- DL manuals

- Yamaha

- Outboard Motor

- E8D

- Owner's Manual

Yamaha E8D Owner's Manual

Summary of E8D

Page 1

Owner’s manual e8d 677-28199-20-e0 u67720e0.Book page 1 friday, march 26, 2004 10:36 am.

Page 2

Read this owner’s manual carefully before operating your outboard motor. U67720e0.Book page 1 friday, march 26, 2004 10:36 am.

Page 3

Important manual information emu25100 to the owner thank you for choosing a yamaha outboard motor. This owner’s manual contains infor- mation needed for proper operation, mainte- nance and care. A thorough understanding of these simple instructions will help you obtain maximum enjoyment from your ne...

Page 4: Table Of Contents

Table of contents general information ...................... 1 identification numbers record ...... 1 outboard motor serial number ....... 1 ec label....................................... 1 safety information ....................... 1 important labels........................... 2 warning labels.......

Page 5: Table Of Contents

Table of contents lubrication (except oil injection models)...... 29 cleaning the outboard motor........ 29 checking painted surface of motor ........................ 29 periodic maintenance................ 29 replacement parts ....................... 29 maintenance chart........................ 30 ...

Page 6: General Information

General information 1 emu25170 identification numbers record emu25182 outboard motor serial number the outboard motor serial number is stamped on the label attached to the port side of the clamp bracket or the upper part of the swivel bracket. Record your outboard motor serial number in the spaces p...

Page 7: General Information

General information 2 ● do not modify the outboard. Modifications could make the motor unfit or unsafe to use. ● never operate after drinking alcohol or tak- ing drugs. About 50% of all boating fatalities involve intoxication. ● have an approved personal flotation device (pfd) on board for every occ...

Page 8: General Information

General information 3 emu25431 label warning ewm01300 ● this engine is equipped with a neutral starting device. ● the engine will not start unless the shift control is in neutral position. Emu25540 fueling instructions warning ewm00010 gasoline and its vapors are high- ly flammable and explosive! ● ...

Page 9: General Information

General information 4 note: select a propeller which will allow the engine to reach the middle or upper half of the oper- ating range at full throttle with the maximum boat load. If operating conditions such as light boat loads then allow the engine r/min to rise above the maximum recommended range,...

Page 10: Basic Components

Basic components 5 emu25795 main components note: * may not be exactly as shown; also may not be included as standard equipment on all models. Emu25802 fuel tank if your model was equipped with a portable fuel tank, its function is as follows. Warning ewm00020 the fuel tank supplied with this engine...

Page 11: Basic Components

Basic components 6 emu25830 fuel joint this joint is used to connect the fuel line. Emu25850 fuel tank cap this cap seals the fuel tank. When removed, the tank can be filled with fuel. To remove the cap, turn it counterclockwise. Emu25860 air vent screw this screw is on the fuel tank cap. To loosen ...

Page 12: Basic Components

Basic components 7 emu25970 throttle friction adjuster a friction device provides adjustable resis- tance to movement of the throttle grip or the remote control lever, and can be set accord- ing to operator preference. To increase resistance, turn the adjuster clockwise. To decrease resistance, turn...

Page 13: Basic Components

Basic components 8 emu26001 engine stop button to open the ignition circuit and stop the en- gine, push this button. Emu26011 choke knob for pull type to supply the engine with the rich fuel mixture required to start, pull out this knob. Emu26070 manual starter handle to start the engine, first gent...

Page 14: Basic Components

Basic components 9 emu30460 tilt lock mechanism the tilt lock mechanism is used to prevent the outboard motor from lifting out of the water when in reverse gear. To lock it, set the tilt lock lever in the “ ” (lock) position. To release, push the tilt lock le- ver in the “ ” (release) position. Emu2...

Page 15: Operation

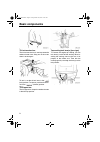

Operation 10 emu26901 installation caution: ecm00110 incorrect engine height or obstructions to smooth water flow (such as the design or condition of the boat, or accessories such as transom ladders or depth finder trans- ducers) can create airborne water spray while the boat is cruising. Severe eng...

Page 16: Operation

Operation 11 tends to occur, thus reducing the propulsion; and if the propeller tips cut the air, the engine speed will rise abnormally and cause the en- gine to overheat. If the mounting height is too low, the water resistance will increase and thereby reduce engine efficiency. Mount the outboard m...

Page 17: Operation

Operation 12 3. Secure the clamp bracket to the transom using the bolts provided with the out- board (if packed). For details, consult your yamaha dealer. Warning ewm00650 avoid using bolts, nuts or washers other than those contained in the engine pack- aging. If used, they must be of at least the s...

Page 18: Operation

Operation 13 emu27101 preoperation checks warning ewm00080 if any item in the preoperation check is not working properly, have it inspected and repaired before operating the outboard motor. Otherwise an accident could occur. Caution: ecm00120 do not start the engine out of water. Over- heating and s...

Page 19: Operation

Operation 14 2. Replace the fuel tank cap and close tight- ly. 3. Shake the fuel tank to mix the fuel thor- oughly. 4. Make sure that the oil and gasoline are mixed. If equipped with a built-in fuel tank 1. Pour oil into a clean fuel can, and then add gasoline. 2. Replace the fuel can cap and close ...

Page 20: Operation

Operation 15 drowsiness. Keep cockpit and cabin ar- eas well ventilated. Avoid blocking ex- haust outlets. 1. If there is an air vent screw on the fuel tank cap, loosen it 2 or 3 turns. 2. If there is a fuel joint on the motor, firmly connect the fuel line to the joint. Then firmly connect the other...

Page 21: Operation

Operation 16 2. Attach the engine stop switch lanyard to a secure place on your clothing, or your arm or leg. Then install the lock plate on the other end of the lanyard into the en- gine stop switch. Warning ewm00120 ● attach the engine stop switch lanyard to a secure place on your clothing, or you...

Page 22: Operation

Operation 17 6. After the engine starts, slowly return the manual starter handle to its original posi- tion before releasing it. 7. Slowly return the throttle grip to the fully closed position. Note: ● when the engine is cold, it needs to be warmed up. For further information, see page 17. ● if the ...

Page 23: Operation

Operation 18 emu27740 shifting warning ewm00180 before shifting, make sure there are no swimmers or obstacles in the water near you. Caution: ecm00220 to change the boat direction or shifting position from forward to reverse or vice- versa, first close the throttle so that the en- gine idles (or run...

Page 24: Operation

Operation 19 remote control models 1. Check that the tilt lock lever is in the lock position. 2. Pull up the neutral interlock trigger (if equipped) and move the remote control lever quickly and firmly from neutral to re- verse. Emu27820 stopping engine before stopping the engine, first let it cool ...

Page 25: Operation

Operation 20 warning ewm00740 excessive trim for the operating condi- tions (either trim up or trim down) can cause boat instability and can make steer- ing the boat more difficult. This increases the possibility of an accident. If the boat begins to feel unstable or is hard to steer, slow down and/...

Page 26: Operation

Operation 21 bow up, the boat may have a greater tenden- cy to steer to one side or the other. Compen- sate for this as you steer. The trim tab can also be adjusted to help offset this effect. When the bow of the boat is down, it is easier to accelerate from a standing start onto plane. Bow up too m...

Page 27: Operation

Operation 22 caution: ecm00230 ● before tilting the outboard motor, follow the procedure under “stopping en- gine”in this chapter. Never tilt the out- board motor while the engine is running. Severe damage from overheating can result. ● do not tilt up the engine by pushing the tiller handle because ...

Page 28: Operation

Operation 23 emu28031 procedure for tilting down (manual tilt models) 1. Slightly tilt the outboard motor up. 2. If the tilt support bar equipped: slowly tilt the outboard motor down while pulling the tilt support bar lever up. 3. If the tilt support knob equipped: pull out it, then slowly tilt the ...

Page 29: Operation

Operation 24 2. Place the tilt lock lever in the release po- sition. 3. Slightly tilt the outboard motor up. The tilt support bar will lock automatically, sup- porting the outboard motor in a partially raised position. Note: the outboard motor is equipped with 2 or 3 positions for shallow water crui...

Page 30: Operation

Operation 25 cruising in turbid water yamaha strongly recommends that you use the optional chromium-plated water pump kit if you use the outboard motor in turbid (mud- dy) water conditions. U67720e0.Book page 25 friday, march 26, 2004 10:36 am.

Page 31: Maintenance

Maintenance 26 emu28215 specifications dimension: overall length: 718 mm (28.3 in) overall width: 328 mm (12.9 in) overall height s: 1044 mm (41.1 in) overall height l: 1184 mm (46.6 in) transom height s: 442 mm (17.4 in) transom height l: 582 mm (22.9 in) weight (al) s: 28.0 kg (62 lb) weight (al) ...

Page 32: Maintenance

Maintenance 27 warning ewm00700 never get under the lower unit while it is tilted, even if a motor support bar is used. Severe injury could occur if the outboard motor accidentally falls. Caution: ecm00660 do not use the tilt support lever or knob when trailering the boat. The outboard mo- tor could...

Page 33: Maintenance

Maintenance 28 emu28301 procedure emu28332 flushing in a test tank caution: ecm00300 do not run the engine without supplying it with cooling water. Either the engine water pump will be damaged or the engine will be damaged from overheating. Before starting the engine, be sure to supply wa- ter to th...

Page 34: Maintenance

Maintenance 29 note: store the fuel tank in a dry, well-ventilated place, not in direct sunlight. Emu28400 lubrication (except oil injection models) 1. Grease the spark plug threads and install the spark plug(s) and torque to proper specification. For information on spark plug installation, see page...

Page 35: Maintenance

Maintenance 30 emu28521 maintenance chart frequency of maintenance operations may be adjusted according to the operating conditions, but the following table gives general guidelines. Refer to the sections in this chapter for expla- nations of each owner-specific action. The “ ” symbol indicates the ...

Page 36: Maintenance

Maintenance 31 emu28940 greasing yamaha grease a (water resistant grease) yamaha grease d (corrosion resistant grease; for propeller shaft) emu28951 cleaning and adjusting spark plug warning ewm00560 when removing or installing a spark plug, be careful not to damage the insulator. A damaged insulato...

Page 37: Maintenance

Maintenance 32 should periodically remove and inspect the spark plug because heat and deposits will cause the spark plug to slowly break down and erode. If electrode erosion becomes ex- cessive, or if carbon and other deposits are excessive, you should replace the spark plug with another of the corr...

Page 38: Maintenance

Maintenance 33 emu28980 inspecting fuel filter warning ewm00310 gasoline is highly flammable, and its va- pors are flammable and explosive. ● if you have any question about properly doing this procedure, consult your yamaha dealer. ● do not perform this procedure on a hot or running engine. Allow th...

Page 39: Maintenance

Maintenance 34 start position during warm-up. The boat could unexpectedly start to move, which could result in an accident. Caution: ecm00490 this procedure must be performed while the outboard motor is in the water. A flush- ing attachment or test tank can be used. A diagnostic tachometer should be...

Page 40: Maintenance

Maintenance 35 ● check each of the propeller blades for wear, erosion from cavitation or ventilation, or other damage. ● check the propeller shaft for damage. ● check the splines / shear pin for wear or damage. ● check for fish line tangled around the pro- peller shaft. ● check the propeller shaft o...

Page 41: Maintenance

Maintenance 36 6. Insert a new cotter pin in the holes, and then bend the cotter pin ends. Note: there is a holder on the bottom cowling for spare shear and cotter pins. Be sure to re- place any used pins. Emu29280 changing gear oil warning ewm00800 ● be sure the outboard motor is securely fastened ...

Page 42: Maintenance

Maintenance 37 6. When the oil begins to flow out of the oil level plug hole, insert and tighten the oil level plug. 7. Insert and tighten the gear oil drain screw. Emu29302 cleaning fuel tank warning ewm00920 gasoline is highly flammable, and its va- pors are flammable and explosive. ● if you have ...

Page 43: Maintenance

Maintenance 38 emu29390 checking top cowling check the fitting of the top cowling by pushing it with both hands. If it is loose have it repaired by your yamaha dealer. Emu29400 coating the boat bottom a clean hull improves boat performance. The boat bottom should be kept as clean of marine growth as...

Page 44: Trouble Recovery

Trouble recovery 39 emu29422 troubleshooting a problem in the fuel, compression, or ignition systems can cause poor starting, loss of pow- er, or other problems. This section describes basic checks and possible remedies, and cov- ers all yamaha outboard motors. Therefore some items may not apply to ...

Page 45: Trouble Recovery

Trouble recovery 40 a. Check for pinched or kinked fuel line or oth- er obstructions in fuel system. Q. Is fuel contaminated or stale? A. Fill tank with clean, fresh fuel. Q. Is fuel filter clogged? A. Clean or replace filter. Q. Have ignition parts failed? A. Have serviced by a yamaha dealer. Q. Ha...

Page 46: Trouble Recovery

Trouble recovery 41 q. Is load on boat improperly distributed? A. Distribute load to place boat on an even plane. Q. Is water pump or thermostat faulty? A. Have serviced by a yamaha dealer. Q. Is there excess water in fuel filter cup? A. Drain filter cup. Engine power loss. Q. Is propeller damaged? ...

Page 47: Trouble Recovery

Trouble recovery 42 a. Inspect spark plug and replace it with rec- ommended type. Q. Is high pressure fuel pump drive belt bro- ken? A. Have serviced by a yamaha dealer. Q. Is engine not responding properly to shift lever position? A. Have serviced by a yamaha dealer. Engine vibrates excessively. Q....

Page 48: Trouble Recovery

Trouble recovery 43 ● do not attach the lanyard to clothing that could tear loose. Do not route the cord where it could become entangled, preventing it from functioning. ● avoid accidentally pulling the lanyard during normal operation. Loss of engine power means the loss of most steering control. Al...

Page 49: Trouble Recovery

Trouble recovery 44 emu29760 treatment of submerged motor if the outboard motor is submerged, immedi- ately take it to a yamaha dealer. Otherwise some corrosion may begin almost immediate- ly. If you cannot immediately take the outboard motor to a yamaha dealer, follow the proce- dure below in order...

Page 50

Yamaha motor co., ltd. Printed on recycled paper printed in japan april 2004–0.1 × 1 cr u67720e0.Book page 1 friday, march 26, 2004 10:36 am.