- DL manuals

- Yamaha

- Outboard Motor

- EK40G

- Service Manual

Yamaha EK40G Service Manual

Summary of EK40G

Page 1

Ek40j service manual 6h9-28197-5g-11 ek40g a4cover6h9 04.7.6 9:31 page 1.

Page 2

Notice this manual has been prepared by yamaha primarily for use by yamaha dealers and their trained mechanics when performing maintenance procedures and repairs to yamaha equipment. It has been written to suit the needs of persons who have a basic understanding of the mechanical and electrical conc...

Page 3: Specifications

Specifications general information periodic checks and adjustments fuel system power unit bracket unit electrical systems troubleshooting index contents lower unit 9 8 7 6 2 1 gen info spec chk adj fuel powr lowr brkt elec trbl shtg 3 4 5 6h95g11_01 04.7.14 21:01 page 1.

Page 4

6h95g11_01 04.7.14 21:01 page 2.

Page 5: General Information

6h95g11 1- 9 8 7 6 5 4 3 2 1 general information how to use this manual ............................................................................... 1-1 manual format .......................................................................................... 1-1 symbols ..............................

Page 6

Gen info 1- 6h95g11 general information 1-1 how to use this manual manual format the format of this manual has been designed to make service procedures clear and easy to under- stand. Use the information below as a guide for effective and quality service. 1 parts are shown and detailed in an explode...

Page 7

6h95g11 9 8 7 6 5 4 3 2 1 1-2 gen info symbols the symbols below indicate the content of a chapter. General information fuel system bracket unit specifications power unit electrical systems periodic checks and adjustments lower unit troubleshooting symbols 1 to 6 indicate specific data. 1 special to...

Page 8

Gen info 1- 6h95g11 general information 1-3 safety while working to prevent an accident or injury and to ensure quality service, follow the safety procedures provided below. Fire prevention gasoline is highly flammable. Keep gasoline and all flammable products away from heat, sparks, and open flames...

Page 9

1-4 6h95g11 9 8 7 6 5 4 3 2 1 6. Keep a supply of clean, lint-free cloths for wiping up spills, etc. Good working practices special service tools use the recommended special service tools to protect parts from damage. Use the right tool in the right manner–do not improvise. Tightening torques follow...

Page 10

Gen info 1- 6h95g11 general information 1-5 identification applicable model this manual covers the following models. Serial number the outboard motor serial number is stamped on a label attached to the port clamp bracket. 1 model name 2 approved model code 3 transom height 4 serial number propeller ...

Page 11

1-6 6h95g11 9 8 7 6 5 4 3 2 1 selection when the engine speed is at the full throttle operating range (4,500–5,500 r/min), the ideal propeller for the boat is one that pro- vides maximum performance in relation to boat speed and fuel consumption. Ek40g ek40j predelivery checks to make the delivery p...

Page 12

Gen info 1- 6h95g11 general information 1-7 2. Check that the positive and negative bat- tery leads are securely connected. Checking the outboard motor mounting height 1. Check that the anti-cavitation plate is between the bottom of the boat and a maximum of 25 mm (1 in) a below it. If the mounting ...

Page 13

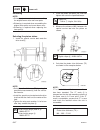

6h95g11 1-8 9 8 7 6 5 4 3 2 1 predelivery checks checking the steering system 1. Check the steering friction for proper adjustment. Note: 9 to increase the friction, turn the friction adjusting bolt in direction a. 9 to decrease the friction, turn the friction adjusting bolt in direction b. 2. Check...

Page 14

Gen info 1-9 6h95g11 general information checking the engine start switch, engine stop lanyard switch and engine stop button 1. Check that the engine starts when the engine start switch is turned to start. (remote control model) 2. Check that the engine turns off when the engine start switch is turn...

Page 15

6h95g11 1-10 9 8 7 6 5 4 3 2 1 break-in during the test run, perform the break-in operation in the following 5 stages. 1. 10 minutes a at the lowest possible speed. A fast idle in neutral is best. 2. 50 minutes b at 1/2 throttle (approxi- mately 3,000 r/min) or less. Vary engine speed occasionally. ...

Page 16: — Memo —

Gen info 1-11 6h95g11 — memo — 6h95g11_01 04.7.14 21:01 page 14.

Page 17: Specifications

6h95g11 9 8 7 6 5 4 3 2 1 spec specifications general specification ................................................................................... 2-1 maintenance specification .......................................................................... 2-3 power unit ...............................

Page 18

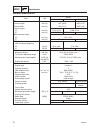

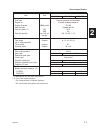

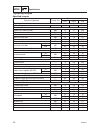

Item unit model ek40gmh ek40jmh ek40jw dimensions overall length mm (in) 997 (39.3) 692 (27.2) overall width mm (in) 484 (19.1) 363 (14.3) overall height (s) mm (in) 1,215 (47.8) 1,208 (47.6) (l) mm (in) 1,342 (52.8) 1,335 (52.6) – boat transom height (s) mm (in) 381 (15.0) (l) mm (in) 508 (20.2) – ...

Page 19

6h95g11 2-2 9 8 7 6 5 4 3 2 1 general specification item unit model ek40gmh ek40jmh ek40jw fuel and oil fuel type regular gasoline and kerosene engine oil 2-stroke outboard motor oil engine oil grade nmma-certified tc-w3 gear oil type hypoid gear oil gear oil grade (*1) api gl-4 sae 90 gear oil quan...

Page 20

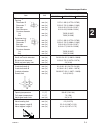

Spec 2-3 6h95g11 specifications maintenance specification power unit item unit model ek40gmh ek40jmh ek40jw power unit minimum compression kpa 400 (4.0, 58) pressure (*1) (kgf/cm 2 , psi) cylinder head warpage limit mm (in) 0.1 (0.0039) (lines indicate straightedge position) cylinders bore size mm (...

Page 21

Item unit model ek40gmh ek40jmh ek40jw piston rings top ring dimension b mm (in) 1.970–1.990 (0.0776–0.0783) dimension t mm (in) 2.500–2.700 (0.0984–0.1063) end gap mm (in) 0.30–0.50 (0.0118–0.0197) side clearance mm (in) 0.02–0.06 (0.0008–0.0024) oversize diameter 1st mm (in) 78.25 (3.0807) 2nd mm ...

Page 22

Electrical item unit model ek40gmh ek40jmh ek40jw ignition and ignition control system ignition timing (full retard) degree btdc 9 at engine idle speed ignition timing (full advanced) degree btdc 23 ignition spark gap mm (in) 0.6–0.7 (0.024–0.028) ignition coil resistance primary coil (o–b) Ω 0.26–0...

Page 23

6h95g11 2-6 9 8 7 6 5 4 3 2 1 maintenance specification item unit model ek40gmh ek40jmh ek40jw secondary coil (spark plug wire–spark plug wire) k Ω 6.8–10.2 at 20°c (68°f) cdi unit output peak voltage (o–b) at cranking (loaded) v 160 at 1,500 r/min (loaded) v 185 at 3,500 r/min (loaded) v 170 pulser...

Page 24

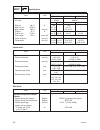

Spec 2-7 6h95g11 specifications 421 (16.6) 6h92001m 444 (17.5) 162 (6.4) ek40jw 175 (6.9) 127 (5.0) 45 (1.8) 30 (1.2)* 533 (20.1)* s: 622 (24.5) l: 691 (27.2) ek40jw s: 764 (30.1) ek40jw s: 421 (16.6) 94 (3.7) 695 (27.4) 294 (11.6)* 205 (8.07) 602 (23.7)* 360 (14.2) 427 (16.8) 188 (7.4) 504 (19.8) 7...

Page 25

6h95g11 2-8 9 8 7 6 5 4 3 2 1 maintenance specification 60 (2.36) 33 (1.30) 124.5 (4.9) 16.5 (0.65) 10.5 (0.41) 93.5 (3.68) 134.5 (5.3) 217.5 (8.56) 249 (9.80) 57 (2.24) 50 (1.97) 32 (1.26) 124.5 (4.9) 93.5 (3.68) 134.5 (5.3) 10.5 (0.41) 6f62002m clamp bracket mm (in) 6h95g11_02 04.8.19 9:35 page 9.

Page 26

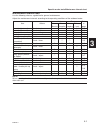

Spec 2-9 6h95g11 specifications tightening torques specified torques part to be tightened thread size tightening torques n·m kgf·m ft·lb fuel system main jet — 4 0.4 3.0 power unit power unit mounting bolt m8 21 2.1 15.5 flywheel nut m20 160 16 115 manual starter nut m6 10 1.0 7.2 manual starter bol...

Page 27

6h95g11 2-10 9 8 7 6 5 4 3 2 1 tightening torques general torques this chart specifies tightening torques for standard fasteners with a standard iso thread pitch. Tightening torque specifications for special components or assemblies are provided in applicable sections of this manu- al. To avoid warp...

Page 28: — Memo —

2-11 6h95g11 spec — memo — 6h95g11_02 04.8.19 9:35 page 12.

Page 29

6h95g11 9 8 7 6 5 4 3 2 1 3 1 periodic checks and adjustments special service tools ................................................................................... 3-1 maintenance interval chart .......................................................................... 3-2 top cowling .............

Page 30

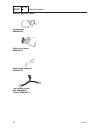

Chk adj 6h95g11 3-1 special service tools periodic checks and adjustments chk adj digital tachometer 90890-06760 leakage tester 90890-06840 6h95g11_03 04.8.6 8:35 page 2.

Page 31

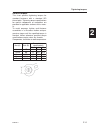

6h95g11 9 8 7 6 5 4 3 2 1 3-2 3 1 maintenance interval chart use the following chart as a guideline for general maintenance. Adjust the maintenance intervals according to the operating conditions of the outboard motor. Special service tools/maintenance interval chart initial every refer item actions...

Page 32

Chk adj 3-3 6h95g11 periodic checks and adjustments top cowling checking the top cowling 1. Check the fitting by pushing the cowling with both hands. Fuel system checking the fuel joint and fuel hoses (fuel joint-to-carburetor) 1. Check the fuel hose connections and fuel joint 1 for leaks. Replace i...

Page 33

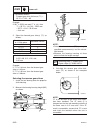

6h95g11 3-4 9 8 7 6 5 4 3 2 1 checking the thermostat 1. Remove the thermostat cover 1, gasket 2, and thermostat 3. 2. Suspend the thermostat in a container of water. 3. Place a thermometer in the water and slowly heat the water. 4. Check the thermostat valve opening at the specified water temperatu...

Page 34

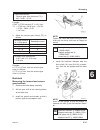

Chk adj 3-5 6h95g11 periodic checks and adjustments control system adjusting the start-in-gear protec- tion 1. Set the gear shift to the neutral position. 2. Loosen the lock nut 1, and then adjust the start-in-gear protection adjusting nut 2 until the top of the plunger a aligns with the centre of t...

Page 35

4. Adjust the position of the cable end 5 until it is aligned with the hole on the pul- ley. W the shift/throttle cable end must be screwed in a minimum of 8.0 mm (0.31in) b. 5. Install the cable joint 3 and tighten the adjusting nut. 6. Check the throttle cable for smooth oper- ation. Note: if the ...

Page 36

Checking the gear shift operation (w) 1. Check that the gear shift operates smoothly when shifting it from neutral to forward or reverse. Adjust the shift cable length if necessary. 2. Set the gear shift to the neutral position. 3. Remove the cable joint 1, and then dis- connect the shift cable 2. 4...

Page 37

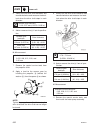

Changing the gear oil 1. Fully tilt the outboard motor down. 2. Place a drain pan under the drain screw 1, remove the drain screw, then the check screw 2 and let the oil drain com- pletely. 3. Check the oil for metal and discoloration, and its viscosity. Check the internal parts of the lower case if...

Page 38

Checking the lower unit for air leak- age c c do not over pressurize the lower unit, oth- erwise the oil seals may be damaged. 1. Remove the check screw 1, and then install the special service tool. 2. Apply the specified pressure to check that the pressure is maintained in the lower unit for at lea...

Page 39

6h95g11 3-10 9 8 7 6 5 4 3 2 1 w battery electrolyte is dangerous; it con- tains sulfuric acid which is poisonous and highly caustic. 9 avoid bodily contact with electrolyte as it can cause severe burns or permanent eye injury. 9 wear protective eye gear when handling or working near batteries. Anti...

Page 40

Chk adj 3-11 6h95g11 periodic checks and adjustments 2. Apply low temperature resistant grease to the area shown. 3. Apply corrosion resistant grease to the area shown. 6f630300 6b430300 6h95g11_03 04.8.6 8:35 page 12.

Page 41: Fuel System

6h95g11 9 8 7 6 5 4 3 2 1 fuel system special service tools ................................................................................... 4-1 hose routing ................................................................................................. 4-2 fuel line ..............................

Page 42

Fuel 4-1 6h95g11 fuel system special service tools vacuum/pressure pump gauge set 90890-06756 digital caliper 90890-06704 6h95g11_04 04.8.6 8:36 page 2.

Page 43

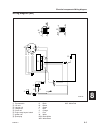

6h95g11 4-2 9 8 7 6 5 4 3 2 1 special service tools/hose routing hose routing 1 fuel hose (fuel joint-to-fuel filter: for gasoline) 2 fuel hose (fuel joint-to-fuel filter: for kerosene) 3 fuel hose (fuel filter-to-fuel pump: for gasoline) 4 fuel hose (fuel filter-to-fuel pump: for kerosene) 5 fuel h...

Page 44

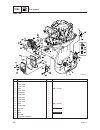

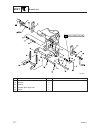

Fuel 4-3 6h95g11 fuel system fuel line 6h94020e no. Part name q’ty remarks 1 clip 12 2 fuel hose 1 3 fuel hose 1 4 bolt 1 m6 × 25 mm 5 fuel joint 1 6 grommet 1 7 fuel hose 1 8 fuel hose 1 9 fuel hose 1 10 fuel hose 1 11 bolt 2 m6 × 55 mm 12 fuel pump 1 13 gasket 1 14 nut 2 15 bolt 1 16 bracket 1 17 ...

Page 45

6h95g11 4-4 9 8 7 6 5 4 3 2 1 fuel line 6h94020e no. Part name q’ty remarks 18 fuel filter element 2 19 o-ring 2 20 cup 2 21 screw 3 ø6 × 30 mm 22 intake silencer 1 23 o-ring 1 24 screw 4 ø6 × 12 mm 25 link lever 1 26 pin 1 27 choke rod 1 28 collar 1 29 link rod 1 30 nut 4 31 washer 4 32 gasket 1 33...

Page 46

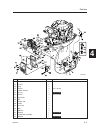

Fuel 4-5 6h95g11 fuel system carburetor 4 n·m (0.4 kgf·m, 3.0 ft·lb) 6h94040e no. Part name q’ty remarks 1 damper 1 2 hose 2 3 screw 4 ø4 × 14 mm 4 cover 1 5 gasket 1 6 throttle stop screw 1 7 spring 1 8 pilot screw 2 9 spring 2 10 o-ring 2 11 screw 1 ø4 × 5 mm 12 gasket 1 13 washer 1 14 joint 1 15 ...

Page 47

6h95g11 4-6 9 8 7 6 5 4 3 2 1 carburetor 4 n·m (0.4 kgf·m, 3.0 ft·lb) 6h94040e no. Part name q’ty remarks 18 lever 1 19 pump lever assembly 1 20 cam 1 21 screw 1 ø4 × 5 mm 22 gasket 1 23 drain screw 1 24 gasket 1 25 screw 4 ø5 × 16 mm 26 main jet 2 27 gasket 2 28 main nozzle 2 29 carburetor body 1 3...

Page 48

Fuel 4-7 6h95g11 fuel system 4 n·m (0.4 kgf·m, 3.0 ft·lb) 6h94040e no. Part name q’ty remarks 35 gasket 1 36 float chamber 1 37 nozzle 1 38 gasket 1 39 o-ring 1 40 o-ring 1 41 stopper 1 42 plunger 1 43 drain screw 1 44 gasket 1 45 drain screw 1 46 gasket 1 47 check valve 1 48 starter jet 1 49 gasket...

Page 49

6h95g11 4-8 9 8 7 6 5 4 3 2 1 carburetor 4 n·m (0.4 kgf·m, 3.0 ft·lb) 6h94040e no. Part name q’ty remarks 52 float arm 1 53 needle valve 1 54 screw 1 ø4 × 5 mm 55 valve seat 1 56 gasket 1 57 ball seat 1 58 ball 1 59 spring 1 60 gasket 1 61 carburetor body 1 62 screw 8 ø5 × 16 mm 63 screw 2 ø6 × 19 m...

Page 50

Fuel 4-9 6h95g11 fuel system 5. Check the float for deterioration. Replace if necessary. 6. Measure the float height a for the kerosene and b for the gasoline. Replace the float and needle valve as a set, if out of specification. Note: 9 the float should be resting on the needle valve 1, but not com...

Page 51

6h95g11 4-10 9 8 7 6 5 4 3 2 1 carburetor assembling the carburetor 1. Install the starter jet 1 and check valve 2, then install the plunger 3 onto the float chamber of the gasoline side. 2. Install the starter plunger 4, new gasket 5, spring 6, ball 7, ball seat 8, new gasket 9 and valve seat 0 ont...

Page 52

Fuel 4-11 6h95g11 fuel system adjusting the throttle stop screw 1. Start the engine and warm it up for 5 min- utes. 2. Turn the throttle stop screw 1 in direc- tion a or b until the specified engine idle speed is obtained. Note: 9 to increase the idle speed, turn the throttle stop screw in direction...

Page 53

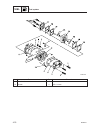

6h95g11 4-12 9 8 7 6 5 4 3 2 1 carburetor/fuel pump fuel pump 6h94030e no. Part name q’ty remarks 1 screw 3 ø5 × 30 mm 2 cover 1 3 diaphragm 1 4 gasket 1 5 fuel pump body 1 6 diaphragm 1 7 spring 1 8 spring plate 1 9 gasket 1 10 check valve 2 11 cover 1 12 gasket 1 13 diaphragm 1 14 pump body 1 15 g...

Page 54

Fuel 4-13 6h95g11 fuel system 6h94030e no. Part name q’ty remarks 18 check valve 2 19 screw 4 ø5 × 24 mm 6h95g11_04 04.8.6 8:36 page 14.

Page 55

6h95g11 4-14 9 8 7 6 5 4 3 2 1 fuel pump checking the fuel pump 1. Place a drain pan under the fuel hose connections, and then disconnect the fuel hoses from the fuel pump. 2. Connect the special service tool to the fuel pump inlet a or b. 3. Cover the fuel pump outlet c or d with a finger, and then...

Page 56

Fuel 4-15 6h95g11 fuel system note: make sure that the gaskets and diaphragms are kept in place through the assembly process. Checking the fuel joint 1. Visually check the fuel joint for cracks or damage. 2. Connect the special service tool at the outlet of fuel joint. 3. Apply the specified pressur...

Page 57: Power Unit

6h95g11 9 8 7 6 5 4 3 2 1 power unit special service tools ................................................................................... 5-1 power unit ..................................................................................................... 5-4 checking the compression pressure .....

Page 58

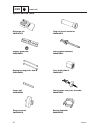

Powr 5-1 6h95g11 power unit special service tools compression gauge 90890-03160 flywheel holder 90890-06522 flywheel puller 90890-06521 crankshaft aligner 90890-03107 driver rod ls 90890-06606 bearing separator 90890-06534 crank jig set 90890-02422 flange 90890-02351 driver rod l3 90890-06652 needle...

Page 59

6h95g11 9 8 7 6 5 4 3 2 1 5-2 special service tools body 90890-02352 bolt 90890-02353 washer 90890-02354 bushing-9 (d30) 90890-02363 b-9 bushing-12 (d35) 90890-02366 b-12 pressure plate 90890-02384 press body 90890-02385 pressure pin b 90890-02390 b bearing pressure c 90890-02393 c support 90890-023...

Page 60

Powr 5-3 6h95g11 power unit height ring (h-18) 90890-02401 h-18 plate c 90890-02402 pressure pin c 90890-02403 spacer c 90890-02404 c small end bearing installer 90890-06527 cylinder gauge 90890-06759 6h95g11_05 04.8.6 11:00 page 4.

Page 61

6h95g11 5-4 9 8 7 6 5 4 3 2 1 special service tools/power unit power unit checking the compression pressure 1. Start the engine, warm it up for 5 min- utes, and then turn it off. 2. Remove the clip from the engine stop lanyard switch. 3. Remove the spark plug caps and all spark plugs, and then insta...

Page 62

Powr 5-5 6h95g11 power unit 6h95010e 21 n·m (2.1 kgf·m, 15.5 ft·lb) w mh no. Part name q’ty remarks 1 power unit 1 2 manual starter assembly 1 3 collar 3 4 grommet 6 5 bolt 3 m8 × 35 mm 6 gasket 1 7 bolt 2 m6 × 12 mm 8 dowel pin 2 9 bolt 2 m6 × 25 mm 10 bolt 8 m8 × 40 mm 11 apron 1 12 spiral tube 1 ...

Page 63

6h95g11 5-6 9 8 7 6 5 4 3 2 1 power unit 6h95030e 160 n·m (16 kgf·m, 115 ft·lb) mh no. Part name q’ty remarks 1 flywheel magnet 1 2 base assembly 1 3 bolt 3 m6 × 40 mm 4 oil seal 1 5 o-ring 1 6 woodruff key 1 7 bolt 3 m8 × 14 mm 8 starter pulley 1 9 nut 1 10 washer 1 11 pulser coil 2 12 screw 4 ø5 ×...

Page 64

Powr 5-7 6h95g11 power unit 6f65050e 29 n·m (2.9 kgf·m, 21 ft·lb) mh no. Part name q’ty remarks 1 electric starter unit and 1 w model cdi unit assembly 2 cdi unit assembly 1 3 bolt 3 m8 × 48 mm 4 bolt 3 m6 × 30 mm 5 bolt 2 m8 × 25 mm 6 bolt 1 m6 × 16 mm 7 ignition coil 1 8 bolt 2 m6 × 25 mm 9 clamp ...

Page 65

6h95g11 5-8 9 8 7 6 5 4 3 2 1 power unit 6f65040e 4 n·m (0.4 kgf·m, 3.0 ft·lb) 29 n·m (2.9 kgf·m, 21 ft·lb) no. Part name q’ty remarks 1 starter motor 1 2 starter relay 1 3 bracket 1 4 bolt 2 m6 × 12 mm 5 spiral tube 1 6 cap 3 7 nut 3 8 spring washer 3 9 starter motor lead 1 10 battery negative lead...

Page 66

Powr 5-9 6h95g11 power unit 6f65040e 4 n·m (0.4 kgf·m, 3.0 ft·lb) 29 n·m (2.9 kgf·m, 21 ft·lb) no. Part name q’ty remarks 18 rectifier 1 19 screw 1 ø6 × 25 mm 20 bolt 1 m6 × 16 mm 21 battery positive lead 1 22 cap 1 all components are for w model only. 6h95g11_05 04.8.6 11:01 page 10

Page 67

6h95g11 5-10 9 8 7 6 5 4 3 2 1 power unit 6f65060e no. Part name q’ty remarks 1 bolt 1 m6 × 30 mm 2 collar 1 3 throttle control lever 1 4 throttle pulley 1 5 throttle cable 2 6 bracket 1 7 bolt 1 m6 × 15 mm 8 link rod 1 9 joint 2 6h95g11_05 04.8.6 11:01 page 11.

Page 68

Powr 5-11 6h95g11 power unit 6f65020e 10 n·m (1.0 kgf·m, 7.2 ft·lb) 15 n·m (1.5 kgf·m, 11.1 ft·lb) no. Part name q’ty remarks 1 manual starter case 1 2 spiral spring 1 3 washer 1 4 sheave drum 1 5 spring 1 6 drive pawl 1 7 spring 1 8 washer 1 9 drive plate 1 10 washer 1 11 bolt 1 m8 × 30 mm 12 colla...

Page 69

6h95g11 5-12 9 8 7 6 5 4 3 2 1 power unit 6f65020e 10 n·m (1.0 kgf·m, 7.2 ft·lb) 15 n·m (1.5 kgf·m, 11.1 ft·lb) no. Part name q’ty remarks 18 washer 2 19 cover 1 20 manual starter handle 1 21 damper 1 22 starter rope guide 1 23 starter rope 1 24 start-in-gear protection cable 1 25 plunger 1 26 sprin...

Page 70

Powr 5-13 6h95g11 power unit disassembling the manual starter 1. Turn the sheave drum 1 clockwise until the spiral spring is free. Note: 9 turn the sheave drum so that the notch on the outer surface of the sheave drum faces toward the manual starter handle. 9 pass the starter rope 2 through the notc...

Page 71

6h95g11 5-14 9 8 7 6 5 4 3 2 1 power unit assembling the manual starter 1. Install the starter rope 1 into the sheave drum 2. 2. Install the drive pawl and springs. 3. Install the manual starter handle 3. Note: 9 tie a knot at the end of the starter rope as shown in the illustration. 9 be sure to le...

Page 72

Powr 5-15 6h95g11 power unit 8. Turn the sheave drum 3 times in the direction of the arrow shown, and then remove the starter rope from the notch e. Note: pull the start-in-gear protection cable 0 while turning the sheave drum as shown. 9. Pull the manual starter handle several times to check that t...

Page 73

6h95g11 5-16 9 8 7 6 5 4 3 2 1 power unit 4. Disconnect the remote control cables (remote control model) or throttle cables (tiller handle model). 5. Disconnect the battery leads and ground leads 5. (w) 6. Disconnect the shift link rod 6. 7. Disconnect the engine stop lanyard switch leads 7 (mh), cd...

Page 74

Powr 5-17 6h95g11 power unit 2. Remove the flywheel magnet. C c to prevent damage to the engine or tools, screw in the flywheel puller set bolts evenly and completely so that the fly- wheel puller plate is parallel to the flywheel mag- net. Note: apply force to the crankshaft end until the fly- whee...

Page 75

6h95g11 5-18 9 8 7 6 5 4 3 2 1 disassembling the base assembly 1. Remove the o-ring and oil seal. Assembling the base assembly 1. Apply grease to a new oil seal, then install it into the base assembly. 2. Install a new o-ring 3. Power unit 6f650240 6f650250 1 2 3 needle bearing attachment 1: 90890-0...

Page 76

Powr 5-19 6h95g11 power unit 6h95070e no. Part name q’ty remarks 1 intake manifold #1 1 2 reed valve assembly #1 1 3 gasket 1 4 intake manifold #2 1 5 reed valve assembly #2 1 6 gasket 1 7 gasket 1 8 gasket 1 9 bolt 2 m6 × 65 mm 10 screw 4 ø5 × 12 mm 11 clip 10 12 hose 5 13 bolt 7 m6 × 25 mm 14 arm ...

Page 77

6h95g11 5-20 9 8 7 6 5 4 3 2 1 reed valves 6h95070e no. Part name q’ty remarks 18 bolt 1 m6 × 30 mm 19 bolt 1 m6 × 15 mm 6h95g11_05 04.8.20 11:05 page 21.

Page 78

2. Measure the valve stopper height b and c. Replace if out of specification. Powr 5-21 6h95g11 power unit removing the reed valve assembly 1. Remove the hoses 1. 2. Remove the intake manifold bolts 2, and then remove the intake manifold cover, gasket and reed valve assembly #1 3. 3. Remove the stay...

Page 79

6h95g11 5-22 9 8 7 6 5 4 3 2 1 cylinder head 6h95080e 15 n·m (1.5 kgf·m, 11 ft·lb) 30 n·m (3.0 kgf·m, 22 ft·lb) 12 n·m (1.2 kgf·m, 8.7 ft·lb) 25 n·m (2.5 kgf·m, 18 ft·lb) 8 n·m (0.8 kgf·m, 5.8 ft·lb) cylinder head no. Part name q’ty remarks 1 gasket 1 2 cylinder head 1 3 thermoswitch 1 4 bolt 1 m6 ×...

Page 80

Powr 5-23 6h95g11 power unit 6h95080e 15 n·m (1.5 kgf·m, 11 ft·lb) 30 n·m (3.0 kgf·m, 22 ft·lb) 12 n·m (1.2 kgf·m, 8.7 ft·lb) 25 n·m (2.5 kgf·m, 18 ft·lb) 8 n·m (0.8 kgf·m, 5.8 ft·lb) no. Part name q’ty remarks 18 anode 1 19 bolt 16 m6 × 25 mm 20 exhaust outer cover 1 21 gasket 1 22 exhaust inner co...

Page 81

6h95g11 5-24 9 8 7 6 5 4 3 2 1 cylinder head removing the cylinder head 1. Remove the spark plugs, thermostat cover, thermostat and thermoswitch. 2. Remove the cylinder head cover bolts 1. 3. Remove the cylinder head bolts in the sequence shown. C c do not scratch or damage the mating sur- faces of ...

Page 82

Powr 5-25 6h95g11 power unit 6f65090e 20 n·m (2.0 kgf·m, 15 ft·lb) 40 n·m (4.0 kgf·m, 29.5 ft·lb) no. Part name q’ty remarks 1 crankshaft assembly 1 2 cylinder block 1 3 anode 1 4 bolt 1 m6 × 16 mm 5 oil seal 2 6 oil seal 1 7 o-ring 1 8 o-ring 1 9 oil seal housing 1 10 circlip 1 11 crankcase 1 12 bo...

Page 83

6h95g11 5-26 9 8 7 6 5 4 3 2 1 crankcase 6f65100e no. Part name q’ty remarks 1 crank 3 1 2 washer 4 3 roller bearing 2 4 connecting rod 2 5 needle bearing 56 6 circlip 4 7 piston 2 8 piston pin 2 9 piston ring set 2 10 crank pin 2 11 crank 4 1 12 ball bearing 1 13 labyrinth seal 1 14 roller bearing ...

Page 84

Removing the crankcase 1. Remove the crankcase bolts in the sequence shown. Note: insert a flat-head screw driver between the pry tabs to pry off the crankcase. Removing the crankshaft assembly and oil seal housing 1. Remove the crankshaft assembly and oil seal housing. Checking the cylinder bore 1....

Page 85

6h95g11 5-28 9 8 7 6 5 4 3 2 1 crankcase 2. Apply grease to new oil seals, then install them into the oil seal housing. 3. Install the circlip 5, apply grease to new o-rings 6, and then install them. Disassembling the piston 1. Remove the clips with pliers, and then remove the piston pin. 2. Separat...

Page 86

Powr 5-29 6h95g11 power unit checking the piston diameter 1. Measure the piston outside diameter at the specified measuring point. Replace if out of specification. Checking the piston clearance 1. Calculate the piston clearance using the piston outside diameter and the cylinder bore specifications. ...

Page 87

6h95g11 5-30 9 8 7 6 5 4 3 2 1 crankcase checking the piston ring side clear- ance 1. Measure the piston ring side clearance. Replace the piston and piston rings as a set if out of specification. Checking the piston pin boss bore 1. Measure the piston pin boss bore. Replace the piston if out of spec...

Page 88

4. Remove the washers, roller bearing and connecting rod. 5. Insert the support 6 between crank 2 and 3 7 with crank 3 on top. Place pres- sure pin b 8 on the shaft, and force it out using a press. 6. Remove the roller bearing 9 from the inner race 0. 7. Remove the crankpin between cranks 2 and 3 by...

Page 89

6h95g11 5-32 9 8 7 6 5 4 3 2 1 crankcase 8. Using the bearing separator to slightly move the inner race off the shaft, and then remove the inner race. Note: use care not to scratch the shaft. Checking the crankpin 1. Measure the crankpin diameter. Replace if out of specification. Assembling the cran...

Page 90

Powr 5-33 6h95g11 power unit 3. Insert the bushing 3 into the body 4. 4. Place the height ring 6 in the body. Note: align the slot in the height ring with the slot in the body. 5. Set the spacer on the crank 2 (or crank 4). 6. Set crank 2 (or crank 4) on the special service tool. 7. Mount the washer...

Page 91

6h95g11 5-34 9 8 7 6 5 4 3 2 1 crankcase 8. Install the bushing 7 on the pressure plate 8. Note: when installing crank 3 to the pressure plate, do not use the bushing 7. 9. Install crank 1 (or crank 3) to the pres- sure plate. 10. Align the crankpin hole in crank 1 (or crank 3) with the crankpin fit...

Page 92

Powr 5-35 6h95g11 power unit note: if any of the measurements are out of speci- fication, reassemble the crankshaft. 13. Install the inner race 0 onto crank 2 by using a press and the bushing 3. Carefully press the inner race onto the shaft. 14. Install the roller bearing e onto crank 2. Note: make ...

Page 93

6h95g11 5-36 9 8 7 6 5 4 3 2 1 crankcase checking the crankshaft 1. Measure the crankshaft widths a and b. Repair or disassemble the crankshaft if out of specification. 2. Measure the connecting rod small end axial play. Replace the bearing and con- necting rod if above specification. 3. Measure the...

Page 94

Powr 5-37 6h95g11 power unit assembling the piston 1. Install the 2nd piston ring 1 and top ring 2 onto the pistons. Note: install the piston rings with the recess for the locating pin facing up toward the piston crown. 2. Install the needle bearings 3, washers 4, piston pin 5, and new clips 6. Note...

Page 95

6h95g11 5-38 9 8 7 6 5 4 3 2 1 crankcase 3. Apply sealant to the mating surface of the crankcase. Note: do not get any sealant on the crankshaft jour- nals. 4. Install the crankcase onto the cylinder block, and then tighten the crankcase bolts to the specified torques in two stages and in the sequen...

Page 96

Powr 5-39 6h95g11 power unit note: apply loctite 572 to the cylinder head bolts and the cylinder head cover bolts before installation. 8. Install the thermostat, a new gasket and thermostat cover. 9. Install the spark plugs, tighten them fin- ger tight, then to the specified torque with a spark plug...

Page 97

6h95g11 5-40 9 8 7 6 5 4 3 2 1 crankcase 7. Tighten the flywheel magnet nut to the specified torque. C c apply force in the direction of the arrows shown, to prevent the flywheel holder from slipping off easily. Note: apply engine oil to the flywheel magnet nut before installation. 8. Install the st...

Page 98: Lower Unit

Lowr 6h95g11 lowr lower unit special service tools ................................................................................... 6-1 lower unit (ek40g) ...................................................................................... 6-5 removing the lower unit ..............................

Page 99

6h95g11 9 8 7 6 5 4 3 2 1 propeller shaft housing ............................................................................. 6-33 removing the propeller shaft housing assembly .................................. 6-34 disassembling the propeller shaft assembly .........................................

Page 100

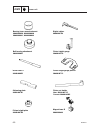

Lowr 6-1 6h95g11 lower unit special service tools dial gauge set 90890-01252 stopper guide plate 90890-06501 bearing puller assembly 90890-06535 drive shaft holder 3 90890-06517 bearing outer race puller assembly 90890-06523 bearing separator 90890-06534 ring nut wrench extension 90890-06513 bearing...

Page 101

6h95g11 6-2 9 8 7 6 5 4 3 2 1 special service tools driver rod ls 90890-06606 needle bearing attachment 90890-06608, 90890-06613, 90890-06616, 90890-06653 needle bearing attachment 90890-06614 bearing outer race attachment 90890-06622 ball bearing attachment 90890-06634, 90890-06637 stopper guide st...

Page 102

Lowr 6-3 6h95g11 lower unit digital caliper 90890-06704 pinion height gauge 90890-06710 pinion height gauge plate b 90890-06712 pinion nut holder new: 90890-06715 current: 90890-06505 magnet base b 90890-06844 bearing inner race attachment 90890-06639, 90890-06640 90890-06641, 90890-06644 ball beari...

Page 103

6h95g11 6-4 9 8 7 6 5 4 3 2 1 special service tools backlash indicator 90890-06706 6h95g11_06 04.8.6 9:32 page 7.

Page 104

Lowr 6-5 6h95g11 lower unit lower unit (ek40g) 6h96050e 21 n·m (2.1 kgf·m, 15.5 ft·lb) 9 n·m (0.9 kgf·m, 6.6 ft·lb) no. Part name q’ty remarks 1 lower unit 1 2 check screw 1 3 gasket 3 4 drain screw 1 5 screw 1 6 dowel 2 7 bolt 3 m6 × 16 mm 8 special washer 3 9 anode 1 10 anode 1 11 propeller 1 12 s...

Page 105

6h95g11 6-6 9 8 7 6 5 4 3 2 1 lower unit (ek40g) 6h96050e 21 n·m (2.1 kgf·m, 15.5 ft·lb) 9 n·m (0.9 kgf·m, 6.6 ft·lb) no. Part name q’ty remarks 18 cover 1 19 screen 1 20 cap 1 21 screw 1 6h95g11_06 04.8.6 9:32 page 9.

Page 106

Lowr 6-7 6h95g11 lower unit 6f66060e 17 no. Part name q’ty remarks 1 shift rod 1 2 holder 1 3 bolt 1 m6 × 10 mm 4 boot 1 5 water pump housing 1 6 bolt 2 m8 × 55 mm 7 woodruff key 1 8 insert cartridge 1 9 impeller 1 10 seal 1 11 gasket 1 12 outer plate cartridge 1 13 gasket 1 14 oil seal housing 1 15...

Page 107

6h95g11 6-8 9 8 7 6 5 4 3 2 1 lower unit (ek40g) 6f66060e 17 no. Part name q’ty remarks 18 bolt 2 m8 × 45 mm 19 screw 1 20 gasket 1 not reusable 6h95g11_06 04.8.6 9:32 page 11.

Page 108

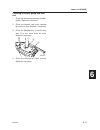

Lowr 6-9 6h95g11 lower unit removing the lower unit 1. Drain the gear oil. 2. Shift the shift lever or remote control lever to neutral, place a block of wood between the anti-cavitation plate and pro- peller to keep the propeller from turning, and then remove the propeller nut and propeller. W 9 do ...

Page 109

6h95g11 6-10 9 8 7 6 5 4 3 2 1 lower unit (ek40g) checking the water pump and shift rod 1. Check the water pump housing for defor- mation. Replace if necessary. 2. Check the impeller and insert cartridge for cracks or wear. Replace if necessary. 3. Check the woodruff key 1 and the key- way a in the ...

Page 110

Lowr 6-11 6h95g11 lower unit propeller shaft housing 6f66070e 4 n·m (0.4 kgf·m, 3.0 ft·lb) 8 n·m (0.8 kgf·m, 5.8 ft·lb) no. Part name q’ty remarks 1 lower case cap 1 2 bolt 9 m6 × 25 mm 3 seal 1 4 taper roller bearing assembly 1 5 forward gear shim — 6 forward gear 1 7 shift plunger 1 8 dog clutch 1...

Page 111

6h95g11 6-12 9 8 7 6 5 4 3 2 1 propeller shaft housing 6f66070e 4 n·m (0.4 kgf·m, 3.0 ft·lb) 8 n·m (0.8 kgf·m, 5.8 ft·lb) no. Part name q’ty remarks 18 oil seal 2 19 propeller shaft housing 1 20 o-ring 1 21 dowel 1 not reusable not reusable 6h95g11_06 04.8.6 9:32 page 15.

Page 112

Lowr 6-13 6h95g11 lower unit removing the propeller shaft hous- ing assembly 1. Remove the bolts, then separate the lower case cap. Note: loosen the bolts in sequence as shown. 2. Remove the propeller shaft housing assembly. Disassembling the propeller shaft assembly 1. Remove the spring 1, then the...

Page 113

6h95g11 6-14 9 8 7 6 5 4 3 2 1 propeller shaft housing disassembling the forward gear 1. Remove the taper roller bearing and shim(s) from the forward gear. Checking the propeller shaft housing 1. Clean the propeller shaft housing using a soft brush and cleaning solvent, and then check it for cracks....

Page 114

Lowr 6-15 6h95g11 lower unit assembling the propeller shaft housing 1. Apply grease to new oil seals, and then install them into the propeller shaft hous- ing to the specified depth. Note: install an oil seal halfway into the propeller shaft housing, then the other oil seal. 2. Install the new ball ...

Page 115

6h95g11 6-16 9 8 7 6 5 4 3 2 1 drive shaft and lower case drive shaft and lower case 6f66080e no. Part name q’ty remarks 1 drive shaft 1 2 circlip 1 3 pinion gear 1 4 roller bearing assembly 1 5 pinion gear shim — 6 thrust bearing 1 7 needle bearing 1 8 sleeve 1 9 needle bearing 1 10 washer 1 11 oil...

Page 116

Lowr 6-17 6h95g11 lower unit removing the drive shaft 1. Remove the circlip 1 from the pinion gear, and then remove the pinion gear and drive shaft assembly. C c when removing the drive shaft assembly, take care to falling the drive shaft assem- bly. Disassembling the lower case 1. Remove the roller...

Page 117

6h95g11 6-18 9 8 7 6 5 4 3 2 1 drive shaft and lower case checking the lower case and lower case cap 1. Check the skeg and torpedo for cracks or damage. Replace the lower case and lower case cap if necessary. Assembling the lower case 1. Install the drive shaft needle bearing into the lower case to ...

Page 118

Lowr 6-19 6h95g11 lower unit 4. Install the thrust bearing and roller bear- ing assembly. Note: apply gear oil to the inside and outside of the thrust washer and roller bearing outer race before installation. Installing the drive shaft 1. Install the roller bearing, then the drive shaft, original sh...

Page 119

6h95g11 6-20 9 8 7 6 5 4 3 2 1 drive shaft and lower case 5. Apply sealant to the mating surface of the lower case cap and propeller shaft cap. 6. Install the propeller shaft housing assem- bly 4 on to the lower case. Note: insert the pins a in the slot or hole of the lower case. 7. Tighten the bolt...

Page 120

Note: when installing the pump housing, apply grease to the inside of the housing, and then turn the drive shaft clockwise while pushing down the pump housing. Installing the lower unit 1. Set the gear shift to the reverse position at the lower unit. Make sure that the shift rod is in the reverse po...

Page 121

6h95g11 6-22 9 8 7 6 5 4 3 2 1 drive shaft and lower case 6. Install the propeller, shear pin and pro- peller nut, and then tighten the nut finger tight. Place a block of wood between the anti-cavitation plate and propeller to keep the propeller from turning, and then tight- en the nut to the specif...

Page 122

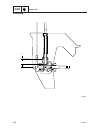

Lowr 6-23 6h95g11 lower unit shimming m t 6f660860 6h95g11_06 04.8.6 9:32 page 26.

Page 123

6h95g11 6-24 9 8 7 6 5 4 3 2 1 shimming shimming note: 9 shimming is not required when assembling the original lower case and inner parts. 9 shimming is required when assembling the original inner parts and a new lower case. 9 shimming is required when replacing the inner part(s). Selecting the pini...

Page 124

Lowr 6-25 6h95g11 lower unit backlash measuring the forward and reverse gear backlash 1. Remove the water pump assembly. 2. Set the lower unit upside down. 3. Remove the lower case cap, propeller shaft assembly from the lower unit. 4. Remove the o-ring, and then install the propeller shaft assembly ...

Page 125

6h95g11 6-26 9 8 7 6 5 4 3 2 1 backlash 10. Adjust the shim(s) to specified thickness (add or remove). 11. Remove the special service tools. Then install the o-ring to the propeller shaft assembly and tighten the lower case cap to specified torque in two stage. 12. Tighten the bolts in sequence as s...

Page 126

Lowr 6-27 6h95g11 lower unit lower unit (ek40j) 6h96010e 4 n·m (0.4 kgf·m, 3.0 ft·lb) 21 n·m (2.1 kgf·m, 15.5 ft·lb) 9 n·m (0.9 kgf·m, 6.6 ft·lb) 35 n·m (3.5 kgf·m, 25.3 ft·lb) no. Part name q’ty remarks 1 lower unit 1 2 check screw 1 3 gasket 3 4 drain screw 1 5 screw 1 6 dowel 2 7 bolt 1 m10 × 30 ...

Page 127

6h95g11 6-28 9 8 7 6 5 4 3 2 1 lower unit (ek40j) 6h96010e 4 n·m (0.4 kgf·m, 3.0 ft·lb) 21 n·m (2.1 kgf·m, 15.5 ft·lb) 9 n·m (0.9 kgf·m, 6.6 ft·lb) 35 n·m (3.5 kgf·m, 25.3 ft·lb) no. Part name q’ty remarks 18 bolt 6 m8 × 30 mm 19 water inlet cover 2 20 screw 1 21 nut 1 6h95g11_06 04.8.11 13:00 page ...

Page 128

Lowr 6-29 6h95g11 lower unit 6f66020e no. Part name q’ty remarks 1 shift rod 1 2 bushing 1 3 bolt 1 m6 × 18 mm 4 boot 1 5 water pump housing 1 6 bolt 2 m8 × 55 mm 7 woodruff key 1 8 insert cartridge 1 9 impeller 1 10 seal 1 11 gasket 1 12 outer plate cartridge 1 13 gasket 1 14 oil seal housing 1 15 ...

Page 129

6h95g11 6-30 9 8 7 6 5 4 3 2 1 lower unit (ek40j) 6f66020e no. Part name q’ty remarks 18 dowel 2 19 bolt 2 m8 × 45 mm 20 screw 1 21 gasket 1 not reusable 6h95g11_06 04.8.11 13:00 page 33.

Page 130

Lowr 6-31 6h95g11 lower unit removing the lower unit 1. Drain the gear oil. 2. Shift the shift lever or remote control lever to neutral, place a block of wood between the anti-cavitation plate and pro- peller to keep the propeller from turning, and then remove the propeller nut and propeller. W 9 do...

Page 131

6h95g11 6-32 9 8 7 6 5 4 3 2 1 lower unit (ek40j) removing the water pump and shift rod 1. Remove the water pump assembly and shift rod assembly 1. Note: before removing the shift rod assembly 1, remove the screw 2. Checking the water pump and shift rod 1. Check the water pump housing for defor- mat...

Page 132

Lowr 6-33 6h95g11 lower unit propeller shaft housing 6f66030e 90 n·m (9.0 kgf·m, 65 ft·lb) no. Part name q’ty remarks 1 shift plunger 1 2 dog clutch 1 3 cross pin 1 4 spring 1 5 slider 1 6 spring 1 7 propeller shaft 1 8 reverse gear 1 9 reverse gear shim — 10 washer 1 11 o-ring 1 12 ball bearing 1 1...

Page 133

6h95g11 6-34 9 8 7 6 5 4 3 2 1 propeller shaft housing removing the propeller shaft hous- ing assembly 1. Remove the ring nut from the propeller shaft housing, use the special service tools. Note: 9 straighten the one tab 1 of the lock wash- er, then turn the ring nut. 9 when the ring nut toward to ...

Page 134

Lowr 6-35 6h95g11 lower unit 2. Remove the ball bearing. C c do not reuse the bearing, always replace it with a new one. 3. Remove the oil seals and needle bearing. Checking the propeller shaft hous- ing 1. Clean the propeller shaft housing using a soft brush and cleaning solvent, and then check it ...

Page 135

6h95g11 6-36 9 8 7 6 5 4 3 2 1 propeller shaft housing assembling the propeller shaft housing 1. Install the needle bearing into the pro- peller shaft housing to the specified depth. Note: install the needle bearing with the manufac- ture identification mark a facing toward the oil seal (propeller s...

Page 136

Lowr 6-37 6h95g11 lower unit drive shaft and lower case 6f66040e 74 n·m (7.4 kgf·m, 54.6 ft·lb) no. Part name q’ty remarks 1 drive shaft 1 2 forward gear 1 3 taper roller bearing assembly 1 4 forward gear shim — 5 nut 1 6 pinion gear 1 7 washer 1 8 lower case 1 9 needle bearing 1 10 sleeve 1 11 pini...

Page 137

6h95g11 6-38 9 8 7 6 5 4 3 2 1 drive shaft and lower case removing the drive shaft 1. Remove the drive shaft assembly and pinion, and then pull out the forward gear. Disassembling the drive shaft 1. Install the pinion nut 1, tighten it finger tight, and then remove the drive shaft bearing 2 using a ...

Page 138

Lowr 6-39 6h95g11 lower unit disassembling the lower case 1. Remove the taper roller bearing outer race and shim(s). Note: install the claws a as shown. 2. Remove the drive shaft bearing outer race, shim(s), and drive shaft sleeve. Note: install the claws as shown. 3. Remove the needle bearing. Chec...

Page 139

6h95g11 6-40 9 8 7 6 5 4 3 2 1 drive shaft and lower case assembling the oil seal housing 1. Apply grease to new oil seals, and then install them into the oil seal housing. Assembling the lower case 1. Install the needle bearing into the lower case to the specified depth. Note: 9 install the needle ...

Page 140

Lowr 6-41 6h95g11 lower unit assembling the forward gear 1. Install a new taper roller bearing into the forward gear using a press. Assembling the drive shaft 1. Install a new drive shaft bearing onto the drive shaft using a press. Installing the drive shaft 1. Install the forward gear, then the dri...

Page 141

6h95g11 6-42 9 8 7 6 5 4 3 2 1 drive shaft and lower case 3. Install the propeller shaft housing assem- bly 5 and lock washer 6 into the lower case, and then tighten the ring nut 7 to the specified torque. Note: to secure the ring nut, and lock washer 6 bend one lobe into the ring nut slot, and the ...

Page 142

Lowr 6-43 6h95g11 lower unit 3. Install the woodruff key into the drive shaft. 4. Align the groove in the impeller 5 with the woodruff key 6, and then install the impeller onto the drive shaft. 5. Install the insert cartridge 7 into the pump housing 8, and then apply grease to the inside of the inse...

Page 143

6h95g11 6-44 9 8 7 6 5 4 3 2 1 drive shaft and lower case installing the lower unit 1. Set the gear shift to the reverse position at the lower unit. Make sure that the shift rod is in the reverse position. 2. Screw in the locknut 1 completely. 3. Install the two dowels 2 into the lower unit. 4. Inst...

Page 144

Lowr 6-45 6h95g11 lower unit 8. Insert a gear oil tube or gear oil pump into the drain hole and slowly fill the gear oil until oil flows out of the check hole and no air bubbles are visible. 9. Install the check screw and quickly install the drain screw. 6f630210 recommended gear oil: hypoid gear oi...

Page 145

6h95g11 6-46 9 8 7 6 5 4 3 2 1 drive shaft and lower case/shimming shimming t3 m3 m2 6f660440 t2 t1 m1 ƒ π ® 6h95g11_06 04.8.11 13:01 page 49.

Page 146

Lowr 6-47 6h95g11 lower unit shimming note: 9 shimming is not required when assembling the original lower case and inner parts. 9 shimming is required when assembling the original inner parts and a new lower case. 9 shimming is required when replacing the inner part(s). Selecting the pinion shims 1....

Page 147

6h95g11 6-48 9 8 7 6 5 4 3 2 1 shimming example: if “m3” is 26.05 mm and “p” is (+5), then t3 = 26.05 – 25.5 – (+5)/100 mm = 0.55 – 0.05 mm = 0.60 mm 5. Select the pinion shim(s) (t3) as follows. Example: if “t3” is 0.43 mm, then the pinion shim is 0.45 mm. If “t3” is 0.38 mm, then the pinion shim i...

Page 148

Example: if “m1” is 25.30 mm and “f” is (+4), then t1 = 25.70 + (+4)/100 – 25.30 mm = 25.70 + 0.04 – 25.30 mm = 0.44 mm 3. Select the forward gear shim(s) (t1) as follows. Example: if “t1” is 0.44 mm, then the forward gear shim is 0.42 mm. If “t1” is 0.50 mm, then the forward gear shim is 0.48 mm. S...

Page 149

6h95g11 6-50 9 8 7 6 5 4 3 2 1 shimming example: if “m2” is 27.32 mm and “r” is (+5), then t2 = 27.32 mm – 26.90 mm – (+5)/100 = 27.32 – 26.90 + 0.05 = 0.47 mm 4. Select the reverse gear shim(s) (t2) as follows. Example: if “t2” is 0.47 mm, then the reverse gear shim is 0.48 mm. If “t2” is 0.41 mm, ...

Page 150

Lowr 6-51 6h95g11 lower unit 5. Slowly turn the drive shaft clockwise and counterclockwise and measure the back- lash when the drive shaft stops in each direction. 6. Add or remove shim(s) if out of specifica- tion. M: measurement 7. Remove the special service tools from the propeller shaft. 8. Appl...

Page 151: Bracket Unit

6h95g11 9 8 7 6 5 4 3 2 1 brkt bracket unit special service tools ................................................................................... 7-1 tiller handle (mh) ......................................................................................... 7-2 assembling the tiller handle .......

Page 152

Brkt 7-1 6h95g11 bracket unit special service tools needle bearing attachment 90890-06613 driver rod l3 90890-06652 6h95g11_07 04.7.14 21:58 page 2.

Page 153

6h95g11 7-2 9 8 7 6 5 4 3 2 1 tiller handle (mh) 6h97010e 3 n·m (0.3 kgf·m, 2.2 ft·lb) no. Part name q’ty remarks 1 throttle cable 2 2 self locking nut 1 3 bolt 1 m12 × 68 mm 4 washer 1 5 collar 1 6 plastic washer 2 7 metal washer 2 8 wave washer 1 9 tiller handle bracket 1 10 throttle friction adju...

Page 154

Brkt 7-3 6h95g11 bracket unit 6h97010e 3 n·m (0.3 kgf·m, 2.2 ft·lb) no. Part name q’ty remarks 18 bolt 2 m6 × 20 mm 19 stay 1 20 nut 1 21 washer 1 22 bushing 1 23 pinion 1 24 bolt 1 m5 × 10 mm 25 bolt 1 m5 × 10 mm 26 rubber grip 1 27 pinion 1 28 pin 1 29 cotter pin 1 30 nut 1 31 stay 1 32 wire clip ...

Page 155

6h95g11 7-4 9 8 7 6 5 4 3 2 1 tiller handle (mh) assembling the tiller handle 1. Install the throttle cables 1 and 2 to the pinion 3. Note: route the throttle cable as shown and clamp the cable protector 4. 2. Install the throttle shaft 5 to the tiller handle bracket. Note: when install the throttle...

Page 156

Brkt 7-5 6h95g11 bracket unit 6h97020e 5 n·m (0.5 kgf·m, 3.6 ft·lb) w no. Part name q’ty remarks 1 bolt 2 m6 × 25 mm 2 cotter pin 1 3 shift lever 1 4 bracket 1 5 shift rod lever 1 1 6 shift control lever 1 7 shift rod lever 2 1 8 bushing 1 9 spring 2 10 screw 2 11 shift rod 1 12 bolt 1 m6 × 10 mm 13...

Page 157

6h95g11 7-6 9 8 7 6 5 4 3 2 1 bottom cowling 6h97020e 5 n·m (0.5 kgf·m, 3.6 ft·lb) w no. Part name q’ty remarks 18 rubber seal 1 19 collar 4 20 choke knob 1 21 grommet 1 22 retaining plate 1 23 bolt 2 m6 × 20 mm 24 engine stop lanyard switch 1 mh model 25 grommet 4 26 bolt 4 m6 × 30 mm 27 locknut 1 ...

Page 158

Brkt 7-7 6h95g11 bracket unit 6f67040e no. Part name q’ty remarks 1 bolt 3 m6 × 25 mm 2 exhaust guide 1 3 gasket 1 4 bolt 4 m6 × 20 mm 5 exhaust manifold 1 6 gasket 1 7 seal 1 8 rubber seal 2 9 pipe 1 not reusable not reusable not reusable not reusable upper case, pivot shaft 6h95g11_07 04.7.14 21:5...

Page 159

6h95g11 7-8 9 8 7 6 5 4 3 2 1 upper case, pivot shaft 6f67030e 28 n·m (2.8 kgf·m, 20 ft·lb) 55 n·m (5.5 kgf·m, 40 ft·lb) no. Part name q’ty remarks 1 cover 2 2 lower mount 2 3 bolt 2 m12 × 130 mm 4 washer 4 5 bolt 4 m6 × 25 mm 6 cover 1 7 nut 2 8 nut 2 9 washer 4 10 bracket 2 11 upper mount 2 12 bol...

Page 160

Brkt 7-9 6h95g11 bracket unit 6f67030e 28 n·m (2.8 kgf·m, 20 ft·lb) 55 n·m (5.5 kgf·m, 40 ft·lb) no. Part name q’ty remarks 18 protector 1 19 upper case assembly 1 20 circlip 1 21 bushing 1 ek40j: l transom model 22 bolt 2 m8 × 130 mm 23 washer 2 24 washer 2 25 seal 2 26 lock tie 2 27 seal 2 28 nut ...

Page 161

6h95g11 7-10 9 8 7 6 5 4 3 2 1 upper case, pivot shaft 6f67035e 14 n·m (1.4 kgf·m, 10 ft·lb) 24 n·m (2.4 kgf·m, 17.7 ft·lb) no. Part name q’ty remarks 1 bolt 2 m8 × 30 mm 2 bolt 2 m8 × 35 mm 3 steering bracket 1 4 dowel 2 5 pivot shaft 1 6 washer 1 7 bushing 1 8 straight key 1 9 spring 1 10 rubber s...

Page 162

Brkt 7-11 6h95g11 bracket unit disassembling the upper case 1. Remove the muffler assembly 1 and gasket 2 from the upper case 3. 2. Remove the exhaust manifold 4 and cooling water pipe 5. 3. Remove the nuts and upper mount, and then remove the protector 6 from the upper case. 4. Remove the circlip 7...

Page 163

6h95g11 7-12 9 8 7 6 5 4 3 2 1 upper case, pivot shaft assembling the upper case 1. Install the drive shaft bushing and the cir- clip to the upper case. (ek40j: l transom model) 2. Install a new gasket 3, the cooling water pipe 4, the exhaust manifold 5, and the bolts, and then tighten the bolts. 3....

Page 164

Brkt 7-13 6h95g11 bracket unit 5. Install a new gasket and the muffler assembly into the upper case. Removing the pivot shaft 1. Remove the pivot shaft from the swivel bracket by pulling the shaft off the brack- et. 2. Remove the oil seal 1 and then remove the bushing 2. 6f670035 6f670130 2 1 6f6701...

Page 165

6h95g11 7-14 9 8 7 6 5 4 3 2 1 upper case, pivot shaft/clamp brackets, swivel bracket 6f67050e 45 n·m (4.5 kgf·m, 33 ft·lb) 45 n·m (4.5 kgf·m, 33 ft·lb) 24 n·m (2.4 kgf·m, 17.7 ft·lb) 10 n·m (1.0 kgf·m, 7.2 ft·lb) no. Part name q’ty remarks 1 tilt pin 1 2 nut 2 3 washer 2 4 bolt 1 m8 × 230 mm 5 tube...

Page 166

Brkt 7-15 6h95g11 bracket unit 6f67050e 45 n·m (4.5 kgf·m, 33 ft·lb) 45 n·m (4.5 kgf·m, 33 ft·lb) 24 n·m (2.4 kgf·m, 17.7 ft·lb) 10 n·m (1.0 kgf·m, 7.2 ft·lb) no. Part name q’ty remarks 18 washer 1 19 wave washer 2 20 pin 2 21 circlip 2 22 tilt stopper plate (starboard side) 1 23 grease nipple 4 24 ...

Page 167

6h95g11 7-16 9 8 7 6 5 4 3 2 1 clamp brackets, swivel bracket 6f67060e 4 n·m (0.4 kgf·m, 3.0 ft·lb) no. Part name q’ty remarks 1 tilt lock lever 1 2 stopper plate (starboard side) 1 3 spring 1 4 bolt 1 m5 × 10 mm 5 circlip 3 6 tilt lever 1 7 tilt lock rod 1 8 tilt lock plate 1 9 spring 2 10 cotter p...

Page 168

Brkt 7-17 6h95g11 bracket unit 6f67060e 4 n·m (0.4 kgf·m, 3.0 ft·lb) no. Part name q’ty remarks 18 pin 1 19 washer 1 20 washer 1 21 stopper plate (port side) 1 22 cover 1 6h95g11_07 04.7.14 21:58 page 18.

Page 169

6h95g11 7-18 9 8 7 6 5 4 3 2 1 clamp brackets, swivel bracket removing the clamp brackets 1. Remove the tilt pin, and then remove the clamp bracket bolt, clamp bracket nut and collar. 2. Remove the cap nuts, then the self-lock- ing nuts and plate. 3. Remove the tilt both stopper plate, cir- clips an...

Page 170

Brkt 7-19 6h95g11 bracket unit 2. Assemble the clamp brackets, washers, and swivel bracket, and then install the clamp bracket bolt. 3. Install the plate, tighten the self-locking nuts 1 to the specified torque, and then tighten the cap nuts. 4. Install the tilt stopper plate bolts and cir- clips. 5...

Page 171: Electrical Systems

6h95g11 9 8 7 6 5 4 3 2 1 elec electrical systems special service tools ................................................................................... 8-1 checking the electrical components ........................................................ 8-2 measuring the peak voltage ....................

Page 172

Elec 8-1 6h95g11 electrical systems special service tools ignition tester 90890-06754 digital circuit tester 90890-03174 peak voltage adaptor b 90890-03172 test harness (4 pins) new: 90890-06871 current: 90890-06771 6h95g11_08 04.7.6 8:55 page 2.

Page 173

6h95g11 8-2 9 8 7 6 5 4 3 2 1 special service tools/checking the electrical components checking the electrical components measuring the peak voltage note: before troubleshooting the peak voltage, check that all electrical connections are tight and free from corrosion. The condition of the ignition s...

Page 174

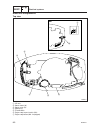

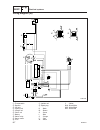

Elec 8-3 6h95g11 electrical systems electrical components top view 6h980010 1 2 3 4 5 6 7 mh 1 cdi unit 2 starter motor (w) 3 starter relay (w) 4 spark plug 5 thermoswitch 6 engine stop lanyard switch (wh) 7 engine stop button (mh: if equipped) 6h95g11_08 04.7.6 8:55 page 4.

Page 175

6h95g11 8-4 9 8 7 6 5 4 3 2 1 electrical components starboard view (mh) 6f680030 3 2 1 1 1 spark plug 2 ignition coil 3 cdi unit 6h95g11_08 04.7.6 8:55 page 5.

Page 176

Elec 8-5 6h95g11 electrical systems starboard view (w) 6f680040 5 2 1 1 3 4 6 7 1 spark plug 2 ignition coil 3 starter relay 4 starter motor 5 cdi unit 6 rectifier 7 fuse 6h95g11_08 04.7.6 8:55 page 6.

Page 177

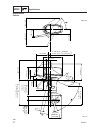

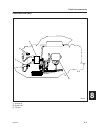

6h95g11 8-6 9 8 7 6 5 4 3 2 1 electrical components/wring diagram b b b b b b b b b b g g g g o o p p p b b o b b b p l l w w w w br br w/b w/b w/r w/r 6f68010m b b p l w br b/w w/b w/r a b 1 3 4 5 6 7 8 8 2 a b wiring diagram (mh) 1 thermoswitch 2 cdi unit 3 lighting coil 4 charge coil 5 pulser coi...

Page 178

Elec 8-7 6h95g11 electrical systems ― + b b m b b b b b b b b b b b b b b b b b r r r r r r r r r g g g g g g g g g g g g o o p p p b b o b b b p l l w w w br brbr br br br br br br w/b w/b w/r w/r b b p l w br b/w b/o w/b w/r 6h98030m a b 1 2 3 4 5 6 7 0 q w w 8 9 a b wiring diagram (w) 1 thermoswi...

Page 179

6h95g11 8-8 9 8 7 6 5 4 3 2 1 wring diagram/ignition and ignition control system ignition and ignition control sys- tem checking the ignition spark gap 1. Disconnect the spark plug caps from the spark plugs. 2. Connect a spark plug cap to the special service tool. 3. Crank the engine and observe the...

Page 180

Elec 8-9 6h95g11 electrical systems checking the charge coil 1. Disconnect the cdi unit coupler. 2. Connect the test harness (4 pins) to the charge coil. 3. Measure the charge coil output peak volt- age. Replace the charge coil if below specification. Pulser coil output peak voltage: white/red (w/r)...

Page 181

6h95g11 8-10 9 8 7 6 5 4 3 2 1 ignition and ignition control system checking the engine stop lanyard switch (mh) 1. Check the engine stop lanyard switch for continuity. Replace if there is no continu- ity. Checking the thermoswitch 1. Place the thermoswitch in a container of water and slowly heat th...

Page 182

Elec 8-11 6h95g11 electrical systems starting system checking the fuse (w) 1. Check the fuse for continuity. Replace if there is no continuity. Checking the starter relay (w) 1. Connect the digital circuit tester leads to the starter relay terminals. 2. Connect the positive battery terminal to the b...

Page 183

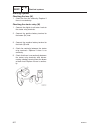

6h95g11 8-12 9 8 7 6 5 4 3 2 1 starting system/starter motor 6f68010e 1.0mm 0.15mm 2.0mm 0.25mm 0.25mm no. Part name q’ty remarks 1 clip 1 2 pinion stopper 1 3 spring 1 4 pinion assembly 1 5 bolt 2 6 housing 1 7 washer set 1 8 o-ring 1 9 armature assembly 1 10 bracket 1 11 brush holder 1 12 brush 2 ...

Page 184

Elec 8-13 6h95g11 electrical systems removing the starter motor pinion 1. Slide the pinion stopper 1 down as shown, and then remove the clip 2. Note: remove the clip with a thin screwdriver. Checking the starter motor pinion 1. Check the teeth of the pinion for cracks or wear. Replace if necessary. ...

Page 185

6h95g11 8-14 9 8 7 6 5 4 3 2 1 starter motor/charging system 4. Check the armature for continuity. Replace if out of specifications. Checking the brushes 1. Measure the brush length a. Replace the brush assembly if below specifica- tion. 2. Check the brush holder assembly for continuity. Replace if ...

Page 186

Elec 8-15 6h95g11 electrical systems checking the lighting coil 1. Measure the lighting coil output peak voltage. Replace the lighting coil if below specification. Digital circuit tester: 90890-3174 peak voltage adaptor b: 90890-03172 digital circuit tester: 90890-3174 peak voltage adaptor b: 90890-...

Page 187: Troubleshooting

6h95g11 9 8 7 6 5 4 3 2 1 trbl shtg trbl shtg troubleshooting power unit ..................................................................................................... 9-1 ignition system ......................................................................................... 9-1 fuel system...

Page 188

Trbl shtg 9-1 6h95g11 trbl shtg troubleshooting note: 9 to diagnose a mechanical malfunction, use the troubleshooting charts pertaining to the trouble located in this chapter. Also, when checking and maintaining the outboard motor, see chapters 4–8 for safe maintenance procedures. 9 check that all e...

Page 189

6h95g11 9-2 9 8 7 6 5 4 3 2 1 power unit ignition system (continued from previous page) replace the cdi unit. Check the fuel system and compression pressure. Check the charge coil output peak voltage. Yes yes check the connection of the leads from cdi unit. Yes replace the charge coil. No replace th...

Page 190

Trbl shtg 9-3 6h95g11 troubleshooting fuel system 9 consult this chart after the ignition system has been checked. Check the fuel hoses for fuel leakage by kinks or craks. Check for water accumulation or clogging of the fuel filter and inside the carburetor. No yes 9 clean the fuel system from the f...

Page 191

6h95g11 9-4 9 8 7 6 5 4 3 2 1 power unit compression pressure 9 consult this chart after the ignition and fuel systems have been checked. Measure the compression pressure. No add a small amount of engine oil into the cylinder through the spark plug hole. Check the piston, piston rings, and cylinder ...

Page 192

Trbl shtg 9-5 6h95g11 troubleshooting symptom: the engine idle speed does not remain steady. Check the operation of the carburetor. Check the throttle cable and link operation. Yes no adjust the throttle cable and throttle link. Yes check the ignition system chart. No adjust the pilot screw accordin...

Page 193

6h95g11 9-6 9 8 7 6 5 4 3 2 1 power unit/lower unit lower unit symptom: the forward and reverse gear shift mechanism does not operate properly. Check the shift rod connection. Check the shift lever operation. Yes no no check the shift lever shaft. Connect correctly or replace the shift rod as necess...

Page 194

Trbl shtg 9-7 6h95g11 troubleshooting electrical system symptom: the starter motor does not operate. (w) 9 engine stop lanyard switch is operating normally. Starting system check the battery for fully charged. Check the fuse for blown. No yes replace the fuse. No fully charge or replae the fully cha...

Page 195

6h95g11 9-8 9 8 7 6 5 4 3 2 1 electrical starting system (continued from previous page) disassemble and check the starter motor. Yes check the starter relay for continuity. No replace the starter relay. Is there continuity? Symptom: the battery loses power quickly. (w) 9 be sure the electrolyte leve...

Page 196

I-1 6h95g11 index a. Adjusting the start-in-gear protection ........ 3-5 adjusting the throttle cable (mh) .............. 3-5 adjusting the throttle cable (w) ................ 3-6 adjusting the throttle link position ............. 3-5 adjusting the throttle stop screw ............. 4-11 after test r...

Page 197

6h95g11 i-2 9 8 7 6 5 4 3 2 1 checking the starter motor pinion ........... 8-13 checking the starter relay (w) ................ 8-11 checking the steering system ................... 1-8 checking the thermostat ........................... 3-4 checking the thermoswitch ..................... 8-10 chec...

Page 198

I-3 6h95g11 index removing the crankcase ........................ 5-27 removing the crankshaft assembly and oil seal housing ..................................... 5-27 removing the cylinder head ................... 5-24 removing the drive shaft ............... 6-17, 6-38 removing the electrical comp...

Page 199

A4cover6h9 04.7.6 9:31 page 3.

Page 200

Yamaha motor co., ltd. Printed in japan aug. 2004 – 0.3 × 1 ! (e) printed on recycled paper a4cover6h9 04.7.6 9:31 page 4.