- DL manuals

- Yamaha

- Motorcycle

- EXCITER

- Service manual

Yamaha EXCITER Service manual

Summary of EXCITER

Page 1

T135 service manual 5yp-f8197-e0 t135se t135s sniper / jupiter mx / spark 135 / exciter / 135lc manual clutch and automatic http://www.Motorcycle.In.Th.

Page 2

Http://www.Motorcycle.In.Th.

Page 3

T135se/t135s service manual ©2005 by yamaha motor co., ltd. First edition, april, 2005 all rights reserved. Any reproduction or unauthorized use without the written permission of yamaha motor co., ltd. Is expressly prohibited. Eas00000 http://www.Motorcycle.In.Th.

Page 4: Notice

Eas00002 notice this manual was produced by the yamaha motor company, ltd. Primarily for use by yamaha dealers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one man- ual. Therefore, anyone who uses this book to perform maintenance and repairs on yama...

Page 5: How To Use This Manual

Easf0001 how to use this manual construction of this manual this manual consists of chapters for the main categories of subjects. (see “illustrated symbols”) 1st title 1 :this is a chapter with its symbol on the upper right of each page. 2nd title 2 :this title appears on the upper of each page on t...

Page 6

Http://www.Motorcycle.In.Th.

Page 7: Gen

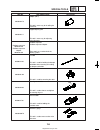

Symbols the following symbols are not relevant to every vehicle. Symbols 1 to 9 indicate the subject of each chapter. 1 general information 2 specifications 3 periodic checks and adjustments 4 engine 5 cooling system 6 carburetor 7 chassis 8 electrical system 9 troubleshooting symbols 0 to u indicat...

Page 8

Http://www.Motorcycle.In.Th.

Page 9: Specifications

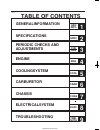

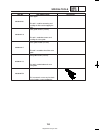

Specifications troubleshooting electricalsystem chassis engine periodic checks and adjustments generalinformation gen info trbl shtg elec chas eng chk adj spec table of contents 4 7 8 9 3 2 1 coolingsystem cool 5 carburetor carb 6 eas00011 http://www.Motorcycle.In.Th.

Page 10

Http://www.Motorcycle.In.Th.

Page 11: Gen

Gen info chapter 1 generalinformation vehicle identification ...................................................................................1-1 vehicle identification number .............................................................1-1 engine serialnumber.........................................

Page 12: Gen

Gen info http://www.Motorcycle.In.Th.

Page 13: Gen

1-1 gen info vehicle identification eas00014 generalinformation vehicleidentification eas00017 vehicle identification number the number 1 is stamped into the center of the frame. Engine serialnumber the engine serial number 1 is stamped into the crankcase. Note: designs and specifications are subjec...

Page 14: Gen

Gen info important information eas00020 important information preparation for removaland disassembly 1. Before removal and disassembly, remove all dirt, mud, dust and foreign material. 2. Use only the proper tools and cleaning equipment. Refer to the “specialtools”. 3. When disassembling, always kee...

Page 15: Gen

Eas00024 bearings and oilseals install bearings and oil seals so that the manu- facturer’s marks or numbers are visible. When installing oil seals, lubricate the oil seal lips with a light coat of lithium-soap-based grease. Oil bearings liberally when installing, if appropriate. 1 oil seal c c do no...

Page 16: Gen

Gen info checking the connections 1 eas00026 checking the connections check the leads, couplers, and connectors for stains, rust, moisture, etc. 1. Disconnect: 9 lead 9 coupler 9 connector 2. Check: 9 lead 9 coupler 9 connector moisture → dry with compressed air. Rust/stains → connect and disconnect...

Page 17: Gen

Gen info specialtools 1-5 eas00027 specialtools the following special tools are necessary for complete and accurate tune-up and assembly. Use only the appropriate special tools as this will help prevent damage caused by the use of inappropriate tools or improvised techniques. Special tools, part num...

Page 18: Gen

Gen info specialtools 1-6 90890-01278 adoptor (m12) this tool is necessary for installing the crankshaft. 90890-01311 tappet adjusting tool this tool is necessary for adjusting valve clearance. Radiator cap tester 90890-01325 radiator cap tester adapter 90890-01352 radiator cap tester radiator cap t...

Page 19: Gen

Gen info specialtools 1-7 90890-03081 compression gauge these tools are used to measure the engine compression. 90890-03112 pocket tester this instrument is necessary for checking the electrical system. 90890-03113 engine tachometer this tool is needed for detecting engine rpm. Middle driven shaft b...

Page 20: Gen

Gen info specialtools 1-8 90890-04101 valve lapper this tool is used for removeing and installing the lifter and for lapping the valve. 90890-04116 valve guide remover (4.5 mm) this tool is needed to remove and installing the valve guide. 90890-04117 valve guide installer (4.5 mm) this tool is neede...

Page 21: Spec

Spec chapter 2 specifications generalspecifications ...............................................................................2-1 maintenance specifications ......................................................................2-4 engine ............................................................

Page 22: Spec

Spec http://www.Motorcycle.In.Th.

Page 23: Spec

Spec generalspecifications 2-1 specifications generalspecifications model t135se/t135s model code 5yp1 (t135se) 5yp2 (t135s) dimensions overall length 1,945 mm (76.6 in) overall width 705 mm (27.8 in) overall height 1,065mm (41.9 in) seat height 770 mm (30.3 in) wheelbase 1,245 mm (49.0 in) minimum ...

Page 24: Spec

Spec generalspecifications 2-2 model t135se/t135s carburetor type/quantity vm22/1 manufacturer mikuni spark plug type cpr8ea-9 manufacturer ngk spark plug gap 0.8 – 0.9 mm (0.031 – 0.035 in) clutch type wet, multiple-disc and centrifugal automatic transmission primary reduction system spur gear prim...

Page 25: Spec

Spec generalspecifications 2-3 model t135se/t135s brake front brake type single disc brake operation right hand operation rear brake type drum brake operation right foot operation suspension front suspension telescopic fork rear suspension swingarm (monocross) shock absorber front shock absorber coi...

Page 26: Spec

Item standard limit cylinder head max. Warpage “*” ---- 0.03 mm (0.0012 in) cylinder bore 54.000 – 54.010 mm (2.1260 – 2.1264 in) 54.1 mm (2.1299 in) out of round limit ---- 0.05 mm (0.002 in) camshaft drive method chain drive (left) cam dimensions intake “a” 29.643 – 29.743 mm (1.1670 – 1.1710 in) ...

Page 27: Spec

Spec maintenance specifications 2-5 item standard limit valve, valve seat, valve guide valve clearance (cold) in 0.10 – 0.14 mm (0.0039 – 0.0055 in) ---- ex 0.16 – 0.20 mm (0.0063 – 0.0079 in) ---- valve dimensions “a” head diameter in 19.40 – 19.60 mm (0.7638 – 0.7717 in) ---- ex 16.90 – 17.10 mm (...

Page 28: Spec

Spec 2-6 maintenance specifications item standard limit valve spring free length in/ex 47.33 mm (1.86 in) 44.96 mm (1.77 in) installed length (valve closed) in/ex 35.30 mm (1.39 in) ---- compressed spring force in/ex 135.6 – 156.0 n (13.8 – 15.8 kgf) ---- at 35.3 mm (1.39 in) tilt limit “*” in/ex --...

Page 29: Spec

Spec 2-7 maintenance specifications item standard limit crankshaft crank width “a” 45.95 – 46.00 mm (1.81-1.81 in) ---- max. Runout limit “c” ---- 0.03 mm (0.0012 in) big end side clearance “d” 0.11 – 0.41 mm (0.0403 – 0.016 in) ---- big end radial clearance “e” 0.004 – 0.014 mm (0.10 – 0.11 in) ---...

Page 30: Spec

Item standard limit kickstarter kickstarter type ratchet type ---- spring free length 15.5 mm (0.61 in) ---- carburetor type vm22 ---- i.D. Mark 5yp1 00 ---- main jet (m.J) #105 ---- main air jet (m.A.J) ø1.2 ---- jet needle (j.N) 5 k010 ---- needle jet (n.J) n-9m ---- pilot outlet (p.O) ø1 ---- pil...

Page 31: Spec

Spec maintenance specifications 2-9 tightening torques engine cylinder head bolt m8 4 22 2.2 16 cylinder head (timing chain side) bolt m6 2 10 1.0 7.2 cylinder head (oil check) screw m6 1 7 0.7 5.0 spark plug — m10 1 13 1.3 9.5 cylinder head cover bolt m6 5 10 1.0 7.2 reed valve assembly bolt m6 2 1...

Page 32: Spec

Spec 2-10 maintenance specifications drive sprocket bolt m6 1 10 1.0 7.2 main axle bearing retainer screw m6 2 7 0.7 5.0 clutch release adjusting locknut nut m6 1 8 0.8 6.0 shift pedal bolt m8 1 18 1.8 13 shift drum segment bolt m6 1 12 1.2 9.0 shift drum stopper lever bolt m6 1 10 1.0 7.2 shift lev...

Page 33: Spec

Item standard limit steering system steering bearing type ball and race bearing ---- lock-to-lock angle (left/right) 45° ---- front suspension front fork travel 100 mm (3.94 in) ---- fork spring free length 295.3 mm (11.63 in) 289.4 mm (11.39 in) installed length 288.3 mm (11.35 in) ---- spring rate...

Page 34: Spec

Item standard limit rear wheel type spoke wheel ---- rim size 17 ⋅ 1.60 ---- rim material steel ---- max. Radial wheel runout ---- 1.0 mm (0.04 in) max. Lateral wheel runout ---- 0.5 mm (0.02 in) drive chain type/manufacturer 428/daido ---- link quantity 112 ---- drive chain slack 25 – 35 mm (0.98 –...

Page 35: Spec

Spec 2-13 maintenance specifications tightening torques chassis handlebar bracket and lower bracket m10 53 5.3 39 handlebar and handlebar bracket m8 23 2.3 13 brake hose and brake master cylinder m10 26 2.6 19 brake hose and brake caliper m10 26 2.6 19 brake master cylinder and holder m6 11 1.1 8.0 ...

Page 36: Spec

Spec 2-14 maintenance specifications note: 1. First tighten the lower ring nut 30 nm (3.0 m • kg, 22 ft • lb) by using a torque wrench, then loosen the ring nut 1/4 turn. 2. Then, hold the lower ring nut and tighten the upper ring nut 75 nm (7.5 m • kg, 54 ft • lb) by using a torque wrench. Fuel tan...

Page 37: Spec

Spec 2-15 maintenance specifications electrical item standard limit system voltage 12 v ---- ignition system ignition timing (b.T.D.C.) 10° at 1,400 r/min ---- advanced type digital ---- dc-c.D.I pickup coil resistance/color 248 – 372 Ω at 20 ° c (68 ° f)/r–w ---- c.D.I. Unit model/manufacturer 5yp/...

Page 38: Spec

Spec 2-16 maintenance specifications item standard limit electric starting system (t135se) type constant mesh ---- starter motor model/manufacturer 5yp/ptmoric ---- operation voltage 12 v ---- power output 0.20 kw ---- armature coil resistance 0.032 – 0.039 Ω at 20 ° c (68 ° f) ---- brush overall le...

Page 39: Spec

Spec 2-17 conversiontable/ generaltightening torque specifications eas00029 generaltightening torque specifications this chart specifies tightening torques for stan- dard fasteners with a standard iso thread pitch. Tightening torque specifications for special com- ponents or assemblies are provided ...

Page 40: Spec

Spec 2-18 lubrication points and lubricant types lubrication points and lubricant types engine lubrication point lubricant oil seal lips bearings o-rings cylinder head tightening washer and bolt thread rocker arm inner surfaces rocker arm shaft camshaft valve stem (in, ex) valve stem guide (in, ex) ...

Page 41: Spec

Lubrication point lubricant transmission side plate inner surface transmission pinion gears inner surface generator lead grommet yamaha bond no.1215 crankcase mating surface yamaha bond no.1215 timing chain tensioner bolts yamaha bond no.1215 spec 2-19 lubrication points and lubricant types http://w...

Page 42: Spec

Spec 2-20 lubrication points and lubricant types chassis lubrication point lubricant front wheel oil seal lips speedometer gear unit inner surface rear wheel oil seal lips rear brake camshaft brake torque rod bolt front wheel axle rear wheel axle upper brake caliper retaining bolt lower brake calipe...

Page 43: Spec

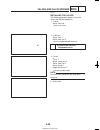

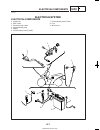

Spec 2-21 coolingsystem diagrams cooling system diagrams 1 radiator inlet hose 2 radiator cap 3 hose clamp 4 coolant reservoir hose 5 frame cross pipe 6 radiator 7 radiator outlet hose 8 over flow hose 9 coolant reservoir tank å align the white paint mark on the clamp with the white paint mark on th...

Page 44: Spec

Spec 2-22 cable routing cable routing 1 turn signal light relay 2 meter assembly 3 left handlebar switch lead 4 speedometer cable 5 wireharness 6 brake hose 7 throttle cable 8 front brake light switch lead å install the turn signal relay onto the bracket. ∫ connect the left handlebar switch lead cou...

Page 45: Spec

Spec 2-23 cable routing ˆ pass the wireharness behind the turn signal relay and brake hose, and then connect the front brake switch. ∆ route the right handlebar switch lead behind the handle- bar and connect the coupler with handlebar right side, and then set the turn signal light relay. ˚ take care...

Page 46: Spec

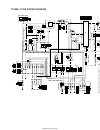

Spec 2-24 cable routing 1 front turn signal light lead 2 fitting tape (red) 3 throttle cable 4 c.D.I. Unit 5 case 6 clamp 7 breather pipe 8 band 9 air vent pipe 0 stopper q negative lead w fuel hose e vacuum hose r overflow pipe t neutral switch lead y a.C. Magneto lead u coolant reservoir hose i wa...

Page 47: Spec

Spec 2-25 cable routing å ∫ ç ∂ ´ƒ © ˙ ˆ ∆ ˚ ¬ b b a a a-a b-b 1 2 3 4 5 6 7 8 9 0 q w w e e r y y t t u i p o µ ˙ install the negative lead, should be stopped. ˆ pass through the fuel hose and vacuum hose into the cable guide. ∆ route the overflow pipe to the left side of the engine and inside of t...

Page 48: Spec

Spec 2-26 cable routing å ∫ ç ∂ ´ ƒ © ˙ ˆ ∆ ˚ 1 2 3 4 4 5 5 5 6 6 7 8 9 0 q w e r t a a b b c a-a b-b c 1 fan relay lead 2 positive lead 3 fuse box 4 starter motor lead (t135se) 5 rear brake switch lead 6 battery breather pipe 7 rectifier/regulator 8 tail/brake light lead 9 wireharness 0 bracket q f...

Page 49: Spec

Spec 2-27 cable routing å ∫ ç ∂ ´ ƒ © ˙ ˆ ∆ ˚ 1 2 3 4 4 5 5 5 6 6 7 8 9 0 q w e r t a a b b c a-a b-b c ˆ route the overflow pipe in front of the cross pipe frame. ∆ pass through the drain hose and battery breather pipe into the guide. ˚ pass through the drain hose into the hole of the protector. Ht...

Page 50: Spec

Spec cable routing 2-28 å ∫ ç ∂ ´ ƒ © ˙ˆ ∆ ˚ ¬ a a b b a-a 1 2 3 4 5 6 7 8 9 0 qw e r c c 1 throttle position sensor lead 2 radiator inlet hose 3 grommet 4 plate 5 fan motor lead 6 high tension cord 7 main switch lead 8 horn lead 9 thermo switch lead 0 bend hose q fuel hose w vacuum hose e overflow ...

Page 51: Spec

Spec cable routing 2-29 å ∫ ç ∂ ´ ƒ © ˙ˆ ∆ ˚ ¬ a a b b a-a 1 2 3 4 5 6 7 8 9 0 qw e r c c ˆ to the a.C. Magneto. ∆ cover the protector completely , after the coupler connected. ˚ set the connected point below the pipe end. ¬ pass through the high tension cord, fan motor lead and ther- mo sensor lead...

Page 52: Spec

Spec cable routing 2-30 å ∫ ç ∂ ´ ƒ 1 2 3 4 5 1 speedometer cable 2 acceleration pump cable 3 throttle cable 4 fuel sender lead 5 choke cable å route the acceleration pump cable into the right side of the stay. ∫ route the throttle cable into the left side of the stay. ç black plating joint. ∂ pass ...

Page 53: Chk

Chk adj chapter 3 periodic checks and adjustments introduction ....................................................................................................3-1 periodic maintenance and lubrication intervals ............................3-1 covers ..................................................

Page 54: Chk

Chk adj checking and adjusting the steering head ...................................3-35 checking the frontfork .......................................................................3-37 checking the tires ...................................................................................3-38 check...

Page 55: Chk

Chk adj introduction/ periodic maintenance and lubrication intervals eas00036 periodic checks and adjustments introduction this chapter includes all information necessary to perform recommended checks and adjustments. If followed, these preventive maintenance procedures will ensure more reliable veh...

Page 56: Chk

Chk adj 3-2 periodic maintenance and lubrication intervals eau18660 note: 7 the air filter needs more frequent service if you are riding in unusually wet or dusty areas. 7 hydraulic brake service 9 regularly check and, if necessary, correct the brake fluid level. 9 every two years replace the intern...

Page 57: Chk

3-3 chk adj covers 2. Disconnect: 9 turn signal light couplers installing the front cowling for installation, reverse the removal procedure. Easf0004 covers removing the side cowlings 1. Remove: 9 screws 9 bolts 9 side cowlings (left and right) installing the side cowlings for installation, reverse ...

Page 58: Chk

3-4 2 3 1 1 1 1 chk adj covers 1 3. Remove: 9 rear panel 1 note: remove the rear panel by sliding it in the direc- tion shown. Removing the center panels 1. Remove: 9 screws 9 center panel (lower) 1 9 main switch cover 2 9 screws 9 center panel (upper) 3 note: remove the main switch cover by turning...

Page 59: Chk

3-5 2 1 1 2 chk adj covers 1 2 4. Remove: 9 screws 9 screw (with washer) 1 9 screws 9 rear cowlings (left and right) 2 installing the rear cowlings 1. Install: 9 rear cowlings (left and right) 1 9 screws 9 screw (with washer) 2 note: before tightening the rear cowling screws, make sure that all proj...

Page 60: Chk

1 1 chk adj covers 3-6 installing the headlight assembly 1. Connect: 9 headlight connectors 1 2. Install: 9 headlight assembly 9 screws 2. Disconnect: 9 headlight connectors 1 1 removing the headlight assembly 1. Remove: 9 screws 9 headlight assembly 1 http://www.Motorcycle.In.Th.

Page 61: Chk

Eas00049 engine adjusting the valve clearance the following procedure applies to all of the valves. Note: 9 valve clearance adjustment should be made on a cold engine, at room temperature. 9 when the valve clearance is to be measured or adjusted, the piston must be at top dead center (tdc) on the co...

Page 62: Chk

1 2 a b chk adj adjusting the valve clearance 3-8 5. Move: 9 radiator assembly to swing the radiator assembly toward the front side. 6. Remove: 9 water pump assembly 9 o-rings 7. Remove: 9 cylinder head cover 9 gasket 8. Remove: 9 timing check plug 1 (with o-ring) 9 center plug 2 (with o-ring) 9. Me...

Page 63: Chk

Chk adj adjusting the valve clearance 3-9 d. Measure the valve clearance with a thick- ness gauge 1 out of specification → adjust. ✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬ c d 1 1 2 a b 3 4 10. Adjust: 9 valve clearance ✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭ a. Loosen the locknut 1 . B. Insert a thickness gauge 2 between the end...

Page 64: Chk

1 chk adj adjusting the valve clearance 3-10 11. Install: 9 o-ring 9 timing check plug (with o-ring) 9 center plug (with o-ring) 12. Install: 9 gasket 1 9 cylinder head cover 13. Install: 9 o-ring 9 water pump assembly 14. Connect 9 water pump inlet hose 9 radiator outlet cover 9 radiator inlet hose...

Page 65: Chk

A b 2 1 chk adj 3-11 5. Adjust: 9 engine idling speed ✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭ a. Turn the pilot air screw 1 in or out until it is lightly seated. B. Turn the pilot air screw out the specified number of turns. C. Turn the throttle stop screw 2 in direction a or b until the specified engine idling sp...

Page 66: Chk

Chk adj 3-12 6. Adjust: 9 throttle cable free play refer to “adjusting the throttle cable free play”. 7. Install: 9 rear cowling (left) 9 front cowling 9 side cowlings (left and right) refer to “installing the rear cowl- ings”, “installing the frontcowl- ing” and “installing the rear cowl- ings”. Ad...

Page 67: Chk

Chk adj 3-13 adjusting the throttle cable free play a b 1 2 1 2 a b c d e 3. Adjust: 9 throttle cable free play ✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭ a. Pull back the adjusting nut cover. B. Loosen the locknut 1 c. Turn the adjusting nut 2 in direction a or b until the specified throttle cable free play is obtai...

Page 68: Chk

Chk adj 3-14 1 2 a checking the spark plug 4. Check: 9 spark plug type incorrect → change. Eas00060 checking the spark plug 1. Remove: 9 side cowling (right) refer to “removing the side cowl- ings”. 9 ais resonator c c be sure to remove the ais hose, before removing the ais resonator, otherwise to b...

Page 69: Chk

Chk adj 3-15 checking the spark plug/ measuring the compression pressure eas00067 measuring the compression pressure note: insufficient compression pressure will result in a loss of performance. 1. Remove: 9 side cowling (right) refer to “removing the side cowl- ing”. 2. Measure: 9 valve clearance o...

Page 70: Chk

Chk adj 3-16 measuring the compression pressure ✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭ a. Set the main switch to “on”. B. With the throttle wide open and push the “start” switch, then crank the engine until the reading on the compression gauge sta- bilizes. W to prevent sparking, ground the spark plug lead before...

Page 71: Chk

8. Install: 9 spark plug 9. Connect: 9 spark plug cap 10. Install: 9 side cowling (right) refer to “installing the side cowl- ings”. 1 b a chk adj 3-17 measuring the compression pressure/ checking the engine oillevel eas00070 checking the engine oillevel 1. Stand the vehicle on a level surface. Note...

Page 72: Chk

1 chk adj 3-18 3. Remove: 9 oil level plug 1 9 engine oil drain plug 2 (with o-ring) 9 spring 9 oil strainer 4. Drain: 9 engine oil (completely from the crankcase) 5. Check: 9 oil strainer clog → clean. Damage → replace. 6. Install: 9 oil strainer 9 spring 9 o-ring 9 engine oil drain plug 7. Fill: 9...

Page 73: Chk

2 1 chk adj 3-19 checking the oilfilter 1. Remove: 9 oil filter element cover 9 o-ring 9 oil filter element 2. Check: 9 oil filter element dirt or clog → replace. 3. Install: 9 oil filter element 9 o-ring 1 9 oil filter element cover changing the engine oil/ checking the exhaust system 10 nm (1.0 m•...

Page 74: Chk

2 chk adj 3-20 cleaning the air filter element eas00086 cleaning the air filter element 1. Remove: 9 center panel (lower) refer to “removing the center pan- els”. 2. Remove: 9 air filter case cover 1 9 air filter element 2 3. Clean: 9 air filter elements apply compressed air to the outer surface of ...

Page 75: Chk

1 2 1 2 chk adj 3-21 cleaning the air filter element/ adjusting the clutch release system/ checking the carburetor joint and intake manifold 6. Install: 9 center panel (lower) refer to “installing the centerpan- els”. Eas00086 adjusting the clutch release system 1. Adjust: 9 clutch release system ✭✭...

Page 76: Chk

1 2 chk adj 3-22 checking the carburetor joint and intake manifold/ checking the fueland vacuum hoses 3. Install: 9 inner panel 9 rear cowlings (left and right) 9 front cowling 9 center panels (upper and lower) 9 side cowlings (left and right) refer to “covers”. Eas00096 checking the fueland vacuum ...

Page 77: Chk

1 a b chk adj 3-23 checking the crankcase breather pipe/ checkingthecoolantlevel eas00098 checking the crankcase breather pipe 1. Remove: 9 side cowlings (left and right) 9 center panels (upper and lower) 9 front cowling 9 rear cowlings (left and right) 9 inner panel refer to “covers”. 2. Check: 9 c...

Page 78: Chk

1 2 3 4 5 chk adj 3-24 checkingthecoolantlevel/ checkingthecoolingsystem c c 9 9 adding water instead of coolant lowers the antifreeze content of the coolant. If water is used instead of coolant check, and if nec- essary, correct the antifreeze concentration of the coolant. 9 9 use only distilled wa...

Page 79: Chk

1 1 1 chk adj 3-25 changingthecoolant eas00105 changing the coolant 1. Remove: 9 side cowlings (left and right) 9 front cowling refer to “removing the side cowl- ings” and “removing the front cowling”. 2. Remove: 9 coolant reservoir tank cover 9 coolant reservoir cap 3. Disconnect: 9 coolant reservo...

Page 80: Chk

A chk adj 3-26 changingthecoolant 8. Install: 9 copper washer 9 coolant drain bolt 9. Connect: 9 coolant reservoir hose 10. Fill: 9 cooling system (with the specified amount of the recom- mended coolant) note: the specified amount of coolant is a standard amount. Fill the cooling system with coolant...

Page 81: Chk

Chk adj 3-27 c c 9 9 adding water instead of coolant lowers the antifreeze content of the coolant. If water is used instead of coolant check, and if nec- essary, correct the antifreeze concentration of the coolant. 9 9 use only distilled water. However, if dis- tilled water is not available, soft wa...

Page 82: Chk

A b a 1 chk adj 3-28 adjusting the rear brake chassis eas00113 adjusting the rear brake 1. Check: 9 brake pedal free play a out of specification → adjust. Brake pedal free play (at the end of the brake pedal) 25–35 mm (0.98–1.38 in) 2. Adjust: 9 brake pedal free play ✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭ a. Turn...

Page 83: Chk

1 1 1 2 chk adj 3-29 checking the front brake pads/ checking the rear brake shoes/ adjusting the rear brake light switch eas00120 checking the front brake pads the following procedure applies to all of the brake pads. 1. Operate the brake. 2. Check: 9 front brake pad wear indicator groove 1 almost d...

Page 84: Chk

B a 1 2 chk adj 3-30 adjusting the rear brake light switch/ checking the front brake hose 2. Adjust: 9 rear brake light operation timing ✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭ a. Hold the main body 1 of the rear brake light switch so that it does not rotate and turn the adjusting nut 2 in direction a or b until t...

Page 85: Chk

1 2 chk adj 3-31 bleeding the hydraulic brake system eas00133 bleeding the hydraulic brake system w bleed the hydraulic brake system whenever: 9 9 the system is disassembled. 9 9 a brake hose is loosened, disconnected or replaced. 9 9 the brake fluid level is very low. 9 9 brake operation is faulty....

Page 86: Chk

Chk adj 3-32 bleeding the hydraulic brake system/ adjusting the drive chain slack note: loosening the bleed screw will release the pres- sure and cause the brake lever to contact the throttle grip. H. Tighten the bleed screw and then release the brake lever. I. Repeat steps (e) to (h) until all of t...

Page 87: Chk

A a b 1 2 chk adj 3-33 adjusting the drive chain slack 1. Stand the vehicle on a level surface. W securely support the vehicle so that there is no danger of it falling over. Note: place the vehicle on a suitable stand so that the rear wheel is elevated. 2. Spin the rear wheel several times and find ...

Page 88: Chk

A chk adj 3-34 lubricating the drive chain/ checking the brake fluid level eas00143 lubricating the drive chain the drive chain consists of many interacting parts. If the drive chain is not maintained prop- erly, it will wear out quickly. Therefore, the drive chain should be serviced, especially whe...

Page 89: Chk

Chk adj 3-35 checking the brake fluid level/ checking and adjusting the steering head c c brake fluid may damage painted surfaces and plastic parts. Therefore, always clean up any spilt brake fluid immediately. Note: in order to ensure a correct reading of the brake fluid level, make sure the top of...

Page 90: Chk

1 2 4 3 5 2 chk adj 3-36 checking and adjusting the steering head 4. Adjust: 9 steering head ✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭ a. Loosen the upper ring nut 1 . B. Loosen the lower ring nut 2 and then tight- en it to specification with a steering nut wrench 3 . Note: set the torque wrench at a right angle to ...

Page 91: Chk

Chk adj 3-37 checking the front fork eas00149 checking the front fork 1. Stand the vehicle on a level surface. W securely support the vehicle so that there is no danger of it falling over. 2. Check: 9 inner tube damage/scratches → replace. 9 oil seal oil leakage → replace. 3. Hold the vehicle uprigh...

Page 92: Chk

Chk adj 3-38 checking the tires easf0015 checking the tires the following procedure applies to both of the tires. 1. Check: 9 tire pressure out of specification → regulate. W 9 9 the tire pressure should only be checked and regulated when the tire temperature equals the ambient air temperature. 9 9 ...

Page 93: Chk

Chk adj 3-39 checking the tires 2. Check: 9 tire surfaces damage/wear → replace the tire. 1 tire tread depth 2 sidewall 3 wear indicator w 9 9 do not use a tubeless tire on a wheel designed only for tube tires to avoid tire failure and personal injury from sudden deflation. 9 9 when using tube tires...

Page 94: Chk

Chk adj 3-40 eas00169 checking and tightening the spokes the following procedure applies to all of the spokes. 1. Check: 9 spoke 1 bends/damage → replace. Loose → tighten. Tap the spokes with a screwdriver. Note: atight spoke will emit a clear, ringing tone; a loose spoke will sound flat. 2. Tighten...

Page 95: Chk

Chk adj 3-41 checking and lubricating the cables/ lubricating the lever and pedals/ lubricating the sidestand/lubricating the centerstand eas00170 checking and lubricating the cables the following procedure applies to all of the inner and outer cables. W damaged outer cable may cause the cable to co...

Page 96: Chk

1 chk adj 3-42 checking and charging the battery eas00176 electricalsystem checking and charging the battery w batteries generate explosive hydrogen gas and contain electrolyte which is made of poi- sonous and highly caustic sulfuric acid. Therefore, always follow these preventive measures: 9 9 wear...

Page 97: Chk

2 1 a b chk adj 3-43 3. Disconnect: 9 battery leads (from the battery terminals) c c first, disconnect the negative battery lead 1 , and then the positive battery lead 2 . 4. Disconnect: 9 battery breather hose 5. Remove: 9 battery checking and charging the battery 6. Check: 9 electrolyte level the ...

Page 98: Chk

Chk adj 3-44 c c 9 9 loosen the battery sealing caps. 9 9 make sure the battery breather hose and battery vent are free of obstructions. 9 9 to ensure maximum performance, always charge a new battery before using it. 9 9 do not use a high-rate battery charger. They force a high-amperage current into...

Page 99: Chk

1 1 2 chk adj 3-45 9 warpage or buckling of the battery plates or insulators is evident. 9. Check: 9 battery breather hose and battery vent obstruction → clean. Damage → replace. 10. Install: 9 battery checking and charging the battery 13. Connect: 9 battery leads (to the battery terminals) c c firs...

Page 100: Chk

1 chk adj 3-46 easf0017 checking the fuse c c to avoid a short circuit, always set the main switch to “off” when checking or replacing a fuse. 1. Open the seat and battery cover. Checking the fuse 2. Remove: 9 fuse holder 1 3. Check: 9 fuse ✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭ a. Connect the pocket tester to th...

Page 101: Chk

1 2 chk adj 3-47 eas00183 replacing the headlight bulbs the following procedure applies to both of the headlight bulbs. 1. Remove: 9 headlight assembly refer to “removing the headlight assembly”. 2. Remove: 9 headlight bulb holder 1 replacing the headlight bulbs 3. Remove: 9 headlight bulb w since t...

Page 102: Chk

A b 1 chk adj 3-48 eas00186 adjusting the headlight beam 1. Adjust: 9 headlight beam (vertically) ✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭ a. Loosen the bolt 1 . B. Slide the bottom of the headlight unit for- ward a or backward b . C. Tighten the bolt 1 . ✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬ adjusting the headlight beam slide ...

Page 103: Eng

Eng chapter 4 engine removing the engine .....................................................................................4-1 cooling system ..........................................................................................4-1 engine oil......................................................

Page 104: Eng

Eng cylinder and piston ......................................................................................4-31 removing the cylinder and piston ....................................................4-32 checking the cylinder and piston .....................................................4-33 chec...

Page 105: Eng

Eng checking the bearings ...........................................................................4-67 checking the timing chain guide .........................................................4-67 checking the timing chain .....................................................................4-67 ...

Page 106: Eng

Eng http://www.Motorcycle.In.Th.

Page 107: Eng

4-1 eng removing the engine easf0018 engine removing the engine note: it is not necessary to remove the engine in order to remove the following components. 9 cylinder head 9 cylinder 9 piston 9 clutch 9 shift shaft 9 oil pump 9 generator 9 starter clutch 1. Remove: 9 side cowlings (left and right) 9...

Page 108: Eng

4-2 eng removing the engine 1 2 2 1 muffler 1. Remove: 9 exhaust pipe nuts 1 9 exhaust pipe 2 2. Remove: 9 lower muffler bolt 1 9 washer 9 upper muffler bolt 2 9 washers 9 nut 9 muffler 3 brake pedal 1. Remove: 9 rear brake light switch spring 9 brake pedal spring 9 cotter pin 9 brake pedal shift pe...

Page 109: Eng

Eng removing the engine 1 2 1 2 2 1 3 1 side cowling bracket 1. Remove: 9 side cowling bracket bolts 1 9 side cowling bracket 2 wire, cable and hose 1. Disconnect: 9 neutral switch lead coupler 1 9 stator coil lead coupler 2 9 pick up coil lead coupler 3 9 crankcase breather pipe 2. Remove: 9 starte...

Page 110: Eng

4-4 eng removing the engine 6 0 q 9 engine assembly 1. Loosen: 9 rear lower mounting nut 1 9 plate nuts (front and rear) 2 9 front mounting nut 3 9 rear upper mounting nut 4 9 pivot shaft nut 5 2. Remove: 9 rear lower mounting nut 1 9 washer 9 rear lower mounting bolt 6 9 plate nuts (front and rear)...

Page 111: Eng

4-5 eng installing the engine easf0019 installing the engine engine assembly w securely support the vehicle so there is no danger of it falling over when installing engine. 1. Install: 9 engine assembly 9 pivot shaft 1 9 washer 9 pivot shaft nut 9 rear upper mounting bolt 2 9 washer 9 rear upper mou...

Page 112: Eng

Muffler 1. Install: 9 muffler 9 washers 9 nut 9 upper muffler bolt 9 washer 9 lower muffler bolt 2. Install: 9 exhaust pipe nuts 4-6 eng installing the engine brake pedal 1. Install: 9 brake pedal 9 circlip 9 brake pedal spring 9 rear brake light switch spring wire, cable and hose 1. Connect: 9 star...

Page 113: Eng

4-7 eng installing the engine 1 carburetor 1. Install: 9 carburetor assembly refer to “carburetor” in chapter 6. 2. Adjust: 9 throttle cable free play 9 rear brake light operation timing refer to “adjusting the throttle cable free play” and “adjusting the rear brake lightswitch” in chapter 3. Footre...

Page 114: Eng

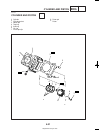

4-8 eng cylinder head 3 8 2 6 5 7 9 0 1 10 nm (1.0 m•kg, 7.2 ft•lb ) 10 nm (1.0 m•kg, 7.2 ft•lb ) 10 nm (1.0 m•kg, 7.2 ft•lb ) 10 nm (1.0 m•kg, 7.2 ft•lb ) 13 nm (1.3 m•kg, 9.5 ft•lb ) 22 nm (2.2 m•kg, 16 ft•lb ) 30 nm (3.0 m•kg, 22 ft•lb ) 10 nm (1.0 m•kg,7.2 ft•lb ) ls e e easf0023 cylinder head 1...

Page 115: Eng

4-9 eng cylinder head eas00222 removing the cylinder head 1. Remove 9 side cowlings (left and right) 9 front cowling 9 center panels (upper and lower) 9 rear cowlings (left and right) refer to “covers” in chapter 3. 9 carburetor assembly refer to “carburetor” in chapter 6. 9 muffler refer to “removi...

Page 116: Eng

4-10 eng cylinder head a b c d 1 2 1 1 2 3 6. Align: 9 “i” mark a on the generator rotor (with the stationary pointer b on the crankcase) ✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭ a. Turn the crankshaft counterclockwise. B. When the piston is at tdc on the compres- sion stroke, align the “i” mark c on the camshaft s...

Page 117: Eng

4-11 eng cylinder head 3 6 5 4 2 1 2 3 1 10. Remove: 9 engine mount nut 9 washer 9 engine mount bolt 9 cylinder head bolts 9 cylinder head bolts 9 washers 9 cylinder head note: 9 loosen the nuts in the proper sequence as shown. 9 loosen each nut 1/2 of a turn at a time. After all of the nuts are ful...

Page 118: Eng

4-12 eng cylinder head 3. Measure: 9 cylinder head warpage out of specification → resurface the cylin- der head. ✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭ a. Place a straightedge 1 and a thickness gauge 2 across the cylinder head. B. Measure the warpage. C. If the limit is exceeded, resurface the cylin- der head as ...

Page 119: Eng

4-13 eng cylinder head 1 3 1 2 eas00210 checking the timing chain tensioner 1. Check: 9 timing chain tensioner cracks/damage → replace. ✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭ a. While lightly pressing the timing chain ten- sioner rod by hand, turn the tensioner rod fully clockwise with a thin screwdriver 1 . B. R...

Page 120: Eng

4-14 eng cylinder head 4 1 2 3 5 6 1 2 a b c d 3. Tighten: 9 cylinder head bolts 9 cylinder head bolts 9 engine mount nut note: 9 lubricate the cylinder head bolts with engine oil. 9 tighten the cylinder head bolts in the proper tightening sequence as shown and torque them in two stages. 4. Install:...

Page 121: Eng

4-15 eng cylinder head 1 2 5. Install: 9 timing chain tensioner ✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭ a. While lightly pressing the timing chain ten- sioner rod by hand, turn the tensioner rod fully clockwise with a thin screwdriver 1 . Note: make sure that the tensioner rod has been fully set clockwise. B. Inst...

Page 122: Eng

4-16 eng cylinder head a b c d 8. Check: 9 “i”mark a align the “i” mark on the generator rotor with the stationary pointer b on the crankcase. 9 “i”mark c align the “i”mark on the camshaft sprocket with the stationary pointer d on the cylinder head. Out of alignment → correct. Refer to the installat...

Page 123: Eng

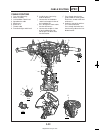

Eng 1 26 5 5 4 3 1 2 6 e e e 7 nm (0.7 m•kg, 5.0 ft•lb ) 7 nm (0.7 m•kg, 5.0 ft•lb ) ls e 4-17 camshaft easf0020 camshaft 1 locknut 2 adjusting screw 3 camshaft retainer 4 camshaft 5 rocker arm shaft 6 rocker arm http://www.Motorcycle.In.Th.

Page 124: Eng

4-18 eng camshaft 1 2 1 1 2 easf0022 removing the rocker arms and camshaft note: prior to remove the rocker arms and camshaft, remove the cylinder head. 1. Loosen: 9 locknuts 1 9 adjusting screws 2 2. Remove: 9 camshaft retainer 1 3. Remove: 9 camshaft 1 note: screw an 8 mm bolt 2 into the threaded ...

Page 125: Eng

Eng 4-19 camshaft eas00205 checking the camshaft 1. Check: 9 camshaft lobes blue discoloration/pitting/scratches → replace the camshaft. 2. Measure: 9 camshaft lobe dimensions a and b out of specification → replace the camshaft. 3. Check: 9 camshaft oil passage obstructions → blow out with compresse...

Page 126: Eng

4-20 eng camshaft 2. Check: 9 rocker arm shaft blue discoloration/excessive wear/pitting/ scratches → replace or check the lubrica- tion system. 3. Measure: 9 rocker arm inside diameter out of specification → replace. 4. Measure: 9 rocker arm shaft outside diameter out of specification → replace. 5....

Page 127: Eng

4-21 eng camshaft eas00207 checking the camshaft sprocket 1. Check: 9 camshaft sprocket worn more than 1/4 tooth a → replace the camshaft sprocket and the timing chain as a set. A 1/4 tooth b correct 1 timing chain 2 camshaft sprocket a 1 eas00219 installing the camshaft and rocker arms 1. Lubricate...

Page 128: Eng

4-22 eng valves and valve springs 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5 6 6 7 7 easf0024 valves and valve springs 1 valve cotter 2 upper spring seat 3 valve spring 4 valve stem seal 5 lower spring seat 6 intake valve 7 exhaust valve http://www.Motorcycle.In.Th.

Page 129: Eng

4-23 eng valves and valve springs easf0025 removing the valves note: prior to remove the valves, remove the cylinder head, camshaft and rocker arms. The following procedure applies to all of the valves and related components. Note: before removing the internal parts of the cylin- der head (e.G., val...

Page 130: Eng

4-24 eng valves and valve springs 1 2 2. Remove: 9 valve cotters 1 note: remove the valve cotters by compressing the valve spring with the valve spring compressor 2 . 3. Remove: 9 upper spring seat 1 9 valve spring 2 9 valve stem seal 3 9 lower spring seat 4 9 valve 5 note: identify the position of ...

Page 131: Eng

4-15 eng cylinder head 1 2 5. Install: 9 timing chain tensioner ✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭ a. While lightly pressing the timing chain ten- sioner rod by hand, turn the tensioner rod fully clockwise with a thin screwdriver 1 . Note: make sure that the tensioner rod has been fully set clockwise. B. Inst...

Page 132: Eng

4-16 eng cylinder head a b c d 8. Check: 9 “i”mark a align the “i” mark on the generator rotor with the stationary pointer b on the crankcase. 9 “i”mark c align the “i”mark on the camshaft sprocket with the stationary pointer d on the cylinder head. Out of alignment → correct. Refer to the installat...

Page 133: Eng

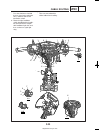

Eng 1 26 5 5 4 3 1 2 6 e e e 7 nm (0.7 m•kg, 5.0 ft•lb ) 7 nm (0.7 m•kg, 5.0 ft•lb ) ls e 4-17 camshaft easf0020 camshaft 1 locknut 2 adjusting screw 3 camshaft retainer 4 camshaft 5 rocker arm shaft 6 rocker arm http://www.Motorcycle.In.Th.

Page 134: Eng

4-18 eng camshaft 1 2 1 1 2 easf0022 removing the rocker arms and camshaft note: prior to remove the rocker arms and camshaft, remove the cylinder head. 1. Loosen: 9 locknuts 1 9 adjusting screws 2 2. Remove: 9 camshaft retainer 1 3. Remove: 9 camshaft 1 note: screw an 8 mm bolt 2 into the threaded ...

Page 135: Eng

Eng 4-19 camshaft eas00205 checking the camshaft 1. Check: 9 camshaft lobes blue discoloration/pitting/scratches → replace the camshaft. 2. Measure: 9 camshaft lobe dimensions a and b out of specification → replace the camshaft. 3. Check: 9 camshaft oil passage obstructions → blow out with compresse...

Page 136: Eng

4-20 eng camshaft 2. Check: 9 rocker arm shaft blue discoloration/excessive wear/pitting/ scratches → replace or check the lubrica- tion system. 3. Measure: 9 rocker arm inside diameter out of specification → replace. 4. Measure: 9 rocker arm shaft outside diameter out of specification → replace. 5....

Page 137: Eng

4-21 eng camshaft eas00207 checking the camshaft sprocket 1. Check: 9 camshaft sprocket worn more than 1/4 tooth a → replace the camshaft sprocket and the timing chain as a set. A 1/4 tooth b correct 1 timing chain 2 camshaft sprocket a 1 eas00219 installing the camshaft and rocker arms 1. Lubricate...

Page 138: Eng

4-22 eng valves and valve springs 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5 6 6 7 7 easf0024 valves and valve springs 1 valve cotter 2 upper spring seat 3 valve spring 4 valve stem seal 5 lower spring seat 6 intake valve 7 exhaust valve http://www.Motorcycle.In.Th.

Page 139: Eng

4-23 eng valves and valve springs easf0025 removing the valves note: prior to remove the valves, remove the cylinder head, camshaft and rocker arms. The following procedure applies to all of the valves and related components. Note: before removing the internal parts of the cylin- der head (e.G., val...

Page 140: Eng

4-24 eng valves and valve springs 1 2 2. Remove: 9 valve cotters 1 note: remove the valve cotters by compressing the valve spring with the valve spring compressor 2 . 3. Remove: 9 upper spring seat 1 9 valve spring 2 9 valve stem seal 3 9 lower spring seat 4 9 valve 5 note: identify the position of ...

Page 141: Eng

4-25 eng valves and valve springs 2. Replace: 9 valve guide note: to ease valve guide removal and installation, and to maintain the correct fit, heat the cylinder head to 100 ° c in an oven. ✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭ a. Remove the valve guide with the valve guide remover 1 . B. Install the new valve ...

Page 142: Eng

4-26 eng valves and valve springs 6. Measure: 9 valve stem runout out of specification → replace the valve. Note: 9 when installing a new valve, always replace the valve guide. 9 if the valve is removed or replaced, always replace the valve stem seal. Eas00240 checking the valve seats the following ...

Page 143: Eng

4-27 eng valves and valve springs m note: where the valve seat and valve face contacted one another, the blueing will have been removed. ✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬ 4. Lap: 9 valve face 9 valve seat note: after replacing the cylinder head or replacing the valve and valve guide, the valve seat and valve...

Page 144: Eng

4-28 eng valves and valve springs j. Measure the valve seat width c again. If the valve seat width is out of specification, reface and lap the valve seat. ✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬ eas00241 checking the valve springs the following procedure applies to all of the valve springs. 1. Measure: 9 valve spr...

Page 145: Eng

4-29 eng valves and valve springs m eas00245 installing the valves the following procedure applies to all of the valves and related components. 1. Deburr: 9 valve stem end (with an oil stone) 2. Lubricate: 9 valve stem 1 9 valve stem seal 2 (with the recommended lubricant) 3. Install: 9 valve 1 9 lo...

Page 146: Eng

4-30 eng valves and valve springs 1 2 4. Install: 9 valve cotters 1 note: install the valve cotters by compressing the valve spring with the valve spring compressor 2 5. To secure the valve cotters onto the valve stem, lightly tap the valve tip with a soft- face hammer. C c hitting the valve tip wit...

Page 147: Eng

Eng cylinder and piston e 4 5 6 7 9 8 3 3 2 1 e 7 e easf0027 cylinder and piston 1 cylinder 2 cylinder gasket 3 dowel pin 4 top ring 5 2nd ring 6 oil ring 7 piston pin clip 8 piston pin 9 piston 4-31 http://www.Motorcycle.In.Th.

Page 148: Eng

4-32 eng cylinder and piston 1 1 2 2 1 3 easf0028 removing the cylinder and piston note: prior to removing the cylinder and piston, remove the cylinder head. 1. Remove: 9 cylinder 1 2. Remove: 9 dowel pins 1 9 gasket 2 3. Remove: 9 piston pin clip 1 9 piston pin 2 9 piston 3 c c do not use a hammer ...

Page 149: Eng

4-33 eng cylinder and piston eas00255 checking the cylinder and piston 1. Check: 9 piston surface 9 cylinder wall vertical scratches → replace the cylinder, and replace the piston and piston rings as a set. 2. Measure: 9 piston-to-cylinder clearance ✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭ a. Measure cylinder bore ...

Page 150: Eng

4-34 eng cylinder and piston f. If out of specification, replace the cylinder, and replace the piston and piston rings as a set. ✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬ eas00263 checking the piston rings 1. Measure: 9 piston ring side clearance out of specification → replace the piston and piston rings as a set. N...

Page 151: Eng

4-35 eng cylinder and piston 3. Measure: 9 piston ring end gap out of specification → replace the piston ring. Note: the end gap of the oil ring expander cannot be measured. If the end gaps of the oil ring rails are excessive, replace all three piston rings. Eas00265 checking the piston pin 1. Check...

Page 152: Eng

4-36 eng cylinder and piston 1 2 3 5 4 1 2 5 3 4 1 3 2 a 4. Calculate: 9 piston-pin-to-piston-pin-bore clearance out of specification → replace the piston pin and piston as a set. Eas00267 installing the piston and cylinder 1. Install: 9 top ring 1 9 2nd ring 2 9 oil ring expander 3 9 lower oil ring...

Page 153: Eng

4-37 eng cylinder and piston 2 1 1 3. Install: 9 gasket 1 9 dowel pins 2 4. Lubricate: 9 piston 9 piston rings 9 cylinder (with the recommended lubricant) note: be sure to apply enough engine oil onto them. 5. Offset: 9 piston ring end gaps a top ring b lower oil ring rail c upper oil ring rail d 2n...

Page 154: Eng

4-38 eng generator and starter clutch t135s 1 8 9 5 2 3 4 7 e w r q 0 6 14 nm (1.4 m•kg, 20 ft•lb ) 70 nm (7.0 m•kg, 50 ft•lb ) 10 nm (1.0 m•kg, 7.2 ft•lb ) 14 nm (1.4 m•kg, 20 ft•lb ) e t135se easf0034 generator and starter clutch 1 starter clutch gear 2 starter clutch roller 3 starter clutch sprin...

Page 155: Eng

4-39 eng generator and starter clutch 2 1 1 3 1 2 eas00346 removing the generator 1. Drain: 9 engine oil (completely from the crankcase) refer to “changing the engine oil” in chapter 3. 2. Remove: 9 side cowling (left) refer to “removing the side cowl- ings” in chapter 3. 9 shift pedal 9 drive sproc...

Page 156: Eng

4-40 eng generator and starter clutch 2 1 2 1 3 6. Remove: 9 generator rotor 1 (with the flywheel puller 2 ) 9 woodruff key eas00344 removing the starter clutch (t135se) 1. Remove: 9 starter clutch idle gear shaft 1 9 starter clutch idle gear 2 9 starter clutch gear 3 9 washer 2. Remove: 9 starter c...

Page 157: Eng

4-41 eng generator and starter clutch 2 1 a eas00351 checking the starter clutch (t135se) 1. Check: 9 starter clutch rollers 1 damage/wear → replace. 2. Check: 9 starter clutch idle gear 1 9 starter clutch gear 2 burrs/chips/roughness/wear → replace the defective part(s). 3. Check: 9 starter clutch ...

Page 158: Eng

4-42 eng generator and starter clutch 3 1 2 eas00355 installing the starter clutch (t135se) 1. Install: 9 starter clutch 1 note: 9 while holding the generator rotor 2 with the sheave holder, tighten the starter clutch bolt. 9 do not allow the sheave holder to touch the projection on the generator ro...

Page 159: Eng

4. Apply: 9 sealant note: be sure to apply the sealant onto the crankcase cover bolt thread as shown one. 5. Install: 9 gasket 9 crankcase cover 4-43 eng generator and starter clutch 3. Apply: 9 sealant (on to the generator lead grommet) yamaha bond no. 1215 90890-85505 yamaha bond no. 1215 90890-85...

Page 160: Eng

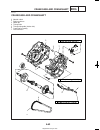

Eng 5 7 6 0 9 8 4 3 2 1 10 nm (1.0 m•kg, 7.2 ft•lb ) 10 nm (1.0 m•kg, 7.2 ft•lb ) 32 nm (3.2 m•kg, 23 ft•lb ) 7 nm (0.7 m•kg, 5.0 ft•lb ) 4-44 oilpump 1 oil drain bolt 2 o-ring 3 spring 4 oil strainer 5 oil filter cover 6 o-ring 7 oil filter 8 gear cover 9 oil pump assembly 0 gasket easf0035 oilpump...

Page 161: Eng

Eng 1 1 2 3 4 5 6 4-45 oilpump removing the oilpump 1. Drain: 9 engine oil (completely from the crankcase) refer to “changing the engine oil” in chapter 3. 2. Remove: 9 generator refer to “generator and starter clutch”. 3. Remove: 9 clutch release shift arm 4. Remove: 9 gear cover 5. Remove: 9 oil p...

Page 162: Eng

Eng 1 2 3 4 4-46 oilpump eas00364 checking the oilpump 1. Check: 9 oil pump driven gear 1 9 oil pump housing 2 9 outer rotor 9 inner rotor cracks/damage/wear → replace the defec- tive part(s). 2. Measure: 9 inner-rotor-to-outer-rotor-tip clearance a 9 outer-rotor-to-oil-pump-housing clearance b 9 oi...

Page 163: Eng

Eng 1 2 a 4 3 4-47 oilpump eas00375 assembling the oilpump 1. Lubricate: 9 inner rotor 9 outer rotor 9 oil pump shaft (with the recommended lubricant) 2. Install: 9 oil pump shaft (to the oil pump housing) 9 inner rotor 1 9 outer rotor 9 pin 2 9 oil pump housing cover 3 9 screw 4 note: when installi...

Page 164: Eng

Eng 4-48 oilpump 1 a eas00376 installing the oilpump 1. Install: 9 gasket 1 9 oil pump assembly note: install the gasket with section a in the position as shown in the illustration. C c after tightening the bolts, make sure the oil pump turns smoothly. 7 nm (0.7 m•kg, 5.0 ft•lb) http://www.Motorcycl...

Page 165: Eng

4-49 eng 3 4 5 1 2 7 8 q 0 9 w e r t a p o i u y 70 nm (7.0 m•kg, 50 ft•lb ) 12 nm (1.2 m•kg, 9.0 ft•lb ) 8 nm (0.8 m•kg, 6 ft•lb ) 50 nm (5.0 m•kg, 36 ft•lb ) e e e e e 6 clutch easf0029 clutch 1 clutch pressure plate bolt 2 clutch spring 3 clutch pressure plate 4 friction plate #1 5 clutch plate 6...

Page 166: Eng

Eng 1 1 1 2 1 2 4 5 6 3 4-50 clutch eas00277 removing the clutch 1. Drain: 9 engine oil (completely from the crankcase) refer to “changing the engine oil” in chapter 3. 2. Remove: 9 side cowlings (left and right) refer to “removing the side cowl- ings” in chapter 3. 9 muffler 9 footrest 9 brake peda...

Page 167: Eng

Eng 2 1 3 1 2 3 4 5 6 7 1 3 2 4-51 clutch 7. Straighten the lock washer tab. 8. Loosen: 9 clutch boss nut 1 note: while holding the clutch boss 2 with the univer- sal clutch holder 3 , loosen the clutch boss nut. 9. Remove: 9 clutch boss nut 1 9 lock washer 2 9 clutch boss 3 9 washer 4 9 clutch hous...

Page 168: Eng

Eng 1 2 5 4 3 6 7 8 4-52 clutch 11. Remove: 9 collar 1 9 clutch shoe housing 2 9 washer 3 9 rollers 4 9 cage springs 5 9 cage 6 9 clutch shoe housing boss 7 9 clutch shoe 8 eas00280 checking the friction plates the following procedure applies to all of the fric- tion plates. 1. Check: 9 friction pla...

Page 169: Eng

Eng 4-53 clutch eas00282 checking the clutch springs the following procedure applies to all of the clutch springs. 1. Check: 9 clutch spring damage → replace the clutch springs as a set. 2. Measure: 9 clutch spring free length a out of specification → replace the clutch springs as a set. Eas00284 ch...

Page 170: Eng

Eng 4-54 clutch eas00286 checking the clutch pressure plate 1. Check: 9 clutch pressure plate cracks/damage → replace. Eas00288 checking the clutch push rods 1. Check: 9 clutch push rod #1 cracks/damage/wear → replace the clutch push rod #1. 9 clutch push rod #2 cracks/damage/wear → replace the clut...

Page 171: Eng

Eng a 1 2 1 2 4-55 clutch checking the clutch shoe housing 1. Check: 9 clutch shoe housing damage/wear → replace. 2. Measure: 9 clutch shoe housing inside diameter a out of specification → replace. Checking the clutch shoe 1. Check: 9 clutch shoe scratches → smooth using coarse sandpa- per. Damage/w...

Page 172: Eng

Eng 4-56 clutch 1 2 1 3 2 7 6 5 4 3 2 1 4 checking the clutch release shift arm 1. Check: 9 clutch release shift arm 1 damage/wear → replace. 9 clutch release adjusting screw 2 damage/wear → replace. Eas00293 installing the clutch 1. Install: 9 washer 9 cage 1 9 cage springs 2 9 rollers 3 9 clutch s...

Page 173: Eng

Eng 4-57 clutch 2 1 3 1 2 3 4 5 1 1 2 a b 4. Tighten: 9 clutch boss nut 1 note: while holding the clutch boss 2 with the univer- sal clutch holder 3 , tighten the clutch boss nut. 5. Bend the lock washer tab along a flat side of the nut. 6. Lubricate: 9 seat plate 9 cushion ring 9 friction plates #1...

Page 174: Eng

4-58 eng w r y u t e 0 q 8 9 8 7 6 5 3 2 4 1 12 nm (1.2 m•kg, 9.0 ft•lb ) 10 nm (1.0 m•kg, 7.2 ft•lb ) 18 nm (1.8 m•kg, 13 ft•lb ) e e e e ls shift shaft easf0032 shift shaft 1 shift pedal 2 washer 3 spring 4 shift fork guide bar 5 shift guide 6 pawl holder 7 guide 8 washer 9 thrust bearing 0 dowel ...

Page 175: Eng

Eng 4-59 shift shaft 1 2 2 1 3 4 2 1 removing the shift shaft 1. Drain: 9 engine oil (completely from the crankcase) refer to “changing the engine oil” in chapter 3. 2. Remove: 9 clutch refer to “clutch”. 3. Remove: 9 shift pedal 9 crankcase cover bolts 9 crankcase cover (left) 4. Remove: 9 shift fo...

Page 176: Eng

Eng 4-60 shift shaft 2 1 3 4 1 2 3 1 7. Remove: 9 shift shaft assembly 1 9 shift lever assembly 2 8. Remove: 9 stopper lever assembly 3 9 stopper lever spring 4 9 collar 9. Remove: 9 stopper lever spring 1 9 stopper lever 2 9 collar 3 10. Remove: 9 plate 9 shift drum segment 1 http://www.Motorcycle....

Page 177: Eng

Eng 1 2 1 1234 4-61 shift shaft eas00328 checking the shift shaft 1. Check: 9 shift shaft 1 9 shift lever 2 bends/damage/wear → replace. 9 springs damage/wear → replace. Eas00330 checking the stopper lever 1. Check: 9 stopper lever 1 bends/damage → replace. Roller turns roughly → replace. 9 stopper ...

Page 178: Eng

Eng 4-62 shift shaft 1 1 2 1 2 eas00331 installing the shift shaft 1. Install: 9 shift drum segment 1 9 plate note: apply locking agent (loctite r ) to the threads of shift drum segment screw. 2. Install: 9 collar 9 stopper lever 1 9 stopper lever spring 2 note: 9 apply locking agent (loctite r ) to...

Page 179: Eng

Eng 2 3 7 1 3 6 4 5 14 nm (1.4 m•kg, 20 ft•lb ) 10 nm (1.0 m•kg, 7.2 ft•lb ) e 4 nm (0.4 m•kg, 3.0 ft•lb ) 4-63 crankcase and crankshaft easf0037 crankcase and crankshaft 1 neutral switch 2 right crankcase 3 dowel pin 4 timing chain 5 timing chain guide (intake side) 6 crankshaft assembly 7 left cra...

Page 180: Eng

Eng 4-64 crankcase and crankshaft 1 2 3 eas00385 disassembling the crankcase 1. Remove: 9 engine refer to “removing the engine”. 2. Remove: 9 starter motor lead (t135se) 9 starter motor (t135se) refer to “starter motor (t135se)” in chapter 8. 3. Remove: 9 cylinder head refer to “cylinder head”. 9 cy...

Page 181: Eng

Eng 4-65 crankcase and crankshaft 5. Remove: 9 crankcase bolts note: loosen each bolt 1/4 of a turn at a time, in stages and in a crisscross pattern. After all of the bolts are fully loosened, remove them. 6. Remove: 9 right crankcase 9 dowel pins c c tap on one side of the crankcase with a soft- fa...

Page 182: Eng

Eng 4-66 crankcase and crankshaft 2. Measure: 9 big end side clearance out of specification → replace the crank- shaft. 3. Measure: 9 crankshaft width out of specification → replace the crank- shaft. 4. Check: 9 crankshaft sprocket 1 damage/wear → replace the crankshaft. 9 bearing 2 cracks/damage/we...

Page 183: Eng

Eng 4-67 crankcase and crankshaft eas00399 checking the crankcase 1. Thoroughly wash the crankcase halves in a mild solvent. 2. Thoroughly clean all the gasket surfaces and crankcase mating surfaces. 3. Check: 9 crankcase cracks/damage → replace. 9 oil delivery passages obstructions → blow out with ...

Page 184: Eng

Eng 1 2 3 4 5 2 2 1 4-68 crankcase and crankshaft eas00408 installing the crankshaft 1. Install: 9 crankshaft assembly 1 note: use the crankshaft installing tool (spacer 2 , installer pot 3 , installer bolt 4 , adaptor 5 ) to install the crankcase (left). C c to avoid scratching the crankshaft and t...

Page 185: Eng

Eng 4-69 crankcase and crankshaft 4. Install: 9 neutral switch 9 crankcase bolts 5. Apply: 9 engine oil (onto the crankshaft bearings and oil deliv- ery holes) 6. Check: 9 crankshaft and transmission operation rough movement → repair. 7. Install: 9 timing chain 9 timing chain guide (intake side) 9 t...

Page 186: Eng

Eng 1 3 2 4 w 5 6 e q 8 9 0 7 12 nm (1.2 m•kg, 9.0 ft•lb ) m 50 nm (5.0 m•kg, 36 ft•lb ) 4-70 1 oil level plug 2 kickstarter lever 3 crankcase cover (right) 4 gasket 5 washer 6 kickstarter gear 7 guide stopper 8 collar 9 kickstarter spring 0 washer q spring w kickstarter ratchet gear e kickstarter s...

Page 187: Eng

Eng 4-71 1 2 3 kickstarter removing the kickstarter 1. Drain: 9 engine oil (completely from the crankcase) refer to “changing the engine oil” in chapter 3. 9 coolant (completely from the water jacket) refer to “changing the coolant” in chapter 3. 2. Remove: 9 side cowlings (left and right) 9 front c...

Page 188: Eng

Eng kickstarter 4-72 6. Remove: 9 clutch refer to “clutch”. 9 shift shaft refer to “shiftshaft”. 9 oil pump assembly refer to “soilpump”. 9 generator 9 starter clutch refer to “generator and starter clutch. 7. Remove: 9 starter motor (t135se) refer to “starter motor” in chapter 8. 8. Remove: 9 engin...

Page 189: Eng

Eng 4-73 kickstarter 1 2 3 4 5 6 7 11. Remove: 9 washer 1 9 kickstarter gear 2 9 kickstarter spring 3 9 collar 4 9 washer 5 9 spring 6 9 kickstarter ratchet gear 7 9 kickstarter shaft eas00339 checking the kickstarter 1. Check: 9 kickstarter ratchet gear 1 9 kickstarter gear 2 damage/wear → replace....

Page 190: Eng

Eng 4-74 90 ˚ 1 2 a b 4 3 kickstarter installing the kickstarter 1. Install: 9 kickstarter ratchet gear 1 (on to the kickstarter shaft) 9 kickstarter shaft 2 9 kickstarter spring note: 9 offset the kickstarter ratchet gear as shown, and then align the spline to install the kick- starter ratchet gear...

Page 191: Eng

Eng kickstarter 4-75 9. Install: 9 piston 9 cylinder refer to “cylinder and piston”. 9 cylinder head refer to “cylinder head”. 9 radiator assembly refer to “radiator” in chapter 5. 9 cylinder head refer to “cylinder head”. 10. Install: 9 muffler 9 footrest 9 brake pedal refer to “removing the engine...

Page 192: Eng

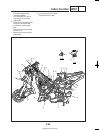

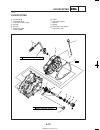

Eng 4-76 transmission 9 0 q y r t e w 8 7 6 6 4 1 2 3 m m m m e e e e easf0041 transmission 1 shift fork guide bar 2 shift fork “r” 3 shift fork “l” 4 shift drum 5 2nd pinion gear 6 3rd pinion gear 7 4th pinion gear 8 main axle/1st pinion gear 9 1st wheel gear 0 4th wheel gear q 3rd wheel gear w 2nd...

Page 193: Eng

Eng 4-77 transmission 4 2 3 1 1 2 1 2 3 4 4 5 6 7 easf0042 removing the transmission note: prior to removing the transmission, separate the crankcase. 1. Remove: 9 shift fork guide bar 1 9 shift fork guide bar springs 9 shift fork “r” 2 9 shift fork “l” 3 9 shift drum 4 note: note the position of ea...

Page 194: Eng

Eng 4-78 transmission 1 2 1 2 1 3 4 5 6 7 8 9 2. Remove: 9 circlips 1 9 washers 2 9 1st wheel gear 3 9 4th wheel gear 4 9 3rd wheel gear 5 9 side plate 6 9 side plate spring 7 9 2nd wheel gear 8 9 drive axle 9 eas00421 checking the shift forks the following procedure applies to both of the shift for...

Page 195: Eng

Eng 1 4-79 transmission eas00422 checking the shift drum assembly 1. Check: 9 shift drum grooves 1 damage/scratches/wear → replace the shift drum assembly. 9 shift drum bearing damage/pitting → replace the shift drum assembly. Eas00424 checking the transmission 1. Measure: 9 main axle runout (with a...

Page 196: Eng

Eng 4-80 transmission 21.1~21.3 mm 1 2 4 2 3 1 4. Check: 9 transmission gear engagement (each pinion gear to its respective wheel gear) incorrect → reassemble the transmission axle assemblies. Note: when reassembling the drive axle, press the 2nd wheel gear 1 onto the drive axle 2 as shown. 5. Check...

Page 197: Eng

Eng 4-81 transmission 2. Check: 9 transmission 9 shift drum 9 shift forks rough movement → repair. Note: 9 oil each gear, shaft, and bearing thoroughly. 9 before assembling the crankcase, be sure that the transmission is in neutral and that the gears turn freely. Http://www.Motorcycle.In.Th.

Page 198: Eng

Eng http://www.Motorcycle.In.Th.

Page 199: Cool

Cool chapter 5 coolingsystem radiator ............................................................................................................5-1 water pump.......................................................................................................5-2 removing the radiator ..............

Page 200: Cool

Cool http://www.Motorcycle.In.Th.

Page 201: Cool

5-1 cool cooling system eas00454 cooling system radiator 0 3 1 9 5 2 7 6 8 4 10 nm (1.0 m•kg, 7.2 ft•lb ) 10 nm (1.0 m•kg, 7.2 ft•lb ) 10 nm (1.0 m•kg, 7.2 ft•lb ) 1 radiator cap 2 bracket 3 water pump inlet hose 4 radiator outlet hose 5 radiator inlet hose 6 bracket 7 thermostat housing cover 8 the...

Page 202: Cool

5-2 cool cooling system eas00468 water pump 5 7 8 6 0 q 1 9 2 4 3 ls ls ls 10 nm (1.0 m•kg, 7.2 ft•lb ) 10 nm (1.0 m•kg, 7.2 ft•lb ) 1 o-ring 2 o-ring 3 water pump cover 4 gasket 5 plate 6 impeller 7 plate 8 housing cover gasket 9 bearing 0 water pump seal q water pump housing http://www.Motorcycle....

Page 203: Cool

5-3 cool cooling system removing the radiator w ahot radiator is under pressure. Therefore,do not remove the radiator cap when the engine is hot. Scalding hot fluid and steam may be blown out, which could cause serious injury. When the engine has cooled, open the radiator cap as fol- lows: place a t...

Page 204: Cool

5-4 cool coolingsystem 1 2 5. Remove: 9 bracket 9 thermostat cover 1 9 thermostat 2 6. Remove: 9 fan motor eas00455 checking the radiator 1. Check: 9 radiator fins obstruction → clean. Apply compressed air to the rear of the radi- ator. Damage → repair or replace. Note: straighten any flattened fins...

Page 205: Cool

5-5 cool cooling system 3. Measure: 9 radiator cap opening pressure below the specified pressure → replace the radiator cap. ✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭ a. Install the radiator cap tester 1 and radiator cap tester adapter 2 to the radiator cap 3 . B. Apply the specified pressure for ten seconds and mak...

Page 206: Cool

5-6 cool coolingsystem eas00462 checking the thermostat 1. Check: 9 thermostat 1 does not open at 80.5 – 83.5° c (176.9 – 182.3° f) → replace. ✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭ a. Suspend the thermostat in a container filled with water. B. Slowly heat the water. C. Place a thermometer in the water. D. While ...

Page 207: Cool

5-7 cool cooling system 2 1 4 3 3. Remove: 9 impeller 1 9 bearing 2 note: remove the bearing from the outside of the water pump housing. 3 water pump housing eas00473 checking the water pump 1. Check: 9 water pump housing cover 9 water pump housing 9 impeller 9 rubber damper 9 rubber damper holder 9...

Page 208: Cool

Eas00467 installing the thermostat 1. Install: 9 thermostat 1 9 thermostat cover 2 9 bracket note: face the hole toward to the forward to install. 5-8 cool coolingsystem 2 1 fwd 10 nm (1.0 m•kg, 7.2 ft•lb) eas00475 assembling the water pump 1. Install: 9 water pump seal 1 note: install the water pum...

Page 209: Cool

Eas00456 installing the radiator 1. Install: 9 radiator assembly 2. Connect: 9 fan motor coupler 9 radiator outlet pipe 9 radiator outlet hose 9 radiator inlet hose 3. Fill: 9 cooling system (with the specified amount of the recom- mended coolant) refer to “changing the coolant“ in chapter 3. 5-9 co...

Page 210: Cool

5-10 cool coolingsystem 4. Check: 9 cooling system leaks → repair or replace any faulty part. ✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭ a. Attach the radiator cap tester 1 to the radi- ator. B. Apply 100 kpa (1.0 kg/cm 2 , 14.22 psi) of pressure. C. Measure the indicated pressure with the gauge. ✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬...

Page 211: Carb

Carb chapter 6 carburetor carburetor......................................................................................................6-1 removing the carburetor.....................................................................6-2 disassembling the carburetor.....................................

Page 212: Carb

Carb http://www.Motorcycle.In.Th.

Page 213: Carb

Carb carburetor 6-1 easf0043 carburetor carburetor t 1 4 5 3 2 6 7 0 9 q 8 e w r y u 1 coasting enricher assembly 2 carburetor top cover 3 throttle valve spring 4 needle set 5 throttle valve 6 throttle stop screw set 7 pilot air screw set 8 needle jet 9 main jet 0 needle valve assembly q float w flo...

Page 214: Carb

Carb carburetor 6-2 removing the carburetor w gasoline is highly flammable. Avoid spilling fuel on the hot engine. 1. Remove: 9 battery 9 seat assembly with battery box 2. Remove: 9 starter relay 1 (t135se) 3. Remove: 9 positive lead 1 (from the battery box) 1 1 4. Remove: 9 negative lead (from the ...

Page 215: Carb

Carb carburetor 6-3 6. Loosen: 9 fuel drain screw 1 7. Drain: 9 fuel (from float chamber) 1 1 2 3 2 1 8. Loosen: 9 clamp screw 9 air filter assembly bolt 9. Remove: 9 carburetor top cover 1 9 o-ring 9 choke cable 2 9 accelerator pump cable 3 10. Remove: 9 throttle valve assembly 1 9 throttle valve s...

Page 216: Carb

Carb carburetor 6-4 12. Remove: 9 carburetor assembly note: use the ball point hexagon wrench to loosen the bolts. 2 3 1 5 4 14. Remove: 9 carburetor assembly 13. Disconnect: 9 fuel hose 1 9 carburetor overflow hose 2 9 vacuum sensing hose 3 9 air vent hose 4 9 vacuum sensing hose 5 1 2 15. Remove: ...

Page 217: Carb

Carb carburetor 6-5 1 1 1. Remove: 9 coasting enricher assembly 9 o-ring 2. Remove: 9 pilot air screw set 1 3. Remove: 9 throttle stop screw set 1 disassembling the carburetor note: the following parts can be cleaned and inspect- ed without disassembly. 9 coasting enricher 9 throttle stop screw 9 pi...

Page 218: Carb

Carb carburetor 6-6 3. Check: 9 float chamber body dirt → clean. 4. Check: 9 float chamber rubber gasket cracks/damage/wear → replace. 1 2 3 5. Remove: 9 main jet 1 9 needle jet 2 9 pilot jet 3 3 1 2 6. Remove: 9 float pivot pin 1 9 float 2 9 needle valve 3 eas00485 checking the carburetor 1. Check:...

Page 219: Carb

Carb carburetor 6-7 1 1 2 3 4 5 6 6. Check: 9 needle valve damage/wear → replace. 7. Check: 9 coasting enricher assembly 1 cracks/damage → replace. 8. Check: 9 jet needle 1 9 needle jet 2 9 main jet 3 9 pilot jet 4 9 pilot air screw 5 9 throttle stop screw 6 bends/damage/wear → replace. Obstruction ...

Page 220: Carb

Carb carburetor 6-8 10. Check: 9 accelerator pump stuck or unsmooth operation → replace the float chamber. 11. Check: 9 air vent hose 9 fuel hoses cracks/damage/wear → replace. Obstructions → clean. Blow out the hoses with compressed air. Http://www.Motorcycle.In.Th.

Page 221: Carb

Carb carburetor 6-9 eas00487 assembling the carburetor c c 9 9 before assembling the carburetor, wash all of the parts in a petroleum-based solvent. 9 9 always use a new gasket and new o-rings. 1. Measure: 9 float height a out of specification → adjust. ✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭ a. Hold the carbureto...

Page 222: Carb

Carb carburetor 6-10 2 1 2 3 1 5 4 a b 3 2 1 eas00492 installing the carburetor 1. Install: 9 needle set 2. Install: 9 joint 1 9 intake manifold 2 3. Connect: 9 fuel hose 1 9 carburetor overflow hose 2 9 vacuum sensing hose 3 9 air vent hose 4 9 vacuum sensing hose 5 4. Install: 9 carburetor assembl...

Page 223: Carb

Carb carburetor 6-11 eas00916 checking and adjusting the throttle position sensor note: 9 before adjusting the throttle position sensor, the engine idling speed should be properly adjusted. 9 be sure to adjust the angle when removed the throttle position sensor. 1. Check: 9 throttle position sensor ...

Page 224: Carb

Carb carburetor 6-12 c. Connect the pocket tester (dc20v) to the terminals of the throttle position sensor. ✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬✬ 2. Adjust: 9 throttle position sensor angle ✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭ a. Connect the digital circuit tester to the throt- tle position sensor 1 . B. Measure the throttl...

Page 225: Carb

Carb carburetor 6-13 1 eas00506 checking the fuelcock opera- tion 1. Remove: 9 rear cowling (left) refer to “removing the rear cowl- ings” in chapter 3. 2. Place a container under the end of the fuel hose 1 . 1 3. Check: 9 fuel cock operation ✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭ a. Suck on the end of the vacuum...

Page 226: Carb

Carb air induction system 6-14 air induction system air injection the air induction system burns unburned exhaust gases by injecting fresh air (secondary air) into the exhaust port, reducing the emission of hydrocarbons. When there is negative pressure at the exhaust port, the reed valve opens, allo...

Page 227: Carb

Carb air induction system 6-15 air induction system diagrams 1 bend hose (air filter case to air cut-off valve) 2 air cut-off valve 3 ais resonator 4 vacuum sensing hose 1 2 3 4 http://www.Motorcycle.In.Th.

Page 228: Carb

Carb air induction system 6-16 checking the air induction sys- tem 1. Check: 9 hoses loose connections → connect properly. Cracks/damage → replace. 9 pipes cracks/damage → replace. 2. Check: 9 reed valve 9 reed valve stopper 9 reed valve seat cracks/damage → replace the reed valve. 3. Check: 9 air c...

Page 229: Chas

Chas chapter 7 chassis front wheeland brake disc.....................................................................7-1 removing the frontwheel....................................................................7-2 checking the frontwheel................................................................

Page 230: Chas

Chas rear shock absorber assemblyand swingarm................................7-49 removing the rear shock absorber assemblies and swingarm..............................................................................................7-50 checking the rear shock absorber assemblies.......................

Page 231: Chas

Chas 7-1 front wheeland brake disc easf0044 chassis front wheeland brake disc 1 23 nm (2.3 m•kg, 17 ft•lb ) ls ls 40 nm (4.0 m•kg, 29 ft•lb ) 2 3 4 5 6 5 7 1 front wheel axle 2 brake disc 3 spacer 4 oil seal 5 bearing 6 spacer 7 speedometer gear unit http://www.Motorcycle.In.Th.

Page 232: Chas

Chas front wheeland brake disc 7-2 1 3 2 1 2 3 eas00519 removing the front wheel 1. Stand the vehicle on a level surface. W securely support the vehicle so that there is no danger of it falling over. 2. Remove: 9 speedometer cable 1 9 axle nut 2 9 washer 3 3. Elevate: 9 front wheel note: place the v...

Page 233: Chas

Chas front wheeland brake disc 7-3 eas00526 checking the front wheel 1. Check: 9 wheel axle roll the wheel axle on a flat surface. Bends → replace. W do not attempt to straighten a bent wheel axle. 2. Check: 9 tire damage/wear → replace. Refer to “checking the tires” in chap- ter 3. 3. Check: 9 spok...

Page 234: Chas

Chas front wheeland brake disc 7-4 new 1 2 5. Check: 9 spacers damage/wear → replace. W 9 9 after mounting a new tire, ride conserva- tively for a while to become accustomed to the “feel” of the new tire and to allow the tire to seat itself properly in the rim. Failure to do so could lead to an acci...

Page 235: Chas

Chas front wheeland brake disc 7-5 d. Install the new wheel bearings and oil seals in the reverse order of disassembly. C c do not contact the wheel bearing inner race 4 4 or balls 5 5 . Contact should be made only with the outer race 6 6 . Note: use a socket 7 that matches the diameter of the wheel...

Page 236: Chas

Chas front wheeland brake disc 7-6 3. Measure: 9 brake disc thickness measure the brake disc thickness at a few different locations. Out of specification → replace. 4. Adjust: 9 brake disc deflection ✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭ a. Remove the brake disc. B. Rotate the brake disc by one bolt hole. C. Ins...

Page 237: Chas

Chas front wheeland brake disc 7-7 eas00542 installing the front wheel 1. Lubricate: 9 wheel axle 9 wheel bearings 9 oil seal lips 9 speedometer gear unit 2. Install: 9 brake disc 9 front wheel refer to “checking the brake disc”. Note: make sure the projection a on the speedometer gear unit fits bet...

Page 238: Chas

Chas rear wheeland brake 7-8 easf0049 rear wheeland brake ls ls 7 nm (0.7 m•kg, 5.0 ft•lb ) t 19 nm (1.9 m•kg, 14 ft•lb ) 16 nm (1.6 m•kg, 12 ft•lb ) 7 nm (0.7 m•kg, 5.0 ft•lb ) 60 nm (6.0 m•kg, 43ft•lb ) 30 nm (3.0 m•kg, 22 ft•lb ) 0 0 8 ls 4 7 y 9 1 3 2 5 6 q ls w e r ls 1 collar 2 brake camshaft ...

Page 239: Chas

Chas rear wheeland brake 7-9 1 4 3 2 1 2 1 2 eas00563 removing the rear wheel 1. Stand the vehicle on a level surface. W securely support the vehicle so that there is no danger of it falling over. Note: place the vehicle on a suitable stand so that the rear wheel is elevated. 2. Remove: 9 brake rod ...

Page 240: Chas

Chas rear wheeland brake 7-10 1 2 1 1 1 2 1 5. Remove: 9 rear wheel axle nut 1 9 washer 9 rear wheel axle 2 9 washer 9 collar 6. Remove: 9 rear wheel assembly 1 note: push the rear wheel forward and remove the drive chain from the driven sprocket. 7. Remove: 9 brake shoe plate assembly 1 8. Remove: ...

Page 241: Chas

Chas rear wheeland brake 7-11 1 1 1 3 2 1 10. Remove: 9 o-ring 9 rear wheel drive hub dampers 1 disassembling the brake shoe plate 1. Remove: 9 brake shoes 1 9 brake shoe springs 2 (48 mm, 1.89 in) 9 brake shoe springs 3 (52 mm, 2.01 in) 2. Remove: 9 brake camshaft lever nut 9 brake camshaft lever b...

Page 242: Chas

Chas rear wheeland brake 7-12 2. Check: 9 tire damage/wear → replace. Refer to “checking the tires” in chap- ter 3. 3. Measure: 9 radial wheel runout 9 lateral wheel runout refer to “frontwheeland brake disc”. Eas00567 checking the rear wheeldrive hub 1. Check: 9 rear wheel drive hub cracks/damage →...

Page 243: Chas

Chas rear wheeland brake 7-13 a eas00539 checking the brake the following procedure applies to all of the brake shoes. 1. Check: 9 brake shoe lining glazed areas → repair. Sand the glazed areas with course sandpa- per. Note: after sanding the glazed areas, clean the brake shoe with a cloth. 2. Measu...

Page 244: Chas

Chas rear wheeland brake 7-14 1 eas00570 assembling the brake shoe plate 1. Install: 9 brake camshaft 1 9 brake shoe wear indicator 2 9 brake camshaft lever ✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭✭ a. Install the brake camshaft so its punch mark a is positioned as shown. B. Align the projection b on the brake shoe ...

Page 245: Chas

Chas rear wheeland brake 7-15 4. Adjust: 9 drive chain slack refer to “adjusting the drive chain slack” in chapter 3. 5. Tighten: 9 wheel axle nut c c do not loosen the wheel axle nut after tight- ening it to the specified torque. Drive chain slack 25–35 mm (0.98–1.38 in) 60 nm (6.0 m·kg, 43 ft·lb) ...

Page 246: Chas

7-16 chas front brake front brake easf0052 front brake caliper 35 nm (3.5 m•kg, 25 ft•lb ) 3 2 ls 4 1 5 ls 6 nm (0.6 m•kg, 4.6 ft•lb ) 6 7 8 9 0 1 brake pad retaining pin 2 air bleed screw 3 brake caliper 4 brake caliper bracket 5 lower brake caliper retaining bolt 6 brake caliper piston 7 brake cal...

Page 247: Chas

Chas front brake 7-17 1 eas00579 c c disc brake components rarely require disas- sembly. Therefore, always follow these preventive measures: 9 9 never disassemble brake components unless absolutely necessary. 9 9 if any connection on the hydraulic brake system is disconnected, the entire brake syste...

Page 248: Chas

Chas front brake 7-18 1 a 1 2 2. Remove: 9 clips 9 brake pad retaining pin 9 brake pads 1 9 brake pad spring 3. Measure: 9 brake pad wear limit a out of specification → replace the brake pads as a set. 4. Install: 9 brake pad spring 9 brake pads note: always install new brake pads and a new brake pa...

Page 249: Chas

Chas front brake 7-19 a 5. Lubricate: 9 brake pad retaining pin c c 9 do not allow grease to contact the brake pads. 9 remove any excess grease. 6. Install: 9 brake caliper bolts 7. Check: 9 brake fluid level below the minimum level mark a → add the recommended brake fluid to the proper level. Refer...

Page 250: Chas

Chas front brake 7-20 1 2 1 1 2 3 1 1. Remove: 9 union bolt 1 9 copper washers 2 9 brake hose note: put the end of the brake hose into a container and pump out the brake fluid carefully. 2. Remove: 9 brake caliper 1 9 pin 9 brake pad retaining pin 9 brake pads 9 brake pad spring 3. Remove: 9 brake c...

Page 251: Chas

Chas front brake 7-21 1 2 3 1 eas00631 checking the front brake caliper recommended brake component replacement schedule brake pads if necessary piston seal every two years brake hose every four years every two years and brake fluid whenever the brake is disassembled 1. Check: 9 brake caliper piston...

Page 252: Chas

Chas front brake 7-22 3 2 a b 1 eas00634 assembling and installing the front brake caliper w 9 9 before installation, all internal brake com- ponents should be cleaned and lubricated with clean or new brake fluid. 9 9 never use solvents on internal brake com- ponents as they will cause the piston se...

Page 253: Chas