trim & tilt wrench: 90890-06548 60h71030 trim rod end cap: 130 n • m(13 ...

Page 220

60h5e11 bracket unit brkt 60h71070 60h71080 bleeding the power trim and tilt unit note: • make sure that the manual valve 1 is tight- ened up. • fix the power trim and tilt unit in the upright position, and check the fluid level. If it is low, add the fluid of recommended type to the cor- rect level...

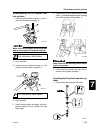

Page 221

60h5e11 7 a a a 242 lt a a 2. Connect the power trim and tilt motor leads to the battery terminals, and fully extend the trim and tilt rods. 60h71090 3. Repeat the procedures above for four or five times. Note: wait for a few seconds before switching the ptt motor leads connections. Assist the rods ...

Page 222

60h5e11 bracket unit brkt 7-41 60h70035 1 steering arm 1 2 washer 1 3 bushing 2 4 swivel bracket 1 5 o-ring 1 6 bushing 1 7 washer 1 8 steering yoke 1 9 circlip 1 10 nut 2 11 thrust receiver 2 12 damper 1 13 clamp bracket 1 starboard 14 clamp bracket 1 port no. Part name q’ty remarks steering arm 1 ...

Page 223

60h5e11 7 removing the steering arm 1. Remove the circlip 1 . 2. Remove the steering yoke 2 by striking it with a plastic hammer or the like. 60h71170 3. Pull off the steering arm, and remove the washer, o-ring, and bushing. Installing the steering arm 1. Install the washer and bushing onto the stee...

Page 224

60h5e11 bracket unit brkt 7-43 5. Inject yamaha grease a through the grease nipple. 60h71200 note: inject the grease until it comes out from both the upper bushing c ..

Page 225

60h5e11 7 1 2 3 4 5 5 5 6 6 7 8 9 9 10 10 11 12 13 14 15 16 17 18 19 20 21 22 23 25 24 22 22 24 26 27 28 29 22 30 10 31 32 33 60h71210 1 swivel brcket assembly 1 2 clamp bracket 1 starboard 3 clamp bracket 1 port 4 self-locking nut 1 5 grease nipple 5 6 ground lead 1 7 washer 2 8 bolt 2 m6 x 11 mm 9...

Page 226

60h5e11 bracket unit brkt 1 2 3 4 5 5 5 6 6 7 8 9 9 10 10 11 12 13 14 15 16 17 18 19 20 21 22 23 25 24 22 22 24 26 27 28 29 22 30 10 31 32 33 7-45 60h71210 18 anode 1 19 through tube 1 20 bolt 1 m8 x 20 mm 21 tilt stop lever 1 22 bush 4 23 collar 1 24 distance collar 2 25 spring pin 2 26 pin 1 27 sp...

Page 227

60h5e11 7 a a a a a a self-locking nut: 15 n • m (1.5 kgf • m, 11 ft • lb) t r . . Trim rod receiver nuts: 36 n • m(3.6 kgf • m, 26 ft • lb) t r . . Lt 271 disassembling the clamp brackets 1. Remove the power trim and tilt unit. 2. Remove the anode. 3. Disconnect the ground lead. 4. Remove the self-...

Page 228

60h5e11 bracket unit brkt trim sensor resistance: pink (p) - black (b) 9-11 at 20°c (68°f) trim sensor cam screw 1 : 2 n • m(0.2 kgf • m, 2 ft • lb) t r . . Gy p b 7-47 install the upper case 1. Install the upper cace and tighten the up- per mount and lower mount nuts. 60h71260 2. Install the lower ...

Page 229

60h5e11 7 trim sensor resistance: pink (p) - black (b) 238.8-378.8 at 20°c (68°f) 7-48 5. Check the trim sensor resistance. If the resistance is out of specification, adjust the trim sensor cam position, and check the trims sensor. Clamp brackets.

Page 230: Electrical Systems

60h5e11 electrical systems elec electrical systems special service tools ..................................................................................................... 8-1 checking the electrical components ........................................................................... 8-2 measur...

Page 231

60h5e11 8 choke solenoid ............................................................................................................ 8-19 checking the choke solenoid .................................................................................. 8-19 charging system ................................

Page 232

60h5e11 electrical systems elec 8-1 special service tools ignition tester 90890-06754 digital circuit tester 90890-03174 peak voltage adaptor b 90890-03172 test harness (fwy-4) 90890-06771 test harness (fwy-6) 90890-06772.

Page 233

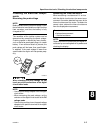

60h5e11 8 special service tools / checking the electrical components 8-2 checking the electrical compo- nents measuring the peak voltage note: before troubleshooting the peak voltage, check that all electrical connections are tight and free from corrosion, and that the battery is fully charged to 12...

Page 234

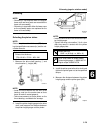

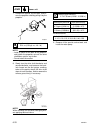

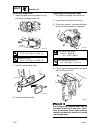

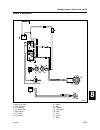

60h5e11 electrical systems elec electrical components starboard view 60h80030 1 thermoswitch 2 hour meter 3 rectifier regulator 4 choke solenoid 8-3.

Page 235

60h5e11 8 port view 1 starter motor 2 starter relay 3 power trim and tilt relay 60h80040 electrical components 8-4 2 3 1.

Page 236

60h5e11 electrical systems elec top view 60h80050 1 spark plug 2 thermoswitch 3 rectifier regulator 4 starter motor 5 starter coil 6 pulser coil 8-5.

Page 237

60h5e11 8 rear view 60h80045 1 ignition coil 2 spark plug 3 cdi unit 1 2 3 8-6 electrical components.

Page 238

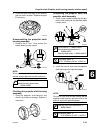

60h5e11 electrical systems elec wiring harness connect to: 1 battery 2 starter relay 3 power trim and tilt relay 4 power trim and tilt switch 5 cdi unit 6 thermoswitch 7 thermoswitch 60h80060 8 ground lead 9 rectifier regulator 0 hour meter a choke solenoid b remote control br : brown sb : sky blue ...

Page 239

60h5e11 8 ignition system 60h80070 1 spark plug 2 ignition coil 3 pulser coil 4 stator coil 5 cdi unit 6 thermoswitche l : blue b : black br : brown p : pink r : red w : white b/r : black/red b/w : black/white w/b : white/black w/g : white/green w/r : white/red w/y : white/yellow w/l : white/blue w/...

Page 240

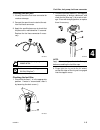

60h5e11 electrical systems elec ignition spark gap: 6 mm (0.24 in) ignition tester: 90890-06754 8-9 checking the ignition spark gap 1. Disconnect the spark plug caps from the spark plugs. 2. Connect the spark gap tester to the spark plug cap. 60h80090 3. Set the specified spark gap length on the adj...

Page 241

60h5e11 8 spark plug cap resistance : 4.0 - 6.0 k Ω 3 8-10 ignition system 2. Remove the spark plug cap 1 , and remove the plug cap spring 3 from the spark plug wire 2 . 60h80123 3. Cut to remove the insulation a on the spark plug wire 2 by approximately 5mm from the wire end. 60h80125 4. Press-in t...

Page 242

60h5e11 electrical systems elec pulser coil output peak voltage : white/black (w/b) – white/blue(w/l) white/brown(w/br)– white/yellow(w/y) white/green(w/g)– white/red(w/r) ignition coil resistance: primary coil a : black/white (b/w) – black (b) 0.18 – 0.24 Ω at 20°c (68°f) secondary coil b : spark p...

Page 243

60h5e11 8 pulser coil resistance (use as refer- ence): white/black(w/b)– white/blue(w/l) white/brown(w/br)– white/yellow(w/y) white/green(w/g)– white/red(w/r) 256 - 384 Ω at 20°c (68°f) digital circuit tester : 90890-03174 peak voltage adapter b : 90890-03172 test harness (fwy-4) : 90890-06771 charg...

Page 244

60h5e11 electrical systems elec digital circuit tester : 90890-03174 peak voltage adapter b : 90890-03172 note: replace the cdi unit, if output peak voltages of the pulser coil and the charge coil are on or above specifications and the cdi unit output peak voltage is below specification. Thermoswitc...

Page 245

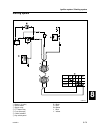

60h5e11 8 60h80200 1 battery (12 volts) 2 starter motor 3 starter relay 4 ptt down relay 5 fuse (20 amps) 6 choke solenoid 7 key switch panel b :black r :red br :brown l :blue y :yellow 8-14 ignition system / starting system starting system off on start w b r y br.

Page 246

60h5e11 electrical systems elec checking the fuse 1. Check the fuse for continuity. Replace if there is no continuity. 60h80210 checking the wiring harness (10 pins) 1. Check the wiring harness for continuity. Replace if there is no continuity. Checking the starter relay 1. Connect the digital circu...

Page 247

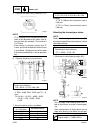

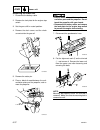

60h5e11 8 60h80260 11 12 13 14 15 16 17 18 20 19 9 10 1 4 5 6 8 3 2 7 c 1 bolt 2 m8 x 25 mm 2 starter motor cover 1 3 clip 2 4 pinion stopper 1 5 spring 1 6 pinion 1 7 housing 1 8 washer 2 9 armature 1 10 stator 1 11 spring 4 12 brush holder 1 13 washer 1 14 washer 1 15 washer 1 16 nut 1 17 washer 2...

Page 248

60h5e11 electrical systems elec 11 12 13 14 15 16 17 18 20 19 9 10 1 4 5 6 8 3 2 7 c 60h80260 18 lower bracket 1 19 bolt 1 m8 x 25 mm 20 bolt 1 m6 x 115 mm no. Part name q’ty remarks 8-17.

Page 249

60h5e11 8 commutator diameter limit: 32.0 mm (1.26 in) commutator undercut limit a : 0.2 mm (0.0079 in) 60h80300 8-18 starter motor removing the starter motor pinion 1. Remove the starter motor cover. 2. Remove the adhesive. Attach with adhesive after reassembly. 3. Push down the pinion stopper 1 as...

Page 250

60h5e11 electrical systems elec brush length limit a : 10.0 mm (0.39 in) brush continuity brush 1 – brush 2 no continuity 8-19 choke solenoid resistance: 3.4 - 4.0 Ω 4. Check the armature for continuity. Replace if out of specification. 60h80310 checking the brushes 1. Measure the brush length. Repl...

Page 251

60h5e11 8 charging system 60h80230 1 battery 2 fuse (20 amps) 3 lighting coil 4 rectifier regulator 5 hour meter b : black r : red g : green y : yellow g/w : green/white 8-20 starter motor / charging system.

Page 252

60h5e11 electrical systems elec checking the lighting coil 1. Remove the rectifier regulator cover, and connect the digital circuit tester lead to the lighting coil. 2. Measure the lighting coil output peak volt- age. If the measurement is below specifi- cation, check the lead and measure the lighti...

Page 253

60h5e11 8 power trim and tilt 60h80365 1 battery (12 volts) 2 fuse (20 amps) 3 ptt up relay 4 ptt down relay 5 trailer switch 6 ptt motor 7 trim sender b : black r : red sb : sky blue lg : light green gy : gray p : pink g : green l : blue 8-22 charging system / power trim and tilt.

Page 254

60h5e11 electrical systems elec lead color: trim sender resistance: pink(p)- black(b) 9 - 11 Ω at 20°c (68°f) a 239 - 379 Ω at 20°c (68°f) b switch position sky blue(sb) red (r) light green(lg) up free down 8-23 checking the power trim and tilt relay 1. Connect the digital circuit tester between pow...

Page 255: Troubleshooting

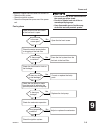

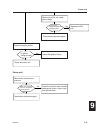

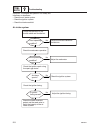

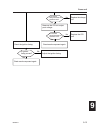

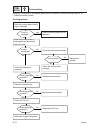

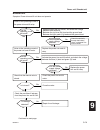

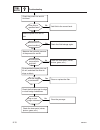

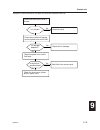

60h5e11 9 troubleshooting power unit ...................................................................................................................... 9-1 starting system ......................................................................................................... 9-1 ignition syste...

Page 256

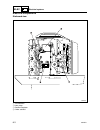

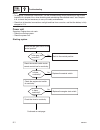

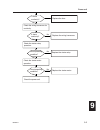

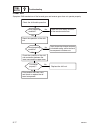

60h5e11 troubleshooting trbl shtg note: • to diagnose a mechanical malfunction, use the troubleshooting charts pertaining to the trouble located in this chapter. Also, when checking and maintaining the outboard motor, see chapters 4–8, to check the part necessary to carry out safety maintenance. • c...

Page 257