- DL manuals

- Yamaha

- Motorcycle

- 2011 YZ250

- Owner's Manual

Yamaha 2011 YZ250 Owner's Manual

OWNER’S SERVICE MANUAL

MANUEL D’ATELIER DU

PROPRIETAIRE

FAHRER- UND

WARTUNGSHANDBUCH

MANUALE DI SERVIZIO DEL

PROPRIETARIO

YZ250

YZ250F2

1SS-28199-33

PRINTED IN JAPAN

2014.06–0.6 × 1

!

(E, F, G, H)

PRINTED ON RECYCLED PAPER

2015

YZ250

YZ250F2

2015

q

Read this manual carefully before operating this vehicle.

q

Il convient de lire attentivement ce manuel avant la première utilisation du véhicule.

q

Bitte lesen Sie diese Bedienungsanleitung sorgfältig durch, bevor Sie das Fahrzeug in Betrieb nehmen.

q

Leggere attentamente questo manuale prima di utilizzare questo veicolo.

1SS-28199-33_cover.indd 1

2014/05/29 11:59:59

Summary of 2011 YZ250

Page 1

Owner’s service manual manuel d’atelier du proprietaire fahrer- und wartungshandbuch manuale di servizio del proprietario yz250 yz250f2 1ss-28199-33 printed in japan 2014.06–0.6 × 1 ! (e, f, g, h) printed on recycled paper 2015 yz250 yz250f2 2015 q read this manual carefully before operating this ve...

Page 2

Q read this manual carefully before operating this vehicle. This manual should stay with this vehicle if it is sold. Q il convient de lire attentivement ce manuel avant la première utilisation du véhicule. Le manuel doit être remis avec le véhicule en cas de vente de ce dernier. Q leggere attentamen...

Page 3: Yz250F2

Yz250f2 yz250f2 2015 2015 yz250 yz250 1ss-28199-33-e0 1ss-28199-33-e0 owner’s service manual owner’s service manual read this manual carefully before operating this vehicle. Read this manual carefully before operating this vehicle..

Page 5

Yz250 yz250f2 owner's service manual ©2014 by yamaha motor co., ltd. 1st edition, june 2014 all rights reserved. Any reprinting or unauthorized use without the written permission of yamaha motor co., ltd. Is expressly prohibited. Printed in japan.

Page 6

Foreword introduction congratulations on your purchase of a yamaha yz series. This model is the culmination of yamaha's vast ex- perience in the production of paceset- ting racing machines. It represents the highest grade of craftsmanship and reliability that have made yama- ha a leader. This manual...

Page 7

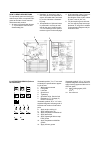

How to use this manual finding the required page 1. This manual consists of seven chapters; "general information", "specifications", "regular inspec- tion and adjustments", "engine", "chassis", "electrical" and "tun- ing" 2. The table of contents is at the be- ginning of the manual. Look over the ge...

Page 8

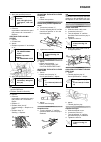

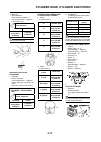

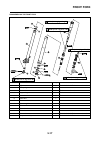

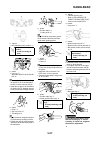

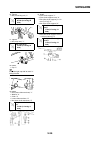

How to read descriptions to help identify parts and clarify pro- cedure steps, there are exploded dia- grams at the start of each removal and disassembly section. 1. An easy-to-see exploded diagram "1" is provided for removal and disassembly jobs. 2. Numbers "2" are given in the or- der of the jobs ...

Page 9: Table of Contents

Table of contents general information 1 specifications 2 regular inspection and adjustments 3 engine 4 chassis 5 electrical 6 tuning 7.

Page 10

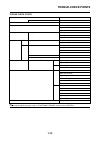

Contents chapter 1 general information location of important labels ..... 1-1 description ................. 1-5 consumer information................. 1-6 included parts .......... 1-6 important information................. 1-6 checking of connection.................. 1-7 special tools ............. ...

Page 11

1-1 location of important labels general information location of important labels please read the following important labels carefully before operating this vehicle. Canada 1.

Page 12

1-2 location of important labels europe.

Page 13

1-3 location of important labels aus, nz, za.

Page 14

1-4 location of important labels familiarize yourself with the following pictograms and read the explanatory text. Read owner's service manual. This unit contains high-pressure nitrogen gas. Mishandling can cause explosion. Do not incinerate, puncture or open. Turn off the main switch after riding t...

Page 15

1-5 description description • the machine you have purchased may differ slightly from those shown in the following. • designs and specifications are subject to change without notice. 1. Clutch lever 2. Engine stop switch 3. Front brake lever 4. Throttle grip 5. Radiator cap 6. Fuel tank cap 7. Kicks...

Page 16

1-6 consumer information consumer information there are two significant reasons for knowing the serial number of your machine: 1. When ordering parts, you can give the number to your yamaha dealer for positive identification of the model you own. 2. If your machine is stolen, the au- thorities will ...

Page 17

1-7 checking of connection all replacement parts 1. We recommend to use yamaha genuine parts for all replace- ments. Use oil and/or grease rec- ommended by yamaha for assembly and adjustment. Gaskets, oil seals and o- rings 1. All gaskets, oil seals, and o-rings should be replaced when an en- gine i...

Page 18

1-8 special tools special tools the proper special tools are necessary for complete and accurate tune-up and assembly. Using the correct special tool will help prevent damage caused by the use of improper tools or improvised techniques. The shape and part number used for the special tool differ by c...

Page 19

1-9 special tools radiator cap tester yu-24460-a, 90890-01325 radiator cap tester adapter yu-33984, 90890-01352 these tools are used for checking the cooling system. Steering nut wrench yu-a9472, 90890-01403 this tool is used when tighten the steering ring nut to specification. Cap bolt wrench ym-01...

Page 20

1-10 special tools clutch holding tool ym-91042, 90890-04086 this tool is used to hold the clutch when removing or installing the clutch boss securing nut. Dynamic spark tester ym-34487 ignition checker 90890-06754 this instrument is necessary for checking the ignition system compo- nents. Digital t...

Page 21

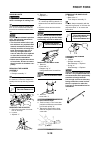

1-11 control functions control functions engine stop switch the engine stop switch "1" is located on the left handlebar. Continue push- ing the engine stop switch till the en- gine comes to a stop. Clutch lever the clutch lever "1" is located on the left handlebar; it disengages or en- gages the clu...

Page 22

1-12 starting and break-in handling note before starting the machine, per- form the checks in the pre-opera- tion check list. Never start or run the engine in a closed area. The exhaust fumes are poisonous; they can cause loss of consciousness and death in a very short time. Always oper- ate the mac...

Page 23

1-13 torque-check points torque-check points concerning the tightening torque, refer to "tightening torques" section in the chapter 2. Frame construction frame to rear frame combined seat and fuel tank fuel tank to frame exhaust system silencer to rear frame engine mounting frame to engine engine br...

Page 24

1-14 maintenance after break-in maintenance after break-in after a break-in, perform careful maintenance to get ready for the next practice or race. Refer to "pre-operation in- spection and maintenance" section in the chapter 3. Major maintenance 1. For the engine • leaks around the engine check for...

Page 25

2-1 general specifications specifications general specifications model name: yz250f2 (usa, cdn, aus, nz) yz250 (europe, za) model code number: 1ssd (usa, cdn) 1sse (europe) 1ssg (aus, nz, za) dimensions: overall length 2,147 mm (84.4 in) overall width 827 mm (32.6 in) overall height 1,299 mm (51.2 i...

Page 26

2-2 general specifications transmission: primary reduction system gear primary reduction ratio 3.000 (63/21) final drive chain secondary reduction ratio 3.571 (50/14) transmission type constant mesh, 5-speed operation left foot operation gear ratio: 1st 1.929 (27/14) 2nd 1.533 (23/15) 3rd 1.278 (23/...

Page 27

2-3 maintenance specifications maintenance specifications engine item standard limit cylinder head: combustion chamber volume 21.35–21.65 cm 3 (1.30–1.32 cu.In) ---- warp limit ---- 0.03 mm (0.0012 in) cylinder: bore size 66.400–66.414 mm (2.6142–2.6147 in) 66.500 mm (2.6181 in) taper limit ---- 0.0...

Page 28

2-4 maintenance specifications crankshaft: crank width "a" 59.95–60.00 mm (2.360–2.362 in) ---- runout limit "c" 0.030 mm (0.0012 in) 0.050 mm (0.0020 in) connecting rod big end side clearance "d" 0.250–0.750 mm (0.0098–0.0295 in) ---- small end free play "f" 0.40–1.00 mm (0.02–0.04 in) 2.0 mm (0.08...

Page 29

2-5 maintenance specifications carburetor: usa, cdn europe aus, nz, za type/manufacturer pwk38s/ keihin ← ← ---- i.D. Mark 1p87 50 1p86 40 ← ---- main jet (m.J.) #178 #180 ← ---- main air jet (m.A. J.) #200 ← ← ---- jet needle-clip position (j.N.) n3ew-2 n3ew-3 ← ---- main nozzle (n.J.) ø2.9 ← ← ---...

Page 30

2-6 maintenance specifications chassis item standard limit steering system: steering bearing type taper roller bearing ---- front suspension: front fork travel 300.0 mm (11.81 in) ---- fork spring free length 454.0 mm (17.87 in) 449.0 mm (17.68 in) spring rate, std k=4.30 n/mm (0.44 kg/mm, 24.55 lb/...

Page 31

2-7 maintenance specifications electrical front disc brake: disc outside dia.×thickness 250 × 3.0 mm (9.8 × 0.12 in) 250 × 2.5 mm (9.8 × 0.10 in) pad thickness 4.4 mm (0.17 in) 1.0 mm (0.04 in) master cylinder inside dia. 9.52 mm (0.37 in) ---- caliper cylinder inside dia. 22.65 mm (0.89 in) × 2 ---...

Page 32

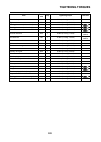

2-8 tightening torques tightening torques engine △ - marked portion shall be checked for torque tightening after break-in or before each race. Item thread size q'ty tightening torque remarks spark plug m14s 1 20 nm (2.0 m•kg, 14 ft•lb) cylinder head (nut) m8 6 25 nm (2.5 m•kg, 18 ft•lb) copper washe...

Page 33

2-9 tightening torques drive chain sprocket cover m6 2 5 nm (0.5 m•kg, 3.6 ft•lb) right crankcase cover m6 9 10 nm (1.0 m•kg, 7.2 ft•lb) bearing plate cover (drive axle left) m6 2 10 nm (1.0 m•kg, 7.2 ft•lb) bearing plate cover (main axle right) m6 2 10 nm (1.0 m•kg, 7.2 ft•lb) holder m6 2 10 nm (1....

Page 34

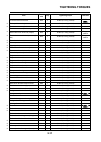

2-10 tightening torques chassis △ - marked portion shall be checked for torque tightening after break-in or before each race. Item thread size q'ty tightening torque remarks △ upper bracket and outer tube m8 4 21 nm (2.1 m•kg, 15 ft•lb) △ lower bracket and outer tube m8 4 21 nm (2.1 m•kg, 15 ft•lb) ...

Page 35

2-11 tightening torques footrest bracket and frame m10 4 55 nm (5.5 m•kg, 40 ft•lb) torx △ brake pedal mounting m8 1 26 nm (2.6 m•kg, 19 ft•lb) △ rear brake master cylinder and frame m6 2 10 nm (1.0 m•kg, 7.2 ft•lb) rear brake master cylinder cap m4 2 2 nm (0.2 m•kg, 1.4 ft•lb) △ rear brake hose uni...

Page 36

2-12 tightening torques 1. First, tighten the steering ring nut approximately 38 nm (3.8 m•kg, 27 ft•lb) by using the steering nut wrench, then loosen the steering ring nut one turn. 2. Retighten the steering ring nut 7 nm (0.7 m•kg, 5.1 ft•lb). Electrical △ front fender m6 4 10 nm (1.0 m•kg, 7.2 ft...

Page 37

2-13 tightening torques general torque specifications this chart specifies torque for stan- dard fasteners with standard i.S.O. Pitch threads. Torque specifications for special components or assem- blies are included in the applicable sections of this book. To avoid warp- age, tighten multi-fastener...

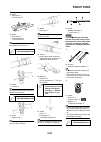

Page 38

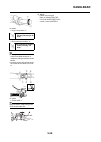

2-14 cable routing diagram cable routing diagram 1. Engine stop switch lead 2. Throttle cable 3. Clutch cable 4. Clamp 5. Wire harness 6. Radiator breather hose 7. Air vent hose 8. Crankcase breather hose 9. Overflow hose a. Pass the clutch cable on the out- side of the throttle cable and en- gine s...

Page 39

2-15 cable routing diagram f. Clamp the throttle cable and wire harness to the frame. G. Pass the clutch cable in front of the center of the cylinder head tightening nut. H. Pass the air vent hose, overflow hose and crankcase breather hose between the frame and connecting rod. I. Locate the clamp en...

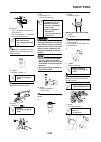

Page 40

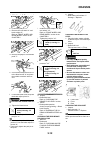

2-16 cable routing diagram 1. Ignition coil lead 2. Clamp 3. Cdi magneto lead 4. Neutral switch lead 5. Radiator breather hose 6. Ypvs breather hose 7. Connector cover a. Clamp the ignition coil lead to the frame at its locating tape. Clamp it in front of the radiator fitting boss. B. Clamp the cdi ...

Page 41

2-17 cable routing diagram g. Clamp the radiator breather hose, cdi magneto lead and neutral switch lead to the frame. H. Pass the cdi magneto lead, ra- diator breather hose and neutral switch lead in front of the radia- tor hose. Then pass the radiator breather hose inside the cdi magneto lead and ...

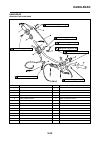

Page 42

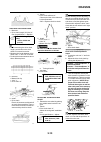

2-18 cable routing diagram 1. Clamp 2. Wire harness 3. High tension cord 4. Cdi unit band 5. Cdi unit 6. Cdi unit lead 7. Connector cover 8. Radiator hose 9. Radiator breather hose 10. Cdi unit stay a. Clamp the wire harness protect- ing tube to the right engine bracket. B. Pass the high tension cor...

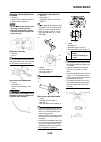

Page 43

2-19 cable routing diagram 1. Master cylinder 2. Brake hose holder 3. Brake hose a. Install the brake hose so that its pipe portion directs as shown and lightly touches the projec- tion on the caliper. B. Pass the brake hose into the brake hose holders. C. If the brake hose contacts the spring (rear...

Page 44

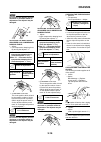

2-20 cable routing diagram 1. Brake hose 2. Master cylinder 3. Engine stop switch lead 4. Engine stop switch 5. Throttle cable 6. Clutch cable 7. Clamp 8. Cable guide a. Install the brake hose so that its pipe portion directs as shown and lightly touches the projec- tion on the master cylinder. B. P...

Page 45

3-1 maintenance intervals regular inspection and adjustments maintenance intervals • the following schedule is intended as a general guide to maintenance and lubrication. Bear in mind that such factors as weather, terrain, geographical location, and individual usage will alter the required maintenan...

Page 46

3-2 maintenance intervals rotor nut retighten ● ● muffler inspect ● ● clean ● retighten ● ● replace fiber ● * * when the exhaust sound be- comes louder or when a per- formance drop is felt. Crank inspect and clean ● ● carburetor inspect, adjust and clean ● ● spark plug inspect and clean ● ● replace ...

Page 47

3-3 maintenance intervals brakes adjust lever position and pedal height ● ● lubricate pivot point ● ● check brake disc surface ● ● check fluid level and leak- age ● ● retighten brake disc bolts, caliper bolts, master cylin- der bolts and union bolts ● ● replace pads ● replace brake fluid ● every one...

Page 48

3-4 maintenance intervals tire, wheels inspect air pressure, wheel runout, tire wear and spoke looseness ● ● retighten sprocket bolt ● ● inspect bearings ● replace bearings ● lubricate ● lithium base grease throttle, control ca- ble check routing and connec- tion ● ● lubricate ● ● yamaha cable lube ...

Page 49

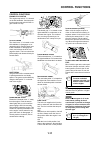

3-5 pre-operation inspection and maintenance pre-operation inspection and maintenance before riding for break-in operation, practice or a race, make sure the machine is in good operating condition. Before using this machine, check the following points. General inspection and maintenance item routine...

Page 50

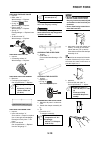

3-6 engine engine checking the coolant level do not remove the radiator cap "1", drain bolt and hoses when the engine and radiator are hot. Scald- ing hot fluid and steam may be blown out under pressure, which could cause serious injury. When the engine has cooled, place a thick towel over the radia...

Page 51

3-7 engine 2. Apply the specified pressure. 3. Inspect: • pressure impossible to maintain the speci- fied pressure for 10 seconds → replace. Checking the cooling system 1. Inspect: • coolant level 2. Attach: • radiator cap tester "1" and adapt- er "2" 3. Apply the specified pressure. • do not apply ...

Page 52

3-8 engine prior to adjusting throttle grip free play, the engine idling speed should be adjusted. After adjusting the throttle grip free play, turn the handlebar to the right and to the left to ensure that this does not cause the engine idling speed to change. Lubricating the throttle 1. Remove: • ...

Page 53

3-9 engine never attempt to remove the oil check bolt just after high speed operation. The heated oil could spout out, causing danger. Wait until the oil cools down. Oil flows out → oil level is correct. Oil does not flow out → oil level is low. Add transmission oil until oil flows out. C. Inspect t...

Page 54

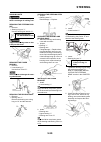

3-10 chassis chassis bleeding the hydraulic brake system bleed the brake system if: • the system has been disassem- bled. • a brake hose has been loosened or removed. • the brake fluid is very low. • the brake operation is faulty. A dangerous loss of braking per- formance may occur if the brake syst...

Page 55

3-11 chassis checking and replacing the front brake pads 1. Inspect: • brake pad thickness "a" out of specification → replace as a set. 2. Replace: • brake pad brake pad replacement steps: a. Remove the pad pin plug "1". B. Loosen the pad pin "2". C. Remove the brake caliper "3" from the front fork....

Page 56

3-12 chassis b. Loosen the pad pin "3". C. Remove the rear wheel "4" and brake caliper "5". Refer to "front wheel and rear wheel" section in the chapter 5. D. Remove the pad pin "6" and brake pads "7". E. Connect the transparent hose "8" to the bleed screw "9" and place the suitable container under ...

Page 57

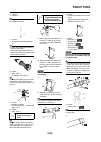

3-13 chassis checking the drive chain 1. Measure: • drive chain length (15 links) "a" out of specification → replace. • while measuring the drive chain length, push down on the drive chain to increase its tension. • measure the length between drive chain roller "1" and "16" as shown. • perform this ...

Page 58

3-14 chassis d. Tighten the axle nut while pushing down the drive chain. E. Tighten the locknuts. Checking the front fork 1. Inspect: • front fork smooth action operate the front brake and stroke the front fork. Unsmooth action/oil leakage → repair or replace. Checking the front fork protector guide...

Page 59

3-15 chassis do not force the adjuster past the minimum or maximum extent of adjustment. The adjuster may be damaged. Always adjust each front fork to the same setting. Uneven adjust- ment can cause poor handling and loss of stability. Checking the rear shock absorber 1. Inspect: • swingarm smooth a...

Page 60

3-16 chassis do not force the adjuster past the minimum or maximum extent of adjustment. The adjuster may be damaged. Adjusting the rear shock absorber low compression damping force 1. Adjust: • low compression damping force by turning the adjuster "1". • standard position: this is the position whic...

Page 61

3-17 chassis checking the wheels 1. Inspect: • wheel runout elevate the wheel and turn it. Abnormal runout → replace. 2. Inspect: • bearing free play exist play → replace. Checking and adjusting the steering head 1. Place a stand under the engine to raise the front wheel off the ground. Warning! Sec...

Page 62

3-18 chassis.

Page 63

3-19 chassis lubrication to ensure smooth operation of all components, lubricate your machine during setup, after break-in, and after every race. 1. All control cable 2. Clutch lever pivot 3. Shift pedal pivot 4. Footrest pivot 5. Throttle-to-handlebar contact 6. Drive chain 7. Throttle roller cable...

Page 64

3-20 electrical electrical checking the spark plug 1. Remove: • spark plug 2. Inspect: • electrode "1" wear/damage → replace. • insulator color "2" normal condition is a medium to light tan color. Distinctly different color → check the engine condition. When the engine runs for many hours at low spe...

Page 65

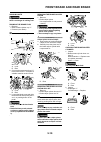

4-1 seat, fuel tank and side covers engine this section is intended for those who have basic knowledge and skill concerning the servicing of yamaha motorcycles (e.G., yamaha dealers, service engineers, etc.). Those who have little knowledge and skill concerning servicing are request- ed not to under...

Page 66

4-2 seat, fuel tank and side covers removing the side cover 1. Remove: • bolt (side cover) • side cover (left and right) "1" draw the side cover backward to re- move it because its claws "a" are in- serted in the air filter case. Removing the number plate 1. Remove: • bolt (number plate) • number pl...

Page 67

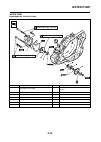

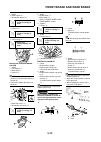

4-3 exhaust pipe and silencer exhaust pipe and silencer removing the exhaust pipe and silencer order part name q'ty remarks right side cover refer to "seat, fuel tank and side covers" section. 1 bolt (silencer) 2 2 washer [ø=26 mm (1.02 in)] 1 3 washer [ø=22 mm (0.87 in)] 1 4 silencer 1 5 collar [l=...

Page 68

4-4 exhaust pipe and silencer changing the silencer fiber 1. Remove: • side cover (right) • bolt (silencer) "1" • silencer "2" • bolt (fiber) "3" 2. Remove: • inner pipe "1" 3. Replace: • fiber "2" 4. Install: • inner pipe fully apply quick gasket ® (yamaha bond no.1215) or equivalent as shown. 5. I...

Page 69

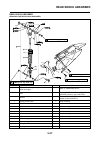

4-5 radiator radiator removing the radiator order part name q'ty remarks drain the coolant. Refer to "changing the coolant" sec- tion in the chapter 3. Seat and fuel tank refer to "seat, fuel tank and side covers" section. 1 radiator guard 2 2 radiator hose clamp (radiator hose 2) 2 only loosening. ...

Page 70

4-6 radiator handling note do not remove the radiator cap when the engine and radiator are hot. Scalding hot fluid and steam may be blown out under pressure, which could cause serious injury. When the engine has cooled, open the radiator cap by the following procedure: place a thick rag, like a towe...

Page 71

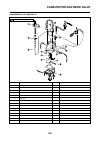

4-7 carburetor and reed valve carburetor and reed valve removing the carburetor and reed valve order part name q'ty remarks fuel tank refer to "seat, fuel tank and side covers" section. 1 solenoid valve lead 1 disconnect the solenoid valve lead. 2 throttle position sensor lead 1 disconnect the throt...

Page 72

4-8 carburetor and reed valve disassembling the carburetor order part name q'ty remarks 1 mixing chamber top 1 2 throttle valve 1 refer to removal section. 3 needle holder 1 4 jet needle 1 5 float chamber 1 6 float pin 1 7 float 1 8 needle valve 1 9 main jet 1 10 pilot jet 1 11 starter plunger 1 12 ...

Page 73

4-9 carburetor and reed valve handling note do not loosen the screw (throttle position sensor) "1" except when changing the throttle position sen- sor due to failure because it will cause a drop in engine perfor- mance. Removing the throttle valve 1. Remove: • throttle valve "1" • ring "2" • spring ...

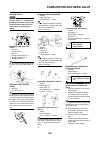

Page 74

4-10 carburetor and reed valve checking the float 1. Inspect: • float "1" damage → replace. Checking the reed valve 1. Measure: • reed valve bending "a" out of specification → replace. 2. Measure: • valve stopper height "a" out of specification → adjust stop- per/replace valve stopper. Installing th...

Page 75

4-11 carburetor and reed valve 4. Install: • starter plunger "1" 5. Install: • pilot jet "1" • main jet "2" 6. Install: • needle valve "1" • float "2" • float pin "3" • after installing the needle valve to the float, install them to the carbure- tor. • check the float for smooth move- ment. 7. Insta...

Page 76

4-12 carburetor and reed valve 3. Tighten: • screw (air cleaner joint) "1" place the screw head "a" with its top as shown and secure the clamp in alignment with the horizontal line "b" that passes the center of the carbure- tor. 4. Connect: • throttle position sensor lead "1" • solenoid valve lead "...

Page 77

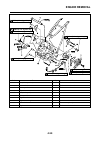

4-13 cylinder head, cylinder and piston cylinder head, cylinder and piston removing the cylinder head and cylinder order part name q'ty remarks seat and fuel tank refer to "seat, fuel tank and side covers" section. Exhaust pipe and silencer refer to "exhaust pipe and silencer" section. Radiator hose...

Page 78

4-14 cylinder head, cylinder and piston removing the piston and power valve order part name q'ty remarks 1 piston pin clip 2 refer to removal section. 2 piston pin 1 refer to removal section. 3 piston 1 refer to removal section. 4 small end bearing 1 refer to removal section. 5 piston ring 2 refer t...

Page 79

4-15 cylinder head, cylinder and piston removing the push rod 1. Remove: • bolt (push rod) "1" • push rod "2" insert the set pin "3" included in own- er's tool kit to remove the bolt (push rod). Be sure to use the set pin. If the set pin is not used, the power valve constituent parts will result in ...

Page 80

4-16 cylinder head, cylinder and piston 3. Measure: • cylinder bore "c" use cylinder gauge "1". Out of specification → replace. Measure the cylinder bore "c" in par- allel (a, b, c) to and at right angles to the crankshaft (a, b). Then, find the average of the measurements. Checking the piston 1. El...

Page 81

4-17 cylinder head, cylinder and piston 3. Measure: • side clearance use a thickness gauge "1". Out of specification → replace piston and/or ring. Check at several points. Checking the piston clearance 1. Calculate: • piston clearance out of specification → replace piston, and piston ring and/or cyl...

Page 82

4-18 cylinder head, cylinder and piston installing the power valve 1. Install: • power valve 1 "1" • valve holder 2 "2" • bolt (valve holder 2) "3" • install the power valve 1 with its gouge "a" facing upside. • apply the molybdenum disulfide oil on the power valve 1. 2. Install: • power valve 2 "1"...

Page 83

4-19 cylinder head, cylinder and piston installing the piston ring and piston 1. Install: • piston ring "1" • take care not to scratch the piston or damage the piston ring. • align the piston ring gap with the pin "2". • after installing the piston ring, check the smooth movement of it. 2. Install: ...

Page 84

4-20 cylinder head, cylinder and piston 5. Install: • gasket (power valve housing) • power valve housing "1" • bolt (power valve housing) "2" 6. Install: • o-ring "1" • dowel pin "2" apply the lithium soap base grease on the o-rings. 7. Install: • cylinder head "1" • copper washer "2" • nut (cylinde...

Page 85

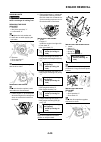

4-21 clutch clutch removing the clutch order part name q'ty remarks drain the transmission oil. Refer to "changing the transmission oil" section in the chapter 3. Bolt (brake pedal) shift the brake pedal downward. Rotor and stator refer to "cdi magneto" section. Clutch cable disconnect at engine sid...

Page 86

4-22 clutch removing the clutch boss order part name q'ty remarks 1 push rod 1 1 2 circlip 1 3 washer 1 4 bearing 1 5 push rod 2 1 6 nut (clutch boss) 1 refer to removal section. 7 lock washer 1 refer to removal section. 8 clutch boss 1 refer to removal section. 9 thrust washer [d=ø44mm (1.73 in)] 1...

Page 87

4-23 clutch removing the clutch boss 1. Remove: • nut "1" • lock washer "2" • clutch boss "3" straighten the lock washer tab and use the clutch holding tool "4" to hold the clutch boss. A. For usa and cdn b. Except for usa and cdn checking the clutch housing and boss 1. Inspect: • clutch housing "1"...

Page 88

4-24 clutch 2. Install: • thrust washer [d=ø44 mm (1.73 in)] "1" • clutch boss "2" 3. Install: • lock washer "1" • nut (clutch boss) "2" use the clutch holding tool "3" to hold the clutch boss. A. For usa and cdn b. Except for usa and cdn 4. Bend the lock washer "1" tab. 5. Install: • friction plate...

Page 89

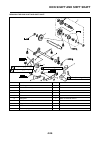

4-25 kick shaft and shift shaft kick shaft and shift shaft removing the primary drive gear order part name q'ty remarks drain the transmission oil. Refer to "changing the transmission oil" section in the chapter 3. Bolt (brake pedal) shift the brake pedal downward. Radiator hose 4 disconnect at wate...

Page 90

4-26 kick shaft and shift shaft removing the kick shaft and shift shaft order part name q'ty remarks 1 kick idle gear 1 2 kick shaft assembly 1 refer to removal section. 3 shift pedal 1 4 shift shaft 1 5 roller 1 6 shift guide 1 refer to removal section. 7 shift lever assembly 1 refer to removal sec...

Page 91

4-27 kick shaft and shift shaft removing the primary drive gear 1. Loosen: • bolt (primary drive gear) "1" place an aluminum plate "a" between the teeth of the primary drive gear "2" and driven gear "3". Removing the kick shaft assembly 1. Remove: • kick shaft assembly "1" unhook the torsion spring ...

Page 92

4-28 kick shaft and shift shaft installing the segment 1. Install: • segment "1" • bolt (segment) align the notch "a" on the segment with the pin "b" on the shift cam. If the segment gets an impact, the stopper lever may be damaged. Take care not to give an impact to it when tightening the bolt. Ins...

Page 93

4-29 kick shaft and shift shaft 3. Install: • spring guide "1" slide the spring guide into the kick shaft, make sure the groove "a" in the spring guide fits on the stopper of the torsion spring. 4. Install: • washer "1" • kick shaft assembly "2" • apply the molybdenum disulfide grease on the contact...

Page 94

4-30 kick shaft and shift shaft 8. Install: • shift pedal "1" • bolt (shift pedal) "2" install the shift pedal so that the top of the shift pedal outer diameter "a" is highest without exceeding the line "b" connecting the center of the shift shaft and bottom of the screw [crank- case cover (left)] "...

Page 95

4-31 ypvs governor ypvs governor removing the ypvs governor order part name q'ty remarks crankcase cover (right) refer to "kick shaft and shift shaft" section. 1 governor assembly 1 2 dowel pin 1 refer to removal section. 3 retainer 1 4 ball 4 5 retainer weight 1 6 washer 4 7 thrust bearing 2 8 coll...

Page 96

4-32 ypvs governor removing the governor 1. Remove: • dowel pin "1" while compressing the spring, re- move the dowel pin. Checking the governor groove 1. Inspect: • washer "1" • collar "2" wear/damage → replace. Checking the bearing 1. Inspect: • thrust bearing "1" • washer "2" wear/damage → replace...

Page 97

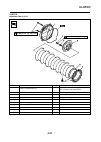

4-33 water pump water pump disassembling the water pump order part name q'ty remarks crankcase cover (right) refer to "kick shaft and shift shaft" section. 1 water pump housing cover 1 2 impeller 1 refer to removal section. 3 washer 1 refer to removal section. 4 impeller shaft 1 refer to removal sec...

Page 98

4-34 water pump removing the impeller shaft 1. Remove: • impeller "1" • washer "2" • impeller shaft "3" hold the impeller shaft on its width across the flats "a" with spanners, etc. And remove the impeller. Removing the oil seal it is not necessary to disassemble the water pump, unless there is an a...

Page 99

4-35 water pump 4. Install: • water pump housing cover "1" • bolt (water pump housing cover) "2" • copper washer (coolant drain bolt) "3" • coolant drain bolt "4" bolt (water pump hous- ing cover): 10 nm (1.0 m•kg, 7.2 ft•lb) coolant drain bolt: 10 nm (1.0 m•kg, 7.2 ft•lb).

Page 100

4-36 cdi magneto cdi magneto removing the cdi magneto order part name q'ty remarks seat and fuel tank refer to "seat, fuel tank and side covers" section. Bolt (radiator) refer to "radiator" section. Disconnect the cdi magneto lead. 1 left crankcase cover 1 2 nut (rotor) 1 refer to removal section. 3...

Page 101

4-37 cdi magneto removing the rotor 1. Remove: • nut (rotor) "1" • washer "2" use the rotor holding tool "3". 2. Remove: • rotor "1" use the flywheel puller "2". When installing the flywheel puller, turn it counterclockwise. Checking the cdi magneto 1. Inspect: • rotor inner surface "a" • stator out...

Page 102

4-38 engine removal engine removal removing the engine order part name q'ty remarks hold the machine by placing the suitable stand under the frame. Refer to "handling note". Drain the transmission oil. Refer to "changing the transmission oil" section in the chapter 3. Seat and fuel tank refer to "se...

Page 103

4-39 engine removal 3 nut (drive sprocket) 1 refer to removal section. 4 lock washer 1 refer to removal section. 5 drive sprocket 1 refer to removal section. 6 clip 1 7 bolt (brake pedal) 1 8 brake pedal 1 9 engine bracket 2 10 engine mounting bolt 3 11 pivot shaft 1 remove completely. 12 engine 1 r...

Page 104

4-40 engine removal handling note support the machine securely so there is no danger of it falling over. Removing the drive sprocket 1. Remove: • nut (drive sprocket) "1" • lock washer "2" • straighten the lock washer tab. • loosen the nut while applying the rear brake. 2. Remove: • drive sprocket "...

Page 105

4-41 engine removal 2. Install: • lock washer "1" • nut (drive sprocket) "2" tighten the nut while applying the rear brake. 3. Bend the lock washer tab to lock the nut. 4. Install: • drive chain sprocket guide "1" • drive chain sprocket cover "2" • screw (drive chain sprocket cov- er) "3" 5. Connect...

Page 106

4-42 crankcase and crankshaft crankcase and crankshaft removing the crankshaft order part name q'ty remarks engine refer to "engine removal" section. Piston refer to "cylinder head, cylinder and piston" section. Primary drive gear refer to "kick shaft and shift shaft" section. Kick idle gear refer t...

Page 107

4-43 crankcase and crankshaft 9 crankcase (left) 1 refer to removal section. 10 crankshaft 1 refer to removal section. 11 oil seal 2 12 bearing 2 refer to removal section. Order part name q'ty remarks 10 nm (1.0 m kg, 7.2 ft lb) 10 nm (1.0 m kg, 7.2 ft lb) 30 nm (3.0 m kg, 22 ft lb) 14 nm (1.4 m kg,...

Page 108

4-44 crankcase and crankshaft removing the segment 1. Remove: • bolt (segment) "1" • segment "2" turn the segment counterclockwise until it stops and loosen the bolt. If the segment gets an impact, the stopper lever may be damaged. Take care not to give an impact to it when removing the bolt. Disass...

Page 109

4-45 crankcase and crankshaft installing the crankcase bearing 1. Install: • bearing "1" to left and right crankcase. • apply the engine oil on the bearing. • install the bearing by pressing its outer race parallel. Installing the oil seal 1. Install: • oil seal (left) "1" • oil seal (right) "2" • a...

Page 110

4-46 crankcase and crankshaft 6. Install: • holder "1" • bolt (holder) "2" • bolt (crankcase) tighten the crankcase tightening bolts in stage, using a crisscross pat- tern. 7. Install: • tension spring "1" • holder "2" • bolt (holder) "3" install the holder so that it contacts the projection "a" on ...

Page 111

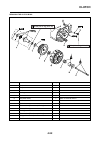

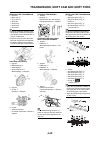

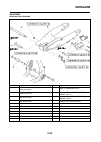

4-47 transmission, shift cam and shift fork transmission, shift cam and shift fork removing the transmission, shift cam and shift fork order part name q'ty remarks engine refer to "engine removal" section. Separate the crankcase. Refer to "crankcase and crank- shaft" section. 1 main axle 1 refer to ...

Page 112

4-48 transmission, shift cam and shift fork removing the transmission 1. Remove: • main axle "1" • drive axle "2" • shift cam • shift fork 3 • shift fork 2 • shift fork 1 • remove assembly carefully. Note the position of each part. Pay partic- ular attention to the location and di- rection of shift ...

Page 113

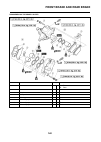

4-49 transmission, shift cam and shift fork 3. Install: • washer "1" • circlip "2" • be sure the circlip sharp-edged cor- ner "a" is positioned opposite side to the washer and gear "b". • be sure the circlip end "c" is posi- tioned at axle spline groove "d". 4. Install: • collar "1" • apply the lith...

Page 114

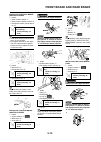

5-1 front wheel and rear wheel chassis this section is intended for those who have basic knowledge and skill concerning the servicing of yamaha motorcycles (e.G., yamaha dealers, service engineers, etc.). Those who have little knowledge and skill concerning servicing are request- ed not to undertake...

Page 115

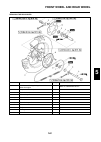

5-2 front wheel and rear wheel removing the rear wheel order part name q'ty remarks hold the machine by placing the suitable stand under the engine. Refer to "handling note". 1 nut (rear wheel axle) 1 2 rear wheel axle 1 3 drive chain puller 2 4 rear wheel 1 refer to removal section. 5 collar 2 6 re...

Page 116

5-3 front wheel and rear wheel handling note support the machine securely so there is no danger of it falling over. Removing the rear wheel 1. Remove: • wheel "1" push the wheel forward and remove the drive chain "2". Removing the wheel bearing 1. Remove: • bearing "1" remove the bearing using a gen...

Page 117

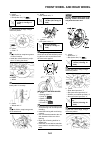

5-4 front wheel and rear wheel 2. Install: • brake disc "1" • bolt (brake disc) "2" tighten the bolts in stage, using a crisscross pattern. 3. Install: • collar "1" • apply the lithium soap base grease on the oil seal lip. • install the collars with their projec- tions "a" facing the wheel. 4. Insta...

Page 118

5-5 front wheel and rear wheel 4. Install: • collar "1" apply the lithium soap base grease on the oil seal lip. 5. Install: • wheel install the brake disc "1" between the brake pads "2" correctly. 6. Install: • drive chain "1" push the wheel "2" forward and install the drive chain. 7. Install: • lef...

Page 119

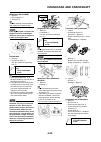

5-6 front brake and rear brake front brake and rear brake removing the front brake order part name q'ty remarks hold the machine by placing the suitable stand under the engine. Refer to "handling note". Drain the brake fluid. Refer to removal section. 1 brake hose holder (protector) 2 2 union bolt 2...

Page 120

5-7 front brake and rear brake removing the rear brake order part name q'ty remarks hold the machine by placing the suitable stand under the engine. Refer to "handling note". Rear wheel refer to "front wheel and rear wheel" section. Drain the brake fluid. Refer to removal section. 1 brake pedal 1 2 ...

Page 121

5-8 front brake and rear brake disassembling the brake caliper order part name q'ty remarks a. Front b. Rear a b 1 pad pin 1 1 2 brake pad 2 2 3 pad support 1 1 4 brake caliper piston 2 1 refer to removal section. 5 brake caliper piston dust seal 2 1 refer to removal section. 6 brake caliper piston ...

Page 122

5-9 front brake and rear brake disassembling the brake master cylinder order part name q'ty remarks a. Front b. Rear 1 brake master cylinder cap 1 2 diaphragm 1 3 reservoir float 1 4 push rod (front) 1 5 brake master cylinder boot 1 6 circlip 1 use a long nose circlip pliers. 7 washer 1 8 push rod (...

Page 123

5-10 front brake and rear brake handling note support the machine securely so there is no danger of it falling over. Draining the brake fluid 1. Remove: • brake master cylinder cap "1" • protector (rear brake) do not remove the diaphragm. A. Front b. Rear 2. Connect the transparent hose "2" to the b...

Page 124

5-11 front brake and rear brake 3. Inspect: (front brake only) • reservoir float "1" damage → replace. 4. Inspect: • brake master cylinder piston "1" • brake master cylinder cup "2" wear/damage/score marks → replace brake master cylinder kit. Checking the brake caliper 1. Inspect: • brake caliper cy...

Page 125

5-12 front brake and rear brake 2. Install: • brake caliper "1" • bolt (brake caliper) "2" 3. Tighten: • pad pin "3" 4. Install: • pad pin plug "4" installing the rear brake caliper 1. Install: • pad support "1" • brake pad "2" • pad pin "3" • install the brake pads with their pro- jections "a" into...

Page 126

5-13 front brake and rear brake installing the front brake master cylinder 1. Install: • brake master cylinder "1" • brake master cylinder bracket "2" • bolt (brake master cylinder brack- et) "3" • install the bracket so that the arrow mark "a" face upward. • first tighten the bolts on the upper sid...

Page 127

5-14 front brake and rear brake 2. Install: • brake hose holder "1" • bolt (brake hose holder) "2" align the top "a" of the brake hose holder with the paint "b" of the brake hose. 3. Pass the brake hose through the cable guide "1". 4. Install: • copper washer "1" • brake hose "2" • union bolt "3" al...

Page 128

5-15 front brake and rear brake 2. Air bleed: • brake system refer to "bleeding the hy- draulic brake system" sec- tion in the chapter 3. 3. Inspect: • brake fluid level fluid at lower level → fill up. Refer to "checking the brake fluid level" section in the chapter 3. 4. Install: • reservoir float ...

Page 129

5-16 front fork front fork removing the front fork order part name q'ty remarks hold the machine by placing the suitable stand under the engine. Refer to "handling note". Front wheel refer to "front wheel and rear wheel" section. Front brake caliper refer to "front brake and rear brake" section. Num...

Page 130

5-17 front fork disassembling the front fork order part name q'ty remarks 1 adjuster 1 drain the fork oil. Refer to removal section. 2 fork spring 1 3 dust seal 1 refer to removal section. 4 stopper ring 1 refer to removal section. 5 inner tube 1 refer to removal section. 6 outer tube 1 7 piston met...

Page 131

5-18 front fork handling note support the machine securely so there is no danger of it falling over. The front fork requires careful atten- tion. So it is recommended that the front fork be maintained at the deal- ers. To prevent an accidental explosion of air, the following instructions should be o...

Page 132

5-19 front fork checking the base valve 1. Inspect: • base valve "1" wear/damage → replace. Contamination → clean. • o-ring "2" wear/damage → replace. • piston metal "3" wear/damage → replace. • spring "4" damage/fatigue → replace base valve. • air bleed screw "5" wear/damage → replace. Checking the...

Page 133

5-20 front fork 6. Tighten: • locknut "1" fully finger tighten the locknut onto the damper assembly. 7. Loosen: • compression damping adjuster "1" • loosen the compression damping adjuster finger tight. • record the set position of the ad- juster (the amount of turning out the fully turned in positi...

Page 134

5-21 front fork 17. Install: • outer tube "1" to inner tube "2". 18. Install: • slide metal "1" • oil seal washer "2" to outer tube slot. Press the slide metal into the outer tube with fork seal driver "3". 19. Install: • oil seal "1" press the oil seal into the outer tube with fork seal driver "2"....

Page 135

5-22 front fork 28. Inspect: • gap "a" between the adjuster "1" and locknut "2". Out of specification → retighten and readjust the locknut. If the adjuster is installed out of spec- ification, proper damping force can- not be obtained. 29. Tighten: • adjuster (locknut) "1" hold the locknut "2" and t...

Page 136

5-23 front fork 4. Tighten: • pinch bolt (upper bracket) "1" • pinch bolt (lower bracket) "2" tighten the lower bracket to speci- fied torque. If torqued too much, it may cause the front fork to mal- function. 5. Install: • protector "1" • bolt (protector) "2" 6. Adjust: • rebound damping force turn...

Page 137

5-24 handlebar handlebar removing the handlebar order part name q'ty remarks number plate remove the band only. 1 clutch cable 1 disconnect at the lever side. 2 clutch lever holder 1 3 engine stop switch 1 4 brake master cylinder 1 refer to removal section. 5 throttle cable cap 1 turn over the cap c...

Page 138

5-25 handlebar disassembling the throttle order part name q'ty remarks 1 grip cap (lower) 1 2 grip cap (upper) 1 3 grip assembly 1 4 grip (right) 1 refer to removal section. 5 tube guide 1.

Page 139

5-26 handlebar removing the brake master cylinder 1. Remove: • brake master cylinder bracket "1" • brake master cylinder "2" • do not let the brake master cylin- der hang on the brake hose. • keep the brake master cylinder cap side horizontal to prevent air from coming in. Removing the grip 1. Remov...

Page 140

5-27 handlebar 3. Tighten: • nut (handlebar lower holder) "1" 4. Install: • left grip "1" apply the adhesive to the handle- bar "2". • before applying the adhesive, wipe off grease or oil on the handlebar surface "a" with a lacquer thinner. • install the left grip to the handlebar so that the line "...

Page 141

5-28 handlebar 13. Install: • engine stop switch "1" • clutch lever holder "2" • bolt (clutch lever holder) "3" • clamp "4" • the engine stop switch, clutch lever holder and clamp should be in- stalled according to the dimensions shown. • pass the engine stop switch lead in the middle of the clutch ...

Page 142

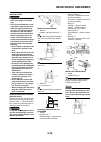

5-29 steering steering removing the steering order part name q'ty remarks tightening steps: • tighten ring nut. 38 nm (3.8 m•kg, 27 ft•lb) • loosen it one turn. • retighten it. 7 nm (0.7 m•kg, 5.1 ft•lb) hold the machine by placing the suitable stand under the engine. Refer to "handling note". Numbe...

Page 143

5-30 steering handling note support the machine securely so there is no danger of it falling over. Removing the steering ring nut 1. Remove: • steering ring nut "1" use the steering nut wrench "2". Support the steering stem so that it may not fall down. Removing the lower bearing 1. Remove: • lower ...

Page 144

5-31 steering 6. Install: • washer "1" 7. Install: • front fork "1" • upper bracket "2" • temporarily tighten the pinch bolts (lower bracket). • do not tighten the pinch bolts (up- per bracket) yet. 8. Install: • washer "1" • steering stem nut "2" 9. After tightening the nut, check the steering for ...

Page 145

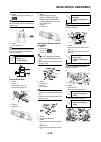

5-32 swingarm swingarm removing the swingarm order part name q'ty remarks hold the machine by placing the suitable stand under the engine. Refer to "handling note". Brake hose holder refer to "front brake and rear brake" section. Rear brake caliper refer to "front brake and rear brake" section. Bolt...

Page 146

5-33 swingarm disassembling the swingarm order part name q'ty remarks 1 cap 2 refer to removal section. 2 relay arm 1 3 connecting rod 1 4 collar 2 5 oil seal 2 6 thrust bearing 2 7 bushing 2 8 oil seal 8 9 bearing 10 refer to removal section..

Page 147

5-34 swingarm handling note support the machine securely so there is no danger of it falling over. Removing the cap 1. Remove: • left cap "1" remove with a slotted-head screw- driver inserted under the mark "a" on the left cap. Removing the bearing 1. Remove: • bearing "1" remove the bearing by pres...

Page 148

5-35 swingarm installing the swingarm 1. Install: • bushing "1" • thrust bearing "2" • oil seal "3" • collar "4" to swingarm "5". Apply the molybdenum disulfide grease on the bushings, thrust bear- ings, oil seal lips and contact surfaces of the collar and thrust bearing. 2. Install: • collar "1" • ...

Page 149

5-36 swingarm 10. Tighten: • nut (connecting rod) "1" 11. Tighten: • nut (relay arm) "1" 12. Install: • cap "1" install the right cap with its mark "a" facing forward. 13. Install: • bolt (lower chain tensioner) "1" • washer "2" • collar "3" • lower chain tensioner "4" • nut (lower chain tensioner) ...

Page 150

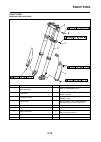

5-37 rear shock absorber rear shock absorber removing the rear shock absorber order part name q'ty remarks hold the machine by placing the suitable stand under the engine. Refer to "handling note". Seat refer to "seat, fuel tank and side covers" section in the chapter 4. Silencer refer to "exhaust p...

Page 151

5-38 rear shock absorber handling note • support the machine securely so there is no danger of it falling over. • this rear shock absorber is pro- vided with a separate type tank filled with high-pressure nitro- gen gas. To prevent the danger of explosion, read and under- stand the following informa...

Page 152

5-39 rear shock absorber 2. Install: • stopper ring (upper bearing) "1" after installing the stopper ring, push back the bearing until it contacts the stopper ring. 3. Install: • lower bearing "1" install the bearing by pressing it on the side having the manufacture's marks or numbers. Installing th...

Page 153

5-40 rear shock absorber 7. Tighten: • bolt (air filter joint) "1".

Page 154

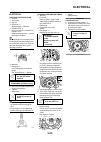

6-1 electrical components and wiring diagram electrical this section is intended for those who have basic knowledge and skill concerning the servicing of yamaha motorcycles (e.G., yamaha dealers, service engineers, etc.). Those who have little knowledge and skill concerning servicing are request- ed...

Page 155

6-2 ignition system ignition system inspection steps use the following steps for checking the possibility of the malfunctioning engine being attributable to ignition system failure and for checking the spark plug which will not spark. *marked: only when the ignition checker is used. • remove the fol...

Page 156

6-3 ignition system spark gap test 1. Disconnect the spark plug cap from spark plug. 2. Connect the dynamic spark tester "1" (ignition checker "2") as shown. • ignition coil "3" • spark plug "4" a. For usa and cdn b. Except for usa and cdn 3. Kick the kickstarter lever. 4. Check the ignition spark g...

Page 157

6-4 ignition system 2. Inspect: • charging coil 1 resistance out of specification → replace. 3. Inspect: • charging coil 2 resistance out of specification → replace. Checking the neutral switch 1. Inspect: • neutral switch conduction not conductive while it is in neutral → replace. Conductive while ...

Page 158

6-5 solenoid valve system solenoid valve system inspection steps if the solenoid valve will not operate, use the following inspection steps. *marked: refer to "ignition system" section. • remove the following parts before inspection. 1. Seat 2. Fuel tank • use 12v battery in this inspection. • use t...

Page 159

6-6 solenoid valve system checking the couplers and leads connection 1. Check: • couplers and leads connection rust/ dust/ looseness/short-cir- cuit → repair or replace. Checking the solenoid valve operation 1. Disconnect the solenoid valve coupler. 2. Connect 12v battery to the sole- noid valve cou...

Page 160

6-7 throttle position sensor system throttle position sensor system inspection steps if the throttle position sensor will not operate, use the following inspection steps. *marked: refer to "ignition system" section. • remove the following parts before inspection. 1. Seat 2. Fuel tank • use the follo...

Page 161

6-8 throttle position sensor system handling note do not loosen the screw (throttle position sensor) "1" except when changing the throttle position sen- sor due to failure because it will cause a drop in engine perfor- mance. Checking the couplers and leads connection 1. Check: • couplers and leads ...

Page 162

6-9 throttle position sensor system 8. Start the engine. 9. Adjust: • throttle position sensor output voltage adjustment steps: a. Adjust the installation angle of the throttle position sensor "1" to ob- tain the specified output voltage. 10. Put the aligning marks "a" on the throttle position senso...

Page 163

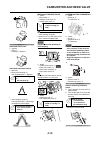

7-1 engine tuning engine carburetor setting • the role of fuel is to cool the engine, and in the case of a 2-stroke en- gine, to lubricate the engine in addi- tion to power generation. Accordingly, if a mixture of air and fuel is too lean, abnormal combus- tion will occur, and engine seizure may res...

Page 164

7-2 engine adjusting the power jet the richness of air-fuel mixture under 8,500 rpm to the extent of 1/2 to full opened throttle can be set by chang- ing the power jet "1". A larger size jet results in a richer mixture, and a smaller size in a leaner mixture. Adjusting the pilot air screw the richne...

Page 165

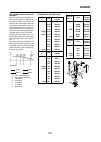

7-3 engine relationship with throttle opening the flow of the fuel through the car- buretor main system is controlled by the main jet and then, it is further reg- ulated by the area between the main nozzle and the jet needle. On the re- lationship between the fuel flow and the throttle opening, the ...

Page 166

7-4 engine road condition and examples of carburetor setting a. For usa and cdn b. Except for usa and cdn optimum pilot air screw setting can be obtained by adding the ex-factory number of the same screw back-out turns to any required value provided in the chart. For example, if the ex-factory numbe...

Page 167

7-5 engine examples of carburetor setting depending on symptom this should be taken simply for an example. It is necessary to set the carburetor while checking the operating conditions of the engine and discoloration of spark plugs. Normally, carburetor setting is made by means of the main jet, need...

Page 168

7-6 chassis change of the heat range of spark plugs judging from the discoloration of spark plugs, if they are found improp- er, it can be corrected by the following two methods; changing carburetor settings and changing the heat range of spark plug. • in principle, it is advisable to first use spar...

Page 169

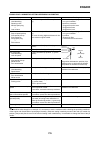

7-7 chassis front fork setting the front fork setting should be made depending on the rider's feeling of an actual run and the circuit conditions. The front fork setting includes the fol- lowing three factors: 1. Setting of air spring characteris- tics • change the fork oil amount. 2. Setting of spr...

Page 170

7-8 chassis choosing set length 1. Place a stand or block under the engine to put the rear wheel above the floor, and measure the length "a" between the rear wheel axle center and the rear fender holding bolt. 2. Remove the stand or block from the engine and with a rider astride the seat, measure th...

Page 171

7-9 chassis • extent of adjustment (spring pre- load) for the spring preload adjustment, re- fer to "adjusting the rear shock absorber spring pre- load" in the chapter 3. Spring part number (-22212-) maximum minimum 5un-00 5un-10 5un-20 5un-30 5un-40 5un-50 5un-60 5un-70 5un-a0 5un-b0 5un-c0 5un-d0 ...

Page 172

7-10 chassis suspension setting (front fork) • if any of the following symptoms is experienced with the standard position as the base, make resetting by reference to the adjustment procedure given in the same chart. • before any change, set the rear shock absorber sunken length to the standard figur...

Page 173

7-11 chassis suspension setting (rear shock absorber) • if any of the following symptoms is experienced with the standard position as the base, make resetting by reference to the adjustment procedure given in the same chart. • adjust the rebound damping in 2-click increments or decrements. • adjust ...

Page 174

Printed in japan (e) printed on recycled paper.