- DL manuals

- Yamaha

- Outboard Motor

- 55DEHD

- Service Manual

Yamaha 55DEHD Service Manual

Summary of 55DEHD

Page 1

Yamaha motor co., ltd. Printed in japan oct. 2006 – 1.1 × 1 ! (e_2) printed on recycled paper 75a service manual 688-28197-5j-11 85a 55d 55d , 75a, 85a 688_cover.Qxd_1 07.9.26 16:21 page 1.

Page 2

Notice this manual has been prepared by yamaha primarily for use by yamaha dealers and their trained mechanics when performing maintenance procedures and repairs to yamaha equipment. It has been written to suit the needs of persons who have a basic understanding of the mechanical and electrical conc...

Page 3

Specification general information periodic check and adjustment fuel system power unit bracket unit electrical system troubleshooting index contents lower unit 9 8 7 6 2 1 gen info spec chk adj fuel powr lowr brkt elec trbl shtg 3 4 5 6885j11_01 07.9.26 15:11 page 1.

Page 4

6885j11_01 07.9.26 15:11 page 2.

Page 5

6885j11 1- 9 8 7 6 5 4 3 2 1 general information how to use this manual................................................................................ 1-1 manual format........................................................................................... 1-1 symbol................................

Page 6

Gen info 1- 6885j11 general information 1-1 how to use this manual manual format the format of this manual has been designed to make service procedures clear and easy to under- stand. Use the information below as a guide for effective and quality service. 9 parts are shown and detailed in an explode...

Page 7

6885j11 9 8 7 6 5 4 3 2 1 1-2 gen info symbol the symbols below are designed to indicate the content of a chapter. General information fuel system bracket unit specification power unit electrical system periodic check and adjustment lower unit troubleshooting symbols 1 to 6 indicate specific data. 1...

Page 8

Gen info 1-3 6885j11 general information abbreviation description aft aft end api american petroleum institute atdc after top dead center atf automatic transmission fluid bow bow end btdc before top dead center cca cold cranking ampere cdi capacitor discharged ignition system dn downside or downward...

Page 9

6885j11 1-4 9 8 7 6 5 4 3 2 1 safety while working to prevent an accident or injury and to ensure quality service, follow the safety procedures provided below. Fire prevention gasoline is highly flammable. Keep gasoline and all flammable products away from heat, sparks, and open flames. Ventilation ...

Page 10

Gen info 1-5 6885j11 general information 6. Keep a supply of clean, lint-free cloths for wiping up spills, etc. Good working practice special service tool use the recommended special service tools to protect parts from damage. Use the right tool in the right manner–do not improvise. Tightening torqu...

Page 11

6885j11 1-6 9 8 7 6 5 4 3 2 1 identification model this manual covers the following models. Serial number the outboard motor serial number is stamped on a label attached to the port clamp bracket. 1 model name 2 approved model code 3 transom height 4 serial number 68810010 applicable model 55dehd, 7...

Page 12

Gen info 1-7 6885j11 general information special service tool digital tachometer 90890-06760 timing light 90890-03141 dial gauge set 90890-01252 leakage tester 90890-06840 vacuum/pressure pump gauge set 90890-06756 test propeller 90890-01620 compression gauge 90890-03160 flywheel holder 90890-06522 ...

Page 13

6885j11 1-8 9 8 7 6 5 4 3 2 1 special service tool bearing separator 90890-06534 cylinder gauge 90890-06759 support 90890-02394 bearing pressure c 90890-02393 c driver rod ss 90890-06604 needle bearing attachment 90890-06607, 90890-06608, 90890-06611, 90890-06612, 90890-06615, 90890-06632, 90890-066...

Page 14

Gen info 1-9 6885j11 general information ring nut wrench 3 90890-06511 ring nut wrench extension 90890-06513 stopper guide plate 90890-06501 bearing housing puller claw l 90890-06502 center bolt 90890-06504 stopper guide stand 90890-06538 bearing puller assembly 90890-06535 driver rod l3 90890-06652...

Page 15

6885j11 1-10 9 8 7 6 5 4 3 2 1 special service tool pinion nut holder 90890-06715 socket adapter 2 90890-06507 bearing outer race puller assembly 90890-06523 driver rod sl 90890-06602 bearing outer race attachment 90890-06621, 90890-06625, 90890-06626, 90890-06628 driver rod ll 90890-06605 shift rod...

Page 16

Gen info 1-11 6885j11 general information shimming plate 90890-06701 backlash indicator 90890-06706 magnet base plate 90890-07003 magnet base b 90890-06844 test harness 90890-06878 ptt oil pressure gauge assembly 90890-06580 cylinder-end screw wrench 90890-06568 ptt piston vice attachment 90890-0657...

Page 17

6885j11 1-12 9 8 7 6 5 4 3 2 1 special service tool throttle sensor adjusting lead 90890-06857 test harness 90890-06871 digital circuit tester 90890-03174 peak voltage adapter b 90890-03172 ignition tester 90890-06754 6885j11_01 07.9.26 15:11 page 15.

Page 18

Gen info 1-13 6885j11 general information predelivery check to make the delivery process smooth and efficient, the predelivery check should be completed as explained below. Checking the fuel system 1. Check that the fuel hoses is securely connected and that the fuel tank is filled with fuel. C c use...

Page 19

6885j11 1-14 9 8 7 6 5 4 3 2 1 note: the optimum mounting height is affected by the combination of the boat and the outboard motor. To determine the optimum mounting height, test run the outboard motor at differ- ent heights. 2. Check that the clamp brackets are secured with the mounting bolts. Chec...

Page 20

Gen info 1-15 6885j11 general information 4. Check that the control lever 1 comes in contact with the adjusting screw 4. Note: to adjust the throttle cable, refer to page 3-7. 5. Set the remote control lever is in “n” posi- tion, and then check that the mark a on the bracket 5 is aligned with the ma...

Page 21

6885j11 1-16 9 8 7 6 5 4 3 2 1 checking the engine start switch and engine stop lanyard switch 1. Check that the engine starts when the engine start switch is turned to start. 2. Check that the engine turns off when the engine start switch is turned to off. å ehd ∫ ed, et 3. Check that the choke sol...

Page 22

Gen info 1-17 6885j11 general information test run 1. Start the engine, and then check that the gear shift operates smoothly. 2. Check that the engine idle speed after the engine has been warmed up. 3. Operate at trolling speed. 4. Run the outboard motor for 1 hour at 3,000 r/min or at half throttle...

Page 23

5. After the first 10 hours. Use standard pre- mix ratio of fuel and oil. Refer to page 1-13. å hours after test run 1. Check for water in the gear oil. 2. Check for fuel leakage in the cowling. 3. Install the flushing kit 1. 4. Set the gear shift to “n” position, and then flush the cooling water pa...

Page 24

Gen info 1-19 6885j11 general information — memo — 6885j11_01 07.9.26 15:11 page 22.

Page 25

6885j11 9 8 7 6 5 4 3 2 1 spec specification general specification .....................................................................................2-1 maintenance specification ............................................................................2-5 power unit (55d, 75a models) ............

Page 26

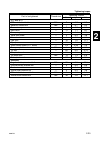

Spec 2-1 6885j11 specification general specification item unit model 55dehd 75aehd 75aed 75aet dimension overall length mm (in) 1,337 (52.6) 726 (28.6) overall width mm (in) 398 (15.7) 374 (14.7) overall height (l) mm (in) 1,422 (56.0) (x) mm (in) — 1,548 (60.9) — boat transom height (l) mm (in) 508...

Page 27

6885j11 2-2 9 8 7 6 5 4 3 2 1 general specification (*1) meeting both api and sae requirements (*2) cca: cold cranking ampere en: european norm (european standard) iec: international electrotechnical commission item unit model 55dehd 75aehd 75aed 75aet cooling system water exhaust system propeller b...

Page 28

Spec 2-3 6885j11 item unit model 85aehd 85aed 85aet dimension overall length mm (in) 1,337 (52.6) 726 (28.6) overall width mm (in) 398 (15.7) 374 (14.7) overall height (l) mm (in) 1,422 (56.0) (y) mm (in) 1,473 (58.0) — (x) mm (in) — 1,548 (60.9) boat transom height (l) mm (in) 508 (20.0) (y) mm (in...

Page 29

6885j11 2-4 9 8 7 6 5 4 3 2 1 item unit model 85aehd 85aed 85aet cooling system water exhaust system propeller boss lubrication system pre-mixed fuel and oil fuel and oil fuel type regular unleaded gasoline engine oil 2-stroke outboard motor oil engine oil grade nmma-certified tc-w3 gear oil type hy...

Page 30

Spec 2-5 6885j11 specification maintenance specification power unit (55d, 75a models) (*1) measuring conditions: ambient temperature 20°c (68°f), wide open throttle, with spark plugs removed from all cylinders. The figures are for reference only. Item unit model 55dehd 75aehd 75aed 75aet power unit ...

Page 31

Item unit model 55dehd 75aehd 75aed 75aet piston ring top ring dimension b mm (in) 1.965–1.980 (0.0774–0.0780) dimension t mm (in) 3.100–3.300 (0.1220–0.1299) end gap (reference data) mm (in) 0.40–0.60 (0.0157–0.0236) side clearance mm (in) 0.05–0.08 (0.0020–0.0032) oversize outside diameter 1st mm ...

Page 32

Spec 2-7 6885j11 specification electrical (55d, 75a models) item unit model 55dehd 75aehd 75aed 75aet ignition and ignition control system spark plug gap mm (in) 0.9–1.0 (0.035–0.039) spark plug cap resistance k Ω 4.0–6.0 ignition timing (full retarded) degree btdc 1–3 ignition timing (full advanced...

Page 33

6885j11 2-8 9 8 7 6 5 4 3 2 1 maintenance specification item unit model 55dehd 75aehd 75aed 75aet charge coil output peak voltage (r–br) at cranking (unloaded) v 50 at cranking (loaded) v 60 at 1,500 r/min (loaded) v 150 at 3,500 r/min (loaded) v 160 (r–l) at cranking (unloaded) v 150 at cranking (l...

Page 34

Spec 2-9 6885j11 specification item unit model 55dehd 75aehd 75aed 75aet ptt system trim sensor resistance Ω — 168.3–288.3 at 20°c (68°f) (p–b) trim sensor setting resistance Ω — 9–11 at 20°c (68°f) (p–b) fluid type — atf dexron 2 motor type — 6h102 output kw — 0.3 brushes standard length mm (in) — ...

Page 35

6885j11 2-10 9 8 7 6 5 4 3 2 1 maintenance specification power unit (85a models) (*1) measuring conditions: ambient temperature 20°c (68°f), wide open throttle, with spark plugs removed from all cylinders. The figures are for reference only. Item unit model 85aehd 85aed 85aet power unit minimum comp...

Page 36

Spec 2-11 6885j11 item unit model 85aehd 85aed 85aet piston ring top ring dimension b mm (in) 1.965–1.980 (0.0774–0.0780) dimension t mm (in) 3.100–3.300 (0.1220–0.1299) end gap (reference data) mm (in) 0.40–0.60 (0.0157–0.0236) side clearance mm (in) 0.05–0.08 (0.0020–0.0032) oversize outside diame...

Page 37

6885j11 2-12 9 8 7 6 5 4 3 2 1 electrical (85a models) item unit model 85aehd 85aed 85aet ignition and ignition control system spark plug gap mm (in) 0.9–1.0 (0.035–0.039) spark plug cap resistance k Ω 4.0–6.0 ignition timing (full retarded) degree btdc 1–3 ignition timing (full advanced) degree btd...

Page 38

Spec 2-13 6885j11 item unit model 85aehd 85aed 85aet charge coil output peak voltage (r–br) at cranking (unloaded) v 50 at cranking (loaded) v 60 at 1,500 r/min (loaded) v 150 at 3,500 r/min (loaded) v 160 (r–l) at cranking (unloaded) v 150 at cranking (loaded) v 110 at 1,500 r/min (loaded) v 150 at...

Page 39

6885j11 2-14 9 8 7 6 5 4 3 2 1 item unit model 85aehd 85aed 85aet ptt system trim sensor resistance Ω — 168.3–288.3 at 20°c (68°f) (p–b) trim sensor setting resistance Ω — 9–11 at 20°c (68°f) (p–b) fluid type — atf dexron 2 motor type — 6h102 output kw — 0.3 brushes standard length mm (in) — 9.75 (0...

Page 40

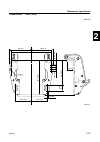

Spec 2-15 6885j11 520 (20.5) 459 (18.1) l: 968 (38.1) y: 1,015 (40.0) x: 1,080 (42.5) 180 (7.1) 545 (21.5) 67 (2.6) 790 (31.1) 547 (21.5) 164 (6.5) 199 (7.8) 47 (1.9) 23 (0.9) 743 (29.3) l: 901 (35.5) y: 952 (37.5) x: 1,028 (40.5) l: 520 (20.5) y: 571 (22.5) x: 647 (25.5) 191 (7.5) l: 698 (27.5) y: ...

Page 41

6885j11 2-16 9 8 7 6 5 4 3 2 1 520 (20.5) 459 (18.1) l: 968 (38.1) x: 1,080 (42.5) 180 (7.1) 545 (21.5) 67 (2.6) 547 (21.5) 164 (6.5) 199 (7.8) 47 (1.9) 23 (0.9) 743 (29.3) l: 901 (35.5) x: 1,028 (40.5) l: 520 (20.5) x: 647 (25.5) 191 (7.5) l: 698 (27.5) x: 764 (30.1) l: 14.0 (0.6) x: 23.0 (0.9) 27....

Page 42

Spec 2-17 6885j11 180 (7.1) 180 (7.1) 163.5 (6.4) 163.5 (6.4) 125 (4.9) 125.4 (4.9) 13 (0.5) 68.5 (2.7) 18.5 (0.7) 351 (13.8) 50.8 (2.0) 13 (0.5) 55.5 (2.2) 254 (10.0) 6882003m clamp bracket 55dehd, 75aehd, 75aed, 85aehd, 85aed mm (in) specification 6885j11_02_1 04.1.1 0:43 page 18.

Page 43

6885j11 2-18 9 8 7 6 5 4 3 2 1 180 (7.1) 180 (7.1) 163.5 (6.4) 163.5 (6.4) 125.4 (4.9) 125.4 (4.9) 13 (0.5) 68.5 (2.7) 18.5 (0.7) 351 (13.8) 50.8 (2.0) 13 (0.5) 55.5 (2.2) 254 (10.0) 6882003m clamp bracket 75aet, 85aet mm (in) maintenance specification 6885j11_02_1 04.1.1 0:43 page 19.

Page 44

Spec 2- 6885j11 2-19 specification tightening torque specified torque part to be tightened thread size tightening torques n·m kgf·m ft·lb power unit power unit mount bolt m8 21 2.1 15.5 flywheel magnet nut — 160 16.0 118 ignition coil mount bolt m6 7 0.7 5.2 spark plug m14 25 2.5 18 intake manifold ...

Page 45

6885j11 2-20 9 8 7 6 5 4 3 2 1 tightening torque part to be tightened thread size tightening torques n·m kgf·m ft·lb ptt unit (et) ptt motor mount bolt m6 7 0.7 5.2 reservoir mount bolt m6 7 0.7 5.2 reservoir cap — 7 0.7 5.2 main valve — 11 1.1 8.1 trim spring screw — 4 0.4 3.0 valve lock screw — 4 ...

Page 46

Spec 2-21 6885j11 specification general torque this chart specifies tightening torques for standard fasteners with a standard iso thread pitch. Tightening torque specification for special components or assemblies are provided in applicable sections of this manu- al. To avoid warpage, tighten multi-f...

Page 47

6885j11 9 8 7 6 5 4 3 2 1 3 1 periodic check and adjustment maintenance interval chart .......................................................................... 3-1 top cowling .................................................................................................. 3-2 checking the top co...

Page 48

Chk adj 3-1 6885j11 periodic check and adjustment maintenance interval chart use the following chart as a guideline for general maintenance. Adjust the maintenance intervals according to the operating conditions of the outboard motor. Initial every refer item actions 10 hours 50 hours 100 hours 200 ...

Page 49

6885j11 3-2 9 8 7 6 5 4 3 2 1 top cowling checking the top cowling 1. Check the top cowling. Replace the top cowling if cracked or other damaged. 2. Check the fitting by pushing the top cowl- ing with both hands. Adjust the fittings of the top cowling following the procedures below if it does not fi...

Page 50

Chk adj 3-3 6885j11 periodic check and adjustment checking the fuel filter 1. Remove the nut, and then remove the fuel filter assembly. Note: be sure not to spill any fuel when removing the fuel cap assembly. 2. Check the fuel filter element 1. Clean if there is dirt or residue. 3. Check the fuel fi...

Page 51

6885j11 3-4 9 8 7 6 5 4 3 2 1 fuel system / power unit 3. Place a thermometer in the water and slowly heat the water. 4. Check the thermostat valve opening at the specified water temperatures. Replace if out of specification. 5. Install the new gasket 6 thermostat 5, pcv 4, spring 3 and thermostat c...

Page 52

Chk adj 3-5 6885j11 periodic check and adjustment control system synchronizing the carburetor note: make sure to synchronizing the carburetor, always disassemble or replace. 1. Disconnect the throttle cable 1 and remove the intake silencer cover 2. Note: to disconnect and connect the throttle cable,...

Page 53

6885j11 3-6 9 8 7 6 5 4 3 2 1 control system 6. Tighten the throttle lever tightening screws 8 on the carburetor assembly #1 and #3 by pushing down throttle lever 9 with your finger. 7. Tighten the throttle stop screw 6 until contacts the stopper 7. 8. Install the throttle link rod 3. 9. Check that ...

Page 54

Chk adj 3-7 6885j11 periodic check and adjustment 3. Remove the control link rod 2, and then measure the length a of the link. 4. Adjust the length a if out of specification. 5. Install the control link rod 2. 6. Check that the ignition timing to the spec- ified position at full retard. Note: 9 to c...

Page 55

6885j11 3-8 9 8 7 6 5 4 3 2 1 control system w the throttle cable joint 3 must be screwed in a minimum of 8.0 mm (0.31 in) a. Note: pull the throttle cable toward the engine to remove any free play in the cable before adjusting the position of the throttle cable joint. 4. Connect the throttle cable ...

Page 56

Checking the ignition timing note: install the test propeller, when checking the ignition timing. 1. Place the lower unit in water, and then start the engine and warm it for 5 min- utes. 2. Turn off the engine when the engine has been completely warmed up. 3. Disconnect the throttle cable 1 and remo...

Page 57

6. Set the control lever 2 3 to full advanced position. 7. Check that the ignition timing advances to the specified position b, when the full advanced. 8. If the ignition timing is not specification, check the ignition timing plate position and timing stopper position. Note: 9 to check the timing pl...

Page 58

Chk adj 3-11 6885j11 periodic check and adjustment 3. While checking the dial gauge, slightly turn the flywheel magnet counterclock- wise to the specified position. 4. Check that the timing plate 2 is aligned with the specified position. 5. If it is not aligned, loosen the tightening screw 3 and ali...

Page 59

6885j11 3-12 9 8 7 6 5 4 3 2 1 control system 4. Check that the mark b on the flywheel magnet is aligned with the pointer 4 on the pulser coil assembly. 5. If it is not aligned, remove the control link rod 5, and then adjust the control link rod length c. Note: to adjust the control link rod, refer ...

Page 60

Chk adj 3-13 6885j11 periodic check and adjustment 8. Set the control lever 2 2 to the full retard position, and then check that the adjust- ing screw 6 comes in contact with the crankcase. 9. Check that the mark b on the flywheel magnet is aligned with the pointer 4 on the pulser coil assembly. 10....

Page 61

6885j11 3-14 9 8 7 6 5 4 3 2 1 control system 1. Check that the neutral switch 1 is pushed by the shift lever 2, when the gear shift is in the “n” position. 2. Set the gear shift to “f” or “r” position. 3. Check that the starter motor can not operate, when turning the engine start switch to “start”....

Page 62

Chk adj 3-15 6885j11 periodic check and adjustment 3. Check the choke solenoid. Note: 9 to measure the choke solenoid resistance, refer to page 8-11. 9 to check the choke solenoid operation, refer to page 1-16. Bracket checking the ptt operation (et) 1. Fully tilt the outboard motor up and down 2-3 ...

Page 63

6885j11 3-16 9 8 7 6 5 4 3 2 1 control system / bracket 2. Remove the reservoir cap 2, and then check the fluid level in the reservoir. W make sure that the trim and tilt rams are fully extended when removing the reser- voir cap, otherwise fluid can spurt out from the unit due to internal pressure. ...

Page 64

4. Fully tilt the outboard motor up, and then support it with the tilt stop lever 2 to check the lock mechanism of the lever. Checking the tilt pin 1. Check the tilt pin 1. Replace the tilt pin if corroded, worn or bent. 2. Check the standard of the tilt pin 1 posi- tion. Adjust the standard positio...

Page 65

6885j11 3-18 9 8 7 6 5 4 3 2 1 bracket / lower unit 3. Check the oil for metal, discoloration and its viscosity. Check the internal parts of the lower case if necessary. 4. Fully tilt the outboard motor down. 5. Insert a gear oil tube into the drain hole and slowly fill the gear oil until oil flows ...

Page 66

Chk adj 3-19 6885j11 periodic check and adjustment checking the propeller 1. Check the propeller blades. Replace if cracked. Check the splines. Replace if damaged or worn. General checking the anode 1. Check the anodes. Clean if there are scales, grease, or oil. C c do not oil, grease, or paint the ...

Page 67

Lubricating the outboard motor 1. Apply yamaha grease a to the areas shown. Note: apply yamaha grease a to the grease nipple until it flows from the bushings a. 6885j11 3-20 9 8 7 6 5 4 3 2 1 lower unit / general 2. Fully charge the battery. Check the spe- cific gravity of the electrolyte. Replace t...

Page 68

Chk adj 3-21 6885j11 periodic check and adjustment 2. Apply temperature resistant grease to the areas shown. 3. Apply corrosion resistant grease to the area shown. 68830570 6b430300 68830490 a a 68830510 68830500 68830520 6885j11_03 07.9.26 10:24 page 22.

Page 69

6885j11 9 8 7 6 5 4 3 2 1 fuel system hose routing ................................................................................................. 4-1 fuel line ........................................................................................................ 4-3 fuel pump .....................

Page 70

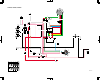

Fuel 4-1 6885j11 fuel system hose routing 1 fuel hose (fuel tank-to-primer pump) 2 fuel hose (primer pump-to-fuel joint) 3 fuel hose (fuel joint-to-fuel filter) 4 fuel hose (fuel filter-to-fuel pump) 5 fuel hose (fuel pump-to-carburetor) 6 cooling water hose out in 4 1 2 3 5 6 6884006e 6885j11_04 06...

Page 71

6885j11 4-2 9 8 7 6 5 4 3 2 1 hose routing 6884007e 2 3 1 4 1 breather hose : 275 mm (10.8 in) 2 breather hose : 185 mm (7.3 in) 3 breather hose : 102 mm (4.0 in) 4 breather hose : 465 mm (18.3 in) 6885j11_04 06.10.3 11:49 page 3.

Page 72

Fuel 4-3 6885j11 fuel system fuel line 6884030e no. Part name q’ty remarks 1 fuel joint 1 2 bolt 1 m6 × 20 mm 3 clip 14 4 fuel hose 1 5 fuel hose 1 6 fuel filter assembly 1 7 bolt 1 m6 × 14 mm 8 bracket 1 9 nut 1 10 fuel hose 1 11 joint 2 m6 × 40 mm 12 fuel hose 1 13 fuel hose 1 14 fuel hose 1 15 fu...

Page 73

6885j11 4-4 9 8 7 6 5 4 3 2 1 6884030e no. Part name q’ty remarks 18 bolt 2 m6 × 40 mm 19 fuel filter element 1 20 float 1 21 o-ring 1 22 cup 1 not reusable fuel line 6885j11_04 06.10.3 11:49 page 5.

Page 74

Fuel 4-5 6885j11 fuel system 6884050e fuel pump no. Part name q’ty remarks 1 screw 3 ø5 × 30 mm 2 cover 1 3 diaphragm 1 4 gasket 1 5 nut 2 6 screw 2 ø3 × 5 mm 7 check valve 2 8 fuel pump body 1 9 gasket 2 10 diaphragm 1 11 base 1 not reusable not reusable 6885j11_04 06.10.3 11:49 page 6.

Page 75

6885j11 9 8 7 6 5 4 3 2 1 checking the primer pump 1. Place a drain pan under the fuel hose connections, and then disconnect the fuel hose from the primer pump. 2. Connect the special service tool 1 to the primer pump inlet hose. 3. Cover the fuel outlet 2 with a finger. 4. Apply the specified posit...

Page 76

Fuel 4- 6885j11 4-7 fuel system 6. Apply the specified positive pressure and check that there is no air leakage. Disassemble the fuel pump if air leaked. Disassembling the fuel pump 1. Remove the 3 screws securing the pump together. Note: to disassemble the fuel pump, refer to page 4-5. 2. Check the...

Page 77

6885j11 9 8 7 6 5 4 3 2 1 4-8 fuel pump assembling the fuel pump note: clean the parts and soak the valves and the diaphragms in gasoline before assembly. 1. Install the check valves 1 onto the fuel pump body 2. 2. Install the new gaskets 3, 4, diaphragms 5, 6, cover 7 and base 8 to the fuel pump bo...

Page 78

Fuel 4- 6885j11 4-9 fuel system carburetor ed, et 12 n·m (1.2 kgf·m, 8.9 ft·lb) 6884060e no. Part name q’ty remarks 1 screw 2 ø6 × 15 mm 2 washer 2 3 cover 1 4 gasket 1 5 bolt 6 m6 × 18 mm 6 intake silencer 1 7 cap 3 8 gasket 1 9 carburetor assembly #1 1 10 carburetor assembly #2 1 11 carburetor ass...

Page 79

6885j11 4-10 9 8 7 6 5 4 3 2 1 ed, et 12 n·m (1.2 kgf·m, 8.9 ft·lb) 6884060e no. Part name q’ty remarks 18 choke solenoid 1 ed, et 19 screw 2 ø6 × 15 mm : ed, et carburetor 6885j11_04 06.10.3 11:49 page 11.

Page 80

Fuel 4- 6885j11 4-11 fuel system 6884070e no. Part name q’ty remarks 1 screw 6 ø5 × 10 mm 2 cover 3 3 rubber seal 2 6 4 plate 2 3 5 rubber seal 1 3 6 plate 1 3 7 throttle stop screw 1 8 spring 1 9 carburetor body 3 10 spring 3 11 pilot screw 3 12 main nozzle 3 13 main jet 3 14 float pin 3 15 needle ...

Page 81

6885j11 4-12 9 8 7 6 5 4 3 2 1 6884070e no. Part name q’ty remarks 18 cap 3 19 float 3 20 screw 3 ø4 × 8 mm 21 gasket 3 22 screw 12 ø4 × 14 mm 23 float chamber 3 24 o-ring 3 25 drain bolt 3 26 carburetor assembly #1 1 27 carburetor assembly #3 1 not reusable not reusable carburetor 6885j11_04 06.10....

Page 82

4. Check the pilot screw and needle valve. Replace the pilot screw and needle valve if bend or worn. 5. Check the float. Replace the float if cracked or damaged. Checking the float height 1. Measure the float height. Replace the float and needle valve as a set, if out of specification. Note: when me...

Page 83

6885j11 9 8 7 6 5 4 3 2 1 4-14 carburetor 4. Install the new gasket 9, float chamber 0, and then tighten the float chamber screws q. 5. Install the new o-ring w, and then tight- en the drain screw e to specified torque. 6. Install the plate 1 r, rubber seal 1 t, plate 2 y, rubber seals 2 u, cover i,...

Page 84

Fuel 4- 6885j11 7. Install the spring p, pilot screw a, then turn it in until it is lightly seated, and then turn it out the specified number of turns. 8. Install the new gaskets s, carburetor assembly d, new gasket f, carburetor caps g, intake silencer h and bolts j. 9. Install the new gasket k, co...

Page 85

6885j11 9 8 7 6 5 4 3 2 1 4-16 — memo — 6885j11_04 06.10.3 11:49 page 17.

Page 86

Powr 6885j11 power unit power unit ..................................................................................................... 5-1 checking the compression pressure ....................................................... 5-1 removing the power unit ............................................

Page 87

6885j11 9 8 7 6 5 4 3 2 1 disassembling the oil seal housing ....................................................... 5-31 checking the oil seal housing ................................................................ 5-31 assembling the oil seal housing .................................................

Page 88

Powr 5-1 6885j11 power unit power unit checking the compression pressure 1. Start the engine, warm it up for 5 min- utes, and then turn it off. 2. Remove the lock plate from the engine stop lanyard switch. 3. Remove the all spark plug caps and all spark plugs, and then install the special service to...

Page 89

6885j11 5-2 9 8 7 6 5 4 3 2 1 power unit ed, et ehd 21 n·m (2.1 kgf·m, 15.5 ft·lb) 21 n·m (2.1 kgf·m, 15.5 ft·lb) 6885010e no. Part name q’ty remarks 1 power unit 1 2 gasket 1 3 dowel 2 4 bolt 2 m6 × 20 mm 5 bolt 2 m6 × 30 mm 6 bolt 1 m8 × 30 mm 7 bolt 8 m8 × 90 mm 8 bolt 2 m8 × 35 mm 9 apron 1 10 a...

Page 90

Powr 5-3 6885j11 power unit 160 n·m (16.0 kgf·m, 118 ft·lb) 6885020e no. Part name q’ty remarks 1 nut 1 2 washer 1 3 flywheel magnet 1 4 bolt 3 m6 × 30 mm 5 stator assembly 1 6 pulser coil assembly 1 7 screw 3 ø6 × 12 mm 8 plate 3 9 control link 1 10 retainer 1 11 woodruff key 1 12 timing plate 1 13...

Page 91

6885j11 5-4 9 8 7 6 5 4 3 2 1 power unit 6885030e no. Part name q’ty remarks 1 bolt 1 m8 × 45 mm 2 collar 1 3 bushing 1 4 control lever 1 1 5 bushing 1 6 spring 1 7 cap 2 8 lock nut 1 9 spring 1 10 control lever 2 1 11 screw 1 12 plastic washer 1 13 washer 1 14 shift lever 1 15 bolt 2 m8 × 30 mm 16 ...

Page 92

Powr 5-5 6885j11 power unit 6885030e no. Part name q’ty remarks 18 lock nut 1 19 throttle link rod 1 20 bolt 1 m6 × 35 mm 21 wave washer 1 22 collar 1 23 cam 1 24 screw 1 25 lock nut 1 6885j11_05 07.9.26 15:44 page 8.

Page 93

6885j11 5-6 9 8 7 6 5 4 3 2 1 power unit 7 n·m (0.7 kgf·m, 5.2 ft·lb) 4 n·m (0.4 kgf·m, 3.0 ft·lb) et 7 n·m (0.7 kgf·m, 5.2 ft·lb) 6885060e no. Part name q’ty remarks 1 bolt 2 m6 × 20 mm 2 rectifier regulator 1 3 bolt 2 m6 × 30 mm 4 grommet 6 5 bracket 1 6 collar 3 7 ignition coil 3 8 bolt 3 m6 × 20...

Page 94

Powr 5-7 6885j11 power unit 7 n·m (0.7 kgf·m, 5.2 ft·lb) 4 n·m (0.4 kgf·m, 3.0 ft·lb) et 7 n·m (0.7 kgf·m, 5.2 ft·lb) 6885060e no. Part name q’ty remarks 18 ptt motor lead 1 green : et 19 spring washer 2 et 20 nut 2 et 21 ptt motor lead 1 blue : et 22 screw 2 ø6 × 40 mm 23 pulser coil coupler 1 24 m...

Page 95

6885j11 5-8 9 8 7 6 5 4 3 2 1 power unit 30 n·m (3.0 kgf·m, 22.1 ft·lb) 30 n·m (3.0 kgf·m, 22.1 ft·lb) 9 n·m (0.9 kgf·m, 6.6 ft·lb) 30 n·m (3.0 kgf·m, 22.1 ft·lb) 6885050e no. Part name q’ty remarks 1 bolt 3 m8 × 30 mm 2 negative battery cable 1 3 nut 1 4 spring washer 1 5 positive battery lead 1 6 ...

Page 96

Powr 5-9 6885j11 power unit removing the power unit note: it is recommended to loosen the flywheel magnet nut before removing the power unit to improve working efficiency. 1. Set the gear shift to “n” position, and then remove the retaining plate 1, throttle cable 2, shift cable 3, main harness coup...

Page 97

6885j11 5-10 9 8 7 6 5 4 3 2 1 power unit 8. Install the special service tool f as shown. C c to prevent damage to the engine or tools, screw in the flywheel puller set bolts even- ly and completely so that the flywheel puller is parallel to the flywheel magnet. 9. Remove the bolts g and lift up the...

Page 98

C c to prevent damage to the engine or tools, screw in the flywheel puller set bolts even- ly and completely so that the flywheel puller is parallel to the flywheel magnet. Note: apply force to the crankshaft end until the fly- wheel magnet comes off the tapered portion of the crankshaft. 3. Remove ...

Page 99

6885j11 5-12 9 8 7 6 5 4 3 2 1 power unit 3. Disconnect the ignition coil leads 6, and then remove the ignition coils 7. 4. Remove the cdi unit bracket 8, ground lead 9, collars 0 and grommets q. 5. Remove the starter relay w, ptt relay e (et), rectifier regulator r and cdi unit t from the cdi unit ...

Page 100

Powr 5-13 6885j11 power unit 12 n·m (1.2 kgf·m, 8.9 ft·lb) 6885070e intake manifold no. Part name q’ty remarks 1 bolt 12 m6 × 30 mm 2 intake manifold 1 3 gasket 2 4 plate 1 5 screw 6 ø5 × 20 mm 6 reed valve assembly 3 not reusable 6885j11_05 07.9.26 15:44 page 16.

Page 101

6885j11 5-14 9 8 7 6 5 4 3 2 1 intake manifold removing the reed valve assembly 1. Remove the intake manifold bolts 1, and then remove the intake manifold 2. 2. Remove the reed valve assembly 3, gasket 4, plate 5 and gasket 6. Checking the reed valve 1. Check the reed valves for bends a. Replace the...

Page 102

Powr 5- 6885j11 power unit 25 n·m (2.5 kgf·m, 18.4 ft·lb) 15 n·m (1.5 kgf·m, 11.1 ft·lb) 30 n·m (3.0 kgf·m, 22.1 ft·lb) 6885090e cylinder head, exhaust cover 5-15 no. Part name q’ty remarks 1 bolt 4 m6 × 35 mm 2 holder 1 3 thermostat cover 1 4 spring 1 5 pcv 1 6 thermostat 1 7 gasket 1 8 grommet 1 9...

Page 103

6885j11 5-16 9 8 7 6 5 4 3 2 1 cyilnder head, exhaust cover 25 n·m (2.5 kgf·m, 18.4 ft·lb) 15 n·m (1.5 kgf·m, 11.1 ft·lb) 30 n·m (3.0 kgf·m, 22.1 ft·lb) 6885090e no. Part name q’ty remarks 18 screw 2 ø4 × 15 mm 19 anode 2 6885j11_05 07.9.26 15:44 page 19.

Page 104

Powr 5- 6885j11 power unit 6885080e no. Part name q’ty remarks 1 bolt 18 m8 × 40 mm 2 exhaust outer cover 1 3 gasket 1 4 exhaust inner cover 1 5 gasket 1 not reusable not reusable 5-17 6885j11_05 07.9.26 15:44 page 20

Page 105

6885j11 5-18 9 8 7 6 5 4 3 2 1 cyilnder head, exhaust cover removing the cylinder head 1. Remove the spark plugs. 2. Remove the thermostat cover 1, spring 2, pcv 3, thermostat 4, gasket 5 and grommet 6. 3. Remove the cylinder head cover bolts in the sequence shown. 4. Remove the cylinder head cover ...

Page 106

Powr 5-19 6885j11 power unit 2. Check the cylinder head warpage using a straightedge 1 and thickness gauge 2 in directions as shown. Replace the cylin- der head if above specification. Removing the exhaust cover 1. Remove the exhaust cover bolts in the sequence shown. 1 2 68850300 68850310 cylinder ...

Page 107

6885j11 5-20 9 8 7 6 5 4 3 2 1 cyilnder head, exhaust cover 2. Remove the exhaust outer cover 1, gas- ket 2, exhaust inner cover 3 and gasket 4. Note: insert a flat-head screw driver between the pry tabs to pry off the exhaust covers. Checking the exhaust cover 1. Check the exhaust cover. Replace th...

Page 108

Powr 5-21 6885j11 power unit 4 n·m (0.4 kgf·m, 3.0 ft·lb) 12 n·m (1.2 kgf·m, 8.9 ft·lb) 20 n·m (2.0 kgf·m, 14.8 ft·lb) 40 n·m (4.0 kgf·m, 29.5 ft·lb) 20 n·m (2.0 kgf·m, 14.8 ft·lb) 40 n·m (4.0 kgf·m, 29.5 ft·lb) 6885100e crankcase no. Part name q’ty remarks 1 bolt 2 m8 × 20 mm 2 engine hanger 1 3 do...

Page 109

6885j11 5-22 9 8 7 6 5 4 3 2 1 crankcase 12 n·m (1.2 kgf·m, 8.9 ft·lb) 35 n·m (3.5 kgf·m, 25.8 ft·lb) * 12 n·m (1.2 kgf·m, 8.9 ft·lb) 35 n·m (3.5 kgf·m, 25.8 ft·lb) 6885110e no. Part name q’ty remarks 1 o-ring 1 2 oil seal 1 3 needle bearing 1 4 crankshaft 1 5 roller bearing 3 set 6 piston and conne...

Page 110

Powr 5-23 6885j11 power unit 6885120e no. Part name q’ty remarks 1 connecting rod 3 2 piston 3 3 washer 6 4 needle bearing 84 5 clip 6 6 piston pin 3 7 piston ring 6 not reusable 6885j11_05 07.9.26 15:44 page 26.

Page 111

6885j11 5-24 9 8 7 6 5 4 3 2 1 crankcase removing the crankcase 1. Disconnect the breather hoses. 2. Remove the oil seal housing bolts 1. 3. Remove the crankcase bolts and nuts in the sequence shown. Note: insert a flat-head screw driver between the pry tabs to pry off the crankcase. 4. Remove the o...

Page 112

Disassembling the piston and con- necting rod assembly 1. Remove the piston pin clips 1 with pliers, and then remove the piston pin 2, nee- dle bearings 3 and washers 4. 2. Remove the top piston ring 5 and 2nd piston ring 6. Checking the bearing 1. Check the needle bearings, main bearing and ball be...

Page 113

6885j11 5-26 9 8 7 6 5 4 3 2 1 crankcase c c do not reuse the ball bearing, always replace it with a new one. Checking the cylinder bore 1. Measure the cylinder bore (d 1 –d 6 ) at measuring points a, b, and c, and in direction d (d 1 , d 3 , d 5 ), which is parallel to the crankshaft, and direction...

Page 114

Checking the piston diameter 1. Measure the piston outside diameter at the specified measuring point. Replace the piston if out of specification. Checking the piston ring side clear- ance 1. Measure the piston ring side clearance. Replace the piston and piston rings as a set if out of specification....

Page 115

Checking the crankshaft 1. Measure the crankshaft journal diameter a and crankpin diameter b. Replace the crankshaft if out of specification. 6885j11 5-28 9 8 7 6 5 4 3 2 1 crankcase 1 1 a b 68850440 piston ring end gap a: (reference data) top and 2nd piston ring: 0.40–0.60 mm (0.0157–0.0236 in) mea...

Page 116

Powr 5-29 6885j11 power unit assembling the upper bearing 1. Apply grease to the new oil seal 1, new o-ring 2, and then install them onto the upper bearing. 1 3 2 68850580 bearing inner race attachment 3: 90890-06640 checking the connecting rod small end axial play 1. Install the bearing and connect...

Page 117

6885j11 5-30 9 8 7 6 5 4 3 2 1 crankcase assembling the crankshaft 1. Install a new ball bearing 1 into the crankshaft using a press, then install the circlip. C c do not reuse the ball bearing, always replace it with a new one. 2. Install the main bearings 4 and circlips 5 onto the crankshaft journ...

Page 118

Powr 5-31 6885j11 power unit c c do not scratch the pistons or break the piston rings. Note: install the piston rings with the recess for the locating pin facing up toward the piston crown. Disassembling the oil seal housing 1. Remove the o-ring and oil seals. Checking the oil seal housing 1. Check ...

Page 119

6885j11 5-32 9 8 7 6 5 4 3 2 1 crankcase 3. Install the connecting rod bearings and connecting rod caps onto the connecting rods, and then tighten the connecting rod bolts 4 to the specified torques in 5 stages. Note: 9 align the identification numbers b, which you made during disassembly, on the co...

Page 120

Powr 5-33 6885j11 power unit 4. Install the oil seal housing 5 onto the cylinder block. 5. Apply sealant to the mating surface of the crankcase. Note: do not get any sealant on the journals. 68850620 5 68850630 6. Install the dowels 6, crankcase 7 onto the cylinder block, and then temporarily tighte...

Page 121

6885j11 5-34 9 8 7 6 5 4 3 2 1 crankcase 11. Install the new gasket 9, exhaust inner cover 0, new gasket q, exhaust outer cover w, and then tighten the exhaust cover bolts e to the specified torques in the sequence as shown. 8. Tighten the crankcase bolts and nuts to the specified torques in 2 stage...

Page 122

Powr 5-35 6885j11 power unit 12. Install the new gasket r and cylinder head t, and then tighten the cylinder head bolts y to the specified torques in 2 stages and in the sequence as shown. Note: remove any oil or grease from the cylinder head mating surfaces. Y r t 68850690 68850760 cylinder head bo...

Page 123

6885j11 5-36 9 8 7 6 5 4 3 2 1 crankcase 14. Install the grommet a, thermostat s, pcv d, spring f, new gasket g, ther- mostat cover h, holder j, and then tighten the bolts k. 15. Install the new gasket l, plate ;, new gasket z and reed valve assembly x onto the intake manifold c. 16. Install the int...

Page 124

Powr 5-37 6885j11 power unit 3. Install the ignition coils 0, and then con- nect the ignition coil leads q. 4. Install the retainer w and pulser coil assembly e, then install the stator assembly r control link t. 5. Connect the pulser coil coupler y, light- ing coil leads u and charge coil coupler i...

Page 125

6885j11 5-38 9 8 7 6 5 4 3 2 1 crankcase install the control lever and throttle cam 1. Install the spring 1 onto the control lever 2 2, and then install the control lever 1 3. 2. Install the control lever assembly 4, throttle cam 5, and then install the throt- tle link rod 6. Installing the power un...

Page 126

Powr 5-39 6885j11 power unit c c to prevent damage to the engine or tools, screw in the flywheel puller set bolts even- ly and completely so that the flywheel puller is parallel to the flywheel magnet. 5. Remove the special service tool from the flywheel magnet. 6. Tighten the flywheel magnet nut to...

Page 127

6885j11 5-40 9 8 7 6 5 4 3 2 1 crankcase 9. Connect the fuel hose. Note: to connect the fuel hose, refer to page 4-3. 10. Connect the ground leads e and pilot water hose r. 11. Connect the main harness coupler t, thermoswitch leads y, rectifier regulator leads u, ptt motor leads i (et), fuse holder ...

Page 128

Powr 5-41 6885j11 power unit 14. Install the spark plug caps to the spark plugs. 15. Connect the positive battery lead ; and negative battery cable z to the starter motor. ; z 6885004a port positive battery terminal nut: 9 n·m (0.9 kgf·m, 6.6 ft·lb) negative battery terminal bolt: 30 n·m (3.0 kgf·m,...

Page 129

6885j11 9 8 7 6 5 4 3 2 1 lowr lower unit lower unit ..................................................................................................... 6-1 removing the lower unit .......................................................................... 6-4 removing the water pump .................

Page 130

Lowr 6-1 6885j11 lower unit lower unit 9 n·m (0.9 kgf·m, 6.6 ft·lb) 9 n·m (0.9 kgf·m, 6.6 ft·lb) 35 n·m (3.5 kgf·m, 25.8 ft·lb) 4 n·m (0.4 kgf·m, 3.0 ft·lb) 40 n·m (4.0 kgf·m, 29.5 ft·lb) 40 n·m (4.0 kgf·m, 29.5 ft·lb) ≈ ¥ 6886010e no. Part name q’ty remarks 1 cover 1 2 bolt 1 m8 × 40 mm 3 dowel 2 l...

Page 131

6885j11 6-2 9 8 7 6 5 4 3 2 1 lower unit 9 n·m (0.9 kgf·m, 6.6 ft·lb) 9 n·m (0.9 kgf·m, 6.6 ft·lb) 35 n·m (3.5 kgf·m, 25.8 ft·lb) 4 n·m (0.4 kgf·m, 3.0 ft·lb) 40 n·m (4.0 kgf·m, 29.5 ft·lb) 40 n·m (4.0 kgf·m, 29.5 ft·lb) ≈ ¥ 6886010e no. Part name q’ty remarks 17 spacer 1 18 propeller 1 19 spacer 1 ...

Page 132

Lowr 6-3 6885j11 lower unit 6886020e no. Part name q’ty remarks 1 bolt 2 m8 × 70 mm 2 bolt 2 m8 × 50 mm 3 screw 2 ø4 × 12 mm 4 grommet 1 5 seal 1 6 water pump housing 1 7 insert cartridge 1 8 impeller 1 9 dowel 2 10 gasket 1 11 outer plate cartridge 1 12 gasket 1 13 oil seal housing 1 14 gasket 1 15...

Page 133

6885j11 6-4 9 8 7 6 5 4 3 2 1 lower unit w 9 do not hold the propeller with your hands when loosening or tightening it. 9 be sure to disconnect the battery cables from the battery and the lock plate from the engine stop lanyard switch. 9 put a block of wood between the anti- cavitation plate and pro...

Page 134

Lowr 6-5 6885j11 lower unit 8. Mark the trim tab at the area shown. 9. Remove the cover 3, then remove the trim tab bolt 4 and trim tab 5. 10. Loosen the bolts(nuts) 6, and then remove the lower unit (x, y-transom: and extension 7) from the upper case. å l-transom ∫ x-transom ç y-transom 68860455 4 ...

Page 135

6885j11 6-6 9 8 7 6 5 4 3 2 1 lower unit 4. Remove the oil seal housing 7 and gas- ket 8. Note: insert a flat-head screw driver between the pry tabs to pry off the oil seal housing 7. Checking the water pump 1. Check the water pump housing. Replace the water pump housing if deformed. 2. Check the im...

Page 136

6-7 lowr 6885j11 lower unit propeller shaft housing 105 n·m (10.5 kgf·m, 77.4 ft·lb) 6886030e no. Part name q’ty remarks 1 shift plunger 1 2 shift slider 1 3 spring 1 4 dog clutch 1 5 cross pin 1 6 spring 1 7 propeller shaft 1 8 reverse gear shim — 9 reverse gear 1 10 washer 1 11 o-ring 1 12 ball be...

Page 137

6-8 6885j11 9 8 7 6 5 4 3 2 1 propeller shaft housing 3. Remove the propeller shaft housing 4 and straight key 5. 4. Remove the propeller shaft assembly and shim(s) from propeller shaft housing. Disassembling the propeller shaft assembly 1. Remove the shift plunger 1 and spring 2 from dog clutch 3. ...

Page 138

Lowr 6-9 6885j11 lower unit 2. Remove the cross pin 4, and then remove the dog clutch 3. 3. Remove the shift slider 5 and spring 6. Disassembling the propeller shaft housing 1. Set the special service tools as shown. 2. Remove the reverse gear and washer. 3 4 5 6 68860075 68860080 1 2 3 4 3. Set the...

Page 139

6885j11 6-10 9 8 7 6 5 4 3 2 1 propeller shaft housing checking the propeller shaft hous- ing 1. Check the propeller shaft housing. Replace the propeller shaft housing if cracked or corroded. Checking the reverse gear 1. Check the teeth and dogs of the reverse gear. Replace the reverse gear if crack...

Page 140

6-11 lowr 6885j11 lower unit lower unit note: install a new ball bearing with the identifica- tion mark e facing toward the forward gear side. 4. Install the reverse gear assembly into the propeller shaft housing using a press. Note: after installing the reverse gear, check that the reverse gear rot...

Page 141

6885j11 6-12 9 8 7 6 5 4 3 2 1 propeller shaft housing assembling the propeller shaft assembly 1. Install the spring 1, dog clutch 2, shift slider 3, cross pin 4, and then install the shift plunger 5 temporarily. Note: 9 align the hole a of the dog clutch 2, hole b of shift slider 3 with the slot c ...

Page 142

Lowr 6-13 6885j11 lower unit lower unit drive shaft and lower case 95 n·m (9.5 kgf·m, 70.1 ft·lb) 6886040e no. Part name q’ty remarks 1 drive shaft 1 2 taper roller bearing 1 3 pinion shim — 4 sleeve 1 5 needle bearing 1 6 oil seal 1 7 bolt 2 m6 × 16 mm 8 plate 1 9 o-ring 1 10 shift rod 1 11 circlip...

Page 143

6885j11 6-14 9 8 7 6 5 4 3 2 1 drive shaft and lower case removing the drive shaft 1. Loosen the pinion nut 1 as shown. 2. Remove the pinion nut 1, drive shaft 5, pinion 6, and then remove the forward gear 7 as shown. 2 4 3 1 68860180 68860190 5 6 1 7 drive shaft holder 5 2: 90890-06519 pinion nut h...

Page 144

Lowr 6-15 6885j11 lower unit lower unit 3. Remove the taper roller bearing outer race and shim(s). 4. Remove the sleeve 8 and needle bear- ing 9. 69r60160 6 7 5 stopper guide plate 5: 90890-06501 stopper guide stand 6: 90890-06538 bearing puller assembly 7: 90890-06535 68860240 0 q q 0 8 9 9 needle ...

Page 145

6885j11 6-16 9 8 7 6 5 4 3 2 1 drive shaft and lower case checking the pinion and forward gear 1. Check the teeth of pinion. Check the teeth and dogs of forward gear. Replace the pinion and forward gear if cracked or worn. Checking the drive shaft 1. Check the drive shaft spline. Replace the drive s...

Page 146

Lowr 6-17 6885j11 lower unit assembling the lower case 1. Install a new needle bearing into the lower case to specified depth. C c do not reuse the bearing, always replace it with a new one. Note: 9 install a needle bearing with the identifica- tion mark a facing up. 9 apply gear oil to the needle b...

Page 147

6885j11 6-18 9 8 7 6 5 4 3 2 1 drive shaft and lower case installing the shift rod 1. Install the shift cam 1, shift rod 2 and plate 3, then tighten the bolts 4. Note: install the shift cam 1 with the “up” mark a facing up. Installing the drive shaft 1. Install the forward gear 1, pinion 2, drive sh...

Page 148

6-19 lowr 6885j11 lower unit lower unit 2. Tighten the pinion nut 4 to the specified torque. Installing the oil seal housing 1. Install the new gasket 1 and oil seal housing 2. 7 6 4 5 68860330 drive shaft holder 5 5: 90890-06519 pinion nut holder 6: 90890-06715 socket adapter 2 7: 90890-06507 pinio...

Page 149

6885j11 6-20 9 8 7 6 5 4 3 2 1 drive shaft and lower case 4. Install the propeller shaft housing assem- bly 4, straight key 6 and lock washer 7 into the lower case, then tighten the ring nut 8 to the specified torque. Note: 9 to secure the ring nut, bend 1 tab q of the lock washer into a slot in the...

Page 150

6-21 lowr 6885j11 lower unit lower unit 2. Install the woodruff key 5 onto the drive shaft groove. 3. Align the groove a in the impeller 6 with the woodruff key 5, and then install the impeller. 4. Install the insert cartridge 7 into the water pump housing 8. Note: align the insert cartridge project...

Page 151

6885j11 6-22 9 8 7 6 5 4 3 2 1 drive shaft and lower case installing the lower unit w 9 when installing the lower unit without removing the power unit, be sure to sus- pend the outboard motor. Otherwise, the outboard motor could suddenly fall and result in injury. 9 be sure to tilt the outboard moto...

Page 152

6-23 lowr 6885j11 lower unit lower unit 4. Install the dowels 4 onto the lower case and extension 5 (x, y-transom). å l-transom ∫ x-transom ç y-transom 68860450 8 4 9 6 6 7 4 6 å 68860460 9 5 5 6 6 7 6 ∫ ç 8 4 4 4 4 5. Install the lower unit to the upper case, and then tighten the lower case bolts (...

Page 153

6885j11 6-24 9 8 7 6 5 4 3 2 1 drive shaft and lower case 11. Insert a gear oil tube into the drain hole and slowly fill the gear oil until oil flows out of the check hole and no air bubbles are visible. Note: to check the gear oil, refer to page 3-17. 12. Install the new gaskets t, check screw y, d...

Page 154

Lowr 6-25 6885j11 lower unit shimming t3 m3 m2 68860480 t2 t1 m1 p r f 6885j11_06 07.10.10 10:58 page 26.

Page 155

6885j11 6-26 9 8 7 6 5 4 3 2 1 shimming shimming note: 9 shimming is not required when assembling the original lower case and inner parts. 9 shimming is required when assembling a new lower case and the original inner parts. 9 shimming is required when replacing the inner part(s). Selecting the pini...

Page 156

Lowr 6-27 6885j11 lower unit 4. Calculate the pinion shim thickness (t3) as shown in the examples below. Note: “p” is the deviation of the lower case dimen- sion from standard. The “p” mark a is stamped on the trim tab mounting surface of the lower case in 0.01 mm units. If the “p” mark is unreadabl...

Page 157

6885j11 6-28 9 8 7 6 5 4 3 2 1 shimming 2. Calculate the forward gear shim thick- ness (t1) as shown in the examples below. Note: “f” is the deviation of the lower case dimen- sion from standard. The “f” mark a is stamped on the trim tab mounting surface of the lower case in 0.01 mm units. If the “f...

Page 158

Lowr 6-29 6885j11 lower unit 3. Calculate the reverse gear shim thick- ness (t2) as shown in the examples below. Note: “r” is the deviation of the lower case dimen- sion from standard. The “r” mark a is stamped on the trim tab mounting surface of the lower case in 0.01 mm units. If the “r” mark is u...

Page 159

6885j11 6-30 9 8 7 6 5 4 3 2 1 shimming / backlash 3. Install the special service tools so that it pushes against the propeller shaft, and then turn the lower unit 90° to the upside position. Note: while turning the drive shaft clockwise 5–6 times so that the forward gear taper roller bearing is sea...

Page 160

6. Add or remove shim(s) if out of specifica- tion. M: measurement 7. Remove the special service tools from the propeller shaft and drive shaft. 8. Apply a load to the reverse gear by installing the propeller 9 without the spacer 0 , then install the spacer q, spacer w and propeller nut e as shown. ...

Page 161

6885j11 6-32 9 8 7 6 5 4 3 2 1 backlash 9. While pushing the drive shaft slightly, turn the drive shaft slowly clockwise and counterclockwise, then measure the backlash when the drive shaft stops in each direction. 10. Add or remove the shim(s) if out of spec- ification. M: measurement 11. Remove th...

Page 162

Brkt 6885j11 bracket unit tiller handle .................................................................................................. 7-1 checking the throttle cable and shift cable (ehd) .................................. 7-3 assembling the tiller handle (ehd) ....................................

Page 163

6885j11 9 8 7 6 5 4 3 2 1 gear pump .................................................................................................. 7-46 disassembling the gear pump, down relief valve and main valve ......... 7-48 disassembling the relief valve and manual valve .................................. ...

Page 164

Brkt 7-1 6885j11 bracket unit tiller handle 37 n·m (3.7 kgf·m, 27.3 ft·lb) 5 n·m (0.5 kgf·m, 3.7 ft·lb) 37 n·m (3.7 kgf·m, 27.3 ft·lb) 11 n·m (1.1 kgf·m, 8.1 ft·lb) 6887010e ehd no. Part name q’ty remarks 1 throttle grip 1 2 washer 1 3 spring 1 4 bushing 1 5 tiller handle 1 6 grommet 1 7 throttle ca...

Page 165

6885j11 7-2 9 8 7 6 5 4 3 2 1 tiller handle 37 n·m (3.7 kgf·m, 27.3 ft·lb) 5 n·m (0.5 kgf·m, 3.7 ft·lb) 37 n·m (3.7 kgf·m, 27.3 ft·lb) 11 n·m (1.1 kgf·m, 8.1 ft·lb) 6887010e ehd no. Part name q’ty remarks 18 plate 1 19 shift lever 1 20 bushing 1 21 spring 1 22 ball 1 23 collar 1 24 washer 1 25 bushi...

Page 166

Brkt 7-3 6885j11 bracket unit checking the throttle cable and shift cable (ehd) 1. Check the throttle cable and shift cable for smooth operation. 2. Check the inner wire, outer wire of the throttle cable and shift cable. Replace if the outer wire is bent or damaged or the rubber seals are damaged. A...

Page 167

6885j11 7-4 9 8 7 6 5 4 3 2 1 tiller handle 6. Push the throttle grip so that the throttle grip holes are aligned with the throttle shaft holes. Lubricating the throttle gear (ehd) 1. Inject grease into the grease nipple until grease comes out from the screw hole a. 68870030 69d70170 a a 6885j11_07a...

Page 168

Brkt 7-5 6885j11 bracket unit bottom cowling ehd 6887020e no. Part name q’ty remarks 1 washer 1 2 bracket 1 3 bolt 1 4 spring 1 5 ball 1 6 bushing 1 7 arm 1 8 bolt 2 m8 × 30 mm : ehd 9 neutral switch assembly 1 ehd 10 shift lever 1 11 washer 2 12 bracket 1 13 shift lever 1 14 bushing 1 15 shift rod ...

Page 169

6885j11 7-6 9 8 7 6 5 4 3 2 1 bottom cowling 4 n·m (0.4 kgf·m, 3.0 ft·lb) ehd ehd ehd, ed 6887030e no. Part name q’ty remarks 1 lock lever 2 2 bushing 2 3 bushing 2 4 wave washer 2 5 clamp lever 2 6 bolt 2 m6 × 12 mm 7 grommet 1 8 grommet 1 ed, et 9 grommet 1 ehd 10 retaining plate 1 11 bolt 2 m6 × ...

Page 170

Brkt 7-7 6885j11 bracket unit 4 n·m (0.4 kgf·m, 3.0 ft·lb) ehd ehd ehd, ed 6887030e no. Part name q’ty remarks 18 clip 2 19 hose 1 20 grommet 1 ehd, ed 21 grommet 1 22 grommet 4 23 collar 4 24 bracket 1 25 screw 1 ø6 × 20 mm 26 bolt 4 m6 × 30 mm 6885j11_07a 07.10.12 15:16 page 10

Page 171

6885j11 7-8 9 8 7 6 5 4 3 2 1 bottom cowling / upper case, steering arm upper case, steering arm x, y 6887090e no. Part name q’ty remarks 1 nut 2 2 washer 2 3 nut 2 4 cover 2 5 screw 2 ø6 × 15 mm 6 ground lead 1 7 bolt 4 m8 × 25 mm 8 mount housing 2 9 spring 4 10 lower mount 2 11 rubber washer 2 12 ...

Page 172

Brkt 7-9 6885j11 bracket unit x, y 6887090e no. Part name q’ty remarks 18 upper mount 2 19 washer 2 20 rubber washer 2 21 washer 2 22 bolt 2 m10 × 175 mm 23 damper 2 24 rubber seal 1 25 upper case assembly 1 not reusable 6885j11_07a 07.10.12 15:16 page 12.

Page 173

6885j11 7-10 9 8 7 6 5 4 3 2 1 upper case, steering arm 21 n·m (2.1 kgf·m, 15.5 ft·lb) 21 n·m (2.1 kgf·m, 15.5 ft·lb) 21 n·m (2.1 kgf·m, 15.5 ft·lb) 6887100e no. Part name q’ty remarks 1 bolt 2 m8 × 30 mm 2 exhaust guide 1 3 gasket 1 4 collar 1 5 gasket 1 6 exhaust manifold 1 7 bolt 3 m8 × 30 mm 8 c...

Page 174

Brkt 7-11 6885j11 bracket unit disassembling the upper case 1. Remove the bolts 1, muffler assembly 2, dowels 3 and rubber seal 4 from the upper case 5. 2. Remove the bolts 6, muffler 7, cooling water pipe 8, rubber damper 9 and gas- ket 0. 3. Remove the bolts q, exhaust manifold w, gasket e and rub...

Page 175

6885j11 7-12 9 8 7 6 5 4 3 2 1 upper case, steering arm 2. Install the rubber damper 5 onto the muffler 6. 3. Install the cooling water pipe 7 onto the muffler 6. 4. Install the new gasket 8, muffler 6 onto the exhaust guide assembly 9, and then tighten the bolts 0 to the specified torque. 5. Instal...

Page 176

Brkt 7-13 6885j11 bracket unit 8. Install the upper mounts r and bracket y into the upper case assembly, and then tighten it with the bolts u. Note: first tighten the center located bolt, when tightening the bolts u. 9. Install the lower mounts i and bolts o as shown below. 10. Install the lower mou...

Page 177

6885j11 7-14 9 8 7 6 5 4 3 2 1 upper case, steering arm 20 n·m (2.0 kgf·m, 14.8 ft·lb) ed,et 6887110e no. Part name q’ty remarks 1 steering hook 1 ed, et 2 nut 2 ed, et 3 washer 2 ed, et 4 steering arm 1 5 washer 1 6 bushing 1 7 o-ring 1 8 bushing 2 9 clamp bracket assembly 1 10 o-ring 1 11 washer 1...

Page 178

Brkt 7-15 6885j11 bracket unit removing the steering arm 1. Fully tilt the swivel bracket up, and then support it with the tilt stop lever 1. 2. Remove the circlip 2. 3. Remove the steering yoke 3 as shown. 4. Remove the washer, o-ring, bushing, steering arm, washer, bushing, o-ring, and bushing. 5 ...

Page 179

7. Inject grease into the grease nipple until grease comes out from both the upper and lower bushings c. 6885j11 7-16 9 8 7 6 5 4 3 2 1 upper case, steering arm 5. Install the steering yoke 0 to the steer- ing arm 5 by aligning the center a of the steering yoke with the center b of the steering arm....

Page 180

3. Install the covers. Brkt 7-17 6885j11 bracket unit installing the upper case 1. Install the upper and lower mount assem- bly into the bracket assembly 1 simulta- neously. 2. Install the upper mount nuts 2 and lower mount nuts 3, and then tighten them. Note: before tightening the upper case, insta...

Page 181

6885j11 7-18 9 8 7 6 5 4 3 2 1 upper case, steering arm / clamp bracket and swivel bracket clamp bracket and swivel bracket 8 n·m (0.8 kgf·m, 5.9 ft·lb) 6887070e ehd, ed no. Part name q’ty remarks 1 pin 1 2 bushing 4 3 bracket 1 4 bushing 2 5 shock absorber 1 6 bolt 1 m6 × 10 mm 7 reverse lock lever...

Page 182

Brkt 7-19 6885j11 bracket unit 15 n·m (1.5 kgf·m, 11.1 ft·lb) 6887050e ehd, ed no. Part name q’ty remarks 1 cap 2 2 self-locking nut 1 3 clamp bracket 1 4 ground lead 1 5 screw 1 ø6 × 12 mm 6 washer 2 7 bushing 2 8 cap 3 9 grease nipple 3 10 ground lead 1 11 swivel bracket assembly 1 12 clamp bracke...

Page 183

6885j11 7-20 9 8 7 6 5 4 3 2 1 clamp bracket and swivel bracket 15 n·m (1.5 kgf·m, 11.1 ft·lb) 6887050e ehd, ed no. Part name q’ty remarks 18 washer 2 19 bolt 2 m6 × 12 mm 20 bolt 2 m6 × 16 mm 6885j11_07a 07.10.12 15:16 page 23.

Page 184

Brkt 7-21 6885j11 bracket unit 30.3 30.4 mm (1.19 1.20 in) 6887040e ehd, ed no. Part name q’ty remarks 1 tilt stop lever 1 2 tilt stop lever 1 3 bushing 2 4 swivel bracket 1 5 spring 1 6 plate 1 7 bolt 1 m6 × 10 mm 8 pin 3 9 distance collar 1 10 bushing 2 11 collar 1 12 lever 1 13 cap 2 6885j11_07a ...

Page 185

6885j11 7-22 9 8 7 6 5 4 3 2 1 clamp bracket and swivel bracket removing the clamp bracket (ehd, ed) w 9 be sure to tilt the outboard motor fully and support it with the tilt stop lever. It can not be tilted up partially. Otherwise the outboard motor could fall back down suddenly. 9 do not disassemb...

Page 186

Brkt 7-23 6885j11 bracket unit 6. Remove the starboard clamp bracket t in the direction of the arrow shown in the illustration. 7. Remove the washer y. 8. Remove the swivel bracket u. Checking the shock absorber 1. Check the shock absorber. Replace the shock absorber if damaged or corroded. Disassem...

Page 187

Note: install the pins 7 so that they extend equal distances a. 5. Install the spring 8 as shown. Note: install the spring on the longer length side b with the tilt stop lever side. Assembling the clamp bracket (ehd, ed) 1. Pass the through tube 1 into the clamp bracket 2 and washer 3. 6885j11 7-24 ...

Page 188

Brkt 7-25 6885j11 bracket unit 2. Install the swivel bracket 4 to the clamp bracket 2. 3. Install the washer 3, starboard clamp bracket 5 and ground lead 6. 4. Fully tilt the swivel bracket up, and then support it with tilt stop lever. 5. Tighten the self-locking nut 7 temporari- ly. 6. Install the ...

Page 189

6885j11 7-26 9 8 7 6 5 4 3 2 1 clamp bracket and swivel bracket 6887080e et no. Part name q’ty remarks 1 lock tie 3 2 pin 1 3 tube 1 4 bolt 6 m10 × 45 mm 5 trim sensor lead 1 6 ptt motor lead 1 7 circlip 1 8 bushing 2 9 bushing 2 10 ptt unit 1 11 ground lead 1 12 bolt 1 m6 × 10 mm not reusable 6885j...

Page 190

Brkt 7-27 6885j11 bracket unit 15 n·m (1.5 kgf·m, 11.1 ft·lb) 18 n·m (1.8 kgf·m, 13.3 ft·lb) 6887060e et no. Part name q’ty remarks 1 cap 2 2 self-locking nut 1 3 clamp bracket 1 4 ground lead 1 5 screw 1 ø6 × 12 mm 6 washer 2 7 bushing 2 8 cap 3 9 grease nipple 3 10 ground lead 1 11 swivel bracket ...

Page 191

6885j11 7-28 9 8 7 6 5 4 3 2 1 clamp bracket and swivel bracket 15 n·m (1.5 kgf·m, 11.1 ft·lb) 18 n·m (1.8 kgf·m, 13.3 ft·lb) 6887060e et no. Part name q’ty remarks 18 spring 1 19 tilt pin 1 20 plate 1 21 anode 1 22 ground lead 1 23 washer 2 24 bolt 2 m6 × 12 mm 25 bolt 2 m6 × 16 mm 6885j11_07a 07.1...

Page 192

Brkt 7-29 6885j11 bracket unit 30.3 30.4 mm (1.19 1.20 in) 6887045e et no. Part name q’ty remarks 1 tilt stop lever 1 2 tilt stop lever 1 3 bushing 2 4 swivel bracket 1 5 spring 1 6 plate 1 7 bolt 1 m6 × 10 mm 8 pin 2 9 distance collar 1 10 bushing 2 11 collar 1 6885j11_07a 07.10.12 15:16 page 32.

Page 193

6885j11 7-30 9 8 7 6 5 4 3 2 1 clamp bracket and swivel bracket removing the ptt unit (et) 1. Fully tilt the outboard motor up, and then support it with the tilt stop lever 1. W 9 when removing the ptt unit without removing the power unit, be sure to sus- pend the outboard motor. Otherwise, the outb...

Page 194

Brkt 7-31 6885j11 bracket unit 7. Remove the circlip 9, and then remove the pin 0. 8. Remove the ptt unit q, bushings w and e. Removing the clamp bracket (et) 1. Remove the ptt unit. 2. Remove the cap 1 and grease nipples 2, and then disconnect the ground leads 3. 3. Remove the cap 4 and self-lockin...

Page 195

6885j11 7-32 9 8 7 6 5 4 3 2 1 clamp bracket and swivel bracket installing the ptt unit (et) 1. Fully tilt the outboard motor up, and then support it with the tilt stop lever 1. W 9 when installing the ptt unit without removing the power unit, be sure to sus- pend the outboard motor. Otherwise, the ...

Page 196

Brkt 7-33 6885j11 bracket unit 5. Tighten the self-locking nut 8 to the specified torque. 6. Install the ground lead 9, anode 0 and tilt pin q. 7. Pass the ptt motor lead w through the hole of the port clamp bracket. 8. Fasten the ptt motor lead and trim sen- sor lead with the lock ties e. 9. Inject...

Page 197

6885j11 7-34 9 8 7 6 5 4 3 2 1 clamp bracket and swivel bracket 5. Fully tilt the outboard motor up, and then support it with the tilt stop lever 4. 6. Loosen the screws 5. 7. Adjust the position of the trim sensor, and then tighten the screws 5 temporarily. 8. Repeat the steps 1–7 if out of specifi...

Page 198

Brkt 7-35 6885j11 bracket unit 7 n·m (0.7 kgf·m, 5.2 ft·lb) 15 n·m (1.5 kgf·m, 11.1 ft·lb) 11 n·m (1.1 kgf·m, 8.1 ft·lb) 20 n·m (2.0 kgf·m, 14.8 ft·lb) 3 n·m (0.3 kgf·m, 2.2 ft·lb) 7 n·m (0.7 kgf·m, 5.2 ft·lb) 6887120e no. Part name q’ty remarks 1 bolt 3 m6 × 20 mm 2 ptt motor 1 3 bolt 3 m6 × 20 mm ...

Page 199

6885j11 7-36 9 8 7 6 5 4 3 2 1 ptt unit 7 n·m (0.7 kgf·m, 5.2 ft·lb) 15 n·m (1.5 kgf·m, 11.1 ft·lb) 11 n·m (1.1 kgf·m, 8.1 ft·lb) 20 n·m (2.0 kgf·m, 14.8 ft·lb) 3 n·m (0.3 kgf·m, 2.2 ft·lb) 7 n·m (0.7 kgf·m, 5.2 ft·lb) 6887120e no. Part name q’ty remarks 18 pin 1 19 bushing 2 20 manual valve seal 2 ...

Page 200

Brkt 7-37 6885j11 bracket unit checking the hydraulic pressure 1. Check the hydraulic pressure. Check the internal parts if out of specification. 2. Fully extend the ptt rams. 3. Loosen the pipe joints 1, and then remove the pipe joint a. 4. Install the special service tool 2. Note: 9 put the ptt un...

Page 201

6885j11 7-38 9 8 7 6 5 4 3 2 1 ptt unit 9. Connect the ptt motor leads to the bat- tery terminals to fully retract the trim and tilt rams. 10. Loosen the pipe joints 3, and then remove the pipe joint b. 11. Install the special service tool as shown. Note: 9 put the ptt unit in the drain pan. 9 quick...

Page 202

Brkt 7-39 6885j11 bracket unit 14. Reverse the ptt motor leads between the battery terminals to fully retract the rams. 15. Remove the ptt unit from a vice. 16. Remove the special service tool, and then install the pipe joint. Note: 9 put the ptt unit in the drain pan. 9 quickly install the pipe joi...

Page 203

6885j11 7-40 9 8 7 6 5 4 3 2 1 ptt unit note: if the fluid is at the correct level, the fluid should overflow out of the filler hole when the reservoir cap is removed. 21. Install the new o-ring and reservoir cap 5, then tighten it to the specified torque. Note: bleeding the ptt unit 2–3 times, and ...

Page 204

Brkt 7-41 6885j11 bracket unit 3.4 n·m (0.34 kgf·m, 2.5 ft·lb) 6887130e no. Part name q’ty remarks 1 stator 1 2 screw 3 ø6 × 16 mm 3 armature 1 4 screw 2 ø4 × 10 mm 5 brush 1 1 6 plate 1 7 bushing 1 8 o-ring 1 9 brush 2 1 10 holder 2 11 spring 2 12 ptt motor base 1 13 oil seal 1 not reusable not reu...

Page 205

6885j11 7-42 9 8 7 6 5 4 3 2 1 ptt motor disassembling the ptt motor 1. Remove the bolts 1, then remove the ptt motor 2, o-ring 3, and joint 4 from the ptt unit. W 9 make sure that the trim and tilt rams are fully extended when removing the ptt motor, otherwise fluid can spurt out from the unit due ...

Page 206

Brkt 7-43 6885j11 bracket unit 5. Remove the o-ring 0, screws q, then remove the brushes w and springs e. C c 9 do not pull the ptt motor leads out from the ptt motor base. 9 do not deform or damage the bimetal a, otherwise the operation of the circuit breaker can be affected. Checking the ptt motor...

Page 207

4. Check the armature for continuity. Replace the armature if not shown in the chart below. 5. Measure the brush length. Replace if below specification limit. 6. Check the ptt motor base. Replace the motor base if cracked or damaged. 7. Check the oil seal. Replace the oil seal if damaged or worn. 69...

Page 208

Brkt 7-45 6885j11 bracket unit 3. Push the brushes 3 into the brush hold- er, and then install the armature 6. 4. Install the stator 7 onto the ptt motor base. Note: place a rag over the end of the armature shaft, hold it with a pair of pliers, and then carefully slide the stator over the armature. ...

Page 209

6885j11 7-46 9 8 7 6 5 4 3 2 1 ptt motor / gear pump 6887140e 4 n·m (0.4 kgf·m, 3.0 ft·lb) 4 n·m (0.4 kgf·m, 3.0 ft·lb) no. Part name q’ty remarks 1 spring 1 2 filter 1 3 bolt 4 m4 × 25 mm 4 pin 2 5 gear housing 1 1 6 ball 2 7 driven gear 1 8 drive gear 1 9 gear housing 2 1 10 o-ring 2 11 down-relie...

Page 210

Brkt 7-47 6885j11 bracket unit 6887150e 4 n·m (0.4 kgf·m, 3.0 ft·lb) no. Part name q’ty remarks 1 screw 2 ø5 × 10 mm 2 trim spring 1 3 up-relief spring 1 4 valve support pin 1 5 relief valve seal 1 6 relief valve seat 1 7 o-ring 1 8 filter 1 9 valve lock screw 1 10 o-ring 1 11 ball 1 12 washer 1 13 ...

Page 211

6885j11 7-48 9 8 7 6 5 4 3 2 1 gear pump disassembling the gear pump, down relief valve and main valve 1. Drain the ptt fluid. 2. Remove the spring 1 and filter 2. 3. Remove the bolts 3, and then remove the gear pump assembly 4. 4. Remove the o-rings 5, down-relief spring 6, valve support pin 7 and ...

Page 212

Brkt 7-49 6885j11 bracket unit disassembling the relief valve and manual valve 1. Drain the ptt fluid. 2. Remove the screws 1, trim spring 2, up-relief spring 3, and then remove the valve support pin 4, relief valve seal 5. 3. Remove the relief valve seat 6, o-ring 7, filter 8, valve lock screw 9, o...

Page 213

6885j11 7-50 9 8 7 6 5 4 3 2 1 gear pump checking the manual valve 1. Check the manual valve 1. Clean the manual valve if dirt or residue appears. Checking the gear housing 1. Check the inside of the gear housing. Replace the gear housing if scratched or worm. Checking the reservoir 1. Check the res...

Page 214

Brkt 7-51 6885j11 bracket unit 2. Install the filter 6 and new o-ring 7 into the ptt body. 3. Install the relief valve seal 8, valve sup- port pin 9 and up-relief spring 0 into the relief valve seat q, then install into the ptt body. 4. Install the trim spring w, and then tighten the screws e to the...

Page 215

6885j11 7-52 9 8 7 6 5 4 3 2 1 gear pump assembling the gear pump 1. Install the drive gear 1 and driven gear 2 and balls 3 into the gear housing 1 4, and then install the gear housing 2 5. 2. Hold the gear pump assembly in a vice using aluminum plates a on both side. 3. Install the pin 6 as shown. ...

Page 216

Brkt 7-53 6885j11 bracket unit 65 n·m (6.5 kgf·m, 47.9 ft·lb) 90 n·m (9.0 kgf·m, 66.4 ft·lb) 160 n·m (16.0 kgf·m, 118 ft·lb) 13 n·m (1.3 kgf·m, 9.6 ft·lb) 6887160e no. Part name q’ty remarks 1 tilt ram 1 2 dust seal 1 3 tilt cylinder end screw 1 4 backup ring 1 5 o-ring 1 6 o-ring 1 7 tilt piston 1 ...

Page 217

6885j11 7-54 9 8 7 6 5 4 3 2 1 tilt cylinder and trim cylinder 65 n·m (6.5 kgf·m, 47.9 ft·lb) 90 n·m (9.0 kgf·m, 66.4 ft·lb) 160 n·m (16.0 kgf·m, 118 ft·lb) 13 n·m (1.3 kgf·m, 9.6 ft·lb) 6887160e no. Part name q’ty remarks 18 tilt piston assembly 1 19 tilt ram assembly 1 20 tilt cylinder assembly 1 ...

Page 218

Disassembling the tilt cylinder and trim cylinder 1. Loosen the pipe joint, then remove the pipes 1, 2 and 3. 2. Remove the pin 4, and then remove the tilt cylinder 5 from ptt unit. Brkt 7-55 6885j11 bracket unit 3. Hold the tilt cylinder 5 in a vice using aluminum plates a on both sides. 4. Loosen ...

Page 219

6885j11 7-56 9 8 7 6 5 4 3 2 1 tilt cylinder and trim cylinder 6. Blow compressed air through the hole b to remove the free piston 7. W never look into the tilt cylinder opening when removing the free piston. The free piston and ptt fluid can be forcefully expelled out. Note: be sure to cover the op...

Page 220

Brkt 7-57 6885j11 bracket unit 12. Hold the ptt body e in a vice using alu- minum plates a on both sides. 13. Loosen the trim cylinder end screws r, and then remove them. 14. Remove the trim ram assemblies. 15. Drain the ptt fluid. 16. Remove the o-ring y and backup ring u. Checking the tilt cylinde...

Page 221

6885j11 7-58 9 8 7 6 5 4 3 2 1 tilt cylinder and trim cylinder 3. Hold the tilt piston in a vice using the alu- minum plates a and special service tool 8 on both sides. 4. Tighten the tilt ram 7 to the specified torque. 5. Install the new o-ring 0 and backup ring q onto the tilt piston 6. 6. Install...

Page 222

Brkt 7-59 6885j11 bracket unit assembling the trim ram 1. Install the new o-ring 1, backup ring 2 onto the trim piston 3. 2. Install the new dust seal 4 and new o- ring 5 to the trim cylinder end screw 6. 3. Install the trim cylinder end screw 6 onto the trim ram 7. 1 2 1 2 3 68871160 4 5 6 7 4 5 6 ...

Page 223

6885j11 7-60 9 8 7 6 5 4 3 2 1 tilt cylinder and trim cylinder w do not push the trim rams down while installing them into the trim cylinders. Otherwise, the ptt fluid may spurt out from the unit. Installing the ptt motor 1. Install the filter 1, spring 2 and joint 3 into the gear pump. 2. Fill the ...

Page 224

Brkt 7-61 6885j11 bracket unit 4. Install the new o-ring 4 and ptt motor 5, and then tighten the bolts to the spec- ified torque. Note: align the armature shaft with the recess in the joint. Installing the reservoir 1. Install the new o-ring 1 and reservoir 2, and then tighten the bolts 3 to the spe...

Page 225

6885j11 7-62 9 8 7 6 5 4 3 2 1 tilt cylinder and trim cylinder 3. Remove the reservoir cap, and then check the fluid level in the reservoir. Note: the fluid level should be at the brim of the filler hole. 4. If fluid is below the correct level, add fluid of the recommended type. 5. Install the reser...

Page 226

Brkt 7-63 6885j11 bracket unit note: 9 repeat this procedure so that the rams go up and down 4–5 times (be sure to wait for 2–3 seconds before switching the leads). 9 if the rams do not move up and down easi- ly, push and pull on the rams to assist oper- ation. 8. Check the fluid level when the rams...

Page 227

6885j11 7-64 9 8 7 6 5 4 3 2 1 tilt cylinder and trim cylinder / ptt electrical system 3. Connect the digital circuit tester between ptt relay terminals 3 and 6. 4. Connect the light green (lg) lead to the positive battery terminal and the black (b) lead to the negative battery terminal as shown. 5....

Page 228

Brkt 7-65 6885j11 bracket unit 6. Connect the sky blue (sb) lead to the positive battery terminal and the black (b) lead to the negative battery terminal as shown. 7. Check for continuity between terminals. Replace the ptt relay if not shown in the chart below. Tester probe terminal 3 4 5 6 terminal...

Page 229

6885j11 9 8 7 6 5 4 3 2 1 elec electrical system checking the electrical component..............................................................8-1 measuring the peak voltage ......................................................................8-1 electrical component .................................

Page 230

Elec 8-1 6885j11 electrical system checking the electrical component measuring the peak voltage to check the electrical components or mea- sure the peak voltage, use the special ser- vice tools. A faulty electrical component can be easily checked by measuring the peak voltage. The specified engine s...

Page 231

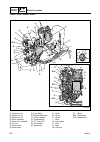

6885j11 8-2 9 8 7 6 5 4 3 2 1 checking the electrical component / electrical component electrical component starboard view 55dehd, 75aehd, 85aehd 1 2 3 4 5 6 7 8 9 0 q w e r y t u b r r r br y/r b p l u u b /w g r w l p br b y 1 e b b/w b/w p b g r g/w g/w g b b/w b br r 2 3 6 0 b r 6888010e 1 ignit...

Page 232

Elec 8-3 6885j11 electrical system 1 2 3 4 5 6 7 9 q e r t t b r r l b p l 8 t w g 0 b /w g r w l p br b r lg sb 1 b b/w b/w p b g r g/w g/w g b br r b/w b g r 2 8 3 6 0 l e r b 6888020e 75aed, 75aet, 85aed, 85aet 1 ignition coil #1 2 ignition coil #2 3 ignition coil #3 4 stator assembly 5 pulser co...

Page 233

6885j11 8-4 9 8 7 6 5 4 3 2 1 electrical component / ignition and ignition control system ignition and ignition control sys- tem checking the ignition spark gap 1. Disconnect the all spark plug caps from the all spark plugs. 2. Connect a spark plug cap to the special service tool. 3. Crank the engin...

Page 234

Elec 8-5 6885j11 electrical system checking the spark plug cap 1. Check the spark plug caps. Replace the spark plug caps if cracked or damaged. 2. Remove the spark plug cap 1 from the spark plug wire 2. 3. Check the spark plug wire terminal 3. Replace the spark plug wire terminal if damaged or corro...

Page 235

Note: remove the all spark plug caps, when mea- suring the cdi unit peak voltage at loaded engine cranking. 6885j11 8-6 9 8 7 6 5 4 3 2 1 ignition and ignition control system checking the cdi unit note: be sure to install the test propeller before checking the peak voltage. 1. Remove the cover. 2. C...

Page 236

Elec 8-7 6885j11 electrical system 6. Measure the pulser coil resistance. Replace the pulser coil assembly if out of specification. Checking the charge coil 1. Remove the cover. 2. Connect the special service tool 1 and digital circuit tester with peak voltage adapter b to the charge coil coupler 2....

Page 237

Checking the thermoswitch 1. Remove the thermoswitch from cylinder head. Note: to remove the thermoswitch, refer to page 5- 18. 2. Place the thermoswitch in a container of water and slowly heat the water. 3. Check the switch for continuity at the specified temperatures. Replace the ther- moswitche i...

Page 238

Elec 8-9 6885j11 electrical systems checking the warning indicator (ehd) 1. Disconnect the warning indicator connec- tor. 2. Check the warning indicator for continu- ity. C c 9 be sure to use the 1.5 v dry sell battery, otherwise the higher voltage batteries will damage the diode. 9 led has an direc...

Page 239

6885j11 8-10 9 8 7 6 5 4 3 2 1 ignition and ignition control system / starting system ∫ ehd checking the engine stop lanyard switch 1. Check the engine stop lanyard switch for continuity. Replace the engine stop lan- yard switch if it is not shown in the chart below. ∫ 2 1 3 5 4 68880115 å ed, et ∫ ...

Page 240

Checking the starter relay 1. Remove the cover and starter relay. 2. Connect the digital circuit tester to the starter relay terminals. 3. Check the starter relay for continuity. Replace the starter relay if it is not shown in the chart below. Checking the neutral switch continu- ity (ehd) 1. Discon...

Page 241

6885j11 8-12 9 8 7 6 5 4 3 2 1 starting system / starter motor 4 n·m (0.4 kgf·m, 3.0 ft·lb) 6888030e no. Part name q’ty remarks 1 screw 3 ø4 × 10 mm 2 cover 1 3 clip 1 4 pinion stopper 1 5 spring 1 6 pinion 1 7 bushing 1 8 front bracket 1 9 washer — 10 armature 1 11 stator assembly 1 12 nut 2 13 spr...

Page 242

Elec 8-13 6885j11 electrical systems 4 n·m (0.4 kgf·m, 3.0 ft·lb) 6888030e no. Part name q’ty remarks 18 brush holder 1 19 rear bracket 1 20 cover 1 21 screw 2 ø4 × 12 mm 22 bolt 2 m5 × 130 mm 6885j11_08 07.10.1 9:02 page 14.

Page 243

6885j11 8-14 9 8 7 6 5 4 3 2 1 starter motor 4. Mark the alignment line on the starter motor before disassembly. Checking the starter motor pinion 1. Check the teeth of the pinion. Replace the pinion if cracked or worn. 2. Check the pinion. Replace the pinion if it does not operate smoothly. Note: t...

Page 244

Elec 8-15 6885j11 electrical systems 2. Measure the commutator diameter a. Replace the armature if below specifica- tion limit. 3. Measure the commutator undercut b. Replace the armature if below specifica- tion limit. A 1 6f680175 digital caliper 1: 90890-06704 4. Check the armature for continuity....

Page 245

6885j11 8-16 9 8 7 6 5 4 3 2 1 starter motor / charging system 2. Check the brush holder assembly for continuity. Replace the brush holder if it is not shown in the chart below. Installing the starter motor pinion 1. Install the starter motor pinion 1, new spring 2, pinion stopper 3 and then press f...

Page 246

Elec 8-17 6885j11 electrical systems 6. Measure the lighting coil resistance. Replace the stator assembly if out of specification. Checking the rectifier regulator note: do not use the peak voltage adapter when measuring the output peak voltage of the rectifier regulator. 1. Remove the cover. 2. Con...

Page 247

6885j11 9 8 7 6 5 4 3 2 1 trbl shtg trbl shtg troubleshooting troubleshooting the power unit ................................................................. 9-1 troubleshooting the power unit ................................................................ 9-1 troubleshooting the ptt unit ...........

Page 248

Troubleshooting the power unit troubleshooting the power unit symptom 1: specific trouble conditions. Symptom 2: trouble conditions of an area or individual part. Cause 1: the content considered as the trouble factors of symptom 2. Cause 2: the content considered as the trouble causes of cause 1 (de...

Page 249

Refer symptom 2 cause 1 cause 2 checking step to page 6885j11 9-2 9 8 7 6 5 4 3 2 1 troubleshooting the power unit refer symptom 2 cause 1 cause 2 checking step to page — stuck piston and crank shaft broken woodruffkey — disassemble and check the power unit. 5-9 piston lock due to water in the combu...

Page 250

Refer symptom 2 cause 1 cause 2 checking step to page trbl shtg 9-3 6885j11 troubleshooting 8-7 8-7 5-3 8-7 pulser coil malfunction measure the pulser coil resistance. Change the pulser coil and check the ignition spark. Pulser coil out- put peak volt- age less than specifications 5-3 8-4 charge coi...

Page 251

6885j11 9-4 9 8 7 6 5 4 3 2 1 trouble shooting the power unit refer symptom 2 cause 1 cause 2 checking step to page symptom 1: unstable engine idle speed, poor acceleration throttle cable adjusting improperly check and adjust the throttle cable. Check and adjust the throttle link length. 3-7 — — — t...

Page 252

Trbl shtg 9-5 6885j11 troubleshooting refer symptom 2 cause 1 cause 2 checking step to page symptom 1: limited engine speed (below 2,000 r/min) clogged cooling water inlet check the cooling water inlet. 3-4 9buzzer comes on (ed, et) 9overheat warn- ing indicator comes on (ehd) 9cooling water does no...

Page 253