- DL manuals

- Yamaha

- Outboard Motor

- F60A

- Supplementary Service Manual

Yamaha F60A Supplementary Service Manual

Summary of F60A

Page 1

Service manual 292098 69w-28197-3d-1x supplementary f60a.

Page 2

Notice this supplementary service manual has been prepared to introduce new service and new data information for the f60 which is based on the f50. For complete information on service procedures, it is necessary to use this supplementary service manual together with the following manual. Important i...

Page 3: Contents

Contents general information 1 gen info specifications 2 spec periodic checks and adjustments 3 chk adj fuel system 4 fuel power unit 5 powr lower unit 6 lowr bracket unit 7 brkt electrical systems 8 elec troubleshooting 9 trbl shtg index – +.

Page 4: General Information

69w3d1x general information how to use this manual .................................................................................... 1 manual format............................................................................................... 1 symbols...............................................

Page 5: Specifications

69w3d1x specifications general specifications.................................................................................... 18 maintenance specifications ........................................................................... 20 power unit......................................................

Page 6: Power Unit

69w3d1x power unit power unit........................................................................................................ 45 checking the compression pressure .......................................................... 55 checking the oil pressure ............................................

Page 7: Electrical Systems

69w3d1x electrical systems wiring harness ................................................................................................ 85 ignition and ignition control system ............................................................. 86 checking the spark plug caps ..............................

Page 8

Gen info general information 1 69w3d1x how to use this manual 1 manual format the format of this manual has been designed to make service procedures clear and easy to under- stand. Use the information below as a guide for effective and quality service. 1 parts are shown and detailed in an exploded d...

Page 9

69w3d1x 2 symbols the symbols below are designed to indicate the content of a chapter. General information specifications periodic checks and adjustments fuel system power unit lower unit bracket unit electrical systems troubleshooting gen info spec chk adj fuel powr lowr brkt elec trbl shtg – + sym...

Page 10

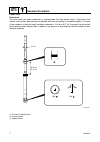

Gen info general information 3 69w3d1x identification 1 applicable models this manual covers the following models. Serial number the outboard motor serial number is stamped on a label attached to the port clamp bracket. 1 model name 2 approved model code 3 transom height 4 serial number applicable m...

Page 11

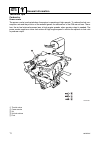

69w3d1x 4 features and benefits 1 power unit based on the power unit of the field-proven f50, newly designed parts have been adopted in the various areas to attain 60 horsepower. The newly designed parts include the intake valves, exhaust valves, cylinder head, pistons, and the intake silencer. Cyli...

Page 12

Gen info general information 5 69w3d1x oil pump the size of the oil pump rotor has been enlarged to increase the oil discharge volume. As a result, reliable lubrication has been realized. 1 rotor 2 embossed letters for identification carburetors to achieve the high power output of the f60, the carbu...

Page 13

69w3d1x 6 although the main jet specification numbers of the f50 differed between cylinders, the f60 uses main jets with the same specification number for all four cylinders due to the change in shape of the intake silencer. È air power nozzle the f60 uses a power nozzle in its carburetors. This noz...

Page 14

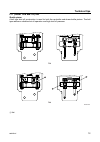

Gen info general information 7 69w3d1x lower unit drive shaft the drive shaft has been machined to accommodate the high power output. The portion that mounts to the pinion gear has been machined with involute splines to increase durability. A section of the midspan of the drive shaft has been reduce...

Page 15

69w3d1x 8 forward gear bearing the size of the forward gear bearing has been increased to accommodate the high power output of the f60. With this increase, the coupling length of the forward gear has been extended as well. In addition, two grooves are provided on the forward gear for identification ...

Page 16

Gen info general information 9 69w3d1x bracket unit ptt (power trim and tilt) unit based on the 62y type ptt unit of the f50, the internal valve and power trim and tilt motor have been changed. The construction of the valves has been changed to increase the shut-off pressure. The unit limits the mov...

Page 17

69w3d1x 10 steering friction the f60 tiller handle models use a newly developed, compact steering friction. 1 steering friction electrical unit starter motor the starter motor uses six magnets and four brushes to enhance its operating torque. 1 bearing 2 starter relay 3 neutral switch 4 engine start...

Page 18

Gen info general information 11 69w3d1x technical tips 1 carburetor power nozzle the power nozzle is activated when the engine is operating at high speeds. To reduce the fuel con- sumption rate and the pollution of the exhaust gases, the carburetors of the f60 are set lean. There- fore, the air-fuel...

Page 19

69w3d1x 12 ptt (power trim and tilt) unit shuttle piston a ball type shut-off construction is used for both the up-shuttle and down-shuttle pistons. The ball type realizes a reliable shut-off operation and high shut-off pressure. 1 ball f50 f60 s69w1310 technical tips.

Page 20

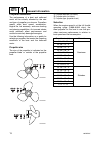

Gen info general information 13 69w3d1x propeller selection 1 the performance of a boat and outboard motor will be critically affected by the size and type of propeller you choose. Propellers greatly affect boat speed, acceleration, engine life, fuel economy, and even boating and steering capabiliti...

Page 21

69w3d1x 14 predelivery checks 1 to make the delivery process smooth and efficient, the predelivery checks should be completed as explained below. Checking the fuel system 1. Check that the fuel hoses are securely connected and that the fuel tank is full with fuel. Caution: this is a 4-stroke engine....

Page 22

Gen info general information 15 69w3d1x note: the optimum mounting height is affected by the combination of the boat and the outboard motor. To determine the optimum mounting height, test run the outboard motor at differ- ent heights. 2. Check that the clamp brackets are secured with the clamp bolts...

Page 23

69w3d1x 16 checking the gearshift and throttle operation 1. Check that the gearshift operates smoothly when the remote control lever or shift lever is shifted from neutral into forward or reverse. 2. Check that the throttle operates smoothly when the remote control lever or throttle grip is shifted ...

Page 24

Gen info general information 17 69w3d1x checking the cooling watger pilot hole 1. Start the engine, and then check that cooling water is discharged from the cooling water pilot hole. Test run 1. Start the engine, and then check that the gearshift operates smoothly. 2. Check the engine idle speed aft...

Page 25

69w3d1x 18 general specifications 2 item unit model f60aeht f60aet dimension overall length mm (in) 1,339 (52.7) 706 (27.8) overall width mm (in) 384 (15.1) overall height (l) mm (in) 1,415 (55.7) boat transom height (l) mm (in) 508 (20.0) weight (with aluminum propeller) (l) kg (lb) 120.0 (265) 114...

Page 26

Spec specifications 19 69w3d1x * pon: pump octane number (research octane number + motor octane number)/2 ron: research octane number fuel and oil fuel type regular unleaded gasoline fuel rating pon* ron 86 91 engine oil type 4-stroke motor oil engine oil grade api sae se, sf, sg, or sh 10w-30, 10w-...

Page 27

69w3d1x 20 maintenance specifications 2 power unit item unit model f60aeht f60aet power unit minimum compression pressure* kpa (kgf/cm 2 , psi) 880 (8.8, 125) lubrication oil pressure (reference data) kpa (kgf/cm 2 , psi) at 900 r/min 110 (1.1, 16) cylinder heads warpage limit mm (in) 0.1 (0.004) (l...

Page 28

Spec specifications 21 69w3d1x piston rings top ring dimension b mm (in) 1.17–1.19 (0.0461–0.0468) dimension t mm (in) 2.30–2.50 (0.0906–0.0984) end gap mm (in) 0.15–0.30 (0.0060–0.0118) side clearance mm (in) 0.02–0.06 (0.0008–0.0023) 2nd ring dimension b mm (in) 1.47–1.49 (0.0578–0.0586) dimension...

Page 29

69w3d1x 22 face width (b) intake mm (in) 1.98–2.40 (0.0780–0.0945) exhaust mm (in) 2.16–2.79 (0.0850–0.1098) seat contact width (c) intake mm (in) 1.3–1.5 (0.0512–0.0590) exhaust mm (in) 1.3–1.5 (0.0512–0.0590) margin thickness (d) intake mm (in) 0.8–1.2 (0.0315–0.0472) exhaust mm (in) 1.0–1.4 (0.03...

Page 30

Spec specifications 23 69w3d1x crankcase main journal bearing thickness yellow mm (in) 1.502–1.506 (0.0591–0.0593) red mm (in) 1.498–1.502 (0.0590–0.0591) pink mm (in) 1.494–1.498 (0.0588–0.0590) green mm (in) 1.490–1.494 (0.0587–0.0588) oil pump type trochoid outer rotor-to-housing clearance mm (in...

Page 31

69w3d1x 24 lower unit electrical item unit model f60aeht f60aet gear backlash pinion-to-forward gear mm (in) 0.18–0.54 (0.0071–0.0212) pinion-to-reverse gear mm (in) 0.71–1.07 (0.0280–0.0421) pinion shims mm 0.10, 0.12, 0.15, 0.18, 0.30, 0.40, 0.50 forward gear shims mm 0.10, 0.12, 0.15, 0.18, 0.30,...

Page 32

Spec specifications 25 69w3d1x ignition control system oil pressure switch on ↔ off kpa (kgf/cm 2 , psi) 29.4–58.8 (0.294–0.588, 4.181–8.361) thermoswitch (gy/b – b) off → on °c (°f) 76–84 (169–183) on → off °c (°f) 63–77 (145–170) starter motor type bendix output kw 1.1 cranking time limit second 3...

Page 33

69w3d1x 26 power trim and tilt system trim sensor setting resistance Ω 9–11 resistance (p – b) Ω 9–288.3 fluid type atf dexron ii brushes standard length mm (in) 10 (0.39) wear limit mm (in) 3.5 (0.14) commutator standard diameter mm (in) 22.0 (0.87) wear limit mm (in) 21.0 (0.83) mica standard unde...

Page 34

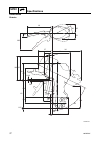

Spec specifications 27 69w3d1x dimensions exterior l3 l6 l7 h9 h5 h2 h7 h1 h11 h4 h3 c1 b6 l5 l8 l9 l4 a3 a2 h6 h10 h8 l2 l1 l10 w2 w6 a1 w5 w1 s69w2150

Page 35

69w3d1x 28 symbol unit model f60aeht l1 mm (in) 584 (23.0) l2 mm (in) 226 (8.9) l3 mm (in) 755 (29.7) l4 mm (in) 533 (21.0) l5 (l) mm (in) 97 (3.8) (x) mm (in) — l6 (l) mm (in) 932 (36.7) (x) mm (in) — l7 mm (in) 417 (16.4) l8 mm (in) 164 (6.5) l9 (l) mm (in) 0 (0) (x) mm (in) — l10 mm (in) 62 (2.4)...

Page 36

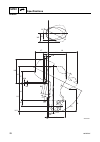

Spec specifications 29 69w3d1x exterior l6 l7 w5 w1 a1 h9 h2 h7 h1 h11 h4 h3 c1 b6 l5 l9 l4 a3 a2 h6 h10 h8 l8 l2 l1 l10 s69w2160

Page 37

69w3d1x 30 symbol unit model f60aet l1 mm (in) 584 (23.0) l2 mm (in) 122 (4.8) l3 mm (in) — l4 mm (in) 533 (21.0) l5 (l) mm (in) 97 (3.8) (x) mm (in) — l6 (l) mm (in) 932 (36.7) (x) mm (in) — l7 mm (in) 417 (16.4) l8 mm (in) 147 (5.8) l9 (l) mm (in) 0 (0) (x) mm (in) — l10 mm (in) 62 (2.4) h1 (l) mm...

Page 38

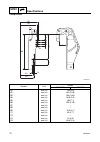

Spec specifications 31 69w3d1x clamp bracket symbol unit model f60aeht f60aet b1 mm (in) 126 (5.0) b2 mm (in) 249 (10.0) b3 mm (in) 163.5 (6.4) b4 mm (in) 50.8 (2.0) b5 mm (in) 180 (7.1) b6 mm (in) 350 (13.8) b7 mm (in) — b8 mm (in) — b9 mm (in) 18.5 (0.7) c1 mm (in) 69 (2.7) c2 mm (in) — d1 mm (in)...

Page 39

69w3d1x 32 tightening torques 2 specified torques part to be tightened thread size tightening torques n·m kgf·m ft·lb power unit flywheel magnet nut — 160 16 116 stator base screw m6 4 0.4 2.9 cover screw m6 3 0.3 2.2 red battery cable nut — 4 0.4 2.9 oil pressure switch — 9 0.9 6.5 oil pressure swi...

Page 40

Spec specifications 33 69w3d1x general torques this chart specifies tightening torques for standard fasteners with a standard iso thread pitch. Tightening torque specifications for special components or assemblies are provided in applicable sections of this man- ual. To avoid warpage, tighten multi-...

Page 41

69w3d1x 34 special service tools 3 digital tachometer 90890-06760 compression gauge 90890-03160 drive shaft holder 4 90890-06518 pinion nut holder 90890-06505 socket adapter 1 90890-06506 bearing separator 90890-06534 bearing inner race attachment 90890-06643 shimming plate 90890-06701 digital calip...

Page 42

Chk adj periodic checks and adjustments 35 69w3d1x dial gauge set 90890-01252 magnet base 90890-06705.

Page 43

69w3d1x 36 maintenance interval chart 3 use the following chart as a guideline for general maintenance. Adjust the maintenance intervals according to the operating conditions of the outboard motor. Note: • flush the engine with fresh water after operating in salt water, or turbid or muddy water. • i...

Page 44

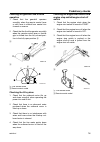

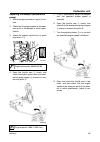

Chk adj periodic checks and adjustments 37 69w3d1x top cowling 3 checking the top cowling 1. Check the fitting by pushing the cowling with both hands. Adjust if necessary. 2. Loosen the nuts 1. 3. Move the hook 2 up or down slightly to adjust its position. Note: • to loosen the fitting, move the hoo...

Page 45

69w3d1x 38 4. Check the thermostat valve opening at the specified water temperatures. Replace if out of specification. 5. Install the thermostat, new gasket, ther- mostat cover, and cover. General 3 checking the anodes 1. Check the anodes and trim tab for scales, grease, or oil. Clean if necessary. ...

Page 46

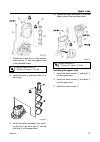

Chk adj periodic checks and adjustments 39 69w3d1x lubrication 1. Apply water resistant grease to the areas shown. Note: apply grease to the grease nipple until it flows from the bushings a. 2. Apply corrosion resistant grease to the areas shown. S69w3120 a a s69w3150 a a.

Page 47

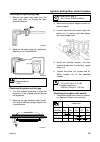

69w3d1x 40 hose routing 4 fuel and blowby hoses 1 blowby hose 2 hose (acceleration pump-to-carburetor) 3 fuel hose (fuel joint-to-fuel filter) 4 fuel hose (fuel filter-to-fuel pump) 5 fuel hose (fuel pump-to-carburetor) 6 hose (carburetor-to-carburetor) 7 hose (acceleration pump-to-acceleration pump...

Page 48

Fuel fuel system 41 69w3d1x cooling water hose 1 pilot water hose 2 flushing hose È flushing device model É view in direction of arrow s69w4020

Page 49

69w3d1x 42 fuel line and fuel filter 4 no. Part name q’ty remarks 1 fuel joint 1 2 bolt 1 m6 × 25 mm 3 seal 1 4 fuel hose 1 fuel joint-to-fuel filter 5 bolt 1 m8 × 14 mm 6 nut 1 7 bracket 1 8 body 1 9 fuel filter element 1 10 float 1 11 o-ring 1 not reusable 12 cup 1 13 fuel hose 2 fuel pump-to-carb...

Page 50

Fuel fuel system 43 69w3d1x carburetor unit 4 no. Part name q’ty remarks 1 acceleration pump 1 2 screw 3 ø5 × 9 mm 3 link rod 1 4 hose 1 5 hose 4 6 link rod 1 7 clip 1 not reusable.

Page 51

69w3d1x 44 adjusting the dashpot (acceleration pump) 1. Start the engine and warm it up for 5 min- utes. 2. Check that the engine speed at the oper- ation point of the dashpot is within speci- fication. 3. Attach the special service tool to spark plug wire #1 1. 4. Open the throttle cam 2 slowly, an...

Page 52

Powr power unit 45 69w3d1x power unit 5.

Page 53

69w3d1x 46 È flushing device model no. Part name q’ty remarks 1 power trim and tilt relay 1 2 bolt 1 m8 × 16 mm 3 black battery cable 1 4 wiring harness 1 10-pin coupler 5 grommet 1 6 nut 1 7 spring washer 1 8 red battery cable 1 9 ptt relay positive lead 1 10 fuse holder lead 1 11 clip 1 12 warning...

Page 54

Powr power unit 47 69w3d1x.

Page 55

69w3d1x 48 no. Part name q’ty remarks 1 bracket 1 2 starter motor 1 3 spark plug cap 4 4 ignition coil 2 5 wiring harness 1 6 thermoswitch 1 7 holder 1 8 bolt 1 m6 × 12 mm 9 ground lead 3 10 bolt 1 m6 × 12 mm 11 oil pressure switch 1 12 oil pressure switch lead 1 13 screw 1 14 ignition coil lead 2 1...

Page 56

Powr power unit 49 69w3d1x.

Page 57

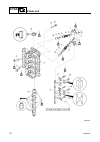

69w3d1x 50 È tightening sequence no. Part name q’ty remarks 1 cylinder head 1 2 plate 1 3 cylinder head cover 1 4 bolt 7 m6 × 20 mm 5 cylinder head cover gasket 1 not reusable 6 bolt 10 m9 × 95 mm 7 spark plug 4 8 bolt 5 m6 × 25 mm 9 dowel pin 2 10 cylinder head gasket 1 not reusable 11 grommet 4 12...

Page 58

Powr power unit 51 69w3d1x.

Page 59

69w3d1x 52 no. Part name q’ty remarks 1 rocker arm assembly 8 2 rocker arm shaft 1 3 cylinder head 1 4 exhaust valve 4 5 intake valve 4 6 camshaft 1 7 valve cotter 16 8 spring retainer 8 9 valve spring 8 10 spring seat 8 11 stem seal 8 not reusable 12 valve guide 8 not reusable 13 retaining bolt 1 1...

Page 60

Powr power unit 53 69w3d1x.

Page 61

69w3d1x 54 È tightening sequence no. Part name q’ty remarks 1 oil filter 1 2 crankshaft 1 3 bolt 10 m8 × 82 mm 4 bolt 10 m6 × 35 mm 5 crankcase 1 6 oil seal 1 not reusable 7 main bearing 10 8 oil seal 1 not reusable 9 connecting rod bearing 8 10 connecting rod cap 4 11 bolt 8 12 dowel pin 2 13 cylin...

Page 62

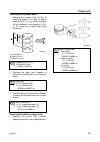

Powr power unit 55 69w3d1x checking the compression pressure 1. Start the engine, warm it up for 5 min- utes, and then turn it off. 2. Remove the lock plate from the engine shut-off switch on the remote control box or tiller handle. 3. Remove all spark plugs, and then install the special service too...

Page 63

69w3d1x 56 checking the cylinder bore 1. Measure the cylinder bore (d 1 –d 6 ) at measuring points a, b, and c, and in direction d (d 1 , d 3 , d 5 ), which is parallel to the crankshaft, and direction e (d 2 , d 4 , d 6 ), which is at a right angle to the crankshaft. A 20 mm (0.8 in) b 60 mm (2.4 i...

Page 64

Lowr lower unit 57 69w3d1x drive shaft and lower case 6.

Page 65

69w3d1x 58 no. Part name q’ty remarks 1 drive shaft 1 2 oil seal 1 not reusable 3 oil seal housing 1 4 o-ring 1 not reusable 5 circlip 1 6 shift rod 1 7 o-ring 1 not reusable 8 taper roller bearing 1 not reusable 9 bearing outer race 1 not reusable 10 pinion shim — as required 11 sleeve 1 12 washer ...

Page 66

Lowr lower unit 59 69w3d1x removing the drive shaft 1. Remove the drive shaft assembly and pinion, and then pull out the forward gear. Disassembling the forward gear 1. Remove the taper roller bearing from the forward gear using a press. Caution: do not reuse the bearing, always replace it with a ne...

Page 67

69w3d1x 60 shimming 6 drive shaft and lower case / shimming.

Page 68

Lowr lower unit 61 69w3d1x shimming note: • shimming is not required when assembling the original lower case and inner parts. • shimming is required when assembling the original inner parts and a new lower case. • shimming is required when replacing the inner part(s). Selecting the forward gear shim...

Page 69

69w3d1x 62 example: if “t1” is 0.45 mm, then the forward gear shim is 0.42 mm. If “t1” is 0.60 mm, then the forward gear shim is 0.58 mm. Shimming.

Page 70

Brkt bracket unit 63 69w3d1x tiller handle 7.

Page 71

69w3d1x 64 no. Part name q’ty remarks 1 tiller handle assembly 1 2 tiller handle wiring harness 1 3 grommet 1 4 clip 1 5 throttle cable 1 6 plate 1 7 bolt 3 m6 × 25 mm 8 bolt 1 m8 × 16 mm 9 black battery cable 1 10 cable guide 1 11 grommet 1 12 nut 1 m6 × 35 mm 13 washer 1 14 red battery cable 1 15 ...

Page 72

Brkt bracket unit 65 69w3d1x bottom cowling 7.

Page 73

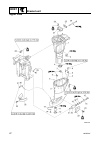

69w3d1x 66 no. Part name q’ty remarks 1 bottom cowling 1 2 rubber seal 1 3 washer 1 4 bushing 2 5 shift rod bracket 1 6 bolt 1 7 spring 1 8 ball 1 9 shift rod 1 10 flushing device 1 flushing device model 11 bracket 1 flushing device model 12 bolt 1 m6 × 16 mm / flushing device model 13 screw 2 ø6 × ...

Page 74

Brkt bracket unit 67 69w3d1x upper case 7.

Page 75

69w3d1x 68 no. Part name q’ty remarks 1 muffler assembly 1 2 upper case 1 3 muffler seal 1 4 rubber seal 1 5 dowel pin 2 6 grommet 1 7 damper 1 8 screw 2 ø5 × 16 mm 9 baffle plate 1 10 bolt 4 m8 × 30 mm 11 drive shaft bushing 1 12 circlip 1 13 ground lead 1 14 screw 1 ø6 × 8 mm 15 cap 2 16 bolt 2 m1...

Page 76

Brkt bracket unit 69 69w3d1x.

Page 77

69w3d1x 70 no. Part name q’ty remarks 1 oil seal 1 not reusable 2 exhaust guide 1 3 grommet 1 4 anode 1 5 cover 1 6 bolt 1 m6 × 20 mm 7 cover 1 8 bolt 1 9 gasket 1 not reusable 10 gasket 1 not reusable 11 relief valve housing 1 12 relief valve 1 13 spring 1 14 cotter pin 1 not reusable 15 bolt 2 m6 ...

Page 78

Brkt bracket unit 71 69w3d1x disassembling the oil pan 1. Remove the muffler 1, plate 2, and exhaust manifold 3 from the oil pan 4. 2. Remove the oil pan 4 and the exhaust guide 5. 3. Remove the oil strainer 6 and the relief valve housing 7. Assembling the oil pan 1. Install the gaskets onto the exh...

Page 79

69w3d1x 72 7. Tighten the oil pan bolts 7 then exhaust manifold bolts 8, and then tighten them to the specified torque. 8. Install the plate 9 and the muffler 0 to the oil pan. 9. Install the muffler assembly a by insert- ing the tip of the water pipe 4 into the joint hole a of the upper case. 10. T...

Page 80

Brkt bracket unit 73 69w3d1x 4. Install the upper and lower mounting bolts into the swivel bracket 6 simulta- neously. 5. Install the upper mounting nut 7 and lower mounting nut 8, and then tighten them to the specified torque. 6. Install the cover 9. T r . . Upper mounting nut 7: 24 n·m (2.4 kgf·m,...

Page 81

69w3d1x 74 clamp brackets 7 no. Part name q’ty remarks 1 swivel bracket assembly 1 2 screw 2 ø6 × 15 mm 3 trim sensor 1 4 trim sensor coupler 1 5 plastic tie 1 not reusable 6 self-locking nut 2 7 cap 2 8 bolt 4 m6 × 25 mm 9 anode 2 10 port clamp bracket 1 11 washer 2 12 bushing 2 13 through tube 1 1...

Page 82

Brkt bracket unit 75 69w3d1x adjusting the trim sensor 1. Fully tilt the outboard motor up, and then support it with the tilt stop lever 1. Warning after tilting up the outboard motor, be sure to support it with the tilt stop lever. Otherwise, the outboard motor could sud- denly lower if the power t...

Page 83

69w3d1x 76 swivel bracket and steering arm 7 no. Part name q’ty remarks 1 steering arm 1 2 washer 1 3 bushing 1 4 o-ring 2 not reusable 5 bushing 2 6 swivel bracket 1 7 bushing 2 8 port tilt stop lever 1 9 circlip 1 10 steering yoke 1 11 bushing 1 12 bushing 2 13 tilt stop lever joint 1 14 spring ho...

Page 84

Brkt bracket unit 77 69w3d1x power trim and tilt unit 7 no. Part name q’ty remarks 1 power trim and tilt unit 1 2 plastic tie 3 not reusable 3 ptt motor lead 2 4 washer 2 5 bolt 2 m8 × 16 mm 6 circlip 1 7 shaft 1 8 bushing 2 9 collar 1 10 tilt pin 1 11 collar 1 12 collar 1 13 shaft 1.

Page 85

69w3d1x 78 no. Part name q’ty remarks 1 bolt 2 m5 × 8 mm 2 relief valve bracket 1 3 bolt 3 m6 × 40 mm 4 valve lock screw 1 5 up-relief spring 1 6 valve support pin 1 7 o-ring 1 not reusable 8 ball 1 9 down-relief spring 1 10 valve support pin 1 11 relief valve seal 1 12 filter 1 13 o-ring 2 not reus...

Page 86

Brkt bracket unit 79 69w3d1x no. Part name q’ty remarks 1 bolt 2 m5 × 20 mm 2 washer 2 3 bracket 1 4 o-ring 2 not reusable 5 spacer 2 6 spring 2 7 valve pin 2 8 ball 2 9 manual release spring 1 10 ball 2 11 gear pump cover 1 12 spring 2 13 shuttle piston 1 14 o-ring 1 not reusable 15 valve seal 2 16...

Page 87

69w3d1x 80 no. Part name q’ty remarks 19 shaft 1 20 driven gear 1 21 ball 2 22 shuttle piston 1 23 valve plate 1 24 plate 1 25 gear pump housing 1 power trim and tilt unit.

Page 88

Brkt bracket unit 81 69w3d1x no. Part name q’ty remarks 1 screw 3 ø5 × 20 mm 2 yoke 1 3 o-ring 1 not reusable 4 armature 1 5 washer 1 6 bushing 1 7 screw 2 ø4 × 12 mm 8 lead 1 9 brush 2 1 10 brush 1 1 11 brush holder 1 12 circuit breaker 1 13 brush spring 2 14 ptt motor base 1 15 oil seal 1 not reus...

Page 89

69w3d1x 82 disassembling the gear pump 1. Remove the manual valve 1 and gear pump 2. 2. Remove the relief valve bracket 3, then the relief valve seal 4 and ball 5. 3. Remove the bracket 6, then the balls 7. 4. Remove the gear pump cover 8, then the shuttle pistons 9 and balls 0. 5. Remove the drive ...

Page 90

Brkt bracket unit 83 69w3d1x 4. Check the main valves for dirt or residue. Clean if necessary. 5. Check the absorber valves for dirt or res- idue. Clean if necessary. Assembling the gear pump 1. Install the drive gear 1, driven gear 2, shaft 3, and pins 4 into the gear pump housing 5. 2. Install the...

Page 91

69w3d1x 84 7. Install the filters h and gear pump i by installing the bolts j, then tightening them to the specified torque. 8. Install the manual valve k and reservoir cap l. 9. Fill the reservoir with the recommended fluid to the correct level a as shown. 10. Install the joint m and power trim and...

Page 92

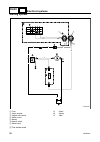

Elec electrical systems – + 85 69w3d1x wiring harness 8 connect to: 1 engine start switch or remote control box extension 2 power trim and tilt relay 3 ground 4 starter relay 5 red battery cable 6 prime start 7 warning indicator 8 cdi unit 9 power trim and tilt switch 0 rectifier regulator a thermos...

Page 93

69w3d1x 86 ignition and ignition control system 8 1 spark plug 2 ignition coil 3 charge coil 4 pulser coil 5 engine start switch 6 engine shut-off switch 7 10-pin coupler 8 cdi unit È tiller handle model b : black br : brown l : blue o : orange w : white b/o : black/orange b/w : black/white w/b : wh...

Page 94

Elec electrical systems – + 87 69w3d1x 1 thermoswitch 2 oil pressure switch 3 cdi unit 4 oil pressure warning indicator 5 overheat warning indicator 6 warning indicator È tiller handle model b : black p : pink gy/b : gray/black p/b : pink/black p/w : pink/white y/b : yellow/black y/r : yellow/red.

Page 95

69w3d1x 88 checking the spark plug caps 1. Remove the spark plug caps from the spark plug wires by turning the caps counterclockwise. 2. Measure the spark plug cap resistance. Replace if out of specification. Checking the pulser coil air gap 1. Turn the flywheel clockwise to align the projection of ...

Page 96

Elec electrical systems – + 89 69w3d1x starting system 8 1 fuse 2 10-pin coupler 3 engine start switch 4 starter motor 5 battery 6 neutral switch 7 starter relay È tiller handle model b : black br : brown r : red off w b r p br on start n s m r br br br r r r r b b b b b b b r r br br br s69w8090e.

Page 97

69w3d1x 90 starter motor 8 no. Part name q’ty remarks 1 clip 1 2 pinion stopper 1 3 spring 1 4 starter motor pinion 1 5 upper bracket 1 6 washer 1 1 7 shim — as required 8 washer 2 1 9 armature 1 10 washer 2 11 stator 1 12 brush holder assembly 1 13 brush set 1 14 o-ring 1 not reusable 15 nut 1 16 l...

Page 98

Elec electrical systems – + 91 69w3d1x checking the armature 1. Check the armature axial free play. Replace the washers and shim(s) 3 if out of specification. 2. Check the commutator for dirt. Clean with #600 grid sandpaper and com- pressed air if necessary. 3. Measure the commutator diameter. Repla...

Page 99

69w3d1x 92 2. Check the brush holder for continuity. Replace if out of specifications. Brush length limit a: 10.0 mm (0.39 in) brush assembly continuity brush 1 – brush assembly holder 4 continuity brush 2 – brush assembly holder 3 brush 1 – brush 2 no continuity brush 1 – brush assembly holder 3 br...

Page 100

Sb r lg up free down sb r lg up free down r b w p br off on st f60aeht gy b p p/b lg lg sb sb r r y/r p/w y/b p/w p/w y/r b/o y/r b/o b/w b/w y/b y/b p/b p/b sb sb lg r sb r sb r lg lg r w sb p br b lg g p r w b br y w/b w/r g/w g g g br l r g/w b l g b r b b b y y p o b b b b b b b o b r r r w w w ...

Page 101

Wiring diagram f60aeht 1 battery 2 engine start switch 3 starter motor 4 power trim and tilt motor 5 power trim and tilt relay 6 engine shut-off switch 7 starter relay 8 neutral switch 9 fuse (20 a) 0 warning indicator a power trim and tilt switch b prime start c oil pressure switch d cdi unit e the...

Page 102

Sb r lg up free down f60aet gy b p p/b y/r p/w y/b p/w p/w y/r b/o y/r b/o b/w b/w y/b y/b p/b p/b sb r sb r lg lg r w sb p br b lg g y w/b w/r g/w g g g br l r g/w b l g b r b b b y y p o b b b b b b b o b r w p g y b r o b b g g y y l l l b b b b b b y p p l l y l y l r r r r g l br br w y/b p/w b...

Page 103

Wiring diagram f60aet 1 battery 2 starter motor 3 power trim and tilt motor 4 power trim and tilt relay 5 starter relay 6 fuse (20 a) 7 trim sensor 8 prime start 9 oil pressure switch 0 cdi unit a thermoswitch b charge coil c pulser coil d lighting coil e rectifier regulator f power trim and tilt sw...

Page 105

Yamaha motor co., ltd. Printed in the netherlands jul. 2001 – 1.3 × 1 cr (f60aeht, f60aet) (e).