- DL manuals

- Yamaha

- Outboard Motor

- F50F

- Owner's Manual

Yamaha F50F Owner's Manual

Summary of F50F

Page 1

Owner’s manual f50f ft50g f60c ft60d 6c1-28199-22-e0

Page 2

Emu25050 read this owner’s manual carefully before operating your outboard motor..

Page 3: Important Manual Information

Important manual information emu25101 to the owner thank you for choosing a yamaha outboard motor. This owner’s manual contains infor- mation needed for proper operation, mainte- nance and care. A thorough understanding of these simple instructions will help you ob- tain maximum enjoyment from your ...

Page 4: Important Manual Information

Important manual information emu25120 f50f, ft50g, f60c, ft60d owner’s manual ©2006 by yamaha motor co., ltd. 1st edition, april 2006 all rights reserved. Any reprinting or unauthorized use without the written permission of yamaha motor co., ltd. Is expressly prohibited. Printed in japan.

Page 5: Table of Contents

Table of contents general information .......................... 1 identification numbers record .......... 1 outboard motor serial number .......... 1 key number....................................... 1 c-tick label ..................................... 1 safety information ...........................

Page 6: Table of Contents

Table of contents manual start and electric start models .......................................... 38 shifting .......................................... 38 forward (tiller handle and remote control models) ............................. 38 reverse (automatic reverse lock and power trim and tilt mod...

Page 7: General Information

1 general information emu25170 identification numbers record emu25183 outboard motor serial number the outboard motor serial number is stamped on the label attached to the port side of the clamp bracket. Record your outboard motor serial number in the spaces provided to assist you in ordering spare ...

Page 8: General Information

General information 2 emu25371 safety information ● before mounting or operating the outboard motor, read this entire manual. Reading it should give you an understanding of the motor and its operation. ● before operating the boat, read any own- er’s or operator’s manuals supplied with it and all lab...

Page 9: General Information

General information 3 watch for obstacles and other traffic. ● always watch carefully for swimmers dur- ing the engine operation. ● stay away from swimming areas. ● when a swimmer is in the water near you shift into neutral and shut off the engine. ● do not illegally discard empty containers used to...

Page 10: General Information

General information 4 emu25473 label caution: ecm01191 transport and store the engine only as shown. Otherwise, engine damage could result from leaking oil. Emu25540 fueling instructions warning ewm00010 gasoline and its vapors are high- ly flammable and explosive! ● do not smoke when refueling, and...

Page 11: General Information

General information 5 caution: ecm01050 all 4-stroke engines are shipped from the factory without engine oil. Emu25700 battery requirement caution: ecm01060 do not use a battery that does not meet the specified capacity. If a battery which does not meet specifications is used, the electric system co...

Page 12: General Information

General information 6 note: select a propeller which will allow the engine to reach the middle or upper half of the oper- ating range at full throttle with the maximum boat load. If operating conditions such as light boat loads then allow the engine r/min to rise above the maximum recommended range,...

Page 13: Basic Components

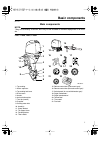

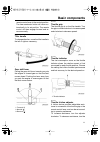

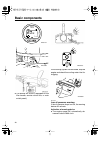

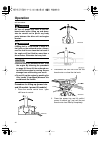

7 basic components emu25799 main components note: * may not be exactly as shown; also may not be included as standard equipment on all mod- els. F50f, ft50g, f60c, ft60d 2 3 4 trip time batt km/h knot mph km mile speed yamaha set mode 13 14 1 9 11 6 7 5 10 8 12 15 18 16 17 19 20 21 22 zmu05107 1. To...

Page 14: Basic Components

Basic components 8 emu25802 fuel tank if your model was equipped with a portable fuel tank, its function is as follows. Warning ewm00020 the fuel tank supplied with this engine is its dedicated fuel reservoir and must not be used as a fuel storage container. Com- mercial users should conform to rele...

Page 15: Basic Components

Basic components 9 the tank can be filled with fuel. To remove the cap, turn it counterclockwise. Emu25860 air vent screw this screw is on the fuel tank cap. To loosen the screw, turn it counterclockwise. Emu26180 remote control the remote control lever actuates both the shifter and the throttle. Th...

Page 16: Basic Components

Basic components 10 emu26201 neutral interlock trigger to shift out of neutral, first pull the neutral in- terlock trigger up. Emu26211 neutral throttle lever to open the throttle without shifting into ei- ther forward or reverse, put the remote con- trol lever in the neutral position and lift the n...

Page 17: Basic Components

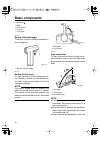

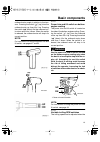

Basic components 11 remote control lever to the neutral position. The free accelerator button will return au- tomatically to its set position. The remote control will then engage forward and re- verse normally. Emu25911 tiller handle to change direction, move the tiller handle to the left or right a...

Page 18: Basic Components

Basic components 12 adjuster counterclockwise. Warning ewm00031 do not overtighten the friction adjuster. If there is too much resistance, it could be difficult to move the remote control lever or throttle grip, which could result in an accident. When constant speed is desired, tighten the adjuster ...

Page 19: Basic Components

Basic components 13 emu26001 engine stop button to open the ignition circuit and stop the en- gine, push this button. Emu26090 main switch the main switch controls the ignition system; its operation is described below. ● “ ” (off) with the main switch in the “ ” (off) posi- tion, the electrical circ...

Page 20: Basic Components

Basic components 14 emu31430 steering friction adjuster a friction device provides adjustable resis- tance to the steering mechanism, and can be set according to operator preference. An ad- juster lever is located on the bottom of the tiller handle bracket. To increase resistance, turn the lever to ...

Page 21: Basic Components

Basic components 15 outboard motor angle in relation to the tran- som. Pressing the switch “ ” (up) trims the outboard motor up, then tilts it up. Pressing the switch “ ” (down) tilts the outboard mo- tor down and trims it down. When the switch is released, the outboard motor will stop in its curren...

Page 22: Basic Components

Basic components 16 outboard motor is trolling. Press the “ ” switch to increase the trolling speed and press the “ ” switch to decrease the trolling speed. Note: ● the trolling speed changes approximately 50 r/min each time a switch is pressed. ● if the trolling speed has been adjusted, the engine ...

Page 23: Basic Components

Basic components 17 emu26340 tilt support lever for power trim and tilt or hydro tilt model to keep the outboard motor in the tilted up position, lock the tilt support lever to the clamp bracket. Emu26372 top cowling lock lever(s) (turn type) to remove the engine top cowling, turn the lock lever(s) ...

Page 24: Basic Components

Basic components 18 emu26302 warning indicator if the engine develops a condition which is cause for warning, the indicator lights up. For details on how to read the warning indicator, see page 27. Emu26470 tachometer this gauge shows the engine speed and has the following functions. Emu26491 digita...

Page 25: Basic Components

Basic components 19 note: the water separator and engine trouble warning indicators only operate when the en- gine is equipped with the appropriate func- tions. Emu26503 low oil pressure warning indicator if oil pressure drops too low, this indicator will flash. For further information, see page 27....

Page 26: Basic Components

Basic components 20 indicator will flash. For further information on reading the indicator, see page 27. Caution: ecm00050 do not continue to run the engine if the overheat warning indicator is on. Serious engine damage will occur. Emu26581 overheat warning indicator (digital type) if the engine tem...

Page 27: Basic Components

Basic components 21 note: after the main switch is first turned on, all segments of the display come on as a test. After a few seconds, the gauge will change to normal operation. Watch the gauge when turning on the main switch to make sure all segments come on. Note: the speedometer displays km/h, m...

Page 28: Basic Components

Basic components 22 engine has been run. It can be set to show the total number of hours or the number of hours for the current trip. The display can also be turned on and off. ● changing the display format ● pressing the “ ” (mode) button chang- es the display format in the following pat- tern: ● t...

Page 29: Basic Components

Basic components 23 note: the clock operates on battery power. Dis- connecting the battery will stop the clock. Reset the clock after connecting the battery. Emu26710 fuel gauge the fuel level is indicated by eight segments. When all segments are showing, the fuel tank is full. Caution: ecm00860 the...

Page 30: Basic Components

Basic components 24 emu31651 6y8 multifunction meters multifunction meters have 6 kinds of meter units; tachometer unit (square or round types), speedometer unit (square type), speed & fuel meter unit (square or round types), and fuel management meter (square type). The indicator system is slightly ...

Page 31: Basic Components

Basic components 25 stop the engine immediately if the buzzer sounds and the low oil pressure warning in- dicator blinks. Check the engine oil quantity and replenish oil if necessary. If the warning device has activated while the appropriate engine oil quantity is maintained, consult your yamaha dea...

Page 32: Basic Components

Basic components 26 caution: ecm00920 in such an event, the engine will not oper- ate properly. Consult a yamaha dealer immediately. Low battery voltage warning when the battery voltage drops, the low bat- tery voltage warning indicator and the bat- tery voltage value will start to blink. Get back t...

Page 33: Basic Components

Basic components 27 tached operation manual. Emu31630 fuel management meter this meter has functions of fuel flow meter, total consumption display, fuel economy dis- play, and remaining fuel display. Note: after the main switch is first turned on, all the displays come on as a test. After a few sec-...

Page 34: Basic Components

Basic components 28 ● the buzzer will sound (if equipped on the tiller handle, remote control box, or main switch panel). If the warning system has activated, stop the engine and check the cooling water inlet for clogging. Emu30167 low oil pressure warning if the oil pressure drops too low, the warn...

Page 35: Basic Components

Basic components 29 ● if equipped with a low oil pressure warning indicator, it will light or blink. ● the buzzer will sound (if equipped on the tiller handle, remote control box, or main switch panel). If the warning system has activated, stop the engine as soon as it is safe to do so. Check the oi...

Page 36: Basic Components

Basic components 30 low oil pressure warning indicator is on. Serious engine damage could occur..

Page 37: Operation

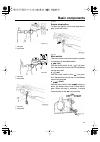

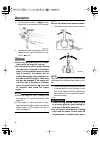

31 operation emu26901 installation caution: ecm00110 incorrect engine height or obstructions to smooth water flow (such as the design or condition of the boat, or accessories such as transom ladders or depth finder transducers) can create airborne water spray while the boat is cruising. Severe engin...

Page 38: Operation

Operation 32 motor greatly affects the water resistance. If the mounting height is too high, cavitation tends to occur, thus reducing the propulsion; and if the propeller tips cut the air, the engine speed will rise abnormally and cause the en- gine to overheat. If the mounting height is too low, th...

Page 39: Operation

Operation 33 line fumes. ● check fuel line connections to be sure they are tight (if equipped yamaha fuel tank or boat tank). ● be sure the fuel tank is positioned on a se- cure, flat surface, and that the fuel line is not twisted or flattened, or likely to contact sharp objects (if equipped yamaha ...

Page 40: Operation

Operation 34 1. Remove the fuel tank cap. 2. Carefully fill the fuel tank. 3. Securely close the cap after filling the tank. Wipe up any spilled fuel. Emu27450 operating engine emu27461 feeding fuel (portable tank) warning ewm00420 ● before starting the engine, make sure that the boat is tightly moo...

Page 41: Operation

Operation 35 the fuel line to the fuel line clamp. Note: during engine operation place the tank hori- zontally, otherwise fuel cannot be drawn from the fuel tank. 4. Squeeze the primer pump with the outlet end up until you feel it become firm. Emu27490 starting engine emu27592 electric start / prime...

Page 42: Operation

Operation 36 4. Turn the main switch to “ ” (start), and hold it for a maximum of 5 seconds. 5. Immediately after the engine starts, re- lease the main switch and allow it to re- turn to “ ” (on). Caution: ecm00191 ● never turn the main switch to “ ” (start) while the engine is running. ● do not kee...

Page 43: Operation

Operation 37 gled, preventing it from functioning. ● avoid accidentally pulling the lanyard during normal operation. Loss of en- gine power means the loss of most steering control. Also, without engine power, the boat could slow rapidly. This could cause people and objects in the boat to be thrown f...

Page 44: Operation

Operation 38 warmed up. For further information, see page 38. ● if the engine is warm and fails to start, open the throttle slightly and try to start the engine again. If the engine still fails to start, see page 71. Emu27670 warming up engine emu27710 manual start and electric start models 1. After...

Page 45: Operation

Operation 39 firmly from neutral to forward. Remote control models 1. Pull up the neutral interlock trigger (if equipped) and move the remote control lever quickly and firmly from neutral to forward. Emu27785 reverse (automatic reverse lock and power trim and tilt models) warning ewm00190 when opera...

Page 46: Operation

Operation 40 emu30880 trolling emu30890 adjusting trolling speed the trolling speed on outboard motors equipped with the variable trolling rpm switches can be adjusted approximately 50 r/min with each press of a switch. To increase the trolling speed, press the “ ” switch. To decrease the trolling s...

Page 47: Operation

Operation 41 2. After stopping the engine, disconnect the fuel line if there is a fuel joint on the outboard motor. 3. Tighten the air vent screw on the fuel tank cap (if equipped). 4. Remove the key if the boat will be left unattended. Note: the engine can also be stopped by pulling the lanyard and...

Page 48: Operation

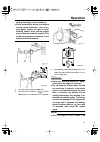

Operation 42 emu27882 adjusting trim angle power trim and tilt models warning ewm00751 ● be sure all people are clear of the out- board motor when adjusting the tilt an- gle, also be careful not to pinch any body parts between the drive unit and clamp bracket. ● use caution when trying a trim positi...

Page 49: Operation

Operation 43 to lower the bow (trim-in), press the switch “ ” (down). Make test runs with the trim set to different angles to find the position that works best for your boat and operating conditions. Emu27911 adjusting boat trim when the boat is on plane, a bow-up attitude results in less drag, grea...

Page 50: Operation

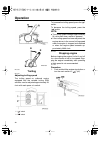

Operation 44 salt corrosion. Warning ewm00220 be sure all people are clear of the out- board motor when tilting up and down, also be careful not to pinch any body parts between the drive unit and engine bracket. Warning ewm00250 leaking fuel is a fire hazard. If there is a fuel joint on the outboard...

Page 51: Operation

Operation 45 4. Push the tilt support knob into the clamp bracket or pull the tilt support lever to- ward you to support the engine. Warning ewm00260 after tilting the outboard motor, be sure to support it with the tilt support knob or tilt support lever. Otherwise the outboard motor could fall back...

Page 52: Operation

Operation 46 tilt support lever / tilt support knob be- comes free. 2. Release the tilt support lever or pull out the tilt support knob. 3. Push the power trim and tilt switch / pow- er tilt switch “ ” (down) to lower the out- board motor to the desired position. Emu28060 cruising in shallow water t...

Page 53: Operation

Operation 47 ting up for and cruising in shallow water. Otherwise severe damage from overheat- ing can result. Emu28185 procedure for power trim and tilt / power tilt models 1. Place the remote control lever / gear shift lever in neutral. 2. Slightly tilt the outboard motor up to the desired positio...

Page 54: Operation

Operation 48 3. To return the outboard motor to the nor- mal running position, press the power trim and tilt switch / power tilt switch and slowly tilt the outboard motor down. Emu28192 cruising in other conditions cruising in salt water after operating in salt water, flush the cooling water passage...

Page 55: Maintenance

49 maintenance emu31480 specifications note: “(al)” stated in the specification data below represents the numerical value for the alumi- num propeller installed. Likewise, “(sus)” represents the value for stainless steel propeller installed and “(pl)” for plastic propeller installed. Emu28218 dimens...

Page 56: Maintenance

Maintenance 50 control system: f50feht tiller f50fet remote control f60ceht tiller f60cet remote control ft50get remote control ft60det remote control starting system: electric starting carburetion system: electronic fuel injection valve clearance (cold engine) in: 0.15–0.25 mm (0.0059–0.0098 in) va...

Page 57: Maintenance

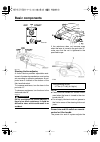

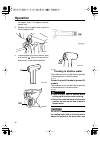

Maintenance 51 emu28222 transporting and storing outboard motor warning ewm00690 ● leaking fuel is a fire hazard. When transporting and storing the outboard motor, close the air vent screw and fuel cock to prevent fuel from leaking. ● use care when transporting fuel tank, whether in a boat or car. ●...

Page 58: Maintenance

Maintenance 52 por separator for a prolonged period of time will break down and could cause damage to the fuel line. Emu28302 procedure emu29953 flushing with the flushing attachment 1. Wash the outboard motor body using fresh water. For further information, see page 55. 2. Disconnect the fuel line ...

Page 59: Maintenance

Maintenance 53 9. Remove the flushing attachment. 10. Install the top cowling. 11. If “fogging oil” is not available, turn off the engine after the 6 step. Then per- form the 8 step procedure. 12. Drain the cooling water completely out of the motor. Clean the body thoroughly. 13. If the “fogging oil...

Page 60: Maintenance

Maintenance 54 follow these preventive measures: ● charge batteries in a well-ventilated ar- ea. ● keep batteries away from fire, sparks, or open flames (for example: welding equipment, lighted cigarettes, and so on.) ● do not smoke when charging or han- dling batteries. Keep batteries and electroly...

Page 61: Maintenance

Maintenance 55 the hose hang free during normal opera- tion. Water will leak out of the connector instead of cooling the engine, which can cause serious overheating. Be sure the connector is tightened securely on the fit- ting after flushing the engine. Note: ● when flushing the engine with the boat...

Page 62: Maintenance

Maintenance 56 emu28522 maintenance chart frequency of maintenance operations may be adjusted according to the operating condi- tions, but the following table gives general guidelines. Refer to the sections in this chapter for explanations of each owner-specific action. Note: when operating in salt ...

Page 63: Maintenance

Maintenance 57 emu28874 maintenance chart (additional) engine oil inspection / change oil filter (cartridge) change spark plug(s) cleaning / adjustment / replacement timing belt inspection / replace- ment valve clearance (ohc, ohv) inspection / adjustment item actions every 500 hours (2.5 years) 100...

Page 64: Maintenance

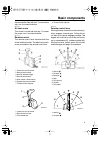

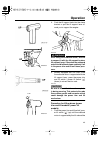

Maintenance 58 emu28940 greasing yamaha grease a (water resistant grease) yamaha grease d (corrosion resistant grease; for propeller shaft) f50f, ft50g, f60c, ft60d zmu05087.

Page 65: Maintenance

Maintenance 59 f50f, f60c emu28952 cleaning and adjusting spark plug warning ewm00560 when removing or installing a spark plug, be careful not to damage the insulator. A damaged insulator could allow external sparks, which could lead to explosion or fire. The spark plug is an important engine com- p...

Page 66: Maintenance

Maintenance 60 place the spark plug with another of the cor- rect type. Before fitting the spark plug, measure the electrode gap with a wire thickness gauge; adjust the gap to specification if necessary. When fitting the plug, always clean the gas- ket surface and use a new gasket. Wipe off any dirt...

Page 67: Maintenance

Maintenance 61 checkpoints ● fuel system parts leakage ● fuel line joint leakage ● fuel line cracks or other damage ● fuel connector leakage emu29041 inspecting idling speed warning ewm00451 ● do not touch or remove electrical parts when starting or during operation. ● keep hands, hair, and clothes ...

Page 68: Maintenance

Maintenance 62 2. Prepare a suitable container that holds a larger amount than the engine oil capac- ity. Loosen and remove the drain screw while holding the container under the drain hole. Then remove the oil filler cap. Let the oil drain completely. Wipe up any spilled oil immediately. 3. Put a ne...

Page 69: Maintenance

Maintenance 63 specified level if it is above the upper mark. 7. Dispose of used oil according to local regulations. Note: ● for more information on the disposal of used oil, consult your yamaha dealer. ● change the oil more often when operating the engine under adverse conditions such as extended t...

Page 70: Maintenance

Maintenance 64 that the trim and tilt rod / the tilt rod oper- ates smoothly. Note: consult your yamaha dealer if any operation is abnormal. Emu29171 checking propeller warning ewm00321 you could be seriously injured if the en- gine accidentally starts when you are near the propeller. ● before inspe...

Page 71: Maintenance

Maintenance 65 emu30660 removing the propeller emu29194 spline models 1. Straighten the cotter pin and pull it out using a pair of pliers. 2. Remove the propeller nut, washer, and spacer (if equipped). 3. Remove the propeller and thrust wash- er. Emu30670 installing the propeller emu29231 spline mod...

Page 72: Maintenance

Maintenance 66 specified torque, tighten the nut further to align it with the hole. Emu29282 changing gear oil warning ewm00800 ● be sure the outboard motor is securely fastened to the transom or a stable stand. You could be severely injured if the outboard motor falls on you. ● never get under the ...

Page 73: Maintenance

Maintenance 67 6. Put a new gasket on the oil level plug. When the oil begins to flow out of the oil level plug hole, insert and tighten the oil level plug. 7. Put a new gasket on the gear oil drain screw. Insert and tighten the gear oil drain screw. Emu29302 cleaning fuel tank warning ewm00920 gaso...

Page 74: Maintenance

Maintenance 68 the screws firmly. Emu29312 inspecting and replacing anode(s) yamaha outboard motors are protected from corrosion by sacrificial anodes. Inspect the external anodes periodically. Remove scales from the surfaces of the anodes. Consult a yamaha dealer for replacement of external anodes....

Page 75: Maintenance

Maintenance 69 equipment, lighted cigarettes, and so on.) ● do not smoke when charging or han- dling batteries. Keep batteries and electrolytic fluid out of reach of children. Caution: ecm00360 ● a poorly maintained battery will quickly deteriorate. ● ordinary tap water contains minerals harmful to ...

Page 76: Maintenance

Maintenance 70 emu29370 disconnecting the battery disconnect the black cable from the neg- ative (-) terminal first. Then disconnect the red cable from the positive (+) terminal. Emu29390 checking top cowling check the fitting of the top cowling by push- ing it with both hands. If it is loose have i...

Page 77: Trouble Recovery

71 trouble recovery emu29424 troubleshooting a problem in the fuel, compression, or igni- tion systems can cause poor starting, loss of power, or other problems. This section de- scribes basic checks and possible remedies, and covers all yamaha outboard motors. Therefore some items may not apply to ...

Page 78: Trouble Recovery

Trouble recovery 72 q. Is fuel system obstructed? A. Check for pinched or kinked fuel line or other obstructions in fuel system. Q. Is fuel contaminated or stale? A. Fill tank with clean, fresh fuel. Q. Is fuel filter clogged? A. Clean or replace filter. Q. Have ignition parts failed? A. Have servic...

Page 79: Trouble Recovery

Trouble recovery 73 a. Have serviced by a yamaha dealer. Q. Is load on boat improperly distributed? A. Distribute load to place boat on an even plane. Q. Is water pump or thermostat faulty? A. Have serviced by a yamaha dealer. Q. Is there excess water in fuel filter cup? A. Drain filter cup. Engine ...

Page 80: Trouble Recovery

Trouble recovery 74 q. Is fuel joint connection incorrect? A. Connect correctly. Q. Is heat range of spark plug incorrect? A. Inspect spark plug and replace it with rec- ommended type. Q. Is high pressure fuel pump drive belt bro- ken? A. Have serviced by a yamaha dealer. Q. Is engine not responding...

Page 81: Trouble Recovery

Trouble recovery 75 emu29522 power trim and tilt / power tilt will not operate if the engine cannot be tilted up or down with the power trim and tilt / the power tilt because of a discharged battery or a failure with the power trim and tilt unit / the power tilt unit, the engine can be tilted manual...

Page 82: Trouble Recovery

Trouble recovery 76 1. Stop the engine. 2. Remove the top cowling. 3. Remove the plastic tie. 4. Disconnect the water detection switch coupler. Caution: ecm01570 be careful not to get any water on the wa- ter detection switch coupler, otherwise a malfunction could occur. 5. Unscrew the filter cup fr...

Page 83: Trouble Recovery

Trouble recovery 77 the filter housing. 8. Connect the water detection switch cou- pler securely until a click is heard. 9. Fasten the water detection switch lead with the plastic tie. 10. Install the top cowling. 11. Start the engine and make sure that the water separator warning indicator re- main...

Page 84: Trouble Recovery

Trouble recovery 78 only as instructed. Do not touch the fly- wheel or other moving parts when the engine is running. Do not install the starter mechanism or top cowling after the engine is running. ● do not touch the ignition coil, spark plug wire, spark plug cap, or other elec- trical components w...

Page 85: Trouble Recovery

Trouble recovery 79 gine is running. Emu29760 treatment of submerged motor if the outboard motor is submerged, immedi- ately take it to a yamaha dealer. Otherwise some corrosion may begin almost immedi- ately. If you cannot immediately take the outboard motor to a yamaha dealer, follow the proce- du...

Page 86

Yamaha motor co., ltd. Printed on recycled paper printed in japan april 2006–0.3 × 1 !.