- DL manuals

- Yamaha

- Motorcycle

- 2013 FJR1300AS

- Service Manual

Yamaha 2013 FJR1300AS Service Manual

Summary of 2013 FJR1300AS

Page 1

2013 service manual fjr1300as 1md-28197-e0

Page 2

Eas20040 fjr1300as 2013 service manual ©2013 by yamaha motor co., ltd. First edition, february 2013 all rights reserved. Any reproduction or unauthorized use without the written permission of yamaha motor co., ltd. Is expressly prohibited..

Page 3: Important

Eas20071 important this manual was produced by the yamaha motor company, ltd. Primarily for use by yamaha dealers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one man- ual. Therefore, anyone who uses this book to perform maintenance and repairs on y...

Page 4: How to Use This Manual

Eas20090 how to use this manual this manual is intended as a handy, easy-to-read reference book for the mechanic. Comprehensive explanations of all installation, removal, disassembly, assembly, repair and check procedures are laid out with the individual steps in sequential order. • the manual is di...

Page 5: Symbols

Eas20101 symbols the following symbols are used in this manual for easier understanding. Tip the following symbols are not relevant to every vehicle. Symbol definition symbol definition serviceable with engine mounted gear oil filling fluid molybdenum disulfide oil lubricant brake fluid special tool...

Page 7: Table of Contents

Eas20110 table of contents general information 1 specifications 2 periodic checks and adjustments 3 chassis 4 engine 5 cooling system 6 fuel system 7 electrical system 8 troubleshooting 9.

Page 9: General Information

1 general information identification ............................................................................................ 1-1 vehicle identification number ..................................................... 1-1 model label......................................................................

Page 10: Identification

Identification 1-1 eas20130 identification eas20140 vehicle identification number the vehicle identification number “1” is stamped into the right side of the steering head pipe. Eas20150 model label the model label “1” is affixed to the frame. This information will be needed to order spare parts. 1.

Page 11: Features

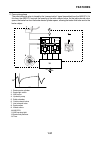

Features 1-2 eas20170 features et2c01025 outline of the fi system the main function of a fuel supply system is to provide fuel to the combustion chamber at the optimum air-fuel ratio in accordance with the engine operating conditions and the atmospheric temperature. In the conventional carburetor sy...

Page 12: Features

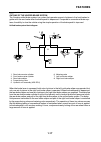

Features 1-3 et3p61042 fi system the fuel pump delivers fuel to the fuel injector via the fuel filter. The pressure regulator maintains the fuel pressure that is applied to the fuel injector at only 324 kpa (3.24 kg/cm², 47.0 psi). Accordingly, when the energizing signal from the ecu energizes the f...

Page 13: Features

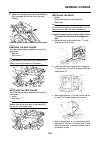

Features 1-4 eas1md1015 outline of the ycc-s (yamaha chip controlled-shift) system and ycc-t (yamaha chip controlled-throttle) mechanism characteristics of the ycc-t yamaha developed the ycc-t system employing the most advanced electronic control technologies. Electronic control throttle systems hav...

Page 14: Features

Features 1-5 mechanism characteristics of the ycc-s ycc-s offers more enjoyable and easy riding by eliminating the need for the user to operate the clutch, which also reduces fatigue during long touring. Ycc-s is not an automatic transmission, although it allows the user to shift gears by foot or ha...

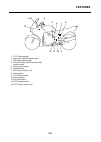

Page 15: Features

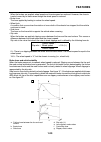

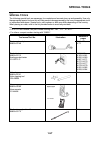

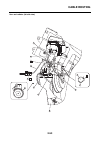

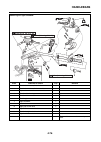

Features 1-6 13 1,2,3 4 5 6 8 11 12 7 10 9 1. Ycc-s warning light 2. Stop mode function indicator light 3. Shift down indicator light 4. Hand shift lever switch and stop mode function switch 5. Gear position sensor 6. Neutral switch 7. Mcu (motor control unit) 8. Shift actuator 9. Ycc-s control rela...

Page 16: Features

Features 1-7 shift pattern this vehicle is equipped with a constant-mesh 5-speed transmission. The gears can be shifted using either the shift pedal “1” or the hand shift switch “2”. The gear positions are shown in the illustration. Attention • do not turn the main switch to “off” while the vehicle ...

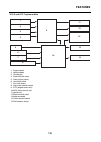

Page 17: Features

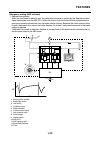

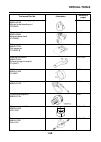

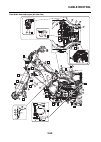

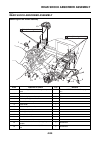

Features 1-8 ycc-s and ycc-t system outline 4 10 9 3 5 6 7 8 2 1 14 11 12 13 15 1. Engine speed 2. Vehicle speed 3. Throttle grip 4. Electric throttle valve 5. Gear position sensor 6. Hand shift switch 7. Foot shift sensor 8. Stop mode function switch 9. Ecu (engine control unit) 10. Mcu (motor cont...

Page 18: Features

Features 1-9 eas1mc1087 outline of the cruise control system this model is equipped with a cruise control system designed to maintain a set cruising speed. Be- cause the vehicle is equipped with the ycc-t system, the cruise control system can be controlled elec- tronically. Based on the signals that...

Page 19: Features

Features 1-10 warning ewa1mc1006 • improper use of the cruise control system may result in loss of control, which could lead to an accident. Do not activate the cruise control system in heavy traffic, poor weather conditions, or among winding, slippery, hilly, rough or gravel roads. • when traveling...

Page 20: Features

Features 1-11 adjusting the set cruising speed while the cruise control system is operating, push the “res+” side of the cruise control setting switch to increase the set cruising speed or the “set–” side to decrease the set speed. Tip • pushing the setting switch once will change the speed in incre...

Page 21: Features

Features 1-12 using the resume function push the “res+” side of the cruise control setting switch to reactivate the cruise control system. The traveling speed will return to the previously set cruising speed. The cruise control setting indicator light “set” will come on. If the “set–” side of the cr...

Page 22: Features

Features 1-13 automatic deactivation of the cruise control system the cruise control system for this model is electronically controlled and is linked with the other control systems. The cruise control system will automatically become deactivated under the following condi- tions: • the cruise control...

Page 23: Features

Features 1-14 meter displays during cruise control system operation self-diagnosis device the cruise control system will also become deactivated when an irregularity with any of the vehicle sys- tems is detected. The cruise control setting indicator light “set” will go off and the cruise control sys...

Page 24: Features

Features 1-15 notice eca1mc1006 if the display indicates a fault code, the vehicle should be checked as soon as possible in order to avoid engine damage. Tip • if the cruise control system turned off because a malfunction was detected by the fi self-diagnosis, the cruise control power switch “ ” mus...

Page 25: Features

Features 1-16 meter displays during cruise control system operation tip this section explains the operation of the cruise control system according to the meter displays when a malfunction is detected in the fuel injection system. The operation of the cruise control system is the same when a malfunct...

Page 26: Features

Features 1-17 et3p61050 outline of the unified brake system the yamaha unified brake system is a system that operates one set of pistons in the front brakes to- gether with the rear brake when the brake pedal is depressed. Compared to conventional brake sys- tems, the ability to slow the vehicle usi...

Page 27: Features

Features 1-18 brake pedal input force and braking force at each wheel metering valve this valve prevents the brake fluid pressure that is transmitted to the right front brake caliper from in- creasing until the pressure exceeds a set level. Only the rear brake caliper is operated when there is an ex...

Page 28: Features

Features 1-19 et3p61019 outline of the abs 1. The yamaha abs (anti-lock brake system) features an electronic control system, which acts on the front and rear brakes independently. However, one set of pistons in the right front brake caliper is operated together with the rear brake and this set of pi...

Page 29: Features

Features 1-20 when the brakes are applied, wheel speed and chassis speed are reduced. However, the chassis travels forward by its inertia even though the wheel speed is reduced. • brake force: the force applied by braking to reduce the wheel speed. • wheel lock: a condition that occurs when the rota...

Page 30: Features

Features 1-21 wheel slip and hydraulic control the abs ecu calculates the wheel speed of each wheel according to the rotation signal received from the front and rear wheel sensors. In addition, the abs ecu calculates the vehicle chassis speed and the rate of speed reduction based on the wheel speed ...

Page 31: Features

Features 1-22 warning ew3p61003 the braking of the vehicle, even in the worst case, is principally executed when the vehicle is advancing straight ahead. During a turn, sudden braking is liable to cause a loss of traction of the tires. Even in vehicles equipped with abs, overturning of the vehicle c...

Page 32: Features

Features 1-23 abs block diagram et3p61051 abs component functions wheel sensors and wheel sensor rotors wheel sensors “1” detect the wheel rotation speed and transmit the wheel rotation signal to the abs ecu. Each wheel sensor contains a hall ic. The wheel sensors are installed in the sensor housing...

Page 33: Features

Features 1-24 abs warning light the abs warning light “1” comes on to warn the rider if a malfunction in the abs occurs. When the main switch is turned to “on”, the abs warning light comes on during the abs self-diagnosis to check the electrical circuit of the light. If there are no problems detecte...

Page 34: Features

Features 1-25 • hydraulic unit assembly the hydraulic unit assembly “1” is composed of hydraulic control valves (each with a outlet solenoid valve and inlet solenoid valve), buffer chambers, hydraulic pumps, an abs motor, and abs ecu. The hydraulic unit adjusts the front and rear wheel brake fluid p...

Page 35: Features

Features 1-26 3. When the abs ecu sends a signal to stop reducing the hydraulic pressure, the outlet solenoid valve “2” closes and the brake fluid is pressurized again. The inlet solenoid valve “1” controls the hydraulic pressure difference between the brake fluid in the upper brake lines (brake mas...

Page 36: Features

Features 1-27 • abs ecu the abs ecu is integrated with the hydraulic unit to achieve a compact and lightweight design. As shown in the block following diagram, the abs ecu receives wheel sensor signals from the front and rear wheels and also receives signals from other monitor circuits. The necessar...

Page 37: Features

Features 1-28 abs control operation the abs control operation performed in the abs ecu is divided into the following two parts. • hydraulic control • self-diagnosis when a malfunction is detected in the abs, a fault code is stored in the memory of the abs ecu for easy problem identification and trou...

Page 38: Features

Features 1-29 et3p61052 abs operation the abs hydraulic circuit consists of two systems: the front wheel, and rear wheel. The following de- scribes the system for the front wheel only, excluding the unified brake system. Normal braking (abs not activated) when the abs is not activated, the inlet sol...

Page 39: Features

Features 1-30 emergency braking (abs activated) 1. Depressurizing phase when the front wheel is about to lock, the outlet solenoid valve is opened by the “depressurization” signal transmitted from the abs ecu. When this occurs, the inlet solenoid valve compresses the spring and closes the brake line...

Page 40: Features

Features 1-31 2. Pressurizing phase the outlet solenoid valve is closed by the “pressurization” signal transmitted from the abs ecu. At this time, the abs ecu controls the opening of the inlet solenoid valve. As the inlet solenoid valve opens, the brake line from the brake master cylinder opens, all...

Page 41: Features

Features 1-32 et3p61053 abs self-diagnosis function abs warning light the abs warning light “1” comes on when a malfunction is detected by the abs self-diagnosis. It is located in the multi-function meter center display. Instances when the abs warning light comes on 1. The abs warning light comes on...

Page 42: Features

Features 1-33 2. The abs warning light comes on while the “ ” side of the start/engine stop switch is being pushed. When the engine is being started, the abs warning light comes on while the “ ” side of the start/en- gine stop switch is being pushed. (refer to “electric starting system” on page 8-7....

Page 43: Features

Features 1-34 5. The abs warning light “1” flashes and a fault code “2” is indicated on the multi-function meter right display when the test coupler adapter “3” is connected to the abs test coupler “4” for troubleshooting the abs. The abs test coupler can be accessed by removing the right upper inne...

Page 44: Features

Features 1-35 et3p61054 abs warning light and operation abs and ubs function warning ewa1mc1024 • when hydraulic control is performed by the abs, the brake system alerts the rider that the wheels have a tendency to lock by generating a reaction-force pulsating action in the brake lever or brake peda...

Page 45: Features

Features 1-36 eas1mc1082 outline of the tcs (traction control system) the traction control system controls excessive spinning (slipping) of the rear wheel when accelerating on slippery surfaces, such as unpaved or wet roads. The ecu monitors the front and rear wheel speeds using the signals from the...

Page 46: Features

Features 1-37 tcs (traction control system) function the traction control system helps maintain traction when accelerating on slippery surfaces, such as un- paved or wet roads. If sensors detect that the rear wheel is starting to slip (uncontrolled spinning), the traction control system assists by r...

Page 47: Features

Features 1-38 tip turn the traction control system off to help free the rear wheel if the motorcycle gets stuck in mud, sand, or other soft surfaces. Notice eca1mc1014 use only the specified tires. Using different sized tires will prevent the traction control system from controlling tire rotation ac...

Page 48: Features

Features 1-39 eas1mc1030 multi-function meter unit warning ewa1mc1008 be sure to stop the vehicle before making any setting changes to the multi-function meter unit. Changing settings while riding can distract the operator and increase the risk of an accident. Tip the select switch “ / ” and the men...

Page 49: Features

Features 1-40 fuel meter the fuel meter indicates the amount of fuel in the fuel tank. The display segments of the fuel meter disappear towards “e” (empty) as the fuel level decreases. When the last segment starts flash- ing, refuel as soon as possible. When the main switch is turned to “on”, all di...

Page 50: Features

Features 1-41 function display push the menu switch “menu” to switch the dis- play between the following functions. The dis- play changes each time the switch is pushed. • grip warmer adjusting function • information display selection function • windshield adjusting function • damping force adjustin...

Page 51: Features

Features 1-42 • an estimated traveling range display • an elapsed time display • an ambient temperature display • a coolant temperature display • an average fuel consumption display • an instantaneous fuel consumption display the items shown in each information display can be selected. To set or sel...

Page 52: Features

Features 1-43 the time that has elapsed since the key was turned to “on” is shown. The maximum time that can be shown is 99:59. This display is automatically reset when the key is turned to “off”. Tip there are also “time-2” and “time-3” elapsed time displays, but they cannot be set to the infor- ma...

Page 53: Features

Features 1-44 instantaneous fuel consumption display: the instantaneous fuel consumption display modes “km/l”, “l/100km” or “mpg” (for the uk only) show the fuel consumption under the cur- rent riding conditions. • the “km/l” display shows the distance that can be traveled on 1.0 l of fuel. • the “l...

Page 54: Features

Features 1-45 adjusting the temperature levels of the grip warmer settings 1. Use the select switch to highlight “grip warmer”. 2. Push the menu switch “menu”. The grip warmer setting display will be shown and “high” will flash in the display. 3. Push the menu switch “menu”. The temper- ature level ...

Page 55: Features

Features 1-46 checking and resetting time-2 and time-3 1. Use the select switch to highlight “time trip”. 2. Push the menu switch “menu” to display “time-2” and “time-3”. To reset a time trip, push the “reset” button to select the item to reset. 3. While the selected item is flashing, push the “rese...

Page 56: Features

Features 1-47 7. Use the select switch to highlight “ ”, and then push the menu switch “menu” to return to the setting mode menu. Selecting the display items 1. Use the select switch to highlight “display”. 2. Push the menu switch “menu”, use the se- lect switch to highlight the display to change, a...

Page 57: Features

Features 1-48 2. Push the menu switch “menu”. 3. Use the select switch to select the desired brightness level, and then push the menu switch “menu” to return to the setting mode menu. Setting the clock 1. Use the select switch to highlight “clock”. 2. Push the menu switch “menu”. 3. When the hour di...

Page 58: Features

Features 1-49 the self-diagnosis device also detects problems in the immobilizer system circuits. If a problem is detected in the immobilizer sys- tem circuits, the immobilizer system indicator light will flash and the information display will in- dicate a fault code when the main switch is turned t...

Page 59: Important Information

Important information 1-50 eas20180 important information eas20190 preparation for removal and disassembly 1. Before removal and disassembly, remove all dirt, mud, dust and foreign material. 2. Use only the proper tools and cleaning equip- ment. Refer to “special tools” on page 1-57. 3. When disasse...

Page 60: Important Information

Important information 1-51 eas20230 bearings and oil seals install bearings “1” and oil seals “2” so that the manufacturer’s marks or numbers are visible. When installing oil seals, lubricate the oil seal lips with a light coat of lithium-soap-based grease. Oil bearings liberally when installing, if...

Page 61: Basic Service Information

Basic service information 1-52 eas30380 basic service information eas30390 quick fasteners rivet type 1. Remove: • quick fastener tip to remove the quick fastener, push its pin with a screwdriver, then pull the fastener out. 2. Install: • quick fastener tip to install the quick fastener, push its pi...

Page 62: Basic Service Information

Basic service information 1-53 eas30402 electrical system electrical parts handling notice eca16600 never disconnect a battery lead while the en- gine is running; otherwise, the electrical components could be damaged. Notice eca16751 when disconnecting the battery leads from the battery, be sure to ...

Page 63: Basic Service Information

Basic service information 1-54 notice eca16620 handle electrical components with special care, and do not subject them to strong shocks. Notice eca16630 electrical components are very sensitive to and can be damaged by static electricity. Therefore, never touch the terminals and be sure to keep the ...

Page 64: Basic Service Information

Basic service information 1-55 checking the connections check the leads, couplers, and connectors for stains, rust, moisture, etc. 1. Disconnect: • lead • coupler • connector notice eca16780 • when disconnecting a coupler, release the coupler lock, hold both sections of the cou- pler securely, and t...

Page 65: Basic Service Information

Basic service information 1-56 4. Check: • continuity (with the pocket tester) tip • if there is no continuity, clean the terminals. • when checking the wire harness, perform steps (1) to (3). • as a quick remedy, use a contact revitalizer available at most part stores. 5. Check: • resistance tip th...

Page 66: Special Tools

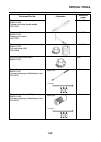

Special tools 1-57 eas20260 special tools the following special tools are necessary for complete and accurate tune-up and assembly. Use only the appropriate special tools as this will help prevent damage caused by the use of inappropriate tools or improvised techniques. Special tools, part numbers o...

Page 67: Special Tools

Special tools 1-58 vacuum/pressure pump gauge set 90890-06756 mityvac brake bleeding tool ys-42423 3-13 magnet base b 90890-06844 magnetic base stand yu-a8438 3-14 dial gauge & stand set 90890-01252 dial gauge set yu-03097-b 3-14 steering nut wrench 90890-01403 exhaust flange nut wrench yu-a9472 3-2...

Page 68: Special Tools

Special tools 1-59 rod holder 90890-01434 damper rod holder double ended ym-01434 4-83, 4-88 damper rod holder 90890-01423 damping rod holder ym-01423 4-84, 4-85 fork seal driver 90890-01502 fork seal driver (48) ym-a0948 4-86, 4-87 fork seal driver attachment 90890-01503 4-86 rod puller 90890-01437...

Page 69: Special Tools

Special tools 1-60 ring gear fix bolt (m14) 90890-01524 ym-01524 4-114 final gear backlash band 90890-01511 middle drive gear lash tool ym-01230 4-115 coupling gear/middle shaft tool 90890-01229 gear holder ym-01229 4-117, 4-120 bearing retainer wrench 90890-04050 pinion bearing retainer & remover y...

Page 70: Special Tools

Special tools 1-61 pivot shaft wrench 90890-01471 frame spanner socket ym-01471 5-8, 5-9 pivot shaft wrench adapter 90890-01476 5-8, 5-9 test harness-tps(3p) 90890-03204 test harness-tps(3p) yu-03204 5-11, 5-64 digital circuit tester 90890-03174 model 88 multimeter with tachometer yu-a1927 5-11, 5-5...

Page 71: Special Tools

Special tools 1-62 valve guide remover (ø5) 90890-04097 valve guide remover (5.0 mm) ym-04097 5-28 valve guide installer (ø5) 90890-04098 valve guide installer (5.0 mm) ym-04098 5-28 valve guide reamer (ø5) 90890-04099 valve guide reamer (5.0 mm) ym-04099 5-28 sheave holder 90890-01701 primary clutc...

Page 72: Special Tools

Special tools 1-63 test harness- speed sensor (3p) 90890-03208 yu-03208 5-65, 8-279, 8-283 bearing retainer wrench 90890-04137 middle drive shaft bearing retainer wrench ym-04137 5-79, 5-81 damper spring compressor 90890-04090 middle drive gear damper spring com- pressor ym-33286 5-79, 5-80 bearing ...

Page 73: Special Tools

Special tools 1-64 piston ring compressor 90890-05158 ym-08037 5-101 slide hammer bolt 90890-01083 slide hammer bolt 6 mm yu-01083-1 5-112 weight 90890-01084 yu-01083-3 5-112 radiator cap tester 90890-01325 mityvac cooling system tester kit yu-24460-a 6-3 tool name/tool no. Illustration reference pa...

Page 74: Special Tools

Special tools 1-65 radiator cap tester adapter 90890-01352 pressure tester adapter yu-33984 6-3 mechanical seal installer 90890-04078 water pump seal installer ym-33221-a 6-13 middle driven shaft bearing driver 90890-04058 middle drive bearing installer 40 & 50 mm ym-04058 6-13 pressure gauge 90890-...

Page 75: Special Tools

Special tools 1-66 test harness- lean angle sensor (6p) 90890-03209 yu-03209 8-273 test harness s- pressure sensor (3p) 90890-03207 yu-03207 8-280 tool name/tool no. Illustration reference pages.

Page 76: Special Tools

Special tools 1-67.

Page 77: Specifications

2 specifications general specifications ........................................................................ 2-1 engine specifications ............................................................................ 2-2 chassis specifications ............................................................

Page 78: General Specifications

General specifications 2-1 eas20280 general specifications model model 1md1 (europe except (f)) 1md2 (b) (f) dimensions overall length 2230 mm (87.8 in) overall width 750 mm (29.5 in) overall height 1325/1455 mm (52.2/57.3 in) seat height 805/825 mm (31.7/32.5 in) wheelbase 1545 mm (60.8 in) ground ...

Page 79: Engine Specifications

Engine specifications 2-2 eas20290 engine specifications engine engine type liquid cooled 4-stroke, dohc displacement 1298.0 cm³ cylinder arrangement inline 4-cylinder bore × stroke 79.0 × 66.2 mm (3.11 × 2.61 in) compression ratio 10.80 : 1 standard compression pressure (at sea level) 1600 kpa/400 ...

Page 80: Engine Specifications

Engine specifications 2-3 relief valve operating pressure 480.0–560.0 kpa (4.80–5.60 kgf/cm², 69.6–81.2 psi) cooling system radiator capacity (including all routes) 2.60 l (2.75 us qt, 2.29 imp.Qt) radiator capacity 0.65 l (0.69 us qt, 0.57 imp.Qt) coolant reservoir capacity (up to the maximum level...

Page 81: Engine Specifications

Engine specifications 2-4 limit 24.897 mm (0.9802 in) camshaft runout limit 0.030 mm (0.0012 in) timing chain tensioning system automatic valve, valve seat, valve guide valve clearance (cold) intake 0.15–0.22 mm (0.0059–0.0087 in) exhaust 0.18–0.25 mm (0.0071–0.0098 in) valve dimensions valve head d...

Page 82: Engine Specifications

Engine specifications 2-5 limit 0.105 mm (0.0041 in) valve stem runout 0.010 mm (0.0004 in) cylinder head valve seat width (intake) 0.90–1.10 mm (0.0354–0.0433 in) cylinder head valve seat width (exhaust) 0.90–1.10 mm (0.0354–0.0433 in) valve spring free length (intake) 39.73 mm (1.56 in) limit 37.7...

Page 83: Engine Specifications

Engine specifications 2-6 height h 5.0 mm (0.20 in) offset 0.50 mm (0.0197 in) offset direction intake side piston pin bore inside diameter 19.004–19.015 mm (0.7482–0.7486 in) limit 19.045 mm (0.7498 in) piston pin outside diameter 18.991–19.000 mm (0.7477–0.7480 in) limit 18.971 mm (0.7469 in) pist...

Page 84: Engine Specifications

Engine specifications 2-7 crankshaft width a 61.60–63.20 mm (2.425–2.488 in) width b 325.10–326.30 mm (12.80–12.85 in) runout limit c 0.030 mm (0.0012 in) big end side clearance d 0.160–0.262 mm (0.0063–0.0103 in) journal oil clearance 0.027–0.045 mm (0.0011–0.0018 in) bearing color code 2.Black 3.B...

Page 85: Engine Specifications

Engine specifications 2-8 shifting mechanism shift mechanism type shift drum and guide bar shift fork guide bar bending limit 0.100 mm (0.0039 in) air filter air filter element dry element fuel pump pump type electrical maximum consumption amperage 6.0 a fuel injector model/quantity 0990/4 resistanc...

Page 86: Engine Specifications

Engine specifications 2-9 ring-gear-to-stopper-bolt clearance 0.30–0.60 mm (0.0118–0.0236 in) ring-gear-to-thrust-washer clearance 0.20 mm (0.0079 in) final gear backlash 0.22–0.45 mm (0.0087–0.0177 in).

Page 87: Chassis Specifications

Chassis specifications 2-10 eas20300 chassis specifications chassis frame type diamond caster angle 26.00° trail 109.0 mm (4.29 in) front wheel wheel type cast wheel rim size 17m/c × mt3.50 rim material aluminum wheel travel 135.0 mm (5.31 in) radial wheel runout limit 1.0 mm (0.04 in) lateral wheel...

Page 88: Chassis Specifications

Chassis specifications 2-11 front disc brake disc outside diameter × thickness 320.0 × 4.5 mm (12.60 × 0.18 in) brake disc thickness limit 4.0 mm (0.16 in) brake disc deflection limit 0.10 mm (0.0039 in) brake pad lining thickness (inner) 5.5 mm (0.22 in) limit 0.5 mm (0.02 in) brake pad lining thic...

Page 89: Chassis Specifications

Chassis specifications 2-12 quantity 580.0 cm³ (19.61 us oz, 20.46 imp.Oz) (left side) quantity 570.0 cm³ (19.27 us oz, 20.10 imp.Oz) (right side) level 123 mm (4.8 in) rear suspension type swingarm (link suspension) spring/shock absorber type coil spring/gas-oil damper rear shock absorber assembly ...

Page 90: Electrical Specifications

Electrical specifications 2-13 eas20310 electrical specifications voltage system voltage 12 v ignition system ignition system tci ignition timing (b.T.D.C.) 5.0°/1050 r/min engine control unit model/manufacturer tbdfh6/denso (europe except (f)) tbdfh9/denso (b) (f) ignition coil minimum ignition spa...

Page 91: Electrical Specifications

Electrical specifications 2-14 engine trouble warning light led abs warning light led cruise control system indicator light led cruise control setting indicator light led immobilizer system indicator light led traction control system indicator/warning light led “stop mode” indicator light led shift ...

Page 92: Electrical Specifications

Electrical specifications 2-15 grip warmer grip warmer resistance (l) 1.21–1.48 Ω grip warmer resistance (r) 1.17–1.43 Ω fuses main fuse 50.0 a cooling system fuse 30.0 a headlight fuse 25.0 a brake light fuse 1.0 a signaling system fuse 10.0 a ignition fuse 20.0 a radiator fan fuse 10.0 a × 2 auxil...

Page 93: Tightening Torques

Tightening torques 2-16 eas20320 tightening torques eas20330 general tightening torque specifications this chart specifies tightening torques for stan- dard fasteners with a standard iso thread pitch. Tightening torque specifications for special com- ponents or assemblies are provided for each chapt...

Page 94: Tightening Torques

Tightening torques 2-17 eas20340 engine tightening torques item thread size q’ty tightening torque remarks spark plug m10 4 13 nm (1.3 m·kg, 9.4 ft·lb) cylinder head bolt m10 10 see tip. Cylinder head bolt m6 2 12 nm (1.2 m·kg, 8.7 ft·lb) camshaft cap bolt m6 20 10 nm (1.0 m·kg, 7.2 ft·lb) cylinder ...

Page 95: Tightening Torques

Tightening torques 2-18 oil pan bolt m6 20 12 nm (1.2 m·kg, 8.7 ft·lb) oil pump drive chain guide bolt m6 2 12 nm (1.2 m·kg, 8.7 ft·lb) oil pump housing cover bolt m6 3 12 nm (1.2 m·kg, 8.7 ft·lb) oil level switch bolt m6 2 10 nm (1.0 m·kg, 7.2 ft·lb) throttle cable holder bolt m5 2 4 nm (0.4 m·kg, ...

Page 96: Tightening Torques

Tightening torques 2-19 upper crankcase damper bolt m6 3 12 nm (1.2 m·kg, 8.7 ft·lb) damper cover bolt (clutch cover) m6 5 12 nm (1.2 m·kg, 8.7 ft·lb) stator coil assembly lead holder bolt m6 1 10 nm (1.0 m·kg, 7.2 ft·lb) main gallery bolt m20 1 8 nm (0.8 m·kg, 5.8 ft·lb) starter clutch bolt m8 3 32...

Page 97: Tightening Torques

Tightening torques 2-20 tip cylinder head bolt tighten the cylinder head bolts to 25 nm (2.5 m·kg, 18 ft·lb) in the proper tightening sequence, loosen and retighten the bolts to 25 nm (2.5 m·kg, 18 ft·lb) in the proper tightening sequence, and then tighten them further to reach the specified angle 1...

Page 98: Tightening Torques

Tightening torques 2-21 tip crankcase bolt tighten the crankcase bolts to 20 nm (2.0 m·kg, 14 ft·lb) in the proper tightening sequence, loosen and retighten the bolts to 20 nm (2.0 m·kg, 14 ft·lb) in the proper tightening sequence, and then tighten them further to reach the specified angle 115–125° ...

Page 99: Tightening Torques

Tightening torques 2-22 eas20350 chassis tightening torques item thread size q’ty tightening torque remarks engine mounting bolt (right front lower side) m12 1 49 nm (4.9 m·kg, 35 ft·lb) engine mounting bolt (right front upper side) m12 1 49 nm (4.9 m·kg, 35 ft·lb) engine mounting bolt (left front l...

Page 100: Tightening Torques

Tightening torques 2-23 rear shock absorber assembly preload adjusting pump bolt m6 3 5 nm (0.5 m·kg, 3.6 ft·lb) rear shock absorber assembly preload adjusting pump bracket bolt m6 2 7 nm (0.7 m·kg, 5.1 ft·lb) rear shock absorber assembly dc motor bolt m5 3 4 nm (0.4 m·kg, 2.9 ft·lb) rear shock abso...

Page 101: Tightening Torques

Tightening torques 2-24 fuel pump bolt m5 6 4 nm (0.4 m·kg, 2.9 ft·lb) front fuel tank bracket and frame bolt m6 2 10 nm (1.0 m·kg, 7.2 ft·lb) fuel tank and front fuel tank bracket bolt m8 2 16 nm (1.6 m·kg, 11 ft·lb) fuel tank and rear upper fuel tank bracket bolt m8 2 16 nm (1.6 m·kg, 11 ft·lb) re...

Page 102: Tightening Torques

Tightening torques 2-25 front brake caliper bolt m10 4 40 nm (4.0 m·kg, 29 ft·lb) front brake hose holder bolt m6 3 7 nm (0.7 m·kg, 5.1 ft·lb) front brake hose joint bolt m6 1 see tip. Front brake caliper bleed screw m8 3 6 nm (0.6 m·kg, 4.3 ft·lb) front brake pad bolt m10 4 17 nm (1.7 m·kg, 12 ft·l...

Page 103: Tightening Torques

Tightening torques 2-26 tip lower ring nut 1. First, tighten the lower ring nut to approximately 52 nm (5.2 m·kg, 37 ft·lb) with a torque wrench, then loosen the lower ring nut completely. 2. Retighten the lower ring nut to 18 nm (1.8 m·kg, 13 ft·lb) with a torque wrench. Tip brake hose joint bracke...

Page 104: Tightening Torques

Tightening torques 2-27 tip front wheel axle pinch bolt 1. Insert the front wheel axle from the right side and tighten it with the front wheel axle bolt from the left side to 91 nm (9.1 m·kg, 66 ft·lb). 2. In the order pinch bolt “2” → pinch bolt “1” → pinch bolt “2”, tighten each bolt to 21 nm (2.1...

Page 105: 2-28

Lubrication points and lubricant types 2-28 eas20360 lubrication points and lubricant types eas20370 engine lubrication point lubricant oil seal lips o-rings bearings crankshaft pins piston surfaces piston pins connecting rod bolts and nuts crankshaft journals camshaft lobes camshaft journals balanc...

Page 106: 2-29

Lubrication points and lubricant types 2-29 cylinder head cover mating surface three bond 1541c® cylinder head cover gasket yamaha bond no.1215 (three bond no.1215®) crankcase mating surface yamaha bond no.1215 (three bond no.1215®) crankshaft position sensor lead grommet yamaha bond no.1215 (three ...

Page 107: 2-30

Lubrication points and lubricant types 2-30 eas20380 chassis lubrication point lubricant steering bearings and upper bearing cover lip lower bearing dust seal lip front wheel oil seal lip rear wheel oil seal lip rear wheel drive hub mating surface rear brake pedal pivoting point footrest assembly pi...

Page 108: 2-31

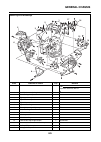

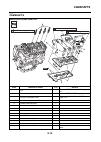

Lubrication system chart and diagrams 2-31 eas20390 lubrication system chart and diagrams eas20400 engine oil lubrication chart 15 13 12 6 5 4 3 2 1 7 8 9 10 11 9 9 9 14.

Page 109: 2-32

Lubrication system chart and diagrams 2-32 1. Oil strainer 2. Oil pump 3. Relief valve assembly 4. Oil filter cartridge 5. Oil cooler 6. Main gallery 7. Front balancer shaft 8. Rear balancer shaft 9. Oil nozzle 10. Intake camshaft 11. Exhaust camshaft 12. Main axle 13. Oil delivery pipe 1 14. Drive ...

Page 110: 2-33

Lubrication system chart and diagrams 2-33 eas20410 lubrication diagrams 5 6 7 1 2 3 4.

Page 111: 2-34

Lubrication system chart and diagrams 2-34 1. Intake camshaft 2. Cylinder head 3. Exhaust camshaft 4. Oil check bolt 5. Main gallery bolt 6. Crankshaft 7. Oil nozzle.

Page 112: 2-35

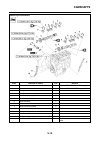

Lubrication system chart and diagrams 2-35 1 3 2.

Page 113: 2-36

Lubrication system chart and diagrams 2-36 1. Main axle 2. Drive axle 3. Oil delivery pipe 1.

Page 114: 2-37

Lubrication system chart and diagrams 2-37 6 5 4 3 2 1.

Page 115: 2-38

Lubrication system chart and diagrams 2-38 1. Oil check bolt 2. Crankshaft 3. Oil cooler 4. Oil strainer 5. Oil delivery pipe 3 6. Oil pump.

Page 116: 2-39

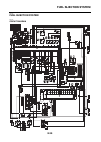

Lubrication system chart and diagrams 2-39 1 2 3 4 5 6 7 8 9.

Page 117: 2-40

Lubrication system chart and diagrams 2-40 1. Rear balancer 2. Oil delivery pipe 2 3. Engine oil drain bolt 4. Oil level switch 5. Crankshaft 6. Front balancer 7. Crank pin 8. Oil delivery pipe 3 9. Relief valve assembly.

Page 118: 2-41

Lubrication system chart and diagrams 2-41 4 5 3 2 1 9 8 6 7.

Page 119: 2-42

Lubrication system chart and diagrams 2-42 1. Oil strainer 2. Oil delivery pipe 2 3. Oil cooler 4. Engine oil drain bolt 5. Oil level switch 6. Oil filter cartridge 7. Oil delivery pipe 3 8. Oil pan 9. Oil pump.

Page 120: Cooling System Diagrams

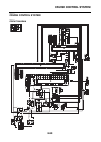

Cooling system diagrams 2-43 eas20420 cooling system diagrams 3 13 4 5 6 7 7 7 8 1 2 10 9 14 15 16 17 11 12 3.

Page 121: Cooling System Diagrams

Cooling system diagrams 2-44 1. Thermostat inlet pipe 1 2. Thermostat inlet hose 1 3. Oil cooler outlet hose 4. Radiator 5. Coolant reservoir breather hose 6. Thermostat inlet pipe 2 7. Coolant reservoir hose 8. Radiator inlet hose 9. Thermostat inlet hose 2 10. Thermostat assembly 11. Water jacket ...

Page 122: Cooling System Diagrams

Cooling system diagrams 2-45 7 1 2 3 4 5 5 8 9 6 8 9 10 11 12.

Page 123: Cooling System Diagrams

Cooling system diagrams 2-46 1. Thermostat inlet pipe 1 2. Thermostat inlet hose 2 3. Radiator inlet hose 4. Radiator 5. Radiator outlet hose 6. Oil cooler outlet hose 7. Water jacket joint inlet hose 8. Water pump outlet pipe 9. Water pump outlet hose 10. Water pump 11. Water jacket joint 12. Water...

Page 124: Cable Routing

Cable routing 2-47 eas20430 cable routing handlebar (front view) 20 19 22 3 5 17 18 21 23 23 22 3 1 2 2 2 3 4 9 8 7 4 13 14 15 16 16 16 b a a c f 5 6 24 g 5 24 9 15 15 d e 6 5 10 10 11 12 10 11.

Page 125: Cable Routing

Cable routing 2-48 1. Right front fork stepping motor 2. Right grip warmer lead 3. Brake hose (front brake master cylinder to brake pipe/lower joint assembly) 4. Coupler rubber cover 5. Right handlebar switch lead 6. Right front fork stepping motor lead 7. Left front fork stepping motor 8. Left hand...

Page 126: Cable Routing

Cable routing 2-49 radiator and battery (right side view) 1 3 4 5 6 7 8 14 14 14 14 18 22 23 24 25 j h k e f g c d d 2 n i 1 21 1 l a a b 10 9 13 12 11 15 15 m 15 16 16 17 17 15 20 19.

Page 127: Cable Routing

Cable routing 2-50 1. Starter motor lead 2. Ecu (engine control unit) 3. Brake hose (front brake master cylinder to brake pipe/lower joint assembly) 4. Right handlebar switch lead 5. Throttle cable (accelerator cable) 6. Throttle cable (decelerator cable) 7. Headlight relay (on/off) 8. Radiator fan ...

Page 128: Cable Routing

Cable routing 2-51 rear brake hose (right side view) 4 5 6 7 8 9 10 11 12 1 13 14 2 3 1 a b c e 15 16 f 17 h 18 d g.

Page 129: Cable Routing

Cable routing 2-52 1. Rear wheel sensor lead 2. Brake hose (rear brake master cylinder to brake pipe/middle joint assembly) 3. Rear brake fluid reservoir hose 4. Rear brake fluid reservoir 5. Brake pipe (hydraulic unit to metering valve) 6. Hydraulic unit assembly 7. Brake pipe (hydraulic unit to pr...

Page 130: Cable Routing

Cable routing 2-53 horn and radiator (left side view) a b 1 1 2 3 4 5 5 6 c 7 7 8.

Page 131: Cable Routing

Cable routing 2-54 1. Radiator inlet hose 2. Left radiator fan motor 3. Radiator 4. Coolant reservoir breather hose 5. Horn 6. Left radiator fan motor coupler 7. Left radiator fan motor lead 8. Coolant reservoir hose a. After connecting the left radiator fan motor coupler, position the coupler betwe...

Page 132: Cable Routing

Cable routing 2-55 front brake hose and engine (left side view) 17 18 19 a b 1 2 3 c d 4 5 5 6 f e 7 8 9 10 g h 11 12 13 14 l k m 15 n o p i j 23 24 25 22 1 t 16 17 18 20 21 q 16 19 16 r s 19.

Page 133: Cable Routing

Cable routing 2-56 1. Ac magneto lead 2. Rectifier/regulator lead 3. Air filter case breather hose 4. Gear position sensor lead 5. Clutch hose 6. Fuel tank breather/overflow hose 7. Foot shift sensor lead 8. Sidestand switch 9. Sidestand switch lead 10. Oil level switch lead 11. Coolant reservoir br...

Page 134: Cable Routing

Cable routing 2-57 rear fender (left side view) c 7 8 9 10 o p q r s 1 2 3 4 14 h g f 13 17 15 16 e 2 3 4 d t u v 21 22 22 28 1 2 3 4 27 18 19 20 k 21 22 23 l m 24 25 26 j n 16 i 1 2 3 4 5 6 7 7 6 6 a a 11 12 13 14 b.

Page 135: Cable Routing

Cable routing 2-58 1. Wire harness 2. Shift actuator motor lead 3. Foot shift sensor lead 4. Shift actuator sensor lead 5. Tail/brake light assembly coupler 6. Tail/brake light 7. Rear turn signal light 8. Tail/brake light assembly lead 9. License plate light lead 10. Seat lock cable 11. License pla...

Page 136: Cable Routing

Cable routing 2-59 throttle bodies (top view) 1 2 3 4 5 6 7 7 8 9 12 13 18 41 a b c d e f g h i j m n o p q r k l s 10 35 36 37 38 39 40 27 28 29 30 31 32 33 34 23 24 25 26 8 21 22 15 16 17 20 14 42 19 11.

Page 137: Cable Routing

Cable routing 2-60 1. Ignition coil #1 coupler 2. Front wheel sensor lead 3. Left front fork stepping motor lead 4. Right front fork stepping motor lead 5. Immobilizer unit lead 6. Main switch lead 7. Throttle cable (decelerator cable) 8. Throttle cable (accelerator cable) 9. Brake hose (brake pipe/...

Page 138: Cable Routing

Cable routing 2-61 rear fender (top view) 10 g 9 e f 8 e 7 d c 6 6 6 b 5 4 1 3 3 2 a 11 i 12 h.

Page 139: Cable Routing

Cable routing 2-62 1. Clutch actuator motor lead 2. Clutch actuator sensor lead 3. Storage compartment 4. Mcu (motor control unit) 5. Yamaha diagnostic tool coupler 6. Yamaha diagnostic tool lead 7. License plate light lead 8. Tail/brake light assembly lead 9. Seat lock cable 10. Mcu leads 11. Scu (...

Page 140: Cable Routing

Cable routing 2-63 front cowling assembly and electrical components board 4 1 2 3 4 5 6 7 8 9 10 14 11 12 13 14 15 16 a b c d d d e i j f g h k l m n a 17 18 19 20 q o p 21 22 23 24 26 25 r v s u w w t.

Page 141: Cable Routing

Cable routing 2-64 1. Right headlight lead 2. Right auxiliary light lead 3. Relay unit lead 4. Relay unit 5. Headlight relay (dimmer) lead 6. Left headlight lead 7. Left auxiliary light lead 8. Windshield drive unit relay (down) lead 9. Left radiator fan motor lead 10. Windshield drive unit relay (u...

Page 142: Cable Routing

Cable routing 2-65 hydraulic unit assembly (top and side view) 1 1 2 3 4 5 6 7 7 8 9 10 1 2 3 4 5 6 7 8 9 10 10 1 3 4 5 6 7 8 9 13 13 11 12 12 a 2 1 5 4 3.

Page 143: Cable Routing

Cable routing 2-66 1. Hydraulic unit assembly 2. Brake pipe/middle joint assembly 3. Brake pipe (hydraulic unit to metering valve) 4. Brake pipe (hydraulic unit to proportioning valve) 5. Brake pipe/upper joint assembly 6. Brake pipe/lower joint assembly 7. Brake pipe (proportioning valve to rear br...

Page 144: Cable Routing

Cable routing 2-67.

Page 145

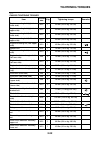

3 periodic checks and adjustments periodic maintenance ............................................................................ 3-1 introduction ....................................................................................... 3-1 periodic maintenance chart for the emission control system ...

Page 146

Measuring the engine oil pressure ........................................ 3-28 checking the coolant level....................................................... 3-29 checking the cooling system .................................................... 3-29 changing the coolant..............................

Page 148: Periodic Maintenance

Periodic maintenance 3-1 eas20450 periodic maintenance eas20460 introduction this chapter includes all information necessary to perform recommended checks and adjustments. If followed, these preventive maintenance procedures will ensure more reliable vehicle operation, a long- er service life and re...

Page 149: Periodic Maintenance

Periodic maintenance 3-2 3 * front brake • check operation, fluid level and vehicle for fluid leakage. √ √ √ √ √ √ • replace brake pads. Whenever worn to the limit 4 * rear brake • check operation, fluid level and vehicle for fluid leakage. √ √ √ √ √ √ • replace brake pads. Whenever worn to the limi...

Page 150: Periodic Maintenance

Periodic maintenance 3-3 eau40550 tip • the air filter needs more frequent service if you are riding in unusually wet or dusty areas. • hydraulic brake and ycc-s clutch service • regularly check and, if necessary, correct the brake and ycc-s clutch fluid levels. • every two years replace the interna...

Page 151: Periodic Maintenance

Periodic maintenance 3-4 eas21030 checking the fuel line 1. Remove: • rider seat refer to “general chassis” on page 4-1. • fuel tank refer to “fuel tank” on page 7-1. • t-bar refer to “general chassis” on page 4-1. 2. Check: • fuel hose “1” • fuel tank breather hose “2” • fuel tank overflow hose “3”...

Page 152: Periodic Maintenance

Periodic maintenance 3-5 10.Install: • t-bar refer to “general chassis” on page 4-1. • fuel tank refer to “fuel tank” on page 7-1. • rider seat refer to “general chassis” on page 4-1. Eas20490 adjusting the valve clearance the following procedure applies to all of the valves. Tip • valve clearance a...

Page 153: Periodic Maintenance

Periodic maintenance 3-6 • measure the valve clearance in the following sequence. D. To measure the valve clearances of the other cylinders, starting with cylinder #1 at tdc, turn the crankshaft clockwise as specified in the following table. ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲▲▲ 5. Remov...

Page 154: Periodic Maintenance

Periodic maintenance 3-7 example: if the valve pad is marked “155”, the pad thickness is 1.55 mm (0.061 in). D. Calculate the sum of the values obtained in steps (b) and (c) to determine the required valve pad thickness and the valve pad num- ber. Example: 1.55 mm (0.061 in) + 0.03 mm (0.001 in) = 1...

Page 155: Periodic Maintenance

Periodic maintenance 3-8 3. Check: • isc (idle speed control) learning value “00” or “01” → check the intake system. “02” → clean the throttle bodies. Refer to “checking and cleaning the throttle bodies” on page 7-7. ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ a. Connect the yamaha diagnostic ...

Page 156: Periodic Maintenance

Periodic maintenance 3-9 adjusting the throttle body synchronization 1. Remove the fuel tank bolts “1” and lift up the fuel tank. Notice eca1mc1024 when lifting up the fuel tank, be careful not to pull the fuel tank breather/overflow hose. 2. Adjust: • throttle body synchronization ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼...

Page 157: Periodic Maintenance

Periodic maintenance 3-10 • exhaust pipe assembly bolts “6” • exhaust pipe assembly and muffler bolts “7” • muffler bolts “8” 4. Install: • side cowlings refer to “general chassis” on page 4-1. Eas20600 adjusting the exhaust gas volume tip be sure to set the co density level to standard, and then ad...

Page 158: Periodic Maintenance

Periodic maintenance 3-11 • to increase the selected cylinder number, press the “tcs” button. 7. After selecting the cylinder number, simulta- neously press the “tcs” button “1” and “re- set” button “2” for 2 seconds or more to execute the selection. 8. Change the co adjustment volume “3” by pressin...

Page 159: Periodic Maintenance

Periodic maintenance 3-12 notice ec3p61043 never operate the engine without the air filter element installed. Unfiltered air will cause rapid wear of engine parts and may damage the engine. Operating the engine without the air filter element will also affect throttle body synchronization, leading to...

Page 160: Periodic Maintenance

Periodic maintenance 3-13 • if bleeding is difficult, it may be necessary to let the clutch fluid settle for a few hours. Repeat the bleeding procedure when the tiny bubbles in the hose have disappeared. 1. Remove: • air filter case refer to “general chassis” on page 4-1. • rear wheel refer to “rear...

Page 161: Periodic Maintenance

Periodic maintenance 3-14 c. Manually engage and disengage the clutch using the manual clutch operation bolt “3” five times, each time for less than 1 second. Tip turn the clutch operation bolt in a continuous motion, without allowing the pressure plate to stop in mid-stroke. D. Install a suitable b...

Page 162: Periodic Maintenance

Periodic maintenance 3-15 c. Shift the transmission into neutral, and then rotate the rear wheel by hand. D. Shift the transmission into 1st gear, and then rotate the rear wheel by hand. ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲▲▲ 2. Check: • shift operation engine stalls → check the pressure ...

Page 163: Periodic Maintenance

Periodic maintenance 3-16 warning ewa13050 a soft or spongy feeling in the brake lever can indicate the presence of air in the brake system. Before the vehicle is operated, the air must be removed by bleeding the brake system. Air in the brake system will consid- erably reduce braking performance. N...

Page 164: Periodic Maintenance

Periodic maintenance 3-17 eas22780 bleeding the hydraulic brake system (abs) warning ewa14000 always bleed the brake system when the brake related parts are removed. Notice ec3p61012 • bleed the brake system in the following or- der. • 1st step: front brake calipers • 2nd step: right front brake cal...

Page 165: Periodic Maintenance

Periodic maintenance 3-18 j. Check the operation of the hydraulic unit. Refer to “hydraulic unit operation tests” on page 4-71. Notice ec3p61029 make sure that the main switch is turned to “off” before checking the operation of the hydraulic unit. K. After operating the abs, repeat steps (e) to (i),...

Page 166: Periodic Maintenance

Periodic maintenance 3-19 c. Tighten the locknut “1” to specification. Warning ew3p61002 a soft or spongy feeling in the brake pedal can indicate the presence of air in the brake system. Before the vehicle is operated, the air must be removed by bleeding the brake system. Air in the brake system wil...

Page 167: Periodic Maintenance

Periodic maintenance 3-20 warning ewa13180 • the tire pressure should only be checked and regulated when the tire temperature equals the ambient air temperature. • the tire pressure and the suspension must be adjusted according to the total weight (including cargo, rider, passenger and ac- cessories...

Page 168: Periodic Maintenance

Periodic maintenance 3-21 warning ewa14090 after extensive tests, the tires listed below have been approved by yamaha motor co., ltd. For this model. The front and rear tires should always be by the same manufacturer and of the same design. No guarantee con- cerning handling characteristics can be g...

Page 169: Periodic Maintenance

Periodic maintenance 3-22 b. Tighten the lower ring nut “4” with the steering nut wrench “5”. Tip set a torque wrench at a right angle to the steer- ing nut wrench. C. Loosen the lower ring nut completely and then tighten it to specification with the steer- ing nut wrench. Warning ewa13140 do not ov...

Page 170: Periodic Maintenance

Periodic maintenance 3-23 eas1mc1042 checking the sidestand 1. Check: • sidestand operation check that the sidestand moves smoothly. Rough movement → repair or replace. Eas21720 lubricating the sidestand lubricate the pivoting point, metal-to-metal mov- ing parts, and spring contact points of the si...

Page 171: Periodic Maintenance

Periodic maintenance 3-24 b. Push the menu switch “menu” “1” to switch the function display “2” to the damping force adjusting function “3”. C. Use the select switch “4” to select “hard”, “std” or “soft” “5”. ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲▲▲ 2. Adjust: • damping force setting level ...

Page 172: Periodic Maintenance

Periodic maintenance 3-25 • the suspension will still operate as normal, only the preload adjusting function cannot be used. • to reset the electronically adjustable suspen- sion system warning light, wait approximately 6 minutes and then turn the key to “off” or immediately turn the key to “off” an...

Page 173: Periodic Maintenance

Periodic maintenance 3-26 • if the preload is adjusted repeatedly, the pre- load setting pictogram will flash 4 times and the preload cannot be adjusted. Wait approx- imately 6 minutes for the preload adjusting function motor to cool down, and then try ad- justing the preload again. ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ...

Page 174: Periodic Maintenance

Periodic maintenance 3-27 eas20780 changing the engine oil 1. Start the engine, warm it up for several min- utes, and then turn it off. 2. Place a container under the engine oil drain bolt. 3. Remove: • engine oil filler cap “1” • engine oil drain bolt “2” (along with the gasket) 4. Drain: • engine ...

Page 175: Periodic Maintenance

Periodic maintenance 3-28 b. Slightly loosen the engine oil check bolt “1”. C. Start the engine and keep it idling until engine oil starts to seep from the engine oil check bolt. If no engine oil comes out after one minute, turn the engine off so that it will not seize. D. Check the engine oil passa...

Page 176: Periodic Maintenance

Periodic maintenance 3-29 8. Install: • right side cowling refer to “general chassis” on page 4-1. Eas21110 checking the coolant level 1. Stand the vehicle on a level surface. Tip • place the vehicle on the centerstand. • make sure the vehicle is upright. 2. Remove: • left side panel refer to “gener...

Page 177: Periodic Maintenance

Periodic maintenance 3-30 3. Install: • exhaust pipe assembly refer to “engine removal” on page 5-3. • side cowlings refer to “general chassis” on page 4-1. Eas21130 changing the coolant 1. Remove: • side cowlings refer to “general chassis” on page 4-1. 2. Remove: • radiator cap “1” warning ewa13030...

Page 178: Periodic Maintenance

Periodic maintenance 3-31 11.Fill: • cooling system (with the specified amount of the recom- mended coolant) handling notes for coolant coolant is potentially harmful and should be handled with special care. Warning ewa13040 • if coolant splashes in your eyes, thorough- ly wash them with water and c...

Page 179: Periodic Maintenance

Periodic maintenance 3-32 4. Install: • final gear oil filler bolt (along with the gasket ) eas21470 changing the final gear oil 1. Place a container under the final gear case. 2. Remove: • final gear oil filler bolt “1” (along with the gasket) • final gear oil drain bolt “2” (along with the gasket)...

Page 180: Periodic Maintenance

Periodic maintenance 3-33 ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲▲▲ 3. Check: • meter display for the rear brake light switch “on” → adjust the brake light switch or check the brake pedal operation. ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ a. Connect the yamaha diagnostic tool. Use ...

Page 181: Periodic Maintenance

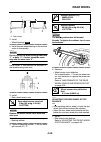

Periodic maintenance 3-34 d. Tighten the locknut. E. Slide the rubber covers to its original position. Warning ewa1mc1010 after adjusting the throttle grip free play, start the engine and turn the handlebars to the right and to the left to ensure that this does not cause the engine idling speed to c...

Page 182: Periodic Maintenance

Periodic maintenance 3-35 tip when removing the right headlight bulb cover, it is necessary to remove the abs test coupler “3” and main fuse holder “4”. 4. Detach: • headlight bulb holder “1” 5. Remove: • headlight bulb “2” warning ewa13320 since the headlight bulb gets extremely hot, keep flammable...

Page 183: Chassis

4 chassis general chassis....................................................................................... 4-1 removing the center rear cowling.......................................... 4-2 installing the center rear cowling ........................................ 4-2 removing the rear cowlin...

Page 184

Front brake ............................................................................................. 4-38 introduction ..................................................................................... 4-43 checking the front brake discs ............................................... 4-43 r...

Page 185

Steering head.......................................................................................... 4-90 removing the lower bracket..................................................... 4-92 checking the steering head ....................................................... 4-92 installing the ste...

Page 186: General Chassis

General chassis 4-1 eas21830 general chassis removing the seats and covers order job/parts to remove q’ty remarks 1 passenger seat 1 2 rider seat 1 3 grab bar 1 4 center rear cowling 1 5 left rear cowling 1 6 right rear cowling 1 7 left side cover 1 8 right side cover 1 9 rider seat height position ...

Page 187: General Chassis

General chassis 4-2 eas1mc1049 removing the center rear cowling 1. Remove: • center rear cowling “1” ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ a. Unhook the projections on the center rear cowling from the rear fender. B. Unhook the projections on the center rear cowling from the rear cowling...

Page 188: General Chassis

General chassis 4-3 b. Make sure that the grommet on the tail/brake light assembly fits into the slot in the rear cowling. ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲▲▲ eas1mc1051 removing the side covers the following procedure applies to both of the side covers. 1. Remove: • side cover “1” tip...

Page 189: General Chassis

General chassis 4-4 ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲▲▲ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ to install the rider seat in the low position a. Install the rider seat height position adjuster “1” so that the “l” mark “a” is aligned with the match mark “b”. B. Insert the proj...

Page 190: General Chassis

General chassis 4-5 removing the side cowlings order job/parts to remove q’ty remarks tip open the accessory box lid. 1 headlight beam adjusting knob 2 2 front cowling inner panel 1 3 right upper inner panel 1 4 right lower inner panel 1 5 right side panel 1 6 right side cowling 1 7 front right turn...

Page 191: General Chassis

General chassis 4-6 16 accessory box 1 17 accessory box solenoid 1 18 auxiliary dc jack 1 19 left upper inner panel 2 1 for installation, reverse the removal proce- dure. Removing the side cowlings order job/parts to remove q’ty remarks 5 3 6 7 4 8 9 11 12 10 19 15 16 1 17 2 13 18 14.

Page 192: General Chassis

General chassis 4-7 eas1mc1056 adjusting the side panels the following procedure applies to both of the side panels. 1. Adjust: • side panel position tip the side panel “1” can be opened 20 mm (0.79 in) for added ventilation to suit the riding condi- tions. ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼...

Page 193: General Chassis

General chassis 4-8 2. Remove: • front cowling inner panel “1” ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ a. Unhook the tabs “a” on the top of the front cowling inner panel from the front cowling. B. Unhook the projections “b” on the bottom of the front cowling inner panel from the upper inne...

Page 194: General Chassis

General chassis 4-9 ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲▲▲ 3. Install: • headlight beam adjusting knob “1” tip align the flat portion “a” of the hole in the head- light beam adjusting knob with the flat portion “b” of the headlight beam adjusting knob joint. Eas1mc1058 removing the side c...

Page 195: General Chassis

General chassis 4-10 removing the front cowling assembly order job/parts to remove q’ty remarks side cowlings refer to “removing the side cowlings”. 1 windshield bracket outer cover 2 2 windshield 1 3 windshield bracket 1 4 windshield bracket inner cover 2 5 center cover assembly 1 6 upper center co...

Page 196: General Chassis

General chassis 4-11 16 headlight assembly 1 for installation, reverse the removal proce- dure. Removing the front cowling assembly order job/parts to remove q’ty remarks 2 (3) (3) (3) (3) (4) 12 11 11 1 3 4 5 6 7 8 14 13 13 15 16 (5) (4) 9 9 10 7 nm (0.7 m • kg, 5.1 ft • ib) t.R . 7 nm (0.7 m • kg,...

Page 197: General Chassis

General chassis 4-12 eas1mc1061 removing the windshield bracket covers the following procedure applies to both of the windshield bracket covers. 1. Remove: • windshield bracket outer cover “1” tip slide the windshield bracket outer cover upward, and then remove it. Eas1mc1064 installing the windshie...

Page 198: General Chassis

General chassis 4-13 tip fit the projections on the upper center cover into the holes in the lower center cover. 2. Install: • center cover assembly “1” tip fit the projections on the lower center cover into the holes in the front cowling. Eas1mc1031 installing the front cowling assembly 1. Install:...

Page 199: General Chassis

General chassis 4-14 removing the meter assembly and electrical components board order job/parts to remove q’ty remarks side cowlings refer to “removing the side cowlings”. Front cowling assembly refer to “removing the front cowling assem- bly”. 1 meter assembly coupler 1 disconnect. 2 meter assembl...

Page 200: General Chassis

General chassis 4-15 removing the windshield drive unit order job/parts to remove q’ty remarks side cowlings refer to “removing the side cowlings”. Front cowling assembly refer to “removing the front cowling assem- bly”. Electrical components board refer to “removing the meter assembly and electrica...

Page 201: General Chassis

General chassis 4-16 eas1mc1079 installing the windshield drive unit 1. Check: • windshield drive unit operation tip after installing the windshield drive unit to the windshield drive unit bracket, check the opera- tion of the drive unit. ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ a. Install ...

Page 202: General Chassis

General chassis 4-17 removing the electrical components tray 1/2 order job/parts to remove q’ty remarks right side cowling refer to “removing the side cowlings”. 1 negative battery lead 1 disconnect. 2 positive battery lead 1 disconnect. 3 battery 1 4 main fuse 1 5 abs test coupler 1 6 starter relay...

Page 203: General Chassis

General chassis 4-18 removing the electrical components tray 2/2 order job/parts to remove q’ty remarks 1 ecu cover 1 2 fuse box 1/fuse box 3 1/1 3 fuse box 2/fuse box 4 1/1 4 cruise control system fuse/brake light fuse 1/1 5 ecu (engine control unit) 1 6 electrical components tray 1 7 electrical co...

Page 204: General Chassis

General chassis 4-19 removing the t-bar order job/parts to remove q’ty remarks rider seat refer to “removing the seats and covers”. Fuel tank refer to “fuel tank” on page 7-1. 1 t-bar 1 2 heat protector 1 for installation, reverse the removal proce- dure. 1 2 37 nm (3.7 m • kg, 27 ft • ib) t.R. 37 n...

Page 205: General Chassis

General chassis 4-20 removing the air filter case order job/parts to remove q’ty remarks left side cover refer to “removing the seats and covers”. Fuel tank refer to “fuel tank” on page 7-1. Shift actuator refer to “shift actuator and shift rod” on page 5-61. T-bar refer to “removing the t-bar”. 1 c...

Page 206: General Chassis

General chassis 4-21 13 air induction system hose (air filter case joint assembly to 3-way joint) 1 disconnect. 14 air filter case joint clamp screw 4 loosen. 15 air filter case assembly 1 16 air filter case breather hose 2 17 filter assembly 1 18 air filter case joint assembly 1 19 air filter case ...

Page 207: Front Wheel

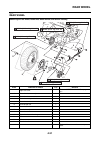

Front wheel 4-22 eas21880 front wheel removing the front wheel, brake discs, wheel sensor, and sensor housing order job/parts to remove q’ty remarks rider seat/t-bar refer to “general chassis” on page 4-1. Fuel tank refer to “fuel tank” on page 7-1. 1 front fender 1 2 front wheel sensor coupler 1 di...

Page 208: Front Wheel

Front wheel 4-23 12 front brake disc 2 for installation, reverse the removal proce- dure. Removing the front wheel, brake discs, wheel sensor, and sensor housing order job/parts to remove q’ty remarks t r . . 21 nm (2.1 m • kg, 15 ft • ib) t r . . 91 nm (9.1 m • kg, 66 ft • ib) t r . . 7 nm (0.7 m •...

Page 209: Front Wheel

Front wheel 4-24 disassembling the front wheel order job/parts to remove q’ty remarks 1 oil seal 2 2 front wheel sensor rotor 1 3 wheel bearing 2 4 spacer 1 for assembly, reverse the disassembly pro- cedure..

Page 210: Front Wheel

Front wheel 4-25 eas21900 removing the front wheel notice eca1mc1028 keep magnets (including magnetic pick-up tools, magnetic screwdrivers, etc.) away from the front wheel hub “1”, otherwise the wheel sensor rotor equipped in the wheel hub may be damaged, resulting in improper performance of the abs...

Page 211: Front Wheel

Front wheel 4-26 2. Check: • tire • front wheel damage/wear → replace. Refer to “checking the tires” on page 3-19 and “checking the wheels” on page 3-19. 3. Measure: • radial wheel runout “1” • lateral wheel runout “2” over the specified limits → replace. 4. Check: • wheel bearings front wheel turns...

Page 212: Front Wheel

Front wheel 4-27 ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ a. Hold the dial gauge at a right angle against the wheel sensor rotor surface. B. Measure the wheel sensor rotor deflection. Tip do not touch the surface of the rotor magnet with a sharp object. C. If the deflection is above specifi...

Page 213: Front Wheel

Front wheel 4-28 ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲▲▲ 2. Install: • front wheel sensor rotor notice eca1mc1032 replace the wheel sensor rotor bolts with new ones. 3. Measure: • wheel sensor rotor deflection out of specification → correct the wheel sen- sor rotor deflection or replace th...

Page 214: Front Wheel

Front wheel 4-29 c. If the heavy spot does not stay in that posi- tion, install a heavier weight. D. Repeat steps (b) and (c) until the front wheel is balanced. ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲▲▲ 4. Check: • front wheel static balance ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ ...

Page 215: Front Wheel

Front wheel 4-30 notice ec3p61022 before tightening the wheel axle bolt, push down hard on the handlebars several times and check if the front fork rebounds smooth- ly. ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ a. Insert the front wheel axle from the right side and tighten it with the front ...

Page 216: Rear Wheel

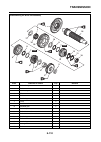

Rear wheel 4-31 eas22030 rear wheel removing the rear wheel, brake disc, wheel sensor, and sensor housing order job/parts to remove q’ty remarks right side cover refer to “general chassis” on page 4-1. 1 rear wheel sensor coupler 1 disconnect. 2 rear wheel sensor 1 3 rear wheel axle pinch bolt 1 loo...

Page 217: Rear Wheel

Rear wheel 4-32 disassembling the rear wheel order job/parts to remove q’ty remarks 1 dust cover 1 2 rear wheel drive hub 1 3 dust seal 1 4 wheel bearing 1 5 rear wheel drive hub damper 6 6 oil seal 1 7 bearing retainer 1 left-hand threads 8 rear wheel sensor rotor 1 9 wheel bearing 1 10 spacer 1 11...

Page 218: Rear Wheel

Rear wheel 4-33 eas22050 removing the rear wheel notice eca1mc1029 keep magnets (including magnetic pick-up tools, magnetic screwdrivers, etc.) away from the rear wheel hub “1”, otherwise the wheel sensor rotor equipped in the wheel hub may be damaged, resulting in improper performance of the abs an...

Page 219: Rear Wheel

Rear wheel 4-34 d. Remove the wheel sensor rotor. E. Remove the wheel bearings “1” with a gener- al bearing puller. ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲▲▲ eas22090 checking the rear wheel 1. Check: • rear wheel axle • rear wheel • wheel bearings • oil seal refer to “checking the front whe...

Page 220: Rear Wheel

Rear wheel 4-35 2. Install: • wheel bearings ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ a. Install the new wheel bearings in the reverse order of disassembly. Notice ec3p61021 do not contact the wheel bearing inner race “1” or balls “2”. Contact should be made only with the outer race “3”. Ti...

Page 221: Rear Wheel

Rear wheel 4-36 eas22170 installing the rear wheel (rear brake disc) 1. Install: • rear brake disc tip tighten the brake disc bolts in stages and in a crisscross pattern. 2. Check: • rear brake disc refer to “checking the rear brake disc” on page 4-56. 3. Lubricate: • oil seal lips 4. Install: • rea...

Page 222: Rear Wheel

Rear wheel 4-37 7. Install: • rear wheel sensor notice eca1mc1030 to route the rear wheel sensor lead, refer to “cable routing” on page 2-47. Tip when installing the rear wheel sensor, check the rear wheel sensor lead for twists and the sensor electrode for foreign materials. 8. Check: • rear wheel ...

Page 223: Front Brake

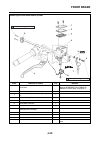

Front brake 4-38 eas22210 front brake removing the front brake pads order job/parts to remove q’ty remarks the following procedure applies to both of the front brake calipers. 1 brake hose holder 1 2 front brake caliper 1 3 brake pad bolt 2 4 brake pad spring 2 5 front brake pad 4 for installation, ...

Page 224: Front Brake

Front brake 4-39 removing the front brake master cylinder order job/parts to remove q’ty remarks brake fluid drain. Refer to “bleeding the hydraulic brake system (abs)” on page 3-17. 1 brake master cylinder reservoir cap 1 2 brake master cylinder reservoir diaphragm hold- er 1 3 brake master cylinde...

Page 225: Front Brake

Front brake 4-40 disassembling the front brake master cylinder order job/parts to remove q’ty remarks 1 brake master cylinder push rod 1 2 dust boot 1 3 circlip 1 4 brake master cylinder kit 1 5 brake master cylinder body 1 for assembly, reverse the disassembly pro- cedure. S.

Page 226: Front Brake

Front brake 4-41 removing the front brake calipers order job/parts to remove q’ty remarks the following procedure applies to both of the front brake calipers. Brake fluid drain. Refer to “bleeding the hydraulic brake system (abs)” on page 3-17. 1 brake hose holder 1 2 brake hose union bolt 1 3 coppe...

Page 227: Front Brake

Front brake 4-42 disassembling the front brake calipers order job/parts to remove q’ty remarks the following procedure applies to both of the front brake calipers. 1 brake pad bolt 2 2 brake pad spring 2 3 front brake pad 4 4 brake caliper piston 4 5 brake caliper piston dust seal 4 6 brake caliper ...

Page 228: Front Brake

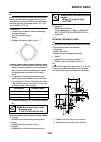

Front brake 4-43 eas22220 introduction warning ewa14100 disc brake components rarely require disas- sembly. Therefore, always follow these pre- ventive measures: • never disassemble brake components un- less absolutely necessary. • if any connection on the hydraulic brake system is disconnected, the...

Page 229: Front Brake

Front brake 4-44 d. Measure the brake disc deflection. E. If out of specification, repeat the adjustment steps until the brake disc deflection is within specification. F. If the brake disc deflection cannot be brought within specification, replace the brake disc. ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ...

Page 230: Front Brake

Front brake 4-45 3. Install: • brake pad bolts • brake caliper 4. Check: • brake fluid level below the minimum level mark “a” → add the specified brake fluid to the proper level. Refer to “checking the brake fluid level” on page 3-16. 5. Check: • brake lever and brake pedal operation soft or spongy ...

Page 231: Front Brake

Front brake 4-46 warning ewa13560 • cover the brake caliper pistons with a rag. Be careful not to get injured when the pis- tons are expelled from the brake caliper. • never try to pry out the brake caliper pis- tons. B. Remove the brake caliper piston dust seals and brake caliper piston seals. ▲▲▲ ...

Page 232: Front Brake

Front brake 4-47 2. Remove: • brake caliper 3. Install: • brake pads • brake pad springs • brake pad bolts • brake caliper • brake hose holder refer to “replacing the front brake pads” on page 4-44. 4. Fill: • brake master cylinder reservoir • brake fluid reservoir (with the specified amount of the ...

Page 233: Front Brake

Front brake 4-48 • copper washers “2” • brake hose (front brake master cylinder to brake pipe/lower joint assembly) “3” tip to collect any remaining brake fluid, place a container under the master cylinder and the end of the brake hose. Eas22500 checking the front brake master cylinder 1. Check: • b...

Page 234: Front Brake

Front brake 4-49 3. Fill: • brake master cylinder reservoir • brake fluid reservoir (with the specified amount of the specified brake fluid) warning ew3p61008 • use only the designated brake fluid. Other brake fluids may cause the rubber seals to deteriorate, causing leakage and poor brake performan...

Page 235: Rear Brake

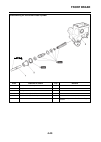

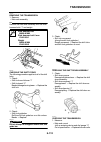

Rear brake 4-50 eas22550 rear brake removing the rear brake pads order job/parts to remove q’ty remarks 1 rear brake caliper bolt 2 2 rear brake caliper 1 3 brake pad shim 2 4 rear brake pad 2 5 brake pad spring 2 for installation, reverse the removal proce- dure. S s.

Page 236: Rear Brake

Rear brake 4-51 removing the rear brake master cylinder order job/parts to remove q’ty remarks brake fluid drain. Refer to “bleeding the hydraulic brake system (abs)” on page 3-17. Right side cover refer to “general chassis” on page 4-1. 1 brake fluid reservoir cap 1 2 brake fluid reservoir diaphrag...

Page 237: Rear Brake

Rear brake 4-52 12 rear brake master cylinder 1 for installation, reverse the removal proce- dure. Removing the rear brake master cylinder order job/parts to remove q’ty remarks 1 2 3 4 5 6 7 9 10 11 8 12 new new 10 new lt lt t r . . 28 nm (2.8 m • kg, 20 ft • ib) t r . . 28 nm (2.8 m • kg, 20 ft • ...

Page 238: Rear Brake

Rear brake 4-53 disassembling the rear brake master cylinder order job/parts to remove q’ty remarks 1 dust boot 1 2 circlip 1 3 brake master cylinder push rod 1 4 brake master cylinder kit 1 5 brake master cylinder body 1 for assembly, reverse the disassembly pro- cedure. S t r . . 16 nm (1.6 m • kg...

Page 239: Rear Brake

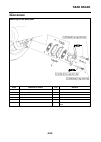

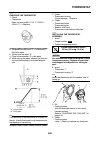

Rear brake 4-54 removing the rear brake caliper order job/parts to remove q’ty remarks brake fluid drain. Refer to “bleeding the hydraulic brake system (abs)” on page 3-17. 1 brake hose union bolt 1 2 copper washer 2 3 brake hose (proportioning valve to rear brake caliper) 1 4 rear brake caliper bol...

Page 240: Rear Brake

Rear brake 4-55 disassembling the rear brake caliper order job/parts to remove q’ty remarks 1 rear brake caliper bolt 2 2 brake pad shim 2 3 rear brake pad 2 4 brake pad spring 2 5 rear brake caliper bracket 1 6 brake caliper piston 1 7 brake caliper piston dust seal 1 8 brake caliper piston seal 1 ...

Page 241: Rear Brake

Rear brake 4-56 eas22560 introduction warning ewa14100 disc brake components rarely require disas- sembly. Therefore, always follow these pre- ventive measures: • never disassemble brake components un- less absolutely necessary. • if any connection on the hydraulic brake system is disconnected, the ...

Page 242: Rear Brake

Rear brake 4-57 tip always install new brake pads, brake pad shims, and brake pad springs as a set. ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ a. Connect a clear plastic hose “1” tightly to the bleed screw “2”. Put the other end of the hose into an open container. B. Loosen the bleed screw an...

Page 243: Rear Brake

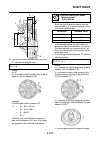

Rear brake 4-58 eas22600 disassembling the rear brake caliper 1. Remove: • brake caliper piston “1” • brake caliper piston dust seal “2” • brake caliper piston seal “3” ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ a. Blow compressed air into the brake hose joint opening “a” to force out the pis...

Page 244: Rear Brake

Rear brake 4-59 • never use solvents on internal brake com- ponents as they will cause the brake caliper piston dust seal and brake caliper piston seal to swell and distort. • whenever a brake caliper is disassembled, replace the brake caliper piston dust seal and brake caliper piston seal. Eas22670...

Page 245: Rear Brake

Rear brake 4-60 4. Remove: • rear brake caliper bolts • rear brake caliper 5. Install: • brake pad springs • rear brake pads • brake pad shims • rear brake caliper bolts • rear brake caliper refer to “replacing the rear brake pads” on page 4-56. 6. Fill: • brake fluid reservoir (with the specified a...

Page 246: Rear Brake

Rear brake 4-61 2. Check: • brake master cylinder kit damage/scratches/wear → replace. 3. Check: • brake fluid reservoir cracks/damage → replace. • brake fluid reservoir diaphragm cracks/damage → replace. 4. Check: • brake hose cracks/damage/wear → replace. Eas22730 assembling the rear brake master ...

Page 247: Rear Brake

Rear brake 4-62 4. Bleed: • brake system refer to “bleeding the hydraulic brake system (abs)” on page 3-17. 5. Check: • brake fluid level below the minimum level mark “a” → add the specified brake fluid to the proper level. Refer to “checking the brake fluid level” on page 3-16. 6. Check: • brake pe...

Page 248: Abs (Anti-Lock Brake System)

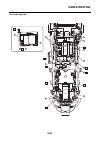

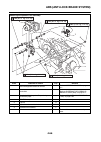

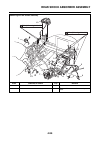

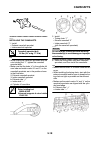

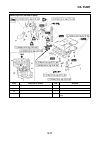

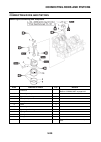

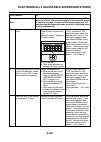

Abs (anti-lock brake system) 4-63 eas22760 abs (anti-lock brake system) et3p61060 abs components chart 4 4 6 5 6 7 8 9 10 11 12,13 14 15 1 1 2 2 3 3 5 21 20 a a 16 17 19 18 11 1. Brake hose (metering valve to right front brake caliper) 2. Brake hose (brake pipe/upper joint assembly to front brake ca...

Page 249: Abs (Anti-Lock Brake System)

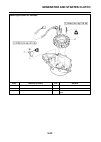

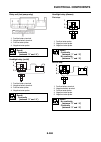

Abs (anti-lock brake system) 4-64 removing the metering valve, proportioning valve, and brake pipes order job/parts to remove q’ty remarks right side cover/air filter case assembly refer to “general chassis” on page 4-1. Brake fluid drain. Refer to “bleeding the hydraulic brake system (abs)” on page...

Page 250: Abs (Anti-Lock Brake System)

Abs (anti-lock brake system) 4-65 12 brake hose (rear brake master cylinder to brake pipe/middle joint assembly) 1 disconnect. 13 brake pipe (front brake master cylinder to brake pipe/lower joint assembly) 1 disconnect. 14 brake pipe/upper joint assembly 1 15 brake pipe/joint assembly stay 1 16 brak...

Page 251: Abs (Anti-Lock Brake System)

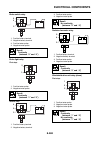

Abs (anti-lock brake system) 4-66 removing the hydraulic unit assembly order job/parts to remove q’ty remarks rear cowlings/side covers/air shroud refer to “general chassis” on page 4-1. Brake fluid drain. Refer to “bleeding the hydraulic brake system (abs)” on page 3-17. Rear fender/metering valve/...

Page 252: Abs (Anti-Lock Brake System)

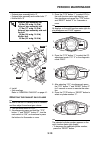

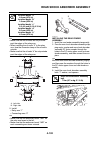

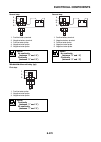

Abs (anti-lock brake system) 4-67 et3p6d003 removing the hydraulic unit assembly notice eca3p6d018 unless necessary, avoid removing and in- stalling the brake pipes of the hydraulic unit assembly. Warning ewa13930 refill with the same type of brake fluid that is already in the system. Mixing fluids ...

Page 253: Abs (Anti-Lock Brake System)

Abs (anti-lock brake system) 4-68 • when using a bolt, do not tighten the bolt until the bolt head touches the hydraulic unit. Other- wise, the brake pipe seating surface could be deformed. Et3p6d004 checking the hydraulic unit assembly 1. Check: • hydraulic unit assembly cracks/damage → replace the...

Page 254: Abs (Anti-Lock Brake System)