- DL manuals

- Yamaha

- Motorcycle

- GLADIATOR

- Ower's Manual

Yamaha GLADIATOR Ower's Manual

Summary of GLADIATOR

Page 1

Ger engine life er maintenance cost er exhaust smoke uces wear and tear printed in india 2y16(om-01)-271-08-06-e starter motor & disc brake g sg troke motor oil 0w40 4 starter motor & disc brake (starter motor & disc brake) owner's manual 5p4-f8199-e1 5p42 5p4-f8199-e1.

Page 2

Take necessary precautions during running-in period. Owner's manual yamaha motor india pvt. Limited all rights reserved. Any reprinting or unauthorised use without the written permission of yamaha motor limited is expressly prohibited. India pvt. Warning please read this manual carefullyand complete...

Page 3

Introduction congratulations on your purchase of the . This motorcycle has been produced using the latest technology in our modern plant, to provide you a happy, enjoyable and safe riding for many thousand kilometers and years. It represents the high degree of craftsmanship and reliability that have...

Page 4

Particularly important information is distinguished in this manual by the following notations: important manual information • • this manual should be considered a permanent part of this motorcycle and should remain with it even if the motorcycle is subsequently sold. Continually seeks advancements i...

Page 5

Road safety tips ....................................... 1-1 description ................................................ 2-1 left view ........................................................ 2-1 right view ...................................................... 2-2 controls/instruments ...............

Page 6

Table of contents air filter ........................................................... 6-10 carburetor adjustment ................................. 6-11 idle speed adjustment ................................. 6-12 throttle cable free play adjustment ............. 6-12 valve clearance adjustment .....

Page 7

Road safety tips safe riding 1. Before riding, you should learn to ride your motorcycle properly and all the control functions should be known to you. 2. Remember that there are no legal “rights” when it comes to survival as far as motorcyclists are concerned. The fact that you may be well within yo...

Page 8

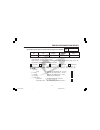

Description 2-1 left view 6. Toolkit (page 6-1) 7. Handle seat (page 3-10) 8. Drive chain free play check window (page 6-19) 9. Side panel (l.H.) lock (page 6-5) 10. Shift pedal (page 3-4) 1. Fuel cock (page 3-6) 2. Starter lever (page 3-7) 3. Fuse (page 6-26) 4. Battery (page 6-24) 5. Storage compa...

Page 9

Description 2-2 right view 11. Rear shock absorber (page 3-9) 12. Air filter (page 6-10) 13. Kick starter (page 3-7) 14. Seat (page 3-8) 15. Engine oil filler cap (page 6-8) 16. Rear brake pedal (page 3-4,6-17) st andard vehicle 15 11 12 13 14 16 fazer5yy8.Pmd 8/28/2006, 11:51 am 5.

Page 10

17. Clutch lever (page 3-3, 6-16) 18. Left hand switch (page 3-3) 19. Speedometer (page 3-2) 20. Main switch cum steering lock (page 3-1) 21. Fuel gauge (page 3-2) 22. Front brake lever (page 3-4, 6-16) 23. Throttle grip (page6-12) 24. Fuel tank cap (page 3-5) 25. Turn indicator switch (page 3-2) 26...

Page 11

Main switch cum steering lock the main switch controls the ignition and lighting systems. Its operation is described below. On: electrical circuits are switched on. The engine can be started. The key cannot be removed in this position. Off: engine will be shut off. All electrical circuits are switch...

Page 12

Instrument and control functions 3-2 1. Turn indicator light “ ” 2. High beam indicator light “ ” 3. Neutral indicator light “n” indicator lights turn indicator light " " neutral indicator light "n" high beam indicator light " " the indicator flashes when the turn switch is moved to the left or righ...

Page 13

Turn signal switch horn switch " " lights switch to signal a right-hand turn, push the switch to " ". To signal a left- hand turn, push the switch to " ". Once the switch is released it will return to the center position. To cancel the signal, push the switch in after it has returned to the center p...

Page 14

Instrument and control functions use both brakes simultaneously 3-4 1. Shift pedal shift pedal the shift pedal is located on the left side of the engine and is used in combination with the clutch when shifting. Use your toe or heel to shift up and your toe to shift down. 1. Front brake lever front b...

Page 15

Instrument and control functions 3-5 1 rear brake pedal rear brake pedal the rear brake pedal is on the right side of the motorcycle. Press down on the brake pedal to apply the rear brake. 1 1. Open fuel tank cap to open: insert the key and turn it 1/4 turn clockwise. The lock will be released and t...

Page 16

1. Arrow mark fuel cock the fuel cock supplies fuel from the tank to the carburetor while filtering it also. The fuel cock has three positions, which should be set as shown in the illustrations. Off: with the fuel cock in this position, fuel will not flow. Always set the fuel cock to this position w...

Page 17

Instrument and control functions 3-7 never mix oil in petrol 1. Arrow mark on: with the fuel cock in this position, fuel flows to the carburettor. Set the fuel cock to this position when starting the engine and while riding. 1. Arrow mark res: this indicates reserve. If you run out of fuel while rid...

Page 18

3-8 instrument and control functions 1. Open (bolt - 1 no.) 2. Open (bolt - 1 no.) opening of seat to remove open side panels as per instructions on page 6-5. Remove the two bolts 1 and 2 as shown in figure. Lift the front of the seat and slide forward to remove. 1. Seat holder 2. Projection to inst...

Page 19

1. Storage compartment storage compartment the storage compartment is located inside the l.H. Side cover 1. Spring preload adjusting ring 2. Position indicator rear shock absorber adjustment each shock absorber is equipped with a spring preload adjusting ring. Adjust spring preload as follows. Turn ...

Page 20

Instrument and control functions 3-10 1. Handleseat 1. Stay lock on saree guard stay lock for mounting helmet lock 1 1.

Page 21

Pre-operation checks 4-1 owners are personally responsible for their vehicle's condition. Your motorcycle's vital functions can start to deteriorate quickly and unexpectedly- even if it remains unused (for instance, if it is exposed to the elements). Any damage. Fluid leak or loss of tyre pressure c...

Page 22

Pre-operation checks 4-2 if waiting at traffic signal is for long, switch off the engine to protect the environment and to lower fuel consumption if any item in the pre-operation check is not working properly, have it inspected and repaired before operating the motorcycle. Warning fuel tank brake an...

Page 23

Operation and important riding points 1. Before riding this motorcycle, become thoroughly familiar with all operating controls and their functions. Consult a yamaha dealer regarding any control or function that you do not thoroughly understand. 2. Never start your engine or let it run for any length...

Page 24

Operation and important riding points starting a warm engine. The starter lever may not be required when the engine is warm. See the "running-in" section prior to operating the motorcycle for the first time. A. Shift pedal n. Neutral, 1,2,3,4,5 gear shift patterns shifting the transmission lets you ...

Page 25

If any engine trouble should occur during the "running-in" period, c o n s u l t ya m a h a d e a l e r operation and important riding points tips for reducing fuel consumption your motorcycle's fuel consumption depends to a large extent on your riding style. The following tips can help reduce fuel ...

Page 26

Operation and important riding points parking when parking the motorcycle, stop the engine and remove the ignition key. Turn the fuel cock to "off" whenever stopping the engine. The exhaust system is hot. Park the motorcycle in a place where pedestrians or children are not likely to touch the motorc...

Page 27

Warning periodic maintenance and minor repair periodic inspection, adjustment and lubrication will keep your motorcycle in the safest and most efficient condition possible. Safety is an obligation of the motorcycle owner. The maintenance and lubrication schedule chart should be considered strictly a...

Page 28

Keep your motorcycle tuned in perfect condition warning note : periodic maintenance and minor repair if you do not have necessary tools required during a service operation, take your motorcycle to a yamaha dealer for service. Modifications to this motorcycle not approved by yamaha may cause loss of ...

Page 29

Periodic maintenance and minor repair 6-3 preventive maintenance schedule valves spark plug carburetor check valve clearances, adjust if necessary. Check condition, gap; clean and reset if necessary. Check idle speed, starter lever operation. Clean, inspect & lubricate. (replace if necessary) check ...

Page 30

Periodic maintenance and minor repair preventive maintenance schedule every 10,000 km every 10,000 km 22 check operation/oil leakage. Rear shock absorber replace if necessary. Front forks 21 check operation/oil leakage. Repair if necessary. Steering bearing 20 check bearing assembly for looseness; c...

Page 31

1. Panel a panel removal and installa- tion the panels illustrated need to be removed to perform some of the maintenance described in this manual. Refer to this section each time a panel has to be removed or reinstalled. 2. Panel b periodic maintenance and minor repair 6-5 1. Lug 2. Panel a 3. Lug r...

Page 32

Periodic maintenance and minor repair 6-6 1. Lug 2. Lug 3. Lug removal of panel b loosen screw completely and follow t h e s a m e p r o c e d u r e a s f o r removing panel a. 1. Lug 2. Lug installation of panel a slide the panel towards the rear of the motorcycle for inserting the lug "2" in the s...

Page 33

A. Spark plug gap spark plug inspection the spark plug is an important engine component and is easy to inspect. The condition of the spark plug can indicate the condition of the engine. The ideal color on the white insulator around the center electrode is a medium-to-light tan color for a motorcycle...

Page 34

Note : always change engine oil at recommended intervals for optimum engine performance and engine life 1. Engine oil filler cap engine oil 1. Oil level measurement a. Place the motorcycle on the centerstand. Warm up the engine for several minutes. Be sure the motorcycle is positioned straight up wh...

Page 35

Always use only the recommended grade of engine oil 1 . Engine oil drain plug c. Remove the drain plug and drain the oil. D. Reinstall the drain plug and tighten it to the specified torque. Tightening torque: drain plug: 14.5 it-lb (2.0 m-kg) e. Fill engine with oil and install the dipstick. Recomme...

Page 36

1. Air filter case cover 2. Screw(4 nos) air filter the air filter should be cleaned at the specified intervals. It should be cleaned more frequently when riding in unusually wet or dusty areas. 1. Remove panel b. (see page 6-6 for removal and installation procedures.) 2. Remove the air filter case ...

Page 37

6-11 caution : caution : 7. Pull the air filter elements over the frame and install the air filter in the case. 8. Install the spring wire 9. Install the air filter case cover and panel do not twist element air cleaner. • make sure the air filter is properly seated in the air filter case. • the engi...

Page 38

Note : note : note : idle speed adjustment a diagnostic tachometer must be used for this procedure. 1. Attach the tachometer. Start the engine and warm it up for a few minutes at approximately 1,300 to 1,500 r/min. Occasionally rev the engine to 4,000 to 5,000 r/min. The engine is warm when it quick...

Page 39

Keep recommended tyre pressure in both the tyres 1. Free play 2. Locknut 3. Adjusting nut 1. Loosen the locknut. 2. Turn the adjusting nut in direction b to increase free play and in direction a to decrease free play. 3. Tighten the locknut. Valve clearance adjustment t h e c o r r e c t v a l v e c...

Page 40

Warning warning m i n i m u m t y r e tread depth : (front and rear) 1.0 mm maximum load* 153 kg front rear cold tyre pressure: single rider 25 psi 25 psi (1.75kg/cm ) 2 (1.75kg/cm ) 2 (2.25kg/cm ) 2 (2.25kg/cm ) 2 32 psi 36 psi with pillion rider tyre inflation pressure should be checked and adjust...

Page 41

Warning 1. It is dangerous to ride with a worn-out tyre. When a tyre tread begins to show lines, have a yamaha dealer replace the tyre immediately. Wheels to ensure maximum performance, long service, and safe operation, note the following: 1. Always inspect the wheels before a ride. Check for cracks...

Page 42

1. Locknut 2. Adjusting bolt 3. Free play (10~15 mm) clutch lever free play adjustment the clutch lever free play should be adjusted to 10 ~ 15 mm. If the free play is incorrect, adjust as follows. 1 . Loosen the locknut. 2. Turn the adjusting bolt at the clutch lever in direction b to increase free...

Page 43

1. Adjusting nut rear brake adjustment the rear brake pedal free play should be adjusted to 20 ~ 30 mm (instruction 2, a ) at the brake pedal end. Turn the adjusting nut in direction a to increase free play and in direction b to decrease free play. A. Freeplay • when it is impossible to make the pro...

Page 44

1 1 1. Brake pad wear indicator groove (x3) checking the front brake pads each front brake pad is provided with wear indicator grooves, which allow you to check the brake pad wear without having to disassemble the brake. To check the brake pad wear, check the wea indicator grooves. Ifa brake pad has...

Page 45

Drive chain slack check spin the wheel several times and find the tightest position of the chain. Check and/or adjust the chain slack while it's in this tightest position. Inspect the drive chain when the motorcycle is on the centerstand. Check the slack at the position shown in the illustration. No...

Page 46

1. Chain joint if the chain is disassembled, be sure the chain lock is placed in the correct direction when installing. 1. Adjusting nut 2. Cotter pin 3. Axle nut drive chain slack adjust- ment 1. Loosen the rear brake pedal free play adjusting nut. 2. Remove the cotter pin from the axle nut. 3. Loo...

Page 47

Caution : • 5. After adjusting, be sure to tighten each chain adjusting locknut. Then tighten the axle nut to the specified torque. Maintain chain slackness within specified limits as per specifications. • to maintain correct axle alignment, ensure the notch on the adjuster is on the same mark on le...

Page 48

Drive chain lubrication the chain consists of many parts which work with each other. If the chain is not maintained properly, it will wear out quickly. Therefore, the chain must be serviced regularly. This service is especially necessary when riding in dusty areas. 1. The drive chain should be lubri...

Page 49

Brake and shift pedal lubrication lubricate the pivoting parts. Brake and clutch lever greasing grease the pivoting parts. Multipurpose recommended grease : center and sidestand lubrication lubricate the pivoting and mating joints. Check to see that the center and sidestand move up and down smoothly...

Page 50

Caution : front fork inspection securely support the motorcycle so there is no danger of it falling over. 1. Visual check check for scratches or damage on the inner tube and excessive oil leakage from the front fork. 2. Operation check place the motorcycle on a level place. A. Hold the motorcycle in...

Page 51

Securely support the motorcycle so there is no danger of it falling over. Wheel bearings if there is play in the front or rear wheel hub or if the wheel does not turn smoothly, have a yamaha dealer inspect the wheel bearings. 1. Maximum level mark 2. Minimum level mark battery 1. Battery is located ...

Page 52

When inspecting the battery, be sure the breather hose is routed correctly. If the breather hose is positioned in such a way as to cause battery electrolyte or gas to exit onto the frame, structural and c o s m e t i c d a m a g e t o t h e motorcycle can occur. Battery electrolyte is poisonous and ...

Page 53

Battery storage 1. When the motorcycle will not be used for a month or longer, remove the battery, fully charge it and store it in a cool, dry place. Completely recharge the battery before reinstallation. 2. If the battery will be stored for longer than two months, check the specific gravity of the ...

Page 54

Periodic maintenance and minor repair 6-28 1. Screw - 2 nos. 2. Bolt - 1 headlight/parking bulb replacement if the head/parking light bulb burns out, replace the bulb as follows: 1. Remove the two screws from the head light cowling "1". 2. Loosen the bolt "2" below the headlight cowling. 3. Slide he...

Page 55

1. Indicator screws (1 no.) turn signal and taillight bulb replacement 1. Remove the screws and the lense. 2. Push the bulb inward and turn it counterclockwise. 3. Place a new bulb in the socket. Push the bulb inward and turn it clockwise until it engages into the socket. 4. I n s t a l l t h e l e ...

Page 56

1. Nut 2. Speedometer cable 1. Place the motorcycle on the centerstand. 2. Loosen the speedometer cable nut '1', & pull the cable '2' out from the front wheel 1. Cotter pin 2. Axle nut 3. Remove the cotter pin '1' and axle nut '2'. 4. Remove the wheel, make sure the motorcycle is properly supported....

Page 57

1. Stopper front wheel installation when installing the front wheel, reverse the removal procedure. Pay attention to the following points: 1. Make sure the slot in the gear meter assembly fits over the stopper on the front fork outer tube. 2. Make sure the axle nut is properly torqued and a new cott...

Page 58

1. Nut 2. Cotter pin 3. Tension bar 1. Place the motorcycle on the centerstand. 2. Remove the cotter pin and nut. Then remove the tension bar from the brake shoe plate. 1. Axle nut 2. Cotter pin 3. Brake rod 4. Brake adjusting nut 3. Remove the brake adjusting nut and brake rod from the brake cam le...

Page 59

Rear wheel installation 1. Install the rear wheel and the axle. 2. Install the axle nut. 3. Insert the brake rod into the brake cam lever and install the brake free play adjusting nut. 4. Install the tension bar onto the brake shoe plate and tighten the tension bar nut to the specified tightening to...

Page 60

Ask yamaha dealer to inspect. Compression check. Engine doesn't start, go to dry with black soot wet no compression. There is compression electrode. Plug and check remove spark use kick starter. Wipe clean with dry cloth and correct spark plug go to ignition check. Enough fuel no fuel go to compress...

Page 61

7-1 a. Cleaning frequent, thorough cleaning of your motorcycle will not only enhance its appearance but will improve its general performance and extend the useful life of many components. 1. Before cleaning the motorcycle: a. Block off the end of the exhaust pipe to prevent water entry; a plastic ba...

Page 62

8. Clean the seat with a vinyl upholstery cleaner to keep the cover pliable and glossy. 9. Automotive-type wax may be applied to all painted and chrome- p l a t e d s u r f a c e s . A v o i d combination cleaner waxes. Many contain abrasive which may mar the paint or protective finish. When finishe...

Page 63

Specifications 8-1 specifications model gladiator dimensions kerb weight :(with engine oil & 90% fuel in tank)- 127 kg. Engine : : overall length 2065 mm overall width 730 mm overall height 1100 mm seat height (upto rider) 800 mm (upto pillion rider) 870 mm wheelbase 1300 mm ground clearance 160 mm ...

Page 64

Specifications 8-2 spark plug : clutch type : transmission : chassis: type/manufacturer cr7hsa (ngk) spark plug gap 0.6-0.7 mm primary reduction system helical gear primary reduction ratio 3.4 (68/20) secondary reduction system chain drive secondary reduction ratio 3.214 (45/14) transmission type co...

Page 65

Specifications 8-3 wheels: brakes: suspension : shock absorber type: size: front : type single disc brake operation right hand lever fluid dot3 front telescopic fork rear : front coil spring/ oil damper rear front spoke wheel rear spoke wheel front 1.60 x 18 rear 1.60 x 18 rear : type drum brake ope...

Page 66

1. Key identification number key identification number the key identification number is stamped on the key. Record this number in the space provided and use it for reference when obtaining a new key. 1. Frame serial number the frame serial number is stamped into the steering head pipe on right hand ...

Page 67

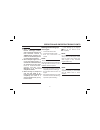

10-1 1. Check for any missing item(s), scratches in painted/plated part(s), saddle or other external visual damages and take corrective action. Check each of the following items individually and mention the corrective action (as per the recommended specifications) in the boxes provided. 2. Check for...

Page 68

Pre-delivery inspection report f. Wheels tyre : tyre pressure solo double (psi) front 25 25 rear 32 36 rim : runout - radial - 1.5 mm (max) - lateral - 1.5 mm (max) spokes : no loosenes g. Locks operation : • ignition • steering • fuel tank cap • side cover (l.H.) h. Fasteners specified torque (ft-l...

Page 69

B. Spark plug : recommended no. (cr7hsa-ngk) gap 0.6-0.7 mm c. Valve clearance : (cold condition) (if required) inlet 0.08 ~ 0.12 mm exhaust 0.10 ~ 0.14 mm (after matching of the mark on sprocket cam chain with mark on cylinder head casting and ensuring the piston at tdc of compression stroke.) d. K...

Page 70

Pre-delivery inspection report 10-4 c. Electrical a. Ignition switch operation b. Left hand switch operation & pass beam • horn • indicator • head light c. All bulbs - functioning d. Battery • electrolyte level • specific gravity • routing of breather pipe • fuse • routing of positive wire (red) bel...

Page 71

10-5 1. Operation of all the locks (ignition, steering, fuel tank cap, side cover l.H.). 2. Fuel cock lever operation and its reserve position; fuel tank capacity including reserve. 3. Operation and function of starter lever. 4. Operation of kick lever. 5. Operation of throttle. 6. Operation of hand...

Page 72

17. Location of storage and tool kit compartments and their use. 18. Procedure of opening and closing of l. H. Side panel. 19. Battery maintenance : checking of electrolyte level (to add only distilled water if required & to maintain its specified level) 20. Correct drive chain slackness (20 ~30 mm)...

Page 73

• list of components impacting emission 3 contents • do’s & don’ts for the motorcycle 1 • procedure for measurement of ‘co’ emission level. 3 greenbook.Pmd 8/28/2006, 2:24 pm 1.

Page 74

1 keep our environment clean. Please follow simple steps do’s ( ) 1 always use genuine ‘spare parts’ purchased from yamaha authorised dealers. 2 always use only genuine oils • 4t - 20w/40 sg grade - yamalube 4t 3 always keep your engine well tuned. Save environment and also improve fuel efficiency 4...

Page 75

Do’s and don’ts for the motorcycle 6 always drive with starter lever in off position. 7 use starter lever for minimum possible period (1 to 2 minutes) only to start and warm up engine (may be required only in winter) 8 if misfiring, get your motorcycle diagnosed & attended immediately without runnin...

Page 76

2. Procedure for measurement of “co” emission level 2.1 important : “co” measurement equipment must be duty calibrated. 2.2 check for “no leakage” from exhaust system. 2.3 starter lever should be in off position. 2.4 all electricals should be in off position. 2.5 set the idle speed of the engine in ...

Page 77

• longer engine life • lower maintenance cost • lower exhaust smoke • reduces wear and tear yamaha motor india private limited a-3, surajpur industrial area, noida dadri road surajpur - 201 306 (up) india printed in india 2y16(om-01)-271-08-06-e starter motor & disc brake sg 4 stroke motor oil 20w40...