- DL manuals

- Yamaha

- Motorcycle

- FZ6-ST

- Supplementary Service Manual

Yamaha FZ6-ST Supplementary Service Manual

Summary of FZ6-ST

Page 1

Fz6-st 5vx-28197-11 supplementary service manual lit-11616-18-43 fz6-stc.

Page 3: Foreword

Fz6-st/ fz6-stc supplementary service manual © 2004 by yamaha motor corporation, u.S.A. First edition, august 2004 all rights reserved. Any reproduction or unauthorized use without the written permission of yamaha motor corporation, u.S.A. Is expressly prohibited. Printed in u.S.A. P/ n lit-11616-18...

Page 4: Notice

Eas00002 notice this manual was produced by the yamaha motor company, ltd. Primarily for use by yamaha deal- ers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manual. Therefore, anyone who uses this book to perform maintenance and repairs on yama...

Page 5: How To Use This Manual

Eas00007 how to use this manual this manual is intended as a handy, easy-to-read reference book for the mechanic. Comprehensive explanations of all installation, removal, disassembly, assembly, repair and check procedures are laid out with the individual steps in sequential order. The manual is divi...

Page 6

Eas00008 symbols the following symbols are not relevant to every vehicle. Symbols to indicate the subject of each chapter. General information specifications periodic checks and adjustments chassis engine cooling system fuel injection system electrical system troubleshooting symbols to indicate the ...

Page 7: Contents

Contents specifications general specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 engine specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 chassis specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 electrical speci...

Page 8: Spec

Spec 1 specifications general specifications engine specifications chassis specifications electrical specifications item standard limit model code 5vx8 (usa except for cal) 5vx9 (cal) • • • • • • item standard limit piston diameter d 65.475 ~ 65.490 mm (2.5778 ~ 2.5783 in) • • • height h 5 mm (0.20 ...

Page 9: Spec

Spec 2 tightening torques engine tightening torques chassis tightening torques item fastener thread size q’ty tightening torque remarks nm m•kg ft•lb connecting rod caps bolt m7 8 15+120° 1.5+120° 11+120° item thread size tightening torque remarks nm m•kg ft•lb pivot shaft and frame m18 125 12.5 90 ...

Page 10: Spec

Spec 3 cable routing left handlebar switch lead main switch lead clutch cable throttle cables right handlebar switch lead clamp the right and left handlebar switch leads and handlebars. Point the tip of the clamp downward in front of the handlebars. Clamp the horn lead and main switch lead (upper si...

Page 11: Spec

Spec 4 point the lead, which comes from the terminal, to the front side of the vehicle body. There should be no slack of leads between the band and terminals. Clamp the brake hose to the inner tube. Point the binding section to the outside of the vehicle body and cut the tip down to the length of 1 ...

Page 12: Spec

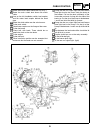

Spec 5 main switch lead stay assembly left handlebar switch lead clutch cable throttle cables battery negative lead coupler starter relay lead battery negative lead fuel tank drain hose rectifier/regulator turn signal relay radiator fan motor relay dimmer relay starting circuit cut-off relay clamp l...

Page 13: Spec

Spec 6 route the throttle cables above the stay assy 1. Route the main switch lead above the clutch cable. Line up the left handlebar switch lead coupler and fan motor lead coupler behind the head pipe. Route the clutch cable over the wire harness. To the main switch. Place three couplers on the fla...

Page 14: Spec

Spec 7 to the rear turn signal light (left) pass the fuel tank drain hose through the clamp located under the coolant reservoir tank. Route it behind the starter motor lead. Point the bend-r section of the throttle cable (pull side) to the inner side horizontally. It is also possible to visually che...

Page 15: Spec

Spec 8 right handlebar switch lead throttle cables battery positive lead coolant reservoir tank hose battery cover connecter cover fuel tank breather hose brake fluid reservoir hose lean angle cut-off switch fuse box rear turn signal light lead (right) license plate light lead rear turn signal light...

Page 16: Spec

Spec 9 either right or left side arrangement for the left handlebar switch lead coupler and radiator fan motor coupler can be accepted. Point the l-shape terminal to the front side of the vehicle. Hook the starter motor lead to the alternate pawls on the battery cover. Route the crankshaft position ...

Page 17: Spec

Spec 10 point the tip of the clamp to the outside of the vehicle. Insert the enwinding clamp of the wire harness into the hole of the rear frame. Attach the rectifier/regulator lead to the clamp of the rectifier bracket. To the engine ground. To the fuel injection. To the fuel pump. Route the clutch...

Page 18: Spec

Spec 11 point the spark plug caps of #1 to #4 to the direc-tion as shown in the illustration. Route the spark plug lead #3 under the air cut-off valve hose. Route the spark plug lead #2 behind the air cut-off valve hose. Route the spark plug lead #4 by the front side of the spark plug leads #2 and #...

Page 19: Spec

Spec 12 fuel pump assembly fuel tank breather hose (except for cal) fuel tank drain hose fuel hose clip clamp charge hose (for cal) roll over valve (for cal) fuel tank protector air opening. Install the o-ring with its lip pointed upward. Fuel tank breather hose has a white point mark. Point the kno...

Page 20: Spec

Spec 13 except for cal coolant breather hose coolant reservoir tank coolant reservoir tank hose clamp fuel tank drain hose front side. Pass the coolant reservoir tank hose hangs down downward from back of the bolt. Insert this portion securely. Spittle is turned back. Insert the clamp certainly. It ...

Page 21: Chas

Chas 14 eas00709 chassis swingarm and drive chain checking the drive chain 1. Measure: • measure the dimension between 15-links on the inner side and outer side of the roller and calculate the dimension between pin centers. • dimension between pin centers = (inner dimension + outer dimension )/2 • 1...

Page 22: Chas

Chas 15 caution: this motorcycle has a drive chain with small rubber o-rings between the drive chain side plates. Never use high-pressure water or air, steam, gasoline, certain sol- vents (e.G., benzine), or a coarse brush to clean the drive chain. High-pressure meth- ods could force dirt or water i...

Page 23: Eng

Eng 16 eas00192 engine engine installing the engine 1. Install: • rear engine mounting bolts note: note: lubricate the rear engine mounting bolt threads with lithium-soap-based grease. 2. Install: • right front engine mounting bolt • left front engine mounting bolts note: note: do not fully tighten ...

Page 24: Eng

Eng 17 5. Tighten • right front engine mounting bolts 6. Install: • shift arm bolt note: note: • before installing, make sure to align the punch mark of the shift shaft with the punch mark of the shift arm. • align the bottom edge of the shift pedal with the mark on the frame-to-swingarm bracket. 55...

Page 25: Eng

Eng 18 eas00252 connecting rods and pistons order job / part q'ty remarks removing the connecting rods and pistons remove the parts in the order listed. Lower crankcase refer to “crankcase”. 1 connecting rod cap 4 2 big end lower bearing 4 3 big end upper bearing 4 4 piston pin clip 8 5 piston pin 4...

Page 26: Eng

Eng 19 eas00393 removing the connecting rods and pistons the following procedure applies to all of the connecting rods and pistons. 1. Remove: • connecting rod cap • big end bearings note: note: identify the position of each big end bearing so that it can be reinstalled in its original place. 2. Rem...

Page 27: Eng

Eng 20 checking the big end bearings 1. Measure: • crankshaft-pin-to-big-end-bearing clear- ance out of specification → replace the big end bearings. The following procedure applies to all of the connecting rods. Caution: do not interchange the big end bearings and connecting rods. To obtain the cor...

Page 28: Eng

Eng 21 e. Tighten the connecting rod bolts. Note: note: install by carrying out the following procedures in order to assemble in the most suitable con- dition. • connecting rod bolts f. Replace the connecting rod bolts with new ones. G. Clean the connecting rod bolts. H. After installing the big end...

Page 29: Eng

Eng 22 k. Tighten the connecting rod bolts. Caution: tighten the connecting rod bolts using the plastic-region tightening angle method. Always install new bolts. L. Clean the connecting rod bolts. M. Tighten the connecting rod bolts. N. Put a mark on the corner of the connect- ing rod bolt and the c...

Page 30: Eng

Eng 23 q. Remove the connecting rod and big end bearings. Refer to "removing the connecting rods and pistons". R. Measure the compressed plastigauge ® width on the crankshaft pin. If the crankshaft-pin-to-big-end-bearing clearance is out of specification, select replacement big end bearings. 2. Sele...

Page 31: Eng

Eng 24 installing the connecting rod and piston the following procedure applies to all of the connecting rods and pistons. 1. Install: • top ring • 2nd ring • upper oil ring rail • oil ring expander • lower oil ring rail note: note: be sure to install the piston rings so that the manufacturer's mark...

Page 32: Eng

Eng 25 4. Offset: • piston ring end gaps top ring lower oil ring rail upper oil ring rail 2nd ring oil ring expander 5. Lubricate: • crankshaft pins • big end bearings • connecting rod big end inner surface (with the recommended lubricant) 6. Install: • big end bearings • connecting rod cap (onto th...

Page 33: Eng

Eng 26 7. Tighten: note: note: install by carrying out the following procedures in order to assemble in the most suitable con- dition. • connecting rod bolts. A. Replace the connecting rod bolts with new ones. B. Clean the connecting rod bolts. C. After installing the big end bearing, assem- ble the...

Page 34: Eng

Eng 27 9. Tighten: • connecting rod bolts caution: tighten the connecting rod bolts using the plastic-region tightening angle method. A. Clean the connecting rod bolts. B. Tighten the connecting rod bolts. C. Put a mark on the corner of the connect- ing rod bolt and the connecting rod cap . D. Tight...

Page 36

Yamaha motor co., ltd. 2500 shingai iwata shizuoka japan.