- DL manuals

- Yamaha

- Outboard Motor

- F30A

- Owner's Manual

Yamaha F30A Owner's Manual

Summary of F30A

Page 1

Q q q q read this manual carefully before operating this outboard motor. Owner’s manual f30a f40b 67c-28199-2a-e0

Page 2

Emu25052 read this manual carefully before operating this outboard motor. Keep this manual onboard in a waterproof bag when boating. This manual should stay with the outboard motor if it is sold..

Page 3: Important Manual Information

Important manual information emu25105 to the owner thank you for choosing a yamaha outboard motor. This owner’s manual contains infor- mation needed for proper operation, mainte- nance and care. A thorough understanding of these simple instructions will help you ob- tain maximum enjoyment from your ...

Page 4: Table of Contents

Table of contents safety information............................. 1 outboard motor safety .................... 1 propeller............................................ 1 rotating parts.................................... 1 hot parts ........................................... 1 electric shock ..........

Page 5: Table of Contents

Table of contents low oil pressure-alert indicator ....... 25 overheat-alert indicator .................. 25 digital tachometer ......................... 25 tachometer ..................................... 26 trim meter....................................... 26 hour meter ..............................

Page 6: Table of Contents

Table of contents inspecting idling speed ................... 65 changing engine oil ........................ 66 checking wiring and connectors ..... 67 checking propeller .......................... 68 removing propeller ......................... 68 installing propeller ........................... 6...

Page 7: Safety Information

1 safety information emu33622 outboard motor safety observe these precautions at all times. Emu36500 propeller people can be injured or killed if they come in contact with the propeller. The propeller can keep moving even when the motor is in neutral, and sharp edges of the propeller can cut even wh...

Page 8: Safety Information

Safety information 2 emu33820 gasoline exposure and spills take care not to spill gasoline. If gasoline spills, wipe it up immediately with dry rags. Dispose of rags properly. If any gasoline spills onto your skin, immedi- ately wash with soap and water. Change clothing if gasoline spills on it. If ...

Page 9: Safety Information

Safety information 3 dling and lead to an accident, capsizing or swamping. Emu33771 avoid collisions scan constantly for people, objects, and other boats. Be alert for conditions that limit your visibility or block your vision of others. Operate defensively at safe speeds and keep a safe distance aw...

Page 10: General Information

4 general information emu25171 identification numbers record emu25183 outboard motor serial number the outboard motor serial number is stamped on the label attached to the port side of the clamp bracket. Record your outboard motor serial number in the spaces provided to assist you in ordering spare ...

Page 11: General Information

General information 5 emu25213 c-tick label engines affixed with this label conform to certain portion(s) of the australian radio communications act. 1. Ce marking location 1. C-tick label location 1 zmu04029 zmu06040 1 zmu04029 zmu01697.

Page 12: General Information

General information 6 emu33520 read manuals and labels before operating or working on this motor: ● read this manual. ● read any manuals supplied with the boat. ● read all labels on the outboard motor and the boat. If you need any additional information, contact your yamaha dealer. Emu33831 warning ...

Page 13: General Information

General information 7 emu33912 contents of labels the above warning labels mean as follows. 1 warning ewm01691 emergency starting does not have start- in-gear protection. Ensure shift control is in neutral before starting engine. 2 warning ewm01681 ● keep hands, hair, and clothing away from rotating...

Page 14: General Information

General information 8 emu33843 symbols the following symbols mean as follows. Notice/warning read owner’s manual hazard caused by continuous rotation electrical hazard remote control lever/gear shift lever operat- ing direction, dual direction engine start/ engine cranking zmu05696 zmu05664 zmu05665...

Page 15: Specifications

9 specifications and requirements emu34520 specifications tip: “(al)” stated in the specification data below represents the numerical value for the alumi- num propeller installed. Likewise, “(sus)” represents the value for stainless steel propeller installed and “(pl)” for plastic propeller installe...

Page 16: Installation Requirements

Specifications and requirements 10 430.0 a min. Rated capacity (20hr/iec): 70.0 ah maximum generator output: 15.0 a drive unit: gear positions: forward-neutral-reverse gear ratio: 2.00 (26/13) trim and tilt system: f30aet power trim and tilt f40bet power trim and tilt f40bwhd hydro tilt f40bwht powe...

Page 17: Battery Requirements

Specifications and requirements 11 move suddenly and unexpectedly, pos- sibly causing a collision or throwing passengers overboard. ● if the engine ever starts in gear, the start-in-gear protection device is not working correctly and you should dis- continue using the outboard. Contact your yamaha d...

Page 18: Start-In-Gear Protection

Specifications and requirements 12 emu25770 start-in-gear protection yamaha outboard motors or yamaha-ap- proved remote control units are equipped with start-in-gear protection device(s). This feature permits the engine to be started only when it is in neutral. Always select neutral before starting ...

Page 19: Muddy Or Acidic Water

Specifications and requirements 13 methanol. Ethanol can be used if the ethanol content does not exceed 10% and the fuel meets the minimum octane ratings. All etha- nol blends containing more than 10% etha- nol can cause fuel system damage or cause engine starting and running problems. Yamaha does n...

Page 20: Manufactured:

Specifications and requirements 14 emu25332 manufactured date label this label is attached to the clamp bracket or the swivel bracket. 1. Approval label location 1. Manufactured date label location zmu05759 1 zmu05159 1 zmu04029 manufactured: zmu04346.

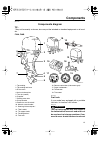

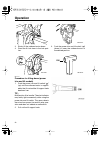

Page 21: Components

15 components emu2579j components diagram tip: * may not be exactly as shown; also may not be included as standard equipment on all mod- els. F30a, f40b emu25802 fuel tank if your model was equipped with a portable fuel tank, its function is as follows. Warning ewm00020 the fuel tank supplied with t...

Page 22: Components

Components 16 licensing or approval authority regula- tions. Emu25830 fuel joint this joint is used to connect the fuel line. Emu25841 fuel gauge this gauge is located on either the fuel tank cap or on the fuel joint base. It shows the ap- proximate amount of fuel remaining in the tank. Emu25850 fue...

Page 23: Components

Components 17 emu26201 neutral interlock trigger to shift out of neutral, first pull the neutral in- terlock trigger up. Emu26211 neutral throttle lever to open the throttle without shifting into ei- ther forward or reverse, put the remote con- trol lever in the neutral position and lift the neutral...

Page 24: Components

Components 18 emu25941 throttle grip the throttle grip is on the tiller handle. Turn the grip counterclockwise to increase speed and clockwise to decrease speed. Emu25961 throttle indicator the fuel consumption curve on the throttle indicator shows the relative amount of fuel consumed for each throt...

Page 25: Components

Components 19 when constant speed is desired, tighten the adjuster to maintain the desired throttle set- ting. Emu25993 engine shut-off cord (lanyard) and clip the clip must be attached to the engine shut- off switch for the engine to run. The cord should be attached to a secure place on the operato...

Page 26: Components

Components 20 emu26070 manual starter handle to start the engine, first gently pull the han- dle out until resistance is felt. From that posi- tion, then pull the handle straight out quickly to crank the engine. Emu26090 main switch the main switch controls the ignition system; its operation is desc...

Page 27: Components

Components 21 if the resistance does not increase even when the lever is turned to the port side “a”, make sure that the nut is tightened to the specified torque. Tip: ● steering movement is blocked when the adjuster lever is set to the “a” position. ● check the tiller handle for smooth move- ment w...

Page 28: Components

Components 22 emu26153 power trim and tilt switch on bottom engine cowling the power trim and tilt switch is located on the side of the bottom engine cowling. Press- ing the switch “ ” (up) trims the outboard motor up, and then tilts it up. Pressing the switch “ ” (down) tilts the outboard motor dow...

Page 29: Components

Components 23 emu26312 tilt lock mechanism the tilt lock mechanism is used to prevent the outboard motor from lifting out of the wa- ter when in reverse gear. To lock it, set the tilt lock lever in the “ ” (lock) position. To release, push the tilt lock lever in the “ ” (release) position. Emu26321 ...

Page 30: Components

Components 24 emu26460 flushing device this device is used to clean the cooling wa- ter passages of the motor using a garden hose and tap water. Tip: for details on usage, see page 58. Emu31752 alert indicator if the engine develops a condition which is cause for alert, the indicator lights up. For ...

Page 31: Instruments and Indicators

25 instruments and indicators emu36014 indicators emu36023 low oil pressure-alert indicator if oil pressure drops too low, this indicator will light up. For further information, see page 29. Notice ecm00022 ● do not continue to run the engine if the low oil pressure-alert indicator is on and the eng...

Page 32: Instruments and Indicators

Instruments and indicators 26 emu36050 tachometer the tachometer displays engine speed in hundreds of revolutions per minute (r/min). For example, if the tachometer display reads “22” then the engine speed is 2200 r/min. Emu26621 trim meter this meter shows the trim angle of your out- board motor. ●...

Page 33: Instruments and Indicators

Instruments and indicators 27 emu26583 overheat-alert indicator if the engine temperature rises too high, the alert indicator will start to blink. For further in- formation on reading the indicator, see page 29. Notice ecm00052 do not continue to run the engine if the overheat-alert indicator is on....

Page 34: Instruments and Indicators

Instruments and indicators 28 emu26574 overheat-alert indicator if the engine temperature rises too high, this indicator will flash. For further information on reading the indicator, see page 29. Notice ecm00052 do not continue to run the engine if the overheat-alert indicator is on. Serious en- gin...

Page 35: Engine Control System

29 engine control system emu26803 alert system notice ecm00091 do not continue to operate the engine if a alert device has activated. Consult your yamaha dealer if the problem cannot be located and corrected. Emu2681a overheat alert this engine has an overheat-alert device. If the engine temperature...

Page 36: Engine Control System

Engine control system 30 vice will activate. ● the engine speed will automatically de- crease to about 2000 r/min. If equipped with a low oil pressure-alert indicator, it will light or blink. ● the buzzer will sound (if equipped on the tiller handle, remote control box, or main switch panel). If the...

Page 37: Installation

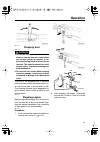

31 installation emu26902 installation the information presented in this section is intended as reference only. It is not possible to provide complete instructions for every possible boat and motor combination. Prop- er mounting depends in part on experience and the specific boat and motor combinatio...

Page 38: Installation

Installation 32 notice ecm01630 ● during water testing, check the buoy- ancy of the boat, at rest, with its maxi- mum load. Check that the static water level on the exhaust housing is low enough to prevent water entry into the power head when water rises due to waves when the outboard is not run- ni...

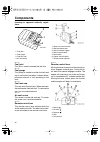

Page 39: Operation

33 operation emu36380 first-time operation emu36390 fill engine oil the engine is shipped from the factory with- out engine oil. If your dealer did not fill the oil, you must fill it before starting the engine. No- tice: check that the engine is filled with oil before first-time operation to avoid s...

Page 40: Operation

Operation 34 heating and serious engine damage can occur. Emu36420 fuel level be sure you have plenty of fuel for your trip. A good rule is to use 1/3 of your fuel to get to the destination, 1/3 to return, and to keep 1/ 3 as an emergency reserve. With the boat level on a trailer or in the water, tu...

Page 41: Operation

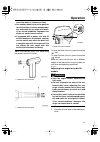

Operation 35 emu27165 engine oil 1. Put the outboard motor in an upright po- sition (not tilted). Notice: if the motor is not level, the oil level indicated on the dipstick may not be accurate. [ecm01790] 2. Remove the top cowling. 3. Remove oil dipstick and wipe it clean. 4. Insert the dipstick and...

Page 42: Operation

Operation 36 gine can overheat during operation. [ecm01800] emu36952 install cowling 1. Be sure that a cowling lock lever is re- leased. 2. Be sure that the rubber seal is seated all the way around the engine. 3. Place the cowling on top of the seal. 4. Check to be sure the rubber seal fits cor- rec...

Page 43: Operation

Operation 37 switches to check that all switches work. 3. Tilt the outboard motor up and check that the trim and tilt rod is pushed out completely. 4. Check that the trim and tilt rod is free of corrosion or other flaws. 5. Tilt the outboard motor down. Check that the trim and tilt rod operates smoo...

Page 44: Operation

Operation 38 water near you. ● when the air vent screw is loosened, gasoline vapor will be released. Gaso- line is highly flammable, and its vapors are flammable and explosive. Refrain from smoking, and keep away from open flames and sparks while loosen- ing the air vent screw. ● this product emits ...

Page 45: Operation

Operation 39 emu27492 starting engine warning ewm01600 before starting the engine, make sure that the boat is tightly moored and that you can steer clear of any obstructions. Be sure there are no swimmers in the wa- ter near you. Emu27545 starting engine warning ewm01840 ● failure to attached engine...

Page 46: Operation

Operation 40 5. After the engine starts, slowly return the manual starter handle to its original po- sition before releasing it. Tip: ● when the engine is cold, it needs to be warmed up. For further information, see page 43. ● if the engine is warm and fails to start, open the throttle slightly and ...

Page 47: Operation

Operation 41 4. Turn the main switch to “ ” (start), and hold it for a maximum of 5 seconds. 5. Immediately after the engine starts, re- lease the main switch and allow it to re- turn to “ ” (on). Notice: never turn the main switch to “ ” (start) while the engine is running. Do not keep the starter ...

Page 48: Operation

Operation 42 cure place on your clothing, or your arm or leg. Then install the clip on the other end of the cord into the engine shut-off switch. 3. Turn the main switch to “ ” (on). 4. Turn the main switch to “ ” (start), and hold it for a maximum of 5 seconds. 5. Immediately after the engine start...

Page 49: Operation

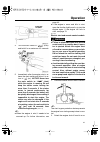

Operation 43 check that no water leaks from the joints be- tween the exhaust cover, cylinder head, and body cylinder. Emu27670 warming up engine emu27715 manual start and electric start models 1. After starting the engine, allow it to idle for 3 minutes to warm up. Failure to do so will shorten engi...

Page 50: Operation

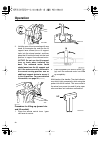

Operation 44 2. Move the remote control lever / gear shift lever firmly and crisply forward (for forward gear) or backward (for reverse gear) [about 35° (a detent can felt) for re- mote control models]. Be sure to check that the tilt lock lever is in the lock/down position (if equipped) before opera...

Page 51: Operation

Operation 45 emu31742 stopping boat warning ewm01510 ● do not use the reverse function to slow down or stop the boat as it could cause you to lose control, be ejected, or im- pact the steering wheel or other parts of the boat. This could increase the risk of serious injury. It could also damage the ...

Page 52: Operation

Operation 46 3. Tighten the air vent screw on the fuel tank cap (if equipped). 4. Remove the key if the boat will be left unattended. Tip: the engine can also be stopped by pulling the cord and removing the clip from the en- gine shut-off switch, then turning the main switch to “ ” (off). Emu27862 t...

Page 53: Operation

Operation 47 when the motor is trimmed or tilted. ● use caution when trying a trim position for the first time. Increase speed gradu- ally and watch for any signs of instabil- ity or control problems. Improper trim angle can cause loss of control. ● if equipped with a power trim and tilt switch loca...

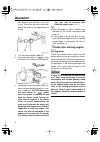

Page 54: Operation

Operation 48 3. Hold the rear of the top cowling with one hand and tilt the engine to the desired angle. 4. Place the tilt lock lever back into the lock position to support the engine. To raise the bow (“trim-out”), tilt the engine up. To lower the bow (“trim-in”), tilt the engine down. Make test ru...

Page 55: Operation

Operation 49 tip: depending on the type of boat, the outboard motor trim angle may have little effect on the trim of the boat when operating. Emu27934 tilting up and down if the engine will be stopped for some time or if the boat is moored in shallows, the out- board motor should be tilted up to pro...

Page 56: Operation

Operation 50 3. Hold the rear of the top cowling with one hand, tilt the engine up, and turn the tilt support lever toward you or tilt support knob into the clamp bracket, and then place the tilt lock lever back into the lock position to support the outboard motor. Notice: do not use the tilt suppor...

Page 57: Operation

Operation 51 3. Push the tilt support knob into the clamp bracket to support the engine. Warning! After tilting the outboard motor, be sure to support it with the tilt support knob or tilt support lever. Otherwise the outboard motor could fall back down suddenly if oil in the power trim and tilt uni...

Page 58: Operation

Operation 52 3. Slowly tilt the outboard motor down. 4. Place the tilt lock lever in the lock posi- tion. Emu33120 procedure for tilting down (power trim and tilt models) 1. Push the power trim and tilt switch “ ” (up) until the outboard motor is support- ed by the tilt rod and the tilt support knob...

Page 59: Operation

Operation 53 emu28061 shallow water emu28081 hydro tilt models the outboard motor can be tilted up partially to allow operation in shallow water. Warning ewm00271 ● run the boat at the lowest possible speed when using the shallow water cruising system. ● use extra care when operating in re- verse. T...

Page 60: Operation

Operation 54 3. Slightly tilt the outboard motor up to the desired position and push the tilt lock le- ver down to the lock position. 4. To return the outboard motor to the nor- mal running position, pull the tilt lock le- ver up to the release position and slowly tilt the outboard motor down. 5. Pu...

Page 61: Operation

Operation 55 3. To return the outboard motor to the nor- mal running position, press the power trim and tilt switch and slowly tilt the out- board motor down. Emu28194 cruising in other conditions cruising in salt water after operating in salt water, flush the cooling water passages with fresh water...

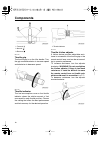

Page 62: Maintenance

56 maintenance emu28226 transporting and storing outboard motor warning ewm00692 ● use care when transporting fuel tank, whether in a boat or car. ● do not fill fuel container to maximum capacity. Gasoline will expand consid- erably as it warms up and can build up pressure in the fuel container. Thi...

Page 63: Maintenance

Maintenance 57 emu28303 procedure emu28334 flushing in a test tank notice ecm00300 do not run the engine without supplying it with cooling water. Either the engine water pump will be damaged or the en- gine will be damaged from overheating. Before starting the engine, be sure to supply water to the ...

Page 64: Maintenance

Maintenance 58 stops. 11. Drain the cooling water completely out of the motor. Clean the body thoroughly. 12. If the “fogging oil” is not available, re- move the spark plug(s). Pour a tea- spoonful of clean engine oil into each cylinder. Crank several times manually. Replace the spark plug(s). 13. D...

Page 65: Maintenance

Maintenance 59 during normal operation. Water will leak out of the connector instead of cooling the engine, which can cause serious overheating. Be sure the con- nector is tightened securely on the fitting after flushing the engine. [ecm00541] tip: ● when flushing the engine with the boat in the wat...

Page 66: Maintenance

Maintenance 60 emu28511 replacement parts if replacement parts are necessary, use only genuine yamaha parts or parts of equivalent design and quality. Any part of inferior quality may malfunction, and the resulting loss of control could endanger the operator and passengers. Yamaha genuine parts and ...

Page 67: Maintenance

Maintenance 61 emu34445 maintenance chart 1 tip: ● refer to the sections in this chapter for explanations of each owner-specific action. ● the maintenance cycle on these charts assume usage of 100 hours per year and regular flushing of the cooling water passages. Maintenance frequency should be adju...

Page 68: Maintenance

Maintenance 62 fuel filter (disposal type) replacement fuel line(high pres- sure) inspection fuel line(high pres- sure) inspection or replace- ment as necessary fuel line(low pres- sure) inspection fuel line(low pres- sure) inspection or replace- ment as necessary fuel pump inspection or replace- me...

Page 69: Maintenance

Maintenance 63 emu34451 maintenance chart 2 water inlet inspection main switch/stop switch/choke switch inspection or replace- ment as necessary wire harness connec- tions/wire coupler con- nections inspection or replace- ment as necessary (yamaha) meter/gauge inspection (yamaha) fuel tank inspectio...

Page 70: Maintenance

Maintenance 64 emu28941 greasing yamaha grease a (water resistant grease) yamaha grease d (corrosion resistant grease; for propeller shaft) f30a, f40b emu28955 cleaning and adjusting spark plug the spark plug is an important engine com- ponent and is easy to inspect. The condition of the spark plug ...

Page 71: Maintenance

Maintenance 65 lead to explosion or fire. [ewm00561] 3. Be sure to use the specified spark plug, otherwise the engine may not operate properly. Before fitting the spark plug, measure the electrode gap with a wire thickness gauge; adjust the gap to spec- ification if necessary. 4. When fitting the pl...

Page 72: Maintenance

Maintenance 66 tip: correct idling speed inspection is only possi- ble if the engine is fully warmed up. If not warmed up fully, the idle speed will measure higher than normal. If you have difficulty ver- ifying the idle speed, or the idle speed re- quires adjustment, consult a yamaha dealer or othe...

Page 73: Maintenance

Maintenance 67 then tighten 1/4 to 1/2 turn more. Tighten the drain screw to the correct torque with a torque wrench as soon as possible. 4. Add the correct amount of oil through the filler hole. Install the filler cap. Notice: overfilling the oil could cause leak- age or damage. If the oil level is...

Page 74: Maintenance

Maintenance 68 emu32111 checking propeller warning ewm01880 you could be seriously injured if the en- gine accidentally starts when you are near the propeller. ● before inspecting, removing, or install- ing the propeller, place the shift control in neutral, turn the main switch to “ ” (off) and remo...

Page 75: Maintenance

Maintenance 69 emu30671 installing propeller emu29233 spline models notice ecm00500 be sure to use a new cotter pin and bend the ends over securely. Otherwise the propeller could come off during opera- tion and be lost. 1. Apply yamaha marine grease or a cor- rosion resistant grease to the propeller...

Page 76: Maintenance

Maintenance 70 tip: ● if a magnetic gear oil drain screw is equipped, remove all metal particles from the screw before installing it. ● always use new gaskets. Do not reuse the removed gaskets. 4. Remove the oil level plug and gasket to allow the oil to drain completely. No- tice: inspect the used o...

Page 77: Maintenance

Maintenance 71 proper assembly can result in a fuel leak, which could result in a fire or ex- plosion hazard. ● dispose of old gasoline according to lo- cal regulations. 1. Empty the fuel tank into an approved container. 2. Pour a small amount of suitable solvent into the tank. Install the cap and s...

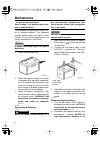

Page 78: Maintenance

Maintenance 72 of ignition near the battery. Refer to page 11 for detailed safety infor- mation about batteries. The procedure for checking the battery var- ies for different batteries. This procedure contains typical checks that apply to many batteries, but you should always refer to the battery ma...

Page 79: Maintenance

Maintenance 73 bles first to avoid a short circuit and damage to the electrical system. [ecm01940] 3. Disconnect the positive cable(s) and re- move the battery from the boat. 4. Clean, maintain, and store the battery according to the manufacturer’s instruc- tions..

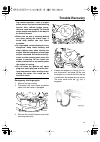

Page 80: Trouble Recovery

74 trouble recovery emu29427 troubleshooting a problem in the fuel, compression, or igni- tion systems can cause poor starting, loss of power, or other problems. This section de- scribes basic checks and possible remedies, and covers all yamaha outboard motors. Therefore some items may not apply to ...

Page 81: Trouble Recovery

Trouble recovery 75 q. Is fuel system obstructed? A. Check for pinched or kinked fuel line or other obstructions in fuel system. Q. Is fuel contaminated or stale? A. Fill tank with clean, fresh fuel. Q. Is fuel filter clogged? A. Clean or replace filter. Q. Have ignition parts failed? A. Have servic...

Page 82: Trouble Recovery

Trouble recovery 76 q. Is load on boat improperly distributed? A. Distribute load to place boat on an even plane. Q. Is water pump or thermostat faulty? A. Have serviced by a yamaha dealer. Q. Is there excess water in fuel filter cup? A. Drain filter cup. Engine power loss. Q. Is propeller damaged? ...

Page 83: Trouble Recovery

Trouble recovery 77 q. Is fuel joint connection incorrect? A. Connect correctly. Q. Is heat range of spark plug incorrect? A. Inspect spark plug and replace it with rec- ommended type. Q. Is high pressure fuel pump drive belt bro- ken? A. Have serviced by a yamaha dealer. Q. Is engine not responding...

Page 84: Trouble Recovery

Trouble recovery 78 emu29512 power trim and tilt will not operate if the engine cannot be tilted up or down with the power trim and tilt because of a dis- charged battery or a failure with the power trim and tilt unit , the engine can be tilted manually. 1. Loosen the manual valve screw by turn- ing...

Page 85: Trouble Recovery

Trouble recovery 79 ing normal operation. Loss of engine power means the loss of most steering control. Also, without engine power, the boat could slow rapidly. This could cause people and objects in the boat to be thrown forward. ● make sure no one is standing behind you when pulling the starter ro...

Page 86: Trouble Recovery

Trouble recovery 80 5. Insert the knotted end of the emergency starter rope into the notch in the flywheel rotor and wind the rope several turns around the flywheel clockwise. 6. Pull the rope slowly until resistance is felt. 7. Give a strong pull straight out to crank and start the engine. Repeat i...

Page 88

Yamaha motor co., ltd. Printed on recycled paper printed in japan april 2008–0.1 × 1 !.