Service manual mini component system crx-e500 1 0 0 8 1 0 important notice this manual has been provided for the use of authorized yamaha retailers and their service personnel. It has been assumed that basic service procedures inherent to the industry, and more specifically yamaha products, are alre...

Cdc-e500 cdc-e500 2 wall outlet equipment under test ac leakage tester or equivalent insulating table ■ to service personnel 1. Critical components information components having special characteristics are marked s a n d m u s t b e r e p l a c e d w i t h p a r t s h a v i n g specifications equal ...

Cdc-e500 cdc-e500 3 varo!: avattaessa ja suojalukitus ohitettaessa olet alttiina nÄkymÄttÖmÄlle laser- sÄteilylle. ÄlÄ katso sÄteeseen. Varning!: osynlig laserstrÅlning nÄr denna del Är Öppnad och spÄrren Är urkopplad. Betrakta ej strÅlen. ■ prevention of electro static discharge some semiconductor ...

Cdc-e500 cdc-e500 4 2 3 ■ front panel power 1 2 3 1 2 3 4 5 6 4 5 6 7 8 9 7 8 0 +10 +100 rep mode random prog a b c text/time disc skip d e tape direction preset tuner preset md cd tape aux md rec/pause tape rec/pause mode sleep display dubbing crx-e500 v891360 volume start ■ remote control panel no...

Cdc-e500 cdc-e500 5 ■ rear panels u, c models a model.

Cdc-e500 cdc-e500 6 3 1 2 4 5 217 (8-9/16") 100 (3-15/16") 8 (5/16") 108 ( 4-1/4" ) 346.5 ( 13-5/8" ) unit : mm (inch) ■ specifications output level 1 khz, 0db ................................................................. 2 ± 0.5 vrms signal to noise ratio (eiaj) ...................................

Cdc-e500 cdc-e500 7 cb1 cb6 cb3 cb2 cb4 cb200 1 1 2 2 3 3 4 top cover front panel 5 6 6 6 cdc mechanism unit ■ disassembly procedures (remove parts in the order as numbered.) disconnect the power plug from the ac outlet. 1. Removal of top cover a. Remove 4 screws (1) and 4 screws (2) in fig. 1. B. L...

Cdc-e500 cdc-e500 8 ■ main p.C.B. Operation check 1. Remove the cdc mechanism unit. 2. Disconnect cable from connector (cb6) in fig. 2. At this time, unwind this cable wound around the ferrite core. 3. Remove 4 screws fixing the main (2) p.C.B. To the chassis. Remove 4 screws fixing the main (1) p.C...

Cdc-e500 cdc-e500 9 rear: drawer closing direction ■ cdc-mechanism repairing procedures 1. Explanation of part names and terms. Front/rear: with the mechanism installed normally, the drawer opening direction is to the front. Top/bottom: with the mechanism installed normally, the drawer is visible fr...

Cdc-e500 cdc-e500 10 2. Opening of drawer a. Move the lever under the left side face of the mechanism toward the front side first and then toward the rear side. The drawer is unlocked and opens by about 5 to 10cm. (photo 2) b. Pull out the drawer to open it fully. (photo 3) photo 2 photo 3 (drawer o...

Cdc-e500 cdc-e500 11 photo 7 4. Removal of carriage a. Turn over the drawer removed as described in procedures 2 and 3 on page 10 and place it with its front facing toward you. (photo 6) b. Check that the bevel gear located on the left side of the drawer is attached to the drawer. If not, attach it ...

Cdc-e500 cdc-e500 12 5. Replacement of parts 5-1. Replacement of motor and belt a. Remove the drawer according to procedures 2 and 3 on page 10. B. Using tweezers without non-slip section (to avoid scratching) or a fine stick, remove 2 belts. (photo 9) c. Remove 4 motor mounting screws. (photo 9) d....

Cdc-e500 cdc-e500 13 5-2. Replacement of switches • switches 6, 7 and 8 a. Remove the drawer according to procedures 2 and 3 on page 10. B. Turn over the mechanism. C. Remove 4 pc board a mounting screws. (photo 11) d. Unsolder the motor terminals and remove the motor. (photo 11) e. Unsolder the swi...

Cdc-e500 cdc-e500 14 d. While moving the arm stopper b in the arrow direction (photo 14), pull the lever toward you (photo 13) and lift the arm. (photo 15) e. Remove 2 screws fixing the arm and while pulling the chassis by the part marked with an arrow, remove the arm. (photo 15) f. Remove the carri...

Cdc-e500 cdc-e500 15 h. While pushing down the point shown in photo 17 with a small tool, like tweezers, move the pc board b to the right to remove it. (photo 17) i. Unsolder the pc board b and replace the switches. J. Reversing the above procedure starting from step “i”, install the pc board b to t...

Cdc-e500 cdc-e500 16 6. Installation of carriages a. Check that the bevel gear is installed to the drawer. If it is not, install it according to step b of procedure 4. B. Turn the bevel gear toward the rear (clockwise) until the upper pinion starts to turn. (photo 20) c. Install the carriage (starti...

Cdc-e500 cdc-e500 17 d. Install the left side of the carriage under the collar of the star gear, and then the right side by pushing it with your fingers. (photo 23) e. Turn the bevel gear toward the rear (clockwise) so that the carriage moves completely forward. (the pinion makes about 5 full turns ...

Cdc-e500 cdc-e500 18 7. Installation of drawer a. While holding the drawer in the normal operating, align the lug located on the left side of the drawer to the position where the collar of the arm stopper b is and push it into the chassis. (photo 27) b. With the right side of the drawer loose, fit t...

Cdc-e500 cdc-e500 19 h. After making sure that the drawer and chassis claws are meshed properly, push in the drawer gradually until it reaches the wall of the chassis. (photo 31) i. Pull the drawer in its opening direction lightly to check that it is locked. J. If the drawer has opened, close it aga...

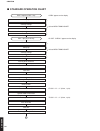

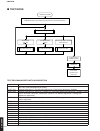

Cdc-e500 cdc-e500 20 ■ standard operation chart a clamp up refer to mech timing chart carriage change clamp down drawer open disc 1 open by disc 1 key “open” appears on the display. “close” “check1” appears on the display. Drawer close refer to mech timing chart clamp up carriage change clamp down t...

Cdc-e500 cdc-e500 21 a tracking balance adj (only open/close) focus gain adj tracking gain adj ~ toc read ~ after searching the beginning, mute is cancelled. Track no. “1” is searched ~ play ~ mute on track search after searching the beginning, mute is cancelled. ~ play ~ mute on spindle motor stop ...

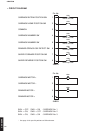

Cdc-e500 cdc-e500 22 • circuit diagram s8beh pin no. 8 slider reverse position sw normal open sw sw8 m 7 slider forward position sw normal open sw sw7 6 drawer open/close detect sw normal open sw sw6 5 carriage number sw normal close sw sw4 4 carriage number sw normal close sw sw5 3 common 2 carriag...

Cdc-e500 cdc-e500 23 • timing chart.

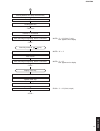

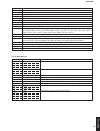

Cdc-e500 cdc-e500 24 standby/on key is pressed while pressing stop key and play/pause key. Test mode indication. Key test mode number up. Test mode number down. Key disc skip key execute test mode. Standby/on key power off the completion of test mode. Power off condition test mode up test mode down ...

Cdc-e500 cdc-e500 25 command function 16:10 kick r 10 kick in the inside direction is repeated every 30msec. 17:10 kick f 10 kick in the outside direction is repeated every 30msec. 18:30 kick r 30 kick in the inside direction is repeated every 40msec. 19:30 kick f 30 kick in the outside direction is...

Cdc-e500 cdc-e500 26 ■ troubleshooting tracking servo defective. Feed servo defective. Pick-up defective. Check by using another disc. Is disc dirty or scratched? Yes no pick-up position within disc range outermost (on mirror surface) pick-up defective. Spindle servo defective. Vco defective. (motor...

Cdc-e500 cdc-e500 27 ■ ic data ic201 : m30622m8a-xxxfp 16 bit µ-com svp svp vct r2 r3 r0l r1l r0h r1h a-d converter (10 bits x 8 channels expandable up to 10 channels) uart/clock synchronous si/o (8 bits x 3 channels) clock synchronous si/o (8 bits x 2 channels) crc arithmetic circuit (ccitt) (polyn...

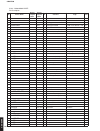

Cdc-e500 cdc-e500 28 ic201 : m30622m8a-xxxfp pin description source circuit no. Device name program diagram i/o contents logic other name name 1 p96/anex1/s out 4 – open 2 p95/anex0/clk4 sqck o mn35511 serial i/f clock (sqck) 3 p94/da1/tb4 in ldrctl o rf amp gain control 2.5v: normal l: rw d/a 4 p93...

Cdc-e500 cdc-e500 29 source circuit no. Device name program diagram i/o contents logic other name name 50 —– p44/cs0 ptest0 o test port 51 p43/a19 psysin sysconi i system control (in) 52 p42/a18 psysout syscono o system control (out) di 53 p41/a17 54 p40/a16 pfeof feof o feed off h: off l: on 55 p37...

Cdc-e500 cdc-e500 30 58 59 56 17 s tat x1 x2 xsel timing generator pitch control vco micro computer interface servo cpu output port d/a converter efm demodulation sync interpolation subcode demodulation circ error correction deinterleave clv servo digital audio interface inter polation soft muting d...

Cdc-e500 cdc-e500 31 ic202 : mn35511al pin description pin no. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 function bit clock output for sr data (nc) l/r identification signal output (nc) serial data output (nc) pow...

Cdc-e500 cdc-e500 32 pin no. 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 function loop filter terminal for dsl loop filter terminal for pll loop filter terminal for vco (+5) power supply for analog circuit (for ad of dsl, pll, da output block...

A b c d e f g h i j 1 2 3 4 5 6 7 cdc-e500 33 ■ display data 14g 13g 12g~1g p19 4-4 p20 5-4 p21 – – 1-5 p22 – – 2-5 p23 – – 3-5 p24 – – 4-5 p25 – 5-5 p26 – 1-6 p27 – – 2-6 p28 – – 3-6 p29 – – 4-6 p30 – – 5-6 p31 – – 1-7 p32 – – 2-7 p33 – – 3-7 p34 – – 4-7 p35 – – 5-7 14g 13g 12g~1g p1 1-1 p2 (1) 2-1...

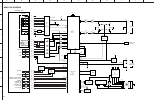

2 a b c d e f g h i j 1 3 4 5 7 cdc-e500 6 34 ■ block diagram ic202 mn35511al spc+dac head amp ic200 an8399sa control system control ic201 16 bit cpu m30624fgafp c o n t r o l display drive ic300 lc75710ne power supply ic5 q4 d14, 15, 18, 19, 20 mute control q4 d4, 5, 10, 11 cb25 display v300 spindl...

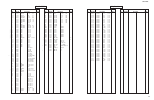

A b c d e f g h i j 1 2 3 4 5 6 7 cdc-e500 35 ■ printed circuit board (foil side) main (2) vf ac f ac f /mute nm2+ nm2- nm1- nm1+ st an flsw /reset fedf vref tr v tvd ecm ecs td fod main (2) dgnd vref syscon flgnd dout -vb l a gnd r dgnd +5 +vb pde pdf d b c a ld pd main (2) rv s fwd o/c d1 com home...

2 a b c d e f g h i j 1 3 4 5 7 cdc-e500 6 36 ■ printed circuit board (foil side) 1 13 27 7 6 26 14 28 20 21 5 8 4 1 analog out digital out system connector main (1) dgnd vref syscon flgnd dout -vb l a gnd r dgnd +5 +vb pde pdf d b c a ld pd main (1) main (1) rv s fwd o/c d1 cdm home ex d2 vf ac f a...

A b c d e f g h i j 1 2 3 4 5 6 7 cdc-e500 37 main (2) 7 3 5 6 8 4 1 2 ac power cable 30 31 57 58 29 28 32 27 2 56 3 45 44 15 16 1 standby/on stop disc 1 disc 2 disc 3 play/pause disc skip main (1) kd1 k2 k0 kd2 kd0 k1 acf ce di gnd /flrst cl +5 vf acf 1 16 17 32 33 48 49 64 main (5) p. C. B. (lead ...

2 a b c d e f g h i j 1 3 4 5 7 cdc-e500 6 38 9 2 6 7 3 8 5 1 stand-by circuit vref circuit thermal shutdown circuit vcc vs vref out 1 out 2 in 1 in 2 gnd ic2, 3: ta8409se full bridge motor driver ic5: njm78m05fa voltage regulator v out v in gnd ic200: an8399sa-e1 cd head amp. + – 21 20 + – 19 + – 2...

A 1 2 3 4 5 6 7 8 9 b c d e f g h i j k l cdc-e500 schematic diagram 39 ★ all voltage are measured with a 10mΩ/v dc electric volt meter. ★ components having special characteristics are marked s and must be replaced with parts having specifications equal to those originally installed. ★ schematic dia...

Cdc-e500 cdc-e500 41 ■ warning components having special characteristics are marked s and must be replaced with parts having specifications equal to those originally installed. Abbreviations in this list are as follows: c.A.El.Chp : chip alumi.Electrolytic cap c.Ce : ceramic cap c.Ce.Array : ceramic...

Cdc-e500 cdc-e500 42 * v9646000 p.C.B. Gd:main uc * v9646100 p.C.B. Gd:main a cb1 v2731000 cn.Fmn 16p cb2 vb390200 cn.Bs.Pin 6p cb3 v7534600 cn.Bs.Pin 4p te cb4 v7534700 cn.Bs.Pin 8p te cb5 vq964100 cn.Bs.Pin 20p cb6 vb390400 cn.Bs.Pin 8p cb7 vq962900 cn.Bs.Pin 8p cb8 vq964100 cn.Bs.Pin 20p cb25 vt7...

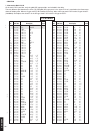

Cdc-e500 43 schm ref. Part no. Description markets ✻ new parts chip resistors schm ref. Part no. Description markets ✻ new parts rd350000 r.Car.Chp 0Ω 1/10w rd354100 r.Car.Chp 10Ω 1/10w rd354470 r.Car.Chp 47Ω 1/10w rd355240 r.Car.Chp 240Ω 1/10w rd355330 r.Car.Chp 330Ω 1/10w rd355390 r.Car.Chp 390Ω 1...

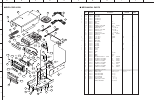

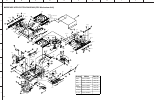

2 a b c d e f g h i j 1 3 4 5 7 cdc-e500 6 44 (5) 11 21 103 203 200 200-1 140 141 101 147 113 147 144 104 5 1-104 1-103 1-110 1-110 1-111 2-12 2-15 2-12 2-5 2-8 2-6 2-1 2-7 1-111 1-102 1-103 1-101 1-11 146 146 112 112 143 142 142 145 143 111 141 145 144 5 (3) 5 (1) 5 (2) 111 110 110 202 204 205 ■ me...

A b c d e f g h i j 1 2 3 4 5 6 7 cdc-e500 45 ■ exploded view (cdc mechanism unit) 19 19 118 12 3 56 62 118 119 119 127 113 123 115 127 121 113 115 115 121 121 120 26 24 27 58 59 57 57 4 11 33 18 19 23 75 34 32 58 41 50 71 77 1 28 31 30 87 48 70 49 29 b a 25 36 40 39 47 85 37 51 54 53 38 52 63 35 2 ...

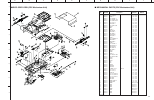

2 a b c d e f g h i j 1 3 4 5 7 cdc-e500 6 46 ■ grease application diagram (cdc mechanism unit) 13 14 15 16 18 19 19 19 20 20 21 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 45 47 48 49 50 54 56 59 64 65 70 70 71 72 72 81 85 87 sc-108 948p x 2 948p x 2 948p 948px2 948px2 g473 x 2 g...

A b c d e 1 2 3 4 5 6 7 cdc-e500 cdc-e500 47 ■ exploded view (pu mecha. Unit) note : neither the pick-up head nor the spindle motor is available independently because they are factory-adjusted for the optimum level after assembly. If the pick-up head or the spindle motor must be replaced, be sure to...

A b c d e 1 2 3 4 5 6 7 cdc-e500 48 ■ grease application diagram (pu mechanism) pg-663 pg-663 pg-663 pg-663 apply the grease molykote pg-663 (p/no. Aax01170).