- DL manuals

- Yamaha

- Outboard Motor

- F-20B

- Owner's Manual

Yamaha F-20B Owner's Manual

Summary of F-20B

Page 1

Read this manual carefully before operating this outboard motor. Owner’s manual f9.9h f15c f20b 6ag-28199-79-e0 6ag-9-79-1e0.Book 1 ページ 2014年11月10日 月曜日 午後4時8分.

Page 2

Emu25053 read this manual carefully before operating this outboard motor. Keep this manual onboard in a waterproof bag when boating. This manual should stay with the outboard motor if it is sold. 6ag-9-79-1e0.Book 1 ページ 2014年11月10日 月曜日 午後4時8分.

Page 3: Important Manual Information

Important manual information emu25108 to the owner thank you for selecting a yamaha outboard motor. This owner’s manual contains infor- mation needed for proper operation, mainte- nance and care. A thorough understanding of these simple instructions will help you ob- tain maximum enjoyment from your...

Page 4: Important Manual Information

Important manual information emu25122 f9.9h, f15c, f20b owner’s manual © 2014 by yamaha motor co., ltd. 1st edition, november 2014 all rights reserved. Any reprinting or unauthorized use without the written permission of yamaha motor co., ltd. Is expressly prohibited. Printed in japan 6ag-9-79-1e0.B...

Page 5: Table of Contents

Table of contents safety information............................. 1 outboard motor safety ..................... 1 propeller .............................................. 1 rotating parts ...................................... 1 hot parts.............................................. 1 electric shoc...

Page 6: Table of Contents

Table of contents flushing device ................................. 25 alert indicator ................................... 25 instruments and indicators ............ 26 indicators ....................................... 26 low oil pressure-alert indicator ......... 26 overheat-alert indicator..........

Page 7: Table of Contents

Table of contents maintenance chart 1.......................... 61 maintenance chart 2.......................... 63 greasing............................................ 64 cleaning and adjusting spark plug .... 65 checking fuel filter............................. 66 inspecting idle speed...............

Page 8: Safety Information

1 safety information emu33623 outboard motor safety observe these precautions at all times. Emu36502 propeller people can be injured or killed if they come in contact with the propeller. The propeller can keep moving even when the motor is in neutral, and sharp edges of the propeller can cut even wh...

Page 9: Safety Information

Safety information 2 emu33821 gasoline exposure and spills take care not to spill gasoline. If gasoline spills, wipe it up immediately with dry rags. Dispose of rags properly. If any gasoline spills onto your skin, immedi- ately wash with soap and water. Change clothing if gasoline spills on it. If ...

Page 10: Safety Information

Safety information 3 emu33773 avoid collisions scan constantly for people, objects, and oth- er boats. Be alert for conditions that limit your visibility or block your vision of others. Operate defensively at safe speeds and keep a safe distance away from people, ob- jects, and other boats. Do not f...

Page 11: General Information

4 general information emu25172 identification numbers record emu25186 outboard motor serial number the outboard motor serial number is stamped on the label attached to the port side of the clamp bracket. Record your outboard motor serial number in the spaces provided to assist you in ordering spare ...

Page 12: General Information

General information 5 tions of the european parliament directive relating to machinery. Each conformed outboard motor accompa- nied with ec doc.Ec doc contains the fol- lowing information; name of engine manufacture model name product code of model (approved model code) code of conformed directives ...

Page 13: General Information

General information 6 emu33524 read manuals and labels before operating or working on this outboard motor: read this manual. Read any manuals supplied with the boat. Read all labels on the outboard motor and the boat. If you need any additional information, contact your yamaha dealer. Emu33834 warni...

Page 14: General Information

General information 7 emu33913 contents of labels the above warning labels mean as follows. 1 warning ewm01692 emergency starting does not have start- in-gear protection. Ensure shift control is in neutral before starting engine. 2 warning ewm01682 keep hands, hair, and clothing away from rotating p...

Page 15: General Information

General information 8 emu33844 symbols the following symbols mean as follows. Notice/warning read owner’s manual hazard caused by continuous rotation electrical hazard remote control lever/gear shift lever operat- ing direction, dual direction engine start/ engine cranking zmu05696 zmu05664 zmu05665...

Page 16: Specifications

9 specifications and requirements emu34522 specifications tip: “(al)” stated in the specification data below represents the numerical value for the alumi- num propeller installed. Likewise, “(sus)” represents the value for stainless steel propeller installed and “(pl)” for plastic propeller installe...

Page 17

Specifications and requirements 10 performance: full throttle operating range: 5000–6000 r/min rated power: f9.9he 7.3 kw (9.9 hp) f9.9hmh 7.3 kw (9.9 hp) rated power: f15ce 11.0 kw (15 hp) f15ceh 11.0 kw (15 hp) f15cep 11.0 kw (15 hp) f15cmh 11.0 kw (15 hp) f20be 14.7 kw (20 hp) f20beh 14.7 kw (20 ...

Page 18: Installation Requirements

Specifications and requirements 11 lower unit: gear shift positions: forward-neutral-reverse gear ratio: 2.08 (27/13) trim and tilt system: f15ce manual tilt f15ceh manual tilt f15cep power tilt f15cmh manual tilt f20be manual tilt f20beh manual tilt f20bep power tilt f20bmh manual tilt f9.9he manua...

Page 19: Remote Control Requirements

Specifications and requirements 12 emu33572 mounting motor warning ewm01571 improper mounting of the outboard mo- tor could result in hazardous condi- tions such as poor handling, loss of control, or fire hazards. Because the motor is very heavy, spe- cial equipment and training is required to mount...

Page 20: Propeller Selection

Specifications and requirements 13 that do not have a rectifier or rectifier regulator. If you wish to use a battery with the models without a rectifier or rectifier regulator, in- stall an optional rectifier regulator. Install an optional rectifier regulator or use accessories rated to withstand 18...

Page 21: Fuel Requirements

Specifications and requirements 14 if oil grades listed under recommended en- gine oil grade 1 are not available, select an alternative oil grade listed under recom- mended engine oil grade 2. Recommended engine oil grade 1 recommended engine oil grade 2 emu36361 fuel requirements emu40202 gasoline ...

Page 22: Anti-Fouling Paint

Specifications and requirements 15 emu36331 anti-fouling paint a clean hull improves boat performance. The boat bottom should be kept as clean of ma- rine growth as possible. If necessary, the boat bottom can be coated with an anti-foul- ing paint approved for your area to inhibit marine growth. Do ...

Page 23: Components

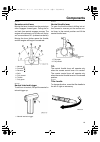

16 components emu2579z components diagram tip: * may not be exactly as shown; also may not be included as standard equipment on all mod- els (order from dealer). Emu25804 fuel tank if your model was equipped with a portable zmu07971 1 2 3 9 8 4 5 6 10 11 12 1 3 15 16 17 19 20 21 14 18 26 24 25 7 11 ...

Page 24: Components

Components 17 fuel tank, its function is as follows. Warning ewm00021 the fuel tank supplied with this engine is its dedicated fuel reservoir and must not be used as a fuel storage container. Com- mercial users should conform to relevant licensing or approval authority regula- tions. Emu25831 fuel j...

Page 25: Components

Components 18 emu26191 remote control lever moving the lever forward from the neutral po- sition engages forward gear. Pulling the le- ver back from neutral engages reverse. The engine will continue to run at idle until the le- ver is moved about 35 (a detent can be felt). Moving the lever farther o...

Page 26: Components

Components 19 emu25925 gear shift lever move the gear shift lever forward to engage the forward gear or rearward to engage the reverse gear. Emu25943 throttle grip the throttle grip is on the tiller handle. Turn the grip counterclockwise to increase speed and clockwise to decrease speed. Emu25963 th...

Page 27: Components

Components 20 when constant speed is desired, tighten the adjuster to maintain the desired throttle set- ting. Emu25996 engine shut-off cord (lanyard) and clip the clip must be attached to the engine shut- off switch for the engine to run. The cord should be attached to a secure place on the operato...

Page 28: Components

Components 21 emu26075 manual starter handle the manual starter handle is used to crank and start the engine. Emu26082 starter button to start the engine with the electric starter, push the starter button. Emu26092 main switch the main switch controls the ignition system; its operation is described ...

Page 29: Components

Components 22 tip: for instructions on using the power tilt switch, see pages 46 and 49. Emu31433 steering friction adjuster a friction device provides adjustable resis- tance to the steering mechanism, and can be set according to operator preference. An ad- juster lever is located on the bottom of ...

Page 30: Components

Components 23 juster. Emu26254 trim tab warning ewm00841 an improperly adjusted trim tab could cause difficult steering. Always test run after the trim tab has been installed or re- placed to be sure steering is correct. Be sure you have tightened the bolt after ad- justing the trim tab. The trim ta...

Page 31: Components

Components 24 sition. To release, push the tilt lock lever in the release position. Emu26322 tilt support knob to keep the outboard motor in the tilted up position, push the tilt support knob under the swivel bracket. Notice ecm00661 do not use the tilt support lever or knob when trailering the boat...

Page 32: Components

Components 25 cure it in the tilt position. Emu26385 cowling lock lever (pull up type) to remove the engine top cowling, pull up the cowling lock lever(s) and lift off the cowl- ing. When installing the cowling, check to be sure it fits properly in the rubber seal. Then lock the cowling by moving th...

Page 33: Instruments and Indicators

26 instruments and indicators emu36016 indicators emu36025 low oil pressure-alert indicator if oil pressure drops too low, this indicator will light up. For further information, see page 27. Notice ecm00023 do not continue to run the engine if the low oil pressure-alert indicator is on and the engin...

Page 34: Engine Control System

27 engine control system emu26804 alert system notice ecm00092 do not continue to operate the engine if a alert device has activated. Consult your yamaha dealer if the problem cannot be located and corrected. Emu2681d overheat alert this engine has an overheat-alert device. If the engine temperature...

Page 35: Engine Control System

Engine control system 28 if the alert system has activated, stop the en- gine as soon as it is safe to do so. Check the oil level and add oil as needed. If the oil level is correct and the alert device does not switch off, consult your yamaha dealer. Zmu02360 6ag-9-79-1e0.Book 28 ページ 2014年11月10日 月曜日...

Page 36: Installation

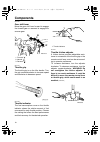

29 installation emu26903 installation the information presented in this section is intended as reference only. It is not possible to provide complete instructions for every possible boat and motor combination. Proper mounting depends in part on experience and the specific boat and motor combination....

Page 37: Installation

Installation 30 line (keel line) of the boat, and ensure that the boat itself is well balanced. Oth- erwise the boat will be hard to steer. For boats without a keel or which are asym- metrical, consult your dealer. Emu26926 mounting height to run your boat at optimum efficiency, the water resistance...

Page 38: Installation

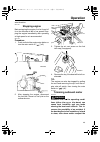

Installation 31 emu26974 clamping the outboard motor 1. Place the outboard motor on the tran- som so that it is positioned as close to the center as possible. Tighten the tran- som clamp screws evenly and securely. Occasionally check the clamp screws for tightness during operation of the out- board ...

Page 39: Operation

32 operation emu36382 first-time operation emu36393 fill engine oil the engine is shipped from the factory with- out engine oil. If your dealer did not fill the oil, you must fill it before starting the engine. Notice: check that the engine is filled with oil before first-time operation to avoid sev...

Page 40: Operation

Operation 33 dent could occur. Notice ecm00121 do not start the engine out of water. Over- heating and serious engine damage can occur. Emu36561 fuel level be sure you have plenty of fuel for your trip. A good rule is to use 1/3 of your fuel to get to the destination, 1/3 to return, and to keep 1/3 ...

Page 41: Operation

Operation 34 turns smoothly and that it completely re- turns to the fully closed position. Look for loose or damaged connections of the throttle and shift cables. Remote control models: turn the steering wheel full-right and full- left. Make sure operation is smooth and unrestricted throughout the w...

Page 42: Operation

Operation 35 pears milky or dirty. Emu27154 engine check the engine and engine mounting. Look for loose or damaged fasteners. Check the propeller for damage. Check for engine oil leaks. Emu36494 flushing device check that the flushing device’s garden hose connector is securely screwed on to the fit-...

Page 43: Operation

Operation 36 emu34783 checking power tilt system warning ewm01971 never get under the lower unit while it is tilted, even when the tilt support knob is locked. Severe injury could oc- cur if the outboard motor accidentally falls. Body parts can be crushed between the motor and the clamp bracket when...

Page 44: Operation

Operation 37 3. Remove the portable tank from the boat. 4. Be sure you are in a well-ventilated out- door area, either securely moored or trailered. 5. Do not smoke and keep away from sparks, flames, static electric discharge, or other sources of ignition. 6. If you use a portable container to store...

Page 45: Operation

Operation 38 tank cap, loosen it 2 or 3 turns. 2. If there is a fuel joint on the motor, align the fuel joint on the fuel line with the fuel joint on the motor and firmly connect the fuel line to the joint while pinching the joint. Then firmly connect the other end of the fuel line to the joint on t...

Page 46: Operation

Operation 39 ing normal operation. Loss of engine power means the loss of most steering control. Also, without engine power, the boat could slow rapidly. This could cause people and objects in the boat to be thrown forward. Starting procedure (cold engine) 1. Place the gear shift lever in neutral. T...

Page 47: Operation

Operation 40 tip: the start-in-gear protection device prevents the engine from starting except when in neu- tral. 2. Attach the engine shut-off cord to a se- cure place on your clothing, or your arm or leg. Then install the clip on the other end of the cord into the engine shut-off switch. 3. Open t...

Page 48: Operation

Operation 41 friction adjuster. If there is too much resistance, it could be difficult to move the throttle grip, which could result in an accident. [ewm02251] emu27606 electric start/prime start models warning ewm01842 failure to attach the engine shut-off cord could result in a runaway boat if ope...

Page 49: Operation

Operation 42 turn to its original position. Notice: never push the starter button while the engine is running. Do not keep the starter motor turning for more than 5 seconds. If the starter motor is turned continuously for more than 5 seconds, the battery will be quickly discharged, thus making it im...

Page 50: Operation

Operation 43 5. Immediately after the engine starts, re- lease the main switch and allow it to re- turn to “ ” (on). Notice: never turn the main switch to “ ” (start) while the engine is running. Do not keep the starter motor turning for more than 5 seconds. If the starter motor is turned continuous...

Page 51: Operation

Operation 44 if necessary. Consult your yamaha dealer if the cause for the low oil pressure alert cannot be found. [ecm01832] emu36532 checks after engine warm up emu36542 shifting while the boat is tightly moored, and without applying throttle, confirm that the engine shifts smoothly into forward a...

Page 52: Operation

Operation 45 tip: tiller handle models: the gear shift lever op- erates only when the throttle grip is in the ful- ly closed position. To shift from in gear (forward/reverse) to neutral 1. Close the throttle so that the engine slows to idle speed. 2. After the engine is at idle speed in gear move th...

Page 53: Operation

Operation 46 wind direction. Emu27822 stopping engine before stopping the engine, first let it cool off for a few minutes at idle or low speed. Stop- ping the engine immediately after operating at high speed is not recommended. Emu27848 procedure 1. Push and hold the engine stop button or turn the m...

Page 54: Operation

Operation 47 trim angle. The trim angle of the outboard motor helps determine the position of the bow of the boat in the water. Correct trim angle will help im- prove performance and fuel economy while reducing strain on the engine. Correct trim angle depends upon the combination of boat, engine, an...

Page 55: Operation

Operation 48 board motor when adjusting the trim angle. Body parts can be crushed be- tween the motor and the clamp bracket when the motor is trimmed or tilted. Use caution when trying a trim position for the first time. Increase speed gradu- ally and watch for any signs of instabil- ity or control ...

Page 56: Operation

Operation 49 bow down too much trim-in causes the boat to “plow” through the water, decreasing fuel economy and making it hard to increase speed. Oper- ating with excessive trim-in at higher speeds also makes the boat unstable. Resistance at the bow is greatly increased, heightening the danger of “b...

Page 57: Operation

Operation 50 2. Disconnect the fuel line from the out- board motor. 3. Place the tilt lock lever (if equipped) in the release/up position. 4. Pull up the shallow water lever (if equipped). 5. Hold the rear of the top cowling with one hand and tilt the engine up fully. 6. Push the tilt support knob i...

Page 58: Operation

Operation 51 3. Push the tilt support knob into the clamp bracket to support the engine. Warning! After tilting the outboard motor, be sure to support it with the tilt support knob or tilt support lever. Otherwise the outboard motor could fall back down suddenly if oil in the power trim and tilt uni...

Page 59: Operation

Operation 52 emu44620 procedure for tilting down (power tilt models) 1. Push the power tilt switch “ ” (up) until the outboard motor is supported by the tilt rod and the tilt support knob becomes free. 2. Pull out the tilt support knob. 3. Push the power tilt switch “ ” (down) to lower the outboard ...

Page 60: Operation

Operation 53 shift lever in neutral. 2. Place the tilt lock lever in the release/up position. 3. Slightly tilt the outboard motor up. The tilt support bar will lock automatically, supporting the outboard motor in a par- tially raised position. This outboard mo- tor has 2 positions for shallow water ...

Page 61: Operation

Operation 54 2. Slightly tilt the outboard motor up to the desired position using the power tilt switch. Warning! Using the power tilt switch on the bottom cowling while the boat is moving or engine is on could increase the risk of falling overboard and could distract the op- erator, increasing the ...

Page 62: Maintenance

55 maintenance emu2822b transporting and storing outboard motor warning ewm02621 use care when transporting fuel tank, whether in a boat or car. Do not fill fuel container to maximum capacity. Gasoline will expand consid- erably as it warms up and can build up pressure in the fuel container. This ca...

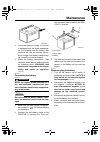

Page 63: Maintenance

Maintenance 56 7. When transporting or storing the out- board motor while removed from a boat, keep the outboard motor in the attitude shown. Tip: place a towel or something similar under the outboard motor to protect it from damage. Emu28242 storing outboard motor when storing your yamaha outboard ...

Page 64: Maintenance

Maintenance 57 right), put it on a cushion after draining the engine oil. Do not place the outboard motor on its side before the cooling water has drained from it completely, otherwise water may enter the cylinder through the exhaust port and cause engine trou- ble. Store the outboard motor in a dry...

Page 65: Maintenance

Maintenance 58 stops. 13. Drain the cooling water completely out of the motor. Clean the body thoroughly. 14. If the “fogging oil” is not available, re- move the spark plug(s). Pour a tea- spoonful of clean engine oil into each cylinder. Crank several times manually. Replace the spark plug(s). 15. D...

Page 66: Maintenance

Maintenance 59 will leak out of the connector instead of cooling the engine, which can cause serious overheating. Be sure the connector is tightened securely on the fitting after flushing the en- gine. [ecm00542] tip: when flushing the engine with the boat in the water, tilting up the outboard motor...

Page 67: Maintenance

Maintenance 60 cessories are available from your yamaha dealer. Emu34152 severe operating conditions severe operating conditions involve one or more of the following types of operation on a regular basis: operating continuously at or near maxi- mum engine speed (rpm) for many hours operating continu...

Page 68: Maintenance

Maintenance 61 emu46071 maintenance chart 1 tip: refer to the sections in this chapter for explanations of each owner-specific action. The maintenance cycle on these charts assume usage of 100 hours per year and regular flushing of the cooling water passages. Maintenance frequency should be adjusted...

Page 69: Maintenance

Maintenance 62 fuel filter (can be disassembled) inspection or replacement as necessary 33 fuel line inspection — fuel line inspection or replacement as necessary — fuel pump inspection or replacement as necessary — fuel/engine oil leakage inspection — gear oil replacement 71 greasing points greasin...

Page 70: Maintenance

Maintenance 63 emu46230 *1 cylinder head, thermostat cover *2 exhaust cover, cooling water passage cover, rectifier regulator cover emu46080 maintenance chart 2 thermostat inspection or replacement as necessary — timing belt inspection or replacement as necessary — valve clearance inspection and adj...

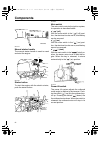

Page 71: Maintenance

Maintenance 64 emu28945 greasing yamaha grease a (water resistant grease) yamaha grease d (corrosion resistant grease; for propeller shaft) f9.9hmh, f15ceh, f15cmh, f20beh, f20bmh zmu05557 6ag-9-79-1e0.Book 64 ページ 2014年11月10日 月曜日 午後4時8分.

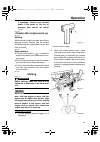

Page 72: Maintenance

Maintenance 65 f9.9he, f15ce, f15cep, f20be, f20bep emu44850 cleaning and adjusting spark plug the spark plug is an important engine com- ponent and is easy to inspect. The condition of the spark plug can indicate something about the condition of the engine. For exam- ple, if the center electrode po...

Page 73: Maintenance

Maintenance 66 when removing or installing a spark plug, be careful not to damage the in- sulator. A damaged insulator could allow external sparks, which could lead to explosion or fire. [ewm00562] 3. Be sure to use the specified spark plug, otherwise the engine may not operate properly. Before fitt...

Page 74: Maintenance

Maintenance 67 fully in neutral until it is running smooth- ly. 2. Once the engine has warmed up, verify whether the idle speed is set to specifi- cation. For idle speed specifications, see page 9. If you have difficulty verifying the idle speed, or the idle speed requires ad- justment, consult a ya...

Page 75: Maintenance

Maintenance 68 tip: if the oil does not drain easily, change the tilt angle or turn the outboard motor to port and starboard to drain the oil. 7. Put a new gasket on the oil drain screw. Apply a light coat of oil to the gasket and install the drain screw. Tip: if a torque wrench is not available whe...

Page 76: Maintenance

Maintenance 69 13. Start the engine and make sure that the low oil pressure-alert indicator remains off. Also, make sure that there are no oil leaks. Notice: if the low oil pressure- alert indicator comes on or if there are oil leaks, stop the engine and find the cause. Continued operation with a pr...

Page 77: Maintenance

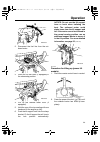

Maintenance 70 sion from cavitation or ventilation, or other damage. Check the propeller shaft for damage. Check the splines for wear or damage. Check for fish line tangled around the pro- peller shaft. Check the propeller shaft oil seal for dam- age. Emu30663 removing propeller emu29198 spline mode...

Page 78: Maintenance

Maintenance 71 4. Align the propeller nut slot with the pro- peller shaft hole. Insert a new cotter pin in the hole and bend the cotter pin ends. Notice: do not reuse the cotter pin. Otherwise, the propeller can come off during operation. [ecm01892] tip: if the propeller nut slot does not align with...

Page 79: Maintenance

Maintenance 72 tip: if a magnetic gear oil drain screw is equipped, remove all metal particles from the screw before installing it. Always use new gaskets. Do not reuse the removed gaskets. 4. Remove the oil level plug and gasket to allow the oil to drain completely. Notice: check the used gear oil ...

Page 80: Maintenance

Maintenance 73 assembly. Pull the assembly out of the tank. 4. Clean the filter (located on the end of the suction pipe) in a suitable cleaning sol- vent. Allow the filter to dry. 5. Replace the gasket with a new one. Re- install the fuel joint assembly and tighten the screws firmly. Emu29317 inspec...

Page 81: Maintenance

Maintenance 74 2. Check the battery’s charge. If your boat is equipped with the digital speedome- ter, the voltmeter and low battery alert functions will help you monitor the bat- tery’s charge. If the battery needs charg- ing, consult your yamaha dealer. 3. Check the battery connections. They shoul...

Page 82: Trouble Recovery

75 trouble recovery emu29428 troubleshooting a problem in the fuel, compression, or igni- tion systems can cause poor starting, loss of power, or other problems. This section de- scribes basic checks and possible remedies, and covers all yamaha outboard motors. Therefore some items may not apply to ...

Page 83: Trouble Recovery

Trouble recovery 76 q. Is fuel system obstructed? A. Check for pinched or kinked fuel line or other obstructions in fuel system. Q. Is fuel contaminated or stale? A. Fill tank with clean, fresh fuel. Q. Is fuel filter clogged? A. Clean or replace filter. Q. Have ignition parts failed? A. Have servic...

Page 84: Trouble Recovery

Trouble recovery 77 q. Is load on boat improperly distributed? A. Distribute load to place boat on an even plane. Q. Is water pump or thermostat faulty? A. Have serviced by a yamaha dealer. Q. Is there excess water in fuel filter cup? A. Drain filter cup. Engine power loss. Q. Is propeller damaged? ...

Page 85: Trouble Recovery

Trouble recovery 78 q. Is fuel joint connection incorrect? A. Connect correctly. Q. Is heat range of spark plug incorrect? A. Inspect spark plug and replace it with rec- ommended type. Q. Is high pressure fuel pump drive belt bro- ken? A. Have serviced by a yamaha dealer. Q. Is engine not responding...

Page 86: Trouble Recovery

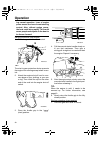

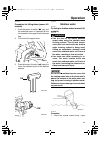

Trouble recovery 79 emu32131 power tilt will not operate if the engine cannot be tilted up or down with the power tilt because of a discharged bat- tery or a failure with the power tilt unit, the en- gine can be tilted manually. 1. Loosen the manual valve screw by turn- ing it counterclockwise until...

Page 87: Trouble Recovery

Trouble recovery 80 ing normal operation. Loss of engine power means the loss of most steering control. Also, without engine power, the boat could slow rapidly. This could cause people and objects in the boat to be thrown forward. Make sure no one is standing behind you when pulling the starter rope...

Page 88: Trouble Recovery

Trouble recovery 81 6. Insert the knotted end of the emergency starter rope into the notch in the flywheel rotor and wind the rope 1 or 2 turn(s) around the flywheel clockwise. 7. Pull the rope slowly until resistance is felt. Give a strong pull straight out to crank and start the engine. If the eng...

Page 89: Trouble Recovery

Trouble recovery 82 5. Remove the starter/flywheel cover after removing the bolt(s). 6. Secure the electrical system plate by tightening the bolt(s), and fix the plate. 7. Prepare the engine for starting. For fur- ther information, see page 38. Be sure that the gear shift is in neutral and that the ...

Page 90: Trouble Recovery

Trouble recovery 83 8. Insert the knotted end of the emergency starter rope into the notch in the flywheel rotor and wind the rope 1 or 2 turn(s) around the flywheel clockwise. 9. Pull the rope slowly until resistance is felt. Give a strong pull straight out to crank and start the engine. If the eng...

Page 91: Index

84 index a alcohol and drugs ................................... 2 alert indicator........................................ 25 alert system .......................................... 27 anode(s), inspecting and replacing ...... 73 anti-fouling paint ................................... 15 avoid collis...

Page 92: Index

Index 85 k key number ............................................ 4 l laws and regulations.............................. 3 low oil pressure alert............................ 27 low oil pressure-alert indicator............. 26 lubrication ............................................ 58 m main switch...

Page 93: Index

Index 86 tilt support bar...................................... 24 tilt support knob ................................... 24 top cowling, installing........................... 35 top cowling, removing.......................... 33 transporting and storing outboard motor ..................................

Page 94

Printed on recycled paper printed in japan december 2014–1.7 1 ! 6ag-9-79-1e0.Book 1 ページ 2014年11月10日 月曜日 午後4時8分.