- DL manuals

- Yamaha

- Motorcycle

- 2010 YZF-R6

- Manual Instruction

Yamaha 2010 YZF-R6 Manual Instruction

Summary of 2010 YZF-R6

Page 2: Introduction

Introduction • this manual is intended for persons with knowledge and experience of motorcycles. Please refer to the yzf-r6 service manual, which shall be published from yamaha motor co. Ltd., for information on part assembly and maintenance. • the design of the yzf-r6 racing kit is based on yzf-r6,...

Page 3: Contents

Contents 1 engine specifications................................................................................... 1 2 kit parts ......................................................................................................... 2 2-1 engine parts.................................................

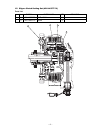

Page 4

3 tightening torque list ............................................................................... 63 4 yzf-r6 wiring diagram.............................................................................. 76.

Page 5: Engine Specifications

– 1 – 1 engine specifications spec ssp stk std displacement 599 cm³ 599 cm³ 599 cm³ bore/storke 67.0 x 42.5 mm 67.0 x 42.5 mm 67.0 x 42.5 mm maximum engine speed (limiter controlled speed) 15800 rpm 15800 rpm 15800 rpm compression ratio (recommended value) 14.5:1 (depend of head-gasket thickness and...

Page 6: Kit Parts

– 2 – 2 kit parts 2-1 engine parts 1. Maintenance set (2c0-maint-71) parts list no. Part no. Part name q'ty remarks ° 1 2c0-11181-76 gasket, cylinder head 3 t=0.45mm * 2 2c0-11603-00 piston ring set 12 * 3 93450-16159 circlip 24 4 2c0-1165a-00 bolt, connecting rod 24 * 5 90179-07001 nut 24 * 6 4sv-1...

Page 7

– 3 – 2. Spark plug set (5fl-r045q-70, 13s-r373a-70) tip since these spark plugs have a copper gasket, caution is needed during installation on the following points. 1. The tightening torque is 12 – 15 n•m (1.2 – 1.5 kgf•m). 2. When not checking the torque, tighten by rotating through 30° after manu...

Page 8

– 4 – 3. Head gasket the thickness of the standard parts is 0.60mm. These parts are used to adjust the squish height. In normal cases, use the one with -76 (0.45mm). After processing the cylinder (upper case), make sure to check the squish height and use the gasket so that the squish height becomes ...

Page 9

– 5 – measuring the volume of the cylinder head combustion chamber tip to obtain the highest performance for race use, the four cylinders should be uniform. If you modify the head cylinder, always measure the combustion chamber volume and do the work based on the measured value. Measure the volume o...

Page 10

– 6 – 4. Piston set (13s-116a0-70) select four pistons so that the difference in their weights does not exceed 0.5g. 5. Connecting rod set (13s-1165b-70) select four connecting rod assemblies so that the difference in their weights does not exceed 2g and combine them so that the small end weights ar...

Page 11

– 7 – 7. Cam shaft and cam sprocket assembly of cam sprocket by making the assembly holes of the cam sprocket of the racing kit long, the valve timing can be adjusted within the range of -2º to +6 º (ca) compared with standard timing. Tip for valve timing adjustment, refer to the kit tools manual. N...

Page 12

– 8 – 8. Valve spring set (2c0-a2110-70) • this set will be effective in improving the engine performance and durability if it is provided exclusively for the kit cam shaft and used in combination. Notice when using this valve spring, use the camshafts 2c0-12171-71, 2c0-12171-72, and 2c0- 12181-71. ...

Page 13

– 9 – 10. Air funnel set (mgc-a300908-10) • this set is capable of higher intake efficiency than the std counterpart. Fitting method 1. Installing the primary funnel screw on the plates on the throttle body. Put only the 2 lower screw like on the schema. Use standard screw. 2. Assemble support and a...

Page 14

– 10 – 3. Mount the assembly secure the lever assembly to the primary funnel. Secure using standard screws in the places illustrated. Then put the screw on the superior part of the supports (shown by a red arrow on the photo below). Make sure that the axle can easily turn without friction. 4. Connec...

Page 15

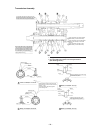

– 11 – 5. Fitting the extention funnel attach the extension funnel to the standard secondary funnel. Note the direction of the groove on the extension funnel and connect with wire so that it does not turn and come off. 6. Fitting the secondary funnel fit the standard rubber seal to the secondary fun...

Page 16

– 12 – 11. Throttle body clamp assembly (2co-1351a-70) this part is used to enhance maintenance performance of the throttle body. Before using it, cut off the protrusion for positioning bands at the cabjoint. The part has a collar to prevent over-tightening. In normal cases, the part will not be tig...

Page 17

– 13 – 12. Ais plug set (13s-a4890-70) this plug set is used when the ais (air induction system), an exhaust gas purification system, is removed. Installation 1. Remove the hose attached to the cylinder head cover and the air cut-off valve assembly accompanying the hose. 2. Remove the cap fitted to ...

Page 18

– 14 – a/c assy. Std kit remove a/c assy. Insertion direction.

Page 19

– 15 – 13. Clutch spring set (2co-a6330-70) the clutch spring should have a bigger mounting load than standard. Parts list no. Part no. Part name q'ty remarks 1 2c0-16334-70 spring, clutch 2 6 identifying color: green.

Page 20

– 16 – 14. Friction plate set (2co-a6321-70) compared to std, the friction plate enhances durability and operation. Parts list no. Part no. Part name q'ty remarks 1 5eb-16321-72 plate, friction 1 9 identification paint (violet).

Page 21

– 17 – 15. Slipper clutch setting set (4b1-a6377-70) parts list no. Part no. Part name q’ty remarks 1 4b1-16377-70 nut, lock 1 2 4b1-16391-70 shim 3 2 a 1 c b 42.4 – 43.0

Page 22

– 18 – (setting of back torque limiter of clutch). A clutch with a back torque limiter mechanism is installed in the yzf-r6 engines. The operation of the back torque limiter can be adjusted through adjusting: the number of shims (set up for the kit); the number of springs; the whole thickness of the...

Page 23

– 19 – as installed in operation stroke load 3 a springs, 3 shims 3 a springs, 2 shims 3 a springs, 1 shim 3 a springs, 0 shim 2 a springs, 3 shims.

Page 24

– 20 – 16. Transmission gear parts list no. Part no. Part name q'ty remarks 1 2c0-17411-80-a axle, main 1 a 1 2c0-17411-90-b axle, main 1 b * 1 2c0-17411-00 axle, main 1 c * 2 2c0-15163-00 hsg., bearing 1 * 3 93306-20562 brg. 1 4 2c0-17151-71-a gear, 5th pinion 1 a 4 2c0-17151-80-b gear, 5th pinion ...

Page 25

– 21 – • gear ratio notice • no gear can be used for the kit transmission except for the specified std gear. • there is no compatibility with the ’06 model transmission set (2c0-a7400-70). * 17 2c0-17211-00 gear, 1st wheel 1 c std a b c 1st 31/12 (2.583) 37/16 (2.313) 42/17 (2.471) 31/12 (2.583) 2nd...

Page 26

– 22 – yzf-r6 mission ratio make sure that the pinion and wheel gear are combined for use according to the chart plan. Pinion gear wheel gear gear plan ratio part number the number of teeth stamp part number the number of teeth stamp 1st a 2.313 2c0-17411-80-a 16 a 2c0-17211-80-a 37 a b 2.471 2c0-17...

Page 27

– 23 – yzf-r6 speed list engine speed (rpm) 16000 tire radius (mm) 315 perimeter (m) 1.979 primary reduction ratio 41 85 2.073 • values in the speed table may vary slightly according to tire manufacturer and size. • select after referring to the value in the speed table. Gear plan the number of teet...

Page 28

– 24 – 17. Mission maintenance set (2c0-a7000-70) parts list no. Part no. Part name q'ty remarks * 21 90387-250r3 collar 3 * 22 90209-21332 washer 6 * 23 93440-25186 circlip 10 * 24 90387-21003 collar 3 * 25 90209-22352 washer 3 * 26 90209-21351 washer 3 * 27 90387-28011 collar 3 * 28 90209-25011 wa...

Page 29

– 25 – 28 29 30 28 29 30 32 31 26 25 24 22 23 33 36 38 28 29 23 37 22 21 34 27 35.

Page 30

– 26 – transmission assembly position the abutment joint of the circlip right between the splines. Circlip shaft edge portion r edge detail of installation of washer detail of installation of washer shaft washer washer matching mark matching mark portion r washer gear the seal side should face outwa...

Page 31

– 27 – 18. Drive sprocket these parts are for 520 chains (std=525 chain). Use the nuts for the kit to mount the drive sprocket. These sprockets are manufactured to be compatible with new and old models. Notice take care not to install the sprocket in the wrong direction. If it is installed in the wr...

Page 32

– 28 – 19. Sprocket nut set (2c0-a7463-70) parts list no. Part no. Part name q'ty remarks 1 90179-20005 nut, sprocket 1 * 2 90215-21256 washer, tongued 1 tighten nut before bending.

Page 33

– 29 – 20. Acm set (2c0-f1400-71) tip regarding assembly 1. Remove grease from the taper surfaces of both rotor and crank before assembling them. 2. Apply engine oil on the thread and flange of mounting bolts before using them. Parts list no. Part no. Part name q'ty remarks 1 2c0-81410-70 stator ass...

Page 34

– 30 – 21. Wire harness set (13s-f2590-71) notice • do not remove the ac generator but leave it to function. Use on the battery alone will make the machine unable to run in a short time. • the wire harness will not function if it is not assembled with the ecu (2c0-8591a-90) of the kit. • the combina...

Page 35

– 31 – • use the 3-prong coupler in front with the red wire attached as the main switch. (see diagram 2.) fitting it turns the power on and removing it turns the power off. Notice be careful not to pull the wire too strongly. • the switch installed to the std machine may be used as is. (see diagram ...

Page 36

– 32 – • the ignition cut switch function can be used by combining the harness and kit ecu. To use the std switch (left side) to function as the ignition cut switch, connect the wire sub-lead that was packaged with this set to the terminal that is normally connected to the left side horn. (see diagr...

Page 37

– 33 – • the bracket regulator provided with this set is for use when fitting a regulator in the position illustrated in diagram 7, such as when not using a standard radiator. • this harness has a coupler that connects to the 2d made data logger. (see diagram 8.) for details of the specifications of...

Page 38

– 34 – • this harness comes with a coupler (black 2-pole, plug) for use with a quick shifter. (connection diagram e/g stp sw) (diagram 9) you can use any quick shifter product. 74 (diagram 9) connector for steering damper connector for quick shifter.

Page 39

– 35 – 22. Ecu set (2c0-8591a-91) • use of this set and a wire harness included in the kit enables regulation (or setting) of fuel injection and ignition timing, etc. • for details as to how to regulate (or set) fuel injection and ignition timings, etc., refer to the manual in the cd-rom that comes ...

Page 40

– 36 – 23. Cable interface (13s-8533a-70) • this cable connects the kit wire harness to the personal computer on which yec fi matching system (yms) is installed. • please see the yms manual for instructions on how to use yms. • when connecting the cable to the pc for the first time, it is necessary ...

Page 41

– 37 – • use of the ecu in the kit and the harness allows functioning of the following codes in the std diagnosis. * yms-monitor: yec fi matching system also allows functioning of the code shown below. Code contents *yms-monitor 01 throttle sensor tps 1(deg) 02 atmospheric pressure sensor atmospheri...

Page 42

– 38 – self-diagnosis functions • the ecu and harness in the kit provide the functions for the following codes of standard self-diagnosis: code description 00 all functions normally. 11 cam angle sensor malfunctions. 12 crank angle sensor malfunctions. 13 intake pressure sensor malfunctions (open ci...

Page 43: 2-2 Vehicle Accessories

– 39 – 2-2 vehicle accessories 24. Engine protector set (2c0-a5491-70) these parts protect the chassis as well as alleviating damage caused by overturning. Parts list no. Part no. Part name q'ty remarks 1 2c0-15491-70 protector 1 * 2 91314-06025 bolt, hex. Socket head 2 * 3 91314-06020 bolt, hex. So...

Page 44

– 40 – 25. Chassis protector set (2c0-c117g-70) parts list no. Part no. Part name q'ty remarks 1 2c0-2117g-70 protector(lh long) 1 2 2c0-2117g-90 protector(rh short) 1 3 2c0-21472-70 collar, protector 2 * 4 91317-10060 bolt, hex. Socket head 1 5 91314-10065 bolt, hex. Socket head 1 * 6 90201-10136 w...

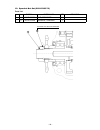

Page 45

– 41 – before mounting the protector, cut the cowling so that the protector can fit against the chassis. As a rough guide, cut by φ 60 centered on the engine mount. See the figures below..

Page 46

– 42 – 26. Oil catch tank set (2c0-c1707-81) this oil tank has the effective capacity of 540 cc. Parts list no. Part no. Part name q'ty remarks 1 2c0-21707-70 oil tank comp. 1 * 2 90450-25037 hose clamp assy. 4 3 13s-15373-70 pipe, breather 1 4 2c0-15393-70 pipe, breather 2 1 * 5 2c0-2419f-00 brkt. ...

Page 47

– 43 – 27. Rear suspension rear suspension performance adjustment method low-speed compression damping, high-speed compression damping, rebound damping and preload can be adjusted. Preload adjustment method turn the adjustor clockwise to increase the preload and anticlockwise to reduce the preload. ...

Page 48

– 44 – rebound damping adjustment method turn clockwise to increase the damping force and anticlockwise to reduce the damping force. The adjustment range is between 3 to 20 steps back from the lightly tightened adjustor position. Shipping position: 15 steps back from the tightened adjustor position ...

Page 49

– 45 – performance and purpose of kit suspension (differences compared with standard suspension on commercially available machines) *spring load: depends on the stroke. Damping force: depends on the stroke speed. Spring characteristics commercially available machine specs purpose to increase comfort...

Page 50

– 46 – 28. Rear shock spring • these springs can be used with the standard or kit shock absorbers. • there is a stamp on the side of the springs for rate identification. • the stamp number indicates the length, diameter and rate. • for spring replacement, see the 13s std. Service manual. • the sprin...

Page 51

– 47 – 29. Front fork front fork performance adjustment method compression low-speed damping, compression high-speed damping, rebound damping and preload can be adjusted. Preload adjustment method turn clockwise to increase the preload and anticlockwise to reduce the preload. The adjustment range is...

Page 52

– 48 – rebound damping adjustor compression low-speed damping adjustor compression high-speed damping adjustor.

Page 53

– 49 – performance and purpose of kit suspension (differences compared with standard suspension on commercially available machines) *spring load: depends on the stroke. Spring characteristics commercially available machine specs purpose to increase comfort when riding in urban areas while preventing...

Page 54

– 50 – *damping force: depends on the stroke speed. Damping force characteristics commercially available machine specs purpose to maintain comfort when riding in urban areas and improve road-holding properties when banking into bends. Performance/characteristics set the lowest possible damping force...

Page 55

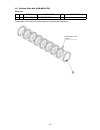

– 51 – 30. Front fork spring • there are slits at the ends of the spring for rate identification. • the number of slits indicates the rate as shown above. • when using an optional spring for the std fork, replace the supplied preload tube with the set. Notice when using an optional spring for the ki...

Page 56

– 52 – front fork spring replacement method 1. Turn the damping adjustor and preload adjustor anticlockwise to set to the weakest position. 2. After fixing the axle bracket in a vice, turn the fork bolt anticlockwise to lower the outer tube until the dust seal touches the upper surface of the axle b...

Page 57

– 53 – 5. Remove the push rod and fit the rod (special tool) to the piston rod. 6. Grip the rod (special tool) firmly and remove the spanner (special tool) . Notice be very careful to apply downward pressure on the rod (special tool) when you remove the spanner (special tool) . Push rod rod (special...

Page 58

– 54 – 7. Remove the spring seat upper and preload tube before removing the rod (special tool) . 8. Remove the washer, special nut and spring guide and replace the spring. Notice when replacing the spring, fit the new spring with the tapered closed end upwards. Washer special nut spring guide.

Page 59

– 55 – 9. Press the rod downwards before adjusting the oil level. • oil level in load state: with the spring removed and the outer tube and rod lowered, 140mm from the top of the outer tube. 10. Reassemble the parts after oil level adjustment by following the disassembly procedure in reverse. Tighte...

Page 60

– 56 – references front and rear load changes and front and rear suspension movement in different scenarios. Accelerating . Load change the wider the throttle is opened, the more the load is concentrated on the rear. . Front fork reaches nearly maximum extended stroke. . Rear cushion up to 20 to 30m...

Page 61

– 57 – 31. Steering damper stay set (2c0-c3495-80) for the steering damper, use [ohlins sd121 stroke 68mm]. Parts list no. Part no. Part name q'ty remarks 1 2c0-23495-80 stay, damper 1 * 2 91317-06025 bolt, hex. Socket head 1 3 2c0-23488-80 spacer 1 * 4 91317-08110 bolt, hex. Socket head 1 5 95607-0...

Page 62

– 58 – 32. Seat cushion (13s-24713-70) anti slip seat. Cut to any size for use. Parts list no. Part no. Part name q’ty remarks 1 13s-24713-70 cushion seat 1.

Page 63

– 59 – 33. Front spare wheel assembly (2c0-25100-70) *this kit does not include a tire. This part is an assembly of bearings, spacers and an air valve in a std wheel. Parts list no. Part no. Part name q'ty remarks 1 2c0-25160-00 cast wheel assy. 1 * 2 93900-00030 valve, rim 1.

Page 64

– 60 – 34. Rear spare wheel assembly (2c0-25300-70) *this kit does not include a tire. This part is an assembly of bearings, spacers and an air valve in a std wheel. Parts list no. Part no. Part name q'ty remarks 1 2c0-25370-00 cast wheel assy. 1 * 2 93900-00030 valve, rim 1.

Page 65

– 61 – 35. Throttle set (2c0-c6300-70) in this throttle set the throttle grip can be removed and maintained by itself. Parts list no. Part no. Part name q'ty remarks ° 1 2c0-26281-70 cap, grip upper 1 * 2 5fl-26282-00 cap, grip under 1 ° 3 5sl-26243-71 tube, guide 1 ° 4 2c0-26391-70 clip, wire 1 1 °...

Page 66

– 62 – 36. Throttle set (13s-c6300-70) in this throttle set the working angle of the throttle grip turning is made smaller for quicker response to the throttle openning. Parts list no. Part no. Part name q'ty remarks ° 1 2c0-26281-70 cap, grip upper 1 * 2 5fl-26282-00 cap, grip under 1 ° 3 5sl-26243...

Page 67: Tightening Torque List

– 63 – 3 tightening torque list engine to be tightened part no. Part name screw dia. X pitch tightening torque n•m (kgf•m) q’ty remarks cap, camshaft x head 90105-06027 bolt, flange m6 x 1.0 10.0±2 (1.0±0.2) 20 cam shaft shall turn lightly. Embedded in head 95612-08625 bolt, stud m8 x 1.25 15.0±2 (1...

Page 68

– 64 – con rod x cap, con rod 2c0-11654- 00 bolt, con rod m7 x 0.75 8 apply molyb- denum disulfide oil to thread 2c0-1165a- 00 bolt, con rod m7 x 0.75 8 apply molyb- denum disulfide oil to thread 90179-07001 nut m7 x 0.75 14.7±1.47 (1.5±0.15) +180°±5° 8 apply molyb- denum disulfide oil to bearing su...

Page 69

– 65 – drain bolt for cover, strainer 90340-14132 plug, straight screw m14 x 1.5 43.0±4 (4.3±0.4) 1 drain bolt tighten union bolt for filter. 90401-20145 bolt, union m20 x 1.5 70.0±5 (7.0±0.5) 1 element, oil filter 5gh-13440- 20 oil cleaner assy m20 x 1.5 17.0±2 (1.7±0.2) 1 apply grease to o-ring. H...

Page 70

– 66 – nut, ring x head 90179-08410 nut m8 x 1.25 20.0±2 (2.0±0.2) 8 tighten exhaust pipe & head. Stay, muffler 1, 2 x muffler 91314-08035 bolt, hexagon socket head m8 x 1.25 20.0±2 (2.0±0.2) 2 install exhaust pipe. Stay, muffler 2 x bracket, muffler 1 90105-08054 bolt, flange (small head) m8 x 1.25...

Page 71

– 67 – crankcase 1 x crankcase 2 90119-08084 bolt, hexagon with washer m8 x 1.25 see page 75 for details. 2 apply oil both to thread and to bearing surface. Crankcase 1 x crankcase 2 90109-06100 bolt m6 x 1.0 10.0±2 (1.0±0.2) 2 apply oil both to thread and to bearing surface. Crankcase 1 x crankcase...

Page 72

– 68 – cover 1 x plug, straight 90340-32004 plug, straight screw m32 x 1.5 close con- tact with bearing sur- face 1 plate, breather x c/ c1 90149-06082 screw m6 x 1.0 12.0±2 (1.2±0.2) 3 cover, crankcase 1 x stator assy 90149-06080 screw m6 x 1.0 10.0±2 (1.0±0.2) 3 plug with communication hole x cran...

Page 73

– 69 – boss, pressure plate x bolt, stud 2c0-16374- 00 bolt, stud m8 x 1.25 25.0±2 (2.5±0.2) 6 install sprocket, drive. 90179-20005 nut m20 x 1.0 85.0±5 (8.5±0.5) 1 with lock washer housing, bearing 90151-06024 screw, cross- recessed counter- sunk m6 x 1.0 12.0±2 (1.2±0.2) 3 crimp. Install stopper, ...

Page 74

– 70 – install o2 sensor. 13s-8592a- 00 o2 sen- sor m18 x 1.5 45.0±5 (4.5±0.5) 1 install thermosensor. 8cc-85790- 01 thermo- sensor assy m12 x 1.5 17.6±2 (1.8±0.2) 1 to be tightened part no. Part name screw dia. X pitch tightening torque n•m (kgf•m) q’ty remarks.

Page 75

– 71 – body to be tightened part no. Part name screw dia. X pitch tightening torque n•m (kgf•m) q’ty remarks handle, crown & outer tube 91314-08030 bolt, hexagon socket head m8 x 1.25 23 – 28 (2.3 – 2.8) 2 handle, crown & steering shaft 90170-28419 nut, hex- agon m28 x 1.0 100 – 125 (10.2 – 12.7) 1 ...

Page 76

– 72 – arm 1 & rear arm 90109-12010 bolt m12 x 1.25 1 screw in from the left side 90185-12119 nut, self locking m12 x 1.25 31 – 49 (3.2 – 5) 1 rear cushion & arm, relay 1 90109-12011 bolt m12 x 1.25 1 screw in from the left side 90185-12119 nut, self locking m12 x 1.25 31 – 49 (3.2 – 5) 1 chain pull...

Page 77

– 73 – rear wheel sprocket & clutch hub 90185-10009 nut, self locking m10 x 1.25 90 – 109 (9.2 – 11.1) 6 split bolt for front axle 91314-08040 bolt, hexagon socket head m8 x 1.25 18 – 23 (1.8 – 2.3) 4 to be tightened part no. Part name screw dia. X pitch tightening torque n•m (kgf•m) q’ty remarks.

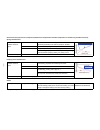

Page 78

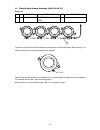

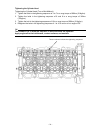

– 74 – tightening the cylinder head tightening the cylinder head (turn-of-nut method) 1. Tighten the bolts in the tightening sequence of 1 to 7 to a snug torque of 28n•m (2.8kgf•m). 2. Tighten the bolts in the tightening sequence of 8 and 9 to a snug torque of 36n•m (3.6kgf•m). 3. Tighten the bolt i...

Page 79

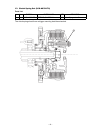

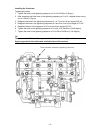

– 75 – installing the crankcase tightening the bolts 1. Tighten the bolts in the tightening sequence of 1 to 10 to 20n•m (2.0kg•m). 2. After loosening the bolts once in the tightening sequence of 1 to 10, retighten them one by one to 12n•m (1.2kg•m). 3. Retighten the bolts in the tightening sequence...

Page 80

– 76 – 4 yzf-r6 wiring diagram rfr hlr exp exm- exm+ c ai thm+ thm- vthm ij24 ij23 ij22 ij21 ij14 ij13 ij12 ig4 ij11 ig3 ig2 ig1 o2 oh crk sgnd1 vcc1 cam at wt pb pa fd sp tc tp2 tp1 vcc2 ss nl txd rxd rst fwe rst2 fwe2 sgnd2 ap2 ap1 st it lan ms vb mr vm yg wy wb l p pw gw brw gy bl rl ly w by lb2 ...

Page 81

Published by yamaha motor engineering co., ltd.