- DL manuals

- Yamaha

- Motorcycle

- FZ-16 2015

- Service Manual

Yamaha FZ-16 2015 Service Manual

Summary of FZ-16 2015

Page 1

Manual service fz-16 21c-f8197-eo.

Page 2

Fz-16 service manual all rights reserved. Any reprinting or unauthorized use without the written permission of yamaha motor india pvt. Ltd. Is expressly prohibited..

Page 3

Attention this manual has been prepared by iym, primarily for use by dealers and their qualified mechanics. Unable to gather in a manual all the knowledge of a mechanic. Any person carrying out maintenance and repairs on yamaha vehicles should have basic mechanical skills and techniques needed to re...

Page 4

3 7 using this guide this book is intended as a practical tool, easy to read reference book for the mechanic. Includes explanations of all installation, removal, disassembly, assembly, repair and check procedures are set out in individual steps in sequential order. The manual is divided into chapter...

Page 5

Symbols the following symbols are used in this manual to facilitate understanding. Note: the following symbols are not relevant each vehicle. 1 2 3 4 5 6 7 8 1. Serviceable with engine mounted 2. Type of liquid 3. Lubricant 4. Special tool 5. Torque 6. Wear limit, tolerance 7. Engine speed 8. Electr...

Page 6

3 table of contents general information 1 specifications 2 inspections and adjustments chassis 4 motor 5 carburetor 6 electrical 7 troubleshooting 8.

Page 7

General information identification of motorcycle .............................................. 1-1 ....... Vehicle identification number .......................................... 1-1 engine serial number ............................................. .................... 1-1 lcd meter ................

Page 8

IdentificaciÓn 1-1 identification vehicle identification number (chassis number) the vehicle identification number "1" is stamped on the chassis. Engine serial number the engine serial number "1" is stamped on the crankcase. Note: designs and specifications are subject to change without notice. 1.

Page 9

1-2 caracterÍsticas multi-function display 1 2 select 1. Multi-function display 2. "select" button (select) the multi-function display is equipped with the following: • a speedometer (which shows the speed) • an odometer (which shows the total distance traveled) • an odometer (which shows the distan...

Page 10

1-3 informaciÓn importante lubrication. Preparation for removal and disassembly 1. Before removal and disassembly, clean all dirt, mud, dust and foreign material. 2. Use only the proper tools and equipment clean. See "special tool s" on page 1-8. 3. When disassembling, always hold together parts of ...

Page 11

1-4 informaciÓn importante bearings and oil seals assemble the bearings and oil seals so that the manufacturer's mark or numbers are visible. When installing oil seals "1", lubricate the edges of oil seals with a thin layer of grease lithium soap base. In bearings, apply oil, if requested. Preacauci...

Page 12

1-5 inspecciÓn de las conexiones checking the connections verify on the cables, couplers and connectors stains, oxidation, moisture, etc. 1. Disconnect: • cable • coupler • connector 2. Verify • cable • coupler • connector moisture dry airjet oxidation / stains connect and disconnect several times. ...

Page 13

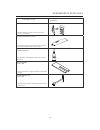

1-6 herramientas especiales special tools special tools shown below, are necessary for mounting and precise adjustments. Use only the appropriate special tools, that will help to prevent damage caused by the use of inappropriate tools or improvised techniques. Tool name / nr tool illustration tappet...

Page 14

1-7 herramientas especiales tool name / nr tool illustration tool to install the crankshaft spacer. (a) ysst- 266 (b) ysst-267 these tools are using to install the crankshaft. (a) (b) tool for removing the crankshaft. Ysst- 265 this tool is used to remove the crankshaft from the crankcase clutch hub...

Page 15

1-8 herramientas especiales tool name / nr tool illustration adapter valve spring compressor a-803 ysst this tool is used to remove and install the valve and the valve spring using ysst 603. Set gauge pump vacuum / pressure this instrument is used to test and verify the vacuum of air induction syste...

Page 16

1-9 herramientas especiales tool name / nr tool illustration multimeter theste instrument is used to verify the electrical circuits or components. Yamaha adhesive no. 1215 this adhesive is used on the contact surfaces, while the housings assembled # 1 and # 2 of the engine. Loctite three bond 1322 t...

Page 17

Specifications specification ................................................ 2-1 ........ Engine specifications ............................................... 2-2 ......... Chassis specifications ............................................... 2-9 ........ Electrical .................................

Page 18

Especificaciones generales 2-1 general model model 21c1 dimensions total length 1973mm total width 770mm height totall 1045mm seat height 790mm wheelbase 1334mm ground clearance 160mm minimum turning radius 2340mm weight with gasoline and oil 135.0kg peak load 195.0kg.

Page 19

2-2 especificaciones de motor engine specifications engine engine type 4-stroke, air-cooled sohc displacem ent 153.0cm 3 cylinder layout a cylinder leaning forward bore x stroke 58.0 x 57.9mm compression ratio 9.50:1 compression pressure (at sea level) 1200kpa starting system electric start, kicksta...

Page 20

2-3 especificaciones de motor spark plug (s) manufacturer / model ngk / cpr8ea-9 electrode gap 0.8-0.9mm butt volume 13.40-14.00cm ³ maximum deformation 0.03mm camshaft traction system transmission chain (left) dimensions of camshaft lobes admission 31,342 - 31.44 2mm limit 31.342mm admission b 25,1...

Page 21

2-4 especificaciones de motor timing chain model silent chain tensioning system automatic rocker / rocker bore rocker 9985-10.000mm limit 10.030mm outside diameter of rocker 9966-9.976mm limit 9.950mm valves, valve seats, valve guides valve clearance (cold) admission 0.08-0.12mm exhaust 0.12-0.16mm ...

Page 22

2-5 especificaciones de motor limit 0.080mm tolerance between the valve stem and the guide (escape) 0.025-0.052mm limit 0.100mm limit deformation of the valve stem 0.010mm valve spring free length (admission) 39.40mm limit 37.40mm free length (escape) 39.40mm limit 37.40mm installed length (admissio...

Page 23

2-6 especificaciones de motor h d deviation - 0.25 mm direction of deviation side a-dmission diameter hole for the piston pin limit outer diameter of piston pin limit 15.002 15.013 mm 15,043 mm 14.995 15.000 mm 14,975 mm piston rings top ring ring type barrel dimensions (b × t) 0.80 x 2.30 mm b t di...

Page 24

2-7 especificaciones de motor rod small end bore 14090-15028 mm large end bore 36000-36009 mm crankshaft width a 47.95-48.00 mm maximum deformation c side clearance 0.030 mm large side d 0110-0140 mm balancer method of synchronizing the balanced gear clutch clutch type oil-bathed multi-disc clutch r...

Page 25

2-8 especificaciones de motor change mechanism type shifting mechanism rod drive mechanism and guide thickness shift fork 4.76-4.89 mm decompression device type of device auto-decompressor air filter air filter element dry element carburetor type x quantity bs26x1 identification mark 21c1110 main je...

Page 26

2-9 especificaciones de chasis chassis specifications chassis chassis type diamond angle 25.00 º avance 101.2 mm front wheel wheel type casting wheel rim size 17 m/cxmt2.50 material of rim aluminum wheel travel 130.0 mm radial deviation limit wheel 1.0 mm lateral deviation limit wheel 0.5 mm rear wh...

Page 27

2-10 especificaciones de chasis front brake disc thickness and outer diameter of the disc 267.0 x 4.0 mm limit brake disc thickness 3.5 mm deviation limit of the brake disc 0.10 mm thickness covering brake pads (interior) 4.5 mm limit 0.8 mm coating thickness of the brake pads (outside) 4.5 mm limit...

Page 28

2-11 especificaciones de chasis spring free length 187.0 mm installed length 178.0 mm spring tension k1 120.0 n / mm spring k1 race 0.0-20.0 mm rocker free game at the end of the swingarm (limit axial) 2.4 mm drive chain type / manufacturer r428hbsx/lgb number of links 128 clearance transmission cha...

Page 29

2-12 especificaciones elÉctricas electrical voltage system voltage 12v ignition system ignition system dc, cdi feed type digital ignition advance (b.T.D.C.) 7.0 ° / 1400r/min coil resistance pulse 192-288Ù at 20 ° c ignition coil primary coil resistance 0.32-0.48Ù at 20 ° c secondary coil resistance...

Page 30

2-13 especificaciones elÉctricas electric power system system type constant mesh starter output power 0.25 kw starter relay amperage 100 a coil resistance 3.51-4.29 Ù horn horn type flat amount maxim um amperage 1 pc 1.5 a turn signal relay type of relay transistor relay integrated self-cancellation...

Page 31

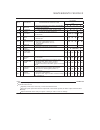

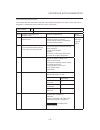

2-14 pares de apriete torque general of torque this chart specifies tightening torques for standard fasteners with thread iso normalized. The torque specifications for special components or assemblies mentioned in each chapter of this manual. To prevent distortion, cross-clamping sets with multiple ...

Page 32

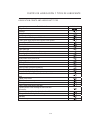

2-15 pares de apriete de motor motor torque item size the threa amount torque observations head screws (interior) m8 4 22 nm (2.2 m kg, 16ft ib) e head screws (side chain) m6 2 10 nm (1.0 m kg, 7ft ib) e plug m10 1 13 nm (1.3 m.Kg, 9ft.Ib) cylinder head cover bolts (conduit) m6 10 10 nm (1.0 m.Kg, 7...

Page 33

Pares de apriete de motor 2-16 item size the threa amount torque observations screw crankcase 1 and 2 m6 1 10 nm (1.0 m.Kg, 7ft.Ib) e kickstarter nut m12 1 50 nm (5.0 m.Kg, 36ft.Ib) e screw guide sprocket m6 2 12 nm (1.2 m.Kg, 9ft.Ib) screw engine clutch boot m6 3 14 (1.4 nm m.Kg, 10ft.Ib) main gear...

Page 34

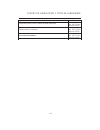

Pares de apriete de motor 2-17 sequence cylinder head tightening 5 torque sequence magneto cover 7 8 1.6 5 9 4 3 2.10 tightening sequence clutch cover 1.9 8 10 11 7 12 6 5 4 3.15 13 2.14.

Page 35

Pares de apriete de motor 2-18 9 crankcase tightening sequence a b 14 1.6 7 8 15 5 2.12 4 10 3.13 11 a. Carter left b. Right side crankcase.

Page 36

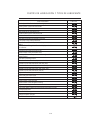

2-19 pares de apriete torque item size the thread amount torque observations screw steering column m8 2 16 nm (1.6 m kg, 12ft ib) e nut of the steering column m22 1 110 nm (11.0 m kg, 80ft ib) e lower ring nut (initial) m25 1 33 nm (3.3 m.Kg, 24ft.Ib) upper ring nut (final) m25 1 22 nm (2.2 m.Kg, 16...

Page 37

2-20 pares de apriete item size the thread amount torque observations nut front wheel axle m14 1 60 nm (6.0 m.Kg, 43ft.Ib) e nut rear wheel axle m14 1 90 nm (9.0 m.Kg, 65ft.Ib) e screw crown and hub clutch m8 6 43 nm (4.3 m.Kg, 31ft.Ib) tension bar and brake shoe plate m8 1 20 nm (2.0 m.Kg, 14ft.Ib)...

Page 38

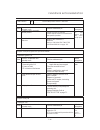

2-21 puntos de lubricaciÓn y tipos de lubricante lubrication points and lubricant types point lubrication lubricant edge oil seals ls bearings e o-rings ls head screws and washers e thrust surface of the large end of the rod e piston, piston rings and the inner surface of the cylinder e inner surfac...

Page 39

2-22 puntos de lubricaciÓn y tipos de lubricante point lubrication lubricant crankshaft position sensor / washer assembly stator lead yamaha adhesive no. 1215 (three bond no.1215r) contact surface of carcasses yamaha adhesive no. 1215 (three bond no.1215r) screws chain tensioner distribution yamaha ...

Page 40

2-23 puntos de lubricaciÓn y tipos de lubricante point lubrication lubricant seal edges of the front wheel (left and right) ls outer surface of the front wheel shaft ls speed sensor unit ls seal edges of the rear wheel hub ls contact surface of the rear wheel hub ls outer surface of the rear wheel a...

Page 41

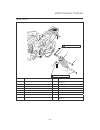

2-24 puntos de lubricaciÓn y tipos de lubricante lubrication system tables and charts table of engine oil lubrication 5 3 4 2 6 1 7 1. Oil strainer 2. Oil pump 3. Oil filter element 4. Crankshaft 5. Camshaft 6. Main shaft 7. Driven shaft.

Page 42

2-25 puntos de lubricaciÓn y tipos de lubricante lubrication diagrams 1 2 a 3 4 5 6 7 1. Clutch thrust lever 2. Main shaft 3. Drive shaft 4. Crankshaft 5. Oil filter 6. Oil pump 7. Oil strainer a. Towards the head.

Page 43

2-26 puntos de lubricaciÓn y tipos de lubricante lubrication diagrams 1 2 3 4 1. Camshaft 2. Crankshaft 3. Main shaft 4. Driven shaft.

Page 44

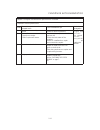

2-27 guiado de cables 7 6 3 1 4 a 3 f 2 2 12 1 a 4 4 2 3 1 b 10 9 6 5 c 8 g 6 11 5 rr c 8 7 13 d 5 14 11 9 9 d r-r 12 b h 1 i.

Page 45

2-28 guiado de cables 1. Front brake hose 2. Throttle cable 3. Cable front brake switch 4. Cable right handlebar switch 5. Cable left handlebar switch 6. Clutch switch lead 7. Clutch cable 8. Cable boot 9. Main switch lead 10. Meter cable 11. Cable the right front turn signal 12. Cable left front di...

Page 46

2-29 guiado de cables 3 17 17 17 13 2 5 4 13 e-e b-b d-d c-c 1 a 3 2 4 b c 14 s s 15 j 16 l i g h 5 f e d c e d c m n d 6 m 7 13 14 11 16 15 l 2 februa ry 12 j 11 8 f 2 e 10 9 13 14 16 15 s-s 12 n 6 6 m-m.

Page 47

2-30 guiado de cables 1. Clutch cable 2. Overflow pipe 3. Throttle cable 4. Cable boot 5. Carburetor vent hose 6. Magneto cable ca 7. Negative cable 8. Breather hose battery 9. Carburetor drain hose 10. Fuel hose 11. Speaker wire 12. Connector cover 13. Harness 14. Cable sensor unit 15. Cables left ...

Page 48

2-31 guiado de cables 6 9 10 8 5 11 february 3 4 1 7 10 3 20 a 19 13 18 17 16 15 21 22 12 14 15 a-a.

Page 49

2-32 guiado de cables 1. Left handlebar switches 2. Clutch switch lead 3. Clutch cable 4. Cable left handlebar switch 5. Cable boot 6. Main switch lead 7. Cable right handlebar switch 8. Brake hose 9. Cable front brake switch 10. Accelerator cable 11. Handlebar switches right 12. Cable left rear dir...

Page 50

2-33 guiado de cables 25 31 16 29 17 28 16 5 30 10 h-h k-k u-u tt 30 251 31 a 18 19 b 10 c 21 24 27 23 26 22 e u 5 t t 16 p m n 15 h 29 14 l 13 k 6 k o 8 7 f 9 g i h j 10 k dec. 11.

Page 51

2-34 guiado de cables 1. Accelerator cable 2. Cable sensor unit 3. Brake hose 4. Speaker wire 5. Cable high 6. Plug cap 7. Starter cable 8. Cable starter relay 9. Fuse holder 10. Negative cable 11. Carburetor drain hose 12. Breather hose battery 13. Starter relay 14. Brake switch 15. Battery 16. Har...

Page 52

Periodic maintenance and adjustment periodic maintenance ................................................ 3-1 .......................... Periodic maintenance and lubrication intervals ... 3-1 adjustment valve clearance ........................................ 3-3 engine idle adjustment ................

Page 53

Troubleshooting electrical ................................................ ...................................... 3-22 inspection and charging ............................................ 3-22 ...... Fuse inspection ............................................... ...................... 3-22 bulb re...

Page 54

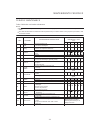

Mantenimiento periÓdico 3-1 periodic maintenance table of lubrication and routine maintenance note: all maintenance must be performed according to routine maintenance program (discussed below) to maintain the best performance of the vehicle. The items marked with an asterisk should be performed by a...

Page 55

Mantenimiento periÓdico 3-2 not. Element or maintenance inspection reading odometer (x 1000 km) 1 3 6 9 12 15 15 * bearing direction • check bearing for play and if the steering for roughness 䌮 䌮 䌮 䌮 䌮 䌮 • lubricating grease based on every 12000 km 16 * fasteners frame • check that all nuts, bolts a...

Page 56

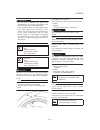

3-3 motor motor adjusting the valve clearance the following procedure applies to all valves. Note: adjusting the valve clearance should be done with the engine cold at room temperature. When you measure or adjust the valve clearance, the piston must be at top dead center (tdc) in the race 1. Remov e...

Page 57

3-4 motor engine idling 1300-1500 r / min 8. Assembly: 2 barrette gasket head cover new 1 head cover see "head" on page 5-5 9. Assembly: hose air induction system refer to "air induction system" on page 6-9 10. Assemble c. Turn the adjustment screw "3" in direction "a" or "b" to obtain the specified...

Page 58

3-5 motor 3. Check: engine idling if out of specification? Adjust. See "engine idle adjustment" on page 3-4. 4. Insert: 1 probe "2" meter co b to (calibrated) by the exhaust pipe "3", using the appropriate adapter "4" direction "a" engine idling increases direction "b" engine idling speed is decreas...

Page 59

3-6 motor caution do not alter carburetor adjustments, if engine performance is good. If necessary, you must register the existing settings (# of turns) mixture screw. To check the configuration of the screw c. Tighten the locknut. 1 c a r b u r e t o r m i x i n g , f o l l o w t h e to co adjustme...

Page 60

3-7 motor checking the spark 1. Disconnect: spark plug 2. Remov e: spark caution before removing the spark plug, clean with compressed air dirt that may have accumulated in the spark plug hole to prevent it from falling into the cylinder 3. Check: type plug (ngk / cpr8ea-9) incorrect switch. 4. Chec...

Page 61

Motor a. Start the engine and warm it up for a few minutes and then leave the engine running at specified idle engine idling 1300-1500 r / min b. Verify that the stationary pointer "a" in the magneto cover is within the firing interval "b" of the rotor magnet. Incorrect firing interval verify the ig...

Page 62

Motor 3-9 compression pressure (with oil applied into the cylinder) reading diagnosis greater than without oil piston rings are worn or damaged יו repair oil-like piston, valves, cylinder head gasket possibly d e f e c t i v e יו repair / replace type sae 20w50 (engine oil yamalube-4 times) 7. Remov...

Page 63

Motor 3-10 c. Assemble the new oil filter element and cover the oil filter element. Cover screw oil filter element 10 nm (1.0 m · kg, 7.2 ft · lb) 7. Ensemble: drain plug washer drain plug 20 nm (2.0 m · kg, 14 ft · lb) verification oil. If no engine oil comes out after one minute, turn the engine s...

Page 64

Motor 3-11 d. Tighten the locknut. E. Slide the rubber cover to its original position. Note: if the free play specified clutch cable, can not be obtained on the handlebar side, the adjusting nut used in the motor side. Motor side a. Loosen the locknut "1" b. Turn the adjustment screw "2" in directio...

Page 65

Motor 3-12 יו 1 caution: never run the engine without the air filter element installed. The unfiltered air will cause rapid wear of engine parts and may damage it. Note: make sure the air filter element is properly installed on the air filter box. Verify unon carburetor and connecting the air filter...

Page 66

Motor 3-13 check the filter of the fuel cock 1. Check: • fuel pipe "1" cracks / damage replace יו 3 1 • fuel filter "1" contaminated / damaged replace יו the fuel wash. 2 a. Turn fuel valve to "off" b. Remove the cup filter fuel valve "3". C. Drain fuel. D. Check the filter of the fuel tap. If dirty...

Page 67

3-14 chasis chassis adjusting the rear brake drum 1. Check: free pedal brake "to" out of specification adjust יו free game 15.0-20.0 mm checking the brake fluid level 1. Place the vehicle on a flat surface. Note: place the vehicle on the center support make sure the vehicle is vertical 2. Check: bra...

Page 68

3-15 chasis 1 checking the front brake pads 2 the procedure applies to all brake pads. 1 1. Apply the front brake. 2. Check: front brake pads wear indicators "1" almost touching the brake disc replace יו play brake pads. See "front brake" on page 4-20 1 checking the brake hose 1. Check: brake hose c...

Page 69

3-16 chasis 1. Remove: cover the brake master cylinder "1" 1 g. Loosen the bleed screw. Note: when you release the bleed screw, the pressure will be released and cause contact with the brake lever the throttle. H. Tighten the bleed screw and then release the brake lever i. Repeat steps "e" to "h" un...

Page 70

3-17 chasis 2. Rotate the rear wheel to find the point of greater tension in the drive chain. 3. Check: note: to maintain proper alignment of the wheel, adjusting both sides equally. Clearance transmission chain "a" oos adjust יו. Clearance transmission chain: 30-40 mm note: measure clearance transm...

Page 71

3-18 chasis b. Tighten the lower ring nut "4" wrench nut steering column "5". Note: set the torque wrench at a right angle to the nut wrench the steering column. 5 4 spray the lubricant within the chain between the inner and outer plates, rollers and bearings. 5 after waiting for lubrication 15 minu...

Page 72

3-19 chasis 5. Assemble: upper fork refer to "steering" on page 4-43 checking the front fork 1. Place the vehicle on a flat surface. Warning securely support the vehicle so there is no risk of falling. 2. Verify: inner tubes damage / scratches יוreplace. Oil seals oil leaks יוreplace. 3. Keep the ve...

Page 73

3-20 chasis warning do not use a tubeless tire wheel tires designed only for camera, avoid failures and personal injury due to sudden deflation. After extensive tests, the tires listed below have been approved by yamaha for this model. The front and rear tires should always be the same manufacturer ...

Page 74

3-21 chasis steering the spring preload is increased (suspension is harder) address b the spring preload is decreased (suspension softer) lubricating the brake lever lubricate the pivot point and the metal-metal moving parts of the lever. Adjuster rear shock ysst-821 recommended lubricant silicone g...

Page 75

3-22 sistema electrico electrical inspection and charging see "electrical components" on page 7- 34 fuse inspection see "electrical components" on page 7-34 bulb change the lantern the following procedure applies to the low beam bulb and high beam. 1. Remove: • side cover "1" 4. Remove: • lamp "1" l...

Page 76

3-23 sistema electrico 4. Assembly: • lamp bulb secure the new lamp bulb holder with bulb lamp caution: avoid touching the glass part of the bulb to keep it free cembran oil, otherwise the transparency of glass, the bulb life and brightness will be adversely affected. If the lamp bulb is dirty, wipe...

Page 77

3-24 sistema electrico to replace the rear light 3. Remove: • coupler taillight "1" • screws "2" from inside the fender 2 2 1 changing the light bulb turn indicator 1. Remove: • screw "1" from the indicator light • lens "2" of light 2. Push the bulb "3" and gently rotate counterclockwise. 3 2 1.

Page 78

Chasis general chassis 4-1 assembly of the air filter box 4-5 front wheel 4-6 removing the front wheel 4-8 front wheel disassembly 4-8 checking the front wheel 4-9 front wheel assembly tera 4-8 front wheel assembly (disc) 4-9 rear wheel 4-12 rear wheel removal 4-14 checking the rear wheel 4-14 check...

Page 79

Chasis steering column 4-43 lower bracket removal 4-45 verification of the steering 4-45 column mount direction n 4-45 rear shock 4-47 removing the rear shock 4-48 checking the rear shock 4-48 rear shock mounting 4-48 tilting 4-49 swingarm removal 4-51 checking the rocker 4-51 tilt mount 4-51 drive ...

Page 80

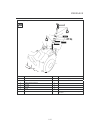

General del chasis 4-1 general chassis 2 nm (0.2 m l kg, 1ft l ib) 25 nm (2.5 m l kg, 18 ft l ib) 1 2 nm (0.2 m l kg, 1ft l ib) 3 4 2 2 nm (0.2 m l kg, 1ft l ib) 7 nm (0.7 m l kg, 5ft l ib) 5 2 nm (0.2 m l kg, 1ft l ib) 6 9 3 7 2 nm (0.2 m l kg, 1ft l ib) 2 nm (0.2 m l kg, 1ft l ib) 2 order procedur...

Page 81

General del chasis 4-2 removing the fuel tank 2 nm (0.2 m l kg, 1ft l ib) 2 1 3 2 4 nm (0.4 m l kg, 3ft l ib) 4 4 nm (0.4 m l kg, 3ft l ib) 5 order procedure / parts to remove amount observations side cover 1 & 2, seat refer to "general chassis" on page 4-1 1 fuel tank cap 1 2 fuel tank cap 2 3 side...

Page 82

General del chasis 4-3 removing the lamp and the meter 2 nm (0.2 m l kg, 1ft l ib) 2 nm (0.2 m l kg, 1ft l ib) 6 2 nm (0.2 m l kg, 1ft l ib) 3 5 2 nm (0.2 m l kg, 1ft l ib) 4 7 1 2 1 7 nm (0.7 m l kg, 5ft l ib) order procedure / parts to remove amount observations 1 side covers 2 2 full farola 1 3 l...

Page 83

General del chasis 4-4 removing the air filter full 1 2 nm (0.2 m l kg, 1ft l ib) 2 4 3 23 nm (2.3 m l kg, 17 ft l ib) 5 8 6 7 7 nm (0.7 m l kg, 5ft l ib) order procedure / parts to remove amount observations seat, side cover 1 & 2 refer to "general chassis" on page 4-1 1 filter box cover 1 2 filter...

Page 84

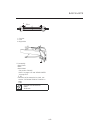

General del chasis 4-5 installing the air filter box 1. Install: • c l a m p u n i o n a i r f i l t e r note; align the projection "a" on the air filter box with slot "b" at the junction of the air filter. To b.

Page 85

4-6 rueda delantera front wheel removing the front wheel and the brake disc 30 nm (3.0 m l kg, 22 ft l ib) ls 3 (5 lt 1 7 nm (0.7 m l kg, 5ft l ib) 6 2 7 ls 60 nm (6.0 m l kg, 43 ft l ib) 6 4 order procedure / parts to remove amount observations 1 cable clamp speed sensor 1 2 nut front wheel axle 1 ...

Page 86

4-7 rueda delantera disassembly of the front wheel 4 3 ls 2 new 1 order procedure / parts to remove amount observations 1 oil seal 1 2 tread 1 3 spacer 1 4 tread 1 for assembly, reverse the disassembly procedure..

Page 87

4-8 rueda delantera removing the front wheel 1. Place the vehicle on a flat surface. Warning securely support the vehicle so there is no risk of falling. 2. Survey: • front wheel note: place the vehicle on a suitable stand so that the front wheel is lifted. 3. Remove: • front wheel • speed sensor un...

Page 88

4-9 rueda delantera 4. Check: • w h e e l b e a r i n g s the front wheel rotates this irregular or loose replace יו the bearings wheel. • o i l s e a l damage / wear replace יו. Front wheel assembly 1. Assembly: • w h e e l b e a r i n g s new • o i l s e a l new a. Assemble the bearings and new oi...

Page 89

4-10 rueda delantera speed sensor. 5. Assembly: • u n i t speed sensor note: make sure the speed sensor and the hub of the wheel is installed with the two projections meshed into the two slots respectively. 6. Assembly: • w h e e l lead note: make sure the slot "a" enters the outer tube and fits ove...

Page 90

4-11 rueda delantera.

Page 91

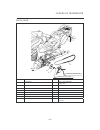

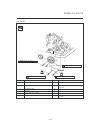

4-12 rueda trasera removal of the rear wheel and the brake band carrier 90 nm (9.0 m kg, 65 ft lb) ls july 6 10 new 11 3 4 1 13 5 2 12 10 14 8 9 ls order procedure / parts to remove amount observations 1 adjusting nut brake rod 1 2 brake rod 1 3 spring 1 4 pin 1 5 rod 1 6 nut 1 7 washer 1 8 rear whe...

Page 92

4-13 rueda trasera disassembly of the rear wheel order procedure / parts to remove amount observations 1 rear wheel sprocket 1 2 necklace 1 3 oil seal 1 4 tread 1 5 rwd cube 1 6 shock rear drive hub 4 7 tread 2 8 spacer 1 9 oil seal 1 for assembly, reverse the disassembly procedure..

Page 93

4-14 rueda trasera removing the rear wheel (drum) 1. Place the vehicle on a flat surface. Warning securely support the vehicle so there is no risk of falling. Note: place the vehicle on a suitable stand so that the front wheel is lifted. 2. Remove: adjusting nut brake rod "1" brake rod "2" spring "3...

Page 94

4-15 rueda trasera note: assemble the sprocket on the rear wheel with the maker's mark out. Tighten the self-locking nuts in stages and in a crisscross pattern rear wheel assembly (drum) 1. Lubricate: oil seal edges 5. Tighten: nut wheel axle nut wheel axle 90 nm (8.0 m · kg, 58 ft · lb) 6. Fit: fre...

Page 95

4-16 freno delantero front brake disassembly of the front brake pads order procedure / parts to remove amount observations 1 fastener brake hose 1 2 screw the front brake caliper 2 3 front caliper 1 4 clip of brake pads 2 5 brake pad pin 1 6 front brake pads 2 7 spring brake 1 for assembly, reverse ...

Page 96

4-17 freno delantero removing the front brake master cylinder 10 nm (1.0 m kg, 7ft ib) 1 2 7 nm (0.7 m kg, 5ft ib) 10 3 4 s 11 9 7 5 6 7 8 new 26 nm (2.6 m kg, 19 ft lb) order procedure / parts to remove amount observations brake fluid drain. Refer to "bleeding the hydraulic brake system" on page 3-...

Page 97

4-18 freno delantero disassemble the front brake master cylinder 2 4 1 5 3 7 6 order procedure / parts to remove amount observations 1 smock 1 2 pushrod 1 3 spring 1 4 pin lock 1 5 complete piston 1 6 spring 1 7 cylinder body 1 for assembly, reverse the disassembly procedure..

Page 98

4-19 freno delantero introduction warning the disc brake components rarely require disassembly. Therefore, always follow these precautions: never disassemble brake components unless absolutely necessary. If any connection is disconnected in the brake hydraulic, must disassemble the entire brake syst...

Page 99

4-20 freno delantero d. Measuring deformation of the brake disk e. If out of specification, repeat the adjustment until the brake disc deflection is within the specified f. If the deformation of disc brake disc can not be brought within specification, replace the brake disc. 6. Assembly: front wheel...

Page 100

4-21 freno delantero removing the front brake caliper note: before disassembling the brake caliper, drain all the brake fluid from the brake system. 1. Disassembly: combination screw brake hose copper washers brake hose note: place the end of the brake hose into a container and pump out the brake fl...

Page 101

4-22 freno delantero assembly front brake caliper warning before installation, all internal brake components should be cleaned and lubricated with a liquid cleaner or brake again. Never use solvents on internal brake components, as it will cause the piston seals and dust seals to swell and deform. W...

Page 102

4-23 freno delantero max. Min checking the front brake master cylinder 1. Check: brake master cylinder "1" damage / scratches / wear replace יו. Flights distribution brake fluid "2" (body brake caliper) obstructed יו blow with compressed air. 1 7. 7. Check: operation of the brake lever soft or spong...

Page 103

4-24 freno delantero 3. Fill: deposit brake master cylinder (with the 2 and recommended specified amount of brake fluid) recommended fluid: dot 3 or dot 4 1 2. Ensemble: copper washers "1" brake hose "2" news warning nte solame use the recommended brake fluid, other brake fluids may cause damage to ...

Page 104

4-25 freno delantero see "purging hydraulic brake system" on page 3-15..

Page 105

4-26 freno trasero rear brake disassembly of the bands 10 nm (1.0 m kl g, 7ft l ib) brake 3 4 ls 2 5 6 s ls 1 new (6) 43 nm (4.3 m l kg, 31 ft l ib) ls order procedure / parts to remove amount observations porta full bands refer to "rear wheel" on page 4-12 1 brake bands 2 2 spring full bands 2 3 le...

Page 106

4-27 freno trasero rear brake 1. Check: • lining brake shoe crystallized areas יו repair. Sand crystallized areas with coarse sandpaper. Note: after sanding crystallized surfaces, clean the brake bands with a cloth. 2. Measure: • c o a t i n g t h i c k n e s s b r a k e b a n d s " a " o u t o f s ...

Page 107

4-28 freno trasero c. Align the slot "c" in the lever brake camshaft with the slot in the brake camshaft. 3 new 1 a b new 1 s a b a-a c b-b d. Verify that the bands are properly positioned. 2. Assembly: • spring brake bands "1" new • brake bands note: • lubricate the pivot with a thin layer of silic...

Page 108

4-29 freno trasero 3. While pressing the brake pedal all the way down, push the lever brake camshaft completely in the direction of the arrow and check that the wear indicator brake bands not wear indicator reaches the drum brake. Not enough יו still can be used. Reach replace יו the wheel..

Page 109

4-30 manillar handlebar removing the handlebar 10 nm (1.0 m • kg, 7ft • ib) 1 2 26 nm (2.6 m • kg, 19 ft • ib) 7 16 ls 5 3 ls 1 ls 4 10 13 17 8 6 9 12 2 15 14 11 ls 7 nm (0.7 m • kg, 5ft • ib) order procedure / parts to remove amount observations 1 rearview mirror 2 2 handlebar plug 2 3 right handle...

Page 110

4-31 manillar removing the handlebar 10 nm (1.0 m • kg, 7ft • ib) 1 2 26 nm (2.6 m • kg, 19 ft • ib) 7 16 ls 5 3 ls 1 ls 4 10 13 17 8 6 9 12 2 15 nov. 14 ls 7 nm (0.7 m • kg, 5ft • ib) order procedure / parts to remove amount observations 15 support the clutch lever 1 16 handlebar clamp upper 2 17 h...

Page 111

4-32 manillar handle removal 1. Place the vehicle on a flat surface handle assy 1. Place the vehicle on a flat surface warning securely support the vehicle so there is no risk of falling. 2. Remove: • switch front brake light "1" note: press the catch to remove the brake light switch front brake mas...

Page 112

4-33 manillar 1 to 4. Assembly: • switch front brake light "1" note: align the projection "a" on the left handlebar switch with the hole "b" on the handlebars. To 6. Assembly: • clutch cable note: lubricate the clutch cable end with a thin layer of grease lithium soap base. 7. Assembly: 1 b • brake ...

Page 113

4-34 manillar 3 1 b 2 to c 9. Fit: • cable free play refer clutch "free play adjustment cable clutch" on page 3- 10. Free play the clutch lever 10.0-15.0 mm 10. Fit: • cable free play refer throttle "free play adjustment throttle cable" on page 3-6. Set throttle cable free 3.0-5.0 mm.

Page 114

4-35 horquilla delantera front fork removing the fork legs 25 nm (2.5 m k • g, 18 ft • ib) lead 3 2 25 nm (2.5 m • k g, 18 ft • ib) 1 4 6 nm (0.6 m • kg 4ft • ib) order procedure / parts to remove amount observations the following procedure applies to both front fork legs front wheel refer to "rear ...

Page 115

4-36 horquilla delantera disassemble the front fork legs new 1 2 12 3 4 6 new 7 new 13 14 new 5 10 15 11 9 8 order procedure / parts to remove amount observations the following procedure applies to both front fork legs 1 screw cap 1 2 o-ring 1 3 spacer 1 4 washer 1 5 fork spring 1 6 smock 1 7 oil se...

Page 116

4-37 horquilla delantera disassemble the front fork legs new 1 2 12 3 4 6 new 7 13 new 14 new 5 10 15 11 9 8 order procedure / parts to remove amount observations 15 outer tube 1 for assembly, reverse the disassembly procedure..

Page 117

4-38 horquilla delantera strip the front fork the following procedure applies to both front fork legs 1. Place the vehicle on a flat surface warning securely support the vehicle so there is no risk of falling. 2. Loosen: • top bracket screw "1" • lower bracket screw "2" warning before loosening the ...

Page 118

4-39 horquilla delantera note: while holding the damper rod with the clip of the damper rod "2" and the t-wrench "3", loosen the damper rod. 3. Check: • damper rod damage / wear replace יו. Obstructed blow compressed air יו all oil passages • oil flow stopper impaired replace יו. Caution when disass...

Page 119

4-40 horquilla delantera recommended oil oil suspension 10w or equivalent 3. Tighten: • screw the damper rod "1" screw the damper rod 28 nm (2.8 m · kg, 20 ft · lb) note: while holding the damper rod with the clip of the damper rod "2" and the t-wrench "3", tighten the damper rod assembly tool oil s...

Page 120

4-41 horquilla delantera 7. Assembly: • dust "1" new (with the mounting tool seal front fork oil "2") assembly tool oil seal front fork ysst-875 new 8. Filling: • sweep the front fork (with the specified amount of oil recommended) 10.Antes to measure the oil level of the fork, wait ten minutes until...

Page 121

4-42 horquilla delantera 13. Assembly: warning • o-ring new make sure the brake hose, cable (the screw cap of the front fork) • screw the top of the front fork clutch, and the cables are guided correctly. • clip new black: • before installing the screw top of the front fork, lubricate the o-ring wit...

Page 122

4-43 columna de la direcciÓn 1st 33 nm (3.3 m • kg, 24 ft • lb) 2nd 22 nm (2.2 m • kg, 16 ft • lb) steering disassembly of the steering column 110 nm (11.0m • kg, 80 ft • lb) 1 22 nm (2.2 m • kg, 16 ft • lb) 2 13 ls 11 14 3 4 new 15 5 6 8 12 9 10 7 7 nm (0.7 m • kg, 5ft • lb) 22 nm (2.2 m • kg, 16 f...

Page 123

4-44 columna de la direcciÓn 1st 33 nm (3.3 m • kg, 24 ft • lb) 2nd 22 nm (2.2 m • kg, 16 ft • lb) disassembly of the steering column 22 nm (2.2 m • kg, 16 ft • lb) 1 22 nm (2.2 m • kg, 16 ft • lb) 2 13 ls 11 14 3 4 new 15 5 6 8 12 9 10 7 7 nm (0.7 m • kg, 5ft • lb) 22 nm (2.2 m • kg, 16 ft • lb) or...

Page 124

4-45 columna de la direcciÓn bottom bracket removal 1. Place the vehicle on a flat surface warning securely support the vehicle so there is no risk of falling. 2. Disassembly: • upper ring nut • grommet • lower ring nut "1" • lower bracket "2" note: disassemble the lower ring nut with the wrench to ...

Page 125

4-46 columna de la direcciÓn • upper ring nut • lockwasher refer to "checking and adjusting the steering head" on page 3-18 3. Assemble: • upper bracket • nut of the steering column 4. Assemble: • front fork bars refer to "front fork" on page 4-35 note: temporarily tighten the mounting bolts top and...

Page 126

4-47 amortiguador trasero rear shock removing the rear shock 60 nm (6.0 m • kg, 43 ft • lb) 1 2 6 1 3 4 5 3 40 nm (4.0 m • kg, 29 ft • lb) order procedure / parts to remove amount observations seat, side covers 1 & 2, mud guard refer to "general chassis" on page 4-1 1 nut / bolt rear upper shock 1/1...

Page 127

4-48 amortiguador trasero removing the rear shock 1. Place the vehicle on a flat surface warning securely support the vehicle so there is no risk of falling. Note: place the vehicle on a suitable stand so that the rear wheel is elevated. Checking the rear shock 1. Check: • rear shock absorber rod. D...

Page 128

4-49 basculante tilting removing the rocker 60 nm (6.0 m • kg, 43 ft • lb) 10 nm (1.0 m • kg, 7 ft • lb) 1 3 5 2 4 10 nm (1.0 m • kg, 7 ft • lb) 30 nm (3.0 m • kg, 22 ft • lb) order procedure / parts to remove amount observations rear wheel rear shock refer to "rear shock" on page 5-1 rear fender re...

Page 129

4-50 basculante removing the rocker 60 nm (6.0 m • kg, 43 ft • lb) 10 nm (1.0 m • kg, 7 ft • lb) 1 3 5 2 4 10 nm (1.0 m • kg, 7 ft • lb) 30 nm (3.0 m • kg, 22 ft • lb) order procedure / parts to remove amount observations 11 tread 2 for assembly, reverse the disassembly procedure..

Page 130

4-51 basculante swingarm removal 1. Place the vehicle on a flat surface warning securely support the vehicle so there is no risk of falling. Note: securely support the vehicle so there is no risk of falling. 2. Measure: warning do not attempt to straighten the pivot axis. • swingarm side play. A. Me...

Page 131

4-52 basculante to 121st a b 2. Rocker a. Left b. Right side to 4. Assembly: • rear shock • rod • rear wheel see section "shock back "on page 4-47 and" rear wheel "on page 4-12. 5. Fit: • clearance of the transmission chain, see section "clearance drive chain" on page 3-16. Clearance transmission ch...

Page 132

4-53 cadena de transmisiÓn drive chain removing the drive chain 4 1 3 2 10 nm (1.0 m • kg, 7 ft • lb) 10 nm (1.0 m • kg, 7 ft • lb) order procedure / parts to remove amount observations rear wheel refer to "rear wheel" on page 4-12 support the right footrest, left footrest support refer to "swingarm...

Page 133

4-54 cadena de transmisiÓn checking the drive chain 1. Measure: • 15 links of the drive chain oos replace יו the chain. Link length limit of 15 191.5 mm a. Measure the length "a" between the inner faces of the roller and the length "b" between the outer faces of the rollers 15 in a section of the ch...

Page 134

4-55 cadena de transmisiÓn 6. Check: • gear refer to "rear wheel" on page 4-12 assembly drive chain 1. Lubricate: • drive chain recommended lubricant chain lubricant suitable for o-ring chains 2. Assemble: • drive chain • drive sprocket • retention of the drive sprocket screw retention of the drive ...

Page 135

Motor engine removal 5-1 engine mounting 5-4 changes arm mount 5-4 head 5-5 removing the head 5-7 head inspection 5-7 gear inspection and distribution guide to the timing chain 5-8 inspection of tension distribution chain 5-8 inspection system decompression 5-9 cylinder assembly 5-9 camshaft 5-12 re...

Page 136

Clutch 5-35 clutch removal 5-38 inspection of records of friction 5-38 checking the clutch plates 5-38 checking the clutch springs 5-39 inspection caddy 5-39 inspection of pressure plate 5-39 checking the clutch push lever short and push rod 5-39 primary drive gear inspection 5-39 primary driven gea...

Page 137

Crankshaft 5-58 remove crankshaft 5-59 crankshaft inspection 5-59 crankshaft assembly 5-59 transmission 5-61 checking the shift forks 5-64 change drum inspection 5-64 transmission inspection 5-64 mount push rods 5-65 main shaft assembly and drive shaft 5-65 fitting the drum forks and changes 5-65.

Page 138

Desmontaje del motor 5-1 engine removal muffler removal 1 2 12 nm (1.2 m • kg, 9 ft • ib) 4 3 15 nm (1.5 m • kg, 11 ft • ib) 20 nm (2.0 m • kg, 14 ft • ib) order procedure / parts to remove amount observations 1 air duct 2 2 air guide 1 3 silencer 1 4 exhaust gasket 1 for assembly, reverse the disas...

Page 139

Desmontaje del motor 5-2 1/1 disconnect disconnect cables and connectors 3 4 8 2 1 6 10 5 10 nm (1.0 m • kg, 7 ft • ib) 7 9 10 nm (1.0 m • kg, 7 ft • ib) order procedure / parts to remove amount observations negative battery cable / battery positive cable motor oil caution first, disconnect the batt...

Page 140

Desmontaje del motor 5-3 engine removal 30 nm (3.4 m • kg, 22 ft • ib) 3 4 2 5 1 3 55 nm (5.5 m • kg, 40 ft • ib) 2 55 nm (5.5 m • kg, 40 ft • ib) order procedure / parts to remove amount observations silencer refer to "engine removal" on page 5- 1 fuel tank refer to "general chassis" on page 4-2 1 ...

Page 141

Desmontaje del motor 5-4 engine mounting 1. Urge: • motor "1" • motor mounting screw (upper side) "2" • motor mounting nut (rear upper side) "3" • motor mounting screw (rear lower side) "4" • motor mounting nut (front side) "5" note: do not fully tighten the screws and nuts. Arm assembly of changes ...

Page 142

5-5 culata head removing the cylinder head 22 nm (1.0 m • kg, 16 ft • ib) 13 nm (1.3 m • kg, 9 ft • ib) 10 nm (1.0 m • kg, 7 ft • ib) 8 nm (0.8 m • kg, 6 ft • ib) 5 9 nm (0.9 m • kg, 7 ft • ib) e 8 e 6 8 nm (0.8 m • kg, 6 ft • ib) 1 new 9 20 nm (2.0 m • kg, 14 ft • ib) new 10 ls ls 7 new 11 2 m e 12...

Page 143

5-6 culata removing the cylinder head 22 nm (2.2 m • kg, 16 ft • ib) 10 nm (1.0 m • kg, 7ft • ib) 8 nm (0.8 m • kg, 6 ft • ib) 5 9 nm (0.9 m • kg, 7 ft • ib) e 8 e 8 nm (0.8 m • kg, 6 ft • ib) 6 1 new 9 20 nm (2.0 m • kg, 14 ft • ib) new 10 ls ls 7 new 11 2 m e 12 14 13 4 15 14 10 nm (1.7 m • kg, 7 ...

Page 144

5-7 culata 2 removing the head 1. Align: • the brand "i" in the magneto rotor "a" 1 (with the stationary mark "b" on the cover magneto) 2 a. Turn the crankshaft counterclockwise. B. When the piston is in neutral higher (pms) on the compression stroke, align the "i" of the timing sprocket "c" with th...

Page 145

5-8 culata whole. 2. Check: • butt. Damage / scratches → replace. • water jacket of the cylinder head mineral deposits oxide / יו delete. 3. Measure: a. ¼ tooth b. Correct 1. Contact roller chain 2. Camshaft sprocket • deformation of the cylinder head. Oos → grind the butt. 2. Check: • guide chain (...

Page 146

5-9 culata inspection system decompression b 2 1. Check: • decompression system a. Check the decompression system with camshaft sprocket and the decompression cam installed on the camshaft. B. Check that the decompression lever "1" moves smoothly. C. Without operate the decompression lever, check th...

Page 147

5-10 culata c. Align the "i" of the timing sprocket "c" with the stationary mark "d" on the plate holding the camshaft. D. Install the timing chain on the sprocket camshaft and then install the camshaft sprocket on the camshaft. C. Tighten the tensioner timing chain "3" to the specified torque. Scre...

Page 148

5-11 culata d c 7. Tighten: • screw camshaft sprocket screw camshaft sprocket 20 nm (2.0 m · kg, 14 ft · lb) prcauciÓn be sure to tighten the screw on the camshaft sprocket with the specified torque to avoid the possibility that the screw loosening and damaging the motor. 8. Measure: • valve clearan...

Page 149

5-12 Árbol de levas camshaft removing the rocker arms and camshaft 22 nm (2.2 m • kg, 16 ft • ib) 10 nm (1.0 m • kg, 7 ft • ib) 7 6 1 13 nm (1.3 m • kg, 9 ft • ib) 3 2 2 1 m m 5 e 4 e m order procedure / parts to remove amount observations butt see "head" on page 5-5 1 locknut 2 2 adjusting screw 2 ...

Page 150

5-13 Árbol de levas removing the rocker arms and camshaft 1. Loosen: • locknut "1" • adjustment screw valve clearance "2" • rocker "3" 2 1 3 2. Remove: • camshaft "1" note: 8-mm screw "2" on the threaded end of the camshaft and then remove the camshaft. Dimensions of the camshaft lobes admission 313...

Page 151

5-14 inspecciÓn del Árbol de levas 2. Check: • rocker shaft blue discoloration / pitting excessive wear / scratches replace יו to verify lubrication system. 3. Measure: • bore rocker "a" oos replace יו. Bore rocker 9985-10000 mm limit 10,030 mm 4. Measure: • outside diameter of rocker "a" oos replac...

Page 152

5-15 vÁlvulas y resortes de vÁlvulas valves and valve springs removing the valves and valve springs 1 1 2 3 2 3 6 new new 6 7 7 m m m m 4 5 order procedure / parts to remove amount observations butt see "head" on page 5-5 rocker / camshaft refer to "camshaft" on page 5-12 1 pin valve 4 2 upper sprin...

Page 153

5-16 vÁlvulas y resortes de vÁlvulas removing the valves the following procedure applies to all valves and related components. Note: before removing the internal parts of the head (eg, valves, valve springs, valve seats), make sure the valves seal well. 1. Check: • sealing of valves leaking valve se...

Page 154

5-17 vÁlvulas y resortes de vÁlvulas 2. Delete: •carbon deposits (from the valve face and valve seat) 3. Check: •valve face pitting / wear rectify יו face valve. •end of the valve stem mushroom or a larger diameter than the valve stem to the valve replace יו. 4. Measure: •thickness d of the valve ma...

Page 155

5-18 vÁlvulas y resortes de vÁlvulas 4. Grind: • valve face • valve seat note: after replacing the head or replace the valve and the valve guide, should be lapped the valve seat and valve face a. Apply lapping compound secondary "a" to the valve face. Caution do not let enter the lapping compound be...

Page 156

5-19 vÁlvulas y resortes de vÁlvulas 2. Measure: free length (admission) 39.40 mm limit 37.40 mm free length (escape) 39.40 mm limit 37.40 mm tilting the compression spring (admission) 2.5 ° / 1.7 mm tilting the compression spring (escape) 2.5 ° / 1.7 mm valve assembly the following procedure applie...

Page 157

5-20 vÁlvulas y resortes de vÁlvulas • seal valve stem "2" new • valve "3" • valve spring "4" • upper spring seat valve "5" (in the butt) note: • ensure that each valve is installed in its original position • install the valve with the long end "a" upwards. B. Short end 4. Install: • pines valve "1"...

Page 158

5-21 cilindro y pistÓn cylinder and piston removing the cylinder and piston 7 e 8 9 6 5 e new 4 4 new 1 e e 2 new 3 3 order procedure / parts to remove amount observations butt see "head" on page 5-5 1 cylinder 1 2 cylinder gasket 1 3 dowel pin 2 4 piston pin 2 5 piston pin 1 6 piston 1 7 top ring 1...

Page 159

5-22 cilindro y pistÓn removal cylinder and piston 1. Remove: • piston pin "1" • piston pin "2" • piston "3" caution do not use a hammer to remove the piston pin note: • before removing the piston pin, cover the crankcase opening with a clean rag to prevent the piston pin from falling into the crank...

Page 160

5-23 cilindro y pistÓn "c" = maximum of d1-d2 "t" = maximum of d1 or d2 - up to d5 or d6 "r" = maximum of d1, d3 or d5 - minimum of d2, d4 or d6 b. If out of specification, replace the cylinder, piston and piston rings as a set. C. Measure the diameter of the piston skirt "d" "a" with the micrometer...

Page 161

5-24 cilindro y pistÓn 3. Measure: • distance between centers of rings oos replace יו the piston rings. Note: the opening of the oil ring spacer can not be measured. In case the oil ring opening is excessive, replace the three segments as a whole. Piston rings top ring distance between tips of ring ...

Page 162

5-25 cilindro y pistÓn • and 120 ° 120 ° to b 120 ° d 45 ° a 45 º c 90 º 2. Install: • piston "1" • piston pin "2" • piston pin "3" new a. Top ring b. Oil ring expander c. Upper guide ring oil d. Oil lower guide ring note: • apply engine oil to piston pin. E. Second ring a. Side exhaust • make sure ...

Page 163

5-26 magneto y embrague del arranque new magneto and starter clutch removing the magneto and starter clutch 1 2 10 nm (1.0 m l kg, 7ft l ib) lt 9 10 nm (1.0 m l kg, 7ft l ib) 12 8 7 new 10 17 14 3 8 ls 19 16 15 e new e 13 4 e 6 new 18 new 5 e 14 nm (1.4 m l kg, 10 ft l ib) ls 20 e 11 70 nm (7.0 m kg...

Page 164

5-27 magneto y embrague del arranque new removing the magneto and starter clutch 1 2 10 nm (1.0 m l kg, 7ft l ib) lt 9 10 nm (1.0 m l kg, 7ft l ib) 12 8 7 new 10 17 14 3 8 ls 19 16 15 e new e 13 4 e 6 new 18 new 5 e 14 nm (1.4 m l kg, 10 ft l ib) new ls 20 e 11 70 nm (7.0 m kg, 51 ft lb) 10 nm (1.0 ...

Page 165

5-28 magneto y embrague del arranque magneto removal 1. Remove: • magneto rotor nut 2 • washer note: • while holding the magneto rotor using the rotor magnet holder "1", loosen the rotor magnet. 1 starter clutch removal 1. Remove: 1 • starter clutch bolts "1" note: • while holding the rotor magnet w...

Page 166

5-29 magneto y embrague del arranque 1 2 3 note: • while holding the rotor magnet, 1 tighten the starter clutch "1". • mark end "a" of each screw starter clutch. 2 3 2 1 3 1 2. Check: • freewheel starter clutch • starter clutch sprocket burrs / chips / roughness replace יו defective parts. 3. Check:...

Page 167

5-30 magneto y embrague del arranque 8 note: • while holding the magneto rotor "2", tighten the magneto rotor nut "1". 7 1.6 5 1 9 4 3 2.10 2 3. Apply: • sealant (in the crankshaft position sensor / the buttonhole for mounting the stator wire) yamaha adhesive no. 1215 tg-1215 ls 4. Install: • magnet...

Page 168

5-31 arranque elÉctrico electric start removing the starter motor 2 nm (0.2 m • kg, 1ft • ib) 10 nm (1.0 m • kg, 7ft • ib) (2) 2 1 order procedure / parts to remove amount observations 1 starter 1 2 starter cable 1 disconnect for assembly, reverse the disassembly procedure..

Page 169

5-32 arranque elÉctrico disassemble the starter 11 2 9 10 3 1 4 5 6 7 8 order procedure / parts to remove amount observations 1 starter 1 2 cover package 1 3 set of carbon brushes 1 4 support carbon brushes 1 5 oil seal 1 6 pin lock 1 7 stop washer 1 8 washer 1 9 tread 1 10 front cover starter 1 11 ...

Page 170

5-33 arranque elÉctrico starter removal 1. Remove: • starter "1" • motor front cover start / brush holder assembly "2" note: before disassembling the starter, make alignment marks "a" in the starter cover and front cover starter / brush holder assembly. 1 2 note: to ensure proper operation of the sw...

Page 171

5-34 arranque elÉctrico 6. Check: • pinion teeth damage / wear replace יו pinion. 7. Check: • tread • oil seal damage / wear replace יו cover front starter / brush holder assembly starter assy 1. Install: • front cover starter / brush holder assembly "1" • starter deck "2" note: align the marks "a" ...

Page 172

Embrague clutch removing the clutch cover 9 nm (0.9 m • kg, 7ft • ib) 1 8 new 7 new 2 e 5 4 6 new ls 3 ls (4) (6) 10 nm (1.0 m • kg, 7ft • ib) 10 nm (1.0 m • kg, 7ft • ib) order procedure / parts to remove amount observations motor oil drain see "engine oil replacement" on page 3-9 1 clutch cable 1 ...

Page 173

Embrague 5-36 clutch removal 70 nm (7.0 m kg, 51 ft lb) 11 new 8 nm (0.8 m kg, 6ft ib) e 3 10 12 6 4 5 1 15 (4) 7 2 8 13 (4) 9 8 7 14 8 7 e e order procedure / parts to remove amount observations 1 locknut 1 2 clutch spring 4 3 pressure plate 1 4 short rod clutch thrust 1 5 fastener the clutch pushr...

Page 174

Embrague 5-37 removing the push lever 1 e 2 3 new e ls 4 new 5 order procedure / parts to remove amount observations clutch refer to "clutch" on page 5-35 1 clutch thrust lever 1 2 spring clutch push lever 1 3 pin lock 1 4 oil seal 1 5 tread 1 for assembly, reverse the disassembly procedure..

Page 175

Embrague 5-38 clutch removal 1. Straighten the lock washer. 2. Loosen: • the clutch disc holder nut "1" note: while holding the tray clutch "2" with the clutch holder "3", loosen the nut on the clutch disc holders. Clutch holder ysst-733 2 a b 1 3 xy a. Friction disc 1 inspection of records of frict...

Page 176

Embrague 5-39 thickness of clutch discs 1.85-2.15 mm strain limit 0.20 mm checking the clutch springs the following procedure applies to all clutch springs. 1. Check: • clutch springs damage replace יו clutch springs a set 2. Measure: • free length of clutch springs "to" out of specification יוrepla...

Page 177

Embrague 5-40 2. Check: • primary drive gear damage / wear replace יו gear primary drive and clutch as a whole. Excessive noise during operation יו replace the primary drive gear and the clutch as a whole. 3. Install: • primary drive gear see "balancer sprocket" on page 5-49. Primary driven gear ins...

Page 178

Embrague 5-41 5. Fold the tab washer along a flat side of the nut. 6. Lubricate: • friction plates • clutch discs (with the recommended lubricant) recommended lubricant engine oil 2 1 9. Fit: • free play of the clutch mechanism a. Verify that the projection "a" on the clutch lever "1" is aligned wit...

Page 179

Embrague 5-42 10. Install: • oil seal "1" • oil seal "2" 1 to 2 b 11. Install: • clutch cover clutch cover screw 10 nm (1.0 m · kg, 7.2 ft · lb) note: tighten the cover screws clutch in the proper tightening sequence as shown. 1.9 8 10 11 7 12 6 5 13. Fit: 13 4 3.15 2.14 • freeplay clutch cable see ...

Page 180

5-43 bomba de aceite oil pump removing the oil pump 3 4 nm (0.4 m • kg, 3ft • ib) 2 4 nm (0.4 m • kg, 3ft • ib) 1 lt lt 10 nm (1.0 m • kg, 7ft • ib) 10 nm (1.0 m • kg, 7ft • ib) order procedure / parts to remove amount observations clutch refer to "clutch" on page 5-35 primary drive gear / pinion ba...

Page 181

5-44 bomba de aceite disassembly of the oil pump 2 6 5 4 3 e 1 e order procedure / parts to remove amount observations 1 housing cover oil pump 1 2 pin 1 3 primary driven gear oil pump 1 4 internal rotor of the oil pump 1 5 external rotor of the oil pump 1 6 pump housing oil 1 for assembly, reverse ...

Page 182

5-45 bomba de aceite checking the oil pump 1. Check: • primary drive gear oil pump • primary driven gear oil pump • pump housing oil cracks / damage / wear replace יו the defective parts. 2. Measure: • clearance between the inner rotor and outer rotor "a" • clearance between the outer rotor and the ...

Page 183

5-46 bomba de aceite 1 2 to 3. Check: • operation of the oil pump refer to "checking the oil pump" on page 5- 45. Mount oil pump 1. Install: • oil pump screw oil bulges 4 nm (0.4 m · kg, 2.4 ft · lb) caution after tightening the screws, make sure the oil pump rotates smoothly..

Page 184

5-47 eje de cambios shift shaft removing the shift shaft and lever stop 6 ls new 2 e 3 lt 4 5 1 9 nm (0.9 m • kg, 7ft • ib) order procedure / parts to remove amount observations clutch refer to "clutch" on page 5-35 shift arm 1 axis of changes 1 2 pin lock 1 3 shift shaft spring 1 4 lever cap 1 5 st...

Page 185

5-48 eje de cambios shift shaft inspection 1. Check: • axis of changes curves / damage / wear replace יו. • changes shaft spring damage / wear replace יו. Inspection stop lever 1. Check: • lever cap curves / damage replace יו. Roller turns roughly replace יו the top of the lever. • stopper lever spr...

Page 186

5-49 piÑÓn del balanceador 1 60 nm (6.0 m • kg, 43 ft • ib) balancer sprocket removing the balancer sprocket and primary drive gear 6 5 15 13 10 4 14 3 9 12 e 11 8 7 new 2 45 nm (4.5 m • kg, 33 ft • ib) order procedure / parts to remove amount observations clutch refer to "clutch" on page 5-35 1 pri...

Page 187

5-50 piÑÓn del balanceador 1 60 nm (6.0 m • kg, 43 ft • ib) removing the balancer sprocket and primary drive gear 6 5 15 13 10 4 14 3 9 12 e 11 8 45 nm (4.5 m • kg, 33 ft • ib) 7 new 2 order procedure / parts to remove amount observations 15 spacer 1 for assembly, reverse the disassembly procedure..

Page 188

5-51 piÑÓn del balanceador balancer sprocket 1. Loosen: • primary drive gear nut "1" assembly primary balancer driven gear 1. Assembly: • dowel pin "1" note: place a sheet of leather or a leather "a" between the primary drive gear anceador bal "2" and led engranaj primary balancer and "3", and then ...

Page 189

5-52 piÑÓn del balanceador b 2 3 1 2 4 to b 3. Fold the tab washer along a flat side of the nut. 3 c 2. Tighten: • nut primary balancer driven gear "1" • primary drive gear "2" nut primary balancer driven gear 45 nm (4.5 m · kg, 33 ft · lb) primary drive gear 60 nm (6.0 m · kg, 43 ft · lb) note: • p...

Page 190

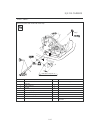

5-53 cÁrter carter crankcase separation 10 nm (1.0 m • kg, 7 ft • ib) 4 10 nm (1.0 m • kg, 7 ft • ib) 5 6 3 1 5 7 2 10 nm (1.0 m • kg, 7 ft • ib) order procedure / parts to remove amount observations engine butt see "head" on page 5-5 cylinder and piston refer to "cylinder and piston" on page 5-21 c...

Page 191

5-54 cÁrter crankcase separation 10 nm (1.0 m • kg, 7 ft • ib) 4 10 nm (1.0 m • kg, 7 ft • ib) 5 6 10 nm (1.0 m • kg, 7 ft • ib) 3 1 5 7 2 10 nm (1.0 m • kg, 7 ft • ib) order procedure / parts to remove amount observations 5 dowel pin 2 6 left housing 1 7 nozzle 1 for assembly, reverse the disassemb...

Page 192

5-55 cÁrter dismantling of bearings and oil seals 3 e 7 nm (0.7 m • kg, 5 ft • ib) 3 e 2 3 3 3 3 lt 1 3 e ls order procedure / parts to remove amount observations crankshaft / balancer see "crankshaft" on page 5-58 transmission see "transmission" on page 5-61 1 oil seal 1 2 bearing retainer 1 3 trea...

Page 193

5-56 cÁrter crankcase separation 1. Remove: • crankcase bolts note: loosen each screw 1/4 turn at a time in stages and in the correct sequence as shown. Caution tap on one side of the pan with a soft-faced hammer. Tap reinforced only on portions of the crankcase, not the contacting surfaces of the c...

Page 194

5-57 cÁrter rough movement replace יו. • oil seals damage / wear replace יו. Bearing retainer assembly 1. Install: • bearing retainer "1" note: • install the bearing retainer "1" marked "out" "to" out. • apply a locking agent (loctite) to the screw threads of the retainer bearing. 3. Install: • hous...

Page 195

5-58 cigÜeÑal crankshaft remove crankshaft and balancer 2 e e ls 1 new ls new order procedure / parts to remove amount observations sump refer to "crankcase" on page 5-53 1 balancer 1 2 crankshaft 1 for assembly, reverse the procedure disassembly..

Page 196

5-59 cigÜeÑal remove crankshaft 1. Remove: • crankshaft "1" note: • remove the crankshaft with the tool to remove the crankshaft "2". • be sure to remove the tool crankshaft is centered on the crankshaft. Caution • to protect the end of the crank, placing a suitably sized wrench removal tool between...

Page 197

5-60 cigÜeÑal 1 caution to avoid scratching the crankshaft and to facilitate the process, assembly, lubricate the edges of oil seals with grease lithium soap base and each bearing with engine oil. Note: maintain the rod in the upper dead center (tdc) with one hand while rotating the nut screw assemb...

Page 198

5-61 transmisiÓn transmission removing the transmission, the shift drum and changes forks 7 1 4 8 2 5 9 e 2 6 2 e e 3 order procedure / parts to remove amount observations sump refer to "crankcase" on page 5-53 1 barra claw guide changes 2 2 spring 4 3 shift drum 1 4 right-shift fork 1 5 shift fork-...

Page 199

5-62 transmisiÓn disassembly of the main shaft m 7 m 6 m 5 4 3 2 1 order procedure / parts to remove amount observations 1 second pinion 1 2 fifth gear 1 3 sprocket third 1 4 pin lock 1 5 toothed washer 1 6 sprocket quarter 1 7 main shaft / sprocket first 1 for assembly, reverse the disassembly proc...

Page 200

5-63 transmisiÓn drive shaft disassembly 5 6 7 8 9 10 11 12 13 4 3 m 2 1 m m order procedure / parts to remove amount observations 1 pin lock 1 2 washer 1 3 second gear 1 4 fifth gear 1 5 washer 1 6 first gear 1 7 necklace 1 8 washer 1 9 fourth gear 1 10 pin lock 1 11 washer 1 12 third gear 1 13 dri...

Page 201

5-64 transmisiÓn l checking the shift forks drum inspection of changes 1. Check: the following procedure applies to all changes forks. 1. Check: l cam pin fork changes "1" clips shift fork "2" curves / damage / stretch marks / wear replace יו changes fork. L grooves changes in the drum damage / scra...

Page 202

5-65 transmisiÓn main shaft assembly and drive shaft 1. Install: l toothed washer "1" l pin lock "2" new note: l be sure to install the lock pin so that its sharp edge "to" be back to the ring gear and the gear. 3. Check: l transmission gears blue discoloration / pitting / wear יו replace damaged ge...

Page 203

5-66 transmisiÓn note: the markings on the shift forks should be facing the right side of the engine and be in the following sequence: "r", "c", "l". 2. Check: l transmission rough movement יו repair note: l apply engine oil to each gear and bearing. L before assembling the crankcase, make sure the ...

Page 204

Fuel system carburetor carburetor removal 6-1 carburetor disassembly 6-2 carburetor inspection 6-4 carburetor assy 6-6 carburetor assembly 6-7 measuring and adjusting the fuel ble 6-7 inspection fuel wrench 6-8 air induction system air induction system 6-9 removal air induction system 6-10 inspectio...

Page 205

Carburador 6-1 carburetor disassembling the carburetor order procedure / parts to remove amount observations seat, side covers 1 & 2, fuel hose refer to "general chassis" on page 4-1 1 fuel overflow hose 1 disconnect 2 fuel hose 1 3 clamp bolt carburetor union 1 loosen 4 screw clamp 1 5 throttle cab...

Page 206

Carburador 6-2 disassemble the carburetor order procedure / parts to remove amount observations disassemble the carburetor remove the parts in the order listed 1. Diaphragm cover 1 2. Diaphragm spring 1 3. Needle valve 1 4. Piston valve 1 5. Diaphragm 1 6. Ring 1 7. Drain bolt 1 8. Float chamber 1 9...

Page 207

Carburador 6-3 disassemble the carburetor 31 order procedure / parts to remove amount observations 14. Float pin 1 15. Float 1 16. Set needle 1 17. Throttle stop screw 1 18. Washer 1 19. Spring 1 20. Pilot supplier 1 21. O-ring 1 22. Washer 1 23. Spring 1 24. O-ring 1 25. Strainer 1 26. Cover plunge...

Page 208

Carburador 6-4 7 disassemble the carburetor order procedure / parts to remove amount observations 28. O-ring 1 29. Plunger spring 1 30. Plunger 1 31. Spring washer 1 32. Throttle stop 1 33. Stop washer 1 34. Spring 1 35. Tps 1 36. O-ring 1 37. Pin lock 1 38. Washer 1 39. Washer 1 for assembly, rever...

Page 209

Carburador 6-5 carburetor disassembly 1. Check: • carburetor body "1" • float chamber "2" • accommodation supplier "3" cracks / damage-replace. 2. Check: • flights fuel clogged - clean. Note: wash the carburetor in petroleum-based solvent. Do not use any caustic carburetor cleaning. Blow out all pas...

Page 210

Carburador 8. Check: • filter mesh "1" damaged / replace clogged ---- 1 1 2 9. Check: • main jet "1" / accommodation supplier "2" / o-ring "3" / main nozzle "4" damage / obstruction - replace 1 2 3 4 10. Check: • jet pilot "1" damage / obstruction - replace 1 11. Check: • mixture screw "1" damage / ...

Page 211

Carburador 6-7 2.Install: • mixture screw "1" • filter mesh "2" 1 4. Install: • float "1" • float pin "2" • screw "3" • packaging of the float chamber "4" • float chamber "5" 3 2 2 1 5 4 3.Instalar: • needle valve "1" 1 5.Instalar: • diaphragm valve "1" caution do not overtighten any screws, this ca...

Page 212

6-8 carburador 6. Install: • diaphragm spring "1" • cover the iris "2", tighten the screws 2 4 1 carburetor assembly 1.Connect al l wi r es a n d c a b l e s . Refer to "engine removal" on page 5- 2. 2.Ajustar • freeplay throttle cable see "free play adjustment throttle cable" on page 3-6 3.Ajustar:...

Page 213

6-9 sistema de inducciÓn de aire air induction system 5 1 2 4 3 3 2 5 1 4 1 hose air induction system (air filter). 2 vacuum hose from the air induction system. 3 through the air induction system (to the engine) 4 air filter 5 air induction system..

Page 214

6-10 sistema de inducciÓn de aire removing the air induction system 1 3 4 2 order procedure / parts to remove amount observations seat, side cover side cover 1 & 2 refer to "general chassis" on page 4-1 fuel tank refer to "general chassis" on page 4-2 1 hose air induction system (air filter). 1 2 va...

Page 215

6-11 sistema de inducciÓn de aire inspection system air induction air injection the air induction system of burning the unburnt exhaust gases by injecting fresh air (secondary air) into the exhaust port of reducing hydrocarbon emissions. When there is negative pressure in the exhaust port, the reed ...

Page 216

6-12 sistema de inducciÓn de aire air switching valve replace valve opens air cutting. Air shutoff valve closed the air cut valve is ok 1 note: this test should be done when the pressure is less than - 50 kpa..

Page 217

Electrical ignition system 7-1 circuit diagram 7-1 troubleshooting 7-3 electric starting system 7-5 circuit diagram 7-5 operation starter cut 7-7 troubleshooting 7-9 charging system 7-11 circuit diagram 7-11 troubleshooting 7-13 light system 7-14 circuit diagram 7-14 troubleshooting 7-16 signal syst...

Page 218

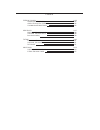

Rwbr wblw l b dg br brwwb ch p igni t ion system igni tion sy stem c irc uit di agram 7-1 sb sb b b r r r 15 a 12 v 5w b l y a n d 12 v 35 w /35 w wb g g b r p b ch ch b br w br w br lw b dg 12 v1 0 w dg b a n d br 12 v1 0 w ch br rw b b l a n d gy br 12 v1 0 w dg b l wb or w b rw a n d b bl l w b r...

Page 219

Sistema de encendido 7-2 1. Magneto ca 3. Unit regulator / rectifier 4. Main fuse 5. Battery 6. Main switch 7. Cdi unit 8. Ignition coil 19. Tps 20. Plug 21. Cable positive + 22. Negative cable - 30. Engine stop switch.

Page 220

Sistema de encendido 7-3 troubleshooting the ignition system is not working (no spark or intermittent spark). Note: • before troubleshooting, remove the following parts: 1. Seat 2. Side cover 1 and 2 3. Fuel tank 1. Check the fuse. See section "checking the fuse" on page 7-34. Ok t 2. Check the batt...

Page 221

Sistema de encendido 7-4 9. Check the engine stop switch. See the "verifying switches" on page 7-30. Ok t 10.Verificar wiring the entire ignition system. See section "circuit diagram" on page 7-1. Ok t replace the cdi. Ng ng the engine stop switch is faulty. Replace the switch 㻚 right handlebar conn...

Page 222

Dg br brwwb ch p elect r ic st art ing sys t em s t a rting circuit cir cuit di agram 7- 5 sb sb b b r r r 15 a 12 v 5w b l y a n d 12 v 35w /3 5w wb g g b r p b ch ch b br w br w br lw b dg 12 v1 0w dg b a n d br 12 v1 0w ch br rw b b l a n d gy br 12 v1 0w dg b l wb or w b rw a n d b bl l w b rb g...

Page 223

Sistema de arranque elÉctrico 7-6 2. Neutral switch 4. Main fuse 5. Battery 6. Main switch 21. Cable positive + 22. Negative cable - 23. Starter relay 24. Starter 26. Start switch 27. Starter cut relay 28. Clutch switch 30. Engine stop switch.

Page 224

Sistema de arranque elÉctrico 7-7 system operation start circuit court if the engine cutoff switch is set to "" and the ignition switch is positioned to "on" (both switches are closed), the starter may work if one of the following conditions is served: • the transmission is in neutral (neutral switc...

Page 225

Sistema de arranque elÉctrico 7-8 a. When the transmission is in neutral b. When the lever is pulled clutch handlebar 1. Battery 2. Fuse 3. Main switch 4. Engine stop switch 5. Starter cut relay 6. Clutch switch 7. Neutral switch 8. Start switch 9. Starter relay 10. Starter.

Page 226

Sistema de arranque elÉctrico 7-9 troubleshooting the starter does not turn. Note: • before troubleshooting, remove the following parts: 1. Seat 2. Side cover 1 and 2 1. Check the fuse. See "checking the fuse" on page 7-34. Ok t 2. Check the battery. Refer to the "checking and charging the battery" ...

Page 227

Sistema de arranque elÉctrico 7-10 8. Check the engine stop switch. See the "verifying switches" on page 7-30. Ok t 9. Check the neutral switch. See "verifying switches "on page 7-30. Ok t 10.Verificar clutch switch. See "verifying switches "on page 7-30. Ok t 11.Verificar the start switch. See the ...

Page 228

Rwbr wblw l b dg br brwwb ch p c h ar g ing system c h ar gi n g s y st e m ci rcui t d ia g r a m 7- 1 1 sb sb b b r r r 15 a 12v 5w b l y a n d 12v 35 w /3 5w wb g g b r p b ch ch b br w br w br lw b dg 1 2v10w dg b a n d br 1 2v10w ch br rw b b l gy br a n d 1 2v10w dg b l wb or w b rw a n d b bl...

Page 229

Sistema de carga 7-12 1. Magneto ca 3. Regulator / rectifier 4. Main fuse 5. Battery 21. Cable positive + 22. Negative cable -.

Page 230

Sistema de carga 7-13 troubleshooting the battery is not charging. Note: • before troubleshooting, remove the following parts: 1. Seat 2. Panel on the left side / side cover. 1. Check the fuse. See "checking the fuse" on page 7-34 ok t 2. Check the battery. Refer to the "checking and charging the ba...

Page 231

Rwbr wblw l b dg br brwwb ch p light s y st em l ig ht s yste m cir cuit di agram 7-1 4 sb 2 sb 2 b b r2 r r2 15 a 12v 5w l y b a n d 12 v 35w /3 5w wb g b g r p b ch b ch br w br w br lw b dg 12v 1 0w dg b a n d br 12v 1 0w br rw b ch b l a n d gy br 12v 1 0w dg b l wb or w b rw a n d b bl l w b rb...

Page 232

Sistema de luces 4. Main fuse 5. Battery 6. Main switch 13. Meter 15. Streetlight 18. Taillight 21. Cable positive + 22. Negative cable - 31 light switch 34. Light switch.

Page 233

Sistema de luces troubleshooting any of the following lights fails: street light, light beam indicator, tail light, auxiliary light or light meter. Note: • before to solve problems, remove the following parts: 1. Seat 2. One side cover and side cover 2 3. Streetlight 4. Fuel tank 1. Check each bulb ...

Page 234

Rwbr wblw l b signal system si gn al s yst em cir cuit di agram 7- 17 sb sb b r r 15 a 12v 5w l y b a n d 12v 35 w /3 5w wb g b g p b ch b ch br w br w br lw dg b 1 2v10w dg b a n d br 1 2v10w br rw b ch b l a n d gy br 1 2v10w dg b l wb or w b b l bl l w b rb gb sb ly bl w w 1 w w 3 b b br r w - w ...

Page 235

Sistema de seÑalizaciÓn 7-18 2. Neutral switch 4. Main fuse 5. Battery 6. Main switch 7. Cdi 9. Horn 10. Relay turn signal 11. Front brake switch 12. Rear brake switch 13. Meter 16. Front turn indicator light (lh) 17. Front light turn indicator (rh) 21. Cable positive + 22. Negative cable - 25. Spee...

Page 236

Sistema de seÑalizaciÓn 7-19 troubleshooting • any of the following fault lights: turn indicator lights, brake light or indicator lights. • the horn does not sound. • the fuel gauge does not work. Note: • before troubleshooting, remove the following parts: 1. Seat 2. Fuel tank 3. Streetlight 4. Mult...

Page 237

Sistema de seÑalizaciÓn 7-20 3. Check the wiring of the signaling system. See section "circuit diagram" on page 7-17. Okt the system circuit is ok 㻚 ng connect or repair wiring 㻚 signaling system the brake light / rear does not light. 1. Check the bulb brake light / back and the socket. Refer to the...

Page 238

Sistema de seÑalizaciÓn 7-21 3.Verificar switch indicator light turn. See the "verifying switches" on page 7-30. Okt 4.Verificar r e l a y s h i f t i n d i c a t o r l i g h t . S e e " v e r i f y i n g r e l a y t u r n i n d i c a t o r l a m p " o n p a g e 7 - 3 8 . Okt 5.Verificar t h e s i g...

Page 239

Sistema de seÑalizaciÓn 7-22 2.Check the signaling system wiring. See section "circuit diagram" on page 7-17. Okt replace the meter 㻚 . Ng connect or repair wiring 㻚 signaling system.

Page 240

7-23 funciÓn de auto-diagnÓstico self-diagnosis function the vehicle is equipped with a self-diagnostic function. If this function detects a malfunction in the system, immediately operate the engine under substitute characteristics and illuminates the warning light engine trouble to alert the driver...

Page 241

7-24 funciÓn de auto-diagnÓstico to b c d c fault code no. No fault code check and repair. See "d ata troubleshooting" monitoring the operation of sensors and actuators in the diagnostic mode. See ection "t ableof operation of sensors" and "actuators operating table" check and repair see "table of t...

Page 242

7-25 funciÓn de auto-diagnÓstico troubleshooting details this section describes the steps to the fault code number displayed on the meter. Check and service elements or components that are the likely cause of the failure. Fault code no. 15 symptom throttle position sensor: open or short circuit dete...

Page 243

7-26 funciÓn de auto-diagnÓstico fault code no. 16 the throttle position sensor is attached component: throttle position sensor order element / components and probable cause check or maintenance job method reintegration 1 condition sensor assembly throttle position. • check for loose or pressed. • c...

Page 244

FunciÓn de auto-diagnÓstico 7-27 symptom: the signals received from the speed sensor is not normal. Component: vehicle speed sensor order element / components and probable cause check or maintenance job method reintegration 1 condition sensor assembly speed. • check for loose or pressed. S t a r t t...

Page 245

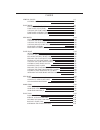

7-28 componentes elÉctricos electrical components 1 2 3 4 5 10 11 12 6 9 14 13 8 7.

Page 246

7-29 componentes elÉctricos 1. Front brake switch 2. Fuel gauge 3. Starter cut relay 4. Cdi unit 5. Main switch 6. Horn 7. Starter relay 8. Neutral switch 9. Rear brake switch 10. Battery 11. Regulator / rectifier 12. Fuse 13. Spark plug 14. Ignition coil.

Page 247

7-30 componentes elÉctricos off on br dg w / b br / w an p ch pass switch inspection 1234 bbr r / b b (black) b rbr gy br br yy (red) 5 sb 12 po off on 11 br l / w 10 l / w b r / w w / b 9 br r / w 87 w / b and g 6 brp cdhg br / w an d g b l b.

Page 248

7-31 componentes elÉctricos 1. Clutch switch 2. Main switch 3. Front brake switch 4. Rear brake switch 5. Neutral switch 6. Switch turn signal 7. Horn switch 8. Light switch 9. Light switch step 10. Engine stop switch 11. Start switch 12. Light switch.

Page 249

7-32 componentes elÉctricos check continuity of each switch with the multimeter. If the continuity reading is incorrect, check the connections, and if necessary, replace the switch. Caution: never insert the tester probes into the slots of the coupling terminal "a". Always insert probes for the oppo...

Page 250

7-33 componentes elÉctricos checking the bulbs and sockets of bulbs check each bulb and bulb socket for damage or wear, proper connections and continuity between terminals. Damage / wear יוrepair or replace bulb, the bulb socket or both. Bad connection יוconnect correctly. No continuity יוrepair or ...

Page 251

7-34 componentes elÉctricos article classification amperage amount fuse 15 a 1 checking the condition of the bulbs sockets the following procedure applies to all of the light bulb sockets. 1. Check: • bulb socket (for continuity) (with multimeter) no continuity replace יו. Multimeter a. Set the main...

Page 252

7-35 componentes elÉctricos interna l • drink plenty of water or milk followed by milk of magnesia, beaten egg or vegetable oil. Get immediate medical attention. 1. Remove: • seat and right side cover refer to "general chassis" on page 4-1. 2. Disconnect: • battery cables (from the battery terminals...

Page 253

7-36 componentes elÉctricos warning do not charge a battery quickly. Caution: do not use a battery charger quick charge, and requiring a high amperage in the battery quickly and can cause overheating and damage the battery plates. If it is impossible to regulate the charging current to the battery c...

Page 254

7-37 componentes elÉctricos charging method with a constant voltage charger a. Measure the open circuit voltage, before loading. Note: the voltage should be measured after 30 minutes without using the battery. B. Connect a charger and an ammeter to the battery and start charging. C. Make sure that t...

Page 255

7-38 componentes elÉctricos starter cut relay b. Turn the ignition switch to "on". C. Measure the input voltage signal relay 1 of rotation. Output voltage relay turn signal 12 v dc 2 3 lb rb rw 1. Positive battery terminal 2. Negative battery terminal 3. Tester positive probe 4. Tester negative prob...

Page 256

7-39 componentes elÉctricos verification plug cap 1.Check: • plug cap resistance oos replace יו. Resistance of the plug cap 5.0 ku at 20 ° c (68 ° f) a. Remove the spark plug cap from the spark plug wire. B. Connect the multimeter (Ù × 1k) to the spark plug cap as shown. Multimeter c. Measure the re...

Page 257

7-40 componentes elÉctricos dynamic spark tester • positive tester probe יו high voltage cable • negative tester probe יו land 1 sensor check crankshaft position 1 .. Disconnect: • coupling crankshaft position sensor (from the wire harness) 2.Check: • reliability of crankshaft position sensor oos יו...

Page 258

7-41 componentes elÉctricos 1 a. Connect the positive battery terminal "1" and the starter cable "2" with a jumper wire "3". Warning • the cable used for the bridge must 2 have at least the same capacity of the cable w battery, otherwise, the jumper cable may be burned. • this check is likely to pro...

Page 259