- DL manuals

- Yamaha

- Outboard Motor

- 40X

- Owner's Manual

Yamaha 40X Owner's Manual

Summary of 40X

Page 1

Read this manual carefully before operating this outboard motor. Owner’s manual 40x e40x 66t-28199-2c-e0 66t-9-2c-1e0.Book 1 ページ 2010年2月10日 水曜日 午前10時18分.

Page 2

Emu25052 read this manual carefully before operating this outboard motor. Keep this manual onboard in a waterproof bag when boating. This manual should stay with the outboard motor if it is sold. 66t-9-2c-1e0.Book 1 ページ 2010年2月10日 水曜日 午前10時18分.

Page 3: Important Manual Information

Important manual information emu25107 to the owner thank you for selecting a yamaha outboard motor. This owner’s manual contains infor- mation needed for proper operation, mainte- nance and care. A thorough understanding of these simple instructions will help you ob- tain maximum enjoyment from your...

Page 4: Table of Contents

Table of contents safety information............................. 1 outboard motor safety ..................... 1 propeller............................................ 1 rotating parts.................................... 1 hot parts ........................................... 1 electric shock..........

Page 5: Table of Contents

Table of contents hour meter ..................................... 24 engine control system.................... 25 alert system ................................... 25 overheat alert ................................. 25 installation ....................................... 26 installation ...............

Page 6: Table of Contents

Table of contents connecting the battery.................... 67 disconnecting the battery ............... 67 trouble recovery............................ 69 troubleshooting ............................. 69 temporary action in emergency..... 72 impact damage ............................... 72 replaci...

Page 7: Safety Information

1 safety information emu33622 outboard motor safety observe these precautions at all times. Emu36501 propeller people can be injured or killed if they come in contact with the propeller. The propeller can keep moving even when the motor is in neutral, and sharp edges of the propeller can cut even wh...

Page 8: Safety Information

Safety information 2 emu33820 gasoline exposure and spills take care not to spill gasoline. If gasoline spills, wipe it up immediately with dry rags. Dispose of rags properly. If any gasoline spills onto your skin, immedi- ately wash with soap and water. Change clothing if gasoline spills on it. If ...

Page 9: Safety Information

Safety information 3 swamping. Emu33772 avoid collisions scan constantly for people, objects, and oth- er boats. Be alert for conditions that limit your visibility or block your vision of others. Operate defensively at safe speeds and keep a safe distance away from people, ob- jects, and other boats...

Page 10: General Information

4 general information emu25171 identification numbers record emu25183 outboard motor serial number the outboard motor serial number is stamped on the label attached to the port side of the clamp bracket. Record your outboard motor serial number in the spaces provided to assist you in ordering spare ...

Page 11: General Information

General information 5 emu25213 c-tick label engines affixed with this label conform to certain portion(s) of the australian radio communications act. 1. Ce marking location 1. Ce marking location 1 zmu04866 1 zmu06081 zmu06040 1. C-tick label location 1. C-tick label location 1 zmu04902 1 zmu06081 z...

Page 12: General Information

General information 6 emu33522 read manuals and labels before operating or working on this outboard motor: ● read this manual. ● read any manuals supplied with the boat. ● read all labels on the outboard motor and the boat. If you need any additional information, contact your yamaha dealer. Emu33832...

Page 13: General Information

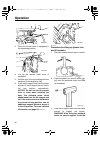

General information 7 emu33912 contents of labels the above warning labels mean as follows. 1 warning ewm01691 emergency starting does not have start- in-gear protection. Ensure shift control is in neutral before starting engine. 2 warning ewm01681 ● keep hands, hair, and clothing away from rotating...

Page 14: General Information

General information 8 emu33843 symbols the following symbols mean as follows. Notice/warning read owner’s manual hazard caused by continuous rotation electrical hazard remote control lever/gear shift lever operat- ing direction, dual direction engine start/ engine cranking zmu05696 zmu05664 zmu05665...

Page 15: Specifications

9 specifications and requirements emu31480 specifications tip: “(al)” stated in the specification data below represents the numerical value for the alumi- num propeller installed. Likewise, “(sus)” represents the value for stainless steel propeller installed and “(pl)” for plastic propeller installe...

Page 16: Installation Requirements

Specifications and requirements 10 e40xmh manual tilt propeller mark: g fuel and oil: recommended fuel: regular unleaded gasoline fuel tank capacity: 24 l (6.34 us gal, 5.28 imp.Gal) recommended engine oil: yamalube 2-stroke outboard motor oil recommended engine oil: tc-w3 fuel:oil ratio: regular ga...

Page 17: Battery Requirements

Specifications and requirements 11 your yamaha dealer. The remote control unit must be equipped with a start-in-gear protection device(s). This device prevents the engine from starting un- less it is in neutral. Emu25694 battery requirements emu25721 battery specifications the engine cannot be start...

Page 18: Start-In-Gear Protection

Specifications and requirements 12 emu25770 start-in-gear protection yamaha outboard motors or yamaha-ap- proved remote control units are equipped with start-in-gear protection device(s). This feature permits the engine to be started only when it is in neutral. Always select neutral before starting ...

Page 19: Motor Disposal Requirements

Specifications and requirements 13 boat bottom can be coated with an anti-foul- ing paint approved for your area to inhibit marine growth. Do not use anti-fouling paint which includes copper or graphite. These paints can cause more rapid engine corrosion. Emu36341 motor disposal requirements never i...

Page 20: Components

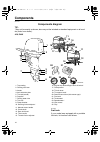

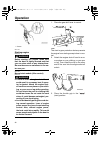

14 components emu2579t components diagram tip: * may not be exactly as shown; also may not be included as standard equipment on all mod- els (order from dealer). 40x, e40x emu25802 fuel tank if your model was equipped with a portable fuel tank, its function is as follows. 1 2 18 11 12 13 16 15 14 11...

Page 21: Components

Components 15 warning ewm00020 the fuel tank supplied with this engine is its dedicated fuel reservoir and must not be used as a fuel storage container. Com- mercial users should conform to relevant licensing or approval authority regula- tions. Emu25830 fuel joint this joint is used to connect the ...

Page 22: Components

Components 16 emu26201 neutral interlock trigger to shift out of neutral, first pull the neutral in- terlock trigger up. Emu26212 neutral throttle lever to open the throttle without shifting into ei- ther forward or reverse, put the remote con- trol lever in the neutral position and lift the neutral...

Page 23: Components

Components 17 the left or right as necessary. Emu25923 gear shift lever move the gear shift lever forward to engage the forward gear or rearward to engage the reverse gear. Emu25941 throttle grip the throttle grip is on the tiller handle. Turn the grip counterclockwise to increase speed and clockwis...

Page 24: Components

Components 18 or throttle grip, which could result in an accident. [ewm00032] when constant speed is desired, tighten the adjuster to maintain the desired throttle set- ting. Emu25994 engine shut-off cord (lanyard) and clip the clip must be attached to the engine shut- off switch for the engine to r...

Page 25: Components

Components 19 emu26012 choke knob for pull type to supply the engine with the rich fuel mix- ture required to start, pull out this knob. Emu26073 manual starter handle the manual starter handle is used to crank and start the engine. Emu26091 main switch the main switch controls the ignition system; ...

Page 26: Components

Components 20 if the resistance does not increase even when the lever is turned to the port side “a”, make sure that the nut is tightened to the specified torque. Tip: ● steering movement is blocked when the adjuster lever is set to the “a” position. ● check the tiller handle for smooth move- ment w...

Page 27: Components

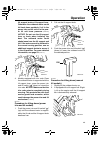

Components 21 emu26244 trim tab with anode warning ewm00840 an improperly adjusted trim tab could cause difficult steering. Always test run after the trim tab has been installed or re- placed to be sure steering is correct. Be sure you have tightened the bolt after ad- justing the trim tab. The trim...

Page 28: Components

Components 22 to lock it, set the tilt lock lever in the lock po- sition. To release, push the tilt lock lever in the release position. Emu26321 tilt support knob to keep the outboard motor in the tilted up position, push the tilt support knob under the swivel bracket. Notice ecm00660 do not use the...

Page 29: Components

Components 23 1. Cowling lock lever(s) zmu02009 1 66t-9-2c-1e0.Book 23 ページ 2010年2月10日 水曜日 午前10時18分.

Page 30: Instruments and Indicators

24 instruments and indicators emu26481 analog tachometer the gauge shows the engine speed. Emu26591 analog speedometer this gauge shows the boat speed in km/h and mph. Emu26631 hour meter this gauge shows the number of hours the engine has been run. Tip: this gauge can be set to count the amount of ...

Page 31: Engine Control System

25 engine control system emu26803 alert system notice ecm00091 do not continue to operate the engine if a alert device has activated. Consult your yamaha dealer if the problem cannot be located and corrected. Emu2681c overheat alert this engine has an overheat-alert device. If the engine temperature...

Page 32: Installation

26 installation emu26902 installation the information presented in this section is intended as reference only. It is not possible to provide complete instructions for every possible boat and motor combination. Proper mounting depends in part on experience and the specific boat and motor combination....

Page 33: Installation

Installation 27 notice ecm01634 ● make sure that the idle hole is high enough to prevent water from entering the engine even if the boat is stationary with the maximum load. ● incorrect engine height or obstructions to the smooth flow of water (such as the design or condition of the boat, or ac- ces...

Page 34: Installation

Installation 28 packaging. If used, they must be of at least the same quality of material and strength and must be tightened se- curely. After tightening, test run the engine and check their tightness. [ewm00651] 1. Bolts zmu02637 1 66t-9-2c-1e0.Book 28 ページ 2010年2月10日 水曜日 午前10時18分.

Page 35: Operation

29 operation emu36381 first-time operation emu30174 breaking in engine your new engine requires a period of break- in to allow mating surfaces of moving parts to wear in evenly. Correct break-in will help en- sure proper performance and longer engine life. Notice: failure to follow the break-in proc...

Page 36: Operation

Operation 30 emu37141 fuel level be sure you have plenty of fuel for your trip. A good rule is to use 1/3 of your fuel to get to the destination, 1/3 to return, and to keep 1/3 as an emergency reserve. With the boat lev- el on a trailer or in the water, check the fuel level. For fuel filling instruc...

Page 37: Operation

Operation 31 ● operate the throttle levers several times to make sure there is no hesitation in their travel. Operation should be smooth over the complete range of motion, and each le- ver should return completely to the idle po- sition. ● look for loose or damaged connections of the throttle and sh...

Page 38: Operation

Operation 32 emu34581 power trim and tilt system warning ewm01930 ● never get under the lower unit while it is tilted, even when the tilt support lever is locked. Severe injury could occur if the outboard motor accidentally falls. ● body parts can be crushed between the motor and the clamp bracket w...

Page 39: Operation

Operation 33 some gasoline in your eyes, see your doctor immediately. If gasoline spills on your skin, wash with soap and wa- ter. If gasoline spills on your clothing, change your clothes. 1. Be sure the engine is stopped. 2. Disconnect the fuel line from the fuel tank and tighten the air vent screw...

Page 40: Operation

Operation 34 if equipped with a portable fuel tank 1. Pour oil into the portable fuel tank, and then add gasoline. 2. Replace the fuel tank cap and close tightly. 3. Shake the fuel tank to mix the fuel thor- oughly. 4. Make sure that the oil and gasoline are mixed. If equipped with a built-in fuel t...

Page 41: Operation

Operation 35 the oil gradually as the gasoline is being add- ed to the tank. Emu27452 operating engine warning ewm00420 ● before starting the engine, make sure that the boat is tightly moored and that you can steer clear of any obstructions. Be sure there are no swimmers in the water near you. ● whe...

Page 42: Operation

Operation 36 emu27493 starting engine warning ewm01600 before starting the engine, make sure that the boat is tightly moored and that you can steer clear of any obstructions. Be sure there are no swimmers in the wa- ter near you. Emu27508 manual start models (tiller control) warning ewm01840 ● failu...

Page 43: Operation

Operation 37 4. Pull out / turn the choke knob fully. After the engine starts, replace / return the knob to the home position. Tip: ● it is not necessary to use the choke when starting a warm engine. ● if the choke knob is left in the “ ” (start) position while the engine is running, the engine will...

Page 44: Operation

Operation 38 emu27636 manual start models (remote control) warning ewm01840 ● failure to attached engine shut-off cord could result in a runaway boat if opera- tor is ejected. Attach the engine shut- off cord to a secure place on your cloth- ing, or your arm or leg while operating. Do not attach the...

Page 45: Operation

Operation 39 tip: ● it is not necessary to use the choke when starting a warm engine. ● if the choke knob is left in the “ ” (start) position while the engine is running, the engine will run poorly or stall. 5. Pull the manual starter handle slowly un- til you feel resistance. Then give a strong pul...

Page 46: Operation

Operation 40 or leg. Then install the clip on the other end of the cord into the engine shut-off switch. 3. Turn the main switch to “ ” (on). 4. Open the throttle slightly without shifting using the neutral throttle lever or free ac- celerator. You may need to change the throttle opening slightly de...

Page 47: Operation

Operation 41 7. Immediately after the engine starts, re- lease the main switch and allow it to re- turn to “ ” (on). Notice: never turn the main switch to “ ” (start) while the engine is running. Do not keep the starter motor turning for more than 5 seconds. If the starter motor is turned continuous...

Page 48: Operation

Operation 42 swimmers or obstacles in the water near you. Notice ecm01610 warm up the engine before shifting into gear. Until the engine is warm, the idle speed may be higher than normal. High idle speed can prevent you from shifting back to neutral. If this occurs, stop the engine, shift to neutral...

Page 49: Operation

Operation 43 2. After the engine is at idle speed in gear move the remote control lever / gear shift lever firmly and crisply into the neu- tral position. Emu31742 stopping boat warning ewm01510 ● do not use the reverse function to slow down or stop the boat as it could cause you to lose control, be...

Page 50: Operation

Operation 44 2. After stopping the engine, disconnect the fuel line if there is a fuel joint on the outboard motor. 3. Tighten the air vent screw on the fuel tank cap (if equipped). 4. Remove the key if the boat will be left un- attended. Tip: the engine can also be stopped by pulling the cord and r...

Page 51: Operation

Operation 45 emu27872 adjusting trim angle for manual tilt models there are 4 or 5 holes provided in the clamp bracket to adjust the outboard motor trim an- gle. 1. Stop the engine. 2. Tilt the outboard motor up, and then re- move the trim rod from the clamp brack- et. 3. Reposition the rod in the d...

Page 52: Operation

Operation 46 board motor when adjusting the trim angle. Body parts can be crushed be- tween the motor and the clamp bracket when the motor is trimmed or tilted. ● use caution when trying a trim position for the first time. Increase speed gradu- ally and watch for any signs of instabil- ity or contro...

Page 53: Operation

Operation 47 also makes the boat unstable. Resistance at the bow is greatly increased, heightening the danger of “bow steering” and making opera- tion difficult and dangerous. Tip: depending on the type of boat, the outboard motor trim angle may have little effect on the trim of the boat when operat...

Page 54: Operation

Operation 48 3. Place the tilt lock lever (if equipped) in the release/up position. 4. Pull up the shallow water lever (if equipped). 5. Hold the rear of the top cowling with one hand and tilt the engine up fully. 6. Push the tilt support knob into the clamp bracket. Or the tilt support bar will tur...

Page 55: Operation

Operation 49 tilt support knob or tilt support lever. Otherwise the outboard motor could fall back down suddenly if oil in the power trim and tilt unit or in the pow- er tilt unit loses pressure. [ewm00262] notice: do not use the tilt support lever or knob when trailering the boat. The outboard moto...

Page 56: Operation

Operation 50 3. If equipped with a tilt support knob: pull it out, then slowly tilt the engine down. Emu28061 shallow water emu28073 cruising in shallow water (manual tilt models) warning ewm01781 ● run the boat at the lowest possible speed when using the shallow water cruising system. The tilt lock...

Page 57: Operation

Operation 51 cruising. 4. To return the outboard motor to the nor- mal running position, place the remote control lever / gear shift lever in neutral. 5. Place the tilt lock lever in the lock/down position, then slightly tilt the outboard motor up until the tilt support bar auto- matically returns t...

Page 58: Operation

Operation 52 emu28195 cruising in other conditions cruising in salt water after operating in salt water, flush the cooling water passages with fresh water to prevent them from becoming clogged. Also rinse the outside of the outboard motor with fresh wa- ter. Cruising in muddy, turbid, or acidic wate...

Page 59: Maintenance

53 maintenance emu2822a transporting and storing outboard motor warning ewm02620 ● use care when transporting fuel tank, whether in a boat or car. ● do not fill fuel container to maximum capacity. Gasoline will expand consid- erably as it warms up and can build up pressure in the fuel container. Thi...

Page 60: Maintenance

Maintenance 54 tip: place a towel or something similar under the outboard motor to protect it from damage. Emu30272 storing outboard motor when storing your yamaha outboard motor for prolonged periods of time (2 months or longer), several important procedures must be performed to prevent excessive d...

Page 61: Maintenance

Maintenance 55 properly done, the engine will smoke ex- cessively and almost stall. 8. Remove the outboard motor from the test tank. 9. Install the silencer cover/cap of fogging hole and top cowling. 10. If the “fogging oil” is not available, run the engine at a fast idle until the fuel sys- tem bec...

Page 62: Maintenance

Maintenance 56 ● the power trim and tilt switches oper- ate even when the ignition key is off. Keep people away from the switches whenever working around the motor. When the motor is tilted, keep away from the area under it or between it and the clamp bracket. Be sure no one is in this area before o...

Page 63: Maintenance

Maintenance 57 emu34446 maintenance chart 1 tip: ● refer to the sections in this chapter for explanations of each owner-specific action. ● the maintenance cycle on these charts assume usage of 100 hours per year and regular flushing of the cooling water passages. Maintenance frequency should be adju...

Page 64: Maintenance

Maintenance 58 fuel line (high pres- sure) inspection or replace- ment as necessary fuel line (low pres- sure) inspection fuel line (low pres- sure) inspection or replace- ment as necessary fuel pump inspection or replace- ment as necessary fuel/engine oil leakage inspection gear oil replacement gre...

Page 65: Maintenance

Maintenance 59 emu34451 maintenance chart 2 (yamaha) meter/gauge inspection fuel tank (yamaha por- table tank) inspection and clean- ing as necessary item actions every 1000 hours exhaust guide/exhaust manifold inspection or replace- ment as necessary item actions initial every 20 hours (3 months) 1...

Page 66: Maintenance

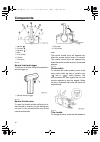

Maintenance 60 emu28943 greasing yamaha grease a (water resistant grease) yamaha grease d (corrosion resistant grease; for propeller shaft) e40xmh zmu03074 66t-9-2c-1e0.Book 60 ページ 2010年2月10日 水曜日 午前10時18分.

Page 67: Maintenance

Maintenance 61 40xwt emu28957 cleaning and adjusting spark plug the spark plug is an important engine com- ponent and is easy to inspect. The condition of the spark plug can indicate something about the condition of the engine. For exam- ple, if the center electrode porcelain is very white, this cou...

Page 68: Maintenance

Maintenance 62 otherwise the engine may not operate properly. Before fitting the spark plug, measure the electrode gap with a wire thickness gauge; replace it if out of spec- ification. 4. When fitting the plug, wipe off any dirt from the threads, and then screw it in to the correct torque. Tip: if ...

Page 69: Maintenance

Maintenance 63 other qualified mechanic. Emu29114 inspecting wiring and connectors ● inspect that each connector is engaged securely. ● inspect that each ground lead is properly secured. Emu32112 checking propeller warning ewm01881 you could be seriously injured if the en- gine accidentally starts w...

Page 70: Maintenance

Maintenance 64 3. Remove the propeller, washer (if equipped), and thrust washer. Emu30672 installing propeller emu29234 spline models notice ecm00501 make sure to use a new cotter pin and bend the ends over securely. Otherwise, the propeller could come off during oper- ation and be lost. 1. Apply ya...

Page 71: Maintenance

Maintenance 65 sible. 2. Place a suitable container under the gear case. 3. Remove the gear oil drain screw and gasket. Notice: if there is an exces- sive quantity of metal particles on the magnetic gear oil drain screw, this can indicate lower unit problem. Con- sult your yamaha dealer. [ecm01900] ...

Page 72: Maintenance

Maintenance 66 ● keep away from sparks, cigarettes, flames, or other sources of ignition when cleaning the fuel tank. ● remove the fuel tank from the boat be- fore cleaning it. Work only outdoors in an area with good ventilation. ● wipe up any spilled fuel immediately. ● reassemble the fuel tank car...

Page 73: Maintenance

Maintenance 67 hydrogen gas. When working near the battery: ● wear protective eye gear and rubber gloves. ● do not smoke or bring any other source of ignition near the battery. The procedure for checking the battery var- ies for different batteries. This procedure contains typical checks that apply ...

Page 74: Maintenance

Maintenance 68 equipped) and main switch. Notice: if they are left on, the electrical system can be damaged. [ecm01930] 2. Disconnect the negative cable(s) from the negative (-) terminal. Notice: al- ways disconnect all negative (-) ca- bles first to avoid a short circuit and damage to the electrica...

Page 75: Trouble Recovery

69 trouble recovery emu29427 troubleshooting a problem in the fuel, compression, or igni- tion systems can cause poor starting, loss of power, or other problems. This section de- scribes basic checks and possible remedies, and covers all yamaha outboard motors. Therefore some items may not apply to ...

Page 76: Trouble Recovery

Trouble recovery 70 q. Is fuel system obstructed? A. Check for pinched or kinked fuel line or other obstructions in fuel system. Q. Is fuel contaminated or stale? A. Fill tank with clean, fresh fuel. Q. Is fuel filter clogged? A. Clean or replace filter. Q. Have ignition parts failed? A. Have servic...

Page 77: Trouble Recovery

Trouble recovery 71 q. Is load on boat improperly distributed? A. Distribute load to place boat on an even plane. Q. Is water pump or thermostat faulty? A. Have serviced by a yamaha dealer. Q. Is there excess water in fuel filter cup? A. Drain filter cup. Engine power loss. Q. Is propeller damaged? ...

Page 78: Trouble Recovery

Trouble recovery 72 q. Is fuel joint connection incorrect? A. Connect correctly. Q. Is heat range of spark plug incorrect? A. Inspect spark plug and replace it with rec- ommended type. Q. Is high pressure fuel pump drive belt bro- ken? A. Have serviced by a yamaha dealer. Q. Is engine not responding...

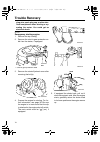

Page 79: Trouble Recovery

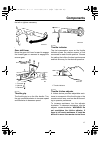

Trouble recovery 73 emu29512 power trim and tilt will not operate if the engine cannot be tilted up or down with the power trim and tilt because of a dis- charged battery or a failure with the power trim and tilt unit , the engine can be tilted manually. 1. Loosen the manual valve screw by turn- ing...

Page 80: Trouble Recovery

Trouble recovery 74 plug wire, spark plug cap, or other elec- trical components when starting or op- erating the motor. You could get an electrical shock. Emu29562 emergency starting engine 1. Remove the top cowling. 2. Remove the start-in-gear protection ca- ble from the starter, if equipped. 3. Re...

Page 81: Trouble Recovery

Trouble recovery 75 6. Insert the knotted end of the emergency starter rope into the notch in the flywheel rotor and wind the rope several turns around the flywheel clockwise. 7. Give a strong pull straight out to crank and start the engine. Repeat if neces- sary. Emu33501 treatment of submerged mot...

Page 82

Yamaha motor co., ltd. Printed on recycled paper printed in japan march 2010–0.3 1 ! 66t-9-2c-1e0.Book 1 ページ 2010年2月10日 水曜日 午前10時18分.