- DL manuals

- Yamaha

- Outboard Motor

- 250G

- Owner's Manual

Yamaha 250G Owner's Manual

Summary of 250G

Page 1

Owner’s manual 250g l250g 6s3-28199-70-e0

Page 2

Emu25050 read this owner’s manual carefully before operating your outboard motor..

Page 3: Important Manual Information

Important manual information emu25101 to the owner thank you for choosing a yamaha outboard motor. This owner’s manual contains infor- mation needed for proper operation, mainte- nance and care. A thorough understanding of these simple instructions will help you ob- tain maximum enjoyment from your ...

Page 4: Table of Contents

Table of contents general information .......................... 1 identification numbers record .......... 1 outboard motor serial number .......... 1 key number....................................... 1 ec label........................................... 1 safety information ..........................

Page 5: Table of Contents

Table of contents procedure ....................................... 33 trimming outboard motor .............. 34 adjusting trim angle ........................ 34 adjusting boat trim .......................... 35 tilting up and down ....................... 36 procedure for tilting up ...................

Page 6: General Information

1 general information emu25170 identification numbers record emu25182 outboard motor serial number the outboard motor serial number is stamped on the label attached to the port side of the clamp bracket or the upper part of the swivel bracket. Record your outboard motor serial number in the spaces p...

Page 7: General Information

General information 2 emu25371 safety information ● before mounting or operating the outboard motor, read this entire manual. Reading it should give you an understanding of the motor and its operation. ● before operating the boat, read any own- er’s or operator’s manuals supplied with it and all lab...

Page 8: General Information

General information 3 watch for obstacles and other traffic. ● always watch carefully for swimmers dur- ing the engine operation. ● stay away from swimming areas. ● when a swimmer is in the water near you shift into neutral and shut off the engine. ● do not illegally discard empty containers used to...

Page 9: General Information

General information 4 dry rags. ● do not overfill the fuel tank. ● tighten the filler cap securely after re- fueling. ● if you should swallow some gasoline, inhale a lot of gasoline vapor, or get gasoline in your eyes, get immediate medical attention. ● if any gasoline spills onto your skin, im- med...

Page 10: General Information

General information 5 and can advise you and install a propeller on your outboard that is best suited to your ap- plication. Note: select a propeller which will allow the engine to reach the middle or upper half of the oper- ating range at full throttle with the maximum boat load. If operating condi...

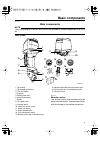

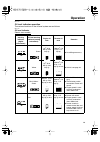

Page 11: Basic Components

6 basic components emu25797 main components note: * may not be exactly as shown; also may not be included as standard equipment on all mod- els. 250g, l250g emu26180 remote control the remote control lever actuates both the shifter and the throttle. The electrical switch- es are mounted on the remot...

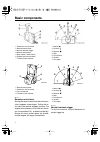

Page 12: Basic Components

Basic components 7 emu26190 remote control lever moving the lever forward from the neutral po- sition engages forward gear. Pulling the le- ver back from neutral engages reverse. The engine will continue to run at idle until the le- ver is moved about 35° (a detent can be felt). Moving the lever far...

Page 13: Basic Components

Basic components 8 emu26211 neutral throttle lever to open the throttle without shifting into ei- ther forward or reverse, put the remote con- trol lever in the neutral position and lift the neutral throttle lever. Note: the neutral throttle lever will operate only when the remote control lever is i...

Page 14: Basic Components

Basic components 9 note: ● the free accelerator button can only be used when the remote control lever is in the neutral position. ● after the button is pushed, the throttle be- gins to open after the remote control lever is moved at least 35°. ● after using the free accelerator, return the remote co...

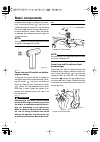

Page 15: Basic Components

Basic components 10 your arm or leg while operating. ● do not attach the lanyard to clothing that could tear loose. Do not route the lanyard where it could become entan- gled, preventing it from functioning. ● avoid accidentally pulling the lanyard during normal operation. Loss of en- gine power mea...

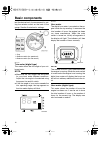

Page 16: Basic Components

Basic components 11 outboard motor angle in relation to the tran- som. Pressing the switch “ ” (up) trims the outboard motor up, then tilts it up. Pressing the switch “ ” (down) tilts the outboard mo- tor down and trims it down. When the switch is released, the outboard motor will stop in its curren...

Page 17: Basic Components

Basic components 12 note: ● on the dual engine control, the switch on the remote control grip controls both out- board motors at the same time. ● for instructions on using the power trim and tilt switches, see pages 34 and 36. Emu26241 trim tab with anode the trim tab should be adjusted so that the ...

Page 18: Basic Components

Basic components 13 emu31320 top cowling lock levers to remove the top cowling, raise the lower part of the front lock lever to release the lock. Next, turn the rear lock levers to release them, allowing the top cowling to be re- moved. When replacing the cowling, check to be sure it fits properly i...

Page 19: Basic Components

Basic components 14 note: the water separator and engine trouble warning indicators only operate when the en- gine is equipped with the appropriate func- tions. Emu26550 oil level indicator (digital type) this indicator shows the engine oil level. If the oil level falls below the lower limit, the wa...

Page 20: Basic Components

Basic components 15 lect the desired unit of measurement by set- ting the selector switch on the back of the gauge. See the illustration for settings. Emu26620 trim meter (digital type) this meter shows the trim angle of your out- board motor. Note: ● memorize the trim angles that work best for your...

Page 21: Basic Components

Basic components 16 ● changing the display format ● pressing the “ ” (mode) button chang- es the display format in the following pat- tern: ● total hours → trip hours → display off ● resetting the trip hours ● simultaneously pressing the “ ” (set) and “ ” (mode) buttons for more than 1 second while ...

Page 22: Basic Components

Basic components 17 note: the clock operates on battery power. Dis- connecting the battery will stop the clock. Reset the clock after connecting the battery. Emu26710 fuel gauge the fuel level is indicated by eight segments. When all segments are showing, the fuel tank is full. Caution: ecm00860 the...

Page 23: Basic Components

Basic components 18 emu26740 fuel management meter the fuel management meter shows the state of the fuel consumption while the engine is running. Note: after the main switch is first turned on, all segments of the display come on as a test. After a few seconds, the gauge will change to normal operat...

Page 24: Basic Components

Basic components 19 ● the fuel consumption meter and fuel economy meter will indicate the same unit of measurement. Emu26760 fuel consumption meter this gauge displays the total amount of fuel consumed since the gauge was last reset. Press the “ ” (mode) button repeatedly until the indicator on the ...

Page 25: Basic Components

Basic components 20 until the indicator on the face of the gauge points to “ ” (synchronizer). Note: if the two engines’ speeds are not synchro- nized while cruising, they can be synchro- nized by adjusting trim angle or throttle. Emu26801 warning system caution: ecm00090 do not continue to operate ...

Page 26: Basic Components

Basic components 21 note: dual engine drive users: should the overheat warning system of one engine activate, the engine will slow down and the buzzer will sound. This will cause the other engine to slow down and the buzzer to sound. To switch off the warning activation on the engine not affected by...

Page 27: Basic Components

Basic components 22 1. Oil filter 1 zmu01952.

Page 28: Operation

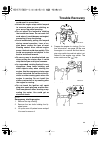

23 operation emu26901 installation caution: ecm00110 incorrect engine height or obstructions to smooth water flow (such as the design or condition of the boat, or accessories such as transom ladders or depth finder transducers) can create airborne water spray while the boat is cruising. Severe engin...

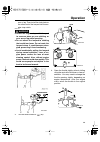

Page 29: Operation

Operation 24 emu26930 mounting height (boat bottom) to run your boat at optimum efficiency, the water resistance (drag) of the boat and out- board motor must be made as little as possi- ble. The mounting height of the outboard motor greatly affects the water resistance. If the mounting height is too...

Page 30: Operation

Operation 25 emu27060 gasoline and engine oil mixing chart (50:1) caution: ecm00150 be sure to mix gasoline and oil complete- ly, otherwise the engine may be dam- aged. Emu30310 procedure for oil injection models run the engine under load (in gear with a propeller installed) as follows. 1. First 10 ...

Page 31: Operation

Operation 26 emu27120 oil ● check to be sure you have plenty of oil for your trip. Emu27130 controls ● check throttle, shift, and steering for prop- er operation before starting the engine. ● the controls should work smoothly, with- out binding or unusual free play. ● look for loose or damaged conne...

Page 32: Operation

Operation 27 ing conditions. No fuel premixing is needed. Simply pour gasoline into the fuel tank and oil into the oil tank. Convenient indicators show the status of the oil supply. For details on how to read the indicators, see page 28. To fill the engine oil tank, proceed as follows: 1. Pour engin...

Page 33: Operation

Operation 28 emu27321 oil level indicator operation the various functions of the oil level system are as follows: emu27381 oil level indicator electric start models oil level warning indicator (digital tachometer) oil level warning indicator (analog tachometer) engine oil tank remote oil tank remark...

Page 34: Operation

Operation 29 emu27450 operating engine emu27480 feeding fuel warning ewm00420 ● before starting the engine, make sure that the boat is tightly moored and that you can steer clear of any obstructions. Be sure there are no swimmers in the water near you. ● when the air vent screw is loosened, gasoline...

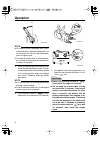

Page 35: Operation

Operation 30 arm or leg. Then install the lock plate on the other end of the lanyard into the en- gine stop switch. Warning ewm00120 ● attach the engine stop switch lanyard to a secure place on your clothing, or your arm or leg while operating. ● do not attach the lanyard to clothing that could tear...

Page 36: Operation

Operation 31 note: ● on remote controls equipped with a neu- tral throttle lever, a good starting point is to lift the lever just until you feel resistance, then lift slightly more. ● the neutral throttle lever or free accelera- tor can only be used when the remote con- trol lever is in neutral. 5. ...

Page 37: Operation

Operation 32 emu27670 warming up engine emu27681 choke start models 1. After starting the engine, allow it to idle for 3 minutes to warm up. Failure to do so will shorten engine life. Gradually re- turn the choke knob to its home position as the engine warms up. 2. Check for a steady flow of water f...

Page 38: Operation

Operation 33 emu27784 reverse (automatic reverse lock and power trim and tilt models) warning ewm00190 when operating in reverse, go slowly. Do not open the throttle more than half. Oth- erwise the boat could become unstable, which could result in loss of control and an accident. Tiller control mode...

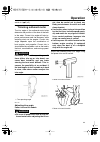

Page 39: Operation

Operation 34 switch to “ ” (off). Emu27861 trimming outboard motor the trim angle of the outboard motor helps determine the position of the bow of the boat in the water. Correct trim angle will help im- prove performance and fuel economy while reducing strain on the engine. Correct trim angle depend...

Page 40: Operation

Operation 35 to raise the bow (trim-out), press the switch “ ” (up). To lower the bow (trim-in), press the switch “ ” (down). Make test runs with the trim set to different angles to find the position that works best for your boat and operating conditions. Note: to adjust the trim angle while the boa...

Page 41: Operation

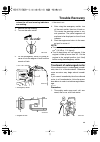

Operation 36 note: depending on the type of boat, the outboard motor trim angle may have little effect on the trim of the boat when operating. Emu27933 tilting up and down if the engine will be stopped for some time or if the boat is moored in shallows, the out- board motor should be tilted up to pr...

Page 42: Operation

Operation 37 4. Push the tilt support knob into the clamp bracket or pull the tilt support lever to- ward you to support the engine. Warning ewm00260 after tilting the outboard motor, be sure to support it with the tilt support knob or tilt support lever. Otherwise the outboard motor could fall back...

Page 43: Operation

Operation 38 emu28053 procedure for tilting down power trim and tilt models / power tilt models 1. Push the power tilt / power trim and tilt switch “ ” (up) until the outboard motor is supported by the tilt rod and the tilt support lever / tilt support knob becomes free. 2. Release the tilt support ...

Page 44: Operation

Operation 39 ting up for and cruising in shallow water. Otherwise severe damage from overheat- ing can result. Emu28184 procedure for power trim and tilt / power tilt models 1. Place the gear shift lever in neutral. 2. Slightly tilt the outboard motor up to the desired position using the power trim ...

Page 45: Operation

Operation 40 note: for cooling system flushing instructions, see page 42. Cruising in turbid water yamaha strongly recommends that you use the optional chromium-plated water pump kit (not available for some models) if you use the outboard motor in turbid (muddy) water conditions..

Page 46: Maintenance

41 maintenance emu28217 specifications dimension: overall length: 854 mm (33.6 in) overall width: 562 mm (22.1 in) overall height x: 1785 mm (70.3 in) transom height x: 641 mm (25.2 in) weight (sus) x: 250geto 240.0 kg (529 lb) l250geto 242.0 kg (534 lb) performance: full throttle operating range: 4...

Page 47: Maintenance

Maintenance 42 55.0 nm (40.6 ft-lb) (5.61 kgf-m) emu28222 transporting and storing outboard motor warning ewm00690 ● leaking fuel is a fire hazard. When transporting and storing the outboard motor, close the air vent screw and fuel cock to prevent fuel from leaking. ● use care when transporting fuel...

Page 48: Maintenance

Maintenance 43 supply water to the cooling water passag- es. Caution: ecm00310 avoid running the outboard motor at high speed while on the flushing attachment, otherwise overheating could occur. 5. Cooling system flushing is essential to prevent the cooling system from clog- ging up with salt, sand,...

Page 49: Maintenance

Maintenance 44 emu28430 battery care warning ewm00330 battery electrolytic fluid is dangerous; it contains sulfuric acid and therefore is poisonous and highly caustic. Always follow these preventive mea- sures: ● avoid bodily contact with electrolytic fluid as it can cause severe burns or permanent ...

Page 50: Maintenance

Maintenance 45 2. Screw the garden hose connector onto a garden hose which is connected to a fresh water supply. 3. With the engine off, turn on the water tap and let the water flush through the cool- ing passages for about 15 minutes. Turn off the water and disconnect the garden hose. 4. When flush...

Page 51: Maintenance

Maintenance 46 emu28476 periodic maintenance warning ewm01070 be sure to turn off the engine when you perform maintenance unless otherwise specified. If you or the owner is not famil- iar with machine servicing, this work should be done by your yamaha dealer or other qualified mechanic. Emu28510 rep...

Page 52: Maintenance

Maintenance 47 emu28522 maintenance chart frequency of maintenance operations may be adjusted according to the operating condi- tions, but the following table gives general guidelines. Refer to the sections in this chapter for explanations of each owner-specific action. Note: when operating in salt ...

Page 53: Maintenance

Maintenance 48 throttle position sen- sor inspection / adjustment water pump inspection / replace- ment oil pump inspection / adjustment oil tank water drain inspection / cleaning spark plug(s) cleaning / adjustment / replacement item actions initial every 10 hours (1 month) 50 hours (3 months) 100 ...

Page 54: Maintenance

Maintenance 49 emu28940 greasing yamaha grease a (water resistant grease) yamaha grease d (corrosion resistant grease; for propeller shaft) 250g, l250g emu28952 cleaning and adjusting spark plug warning ewm00560 when removing or installing a spark plug, be careful not to damage the insulator. A dama...

Page 55: Maintenance

Maintenance 50 of the spark plug can indicate something about the condition of the engine. For exam- ple, if the center electrode porcelain is very white, this could indicate an intake air leak or carburetion problem in that cylinder. Do not attempt to diagnose any problems yourself. Instead, take t...

Page 56: Maintenance

Maintenance 51 checkpoints ● fuel system parts leakage ● fuel line joint leakage ● fuel line cracks or other damage ● fuel connector leakage emu28980 inspecting fuel filter warning ewm00310 gasoline is highly flammable, and its va- pors are flammable and explosive. ● if you have any question about p...

Page 57: Maintenance

Maintenance 52 4. Reinstall the filter element in the cup. Make sure the o-ring is in position in the cup. Insert the cup and o-ring into the fil- ter housing. Lift up and hold the locking tab to screw the ring nut onto the filter housing until the ring is lightly seated. 5. Tighten the ring nut app...

Page 58: Maintenance

Maintenance 53 emu29112 checking wiring and connectors ● check that each grounding wire is properly secured. ● check that each connector is engaged se- curely. Emu29120 exhaust leakage start the engine and check that no exhaust leaks from the joints between the exhaust cover, cylinder head, and body...

Page 59: Maintenance

Maintenance 54 4. Use the tilt support lever to lock the mo- tor in the up position. Operate the tilt down switch briefly so the motor is sup- ported by the tilt support lever. 5. Check that the tilt rod and trim rods are free of corrosion or other flaws. 6. Activate the tilt-down switch until the t...

Page 60: Maintenance

Maintenance 55 checkpoints ● check each of the propeller blades for wear, erosion from cavitation or ventila- tion, or other damage. ● check the propeller shaft for damage. ● check the splines / shear pin for wear or damage. ● check for fish line tangled around the pro- peller shaft. ● check the pro...

Page 61: Maintenance

Maintenance 56 from that expected. Caution: ecm00340 ● be sure to install the thrust washer be- fore installing the propeller, otherwise the lower case and propeller boss could be damaged. ● be sure to use a new cotter pin and bend the ends over securely. Otherwise the propeller could come off durin...

Page 62: Maintenance

Maintenance 57 to drain completely. Caution: ecm00710 inspect the used oil after it has been drained. If the oil is milky, water is getting into the gear case which can cause gear damage. Consult a yamaha dealer for re- pair of the lower unit seals. Note: for disposal of used oil consult your yamaha...

Page 63: Maintenance

Maintenance 58 emu29320 checking battery (for electric start models) warning ewm00330 battery electrolytic fluid is dangerous; it contains sulfuric acid and therefore is poisonous and highly caustic. Always follow these preventive mea- sures: ● avoid bodily contact with electrolytic fluid as it can ...

Page 64: Maintenance

Maintenance 59 tion in the boat. Install a fully charged bat- tery in the holder. Caution: ecm01121 ● make sure the main switch (on applica- ble models) is “ ” (off) before work- ing on the battery. ● reversal of the battery cables will dam- age the electrical parts. ● connect the red battery cable ...

Page 65: Maintenance

Maintenance 60 emu29400 coating the boat bottom a clean hull improves boat performance. The boat bottom should be kept as clean of ma- rine growth as possible. If necessary, the boat bottom can be coated with an anti-foul- ing paint approved for your area to inhibit marine growth. Do not use anti-fo...

Page 66: Trouble Recovery

61 trouble recovery emu29424 troubleshooting a problem in the fuel, compression, or igni- tion systems can cause poor starting, loss of power, or other problems. This section de- scribes basic checks and possible remedies, and covers all yamaha outboard motors. Therefore some items may not apply to ...

Page 67: Trouble Recovery

Trouble recovery 62 q. Is fuel system obstructed? A. Check for pinched or kinked fuel line or other obstructions in fuel system. Q. Is fuel contaminated or stale? A. Fill tank with clean, fresh fuel. Q. Is fuel filter clogged? A. Clean or replace filter. Q. Have ignition parts failed? A. Have servic...

Page 68: Trouble Recovery

Trouble recovery 63 a. Have serviced by a yamaha dealer. Q. Is load on boat improperly distributed? A. Distribute load to place boat on an even plane. Q. Is water pump or thermostat faulty? A. Have serviced by a yamaha dealer. Q. Is there excess water in fuel filter cup? A. Drain filter cup. Engine ...

Page 69: Trouble Recovery

Trouble recovery 64 q. Is fuel joint connection incorrect? A. Connect correctly. Q. Is heat range of spark plug incorrect? A. Inspect spark plug and replace it with rec- ommended type. Q. Is high pressure fuel pump drive belt bro- ken? A. Have serviced by a yamaha dealer. Q. Is engine not responding...

Page 70: Trouble Recovery

Trouble recovery 65 emu29462 replacing fuse if the fuse has blown on an electric start model, open the fuse holder and replace the fuse with a new one of the proper amperage. Warning ewm00630 be sure to use the specified fuse. An in- correct fuse or a piece of wire could allow excessive current flow...

Page 71: Trouble Recovery

Trouble recovery 66 could result in an accident. ● attach the engine stop switch lanyard to a secure place on your clothing, or your arm or leg while operating. ● do not attach the lanyard to clothing that could tear loose. Do not route the cord where it could become entangled, preventing it from fu...

Page 72: Trouble Recovery

Trouble recovery 67 5. Insert the knotted end of the emergency starter rope into the notch in the flywheel rotor and wind the rope around the fly- wheel clockwise. 6. Pull the rope slowly until resistance is felt. 7. Remove the rope from the flywheel tem- porarily. 8. Rewind the rope around the flyw...

Page 73: Trouble Recovery

Trouble recovery 68 unless the oil level warning indicators are working. 1. Remove the top cowling. 2. Turn on the main switch. 3. Lift the emergency switch to pump re- serve oil into the engine oil tank from the remote oil tank. 4. After using the emergency switch, turn off the main switch, then tu...

Page 74: Trouble Recovery

Trouble recovery 69 2. Remove the spark plugs and face the spark plug holes downward to allow any water, mud, or contaminants to drain. 3. Drain the fuel from the carburetor, fuel filter, and fuel line. 4. Feed fogging oil or engine oil through the carburetor(s) and spark plug holes while cranking w...

Page 76

Yamaha motor co., ltd. Printed on recycled paper printed in japan july 2005–0.1 × 1 !.