- DL manuals

- Yamaha

- Engine

- F100B

- Service Manual

Yamaha F100B Service Manual

Summary of F100B

Page 1

Service manual 60c-28197-5d-11 290429 f100b f100c.

Page 2

Notice this manual has been prepared by yamaha primarily for use by yamaha dealers and their trained mechanics when performing maintenance procedures and repairs to yamaha equipment. It has been written to suit the needs of persons who have a basic understanding of the mechanical and electrical conc...

Page 3: Contents

Contents general information 1 gen info specifications 2 spec periodic checks and adjustments 3 chk adj fuel system 4 fuel power unit 5 powr lower unit 6 lowr bracket unit 7 brkt electrical systems 8 elec troubleshooting 9 trbl shtg index – +.

Page 4: General Information

Gen info 60c5d11 general information how to use this manual ................................................................................. 1-1 manual format............................................................................................ 1-1 symbols........................................

Page 5

60c5d11 1 2 3 4 5 6 7 8 9 predelivery checks ...................................................................................... 1-25 checking the fuel system ........................................................................ 1-25 checking the gear oil..........................................

Page 6

Gen info general information 1-1 60c5d11 how to use this manual 1 manual format the format of this manual has been designed to make service procedures clear and easy to under- stand. Use the information below as a guide for effective and quality service. 1 parts are shown and detailed in an exploded...

Page 7

60c5d11 1-2 1 2 3 4 5 6 7 8 9 symbols the symbols below are designed to indicate the content of a chapter. General information specifications periodic checks and adjustments fuel system power unit lower unit bracket unit electrical systems troubleshooting gen info spec chk adj fuel powr lowr brkt el...

Page 8

Gen info general information 1-3 60c5d11 safety while working 1 to prevent an accident or injury and to ensure quality service, follow the safety pro- cedures provided below. Fire prevention gasoline is highly flammable. Keep gasoline and all flammable products away from heat, sparks, and open flame...

Page 9

60c5d11 1-4 1 2 3 4 5 6 7 8 9 6. Keep a supply of clean, lint-free cloths for wiping up spills, etc. Good working practices special tools use the recommended special tools to pro- tect parts from damage. Use the right tool in the right manner—do not improvise. Tightening torques follow the tightenin...

Page 10

Gen info general information 1-5 60c5d11 identification 1 applicable models this manual covers the following models. Serial number the outboard motor serial number is stamped on a label attached to the port clamp bracket. È f100b É f100c 1 model name 2 approved model code 3 transom height 4 serial n...

Page 11

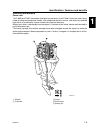

60c5d11 1-6 1 2 3 4 5 6 7 8 9 features and benefits 1 power unit the f100b and f100c have been developed on the bases of the f100a, which has been recog- nized as being environmentally friendly, with established emission control, and which has received high marks as an efficiently superior model wit...

Page 12

Gen info general information 1-7 60c5d11 piston and connecting rod the piston pin has been installed by shrink fitting it to the small end of the connecting rod, as a result, a circlip is not used to install the piston pin. The top ring has been nitrided and the second ring has been chrome plated fo...

Page 13

60c5d11 1-8 1 2 3 4 5 6 7 8 9 new plastic-region tightening bolts to tighten the plastic-region tightening bolts, tighten them to the specified torque, and then tighten them to the specified angle. By tightening the bolts to the specified angle, they are contracted to a more accurate torque, making ...

Page 14

Gen info general information 1-9 60c5d11 fuel pump and fuel filter the fuel pump found in the f115a has been adopted. Although the quantity of parts has been reduced and the necessary servicing time has been decreased as well, the ability of the fuel pump to supply sufficient fuel has been retained....

Page 15

60c5d11 1-10 1 2 3 4 5 6 7 8 9 hour meter a newly developed hour meter is incorporated on the f100b and f100c. The hour meter makes it possible to check the hours of operation of the outboard motor, which can be used to keep track of periodic checks and adjustments. When the engine switch is turned ...

Page 16

Gen info general information 1-11 60c5d11 ignition system a cdi system has been incorporated. The cdi unit uses three signals (i.E., crankshaft position, engine revolution, and throttle position) to determine the optimum ignition timing. Engine speed is controlled by the cdi unit to prevent damage t...

Page 17

60c5d11 1-12 1 2 3 4 5 6 7 8 9 at low speeds, the exhaust gas flows into the water wall through a hole on the side of the exhaust guide. È exhaust gas flow at low speeds É exhaust gas flow at high speeds an identification mark has been stamped on the exhaust manifold and exhaust chamber. 1 identific...

Page 18

Gen info general information 1-13 60c5d11 bracket unit and the ptt unit f100b uses the bracket unit of 2-stroke, v4 outboard motor and f100c uses that of f100a. In addition, the ptt unit has been adopted from the f100a as well. The f100b uses the one found on the proven 2-stroke, v4, and v6 outboard...

Page 19

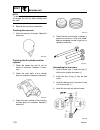

60c5d11 1-14 1 2 3 4 5 6 7 8 9 cooling system a high capacity water pump and a large cylinder head water jacket have been incorporated to enable better cooling. A pressure control valve (pcv) has also been incorporated to control the cooling water pressure, which in turn helps prevent water leakage ...

Page 20

Gen info general information 1-15 60c5d11 water pump the water pump has been hard chrome plated to prevent wear from muddy water. By hard chrome plating the water pump, wear resistance has been enhanced, and as a result, the time necessary between part changes or maintenance has been extended. 1 blu...

Page 21

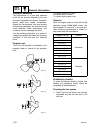

60c5d11 1-16 1 2 3 4 5 6 7 8 9 technical tips 1 carburetor prime start to facilitate the starting of a cold engine, an air-fuel mixture that is richer than normal is required. For this reason, the prime start system has been adopted in the f100b and f100c. In the prime start system, the thermo heate...

Page 22

Gen info general information 1-17 60c5d11 acceleration pump the function of the acceleration pump is to ensure a smooth acceleration by preventing the air-fuel mixture from becoming temporarily lean in case the throttle valve is opened suddenly. When the throttle valve is opened suddenly, a large vo...

Page 23

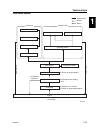

60c5d11 1-18 1 2 3 4 5 6 7 8 9 ignition system the computer controlled cdi system has three basic modes of operation: starting, warm-up, and normal operation. Ignition timing control starting mode ignition timing is fixed at 10° btdc. The starting mode cuts off when the engine has been started and t...

Page 24

Gen info general information 1-19 60c5d11 • low oil pressure control three seconds after starting the engine this mode does not operate. When the oil pressure switch turns on oil pressure is 150 kpa (1.5 kg/cm 2 , 21.3 psi) or below, this mode starts. The buzzer will sound and the warning light will...

Page 25

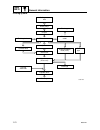

60c5d11 1-20 1 2 3 4 5 6 7 8 9 lubrication system sleeve piston crankshaft pin crankshaft journal retur n route retur n route • oil pressure regulation oil pan • oil sump • oil cooling oil strainer oil pump with relief valve oil filter main gallery oil pressure switch • low oil pressure warning • fi...

Page 26

Gen info general information 1-21 60c5d11 cooling system cooling water inlet oil pan water pump flushing device pilot water outlet pressure control valve (pcv) discharge trim tab water inlet exhaust cover cylinder cylinder head thermostat upper case propeller boss discharge (water wall) discharge ex...

Page 27

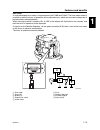

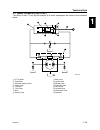

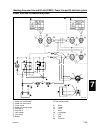

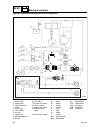

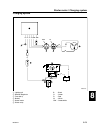

60c5d11 1-22 1 2 3 4 5 6 7 8 9 ptt (power trim and tilt) unit (f100b) the circuit of the ptt unit and the location of its major components are shown in the illustration below. 1 lower chamber shuttle valve 2 up-relief valve 3 pump chamber 4 down-check valve 5 check valve 6 tilt ram 7 trim and tilt h...

Page 28

Gen info general information 1-23 60c5d11 component identification description notes up-relief valve ptt fluid flows upward above 10.8 mpa (110 kg/cm 2 , 1,500 psi). Down-check valve ptt fluid flows easily to the left while some fluid flows to the right through a small restriction. Lower chamber che...

Page 29

60c5d11 1-24 1 2 3 4 5 6 7 8 9 ptt (power trim and tilt) unit (f100c) the circuit of the ptt unit and the location of its major components are shown in the illustration below. 1 ptt cylinder 2 free piston 3 pressure-release valves 4 check valve 5 tilt piston 6 trim piston 7 ram 8 manual valve 9 main...

Page 30

Gen info general information 1-25 60c5d11 propeller selection 1 the performance of a boat and outboard motor will be critically affected by the size and type of propeller you choose. Propellers greatly affect boat speed, acceleration, engine life, fuel economy, and even boating and steering capabili...

Page 31

60c5d11 1-26 1 2 3 4 5 6 7 8 9 caution: this is a 4-stroke engine. Never use pre- mixed fuel. Checking the gear oil 1. Check the gear oil level. Checking the engine oil 1. Check the oil level. Note: • if the engine oil is above the maximum level mark a, drain sufficient oil until the level is betwee...

Page 32

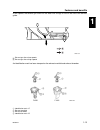

Gen info general information 1-27 60c5d11 checking the remote control cables 1. Set the remote control lever to the neu- tral position and fully close the throttle lever/throttle grip. 2. Check that the throttle control lever 1 touches the fully closed stopper a. 3. Check that the set pin b is in th...

Page 33

60c5d11 1-28 1 2 3 4 5 6 7 8 9 2. Check that the throttle operates smoothly when the remote control lever or throttle grip is shifted from the fully closed posi- tion to the fully open position a. Checking the tilt system 1. Check that the outboard motor tilts up and down smoothly when operating the...

Page 34

Gen info general information 1-29 60c5d11 4. Run the outboard motor for one hour at 2,000 r/min or at half throttle, then for another hour at 3,000 r/min or at 3/4 throttle. 5. Check that the outboard motor does not tilt up when shifting into reverse and that water does not flow in over the transom....

Page 35: Specifications

60c5d11 spec 1 2 3 4 5 6 7 8 9 specifications general specifications................................................................................... 2-1 maintenance specifications .......................................................................... 2-3 power unit...............................

Page 36

Spec specifications 2-1 60c5d11 general specifications 2 item unit model f100bet f100cet dimension overall length mm (in) 825 (32.5) overall width mm (in) 486 (19.1) overall height (l) mm (in) 1,595 (62.8) 1,582 (62.3) (x) mm (in) 1,722 (67.8) 1,710 (67.3) boat transom height (l) mm (in) 508 (20.0) ...

Page 37

60c5d11 2-2 1 2 3 4 5 6 7 8 9 * ron: research octane number fuel and oil fuel type unleaded gasoline/leaded gasoline fuel rating ron* 84 engine oil type 4-stroke motor oil engine oil grade api sae se, sf, sg, or sh 10w-30 or 10w-40 engine oil quantity (with oil filter replacement) l (us qt, lmp qt) ...

Page 38

Spec specifications 2-3 60c5d11 maintenance specifications 2 power unit item unit model f100bet f100cet power unit minimum compression pressure* kpa (kgf/cm 2 , psi) 670 (6.7, 95) lubrication oil pressure (reference data) kpa (kgf/cm 2 , psi) at 850 r/min 520 (5.2, 74) cylinder heads warpage limit m...

Page 39

60c5d11 2-4 1 2 3 4 5 6 7 8 9 2nd ring dimension b mm (in) 1.47–1.49 (0.0579–0.0586) dimension t mm (in) 3.00–3.20 (0.1182–0.1259) end gap mm (in) 0.70–0.90 (0.0276–0.0354) side clearance mm (in) 0.03–0.07 (0.0012–0.0027) oil ring dimension b mm (in) 2.38–2.48 (0.0938–0.0976) dimension t mm (in) 2.4...

Page 40

Spec specifications 2-5 60c5d11 valve springs free length mm (in) 53.20 (2.0945) minimum free length mm (in) 52.25 (2.0570) tilt limit mm (in) 2.6 (0.10) connecting rods small-end inside diameter mm (in) 17.97–17.98 (0.7075–0.7078) big-end inside diameter mm (in) 47.03–47.04 (1.8514–1.8518) crank pi...

Page 41

60c5d11 2-6 1 2 3 4 5 6 7 8 9 lower unit oil pump discharge at 100 °c (212 °f) with 10w-30 engine oil l (us gal, imp gal)/min at 1,000 r/min 5.9 (1.56, 1.30) thermostats opening temperature °c (°f) 50 (122) fully open temperature °c (°f) 60 (140) valve open lower limit mm (in) 4.3 (0.17) fuel pump d...

Page 42

Spec specifications 2-7 60c5d11 electrical item unit model f100bet f100cet ignition system ignition timing (engine idle speed) degree atdc ± 5 pulser coil output peak voltage (w/r – b) at cranking 1 (*1) v 3.5 at cranking 2 (*1) v 2.5 at 1,500 r/min v 9.0 at 3,500 r/min v 14.0 pulser coil resistance...

Page 43

60c5d11 2-8 1 2 3 4 5 6 7 8 9 charging system fuse a 20, 30 lighting coil output peak voltage (w – w) at cranking (*1) v 7.0 at 1,500 r/min (*1) v 38 at 3,500 r/min (*1) v 91 lighting coil resistance (*2) (w – w) Ω 0.32–0.48 rectifier regulator output peak voltage (r – b) at 1,500 r/min (*1) v 17.5 ...

Page 44

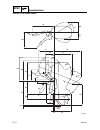

Spec specifications 2-9 60c5d11 dimensions exterior s60c2150 l7 l6 l1 l4 a3 l9 l5 c3 l2 h7 h10 h8 w5 w1 a1 h4 h1 h11 h9 h2 h3 h6 a2 t1 l10 l8 b6.

Page 45

60c5d11 2-10 1 2 3 4 5 6 7 8 9 symbol unit model f100bet f100cet l1 mm (in) 664 (26.1) 647 (25.5) l2 mm (in) 161 (6.3) 171 (6.7) l3 mm (in) — l4 mm (in) 631 (24.8) 574 (22.6) l5 (l) mm (in) 69 (2.7) 65 (2.6) (x) mm (in) 76 (3.0) l6 (l) mm (in) 1,005 (39.6) 998 (39.3) (x) mm (in) 1,122 (44.2) 1,115 (...

Page 46

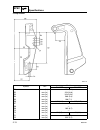

Spec specifications 2-11 60c5d11 exterior (tiller handle model) h9 h5 h2 h7 h10 h8 h4 h3 l8 l9 l4 a3 a2 h6 l5 c3 b6 h1 h11 l7 l6 l1 l2 l10 w6 w2 l3 a1 w5 w1 s60c2160

Page 47

60c5d11 2-12 1 2 3 4 5 6 7 8 9 symbol unit model f100bet f100cet l1 mm (in) 664 (26.1) 651 (25.6) l2 mm (in) 316 (12.4) 268.3 (10.5) l3 mm (in) 832 (32.8) 792.7 (31.2) l4 mm (in) 631 (24.8) 574 (22.6) l5 (l) mm (in) 69 (2.7) 65 (2.6) (x) mm (in) 76 (3.0) l6 (l) mm (in) 1,005 (39.6) 998 (39.3) (x) mm...

Page 48

Spec specifications 2-13 60c5d11 clamp bracket symbol unit model f100bet f100cet b1 mm (in) 125.4 (4.9) b2 mm (in) 254 (10.0) b3 mm (in) 163.5 (6.4) b4 mm (in) 50.8 (2.0) b5 mm (in) 180 (7.1) b6 mm (in) 367 (14.4) 347 (13.7) b7 mm (in) — b8 mm (in) — b9 mm (in) 18.5 (0.7) c2 mm (in) — c3 mm (in) 82 ...

Page 49

60c5d11 2-14 1 2 3 4 5 6 7 8 9 tightening torques 2 specified torques part to be tightened thread size tightening torques n·m kgf·m ft·lb power unit flywheel magnet nut — 186 18.6 135 negative battery lead bolt m8 9 0.9 6.5 positive battery lead nut — 9 0.9 6.5 power unit bolt m10 42 4.2 30 apron bo...

Page 50

Spec specifications 2-15 60c5d11 lower unit (f100b) check screw — 7 0.7 5.1 lower unit bolt m10 39 3.9 28 drain screw — 7 0.7 5.1 propeller nut — 55 5.5 40 trim tab bolt m10 42 4.2 30 ring nut — 103 10.3 74 pinion nut — 93 9.3 67 water inlet cover screw — 4 0.4 2.9 lower unit (f100c) check screw — 7...

Page 51

60c5d11 2-16 1 2 3 4 5 6 7 8 9 general torques this chart specifies tightening torques for standard fasteners with a standard iso thread pitch. Tightening torque specifications for special components or assemblies are provided in applicable sections of this man- ual. To avoid warpage, tighten multi-...

Page 52: — Memo —

Spec specifications 2-17 60c5d11 — memo —.

Page 53

60c5d11 chk adj 1 2 3 4 5 6 7 8 9 periodic checks and adjustments special service tools ..................................................................................... 3-1 maintenance interval chart............................................................................ 3-2 top cowling ......

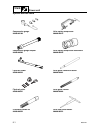

Page 54

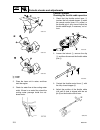

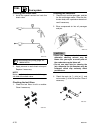

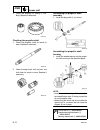

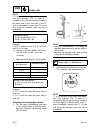

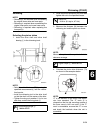

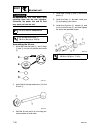

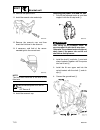

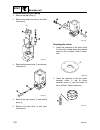

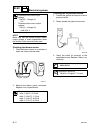

Chk adj periodic checks and adjustments 3-1 60c5d11 special service tools 3 oil filter wrench 90890-01426 digital tachometer 90890-06760 timing light 90890-03141 leakage tester 90890-06762.

Page 55

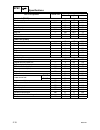

60c5d11 3-2 1 2 3 4 5 6 7 8 9 maintenance interval chart 3 use the following chart as a guideline for general maintenance. Adjust the maintenance intervals according to the operating conditions of the outboard motor. Item remarks initial every refer to page 10 ho urs (b reak-in) 50 ho urs (3 months ...

Page 56

Chk adj periodic checks and adjustments 3-3 60c5d11 note: (*1) if equipped with a portable fuel tank. (*2) be sure to replace the timing belt every 1,000 hours of operation or every five years. (*3) do not adjust the carburetor if it is operating correctly. (*4) the engine should be flushed with fre...

Page 57

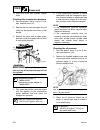

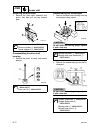

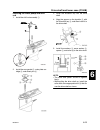

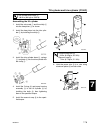

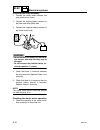

60c5d11 3-4 1 2 3 4 5 6 7 8 9 top cowling 3 checking the top cowling 1. Check the fitting by pushing the cowling with both hands. Adjust if necessary. 2. Loosen the bolts 1. 3. Move the hook 2 up or down slightly to adjust its position. Note: • to loosen the fitting, move the hook toward the seal. •...

Page 58

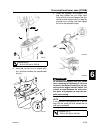

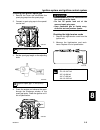

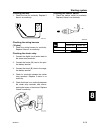

Chk adj periodic checks and adjustments 3-5 60c5d11 note: be sure not to spill any fuel when removing the fuel filter cup. Power unit 3 checking the engine oil 1. Place the outboard motor in an upright position. 2. Remove the engine oil dipstick, wipe it clean, and then insert it back into the oil f...

Page 59

60c5d11 3-6 1 2 3 4 5 6 7 8 9 note: to extract and change the oil through the dip- stick hole a, you can use an oil changer 3 like the one shown in the illustration. 3. Place a rag under the oil filter, and then remove the filter. Note: be sure to clean up any oil spills. 4. Apply a thin coat of eng...

Page 60

Chk adj periodic checks and adjustments 3-7 60c5d11 7. Pour the specified amount of the recom- mended engine oil into the oil filler hole. 8. Install the oil filler cap and dipstick, and then start the engine and warm it up for 5 minutes. 9. Turn the engine off, and then check the oil level and corr...

Page 61

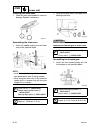

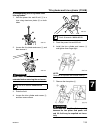

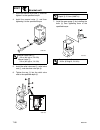

60c5d11 3-8 1 2 3 4 5 6 7 8 9 6. Install the spark plug, tighten it finger tight b, then to the specified torque with a spark plug wrench c. Checking the thermostat 1. Remove the flywheel magnet cover. 2. Disconnect the cooling water hose 1, and then remove the thermostat cover 2 and thermostat 3. 3...

Page 62

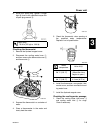

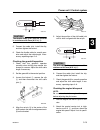

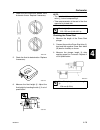

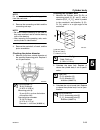

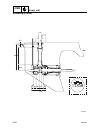

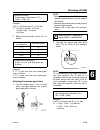

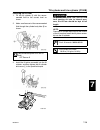

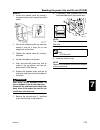

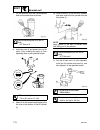

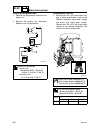

Chk adj periodic checks and adjustments 3-9 60c5d11 È f100b É f100c 2. Place the lower unit in water, and then start the engine. 3. Check for water flow at the cooling water outlet. If there is no water flow, check the cooling water passage inside the out- board motor. Control system 3 checking the ...

Page 63

60c5d11 3-10 1 2 3 4 5 6 7 8 9 caution: the throttle cable joint must be screwed in a minimum of 8.0 mm (0.31 in) c. 5. Connect the cable joint, install the clip, and then tighten the locknut. 6. Check the throttle cable for smooth oper- ation and adjust the cable length, if nec- essary, repeating s...

Page 64

Chk adj periodic checks and adjustments 3-11 60c5d11 3. Turn the throttle stop screw 2 in direc- tion a or b until the specified engine idle speed is obtained. Note: • to increase the idle speed, turn the throttle stop screw in direction a. • to decrease the idle speed, turn the throttle stop screw ...

Page 65

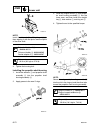

60c5d11 3-12 1 2 3 4 5 6 7 8 9 power trim and tilt unit 3 checking the power trim and tilt operation 1. Fully tilt the outboard motor up and down a few times and check the entire trim and tilt range for smooth operation. Check the power trim and tilt fluid level if necessary. Note: be sure to listen...

Page 66

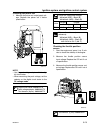

Chk adj periodic checks and adjustments 3-13 60c5d11 4. Install the reservoir cap, and then tighten it to the specified torque. Lower unit 3 checking the gear oil level 1. Fully tilt the outboard motor down. 2. Remove the check screw 1, and then check the gear oil level in the lower case. Note: if t...

Page 67

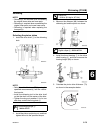

60c5d11 3-14 1 2 3 4 5 6 7 8 9 5. Install the check screw, quickly install the drain screw, and then tighten them to the specified torque. Checking the lower unit (for air leakage) 1. Remove the check screw 1, and then install the special service tool. 2. Apply the specified pressure to check whethe...

Page 68

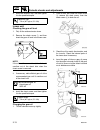

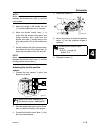

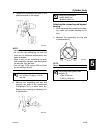

Chk adj periodic checks and adjustments 3-15 60c5d11 È f100b É f100c caution: do not oil, grease, or paint the anodes, otherwise they will be ineffective. 2. Replace the anodes and trim tab if excessively eroded. Checking the battery 1. Check the battery electrolyte level. If the level is at or belo...

Page 69

60c5d11 3-16 1 2 3 4 5 6 7 8 9 warning battery electrolyte is dangerous; it con- tains sulfuric acid which is poisonous and highly caustic. Always follow these preventive measures: • avoid bodily contact with electrolyte as it can cause severe burns or permanent eye injury. • wear protective eye gea...

Page 70

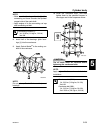

Chk adj periodic checks and adjustments 3-17 60c5d11 È f100b É f100c note: apply grease to the grease nipple until it flows from the bushings a. 2. Apply corrosion resistant grease to the areas shown. S60c3695 a a s60c3700 a s60c3710 a a.

Page 71: Fuel System

60c5d11 fuel 1 2 3 4 5 6 7 8 9 fuel system special service tools ..................................................................................... 4-1 hose routing ................................................................................................... 4-2 fuel, blowby, and cooling wa...

Page 72

Fuel fuel system 4-1 60c5d11 special service tools 4 vacuum/pressure pump gauge set 90890-06756 digital tachometer 90890-06760 vacuum gauge 90890-03159 test harness (3 pins) 90890-06757 digital circuit tester 90890-03174 vacuum gauge (digital) (commercially obtainable) vacuum gauge (4 analog meters)...

Page 73

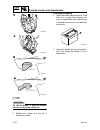

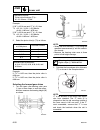

60c5d11 4-2 1 2 3 4 5 6 7 8 9 hose routing 4 fuel, blowby, and cooling water hoses 1 blowby hose 2 fuel hose (fuel pump-to-carburetor) 3 fuel hose (fuel filter-to-fuel pump) 4 fuel hose (fuel joint-to-fuel filter) 5 fuel hose (carburetor-to-carburetor) 6 hose (acceleration pump-to-carburetor) 7 hose...

Page 74

Fuel fuel system 4-3 60c5d11 fuel line and fuel filter 4 s60c4030 8 8 11 10 9 7 7 14 15 7 7 13 8 7 7 13 11 10 9 16 12 26 27 25 24 23 29 28 15 2 19 20 17 1 15 18 21 22 3 4 5 6 t r . . 10 n • m (1.0 kgf • m, 7.2 ft • ib).

Page 75

60c5d11 4-4 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 fuel pump 1 2 body 1 3 fuel filter element 1 4 float 1 5 o-ring 1 not reusable 2 × 36.2 mm 6 fuel filter cup 1 7 clip 9 8 fuel joint 3 9 bolt 2 m6 × 12 mm 10 washer 2 11 clamp 2 12 clamp 1 13 fuel hose 2 fuel joint-to-fuel joint 14 fuel hose...

Page 76

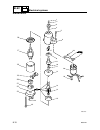

Fuel fuel system 4-5 60c5d11 fuel pump 4 s60c4040 1 2 15 11 12 3 12 11 13 14 10 9 13 14 8 7 4 6 5 t r . . 4 n • m (0.4 kgf • m, 2.9 ft • ib).

Page 77

60c5d11 4-6 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 screw 3 m6 × 35 mm 2 cover 1 3 fuel pump body 2 1 4 fuel pump body 1 1 5 plunger 1 6 spring 1 7 nut 3 8 spring 1 9 pin 1 10 diaphragm 1 11 nut 2 12 spring 2 13 valve 2 14 screw 2 15 gasket 1 not reusable fuel pump.

Page 78

Fuel fuel system 4-7 60c5d11 checking the fuel pump 1. Install the special service tool onto the fuel pump as shown. 2. Apply the specified pressure to each fuel pump port. 3. If air flow is reversed, check the dia- phragm for tears and the valves for cracks. Replace if necessary. Caution: do not ov...

Page 79

60c5d11 4-8 1 2 3 4 5 6 7 8 9 disassembling the fuel pump 1. Disassemble the fuel pump as shown. 2. Push down on the plunger and the dia- phragm, turn the fuel pump body 1 1 approximately 90° to a position where the pin 2 can be removed easily, and then remove the pin. 3. Slowly let up on the plunge...

Page 80

Fuel fuel system 4-9 60c5d11 throttle control 4 s60c4120 7 8 1 12 11 10 9 21 20 13 14 15 16 17 4 19 18 5 6 22 3 23 2.

Page 81

60c5d11 4-10 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 throttle cam 1 2 throttle link rod 1 3 throttle position sensor 1 4 bracket 1 5 throttle control lever 1 6 bracket 1 7 washer 1 8 spring 1 9 washer 1 10 wave washer 1 11 collar 1 12 bolt 1 m6 × 35 mm 13 bolt 1 m6 × 12 mm 14 washer 1 15 wave...

Page 82

Fuel fuel system 4-11 60c5d11 5 8 6 1 9 7 14 10 15 1617 24 4 11 12 3 19 20 20 22 23 21 2 13 18 s60c4130 25 26 27 25 23 25 28 22 25 21 25 21.

Page 83

60c5d11 4-12 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 silencer 1 2 carburetor assembly 1 3 intake manifold 1 4 acceleration pump 1 5 blowby hose 1 6 bolt 8 m6 × 20 mm 7 bolt 3 m8 × 60 mm 8 o-ring 4 not reusable 3.5 × 47.7 mm 9 gasket 1 10 bolt 8 m6 × 120 mm 11 spacer 4 12 o-ring 4 not reusable...

Page 84

Fuel fuel system 4-13 60c5d11 carburetor 4 7 5 6 1 1 1 2 3 4 29 26 25 22 24 23 16 17 15 21 20 19 18 11 13 10 9 8 27 28 12 14 14 s60c4140

Page 85

60c5d11 4-14 1 2 3 4 5 6 7 8 9 È carburetors #1 and #3 É carburetor #2 Ê carburetor #4 no. Part name q’ty remarks 1 carburetor body 1 2 screw 3 m4 × 10 mm 3 cover 1 4 gasket 1 not reusable 5 spring 1 6 o-ring 1 not reusable 7 pilot screw 1 8 prime start 1 9 screw 1 m4 × 10 mm 10 bracket 1 11 o-ring ...

Page 86

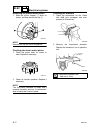

Fuel fuel system 4-15 60c5d11 checking the check valve 1. Install the special service tool onto the check valve. 2. Apply pressure to each check valve port. Replace if necessary. Note: make sure that no air comes out of the oppo- site side of the check valve. Checking the fuel filters 1. Check the f...

Page 87

60c5d11 4-16 1 2 3 4 5 6 7 8 9 4. Check the pilot screw and needle valve for bends or wear. Replace if necessary. 5. Check the float for deterioration. Replace it necessary. 6. Measure the float height a. Adjust the float height by bending the tab 4 if out of specification. Note: • the float should ...

Page 88

Fuel fuel system 4-17 60c5d11 assembling the carburetor 1. Install the main nozzle 1, main jet 2, pilot jet 3, plug 4, and valve seat 5 to the carburetor body as shown. 2. Install the needle valve 6, float 7, float pin 8, and screw 9 as shown, and then check the float for smooth operation. Note: • p...

Page 89

60c5d11 4-18 1 2 3 4 5 6 7 8 9 note: make sure that there is complete clearance between the throttle cam roller 4 and the cam surface. 5. Adjust the length of the throttle link rod 5, and then tighten the nut 6 securely. 6. Move the throttle control lever 1 to check that the throttle valve opens and...

Page 90

Fuel fuel system 4-19 60c5d11 adjusting the pilot screw 1. Start the engine and warm it up for 5 min- utes to check the stability of the engine. Adjust the pilot screw if necessary. 2. Attach the special service tool to high- tension cord #1 1. 3. Turn the pilot screws 2 in direction a until the eng...

Page 91

60c5d11 4-20 1 2 3 4 5 6 7 8 9 synchronizing the carburetors 1. Start the engine and warm it up for 5 min- utes to check the stability of the engine. 2. Attach the special service tool to high- tension cord #1 1. 3. Remove all of the plugs 2 and attach the special service tool and adapters to the ca...

Page 92

Fuel fuel system 4-21 60c5d11 6. Turn the throttle valve adjusting screws 6 to adjust the vacuum pressure of car- buretors #1, #2, and #3 to the same vac- uum variation as carburetor #4. 7. Adjust the engine idle speed to specifica- tion. 8. After adjusting the idle speed, rev the engine a few times...

Page 93: Power Unit

60c5d11 powr 1 2 3 4 5 6 7 8 9 power unit special service tools ..................................................................................... 5-1 power unit....................................................................................................... 5-3 checking the valve clearance...

Page 94

Powr power unit 5-1 60c5d11 special service tools 5 compression gauge 90890-03160 compression gauge adaptor 90890-06563 flywheel holder 90890-06522 flywheel puller 90890-06521 crankshaft holder 20 90890-06552 valve spring compressor 90890-04019 valve spring compressor attachment 90890-06320 valve gu...

Page 95

60c5d11 5-2 1 2 3 4 5 6 7 8 9 valve seat cutter 90890-06315, 90890-06324, 90890-06326, 90890-06328, 90890-06555 crank stand alignment 90890-03107 oil filter wrench 90890-01426 piston slider 90890-06530 special service tools.

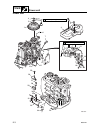

Page 96

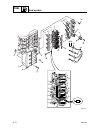

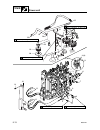

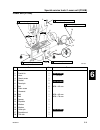

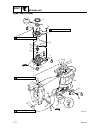

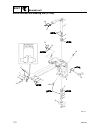

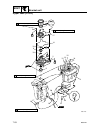

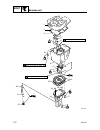

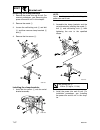

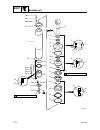

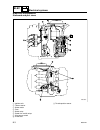

Powr power unit 5-3 60c5d11 power unit 5 s60c5010 2 3 5 1 4 14 17 21 13 15 20 19 18 16 18 19 7 8 9 12 11 10 6 e t r . . 186 n • m (18.6 kgf • m, 135 ft • lb) t r . . 9 n • m (0.9 kgf • m, 6.5 ft • ib) 25 26 27 28 29 30 31 23 32 33 34 24 22.

Page 97

60c5d11 5-4 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 flywheel magnet 1 2 bolt 2 m8 × 20 mm 3 cover 1 4 nut 1 5 washer 1 6 woodruff key 1 7 engine oil dipstick 1 8 bolt 1 m6 × 25 mm 9 plate 1 10 cover 1 11 plastic tie 1 not reusable 12 pilot water hose 1 10 × 330 mm 13 bolt 1 m8 × 16 mm 14 nega...

Page 98

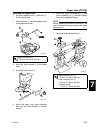

Powr power unit 5-5 60c5d11 no. Part name q’ty remarks 1 power unit 1 2 gasket 1 3 dowel pin 2 4 bolt 5 m6 × 16 mm 5 nut 2 6 apron 1 7 bolt 2 m8 × 35 mm 8 bolt 2 m6 × 40 mm 9 bolt 6 m10 × 130 mm s60c5030 1 2 3 5 6 4 9 8 7 lt 572 572 lt 572 572 3 7 9 3 9 9 t r . . 42 n • m (4.2 kgf • m, 30 ft • ib) t...

Page 99

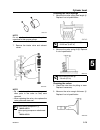

60c5d11 5-6 1 2 3 4 5 6 7 8 9 checking the valve clearance 1. Remove the flywheel magnet cover 1, cover 2, disconnect the high-tension cords 3 and fuel hoses 4, and then remove the spark plugs. 2. Turn the flywheel magnet clockwise and align the tdc mark a on the flywheel magnet with the pointer b, ...

Page 100

Powr power unit 5-7 60c5d11 6. Turn the flywheel magnet 360° clock- wise. Caution: do not turn the flywheel magnet counter- clockwise, otherwise the valve system may be damaged. 7. Check the intake valve clearance for cyl- inders #3 and #4, and the exhaust valve clearance for cylinders #2 and #4. Ad...

Page 101

60c5d11 5-8 1 2 3 4 5 6 7 8 9 10. Measure the valve pad thickness with a micrometer. Select the necessary valve pad by calcu- lating its thickness with the following for- mula. Example: if the “removed valve pad thickness” is 2.10 mm, the “checked valve clearance” is 0.30 mm and the “specified valve...

Page 102

Powr power unit 5-9 60c5d11 21. Install the cover and flywheel magnet cover. Checking the compression pressure 1. Start the engine, warm it up for 5 min- utes, and then turn it off. 2. Remove the clip from the engine shut-off switch on the remote control box or tiller handle. 3. Remove the cover and...

Page 103

60c5d11 5-10 1 2 3 4 5 6 7 8 9 removing the power unit 1. Remove the flywheel magnet cover and flywheel magnet. Caution: • before removing the power unit, discon- nect the battery terminals. • apply force in the direction of the arrows shown, to prevent the flywheel holder from slipping off easily. ...

Page 104

Powr power unit 5-11 60c5d11 3. Disconnect the pilot water hose 7 and remove the engine oil dipstick 8 and cover 9. 4. Disconnect the battery leads 0, wiring harness a, and ptt motor leads b. 5. Remove the apron c and power unit by removing the bolts d. S60c5100 s60c5110 s60c5120

Page 105

60c5d11 5-12 1 2 3 4 5 6 7 8 9 timing belt and sprockets 5 no. Part name q’ty remarks 1 screw 1 m4 × 10 mm 2 bolt 3 m6 × 30 mm 3 lighting coil 1 4 bolt 4 m6 × 30 mm 5 lighting coil base 1 6 dowel pin 1 7 cover 1 8 screw 2 9 screw 3 m6 × 20 mm 10 neutral switch 1 tiller handle model 11 plate 1 tiller...

Page 106

Powr power unit 5-13 60c5d11 s60c5140 67f-46241-00 19 18 29 28 31 26 27 22 15 20 16 30 23 21 24 25 17 t r . . 265 n · m (26.5 kgf · m, 192 ft · lb) e e e t r . . 39 n · m (3.9 kgf · m, 28 ft · ib) t r . . 60 n · m (6.0 kgf · m, 43 ft · ib) 8 11 12 12 7 6 1 4 (b) r 4 5 3 10 9 2 9 13 14 3 (b/w) t r . ...

Page 107

60c5d11 5-14 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 starter motor 1 2 ignition coil 2 3 starter motor lead 1 black/white 4 starter motor lead 1 black 5 washer 2 6 nut 2 7 bolt 3 m8 × 45 mm 8 bolt 1 m6 × 20 mm 9 ground lead 3 10 ignition coil lead 2 11 bolt 4 m6 × 30 mm 12 spark plug cap 4 13...

Page 108

Powr power unit 5-15 60c5d11 s60c5150 1 2 26 3 13 14 19 21 22 20 6 10 7 8 12 11 9 4 18 17 24 16 15 28 23 5 27 25 24 25 t r . . 8 n ¥ m (0.8 kgf ¥ m, 5.8 ft ¥ ib) t r . . 2 n ¥ m (0.2 kgf ¥ m, 1.4 ft ¥ ib).

Page 109

60c5d11 5-16 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 cover 1 2 starter relay 1 3 power trim and tilt relay 2 4 cdi unit 1 5 rectifier regulator 1 6 wiring harness 1 7 oil pressure switch 1 8 bolt 1 m4 × 8 mm 9 oil pressure switch lead 1 10 bolt 2 m6 × 12 mm 11 thermo sensor coupler 1 12 groun...

Page 110

Powr power unit 5-17 60c5d11 removing the timing belt and sprockets 1. Set the cylinder #1 piston position to tdc of the compression stroke by align- ing “ ” marks a and b on the driven sprockets, and the hole c on the retain- ing plate with the notch d on the cylinder block. Caution: do not turn th...

Page 111

60c5d11 5-18 1 2 3 4 5 6 7 8 9 note: do not turn the camshaft when loosening the driven sprocket bolt. 6. Remove the nut 1, drive sprocket a, retaining plate b, and woodruff key c. Checking the timing belt and sprockets 1. Check the interior and exterior of the tim- ing belt for cracks, damage, or w...

Page 112

Powr power unit 5-19 60c5d11 3. Check that the hole c on the retaining plate is aligned with the notch d on the cylinder block. 4. Install the timing belt 7 from the drive sprocket side with its part number in the upright position. Caution: • do not twist, turn inside out, or bend the timing belt be...

Page 113

60c5d11 5-20 1 2 3 4 5 6 7 8 9 7. Tighten the tensioner bolts to the speci- fied torque. 8. Turn the drive sprocket two turns, and then check that the alignment marks are aligned. Caution: do not turn the sprockets counterclock- wise, otherwise the valve system may be damaged. 9. Tighten the driven ...

Page 114

Powr power unit 5-21 60c5d11 cylinder head 5 s60c5320 11 1 8 9 6 7 10 12 4 13 2 3 3 14 4 4 4 5 15 t r . . 8 n • m (0.8 kgf • m, 5.8 ft • ib) lt 271 gm 4 e e e e e e t r . . 1st 8 n • m (0.8 kgf • m, 5.8 ft • lb) 2nd 17 n • m (1.7 kgf • m, 12 ft • lb) t r . . 2 n • m (0.2 kgf • m, 1.4 ft • ib) e t r ...

Page 115

60c5d11 5-22 1 2 3 4 5 6 7 8 9 È tightening sequence no. Part name q’ty remarks 1 cylinder head cover 1 2 camshaft 2 3 camshaft cap 2 4 camshaft cap 8 5 fuel pump bracket 1 6 oil filler cap 1 7 o-ring 1 3.1 × 30.6 mm 8 bolt 14 m6 × 30 mm 9 gasket 1 not reusable 10 breather cover 1 11 screw 8 m4 × 8 ...

Page 116

Powr power unit 5-23 60c5d11 s60c5330 1 4 7 8 9 5 6 3 13 14 22 20 18 17 19 21 23 24 16 15 12 11 10 2 23 22 21 20 19 18 17 e e e e e e lt 271 a a t r . . 1st 14 n • m (1.4 kgf • m, 10 ft • lb) 2nd 28 n • m (2.8 kgf • m, 20 ft • lb) t r . . 1st 15 n • m (1.5 kgf • m, 11 ft • lb) 2nd 30 n • m (3.0 kgf ...

Page 117

60c5d11 5-24 1 2 3 4 5 6 7 8 9 È tightening sequence no. Part name q’ty remarks 1 cylinder head 1 2 exhaust valve 8 3 intake valve 8 4 cylinder head gasket 1 not reusable 5 dowel pin 2 6 bolt 5 m8 × 55 mm 7 bolt 2 m6 × 25 mm 8 cover 1 9 thermostat 1 10 bolt 10 m10 × 143 mm 11 spark plug 4 12 bolt 4 ...

Page 118

Powr power unit 5-25 60c5d11 removing the cylinder head 1. Check that the camshaft dowel pin holes a are in the position shown in the illus- tration. Adjust if necessary. 2. Remove the cylinder head cover. 3. Remove the camshaft cap bolts in the sequence shown. 4. Remove camshaft caps 1 and 2, cam- ...

Page 119

60c5d11 5-26 1 2 3 4 5 6 7 8 9 note: do not mix the valve train parts. Keep them organized in their proper groups. 7. Remove the intake valve and exhaust valves. Note: • be sure to keep the valves, springs, and other parts in the order as they were removed. • when replacing the valve, also replace t...

Page 120

Powr power unit 5-27 60c5d11 3. Measure the valve stem diameter b. Replace if out of specification. 4. Measure the valve stem runout. Replace if out of specification. Checking the valve guides note: • use the valve guide clearance calculation method or the valve runout measurement method to check th...

Page 121

60c5d11 5-28 1 2 3 4 5 6 7 8 9 replacing the valve guides 1. Remove the valve guide 1 by striking the special service tool from the combus- tion chamber side. 2. Install the new valve guide 2 by striking the special tool from the camshaft side to the specified position a. Note: • before installing t...

Page 122

Powr power unit 5-29 60c5d11 4. Measure the valve seat contact width a where the blueing dye is adhered to the valve face. Reface the valve seat if the valve is not seated properly or if the valve seat contact width is out of specification. Replace the valve guide if the valve seat contact is uneven...

Page 123

60c5d11 5-30 1 2 3 4 5 6 7 8 9 caution: do not over cut the valve seat. Be sure to turn the cutter evenly downward at a pres- sure of 40–50 n (4–5 kgf, 8.8–11 lbf) to prevent chatter marks. 3. Use a 30° cutter to adjust the contact width of the top edge of the valve seat. B previous contact width 4....

Page 124

Powr power unit 5-31 60c5d11 8. If the valve seat contact area is too nar- row and situated near the bottom edge of the valve face, use a 60° cutter to cut the bottom edge of the valve seat. If neces- sary, use a 45° cutter to center the area and set its width. B previous contact width 9. Apply a th...

Page 125

60c5d11 5-32 1 2 3 4 5 6 7 8 9 3. Measure the camshaft journal diameter c and cylinder head journal inside diam- eter d. Replace the camshaft and cylin- der head if out of specification. 4. Calculate the camshaft oil clearance e as follows. Replace the camshaft and cylinder head as a set if out of s...

Page 126

Powr power unit 5-33 60c5d11 installing the valves 1. Install the new valve stem seal 1 to the valve guide. 2. Install the valve 2, spring seat 3, valve spring 4, and spring retainer 5 in the sequence shown, and then attach the special service tool. 3. Compress the valve spring, and then install the...

Page 127

60c5d11 5-34 1 2 3 4 5 6 7 8 9 installing the cylinder head 1. Tighten the cylinder head bolts to the specified torques, in the specified stages, and in the sequence detailed in the spec- ification box. Caution: do not reuse the cylinder head gasket, always replace it with a new one. Note: • apply e...

Page 128

Powr power unit 5-35 60c5d11 4. Install the camshaft caps in the proper position as shown and with the stamped numbers facing upside down. 5. Tighten the camshaft cap bolts to the specified torques in two stages and in the sequence shown. Note: apply engine oil to the camshaft cap bolts before insta...

Page 129

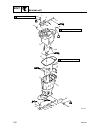

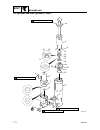

60c5d11 5-36 1 2 3 4 5 6 7 8 9 cylinder body 5 no. Part name q’ty remarks 1 crankshaft 1 2 crankcase 1 3 cylinder body 1 4 piston and connecting rod 4 5 connecting rod cap 4 6 connecting rod bearing 8 7 bolt 8 not reusable m8 × 38 mm 8 oil ring 4 9 second ring 4 10 top ring 4 11 main bearing 10 12 o...

Page 130

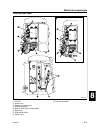

Powr power unit 5-37 60c5d11 s60c5750 2 23 18 6 7 8 15 13 12 19 20 22 21 1 5 3 4 16 17 14 10 11 9 e e a a lt 572 t r . . 1st 6 n • m (0.6 kgf • m, 4.3 ft • lb) 2nd 12 n • m (1.2 kgf • m, 8.7 ft • lb) t r . . 18 n • m (1.8 kgf • m, 13 ft • ib) t r . . 23 n • m (2.3 kgf • m, 17 ft • ib).

Page 131

60c5d11 5-38 1 2 3 4 5 6 7 8 9 È tightening sequence no. Part name q’ty remarks 1 exhaust cover 1 2 oil filter 1 3 gasket 1 not reusable 4 bolt 1 5 gasket 1 not reusable 6 gasket 1 not reusable 7 thermo sensor 1 8 retainer 1 9 bolt 2 m6 × 16 mm 10 clamp 1 11 bolt 1 m6 × 10 mm 12 gasket 1 not reusabl...

Page 132

Powr power unit 5-39 60c5d11 removing and installing the oil filter 1. Place a rag under the oil filter, and then remove the filter. Note: be sure to clean up any oil spills. 2. Apply a thin coat of engine oil to the o- ring of the new oil filter. 3. Install the oil filter, and then tighten it to th...

Page 133

60c5d11 5-40 1 2 3 4 5 6 7 8 9 note: do not remove the ignition timing pointer from the crankcase. 3. Remove the connecting rod bolts and the connecting rod caps. Note: • be sure to keep the bearings in the order as they were removed, and to note the bearing color of the bearing. • after removing th...

Page 134

Powr power unit 5-41 60c5d11 checking the piston clearance 1. Rebore the cylinder or replace the piston and piston rings as a set, or the cylinder body, or all parts if out of specification. Checking the piston rings 1. Check the piston ring dimensions of b and t. Replace if out of specification. 2....

Page 135

60c5d11 5-42 1 2 3 4 5 6 7 8 9 checking the piston ring grooves 1. Measure the piston ring grooves. Replace the piston if out of specification. Checking the piston ring side clearance 1. Measure the piston ring side clearance. Replace the piston and piston rings as a set if out of specification. Che...

Page 136

Powr power unit 5-43 60c5d11 2. Measure the crankshaft runout. Replace the crankshaft if out of specification. Checking the crankshaft pin oil clearance 1. Clean the bearings and the connecting rod. 2. Install the upper half of the bearing into the connecting rod 1 and the lower half into the connec...

Page 137

60c5d11 5-44 1 2 3 4 5 6 7 8 9 5. Tighten the connecting rod bolts to the specified torques in two stages. Note: • reuse the connecting rod bolts. • do not turn the connecting rod until the crank pin oil clearance measurement has been completed. • make a mark on the connecting rod bolts and connecti...

Page 138

Powr power unit 5-45 60c5d11 3. Check the crank pin mark on the crank- shaft 2. 4. Select the suitable color b for the con- necting rod bearing from the table. 5. Subtract the crank pin diameters (#1–#4) from the connecting rod big end diame- ters (#1–#4). Note: the crank pin diameters (#1–#4) can b...

Page 139

60c5d11 5-46 1 2 3 4 5 6 7 8 9 3. Install half of the bearings (grooved bear- ings) 1 and the crankshaft into the cylin- der body 2. Caution: install the bearings in their original posi- tions. Note: install the unified thrust bearing at the posi- tion a shown. 4. Put a piece of plastigauge (pg-1) o...

Page 140

Powr power unit 5-47 60c5d11 8. Remove the crankcase and measure the width of the compressed plastigauge (pg-1) on each main journal. Replace the main bearing if out of specification. Selecting the crankshaft main journal bearing 1. When replacing the main bearing, select the suitable bearing as fol...

Page 141

60c5d11 5-48 1 2 3 4 5 6 7 8 9 5. Select the suitable bearing from the table below according to the calculated values. Caution: • the (*) mark indicates that the color of the upper and lower bearings are differ- ent. • be sure to install the main bearings in the middle of the cylinder body and crank...

Page 142

Powr power unit 5-49 60c5d11 caution: install the bearings in their original posi- tion. 4. Install the piston with the “up” mark on the piston crown facing towards the fly- wheel magnet. Note: apply engine oil to the sides of the piston assembly. 5. Install half of the bearings (grooved bear- ings)...

Page 143

60c5d11 5-50 1 2 3 4 5 6 7 8 9 note: • make sure that the large, flat side c of the connecting rod faces towards the flywheel magnet side of the crankshaft. • apply engine oil to the connecting rod cap and connecting rod bolt. 8. Install half of the bearings (plain bear- ings) b into the crankcase. ...

Page 144

Powr power unit 5-51 60c5d11 11. Install the new gasket and exhaust cover, and then tighten the bolts to the specified torques in two stages and in the sequence shown. Installing the power unit 1. Install the dowel pins 1 and gasket 2. 2. Install the power unit 3 by installing bolts 4 and 5, then ti...

Page 145

60c5d11 5-52 1 2 3 4 5 6 7 8 9 5. Connect the pilot water hose 0 and install the engine oil dipstick a. 6. Connect the shift cable b and throttle cable c, and then adjust their lengths. For adjustment procedures, see chapter 3, “checking the throttle cable opera- tion,” and “checking the gearshift o...

Page 146: Lower Unit

Lowr 60c5d11 lower unit special service tools ..................................................................................... 6-1 lower unit (f100b)......................................................................................... 6-4 removing the lower unit ...............................

Page 147

60c5d11 1 2 3 4 5 6 7 8 9 propeller shaft housing (f100c)................................................................. 6-37 removing the propeller shaft housing assembly..................................... 6-39 disassembling the propeller shaft housing..............................................

Page 148

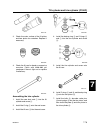

Lowr lower unit 6-1 60c5d11 special service tools 6 ring nut wrench 3 90890-06511 ring nut wrench extension 90890-06513 bearing housing puller claw l 90890-06502 stopper guide plate 90890-06501 center bolt 90890-06504 bearing separator 90890-06534 stopper guide stand 90890-06538 bearing puller 90890...

Page 149

60c5d11 6-2 1 2 3 4 5 6 7 8 9 driver rod ll 90890-06605 driver rod l3 90890-06652 driver rod ss 90890-06604 bearing depth plate 90890-06603 bearing inner race attachment 90890-06639, 90890-06641, 90890-06643, 90890-06661, 90890-06662 drive shaft holder 5 90890-06519 pinion nut holder 90890-06505 soc...

Page 150

Lowr lower unit 6-3 60c5d11 driver rod ls 90890-06606 pinion height gauge 90890-06702 digital caliper 90890-06704 shimming plate 90890-06701 shift rod push arm 90890-06052 backlash indicator 90890-06706 magnet base plate 90890-07003 dial gauge set 90890-01252 magnet base 90890-06705.

Page 151

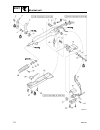

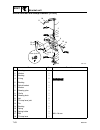

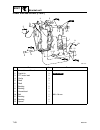

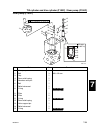

60c5d11 6-4 1 2 3 4 5 6 7 8 9 lower unit (f100b) 6 no. Part name q’ty remarks 1 lower unit 1 2 plastic tie 1 not reusable 3 hose 1 7 × 145 mm 4 check screw 1 5 gasket 2 not reusable 6 dowel pin 2 7 bolt 6 m10 × 45 mm 8 drain screw 1 9 grommet 1 10 bolt 1 m10 × 45 mm 11 bolt 1 m10 × 70 mm 12 spacer 1...

Page 152

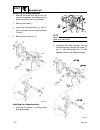

Lowr lower unit 6-5 60c5d11 s60c6025 a a a a 11 12 13 14 15 16 17 18 20 19 21 22 23 24 24 9 10 1 2 3 4 5 6 7 8 lt 572 lt 572 aa.

Page 153

60c5d11 6-6 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 shift rod assembly 1 2 oil seal 1 not reusable 3 oil seal housing 1 4 o-ring 1 not reusable 3.1 × 64.6 mm 5 spring 1 6 circlip 1 7 shift rod 1 8 bolt 3 m6 × 20 mm 9 woodruff key 1 10 bolt 4 m8 × 45 mm 11 cover 1 12 seal 1 13 water pump housi...

Page 154

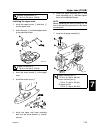

Lowr lower unit 6-7 60c5d11 removing the lower unit 1. Drain the gear oil. For draining proce- dures, see chapter 3, “changing the gear oil.” 2. Set the gearshift to the neutral position, and place a block of wood between the anti-cavitation plate and propeller to keep the propeller from turning, an...

Page 155

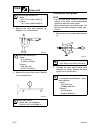

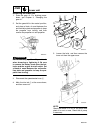

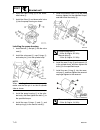

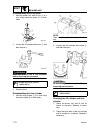

60c5d11 6-8 1 2 3 4 5 6 7 8 9 removing the water pump and shift rod 1. Remove the water pump assembly and shift rod assembly 1. Checking the water pump and shift rod 1. Check the pump housing for deforma- tion. Replace if necessary. 2. Check the impeller 1 and insert car- tridge 2 for cracks or wear...

Page 156

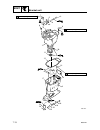

Lowr lower unit 6-9 60c5d11 propeller shaft housing (f100b) 6 s60c6085 24 e a a 23 21 20 19 18 e 22 d 3 1 2 6 7 5 4 d d t r . . 103 n • m (10.3 kgf • m, 74 ft • lb) 8 9 10 11 12 13 9 13 11 16 14 17 15 12 10 12 8 14 15 16 17.

Page 157

60c5d11 6-10 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 propeller shaft assembly 1 2 propeller shaft housing assembly 1 3 reverse gear shim — as required 4 washer 2 5 straight key 1 6 claw washer 1 7 ring nut 1 8 shift rod joint 1 9 ball 2 10 slider 1 11 ball 2 12 ball 2 13 spring 1 14 dog clutc...

Page 158

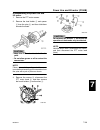

Lowr lower unit 6-11 60c5d11 removing the propeller shaft housing assembly 1. Straighten the claw washer tabs a, and then remove the ring nut and claw washer. 2. Pull out the propeller shaft housing assembly. Disassembling the propeller shaft housing 1. Remove the reverse gear and thrust washer. Not...

Page 159

60c5d11 6-12 1 2 3 4 5 6 7 8 9 2. Remove the ball bearing. 3. Remove the oil seals and needle bear- ing. Disassembling the propeller shaft assembly 1. Remove the spring 1, and then remove the cross pin 2, dog clutch 3, slider, and spring. Checking the propeller shaft housing 1. Clean the propeller s...

Page 160

Lowr lower unit 6-13 60c5d11 3. Check the bearings for pitting or rum- bling. Replace if necessary. Checking the propeller shaft 1. Check the propeller shaft for bends or wear. Replace if necessary. 2. Check the dog clutch, shift rod joint, and shift slider for cracks or wear. Replace if necessary. ...

Page 161

60c5d11 6-14 1 2 3 4 5 6 7 8 9 2. Apply grease to the new oil seals, and then install them into the propeller shaft housing to the specified depth. Note: install an oil seal halfway into the propeller shaft housing, then the other oil seal. 3. Install the thrust washer 6 and ball bear- ing 7 to the ...

Page 162

Lowr lower unit 6-15 60c5d11 drive shaft and lower case (f100b) 6.

Page 163

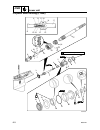

60c5d11 6-16 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 drive shaft 1 2 sleeve 1 3 cover 1 4 oil seal 2 not reusable 5 bolt 4 m8 × 25 mm 6 drive shaft housing 1 7 needle bearing 1 8 o-ring 1 not reusable 3 × 60.5 mm 9 pinion shim — as required 10 thrust bearing 1 11 seal 1 12 plate 1 13 joint 1 ...

Page 164

Lowr lower unit 6-17 60c5d11 removing the drive shaft 1. Remove the drive shaft assembly and pinion, and then pull out the forward gear. Disassembling the drive shaft housing 1. Remove the cover, oil seals, and needle bearing. Disassembling the forward gear 1. Remove the taper roller bearing from th...

Page 165

60c5d11 6-18 1 2 3 4 5 6 7 8 9 disassembling the lower case 1. Remove the taper roller bearing outer race and shim(s). Note: install the claws as shown. 2. Remove the needle bearing. Checking the pinion and forward gear 1. Check the teeth of the pinion, and the teeth and dogs of the forward gear for...

Page 166

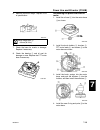

Lowr lower unit 6-19 60c5d11 checking the lower case 1. Check the skeg and torpedo for cracks or damage. Replace if necessary. Assembling the lower case 1. Install the needle bearing into the lower case to the specified depth. Note: • install the needle bearing with the manufac- ture identification ...

Page 167

60c5d11 6-20 1 2 3 4 5 6 7 8 9 2. Install the new taper roller bearing into the forward gear using a press. Assembling the drive shaft housing 1. Install the needle bearing into the drive shaft housing to the specified depth. Note: when using the driver rod, do not strike the special tool in a manne...

Page 168

Lowr lower unit 6-21 60c5d11 note: install the drive shaft by lifting it up slightly, then aligning it with the pinion and the spline of the drive shaft. 4. Tighten the housing bolt. Installing the propeller shaft housing 1. Install the washers 1 and propeller shaft assembly 2 into the propeller sha...

Page 169

60c5d11 6-22 1 2 3 4 5 6 7 8 9 installing the water pump and shift rod 1. Install the shift rod assembly 1. 2. Install the new gasket 2, outer plate car- tridge 3, and dowel pins 4. 3. Install the woodruff key into the drive shaft. 4. Align the groove on the impeller 5 with the woodruff key 6, and t...

Page 170

Lowr lower unit 6-23 60c5d11 6. Install the o-ring a and insert cartridge b into the pump housing c. Note: align the insert cartridge projections b with the holes c in the pump housing. 7. Install the o-ring d and pump housing assembly e into the lower case, tighten the bolts f, and then install the...

Page 171

60c5d11 6-24 1 2 3 4 5 6 7 8 9 4. Install the trim tab 2 to its original posi- tion, and then connect the speedometer hose 3. 5. Install the propeller and propeller nut, and then tighten the nut finger tight. Place a block of wood between the anti- cavitation plate and propeller to keep the propelle...

Page 172

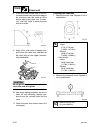

Lowr lower unit 6-25 60c5d11 shimming (f100b) 6 t3 b4 59.0 a3 a1 b2 t2 15.8 a2 34.0 b1 t1 f r p b3 s60c6305.

Page 173

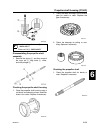

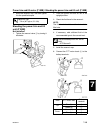

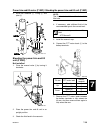

60c5d11 6-26 1 2 3 4 5 6 7 8 9 shimming note: • shimming is not required when assembling the original lower case and inner parts. • shimming is required when assembling the original inner parts and a new lower case. • shimming is required when replacing the inner part(s). Selecting the pinion shims ...

Page 174

Lowr lower unit 6-27 60c5d11 note: “p” is the deviation of the lower case dimen- sion from standard. The “p” mark a is stamped on the trim tab mounting surface of the lower case in 0.01 mm units. If the “p” mark is unreadable, assume that “p” is zero and check the backlash when the unit is assembled...

Page 175

60c5d11 6-28 1 2 3 4 5 6 7 8 9 example: if “m1” is 24.10 mm and “f” is (+5), then t1 = 24.60 + (+5)/100 – 24.10 mm = 24.60 + 0.05 – 24.10 mm = 0.55 mm 3. Select the forward gear shim(s) (t1) as follows. Example: if “t1” is 0.55 mm, then the forward gear shim is 0.52 mm. If “t1” is 0.60 mm, then the ...

Page 176

Lowr lower unit 6-29 60c5d11 3. Select the reverse gear shim(s) (t2) as follows. Example: if “t2” is 0.53 mm, then the reverse gear shim is 0.55 mm. If “t2” is 0.50 mm, then the reverse gear shim is 0.50 mm. Backlash (f100b) 6 measuring the forward and reverse gear backlash 1. Remove the water pump ...

Page 177

60c5d11 6-30 1 2 3 4 5 6 7 8 9 6. Slowly turn the drive shaft clockwise and counterclockwise and measure the back- lash when the drive shaft stops in each direction. 7. Add or remove shims if out of specifica- tion. M: measurement 8. Remove the special service tools from the propeller shaft. 9. Appl...

Page 178

Lowr lower unit 6-31 60c5d11 lower unit (f100c) 6 s60c6385 18 17 16 15 14 13 9 10 8 11 6 3 8 1 4 5 5 7 12 2 d m t r . . 7 n • m (0.7 kgf • m, 5.1 ft • ib) a t r . . 7 n • m (0.7 kgf • m, 5.1 ft • ib) t r . . 34 n • m (3.4 kgf • m, 25 ft • ib) lt 572 t r . . 39 n • m (3.9 kgf • m, 28 ft • ib) lt 572.

Page 179

60c5d11 6-32 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 lower unit 1 2 plastic tie 1 not reusable 3 hose 1 7 × 200 mm 4 check screw 1 5 gasket 2 not reusable 6 bolt 4 m10 × 40 mm 7 drain screw 1 8 dowel pin 2 9 grommet 1 10 bolt 1 m8 × 45 mm 11 trim tab 1 12 bolt 1 m8 × 60 mm 13 spacer 1 14 prop...

Page 180

Lowr lower unit 6-33 60c5d11 s60c6400 8 9 12 10 11 13 15 16 18 19 20 21 23 22 24 25 17 17 14 7 a a a a a lt 572 lt 572 lt 572 2 4 1 5 6 a 3.

Page 181

60c5d11 6-34 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 shift rod 1 2 o-ring 1 not reusable 1.9 × 10.6 mm 3 oil seal 1 not reusable 4 bolt 2 m6 × 16 mm 5 oil seal housing 1 6 o-ring 1 not reusable 3.1 × 55.6 mm 7 circlip 1 8 screw 2 9 cover 1 10 bolt 2 m8 × 75 mm 11 bolt 2 m8 × 50 mm 12 seal 1 1...

Page 182

Lowr lower unit 6-35 60c5d11 removing the lower unit 1. Drain the gear oil. For draining proce- dures, see chapter 3, “changing the gear oil.” 2. Set the gearshift to the neutral position, and place a block of wood between the anti-cavitation plate and propeller to keep the propeller from turning, a...

Page 183

60c5d11 6-36 1 2 3 4 5 6 7 8 9 removing the water pump and shift rod 1. Remove the water pump assembly and shift rod assembly 1. Note: pull up the shift rod assembly a little a to dis- connect it from the shift slider 2, turn it clock- wise 90° b, and then remove it. Checking the water pump and shif...

Page 184

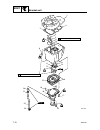

Lowr lower unit 6-37 60c5d11 propeller shaft housing (f100c) 6 s60c6460 13 12 2 11 10 1 14 15 16 17 20 20 19 18 5 6 6 7 3 7 8 9 8 3 3 4 9 5 4 d d a d a a e e t r . . 103 n • m (10.3 kgf • m, 74 ft • lb).

Page 185

60c5d11 6-38 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 propeller shaft assembly 1 2 propeller shaft housing assembly 1 3 ball 2 4 slider 1 5 shift plunger 1 6 cross pin 1 7 dog clutch 1 8 spring 1 9 propeller shaft 1 10 washer 1 11 straight key 1 12 claw washer 1 13 ring nut 1 14 reverse gear 1...

Page 186

Lowr lower unit 6-39 60c5d11 removing the propeller shaft housing assembly 1. Straighten the claw washer tabs a, and then remove the ring nut and claw washer. 2. Pull out the propeller shaft housing assembly. Disassembling the propeller shaft housing 1. Remove the reverse gear and thrust washer. Not...

Page 187

60c5d11 6-40 1 2 3 4 5 6 7 8 9 disassembling the propeller shaft assembly 1. Remove the spring 1, and then remove the cross pin 2, dog clutch 3, slider, and shift plunger 4. Checking the propeller shaft housing 1. Clean the propeller shaft housing using a soft brush and cleaning solvent, and then ch...

Page 188

Lowr lower unit 6-41 60c5d11 2. Check the dog clutch and shift slider for cracks or wear. Replace if necessary. Assembling the propeller shaft assembly 1. Install the dog clutch as shown. Note: install the dog clutch 1 with the “f” mark a facing toward the shift slider. Assembling the propeller shaf...

Page 189

60c5d11 6-42 1 2 3 4 5 6 7 8 9 note: install an oil seal halfway into the propeller shaft housing, then the other oil seal. 3. Install the thrust washer 6 and ball bear- ing 7 to the reverse gear 8 using a press. Note: install the ball bearing with the manufacture identification mark e facing outwar...

Page 190

Lowr lower unit 6-43 60c5d11 drive shaft and lower case (f100c) 6.

Page 191

60c5d11 6-44 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 drive shaft 1 2 taper roller bearing 1 not reusable 3 bearing outer race 1 not reusable 4 pinion shim — as required 5 sleeve 1 6 hose 1 7 × 300 mm 7 plastic tie 1 not reusable 8 joint 1 9 nut 1 10 water inlet cover 2 11 screw 1 12 seal 1 13...

Page 192

Lowr lower unit 6-45 60c5d11 removing the drive shaft 1. Remove the drive shaft assembly and pinion, and then pull out the forward gear. Disassembling the drive shaft 1. Install the pinion nut 1, tighten it finger tight, and then remove the drive shaft bearing 2 using a press. Caution: • do not pres...

Page 193

60c5d11 6-46 1 2 3 4 5 6 7 8 9 disassembling the lower case 1. Remove the taper roller bearing outer race and shim(s). Note: install the claws as shown. 2. Remove the drive shaft bearing outer race, shim(s), and drive shaft sleeve. Note: install the claws as shown. 3. Remove the needle bearing. Chec...

Page 194

Lowr lower unit 6-47 60c5d11 checking the lower case 1. Check the skeg and torpedo for cracks or damage. Replace if necessary. Assembling the lower case 1. Install the needle bearing into the lower case to the specified depth. Note: • install the needle bearing with the manufac- ture identification ...

Page 195

60c5d11 6-48 1 2 3 4 5 6 7 8 9 caution: add or remove shims, if necessary, when replacing the forward gear or lower case. Assembling the forward gear 1. Install the new needle bearing into the forward gear to the specified depth. 2. Install the new taper roller bearing into the forward gear using a ...

Page 196

Lowr lower unit 6-49 60c5d11 installing the propeller shaft housing 1. Install the washer 1, propeller shaft assembly 2, into the propeller shaft housing assembly 3. 2. Apply grease to the new o-rings. 3. Install the propeller shaft housing assem- bly 4 into the lower case, and then install the stra...

Page 197

60c5d11 6-50 1 2 3 4 5 6 7 8 9 note: install the shift rod assembly into the lower case, turn it counterclockwise 90° a, and then push it down b to connect it to the shift slider 2. 2. Install the new oil seals into the oil seal housing as shown. 3. Install the new o-ring 5. 4. Install the new gaske...

Page 198

Lowr lower unit 6-51 60c5d11 7. Install the insert cartridge b and inner plate cartridge c into the pump housing d. Note: align the insert cartridge projections c with the holes d in the pump housing. 8. Install the new gasket e, pump housing assembly f, and dowel pins g to the lower case. 9. Instal...

Page 199

60c5d11 6-52 1 2 3 4 5 6 7 8 9 4. Install the trim tab 2 to its original posi- tion, and then connect the speedometer hose 3. 5. Install the propeller and propeller nut, and then tighten the nut finger tight. Place a block of wood between the anti- cavitation plate and propeller to keep the propelle...

Page 200

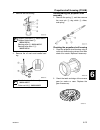

Lowr lower unit 6-53 60c5d11 shimming (f100c) 6.

Page 201

60c5d11 6-54 1 2 3 4 5 6 7 8 9 shimming note: • shimming is not required when assembling the original lower case and inner parts. • shimming is required when assembling the original inner parts and a new lower case. • shimming is required when replacing the inner part(s). Selecting the pinion shims ...

Page 202

Lowr lower unit 6-55 60c5d11 example: if “m” is 32.10 mm and “p” is (+5), then t3 = 32.10 – 31.50 – (+5)/100 mm = 0.60 – 0.05 mm = 0.55 mm if “m” is 32.10 mm and “p” is (–5), then t3 = 32.10 – 31.50 – (–5)/100 mm = 0.60 + 0.05 mm = 0.65 mm 5. Select the pinion shim(s) (t3) as follows. Example: if “t...

Page 203

60c5d11 6-56 1 2 3 4 5 6 7 8 9 example: if “m” is 24.00 mm and “f” is (+5), then t1 = 24.50 + (+5)/100 – 24.00 mm = 0.50 + 0.05 mm = 0.55 mm if “m” is 24.00 mm and “f” is (–5), then t1 = 24.50 + (–5)/100 – 24.00 mm = 0.50 – 0.05 mm = 0.45 mm 3. Select the forward gear shim(s) (t1) as follows. Exampl...

Page 204

Lowr lower unit 6-57 60c5d11 4. Install the backlash indicator onto the drive shaft (20 mm [0.79 in] in diameter), then the dial gauge onto the lower unit. Note: install the dial gauge so that the plunger a contacts the mark b on the backlash indica- tor. 5. Slowly turn the drive shaft clockwise and...

Page 205: Bracket Unit

60c5d11 brkt 1 2 3 4 5 6 7 8 9 bracket unit special service tools ..................................................................................... 7-1 tiller handle .................................................................................................... 7-3 bottom cowling .............

Page 206

Brkt 60c5d11 power trim and tilt motor (f100b) .............................................................. 7-42 disassembling the power trim and tilt motor............................................ 7-44 checking the power trim and tilt motor .................................................... ...

Page 207

60c5d11 1 2 3 4 5 6 7 8 9 power trim and tilt motor (f100c) .............................................................. 7-86 checking the power trim and tilt motor .................................................... 7-87 assembling the power trim and tilt motor .....................................

Page 208

Brkt bracket unit 7-1 60c5d11 special service tools 7 bearing inner race attachment 90890-06662 up relief fitting 90890-06773 down relief fitting 90890-06774 hydraulic pressure gauge 90890-06776 trim & tilt wrench 90890-06548 cylinder-end screw wrench 90890-06544 digital circuit tester 90890-03174.

Page 209: — Memo —

60c5d11 7-2 1 2 3 4 5 6 7 8 9 — memo — special service tools.

Page 210

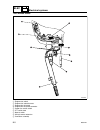

Brkt bracket unit 7-3 60c5d11 tiller handle 7.

Page 211

60c5d11 7-4 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 tiller handle assembly 1 2 wiring harness extension 1 3 engine start switch lead 1 4 ptt switch coupler 1 5 throttle cable 1 6 bolt 1 m6 × 20 mm 7 clamp 1 8 shift cable 1 9 clip 1 10 nut 2 11 cover 1 12 bolt 1 m6 × 25 mm 13 plate 1 14 bolt 2...

Page 212

Brkt bracket unit 7-5 60c5d11.

Page 213

60c5d11 7-6 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 tiller handle sub assembly 1 2 screw 2 m6 × 10 mm 3 shift lever cover 1 4 bolt 1 m8 × 40 mm 5 shift lever 1 6 bushing 1 7 washer 1 8 bushing 2 9 nut 1 10 engine shut-off switch 1 11 nut 1 12 washer 1 13 bracket 1 14 collar 1 15 wave washer 1...

Page 214

Brkt bracket unit 7-7 60c5d11.

Page 215

60c5d11 7-8 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 tiller handle 1 2 cotter pin 1 not reusable 3 friction adjusting knob 1 4 grommet 1 5 plastic tie 2 not reusable 6 cable clamp 1 7 stay 1 8 bolt 1 m6 × 14 mm 9 throttle cable 1 short 10 clip 1 11 throttle arm 1 12 throttle arm shaft 1 13 shi...

Page 216

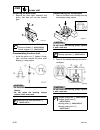

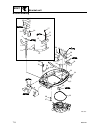

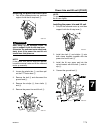

Brkt bracket unit 7-9 60c5d11 bottom cowling 7 s60c7030 29 18 22 23 25 26 27 28 31 32 30 18 19 20 33 37 36 2 24 21 4 5 6 7 8 9 10 3 9 1 11 12 13 14 15 16 12 17 34 34 35 38 a a a a a a a a aa a a a a a a.

Page 217

60c5d11 7-10 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 shift rod 1 2 bottom cowling 1 3 shift rod bracket 1 4 bolt 1 5 spring 1 6 ball 1 7 cotter pin 1 not reusable 8 washer 1 9 bushing 2 10 bolt 2 m6 × 25 mm 11 grommet 1 12 clip 2 13 shift rod lever 1 14 washer 1 15 shift bracket 1 16 bushing ...

Page 218

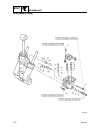

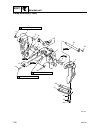

Brkt bracket unit 7-11 60c5d11 upper case (f100b) 7 s60c7040 13 12 12 15 16 17 20 19 21 1 22 23 18 14 13 lt lt 572 5 3 4 6 7 8 9 10 10 2 11 18 a a lt 572 e a a t r . . 73 n • m (7.3 kgf • m, 53 ft • lb) t r . . 53 n • m (5.3 kgf • m, 38 ft • ib) t r . . 4 n • m (0.4 kgf • m, 2.9 ft • ib) t r . . 11 ...

Page 219

60c5d11 7-12 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 upper case assembly 1 2 oil pump body 1 3 oil seal 1 not reusable 4 oil seal 1 not reusable 5 bolt 6 m6 × 45 mm 6 screw 6 m6 × 10 mm 7 cover 1 8 gasket 1 not reusable 9 shaft 1 10 o-ring 2 not reusable 11 oil seal 1 not reusable 12 dowel pi...

Page 220

Brkt bracket unit 7-13 60c5d11 s60c7045 a a a a a a 6 8 3 5 18 19 20 22 21 9 11 10 1 13 15 16 23 24 2 14 lt 572 lt 572 7 4 12 17 a a 17 t r . . 26 n • m (2.6 kgf • m, 19 ft • ib) t r . . 20 n • m (2.0 kgf • m, 14 ft • ib) t r . . 4 n • m (0.4 kgf • m, 2.9 ft • ib) a a.

Page 221

60c5d11 7-14 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 muffler assembly 1 2 upper case 1 3 bolt 2 m12 × 193 mm 4 washer 2 5 plate 1 6 upper mount 1 7 bolt 3 m8 × 45 mm 8 grommet 1 9 bolt 4 m8 × 40 mm 10 muffler seal 1 11 rubber seal 1 12 gasket 1 not reusable 13 screw 2 m6 × 15 mm 14 baffle pla...

Page 222

Brkt bracket unit 7-15 60c5d11 s60c7050 17 16 19 18 20 22 23 14 15 13 12 8 9 7 5 6 4 3 1 10 11 21 16 2 lt 572 lt 572 lt 572 lt 572 lt 572 lt 572 lt 572 lt 572 lt 572 lt 572 a a t r . . 11 n • m (1.1 kgf • m, 8.0 ft • ib) t r . . 11 n • m (1.1 kgf • m, 8.0 ft • ib) a.

Page 223

60c5d11 7-16 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 exhaust guide 1 2 dowel pin 2 3 gasket 1 not reusable 4 gasket 1 not reusable 5 oil strainer 1 6 collar 3 7 bolt 3 m6 × 25 mm 8 bolt 12 m6 × 25 mm 9 oil pan 1 10 gasket 1 not reusable 11 exhaust manifold 1 12 bolt 4 m6 × 70 mm 13 exhaust se...

Page 224

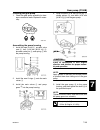

Brkt bracket unit 7-17 60c5d11 disassembling the oil pump 1. Remove oil seals 1 and 2, the cover 3, gasket 4, shaft 5, and o-rings 6. Checking the oil pump 1. Check the shaft for cracks or wear. Replace if necessary. 2. Check the oil seal and o-ring for tears. Replace if necessary. 3. Check the oil ...

Page 225

60c5d11 7-18 1 2 3 4 5 6 7 8 9 3. Install the o-rings 6 into the shaft 7. 4. Install the gasket 8 and the cover 2, and then tighten the screws to the speci- fied torque. Disassembling the oil pan 1. Remove the muffler 1 and plate 2 from the oil pan 3. 2. Remove the exhaust manifold 4 from the oil pa...

Page 226

Brkt bracket unit 7-19 60c5d11 3. Install the oil pan 3 and then tighten the bolts finger tight. 4. Install the exhaust manifold 4 and bolts, and then tighten the bolts finger tight. 5. Tighten the exhaust manifold bolts 5, then the oil pan bolts 6, and then tighten them to the specified torques. 6....

Page 227

60c5d11 7-20 1 2 3 4 5 6 7 8 9 installing the upper case 1. Install the upper mount 1 and bolts 2 into the upper case. 2. Install the bolts 3, and then tighten them to the specified torque. 3. Install the lower mounts 4 to the upper case. 4. Install the mount cover 5. 5. Install the upper and lower ...

Page 228

Brkt bracket unit 7-21 60c5d11 swivel bracket and steering arm (f100b) 7 s60c7115 10 11 1 2 3 15 14 13 4 3 5 6 7 9 8 16 19 20 19 18 23 22 21 17 12 13 a a a a a a a a a a.

Page 229

60c5d11 7-22 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 steering arm 1 2 washer 1 3 bushing 2 4 swivel bracket 1 5 o-ring 1 not reusable 5.6 × 48.2 mm 6 bushing 1 7 washer 1 8 steering yoke 1 9 circlip 1 10 steering hook 1 11 nut 2 12 starboard tilt stop lever 1 13 bushing 2 14 port tilt stop le...

Page 230

Brkt bracket unit 7-23 60c5d11 removing the steering arm 1. Remove the circlip 1. 2. Remove the steering yoke 2 by striking it with a plastic hammer. 3. Remove the steering arm from the swivel bracket by pulling the arm off the bracket. Installing the steering arm 1. Install the washer 1 and bushing...

Page 231

60c5d11 7-24 1 2 3 4 5 6 7 8 9 4. Install the steering arm 3 into the steer- ing yoke 9 by aligning the center a of the yoke with the center b of the steer- ing arm. 5. Install the circlip 0. 6. Inject grease into the grease nipple until grease comes out from both the upper and lower bushings c. A s...

Page 232

Brkt bracket unit 7-25 60c5d11 clamp brackets (f100b) 7 s60c7150 24 t r . . 2 n • m (0.2 kgf • m, 1.4 ft • ib) t r . . 15 n • m (1.5 kgf • m, 11 ft • ib).

Page 233

60c5d11 7-26 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 swivel bracket assembly 1 2 starboard clamp bracket 1 3 port clamp bracket 1 4 self-locking nut 1 5 grease nipple 6 6 ground lead 1 7 washer 1 8 screw 1 m6 × 11 mm 9 washer 2 10 bushing 2 11 trim sensor 1 12 screw 2 m6 × 15 mm 13 trim senso...

Page 234

Brkt bracket unit 7-27 60c5d11 removing the clamp brackets 1. Remove the power trim and tilt unit. For removal procedures, see “removing the power trim and tilt unit” in this chapter. 2. Remove the anode 1. 3. Loosen the self-locking nuts 2, bolt 3, cap 4, and then remove clamp brackets 5 and 6. 4. ...

Page 235

60c5d11 7-28 1 2 3 4 5 6 7 8 9 3. Install the power trim and tilt unit. For installation procedures, see “installing the power trim and tilt unit” in this chap- ter. 4. Inject grease into all grease nipples until grease comes out from the bushings a. Adjusting the trim sensor cam 1. Fully tilt the o...

Page 236

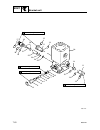

Brkt bracket unit 7-29 60c5d11 power trim and tilt unit (f100b) 7 no. Part name q’ty remarks 1 power trim and tilt unit 1 2 ptt motor lead 2 3 shaft 1 4 plastic tie 3 not reusable 5 circlip 1 6 bolt 2 m8 × 16 mm 7 washer 2 8 shaft 1 9 bushing 6 10 bolt 1 m6 × 10 mm 11 ground lead 1.

Page 237

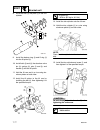

60c5d11 7-30 1 2 3 4 5 6 7 8 9 removing the power trim and tilt unit 1. Fully tilt the outboard motor up, and then support it with the tilt stop lever 1. Warning after tilting up the outboard motor, be sure to support it with the tilt stop lever. Otherwise, the outboard motor could sud- denly lower ...

Page 238

Brkt bracket unit 7-31 60c5d11 tilt cylinder and trim cylinder (f100b) 7 no. Part name q’ty remarks 1 tilt ram 1 2 trim piston assembly 2 3 cylinder body 1 4 free piston 1 5 backup ring 1 6 o-ring 1 not reusable 7 dust seal 2 not reusable 8 seal 2 not reusable 9 trim cylinder end screw 2 10 o-ring 2...

Page 239

60c5d11 7-32 1 2 3 4 5 6 7 8 9 disassembling the tilt cylinder and trim cylinders 1. Hold the power trim and tilt unit 1 in a vise using aluminum plates a on both sides. 2. Loosen the tilt cylinder end screw 2, and then remove it. Warning make sure that the rams are fully extended before removing th...

Page 240

Brkt bracket unit 7-33 60c5d11 note: to remove the free piston, blow compressed air through the hole a while holding down the cloth. 8. Remove the trim piston assemblies. Checking the reservoir 1. Check the reservoir for cracks. Replace if necessary. Checking the tilt cylinder and trim cylinder 1. C...

Page 241

60c5d11 7-34 1 2 3 4 5 6 7 8 9 installing the trim rams 1. Hold the cylinder body 1 in a vise using aluminum plates a on both sides. 2. Add the specified amount of the recom- mended fluid through the cylinder body hole b. 3. Install the new o-ring 2 and backup ring 3 to the free piston 4. 4. Push th...

Page 242

Brkt bracket unit 7-35 60c5d11 warning do not push the trim rams down while installing them into the trim cylinders. Otherwise, the power trim and tilt fluid may spurt out from the unit. Assembling the tilt ram 1. Install the new dust seal 1, and o-rings 2 and 3 into the tilt cylinder end screw 4. 2...

Page 243

60c5d11 7-36 1 2 3 4 5 6 7 8 9 installing the tilt ram 1. Fill the tilt cylinder a with the recom- mended fluid to the correct level as shown. 2. Add a small amount of the recommended fluid through the cylinder body hole b as shown. 3. Install the tilt piston assembly into the tilt cylinder, and the...

Page 244

Brkt bracket unit 7-37 60c5d11 gear pump (f100b) 7.

Page 245

60c5d11 7-38 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 manual valve 1 2 bolt 2 m5 × 16 mm 3 ball 2 4 shuttle piston 2 5 o-ring 2 not reusable 6 main valve 2 7 ball 2 8 bolt 1 m8 × 85 mm 9 bolt 2 m8 × 24 mm 10 circlip 1 11 o-ring 1 not reusable 12 o-ring 1 not reusable 13 backup ring 1 14 spring...

Page 246

Brkt bracket unit 7-39 60c5d11 disassembling the gear pump 1. Remove the main valves 1. Warning never look into the pump housing open- ing because the main valves and power trim and tilt fluid may be expelled out forcefully. Note: to remove the main valves, cover the pump housing with a clean cloth ...

Page 247

60c5d11 7-40 1 2 3 4 5 6 7 8 9 checking the gear pump 1. Check the gear pump assembly for dam- age or excessive wear. Replace if neces- sary. Assembling the pump housing 1. Install the new o-ring 1, up-relief valve seat 2, ball (3.18 mm [0.125 in]) 3, absorber valve pin 4, and spring 5 into the pump...

Page 248

Brkt bracket unit 7-41 60c5d11 6. Install the new o-ring d to the down- relief valve e. 7. Install the filters f and down-relief valve e into the pump housing as shown. Installing the pump housing 1. Install the ball 1 and pin 2 into the valve seat 3. 2. Install the valve seat 3, new o-rings 4, and ...

Page 249

60c5d11 7-42 1 2 3 4 5 6 7 8 9 power trim and tilt motor (f100b) 7 no. Part name q’ty remarks 1 power trim and tilt motor 1 2 reservoir 1 3 reservoir cap 1 4 o-ring 1 not reusable 5 o-ring 1 not reusable 6 bolt 3 m6 × 13 mm 7 bolt 4 m6 × 35 mm 8 o-ring 1 not reusable 9 filter 1 10 joint 1 gear pump ...

Page 250

Brkt bracket unit 7-43 60c5d11 no. Part name q’ty remarks 1 screw 3 m4 × 15 mm 2 yoke 1 3 armature 1 4 o-ring 1 not reusable 5 screw 2 m4 × 10 mm 6 brush holder 1 7 brush 2 1 8 brush 1 1 9 brush holder 1 10 brush spring 2 11 ptt motor base 1 12 oil seal 1 not reusable.

Page 251

60c5d11 7-44 1 2 3 4 5 6 7 8 9 disassembling the power trim and tilt motor 1. Remove the ptt motor screws. 2. Remove the lead holder 1 and spacer 2 from the yoke 3, and then slide them towards the leads. Caution: • keep the ptt motor leads inside the yoke. • do not allow grease or oil to contact the...

Page 252

Brkt bracket unit 7-45 60c5d11 checking the power trim and tilt motor 1. Check the commutator for dirt or foreign substances. Clean with #600 grit sand- paper if necessary. 2. Check the commutator undercut for dirt or foreign substances. Clean with com- pressed air if necessary. 3. Measure the commu...

Page 253

60c5d11 7-46 1 2 3 4 5 6 7 8 9 6. Measure the brush length. Replace if out of specification. 7. Check the base for cracks or damage. Replace if necessary. 8. Check the bearing 1 and oil seal for damage or wear. Replace the ptt motor base if necessary. Assembling the power trim and tilt motor 1. Inst...

Page 254

Brkt bracket unit 7-47 60c5d11 note: place a clean cloth over the end of the arma- ture shaft, hold the shaft with a pair of pliers as shown, then carefully slide the yoke onto the armature. Installing the power trim and tilt motor 1. Install the filter 1 and joint 2 into the pump housing. 2. Fill t...

Page 255

60c5d11 7-48 1 2 3 4 5 6 7 8 9 7. Install the reservoir cap, and then tighten it to the specified torque. Bleeding the power trim and tilt unit (f100b) 7 not installed 1. Tighten the manual valve 1 by turning it clockwise. 2. Place the power trim and tilt unit in an upright position. 3. Check the fl...

Page 256

Brkt bracket unit 7-49 60c5d11 7. Reverse the ptt motor leads between the battery terminals to fully extend the tilt ram and trim rams, and then reverse them again to fully retract the rams. Note: • repeat this procedure so that the rams go up and down four to five times (be sure to wait a few secon...

Page 257

60c5d11 7-50 1 2 3 4 5 6 7 8 9 5. Connect the ptt motor leads to the bat- tery terminals to fully retract the trim and tilt rams. 6. Reverse the ptt motor leads between the battery terminals to fully extend the trim and tilt rams, and then measure the hydraulic pressure. 7. After measuring the hydra...

Page 258

Brkt bracket unit 7-51 60c5d11 10. Remove the special tools. 11. Install the manual valve and circlip. 12. Remove the reservoir cap, and then check the fluid level in the reservoir. 13. If necessary, add fluid of the recom- mended type to the correct level. Note: the fluid level should be at the bri...

Page 259

60c5d11 7-52 1 2 3 4 5 6 7 8 9 built-in 1. Loosen the manual valve by turning it counterclockwise until it cannot be turned further. 2. Fully tilt the outboard motor up, and then release it and let it lower by its own weight four to five times. 3. Tighten the manual valve by turning it clockwise. 4....

Page 260

Brkt bracket unit 7-53 60c5d11 upper case (f100c) 7 s60c7190 13 16 17 20 21 1 18 12 12 14 13 lt 572 t r . . 11 n • m (1.1 kgf • m, 8.0 ft • ib) a a 15 t r . . 53 n • m (5.3 kgf • m, 38 ft • ib) t r . . 53 n • m (5.3 kgf • m, 38 ft • ib) 19 18 a a 3 4 6 7 8 9 10 10 2 t r . . 4 n • m (0.4 kgf • m, 2.9...

Page 261

60c5d11 7-54 1 2 3 4 5 6 7 8 9 no. Part name q’ty remarks 1 upper case assembly 1 2 oil pump body 1 3 oil seal 1 not reusable 4 oil seal 1 not reusable 5 bolt 6 m6 × 45 mm 6 screw 6 m6 × 10 mm 7 cover 1 8 gasket 1 not reusable 9 shaft 1 10 o-ring 2 not reusable 11 oil seal 1 not reusable 12 dowel pi...

Page 262

Brkt bracket unit 7-55 60c5d11 s60c7195 7 6 3 5 26 18 19 20 21 25 9 11 10 1 13 15 16 23 24 2 14 8 4 17 17 22 12 a lt 572 lt 572 lt 572 lt 572 a a lt 572 lt 572 t r . . 4 n • m (0.4 kgf • m, 2.9 ft • ib) a a a t r . . 20 n • m (2.0 kgf • m, 14 ft • ib) t r . . 26 n • m (2.6 kgf • m, 19 ft • ib) a a.

Page 263