- DL manuals

- Yamaha

- Outboard Motor

- F200B

- Owner's Manual

Yamaha F200B Owner's Manual

Summary of F200B

Page 1

Read this manual carefully before operating this outboard motor. Owner’s manual f200b fl200b f200c fl200c f225b fl225b 6p2-28199-27-e0 u6p227e0.Book page 1 wednesday, april 27, 2011 6:03 pm.

Page 2

Read this manual carefully before operating this outboard motor. Keep this manual onboard in a waterproof bag when boating. This manual should stay with the outboard motor if it is sold. U6p227e0.Book page 1 wednesday, april 27, 2011 6:03 pm.

Page 3

Important manual information emu25107 to the owner thank you for selecting a yamaha outboard motor. This owner’s manual contains infor- mation needed for proper operation, mainte- nance and care. A thorough understanding of these simple instructions will help you obtain maximum enjoyment from your n...

Page 4

Important manual information emu25121 f200b, fl200b, f200c, fl200c, f225b, fl225b owner’s manual ©2011 by yamaha motor co., ltd. 1st edition, march 2011 all rights reserved. Any reprinting or unauthorized use without the written permission of yamaha motor co., ltd. Is expressly prohibited. Printed i...

Page 5: Table Of Contents

Table of contents safety information............................. 1 outboard motor safety .................... 1 propeller ............................................. 1 rotating parts ..................................... 1 hot parts............................................. 1 electric shock .....

Page 6: Table Of Contents

Table of contents fuel level-alert indicator ................... 28 low battery voltage-alert indicator ... 28 fuel management meter ............... 28 fuel flow meter................................. 28 fuel consumption meter / fuel economy meter / twin engine speed synchronizer ........... 29 wate...

Page 7: Table Of Contents

Table of contents cleaning and adjusting spark plug ... 64 inspecting idle speed........................ 65 changing engine oil.......................... 65 inspecting wiring and connectors ..... 67 checking propeller ........................... 67 removing propeller .......................... 68 in...

Page 8: Safety Information

1 safety information emu33622 outboard motor safety observe these precautions at all times. Emu36501 propeller people can be injured or killed if they come in contact with the propeller. The propeller can keep moving even when the motor is in neu- tral, and sharp edges of the propeller can cut even ...

Page 9: Safety Information

Safety information 2 if any gasoline spills onto your skin, immedi- ately wash with soap and water. Change clothing if gasoline spills on it. If you swallow gasoline, inhale a lot of gaso- line vapor, or get gasoline in your eyes, get immediate medical attention. Never siphon fuel by mouth. Emu33900...

Page 10: Safety Information

Safety information 3 operate defensively at safe speeds and keep a safe distance away from people, objects, and other boats. ● do not follow directly behind other boats or waterskiers. ● avoid sharp turns or other maneuvers that make it hard for others to avoid you or un- derstand where you are goin...

Page 11: General Information

General information 4 emu25171 identification numbers record emu25184 outboard motor serial number the outboard motor serial number is stamped on the label attached to the port side of the clamp bracket. Record your outboard motor serial number in the spaces provided to assist you in ordering spare ...

Page 12: General Information

General information 5 emu25214 c-tick label engines affixed with this label conform to cer- tain portion(s) of the australian radio com- munications act. 1. Ce marking location 1. C-tick label location zmu06040 zmu01697 u6p227e0.Book page 5 wednesday, april 27, 2011 6:03 pm.

Page 13: General Information

General information 6 emu33523 read manuals and labels before operating or working on this outboard motor: ● read this manual. ● read any manuals supplied with the boat. ● read all labels on the outboard motor and the boat. If you need any additional information, contact your yamaha dealer. Emu33832...

Page 14: General Information

General information 7 emu34651 contents of labels the above warning labels mean as follows. 1 warning ewm01681 ● keep hands, hair, and clothing away from rotating parts while the engine is running. ● do not touch or remove electrical parts when starting or during operation. 2 warning ewm01671 ● read...

Page 15: General Information

General information 8 emu33843 symbols the following symbols mean as follows. Notice/warning read owner’s manual hazard caused by continuous rotation electrical hazard remote control lever/gear shift lever operat- ing direction, dual direction engine start/ engine cranking zmu05696 zmu05664 zmu05665...

Page 16

Specifications and requirements 9 emu34521 specifications tip: “(al)” stated in the specification data below represents the numerical value for the alumi- num propeller installed. Likewise, “(sus)” represents the value for stainless steel propeller installed and “(pl)” for plastic propeller installe...

Page 17

Specifications and requirements 10 min. Rated capacity (20hr/iec): 100 ah maximum generator output: f200bet 42 a f200cet 44 a f225bet 44 a fl200bet 42 a fl200cet 44 a fl225bet 44 a drive unit: gear positions: forward-neutral-reverse gear ratio: 2.00(30/15) trim and tilt system: power trim and tilt p...

Page 18

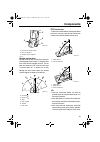

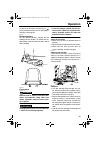

Specifications and requirements 11 emu33571 mounting motor warning ewm01570 ● improper mounting of the outboard mo- tor could result in hazardous conditions such as poor handling, loss of control, or fire hazards. ● because the motor is very heavy, spe- cial equipment and training is required to mou...

Page 19

Specifications and requirements 12 yamaha recommends to use a propeller suit- able for the “shift dampener system (sds)”. For further information, consult your yamaha dealer. To check the propeller, see page 67. Emu36310 counter rotation models standard outboard motors rotate clockwise. Counter rota...

Page 20

Specifications and requirements 13 if oil grades listed under recommended en- gine oil grade 1 are not available, select an al- ternative oil grade listed under recommended engine oil grade 2. Recommended engine oil grade 1 recommended engine oil grade 2 emu36360 fuel requirements emu36811 gasoline ...

Page 21

Specifications and requirements 14 emu36341 motor disposal requirements never illegally discard (dump) the motor. Yamaha recommends consulting the dealer about discarding the motor. Emu36352 emergency equipment keep the following items onboard in case there is trouble with the outboard motor. ● a to...

Page 22

Specifications and requirements 15 u6p227e0.Book page 15 wednesday, april 27, 2011 6:03 pm.

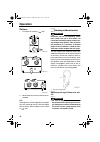

Page 23: Components

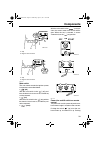

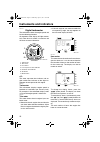

Components 16 emu2579y components diagram tip: * may not be exactly as shown; also may not be included as standard equipment on all models (order from dealer). F200b, fl200b, f200c, fl200c, f225b, fl225b zmu07566 12 12 13 14 15 16 13 13 1. Top cowling 2. Anti-cavitation plate 3. Trim tab (anode) 4. ...

Page 24: Components

Components 17 emu26181 remote control box the remote control lever actuates both the shifter and the throttle. The electrical switches are mounted on the remote control box. 1 2 zmu05949 1. Tachometer unit (square type)* 2. Speed & fuel meter unit (square type)* 1. Power trim and tilt switch 2. Remo...

Page 25: Components

Components 18 emu26190 remote control lever moving the lever forward from the neutral po- sition engages forward gear. Pulling the lever back from neutral engages reverse. The en- gine will continue to run at idle until the lever is moved about 35° (a detent can be felt). Moving the lever farther op...

Page 26: Components

Components 19 matically to its set position. The remote con- trol will then engage forward and reverse normally. Emu25976 throttle friction adjuster a friction device provides adjustable resis- tance to movement of the throttle grip or the remote control lever, and can be set accord- ing to operator...

Page 27: Components

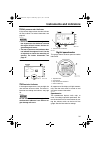

Components 20 emu26091 main switch the main switch controls the ignition system; its operation is described below. ● “ ” (off) with the main switch in the “ ” (off) posi- tion, the electrical circuits are off, and the key can be removed. ● “ ” (on) with the main switch in the “ ” (on) position, the ...

Page 28: Components

Components 21 the switch “ ” (down) tilts the outboard motor down and trims it down. When the switch is re- leased, the outboard motor will stop in its cur- rent position. For instructions on using the power trim and tilt switch, see pages 49 and 51. Emu26155 power trim and tilt switch on bottom cow...

Page 29: Components

Components 22 emu26244 trim tab with anode warning ewm00840 an improperly adjusted trim tab could cause difficult steering. Always test run af- ter the trim tab has been installed or re- placed to be sure steering is correct. Be sure you have tightened the bolt after ad- justing the trim tab. The tr...

Page 30: Components

Components 23 notice ecm00660 do not use the tilt support lever or knob when trailering the boat. The outboard mo- tor could shake loose from the tilt support and fall. If the motor cannot be trailered in the normal running position, use an addi- tional support device to secure it in the tilt positi...

Page 31: Components

Components 24 tip: for details on usage, see page 57. Emu35563 fuel filter/water separator this engine has a combination fuel filter/water separator and associated alert system. If wa- ter separated from the fuel exceeds a specific volume, the alert device of 6y8 multifunction tachometer will activa...

Page 32: Instruments And Indicators

Instruments and indicators 25 emu31414 digital tachometer the tachometer shows the engine speed and has the following functions. All segments of the display will light momen- tarily after the main switch is turned on and will return to normal thereafter. Tip: the water separator-alert indicator and ...

Page 33: Instruments and Indicators

Instruments and indicators 26 emu26524 low oil pressure-alert indicator if oil pressure drops too low, the alert indicator will start to blink. For further information, see page 35. Notice ecm00022 ● do not continue to run the engine if the low oil pressure-alert indicator is on and the engine oil l...

Page 34: Instruments And Indicators

Instruments and indicators 27 emu26713 fuel gauge eight segments indicate the fuel level. When all segments are showing, the fuel tank is full. The fuel level reading can be inaccurate due to the position of the sensor in the fuel tank and the attitude of the boat in the water. Oper- ation with bow-...

Page 35: Instruments and Indicators

Instruments and indicators 28 the clock operates on battery power. Discon- necting the battery will stop the clock. Reset the clock after connecting the battery. Emu36080 voltmeter the voltmeter displays the charge of the bat- tery in volts(v). Emu26721 fuel level-alert indicator if the fuel level d...

Page 36: Instruments And Indicators

Instruments and indicators 29 ● the fuel flow meter displays gallons/hour or liters/hour according to operator prefer- ence. Select the desired units of measure- ment by setting the selector switch on the back of the gauge during installation. ● the fuel consumption meter and fuel econ- omy meter wi...

Page 37: Instruments and Indicators

Instruments and indicators 30 if twin engines are installed on your boat, the gauge will only display the total fuel economy of both engines. ● fuel consumption varies greatly with boat design, weight, propeller used, engine trim angle, sea conditions (including wind), and throttle position. Fuel co...

Page 38: Instruments And Indicators

Instruments and indicators 31 emu26793 water separator-alert indicator this indicator will blink when water has accu- mulated in the water separator. In such an event, stop the engine and drain the water from the separator. This indicator only operates when a water separator sensor is equipped. Emu3...

Page 39: Instruments and Indicators

Instruments and indicators 32 emu36110 start-up checks place the remote control lever in neutral and turn the main switch to “ ” (on). After all the displays come on and the total hour display comes on, the gauge will change to normal operation. If the buzzer sounds and the water separator-alert ind...

Page 40: Instruments And Indicators

Instruments and indicators 33 notice ecm00910 gasoline mixed with water could cause damage to the engine. Emu36160 engine trouble alert this indicator will blink if the engine malfunc- tions while cruising. Get back to the port soon and consult a yamaha dealer immediately. Notice ecm00920 in such an...

Page 41: Instruments and Indicators

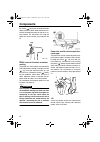

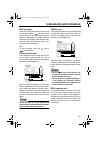

Instruments and indicators 34 1. Set button 2. Mode button 1. Speedometer 2. Fuel meter 3. Multifunction display 2 1 zmu05432 1 2 3 zmu05433 u6p227e0.Book page 34 wednesday, april 27, 2011 6:03 pm.

Page 42: Engine Control System

Engine control system 35 emu26803 alert system notice ecm00091 do not continue to operate the engine if a alert device has activated. Consult your yamaha dealer if the problem cannot be lo- cated and corrected. Emu26827 overheat alert this engine has the overheat alert device. If the engine temperat...

Page 43: Engine Control System

Engine control system 36 ● the engine speed will automatically de- crease to about 2000 r/min. The low oil pressure-alert indicator will light or blink. ● the buzzer will sound. If the alert system has activated, stop the en- gine as soon as it is safe to do so. Check the oil level and add oil as ne...

Page 44: Installation

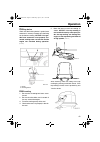

Installation 37 emu26902 installation the information presented in this section is in- tended as reference only. It is not possible to provide complete instructions for every possi- ble boat and motor combination. Proper mounting depends in part on experience and the specific boat and motor combinat...

Page 45: Installation

Installation 38 height. Consult your yamaha dealer or boat manufacturer for further information on deter- mining the proper mounting height. Notice ecm01634 ● make sure that the idle hole is high enough to prevent water from entering the engine even if the boat is stationary with the maximum load. ●...

Page 46: Operation

Operation 39 emu36381 first-time operation emu36391 fill engine oil the engine is shipped from the factory without engine oil. If your dealer did not fill the oil, you must fill it before starting the engine. Notice: check that the engine is filled with oil be- fore first-time operation to avoid sev...

Page 47: Operation

Operation 40 a trailer or in the water, turn the key to “ ” (on) and check the fuel level. For fuel filling in- structions, see page 44. Emu36432 remove cowling for the following checks, remove the top cowling from the engine. To remove the en- gine cowling, release all the lock levers and lift off ...

Page 48: Operation

Operation 41 emu36483 engine shut-off cord (lanyard) inspect the engine shut-off cord and clip for damage, such as cuts, breaks, and wear. Emu37053 engine oil 1. Put the outboard motor in an upright po- sition (not tilted). Notice: if the motor is not level, the oil level indicated on the dipstick m...

Page 49: Operation

Operation 42 emu36493 flushing device check that the flushing device’s garden hose connector is securely screwed on to the fitting on the bottom cowling. Notice: if the gar- den hose connector is not properly con- nected, cooling water can leak out and the engine can overheat during operation. [ecm0...

Page 50: Operation

Operation 43 emu29158 checking power trim and tilt system warning ewm01930 ● never get under the lower unit while it is tilted, even when the tilt support lever is locked. Severe injury could occur if the outboard motor accidentally falls. ● body parts can be crushed between the motor and the clamp ...

Page 51: Operation

Operation 44 8. Tilt the outboard motor down. Check that the tilt rod and trim rods operate smooth- ly. Emu36582 battery check that the battery is in good condition, and fully charged. Check that the battery con- nections are clean, secure and covered by in- sulating covers. The electrical contacts ...

Page 52: Operation

Operation 45 emu31812 sending fuel 1. If there is a fuel joint or a fuel cock on the boat, firmly connect the fuel line to the joint or open the fuel cock. 2. Squeeze the primer pump, with the arrow pointing up, until you feel it become firm. Emu27494 starting engine warning ewm01600 before starting...

Page 53: Operation

Operation 46 3. Turn the main switch to “ ” (on). Tip: dual engine users: when the main switch is turned on, the buzzer operates for a few sec- onds then stops automatically. The buzzer also operates if one of the engines stalls. 4. Turn the main switch to “ ” (start), and hold it for a maximum of 5...

Page 54: Operation

Operation 47 be damaged. If the engine will not start after 5 seconds of cranking, return the main switch to “ ” (on), wait 10 sec- onds, then crank the engine again. [ecm00192] emu36510 checks after starting engine emu36523 cooling water check for a steady flow of water from the cool- ing water pil...

Page 55: Operation

Operation 48 notice ecm01610 warm up the engine before shifting into gear. Until the engine is warm, the idle speed may be higher than normal. High idle speed can prevent you from shifting back to neutral. If this occurs, stop the en- gine, shift to neutral, then restart the en- gine and allow it to...

Page 56: Operation

Operation 49 emu31831 procedure 1. Turn the main switch to “ ” (off). 2. Remove the key if the boat will be left un- attended. Tip: the engine can also be stopped by pulling the cord and removing the clip from the engine shut-off switch, then turning the main switch to “ ” (off). Emu27862 trimming o...

Page 57: Operation

Operation 50 ● use caution when trying a trim position for the first time. Increase speed gradu- ally and watch for any signs of instability or control problems. Improper trim an- gle can cause loss of control. ● if equipped with a power trim and tilt switch located on the bottom cowling, use the sw...

Page 58: Operation

Operation 51 bow up too much trim-out puts the bow of the boat too high in the water. Performance and econ- omy are decreased because the hull of the boat is pushing the water and there is more air drag. Excessive trim-out can also cause the propeller to ventilate, which reduces perfor- mance furthe...

Page 59: Operation

Operation 52 2. Press the power trim and tilt switch “ ” (up) until the outboard motor has tilted up completely. 3. Pull the tilt support lever toward you to support the engine. Warning! After tilting the outboard motor, be sure to support it with the tilt support knob or tilt support lever. Otherwi...

Page 60: Operation

Operation 53 4. Once the outboard motor is supported with the tilt support lever, press the power trim and tilt switch “ ” (down) to retract the trim rods. Notice: make sure that the trim rods retracts completely dur- ing mooring. This protects the rods from marine growth and corrosion, which could ...

Page 61: Operation

Operation 54 emu28062 shallow water emu32871 power trim and tilt models the outboard motor can be tilted up partially to allow operation in shallow water. Notice ecm01490 ● if the engine speed is suddenly in- creased when the outboard motor is par- tially tilted up, the power trim and tilt unit coul...

Page 62: Maintenance

Maintenance 55 emu31844 transporting and storing out- board motor warning ewm02640 ● use care when transporting fuel tank, whether in a boat or car. ● do not fill fuel container to maximum capacity. Gasoline will expand consider- ably as it warms up and can build up pressure in the fuel container. T...

Page 63: Maintenance

Maintenance 56 emu28305 procedure emu31375 flushing with a flushing attachment warning ewm00322 you could be seriously injured if the en- gine accidentally starts when you are near the propeller. ● before inspecting, removing, or install- ing the propeller, remove the ignition coils from the spark p...

Page 64: Maintenance

Maintenance 57 4. Run the engine at a fast idle for a few minutes in neutral position. Warning! Attach the engine shut-off cord to a secure place on your clothing, or your arm or leg while operating.Do not at- tach the cord to clothing that could tear loose. Do not route the cord where it could beco...

Page 65: Maintenance

Maintenance 58 2. Screw the garden hose adapter onto a garden hose, which is connected to a fresh water supply, and then connect it to the garden hose connector. 3. With the engine off, turn on the water tap and let the water flush through the cool- ing passages for about 15 minutes. Turn off the wa...

Page 66: Maintenance

Maintenance 59 perform a maintenance procedure, have a yamaha dealer or other qualified mechan- ic do the work. The procedures involve disassembling the motor and exposing dangerous parts. To reduce the risk of injury from moving, hot, or electrical parts: ● turn off the engine and keep the key(s) a...

Page 67: Maintenance

Maintenance 60 emu34446 maintenance chart 1 tip: ● refer to the sections in this chapter for explanations of each owner-specific action. ● the maintenance cycle on these charts assume usage of 100 hours per year and regular flushing of the cooling water passages. Maintenance frequency should be adju...

Page 68: Maintenance

Maintenance 61 fuel line (high pres- sure) inspection fuel line (high pres- sure) inspection or replace- ment as necessary fuel line (low pres- sure) inspection fuel line (low pres- sure) inspection or replace- ment as necessary fuel pump inspection or replace- ment as necessary fuel/engine oil leak...

Page 69: Maintenance

Maintenance 62 emu34451 maintenance chart 2 emu28911 tip: when using lead or high-sulfur gasoline, inspecting valve clearance may be required more fre- quently than every 500 hours. Valve clearance inspection and adjust- ment cooling water inlet inspection main switch/stop switch/choke switch inspec...

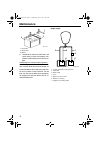

Page 70: Maintenance

Maintenance 63 emu28943 greasing yamaha grease a (water resistant grease) yamaha grease d (corrosion resistant grease; for propeller shaft) f200b, fl200b, f200c, fl200c, f225b, fl225b u6p227e0.Book page 63 wednesday, april 27, 2011 6:03 pm.

Page 71: Maintenance

Maintenance 64 emu30778 cleaning and adjusting spark plug the spark plug is an important engine compo- nent and is easy to inspect. The condition of the spark plug can indicate something about the condition of the engine. For example, if the center electrode porcelain is very white, this could indic...

Page 72: Maintenance

Maintenance 65 5. When fitting the plug, wipe off any dirt from the threads, and then screw it in to the correct torque. Tip: if a torque-wrench is not available when you are fitting a spark plug, a good estimate of the correct torque is 1/4 to 1/2 turn past finger- tight. Have the spark plug adjust...

Page 73: Maintenance

Maintenance 66 1. Put the outboard motor in an upright po- sition (not tilted). Notice: if the out- board motor is not level, the oil level indicated on the oil dipstick may not be accurate. [ecm01861] 2. Start the engine. Warm it up and keep the idle speed for 5-10 minutes. 3. Stop the engine and l...

Page 74: Maintenance

Maintenance 67 11. Start the engine and make sure that the low oil pressure-alert indicator remains off. Also, make sure that there are no oil leaks. Notice: if the low oil pressure- alert indicator comes on or if there are oil leaks, stop the engine and find the cause. Continued operation with a pr...

Page 75: Maintenance

Maintenance 68 checkpoints ● check each of the propeller blades for ero- sion from cavitation or ventilation, or other damage. ● check the propeller shaft for damage. ● check the splines for wear or damage. ● check for fish line tangled around the pro- peller shaft. ● check the propeller shaft oil s...

Page 76: Maintenance

Maintenance 69 fied with the letter “l” after the size indication on the propeller. Otherwise the boat could move in the opposite direction from that expected. Notice ecm00501 make sure to use a new cotter pin and bend the ends over securely. Otherwise, the propeller could come off during opera- tio...

Page 77: Maintenance

Maintenance 70 tip: if the propeller nut slot does not align with the propeller shaft hole after tightening the pro- peller nut to the specified torque, tighten the nut further to align the slot with the hole. Emu29289 changing gear oil warning ewm00800 ● be sure the outboard motor is securely faste...

Page 78: Maintenance

Maintenance 71 6. Put a new gasket on the oil level plug. When the oil begins to flow out of the oil level plug hole, insert and tighten the oil level plug. 7. Put a new gasket on the gear oil drain screw. Insert and tighten the gear oil drain screw. Emu29314 inspecting and replacing anode(s) yamaha...

Page 79: Maintenance

Maintenance 72 tip: inspect ground leads attached to external an- odes on equipped models. Consult a yamaha dealer for inspection and replacement of inter- nal anodes attached to the power unit. Emu29323 checking battery (for electric start models) warning ewm01902 battery electrolyte is poisonous a...

Page 80: Maintenance

Maintenance 73 3. The electrical contacts of the battery and cables must be clean and properly con- nected, or the battery will not start the en- gine. Connecting an accessory battery (optional) if connecting an accessory battery, consult your yamaha dealer about correct wiring. It is recommendable ...

Page 81: Maintenance

Maintenance 74 twin engines emu29371 disconnecting the battery 1. Turn off the battery cut-off switch (if equipped) and main switch. Notice: if they are left on, the electrical system can be damaged. [ecm01930] 2. Disconnect the negative cable(s) from the negative (-) terminal. Notice: al- ways disc...

Page 82: Trouble Recovery

Trouble recovery 75 emu29427 troubleshooting a problem in the fuel, compression, or ignition systems can cause poor starting, loss of pow- er, or other problems. This section describes basic checks and possible remedies, and cov- ers all yamaha outboard motors. Therefore some items may not apply to ...

Page 83: Trouble Recovery

Trouble recovery 76 a. Check for pinched or kinked fuel line or oth- er obstructions in fuel system. Q. Is fuel contaminated or stale? A. Fill tank with clean, fresh fuel. Q. Is fuel filter clogged? A. Clean or replace filter. Q. Have ignition parts failed? A. Have serviced by a yamaha dealer. Q. Ha...

Page 84: Trouble Recovery

Trouble recovery 77 q. Is load on boat improperly distributed? A. Distribute load to place boat on an even plane. Q. Is water pump or thermostat faulty? A. Have serviced by a yamaha dealer. Q. Is there excess water in fuel filter cup? A. Drain filter cup. Engine power loss. Q. Is propeller damaged? ...

Page 85: Trouble Recovery

Trouble recovery 78 a. Connect correctly. Q. Is heat range of spark plug incorrect? A. Inspect spark plug and replace it with rec- ommended type. Q. Is high pressure fuel pump drive belt bro- ken? A. Have serviced by a yamaha dealer. Q. Is engine not responding properly to shift lever position? A. H...

Page 86: Trouble Recovery

Trouble recovery 79 tip: when you are maneuvering at low speed, such as near a dock, it is recommended that both engines be running with one in neutral gear if possible. Emu29474 replacing fuse if a fuse has blown, remove the electrical cov- er, open the fuse holder and remove the fuse with a fuse p...

Page 87: Trouble Recovery

Trouble recovery 80 emu29525 power trim and tilt will not operate if the engine cannot be tilted up or down with the power trim and tilt because of a dis- charged battery or a failure with the power trim and tilt unit, the engine can be tilted man- ually. 1. Loosen the manual valve screw by turn- in...

Page 88: Trouble Recovery

Trouble recovery 81 4. Disconnect the water detection switch coupler. Notice: be careful not to get any water on the water detection switch coupler, otherwise a malfunc- tion could occur. [ecm01950] 5. Unscrew the filter cup from the filter hous- ing. Notice: be careful not to twist the water detect...

Page 89: Trouble Recovery

Trouble recovery 82 10. Install the top cowling. 11. Start the engine and make sure that the water separator-alert indicator remains off. Have a yamaha dealer inspect the outboard motor after returning to port. Emu33501 treatment of submerged motor if the outboard motor is submerged, immedi- ately t...

Page 90

Printed on recycled paper printed in japan may 2011–0.1 × 1 cr u6p227e0.Book page 1 wednesday, april 27, 2011 6:03 pm.