Summary of FZS600 2000

Page 3: Foreword

Foreword this supplementary service manual has been prepared to introduce new service and data for the fzs600 2000. For complete service information procedures it is necessary to use this supplementary service manual together with the following manual. Fzs600 service manual: 5dm1-ae1 fzs600 2000 sup...

Page 4: Notice

Note: warning caution: eb001000 notice this manual was produced by the yamaha motor company primarily for use by yamaha dealers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manual, so it is assumed that anyone who uses this book to perform maint...

Page 5: How To Use This Manual

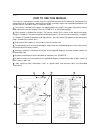

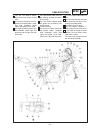

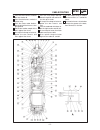

7 2 1 4 3 8 6 5 yp002000 how to use this manual this manual is intended as a handy, easy-to-read reference book for the mechanic. Comprehensive explanations of all installation, removal,disassembly, assembly, repair and inspection procedures are laid out with the individual steps in sequential order...

Page 6: Gen

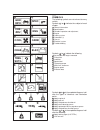

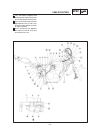

22 1 3 5 7 9 2 4 8 6 24 25 23 21 19 20 18 15 14 13 11 12 10 gen info spec eng carb elec chk adj trbl shtg 16 17 cool chas eb003000 symbols the following symbols are not relevant to every vehicle. Symbols 1 to 9 indicate the subject of each chapter. 1 general information 2 specifications 3 periodic i...

Page 7: Contents

Contents general information features 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Speedometer 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Specifications general specifications 2 . . . . . . . . . ...

Page 9: Gen

–1– features gen info note: general information features speedometer 1 speedometer 2 odometer / tripmeter / clock 3 “select” button 4 “reset” button this speedometer is equipped with: an odometer two tripmeters a clock odometer and tripmeter modes when set to “odo”, the motorcycle’s total mileage is...

Page 10: Spec

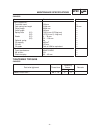

–2– general specifications spec specifications general specifications model fzs600 model code: 5dm7 5dm8 5dm9 fuel: type fuel tank capacity fuel reserve amount regular unleaded gasoline 20 l 3.5 l tire pressure: maximum load-except motorcycle loading condition a* front rear loading condition b* fron...

Page 11: Spec

–3– maintenance specifications spec maintenance specifications engine item standard limit valve spring: free length in / ex set length (valve closed) in / ex compressed pressure in / ex tilt limit in / ex direction of winding in / ex 40.09 mm 34.5 mm 131.4 153.0 n (13.4 15.6 kg) sss clockwise 37.5 m...

Page 12: Spec

–4– maintenance specifications spec chassis item standard limit front suspension: front fork travel fork spring free length fitting length collar length spring rate (k1) (k2) stroke (k1) (k2) optional spring oil capacity oil level oil grade 120 mm 316.8 mm 309.8 mm 183 mm 7.35 n / mm (0.75 kg / mm) ...

Page 13: Spec

–5– maintenance specifications spec electrical item standard limit ignition system: ignition timing (b.T.D.C.) advanced timing (b.T.D.C.) advance type 10 _ / 1,250 r / min 50 _ / 4,500 r / min digital type sss sss sss t.C.I.: pickup coil resistance t.C.I. Unit model / manufacturer 189 231 Ω y-l j4t0...

Page 14: Spec

–6– maintenance specifications spec item standard limit starting circuit cut-off relay: model / manufacture coil winding resistance g8r-30y-b / omron 202.5 247.5 Ω at 20 _ c sss sss fuel pump relay: model / manufacture coil winding resistance g8r-30y-b / omron 202.5 247.5 Ω at 20 _ c sss sss amperag...

Page 15: Spec

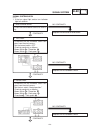

–7– d pass the brake hose out side of the speed sensor lead, then use a plastic clamp to fasten them. A use a plastic band to fasten to- gether the handlebar switch lead (l) and the handlebar. B use a plastic clamp to fasten to- gether the handlebar switch lead (left), clutch cable and starter cable...

Page 16: Spec

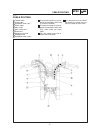

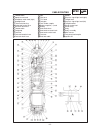

–8– cable routing spec 1 main switch lead 2 handlebar switch lead (left) 3 clutch cable 4 starter cable 5 rectifier / regulator 6 horn lead 7 box 8 air guide plate 9 fan motor lead 10 high tension code 11 relay assembly 12 flasher leray 13 battery 14 starter relay 15 battery positive (+) lead 16 sea...

Page 17: Spec

–9– cable routing spec 34 wire harness 35 relay 36 fuse box 37 to front brake switch 38 to battery negative (–) lead 39 to starter relay 40 starter motor lead 41 pickup coupler 42 sidestand switch coupler 43 oil level / neutral switch coupler 44 ac magneto coupler 45 oil level / neutral switch lead ...

Page 18: Spec

–10– cable routing spec g use a plastic clamp to fasten to- gether the wire harness and the frame. H push couplers into the lock stay of the frame after connecting wires. I use a plastic band to fasten to- gether wireharness, starter mo- tor lead, ac magneto lead, side- stand switch lead and oil lev...

Page 19: Spec

–11– cable routing spec o use a plastic clamp to fasten to- gether the sidestand switch lead and the frame. P pass the sidestand switch lead through the bottom of the coolant pipe. Q do not loosen the fan motor lead here. R pass the clutch cable and starter cable outside of high tension code#1. S us...

Page 20: Spec

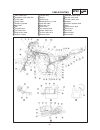

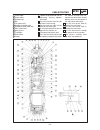

–12– 14 handlebar switch lead (right) 15 throttle cable 16 brake hose 17 guide wire 18 headlight lead 19 main switch lead 20 reservoir tank 21 air filter box bracket 22 swingarm bracket 23 engine bracket 1 rear brake switch lead 2 battery 3 reservoir tank over flow hose 4 cross tube 5 battery negati...

Page 21: Spec

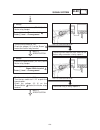

–13– cable routing spec c pass the t.P.S lead as shown, then install cover to the air filter case. D use a plastic clamp to fasten to- gether the throttle cables, head- light lead, handlebar switch (right) and speed sensor lead. E use a plastic locking tie to fasten the handlebar switch (right) and ...

Page 22: Spec

–14– o pass the battery negative lead and rear brake switch lead inside the air filter bracket of the frame. P pass the reservoir tank over flow pipe between the air filter case and cross tube, and then outside of engine bracket. Q use a clamp to fasten together the coolant reservoir hose and the br...

Page 23: Spec

–15– cable routing spec 1 throttle cable 2 speed sensor lead 3 handlebar switch lead (right) 4 headlight lead 5 thermostat housing 6 carburetor heater hose 7 reservoir tank hose 8 throttle cable 9 fuel pump 10 fuel filter 11 fuel tank breather hose 12 fuel tank drain hose 13 pipe 14 fuel hose 15 t.P...

Page 24: Spec

–16– cable routing spec 37 clutch cable 38 starter cable 39 ground lead 40 box 41 fan motor lead 42 rectifier / regulator lead 13 43 handlebar switch lead (left) 44 main switch lead 45 wire harness 46 to taillight 47 rear fender 48 clamp a tighten the ground lead and the thermostat housing together ...

Page 25: Spec

–17– k pass the wire harness inside of the rear fender rib. L pass the wireharness under the starter relay. M pass the starter motor lead un- der the joint of the harness, then pull upward. N set the fuel sender coupler in the cross pipe of the frame. O use a plastic clamp to fasten to- gether the w...

Page 26: Spec

–18– y align the connector position of rear turn signal light leads (left and right), then bend the rear w pass the rectifier / regulator lead, fan motor lead, handlebar switch lead (left), main switch lead, headlight lead, handlebar switch lead (right) and speed sensor lead through front side of th...

Page 27: Chk

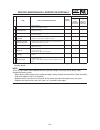

–19– periodic maintenance/lubrication intervals chk adj eb3000000 periodic inspections and adjustments periodic maintenance/lubrication intervals every no. Item checks and maintenance jobs initial (1,000 km) 6,000 km or 6 months (whichever comes first) 12,000 km or 12 months (whichever comes first) ...

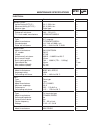

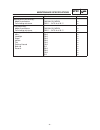

Page 28: Chk

–20– periodic maintenance/lubrication intervals chk adj note: every no. Item checks and maintenance jobs initial (1,000 km) 6,000 km or 6 months (whichever comes first) 12,000 km or 12 months (whichever comes first) 16 sidestand / centerstand s check operation. S lubricate and repair if necessary. √...

Page 29: Chk

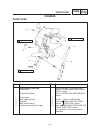

–21– adjusting the front fork legs chk adj warning caution: a b eas00152 chassis adjusting the front fork legs the following procedure applies to both of the front fork legs. Always adjust both front fork legs evenly. Uneven adjustment can result in poor han- dling and loss of stability. Securely su...

Page 30: Chas

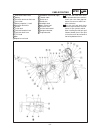

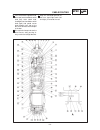

–22– order job name / part name q’ty remarks 1 2 3 4 5 removing the front fork front wheel front brake calipers front fender bolt (upper bracket) cap bolt bolt (lower bracket) front fork assembly (left / right) 1 2 2 2 1 / 1 remove the parts in the order listed. Refer to “front wheel and brake discs...

Page 31: Chas

–23– front fork chas order job name / part name q’ty remarks disassembling the front fork cap bolt o-ring spacer washer front fork spring dust seal oil seal clip bolt gasket damper rod / rebound spring inner tube / inner tube bushing oil seal washer 1 1 1 1 1 1 1 1 1 1 / 1 1 1 1 disassembly the part...

Page 32: Chas

–24– front fork chas order job name / part name q’ty remarks outer tube bushing oil flow stopper 1 1 / 1 refer to “assembling the front fork legs” section. For assembly, reverse the disassembly procedure. 14 15 23 nm (2.3 m kg) 30 nm (3.0 m kg).

Page 33: Chas

–25– front fork chas note: checking the front fork legs 1. Check: cap bolt o-ring 1 damage / wear replace. Eb703700 assembling the front fork legs 1. Fill: front fork leg (with the specified amount of the recom- mended fork oil) quantity (each front fork leg) 0.465 l yamaha fork and shock oil 10 w o...

Page 34: Elec

–26– signal system elec eb806000 electrical signal system circuit diagram.

Page 35: Elec

–27– signal system elec 3 main switch 4 battery 6 fuse (main) 35 flasher relay 40 turn switch 41 hazard switch 42 front turn signal light 43 rear turn signal light 52 fuse (signal) 60 relay 2.

Page 36: Elec

–28– signal system elec 1. Bulb and bulb socket s check the bulb and bulb socket for continu- ity. Replace the bulb and / or bulb socket. Continuity no continuity 2. Turn switch s disconnect the left handlebar switch cou- plers from the wire harness. S set the hazard switch “off” s check for continu...

Page 37: Elec

–29– signal system elec tester (+) lead brown terminal tester (–) lead frame ground 1 4. Voltage s connect the pocket tester (dc 20 v) to the flasher relay coupler. S turn the main switch to “on”. S check the voltage (12 v) of the “brown” lead at the flasher relay terminal. The wiring circuit from t...

Page 38: Elec

–30– signal system elec a b at the flasher light (left): tester (+) lead chocolate lead tester (–) lead frame ground 6. Voltage s connect the pocket tester (dc 20 v) to the bulb socket connector. S turn the main switch to “on”. S turn the turn switch to “l” / “r” or push the hazard switch. S check t...

Page 39: Elec

–31– clock elec tester (+) read brow tester (–) read frame ground 1. Voltage connect the pocket tester (dc 20 v) to the clock coupler. Turn the main switch to “on”. Check the voltage (12 v) on the “brown” lead at the clock terminal. The wiring circuit from the main switch to the clock coupler is fau...

Page 41

Color code b black . . . . . . Br brown . . . . . Ch chocolate . . . . Dg dark green . . . . G green . . . . . Gy gray . . . . L blue . . . . . . P pink . . . . . . Lg light green . . . . . O orange . . . . . R red . . . . . . Sb sky blue . . . . . W white . . . . . Y yellow . . . . . . B / l black ...