- DL manuals

- Yamaha

- Outboard Motor

- F8A

- Owner's Manual

Yamaha F8A Owner's Manual

Summary of F8A

Page 1

F8a f9.9a owner’s manual read this manual carefully before operating this outboard motor..

Page 2

Read this manual carefully before operating this outboard motor. Keep this manual onboard in a waterproof bag when boating. This manual should stay with the outboard motor if it is sold..

Page 3: Important

Important manual information to the owner thank you for selecting a outboards outboard motor. This owner’s manual contains infor- mation needed for proper operation, mainte- nance and care. A thorough understanding of these simple instructions will help you obtain maximum enjoyment from your new out...

Page 4: Table

Table of contents safety information............................ 1 propeller selection ........................ 13 outboard motor safety .................... 1 start-in-gear protection ................. 14 propeller ............................................. 1 engine oil requirements ...............

Page 5: Table

Table of contents instruments and indicators ............ 27 procedure........................................ 47 indicators...................................... 27 trimming outboard motor............. 47 low oil pressure-alert indicator ........ 27 adjusting trim angle for manual tilt engine contr...

Page 6: Table

Table of contents removing propeller .......................... 71 installing propeller ............................ 71 changing gear oil ............................. 72 cleaning fuel tank............................ 73 inspecting and replacing anode(s) ... 74 checking battery (for electric start m...

Page 7: Safety

Safety information outboard motor safety power tilt observe these precautions at all times. Body parts can be crushed between the mo- propeller people can be injured or killed if they come in contact with the propeller. The propeller can keep moving even when the motor is in neu- tral, and sharp edg...

Page 8: Safety

Safety information gasoline exposure and spills take care not to spill gasoline. If gasoline spills, wipe it up immediately with dry rags. Pfds, and everyone should wear pfds when there are potentially hazardous boating condi- tions. Dispose of rags properly. People in the water if any gasoline spil...

Page 9: Safety

Safety information avoid collisions passenger training scan constantly for people, objects, and other make sure at least one other passenger is boats. Be alert for conditions that limit your trained to operate the boat in the event of an visibility or block your vision of others. Emergency. Boating ...

Page 10: General

General information identification numbers record outboard motor serial number the outboard motor serial number is stamped on the label attached to the port side of the clamp bracket. Record your outboard motor serial number in the spaces provided to assist you in ordering spare parts from your outb...

Page 11: General

General information product code of model (approved model code) code of conformed directives ce marking outboard motors affixed with this “ce”mark- ing conform with the directives of; 98/37/ec, 94/25/ec - 2003/44/ec and 2004/108/ec. 1. Ce marking location 1 1. Ce marking location 5.

Page 12: General

General information read manuals and labels before operating or working on this outboard motor: read this manual. Read any manuals supplied with the boat. Read all labels on the outboard motor and the boat. If you need any additional information, contact your outboards dealer. Warning labels if thes...

Page 13: General

General information fpp8aer, fpp9.9aer, fpw8aer, fpw9.9aer 7.

Page 14: General

General information 1 2 3 contents of labels 3 the above warning labels mean as follows. 1 warning read owner’s manuals and labels. Warning emergency starting does not have start- in-gear protection. Ensure shift control is in neutral before starting engine. Wear an approved personal flotation de- v...

Page 15: General

General information symbols electrical hazard the following symbols mean as follows. Notice/warning remote control lever/gear shift lever operat- ing direction, dual direction read owner’s manual engine start/ engine cranking hazard caused by continuous rotation 9.

Page 16: Specifications

Specifications and requirements specifications transom height s: fpp(8/9.9)aer 430 mm (16.9 in) tip: fpp(8/9.9)amh 435 mm (17.1 in) “(al)” stated in the specification data below transom height l: represents the numerical value for the alumi- fpp(8/9.9)aer 557 mm (21.9 in) num propeller installed. Fp...

Page 17: Specifications

Specifications and requirements spark plug (ngk): gear ratio: br6hs-10 fpp(8/9.9)aer 2.08(27/13) spark plug gap: fpp(8/9.9)amh 2.08(27/13) 0.9 –1.0 mm (0.035 –0.039 in) fpw(8/9.9)aer 2.92(38/13) control system: fpw(8/9.9)amh 2.92(38/13) fpp(8/9.9)aer remote control fpp(8/9.9)amh tiller handle trim a...

Page 18: Specifications

Specifications and requirements gear oil quantity: fpp(8/9.9)aer 0.150 l (0.159 us qt, 0.132 imp.Qt) installation requirements boat horsepower rating fpp(8/9.9)amh 0.150 l (0.159 us qt, 0.132 imp.Qt) warning fpw(8/9.9)aer 0.370 l (0.391 us qt, overpowering a boat can cause severe in- 0.326 imp.Qt) s...

Page 19: Specifications

Specifications and requirements the remote control unit must be equipped your outboards dealer can help you select the with a start-in-gear protection device(s). This right propeller for your boating needs. Select device prevents the engine from starting un- a propeller that will allow the engine to...

Page 20: Specifications

Specifications and requirements start-in-gear protection outboards outboard motors affixed with the pic- tured label or outboards-approved remote con- trol units are equipped with start-in-gear protection device(s). This feature permits the engine to be started only when it is in neutral. Always sel...

Page 21: Specifications

Specifications and requirements tor in muddy or acidic water conditions. However, depending on the model it might not be required. Anti-fouling paint a clean hull improves boat performance. The boat bottom should be kept as clean of marine growth as possible. If necessary, the boat bot- tom can be c...

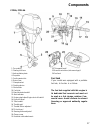

Page 22: Components

Components components diagram tip: * may not be exactly as shown; also may not be included as standard equipment on all models (order from dealer). Fpp8a; fpp9.9a 1. Top cowling 16.Tiller handle* 2. Cowling lock lever 17.Throttle grip* 3. Anti-cavitation plate 18.Throttle friction adjuster* 4. Prope...

Page 23: Components

Components fpp8a; fpp9.9a 1. Top cowling 22.Tilt support knob* 2. Cowling lock lever 23.Remote control box (side mount type)* 3. Anti-cavitation plate 24.Fuel tank 4. Propeller 5. Cooling water inlet fuel tank 6. Drain screw if your model was equipped with a portable 7. Clamp bracket fuel tank, its ...

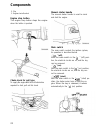

Page 24: Components

Components 3 4 1 2 1. Air vent screw 1. Power tilt switch 2. Fuel gauge 2. Remote control lever 3. Fuel joint 3. Neutral interlock trigger 4. Fuel tank cap 4. Neutral throttle lever 5. Main switch / choke switch fuel joint 6. Engine shut-off switch this joint is used to connect the fuel line. 7. Thr...

Page 25: Components

Components neutral interlock trigger choke switch to shift out of neutral, first pull the neutral in- to activate the choke system, press in the terlock trigger up. Main switch while the key is turned to the “ ” (on) or “ ” (start) position. The choke sys- tem will then supply the rich fuel mixture ...

Page 26: Components

Components throttle indicator the fuel consumption curve on the throttle in- dicator shows the relative amount of fuel con- sumed for each throttle position. Choose the setting that offers the best performance and fuel economy for the desired operation. 1. Forward “ ” 1 2. Neutral “ ” 3. Reverse “ ”...

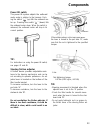

Page 27: Components

Components the loss of most steering control. Also, without engine power, the boat could slow rapidly. This could cause people and ob- jects in the boat to be thrown forward. 1. Cord 2. Clip 3. Engine shut-off switch when constant speed is desired, tighten the adjuster to maintain the desired thrott...

Page 28: Components

Components 2. Clip 3. Engine shut-off switch manual starter handle the manual starter handle is used to crank engine stop button and start the engine. The engine stop button stops the engine when the button is pushed. Main switch the main switch controls the ignition system; its operation is describ...

Page 29: Components

Components power tilt switch the power tilt system adjusts the outboard motor angle in relation to the transom. Push- ing the switch “ ” (up) tilts the outboard mo- tor up. Pressing the switch “ ” (down) tilts the outboard motor down. When the switch is released, the outboard motor will stop in its ...

Page 30: Components

Components trim rod (tilt pin) the position of the trim rod determines the minimum trim angle of the outboard motor in relation to the transom. Notice do not use the tilt support lever or knob when trailering the boat. The outboard mo- tor could shake loose from the tilt support tilt lock mechanism ...

Page 31: Components

Components mal running position, use an additional support device to secure it in the tilt posi- tion. Power tilt unit this unit tilts the outboard motor up and down and is controlled with the power tilt switch. Notice do not step on or exert pressure on the power tilt motor. The power tilt unit cou...

Page 32: Components

Components 1. Low oil pressure-alert indicator 26.

Page 33: Instruments

Instruments and indicators indicators low oil pressure-alert indicator if oil pressure drops too low, this indicator will light up. For further information, see page 28. Notice do not continue to run the engine if the low oil pressure-alert indicator is on and the engine oil level is lower. Serious ...

Page 34: Engine

Engine control system alert system notice do not continue to operate the engine if a alert device has activated. Consult your outboards dealer if the problem cannot be lo- cated and corrected. Low oil pressure alert if the oil pressure drops too low, the alert de- vice will activate. The engine spee...

Page 35: Installation

Installation installation the information presented in this section is in- tended as reference only. It is not possible to provide complete instructions for every possi- ble boat and motor combination. Proper mounting depends in part on experience and the specific boat and motor combination. Warning...

Page 36: Installation

Installation speed will rise abnormally and cause the en- gine to overheat. If the mounting height is too low, the water resistance will increase and thereby reduce engine efficiency. Mount the outboard motor so that the anti-cavitation plate is between the bottom of the boat and a level 25 mm (1 in...

Page 37: Installation

Installation runs at different heights can help determine the boat. Otherwise the engine could be the optimum mounting height. Consult your completely lost if it accidentally falls off outboards dealer or boat manufacturer for the transom. Further information on determining the prop- er mounting hei...

Page 38: Operation

Operation first-time operation fill engine oil 1. For the first hour of operation: run the engine at varying speeds up to 2000 r/min or approximately half throttle. The engine is shipped from the factory without 2. For the second hour of operation: engine oil. If your dealer did not fill the oil, yo...

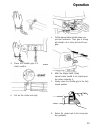

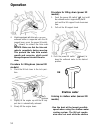

Page 39: Operation

Operation an emergency reserve. With the boat level on a trailer or in the water, check the fuel level. For fuel filling instructions, see page 36. Controls tiller handle models: move the tiller handle fully to the left and remove the top cowling right to make sure operation is smooth. For the follo...

Page 40: Operation

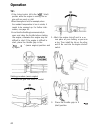

Operation 4. Check the oil level using the dipstick to be sure the level falls between the upper and lower marks. Fill with oil if it is below the lower mark, or drain to the specified level if it is above the upper mark. 1 1. Cord 2. Clip 3. Engine shut-off switch 1. Cord 2. Clip 1. Oil dipstick 1 ...

Page 41: Operation

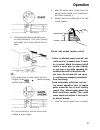

Operation nected, cooling water can leak out and the after installing, check the fitting of the top engine can overheat during operation. Cowling by pushing it with both hands. If the top cowling is loose, have it repaired by your outboards dealer. 1. Fitting 2. Flushing device checking power tilt s...

Page 42: Operation

Operation 2. Operate each of the power tilt switches to check that all switches work. 3. Tilt the outboard motor up and check that the tilt rod is pushed out completely. 4. Check that the tilt rod is free of corrosion or other flaws. 5. Tilt the outboard motor down. Check that the tilt rod operates ...

Page 43: Operation

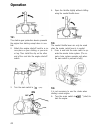

Operation sending fuel (portable tank) 1. If there is an air vent screw on the fuel tank cap, loosen it 2 or 3 turns. 9. Tighten the filler cap securely. 10. Wipe up any spilled gasoline immediately with dry rags. Dispose rags properly ac- cording to local laws or regulations. 2. If there is a fuel ...

Page 44: Operation

Operation tip: avoid accidentally pulling the cord dur- wipe up any spilled gasoline immediately with ing normal operation. Loss of engine dry rags. Dispose rags properly according to power means the loss of most steering local laws or regulations. Control. Also, without engine power, the 3. Squeeze...

Page 45: Operation

Operation 5. Pull the manual starter handle slowly until you feel resistance. Then give a strong pull straight out to crank and start the en- gine. 3. Place the throttle grip in the “ ” (start) position. 6. After the engine starts, slowly return the manual starter handle to its original posi- tion b...

Page 46: Operation

Operation tip: if the choke knob is left in the “ ” (start) position while the engine is running, the en- gine will run poorly or stall. When the engine is cold, for example, when the ambient temperature is low in winter, it needs to be warmed up. For further infor- mation, see page 43. Do not turn ...

Page 47: Operation

Operation 5. After the engine starts, slowly return the manual starter handle to its original posi- tion before releasing it. 6. Slowly return the throttle grip to the fully closed position. 4. Pull the manual starter handle slowly until you feel resistance. Then give a strong pull straight out to c...

Page 48: Operation

Operation 4. Open the throttle slightly without shifting using the neutral throttle lever. Tip: the start-in-gear protection device prevents the engine from starting except when in neu- tip: tral. The neutral throttle lever can only be used 2. Attach the engine shut-off cord to a se- when the remote...

Page 49: Operation

Operation pump is pumping water through the cooling water passages. If the cooling water passag- es are frozen, it may take a while for water to start flowing out of the pilot hole. Notice if water is not flowing out of the pilot hole at all times while the engine is running, overheating and serious...

Page 50: Operation

Operation checks after engine warm up shifting while the boat is tightly moored, and without applying throttle, confirm that the engine shifts smoothly into forward and reverse, and back to neutral. Stop switches turn the main switch to “ ”, or press the engine stop button and make sure the en- 1. N...

Page 51: Operation

Operation 2. After the engine is at idle speed in gear move the remote control lever / gear shift lever firmly and crisply into the neutral po- sition. To shift from in gear (forward/reverse) to neu- tral 1. Close the throttle so that the engine slows to idle speed. 45.

Page 52: Operation

Operation stopping boat warning do not use the reverse function to slow down or stop the boat as it could cause you to lose control, be ejected, or impact the steering wheel or other parts of the boat. This could increase the risk of se- rious injury. It could also damage the shift mechanism. Do not...

Page 53: Operation

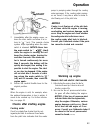

Operation trimming outboard motor warning excessive trim for the operating condi- tions (either trim up or trim down) can cause boat instability and can make steer- ing the boat more difficult. This increases the possibility of an accident. If the boat begins to feel unstable or is hard to steer, sl...

Page 54: Operation

Operation adjusting trim angle (power tilt mod- els) warning be sure all people are clear of the out- board motor when adjusting the trim an- gle. Body parts can be crushed between the motor and the clamp bracket when the motor is trimmed or tilted. 1. Trim rod use caution when trying a trim positio...

Page 55: Operation

Operation make test runs with the trim set to different an- gles to find the position that works best for your boat and operating conditions. Adjusting boat trim when the boat is on plane, a bow-up attitude results in less drag, greater stability and effi- ciency. This is generally when the keel lin...

Page 56: Operation

Operation warning make sure that no one is near the outboard motor when tilting the outboard motor up or down. Otherwise, body parts could be crushed between the outboard motor and the clamp bracket. Warning leaking fuel is a fire hazard. If there is a fuel joint on the outboard motor, discon- nect ...

Page 57: Operation

Operation n 4. Pull up the shallow water lever (if 2. Press the power tilt switch “ ” (up) until equipped). The outboard motor has tilted up com- 5. Hold the rear of the top cowling with one pletely. Hand and tilt the engine up fully. 6. Push the tilt support knob into the clamp bracket. Or the tilt...

Page 58: Operation

Operation procedure for tilting down (power tilt models) 1. Push the power tilt switch “ ” (up) until the outboard motor is supported by the tilt rod and the tilt support knob becomes free. 2. Pull out the tilt support knob. 4. Models equipped with trim rods: once the outboard motor is supported wit...

Page 59: Operation

Operation water cruising system is being used. Hit- ting an underwater obstacle could cause the outboard motor to lift out of the water, resulting in loss of control. Use extra care when operating in re- verse. Too much reverse thrust can cause the outboard motor to lift out of the water, increasing...

Page 60: Operation

Operation procedure for power tilt models 1. Place the remote control lever in neutral. 4. To return the outboard motor to the nor- mal running position, place the remote control lever / gear shift lever in neutral. 5. Place the tilt lock lever in the lock/down position, then slightly tilt the outbo...

Page 61: Operation

Operation cruising in other conditions cruising in salt water after operating in salt water, flush the cooling water passages with fresh water to prevent them from becoming clogged. Also rinse the outside of the outboard motor with fresh wa- ter. Cruising in muddy, turbid, or acidic water outboards ...

Page 62: Maintenance

Maintenance transporting and storing out- board motor disconnect the fuel line from the outboard motor. Tighten the fuel tank cap and its air vent warning screw. When the outboard motor is tilted pro- use care when transporting fuel tank, longed time for mooring or trailering the whether in a boat o...

Page 63: Maintenance

Maintenance 4. To prevent steering movement, turn the adjuster lever to “a” (if equipped with the adjuster lever). To hold the steering bracket easily, raise the tiller handle to the vertical position (if equipped with the tiller handle). 1. Steering bracket 2. Handgrip 5. Loosen the clamp screw(s)....

Page 64: Maintenance

Maintenance the attitude shown when transporting and storing it. If storing or transporting the outboard motor on its side (not up- right), put it on a cushion after draining the engine oil. Do not place the outboard motor on its side before the cooling water has drained from it completely, otherwis...

Page 65: Maintenance

Maintenance plate, or if the water supply is insuffi- 12. If the “fogging oil” is not available, run cient, engine seizure may occur. The engine at a fast idle until the fuel sys- tem becomes empty and the engine 1 2 stops. 13. Drain the cooling water completely out of the motor. Clean the body thor...

Page 66: Maintenance

Maintenance 1. After shutting off the engine, unscrew the operation. Water will leak out of the garden hose connector from the fitting on connector instead of cooling the en- the bottom cowling. Gine, which can cause serious over- heating. Be sure the connector is tightened securely on the fitting a...

Page 67: Maintenance

Maintenance periodic maintenance severe operating conditions severe operating conditions involve one or warning more of the following types of operation on a these procedures require mechanical regular basis: skills, tools, and supplies. If you do not operating continuously at or near maxi- have the...

Page 68: Maintenance

Item actions initial every 20 hours (3 months) 100 hours (1 year) 300 hours (3 years) 500 hours (5 years) anode(s) (external) inspection or replace- ment as necessary anode(s) (cylinder head, thermostat cov- er) inspection or replace- ment as necessary anodes (exhaust cover, cooling water passage co...

Page 69: Maintenance

Maintenance 63 item actions initial every 20 hours (3 months) 100 hours (1 year) 300 hours (3 years) 500 hours (5 years) fuel line (high pres- sure) inspection fuel line (high pres- sure) inspection or replace- ment as necessary fuel line (low pres- sure) inspection fuel line (low pres- sure) inspec...

Page 70: Maintenance

Maintenance chart 2 maintenance 64 item actions initial every 20 hours (3 months) 100 hours (1 year) 300 hours (3 years) 500 hours (5 years) wire harness connec- tions/wire coupler con- nections inspection or replace- ment as necessary fuel tank (outboards por- table tank) inspection and clean- ing ...

Page 71: Maintenance

Maintenance greasing outboards grease a (water resistant grease) outboards grease d (corrosion resistant grease; for propeller shaft) fpp8a; fpp9.9a 65.

Page 72: Maintenance

Maintenance fpw8a; fpw9.9a 66.

Page 73: Maintenance

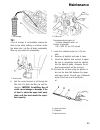

Maintenance cleaning and adjusting spark plug the spark plug is an important engine compo- nent and is easy to inspect. The condition of the spark plug can indicate something about the condition of the engine. For example, if the center electrode porcelain is very white, this could indicate an intak...

Page 74: Maintenance

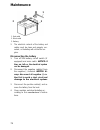

Maintenance changing engine oil notice change the engine oil after the first 20 hours of operation or 3 months, and every 100 hours or at 1-year intervals thereafter. Otherwise the engine will wear quickly. Extract the engine oil with an oil changer. 1. Put the outboard motor in an upright po- inspe...

Page 75: Maintenance

Maintenance 1 1. Oil changer 1. Oil filler cap tip: recommended engine oil: if the oil changer is not available, remove the drain screw while holding a container under the drain hole. Let the oil drain completely. 4-stroke outboard motor oil engine oil quantity: 0.8 l (0.85 us qt, 0.70 imp.Qt) wipe ...

Page 76: Maintenance

Maintenance 11. Start the engine and make sure that the ing, or installing the propeller, place the low oil pressure-alert indicator remains shift control in neutral, turn the main off. Also, make sure that there are no oil switch to “ ” (off) and remove the key, leaks. Notice: if the low oil pressu...

Page 77: Maintenance

Maintenance check the propeller shaft oil seal for dam- 6. Thrust washer age. 3. Remove the propeller, washer (if removing propeller equipped), and thrust washer. Spline models installing propeller 1. Straighten the cotter pin and pull it out us- ing a pair of pliers. Spline models 2. Remove the pro...

Page 78: Maintenance

Maintenance notice: do not reuse the cotter pin. Netic gear oil drain screw, this can in- otherwise, the propeller can come off dicate lower unit problem. Consult during operation. Your outboards dealer. 2 1 tip: 1. Gear oil drain screw 2. Oil level plug if the propeller nut does not align with the ...

Page 79: Maintenance

Maintenance recommended gear oil: hypoid gear oil sae#90 cleaning fuel tank gear oil quantity: fpp(8/9.9)aer 0.150 l (0.159 us qt, 0.132 imp.Qt) warning gasoline is highly flammable, and its va- fpp(8/9.9)amh 0.150 l (0.159 us qt, pors are flammable and explosive. 0.132 imp.Qt) if you have any quest...

Page 80: Maintenance

Maintenance inspecting and replacing anode(s) outboards outboard motors are protected from corrosion by sacrificial anodes. Inspect the external anodes periodically. Remove scales from the surfaces of the anodes. Consult a outboards dealer for replacement of external anodes. Notice do not paint anod...

Page 81: Maintenance

Maintenance tip: inspect ground leads attached to external an- 2. Check the battery’s charge. If your boat is equipped with the digital speedometer, odes on equipped models. Consult a outboards the voltmeter and low battery alert func- dealer for inspection and replacement of inter- tions will help ...

Page 82: Maintenance

Maintenance 1 3 2 1. Red cable 2. Black cable 3. Battery 3. The electrical contacts of the battery and cables must be clean and properly con- nected, or the battery will not start the en- gine. Disconnecting the battery 1. Turn off the battery cut-off switch (if equipped) and main switch. Notice: if...

Page 83: Trouble

Trouble recovery troubleshooting a problem in the fuel, compression, or ignition q. Is fuel filter clogged? A. Clean or replace filter. Systems can cause poor starting, loss of pow- er, or other problems. This section describes basic checks and possible remedies, and cov- q. Is starting procedure in...

Page 84: Trouble

Trouble recovery a. Check for pinched or kinked fuel line or oth- a. Return to home position. Er obstructions in fuel system. Q. Is motor angle too high? Q. Is fuel contaminated or stale? A. Return to normal operating position. A. Fill tank with clean, fresh fuel. Q. Is carburetor clogged? Q. Is fue...

Page 85: Trouble

Trouble recovery q. Is load on boat improperly distributed? A. Remove foreign matter and clean lower a. Distribute load to place boat on an even unit. Plane. Q. Is fuel system obstructed? Q. Is water pump or thermostat faulty? A. Check for pinched or kinked fuel line or oth- a. Have serviced by a ou...

Page 86: Trouble

Trouble recovery a. Connect correctly. If the outboard motor hits an object in the wa- ter, follow the procedure below. Q. Is heat range of spark plug incorrect? A. Inspect spark plug and replace it with rec- ommended type. Q. Is high pressure fuel pump drive belt bro- ken? A. Have serviced by a out...

Page 87: Trouble

Trouble recovery warning use this procedure only in an emergen- cy to return to the nearest port for re- pairs. When the emergency starter rope is used to start the engine, the start-in- gear protection device does not operate. Make sure the remote control lever is in neutral. Otherwise the boat cou...

Page 88: Trouble

Trouble recovery do not touch the ignition coil, spark plug wire, spark plug cap, or other electrical on components when starting or operating off the motor. You could get an electrical shock. Emergency starting engine 1. Remove the top cowling. 2. Remove the start-in-gear protection ca- ble from th...

Page 89: Trouble

Trouble recovery ly. Notice: do not attempt to run the out- board motor until it has been completely inspected. Engine fails to operate emergency engine operation if the battery voltage is low or in the unlikely event of an ignition system malfunction, the engine speed may become erratic or the en- ...

Page 90

Outboards group cv printed in china.