- DL manuals

- Yamaha

- Motorcycle

- Libero

- Workshop Manual

Yamaha Libero Workshop Manual

Summary of Libero

Page 1

Workshop manual.

Page 2: Foreword

R-1 foreword this workshop manual has been prepared for use by the yamaha motor india private ltd. Authorised dealerships and their service personnel to attend to servicing of crux motorcycles. It is not possible to include entire service education into this manual. It is assumed that persons using ...

Page 3

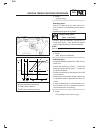

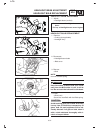

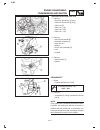

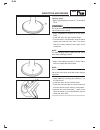

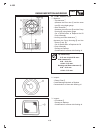

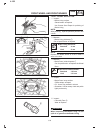

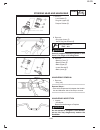

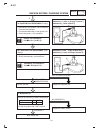

L-2 eng engine assembly and adjustments piston ring, piston and cylinder installation 1. Install in following sequence expander spacer (oil ring) ¿ side rails (oil ring) À 2nd ring Á top ring note : • make sure to install the piston rings so that the gtp top1/gtp-top 2 marks are lo- cated on...

Page 4

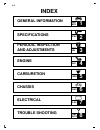

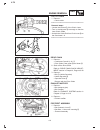

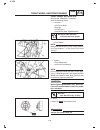

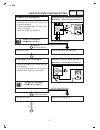

R-3 illustrated symbols illustrated symbols 1 to 8 are designed as thumb tabs to indicate the chapters number and content. Gen info spec insp adj eng carb chas elec trbl shtg illustrated symbols 16 to 21 in the exploded diagrams indicate the types of lubricants and lubrication points. 1. General in...

Page 5: Index

L-4 index general information gen info 1 trouble shooting trbl shtg 8 electrical elec 7 chassis chas 6 carburetion carb 5 engine eng 4 periodic inspection and adjustments insp adj 3 specifications spec 2.

Page 6

R-5 chapter 1 general information motorcycle identification frame serial number ....................................................... 1-1 engine serial number ...................................................... 1-1 important information preparation for disassembly .................................

Page 7

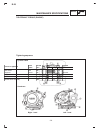

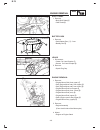

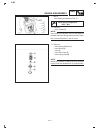

Gen info l-6 frame serial number the frame serial number ¿ is stamped into the right side of the steering head pipe. Engine serial number the engine serial number À is stamped on the top portion of rh crankcase. ( engine serial number does not contain year and month of production) note : designs and...

Page 8

Gen info r-7 preparation for disassembly 1. Remove all dirt, mud, dust and foreign ma- terial before disassembly. 2. Use proper tools and cleaning equipment. Refer to “special service tools”. 3. When disassembling the motorcycle, keep mated parts together. This includes gears, cylinder, piston and o...

Page 9

Gen info l-8 important information 1-3 warning if the circlip is fitted the wrong way it would cause it to jump off its groove and damage related components. Warning caution: do not use compressed air to spin the bearings dry. This causes damage to the bearing surfaces. All replacement parts 1. Use ...

Page 10

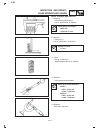

Gen info r-9 special service tools special tools 1-4 special service tools the appropriate special service tools are necessary for proper maintenance of the motorcycle. Using the correct special service tool will help to prevent damage caused by the use of improper tools or improvised techniques. Th...

Page 11

Gen info l-10 special service tools 1-5 this tool is used to remove the crank shaft from the crank case. 9. Crank shaft removal tool. Ysst - 265 these tools are used for installation of crank shaft. 10. Crank shaft installing tool with spacer (a) ysst - 266 (b) ysst - 267 to adjust carburettor pilot...

Page 12

Gen info r-11 special service tools 1-6 this tool is used to hold the tff plunger for loosening and tightening of hex socket head bolt 18. T -handle ysst - 213 this tool is used to remove t.F.F. Oil seal. 19. T.F.F. Oil seal removing tool. Ysst - 270 this tool is used when installing the tff oil sea...

Page 13

Gen info l-12 service instruments the following service instruments are necessary for complete and accurate tune up of motorcycle service instruments 1-7 this instrument is used for checking the engine rpm 1. Tachometer ysst - 613 2. Timing light (skc s14-121) 3. Compression gauge 4. Mutimeter 5. Ve...

Page 14

Gen info r-13 service instruments 1-8 9. Tyre pressure gauge 10. Vaccum gauge 11. Torque wrench (10-50 ft-lb) (20-100 ft-lb) 12. Feeler gauge this instrument is used for checking the tyre pressure this instrument is used for checking intake vaccum. This tool is used to tighten the nuts/bolts at a sp...

Page 15

Chapter 2. Specifications general specifications .................................................... 2-1 maintenance specifications engine ...................................................................................... 2-4 chassis ................................................................

Page 16

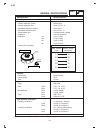

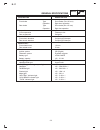

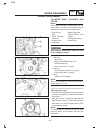

Spec r-15 description specification model : crux model code : 5ka1 engine model code: 5ka dimensions: overall length 1997 mm overall width 735 mm overall height 1055 mm seat height 780 mm wheelbase 1247 mm minimum ground clearance 150 mm minimum turning radius 2000 mm dry weight : 105.5 kg basic wei...

Page 17

Spec l-16 description specification clutch type : wet, multiple disc transmission : primary reduction system helical gear primary reduction ratio 68/18 (3.778 : 1) secondary reduction system chain drive secondary reduction ratio 42/14 (3.00 : 1) transmission type constant mesh 4-speed operation left...

Page 18

Spec r-17 description specification brake : front brake type drum brake (dia 130 mm) operation right hand operation rear brake type drum brake (dia 130 mm) operation right foot operation suspension : front suspension telescopic fork rear suspension swingarm shock absorbser : front shock absorber coi...

Page 19

Spec l-18 description specification cylinder : bore size 49.000 ~ 49.020 mm (in five grades) piston : piston to cylinder clearance 0.017 ~ 0.021 mm piston size “d” 48.962 ~ 48.981 mm cylinder piston grading (in five grades) measuring point “h” 4.5 mm piston offset 0.5 mm piston offset direction inta...

Page 20

Spec r-19 description specification cylinder head : * lines indicate straightedge measurement. Camshaft : drive method chain drive cam dimensions intake “ a ” 25.356 ~ 25.456 mm “ b “ 20.989 ~ 21.089 mm “ c “ 4.4055 mm exhaust “ a “ 21.360 ~ 21.460 mm “ b “ 21.001 ~ 21.101 mm “ c “ 4.4114 mm rocker ...

Page 21

Spec l-20 description specification stem outside diameter in 4.975 ~ 4.990 mm ex 4.960 ~ 4.975 mm in ex guide inside diameter in 5.000 ~ 5.012 mm ex 5.000 ~ 5.012 mm in ex stem to guide clearance in 0.005 ~0.0325 mm ex 0.0125 ~ 0.026 mm in ex stem runout limit 0.010 mm valve seat width in 0.9 ~ 1.1 ...

Page 22

Spec r-21 description specification clutch : friction plate thickness 2.90 ~ 3.10 mm quantity 5 pcs. Clutch plate thickness 1.05 ~ 1.35 mm quantity 4 pcs. 0.05 mm clutch spring free length 33 mm quantity 4 pcs. Minimum length 31.0 mm clutch release method inner push, cam push carburetor : i. D. Mark...

Page 23

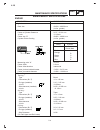

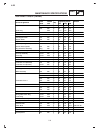

Spec l-22 2-8 maintenance specifications part to be tightened parts name thread size q'ty tightening torque remark nm m.Kg ft.Lb cylinder head bolt m8 4 22 2.2 17 bolt m6 2 10 1.0 7.2 spark plug - m12 1 17.5 1.75 12.6 cylinder head side cover bolt m6 2 10 1.0 7.2 valve cover - m45 2 17.5 1.75 13 cdi...

Page 24

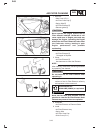

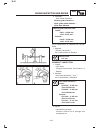

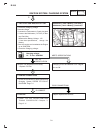

Spec r-23 tightening sequence 2-9 maintenance specifications cylinder head crankcase right - hand left - hand t tightening torque (engine) part to be tightened parts name thread size q'ty tightening torque remark nm m.Kg ft.Lb shift pedal bolt m6 1 10 1.0 7.2 segment screw m6 1 12 1.2 9 torx bolt st...

Page 25

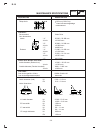

Spec l-24 description specification steering system : (as applicable) old new steering bearing type ball and race bearing retainer ball cage no./size of steel balls (upper) 22 pcs. / 3/16 in 19 pcs. / 1/4 in (lower) 19 pcs. / 1/4 in 16 pcs. / 1/4 in front suspension : front fork travel 110 mm fork s...

Page 26

Spec r-25 description specification front drum brake : type leading, trailing brake drum inside diameter 130mm lining thickness 4.0 mm shoe spring free length 36.5mm rear drum brake : type leading, trailing brake drum inside diameter 130mm lining thickness 4.0 mm shoe spring free length 36.5 mm free...

Page 27

Spec l-26 tightening torque (chassis) maintenance specifications note : 1. First tighten the ring nut approximately 45.5 nm (4.55 m.Kg 32.3 ft.Lb) by using the torque wrench then loosen the ring nut one turn. 2. Retighten the ring nut to specifications 2-12 *.

Page 28

Spec r-27 description specification voltage : 12v ignition system : ignition timing (b.T. D. C) 7º at 1400 r/min advancer type electrical type cdi : digitally controlled magneto model/manufacturer 5ka/denso sensor coil (color) 240 Ω ± 20% cdi unit model/manufacturer 5ka/ denso (japan) ignitioncoil :...

Page 29

Spec l-28 maintenance specifications circuit breaker : type fuse amperage for individual circuit x quantity : main 10a x 1pc. Reserve 10a x 1pc. 2-14.

Page 30

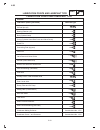

Spec r-29 general torque specifications this chart specifies torque for standard fasteners with standard i.S.O. Pitch threads. Torque speci- fication for special components or assemblies are included in applicable section of this book. To avoid warpage, tighten multi-fastener assemblied in a criss-c...

Page 31

Spec l-30 engine lubrication points (part name) lubricant type oil seal lips (all) bearing retainer (all) bolt (cylinder head) o-ring (cylinder head side cover and valve cover) crank pin connecting rod (big end) piston pin valve stem and valve guide oil seal (valve stem end) rocker arm shaft and roc...

Page 32

Spec r-31 lubrication points and lubricant type chassis lubrication points (part name) lubricant type gear unit (gear meter and drive) oil seal lips (all) pivot shaft (swingarm) pivoting points (brake pedal shaft and frame) ball and ball race (steering head) tube guide (right grip) pivoting points (...

Page 33

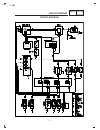

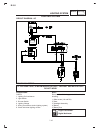

Spec l-32 engine lubrication route engine lubrication route 2-18 warning caution: do not damage crank case surfaces, otherwise oil leakage will start.

Page 34

Spec r-33 engine lubrication route engine lubrication route 2-19 warning caution: for improved performance, always use yamalube oil.

Page 35

Spec l-34 engine bearings engine bearings 2-20

Page 36

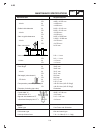

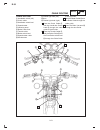

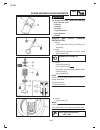

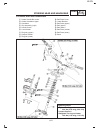

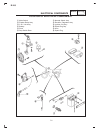

Spec r-35 cable routing ¿ handlebar switch (left) À clutch cable Á handlebar switch lead speedometer à indicator panel Ä brake cable front Å throttle cable Æ brake switch lead Ç speedometer cable È wireharness cable routing É flasher light lead (left) Ê horn Ë flasher light lead (right) a pass the c...

Page 37

Spec l-36 cable routing 2-22 ¿ headlight assembly À handlebar switch lead Á speedometer cable cable guide à clutch cable Ä air vent hose Å fuse Æ cdi unit Ç clamp È stop/tail light É flasher light lead (right) Ê flasher light Ë battery Ì battery breather hose Í neutral switch lead Î over flow hose Ï...

Page 38

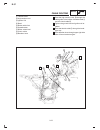

Spec r-37 cable routing ¿ throttle cable À high tension cord Á ignition coil band à brake cable front Ä speedometer Å brake switch lead Æ clutch cable Ç breather hose a pass the high tension cord À through the cable guide to the inside of throttle cable ¿ and the clutch cable Æ. B tighten the ground...

Page 39

Spec l-38 cable routing ¿ clamp À rectifier regulator Á flasher relay flasher light lead a clamp the battery positive (+) lead to the batterybox. B insert hose air bent to holder of frame. ¿ À Á Ã Ä Å Æ b a Á Ã stop/tail light lead Ä wireharness Å battery Æ cdi unit assy. 2-24.

Page 40

R-39 chapter 3 periodic inspection and adjustments periodic maintenance / lubrication intervals ....... 3-1 side cover, seat and fuel tank removal ................................................................................... 3-3 installation .......................................................

Page 41

Insp adj l-40 introduction/ periodic maintenance/lubrication intervals 3-1 introduction this chapter includes all information necessary to perform recommended inspections and adjust- ments. These preventive maintenance procedures, if followed, will ensure more reliable motorcycle operation and a lon...

Page 42

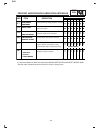

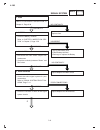

Insp adj r-41 periodic maintenance/lubrication intervals 3-2 22 21 20 19 18 17 sno item free s e r v i c e s operation ii i vi iv iii v paid every 2000km control cables, - throttle battery centerstand and side stand nuts, bolts and fasteners drive chain rear shock absorber check operation/oil leakag...

Page 43

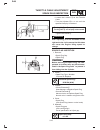

Insp adj l-42 removal side cover (lh) 1. Remove • side cover (lh) ææææææææææææææææææææææææææææææææææ removal steps : • open the lock ¿ using main switch key. • pull the lug À towards you to remove it from the fuel tank. • slide the side cover towards the rear end of the motorcycle for removing the l...

Page 44

Insp adj r-43 side covers, seat and fuel tank 3-4 2. Remove • bolt (fuel tank) ¿ • plate À • damper rubber Á • fuel tank removal fuel tank 1. Disconnect • fuel hose note : • position the fuel cock ¿ to the ‘off’, dis- connect the fuel hose. • place a rag under the fuel line to absorb any spilt fuel....

Page 45

Insp adj l-44 1 installation reverse the removal procedure. Note the following points. 1. Install • fuel tank ¿ • damper rubber À • plate Á • bolt • fuel hose à side covers, seat and fuel tank 3-5 note : • keep the projection on plate Á downward. 2. Install • seat • bolts ¿ and À note : • insert the...

Page 46

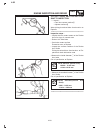

Insp adj r-45 valve clearance checking and adjustment valve clearance checking and adjustment note : valve clearance checking and adjustment should be made with the engine in cold condi- tion, at room temperature. When the valve clearance is to be measured or adjusted, the piston must be at top dead...

Page 47

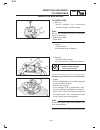

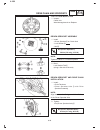

Insp adj l-46 valve clearance checking and adjustment ææææææææææææææææææææææææææææææææææ checking steps : measurement steps : • rotate the crankshaft anticlockwise to align the slit ç third mark on the rotor with the sta- tionary pointer è on the crankcase cover lh when the piston is at top dead cen...

Page 48

Insp adj r-47 1 2 idling co. Measurement and adjustment idling co. Measurement and adjustment 1. Start the engine and let it warm up by run- ning the motorcycle approx. 4 kms. 2. Attach : • inductive tachometer to the spark plug lead. 3. Check : • engine idling speed (standard) out of specification ...

Page 49

Insp adj l-48 idling ‘co’ measurement and adjustment/ throttle cable adjustment 5. Adjust : • ‘co’ concentration ææææææææææææææææææææææææææææææææææ adjustment steps : • turn the pilot screw ¿ in or out until the speci- fied ‘co’ concentration is obtained. Note : for adjusting the engine idling speed...

Page 50

Insp adj r-49 throttle cable adjustment/ spark plug inspection • loosen the locknut ¿ on the throttle cable. • turn the adjuster À in or out until the specified free play is obtained. • tighten the locknut ¿. Spark plug inspection 1. Remove : • spark plug cap • spark plug 2. Check : • spark plug typ...

Page 51

Insp adj l-50 spark plug inspection/ ignition timing checking procedure 3-11 6. Install : • spark plug note : • before installing a spark plug, clean the gas- ket surface and plug surface. • if a torque wrench is not available, a good estimate of the correct tightening torque is to finger tighten ¿ ...

Page 52

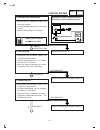

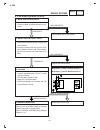

Insp adj r-51 r.P.M. B.T.D.C. 7 0.5 a d b c std. + 28 1.5 + 800 r.P.M 2,000 r.P.M 5,500 r.P.M 1,400 r.P.M auto advance 1 2 3 4 ignition timing checking procedure 3. Check : • ignition timing ********************************************* checking steps : • start the engine and let it warm up for sev-...

Page 53

Insp adj l-52 compression pressure measurement compression pressure measurement note : insufficient compression pressure will result in performance loss. 1. Check : • valve clearance out of specification Ÿ adjust. Refer to “valve clearance adjustment” section. Page no 3-6 2. Start the engine and let...

Page 54

Insp adj r-53 engine oil level inspection/ engine oil replacement engine oil level inspection 1. Stand the motorcycle on a level surface us- ing the center stand. Note: make sure the motorcycle is upright when in- specting the oil level. 2. Start the engine and let it warm up for a few minutes. 3. T...

Page 55

Insp adj l-54 engine oil replacement/ exhaust system inspection 4. Install : • drain plug ¿ with washer 5. Fill : • oil in crankcase 6. Check : • engine oil level refer to “engine oil level inspection” section page no 3-14 7. Install • dip stick (oil level gauge) exhaust system inspection 1. Inspect...

Page 56

Insp adj r-55 air filter cleaning 1. Remove: • side cover (r.H.) • air filter case cap ¿ • spring wire À • air filter element Á • element guide 2. Inspect: • air filter element Á damaged Ÿ replace. 3. Clean: • air filter element Á use kerosene to clean the element. Note : after cleaning, remove the ...

Page 57

Insp adj l-56 clutch cable adjustment clutch cable adjustment 1. Check : • clutch cable free play ç out of specification Ÿ adjust, 2. Adjust: • clutch cable free play ææææææææææææææææææææææææææææææææææ adjustment steps: lever side • loosen the locknut ¿ • turn the adjuster À in or out until the spec...

Page 58

Insp adj r-57 front brake adjustment/ rear brake adjustment front brake adjustment 1. Check : • brake lever free play a out of specification Ÿ adjust. 2. Adjust : • brake lever free play ææææææææææææææææææææææææææææææææææ adjustment steps : lever side • loosen the locknut ¿. • turn the adjuster À in...

Page 59

Insp adj l-58 rear brake adjustment/ brake shoe inspection ææææææææææææææææææææææææææææææææææ adjustment steps : • turn the adjuster ¿ in or until the specified free play is obtained. ææææææææææææææææææææææææææææææææææ 3. Adjust : • brake light switch refer to “brake light switch adjustment”. As giv...

Page 60

Insp adj r-59 drive chain slack adjustment drive chain slack adjustment note: • before checking and adjusting, rotate the rear wheel several revolutions and check the slack at several points to find the tight- est point. • check and if necessary adjust the drive chain slack with the rear wheel in th...

Page 61

Insp adj l-60 drive chain slack adjustment 3-21 warning caution: do not loosen the axle nut after tightening the torque. If the axle nut grooves is not aligned with the cotter pin hole, align the groove with the hole by tightening up the axle nut. Warning always use a new cotter pin. æææææææææææææææ...

Page 62

Insp adj r-61 steering head inspection 3-22 warning securely support the motorcycle so that there is no danger of it falling over. Steering head inspection 1. Stand the motorcycle on a level surface. Note : stand the motorcycle on its center stand. 2. Elevate the front wheel by placing a suit- able ...

Page 63

Insp adj l-62 steering head inspection • check the steering stem by turning it lock to lock. If there is any binding, remove the steer- ing stem assembly and inspect the steering bearings. Refer to “steering head and handle- bar” section in chapter 6 page no 6-29 • install the damper rubber and ring...

Page 64

Insp adj r-63 front fork inspection front fork inspection 1. Stand the motorcycle on a level surface. 2. Check: • inner tube scratches/damage replace. • oil seal excessive oil leakage replace 1. Hold the mitorcycle upright on level surface and apply the front brake 2. Check: • operarion push dow...

Page 65

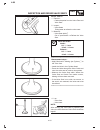

Insp adj l-64 rear shock absorber adjustment ææææææææææææææææææææææææææææææææææ adjustment steps: • turn the adjuster ring in or out. ææææææææææææææææææææææææææææææææææ tyre inspection 1. Measure : • tyre inflation pressure out of specification Ÿ adjust. 3-25 adjustment numbers: standard 3 minimum 1...

Page 66

Insp adj r-65 tyre inspection 2. Inspect : • tyre surfaces wear/damage Ÿ replace ¿ tread depth À side wall Á wear indicator • be sure to install the correct tube when us- ing tube type tyres. • while installing tyre on wheel always check that the tyre lining is seated uniformly with respect to wheel...

Page 67

Insp adj l-66 spoke inspection and tighteneing 3-27 warning never attempt to make any repairs to the wheel rim. Wheel inspection 1. Inspect : • wheels damage/bends Ÿ replace. Note : always balance the wheel when a tyre or wheel has been changed or replaced. Spokes inspection and tightening 1. Inspec...

Page 68

Insp adj r-67 max min 2 1 battery inspection electrical 3-28 warning caution: when inspecting the battery, make sure that the breather hose is routed correctly. If the breather hose is positioned in such a way as to allow battery electrotyte gas to come into contact with the frame, this could dam- a...

Page 69

Insp adj l-68 battery installation replace the battery if: • battery voltage does not rise to a specific value or bubbles fail to rise during charging. • sulphation of one or more cells occurs, (as indicated by the plates turning white, or ma- terial accumulating in the bottom of the cell ). • speci...

Page 70

Insp adj r-69 fuse inspection fuse inspection 1. Remove: • side cover (left) refer to “seat, side covers and fuel tank” section page no 3-3 • fuse holder ¿ 2. Inspect : • fuse ææææææææææææææææææææææææææææææææææ inspection steps : • connect the multimeter to the fuse and check it for continuity. Note...

Page 71

Insp adj l-70 headlight beam adjustment/ headlight bulb replacement headlight beam adjustment 1. Adjust : • headlight beam (vertical) headlight bulb replacement 1. Remove: • cowling (as applicable) • headlight assy. 2. Disconnect : • headlight beam leads • bulb cover 3. Remove : • bulb note : unhook...

Page 72

R-71 chapter 4 engine overhaul engine removal side covers, seat and fuel tank removal ................ 4-1 engine oil drain ................................................................... 4-1 battery .................................................................................... 4-1 carbure...

Page 73

Eng l-72 bearings and oil seals ..................................................... 4-31 circlips and washers ....................................................... 4-31 engine assembly and adjustment ................................ 4-32 crankshaft ..................................................

Page 74

Eng r-73 engine removal engine removal 4-1 it is not necessary to remove the engine in order to remove the following parts. • cylinder head • cylinder • piston • clutch • cdi magneto side covers, seat and fuel tank removal 1. Remove : • side covers (lh and rh) • seat • fuel tank refer to the “side c...

Page 75

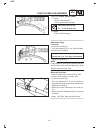

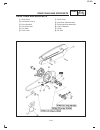

Eng l-74 3 engine removal 4-2 footrest assembly 1. Remove: • bolt (footrest) 4 nos ¿ • bolt axle - lower rear mounting À • footrest assembly drive chain 1. Remove : • crankcase cover#1 (l.H.) ¿ • drive chain case upper À and lower Á 2. Slack off the drive chain refer to “drive chain slack adjust- me...

Page 76

Eng r-75 engine removal 4-3 1 2 shift pedal 1. Remove • bolt (shift pedal) ¿ • shift pedal À battery box 1. Remove • bolt (battery box) ¿ 2 nos • battery box À leads 1. Disconnect: • stator coil lead coupler ¿ • sensor coil lead coupler À 2. Remove : • spark plug cap engine removal 1. Remove : • eng...

Page 77

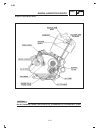

Eng l-76 engine disassembly engine disassembly 4-4 cylinder head, cylinder and piston note: with engine mounted on motorcycle, the cyl- inder head, camshaft and cylinder can be maintained by removing the following parts. Warning caution: before engine disassembly clean the outer body of engine prope...

Page 78

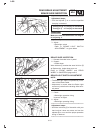

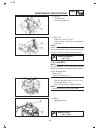

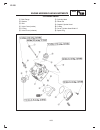

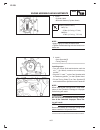

Eng r-77 engine disassembly 4-5 6. Remove : • bolt (cam sprocket) ¿ • plate washer (cam sprocket) À • cam sprocket Á note : hold the nut rotor with socket spanner for opening cam sprocket bolt. Fasten a safety wire to the timing chain to prevent it from falling in the crankcase. 8. Remove : • guide ...

Page 79

Eng l-78 maintenance specifications 4-6 10. Remove : • piston pin circlip ¿ 2 nos • piston pin À , using piston pin replacer • piston Á note : before removing the piston pin circlip, cover the crankcase with a clean cloth to prevent the circlip from falling into the crankcase cavity. 9. Remove : • d...

Page 80

Eng r-79 engine disassembly 4-7 3. Remove: • pressure plate bolts ¿ (4 no’s) • clutch springs À ( 4 no’s) • pressure plate Á with push rod 1 • friction plates à (4 no’s) • clutch plates (3 no’s) note : loosen the pressure plate bolts in a crisscross pattern. 4. Remove : • ball Ä clutch note : the cl...

Page 81

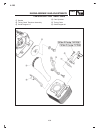

Eng l-80 engine disassembly 4-8 6. Remove : • clutch boss nut ¿ • lock washer À • clutch boss Á • thrust washer • clutch housing à • spacer Ä • washer Å 1. Remove : • gear pump drive ¿ • screw (oil pump-2 nos) À • oil pump assembly Á • gasket (oil pump) • oil strainer 8. Remove • nut • plate washer ...

Page 82

Eng r-81 engine disassembly 4-9 kick starter disassembly 1. Remove : • spacer ¿ • torsion spring À • washer Á • kick gear • clip à • kick axle Ä shift shaft note : the shift shaft can be removed while the engine is mounted by removing the following parts. • shift pedal • kick crank assy. • crankcase...

Page 83

Eng l-82 engine disassembly 4-10 cdi magneto removal 1. Remove : • nut (magneto) • plain washer note : • loosen the nut magneto while holding the magneto À with magneto holder ¿ 2. Attach • bush ¿ note : • place the bush on the crankshaft threaded end before using the magneto puller to avoid thread ...

Page 84

Eng r-83 engine disassembly 4-11 2. Remove : • bolts (crankcase lh-8 nos) note : • loosen the bolts in a crisscross pattern. • loosen each bolts 1/4 turn at a time and re- move them after all are loose. Warning caution: • do not use the flat head screw driver ex- cept at the separating slot. • separ...

Page 85

Eng l-84 engine disassembly: transmission and shifter 4-12 transmission and shifter 1. Remove : • shift fork guide bar ¿ (short) • shift fork guide bar À (long) • shift cam Á • shift fork -c • shift fork -r à • shift fork - l Ä 2. Remove : • axle drive assembly À • axle main assembly ¿ • push rod # ...

Page 86

Eng r-85 disassembly of cylinder head, rocker arms, camshaft and valves 1. Loosen : • valve adjuster locknuts ¿ • valve adjusters À 2. Remove : • stopper plate Á by opening allen bolt engine disassembly 4-13 3. Attach • rocker arm shaft puller ¿ 4. Remove : • rocker arm shafts by tightening the pull...

Page 87

Eng l-86 engine disassembly 4-14 7. Attach valve spring compression tool ¿ 8. Remove : • valve cotters À note : valve spring compressor tool is to be attached between the valve spring retainer and the valve face (inlet and exhaust) one at a time. 9. Remove : • valve spring retainer ¿ • valve spring ...

Page 88

Eng r-87 inspection and repair inspection and repair: cylinder head 4-15 cylinder head 1. Remove : • carbon deposits from combustion chambers using a rounded scraper. Note : do not use a sharp instrument to avoid dam- aging or scratching : • spark plug threads • valve seats 2. Inspect : • cylinder h...

Page 89

Eng l-88 inspection and repair:valve seats 4-16 4. Lap : • valve face • valve seat note : after refacing the valve seat or replacing the valve, the valve seat and valve face should be lapped. ææææææææææææææææææææææææææææææææææ measurement steps : • apply mechanic’s blueing dye (dykem) è to the valve...

Page 90

Eng r-89 inspection and repairs 4-17 ææææææææææææææææææææææææææææææææææ lapping steps : • apply coarse lapping compound ç to the valve face • apply molybdenum disulfide oil to the valve stem. • install the valve into the cylinder head. • turn the valve in one direction using the valve lapping tool u...

Page 91

Eng l-90 inspection and repair : valve springs and valves 4-18 2. Measure : • spring tilt ç out of specification Ÿ replace valve springs and valves 1. Measure : • valve spring free length ç out of specification Ÿ replace. 3. Check • spring contact face wear/pitting/scratches Ÿ replace 5. Measure : v...

Page 92

Eng r-91 engine inspection and repair 4-19 stem-to-guide clearance limit : intake : 0.005 ~ 0.0325 mm exhaust : 0.0125 ~ 0.026 mm 7. Measure : • runout (valve stem) out of specification Ÿ replace out of specification Ÿ replace the cylinder head 6. Calculate : stem guide clearance stem-to-guide clear...

Page 93

Eng l-92 engine inspection and repair 4-20 rocker arms and rocker arm shafts inspection 1. Inspect : • cam lobe contact surface ¿ • adjuster surface À wear/pitting/scratches/blue discoloration Ÿ replace ææææææææææææææææææææææææææææææææææ inspection steps : • inspect the two contact areas on the rock...

Page 94

Eng r-93 engine inspection and repair 4-21 timing chain, sprockets and chain guides 1. Inspect : • timing chain wear out/stiffness/damage Ÿ replace the chain and the sprockets as a set. 2. Inspect : • cam sprocket wear/damage Ÿ replace the cam sprocket and the timing chain as a set. ¿ 1/4 tooth gap ...

Page 95

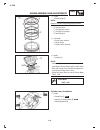

Eng l-94 engine inspection and repair 4-22 cylinder and pistons 1. Inspect : • cylinder and piston walls vertical scratches Ÿ rebore or replace the cylinder and the piston 2. Measure : • piston-to-cylinder clearance ææææææææææææææææææææææææææææææææææ measurement steps : 1st step : • measure the cyli...

Page 96

Eng r-95 1 5mm engine inspection and repair 4-23 piston ring inspection 1. Measure : • side clearance out of specification Ÿ replace the piston and the piston rings as a set note : remove the carbon deposits from the piston ring grooves and rings before measuring the side clearance. 2. Position : • ...

Page 97

Eng l-96 piston pin inspection 1. Inspect : • piston pin blue discoloration/grooves Ÿ replace and inspect the lubrication system 2. Measure : • piston pin-to-piston clearance ææææææææææææææææææææææææææææææææææ measurement steps. • measure the piston pin outside diameter ç using a micrometer. If out ...

Page 98

Eng r-97 engine inspection and repair 4-25 5. Inspect : • crankshaft journal oil passage clogged Ÿ blow the oil passage with compressed air 4. Inspect : • crankshaft sprocket ¿ wear/damage Ÿ replace crankshaft • bearing À wear/crack/damage Ÿ replace crankshaft 3. Measure : • crank width ç out of spe...

Page 99

Eng l-98 2 1 engine inspection and repair 4-26 primary drive gear inspection 1. Inspect : • primary drive gear teeth ¿ • primary driven gear teeth À wear/damage Ÿ replace both gears as a set. Note : refer the general specification for grading. Excessive noise during operation Ÿ replace both gears as...

Page 100

Eng r-99 engine inspection and repair 4-27 push rod inspection 1. Inspect : • ball ¿ • push rod #1 À wear/damage/bend Ÿ replace 2. Inspect : • push rod # 2 ¿ wear/damage/bend Ÿ replace 6. Inspect : • dogs on the primary driven gear ¿ scoring/wear/damage Ÿ deburr or replace • clutch boss splines À sc...

Page 101

Eng l-100 engine inspection and repair 4-28 shift fork shift cam inspection 1. Inspect : • shift fork follower ¿ • shift fork pawl À scoring/bends/wear/damage Ÿ replace 2. Inspect : • shift cam grooves ¿ wear/damage/scratches Ÿ replace • shift cam segment À wear/damage Ÿ replace 3. Check : • shift f...

Page 102

Eng r-101 engine inspection and repair 4-29 5. Measure : • axle runout (main and drive) use a centering device and a dial gauge ¿ out of specifications Ÿ replace the bent axle 6. Inspect : • gear teeth blue discoloration/pitting/wear Ÿ replace • mated dogs rounded edges/cracks/missing portions Ÿ rep...

Page 103

Eng l-102 engine inspection and repair 4-30 oil pump inspection 1. Measure : • tip clearance ç (between the inner rotor ¿ and the outer rotor À) using feeler gauge. • side clearance è (between the outer rotor À and the pump housing Á) using feeler gauge out of specification Ÿ replace the oil pump as...

Page 104

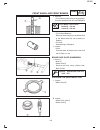

Eng r-103 1 2 engine inspection and repair 4-31 circlips and washers 1. Inspect : • circlips ¿ • washers damage/looseness/bends Ÿ replace bearings and oil seals 1. Inspect : • bearings ¿ clean with solvent and lubricate with multigrade oil, then rotate the bearing using finger roughness/noise Ÿ repl...

Page 105

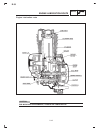

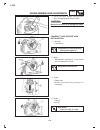

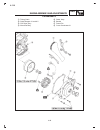

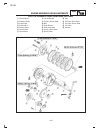

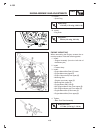

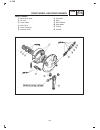

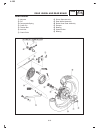

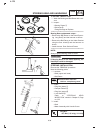

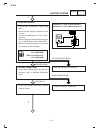

Eng l-104 engine assembly and adjustments engine assembly and adjustments 4-32 valves, rocker arm and camshaft ¿ valve cotters À valve spring retainer Á valve springs valve stem seal à valve spring seat Ä valve (intake) Å valve (exhaust) Æ lock nut Ç adjuster È valve rocker arm É rocker arm shaft Ê ...

Page 106

Eng r-105 engine assembly and adjustments 4-33 warning for engine assembly, replace the following parts with new ones : • o-rings • gaskets • oil seals • copper washers • lock washers • circlips valves and valve springs installation 1. Deburr : • valve stem end ¿ using an oil stone for smoothing. 2....

Page 107

Eng l-106 engine assembly and adjustments 4-34 4. Install : • plate ¿ • bolt À 3. Install : • rocker arm • rocker arm shaft ¿ by pushing it in completely 2. Apply : • molybdenum disulfide oil on the rocker arm and rocker arm shaft camshaft and rocker arm installation 1. Lubricate : • camshaft ¿ 5. S...

Page 108

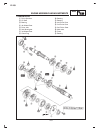

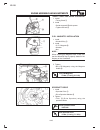

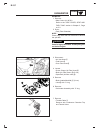

Eng r-107 engine assembly and adjustments 4-35 crankshaft ¿ crank pin À crank shaft Á connecting rod big end bearing à crankshaft bearing Ä wood-ruff key Å bearing Æ spacer.

Page 109

Eng l-108 engine assembly and adjustments 4-36 crankshaft 1. Insert : • crankshaft in the crankcase (l.H.) 2. Attach : • crankshaft installing tool on crankshaft warning caution: to avoid scratching the crankshaft and to ease the installation procedure, apply engine oil onto each bearing and crankca...

Page 110

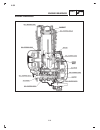

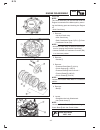

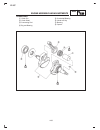

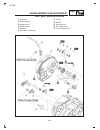

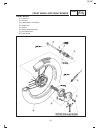

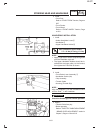

Eng r-109 engine assembly and adjustments 4-37 transmission ¿ drive sprocket À oil seal Á bearing 4th wheel gear à drive axle à 2nd wheel gear Å 3rd wheel gear Æ clutch dog È bearing É bearing Ê 4th pinion gear Ë 3rd pinion gear Ì 2nd pinion gear Í main axle Î plate Ï bearing.

Page 111

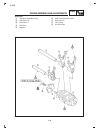

Eng l-110 engine assembly and adjustments 4-38 shifter ¿ shift fork guide bar (long) À shift fork # r Á shift fork # l shift cam à segment Ä shift fork guide bar (short) Å shift fork # c Æ torx screw Ç pin shaft cam.

Page 112

Eng r-111 engine assembly and adjustments 4-39 transmission, shift cam and shift fork installation 1. Measure : • axle main assembled length ç 2. Install : • push rod # 2 ¿ in the axle main. 4. Check : • shift cam operation improper operation Ÿ reassemble/repair note : check the transmission and shi...

Page 113

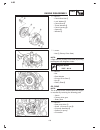

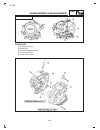

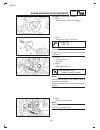

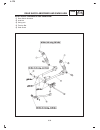

Eng l-112 engine assembly and adjustments 4-40 crankcase ¿ crankcase #1 (lh) À dowel pins Á crankcase breather hose crankcase #2 (rh) Ã holder clutch cable tightening sequence.

Page 114

Eng r-113 engine assembly and adjustments 4-41 crankcase lh 1. Apply : • sealant on the crankcase mating surfaces 2. Install : • dowel pins ¿ note : do not allow any sealant to come in contact with the oil galleries ç and è as shown in the fig- ure. Sealant yamaha bond no. 1215: 90890-85505 3. Insta...

Page 115

Eng l-114 engine assembly and adjustments 4-42 cdi magneto ¿ timing chain À guide stopper # 1 and # 2 Á cdi rotor assy wood-ruff key à stator assy. Ä gasket Å dowel pin Æ cover crankcase #1.

Page 116

Eng r-115 engine assembly and adjustments 4-43 sprocket drive 1. Install • sprocket drive ¿ • drive sprocket washer À 2. Tighten • bolt Á (drive sprocket) using the sprocket holder. Timing chain and guide stopper#2 1. Install • timing chain ¿ 2. Install • guide stopper#2 À with spacer • tighten the ...

Page 117

Eng l-116 engine assembly and adjustments 4-44 shift shaft and kick starter ¿ shift shaft À torsion spring Á stopper lever return spring à segment Ä kick starter assembly Å circlip Æ washer Ç kick idle gear È kick shaft assy. É cover crankcase # 2.

Page 118

Eng r-117 engine assembly and adjustments 4-45 5. Install : • shift shaft assembly Á note : apply oil to the stopper pin and hook the spring ends on the stopper pin 3. Install : • stopper lever ¿ • spring À 4. Tighten • bolt stopper lever Á note : hook the spring ends on the stopper lever ¿ and the ...

Page 119

Eng l-118 engine assembly and adjustments 4-46 kick starter installation 1. Install : • kick axle assembly ¿ • kick gear clip À • torsion spring Á note : turn the torsion spring clockwise and hook into the proper hole ç in the crankcase. 2. Install : following parts on the axle drive Ä • circlip ¿ •...

Page 120

Eng r-119 engine assembly and adjustments 4-47 ¿ clutch spring À pressure plate Á push plate push rod #1 Ã friction plate Ä clutch plate Å clutch boss Æ thrust washer Ç primary driven gear È ball É push rod # 2 Ê push lever axle Ë primary drive gear Ì rotary filter clutch, primary drive gear and oil...

Page 121

Eng l-120 engine assembly and adjustments 4-48 primary drive gear installation 1. Install : • primary drive gear ¿ • key • washer À 2. Tighten : • nut Á note : hold the rotor with magneto holder then tighten the primary drive gear nut. 4. Install • rotary filter note : align the rotary filter dog ç ...

Page 122

Eng r-121 engine assembly and adjustments 4-49 4. Bend : • lock washer tab (along a flat side of the end) 5. Install : • friction plate ¿ 5 nos • clutch plate À 4 nos note : • install the clutch plates and friction plates al- ternately on the clutch boss, starting with a friction plate and ending wi...

Page 123

Eng l-122 a b aligned non aligned engine assembly and adjustments engine assembly and adjustments 4-50 6. Install : • ball 7. Install : • push rod # 1 ¿ • push plate À • plate washer Á • nut (push rod # 1) 8. Install : • pressure plate ¿ • compression springs À • bolts Á (clutch spring) note : match...

Page 124

Eng r-123 1 2 engine assembly and adjustments 4-51 engine assembly and adjustments warning caution: take care not to overtighten the adjuster À and remove the freeplay between both push rods. • hold the adjuster to prevent it from moving and tighten the locknut to specification • tighten the locknut...

Page 125

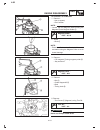

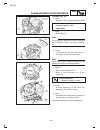

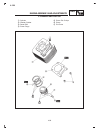

Eng l-124 engine assembly and adjustments 4-52 ¿ cylinder À gasket cylinder Á dowel pins piston rings à piston pin circlips Ä piston Å pin piston cylinder and piston.

Page 126

Eng r-125 engine assembly and adjustments 4-53 ¿ bolt flange À washer Á bolt valve cover (intake) Ã o-ring Ä valve cover (exhaust) Å cylinder head Æ dowel pin Ç gasket cylinder head È o-ring É cover cylinder head side # 3 Ê spark plug cylinder head.

Page 127

Eng l-126 engine assembly and adjustments 4-54 cam sprocket and timing chain ¿ gasket À timing chain tensioner assembly Á guide stopper # 2 cam sprocket à timing chain Ä guide stopper # 1.

Page 128

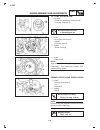

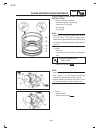

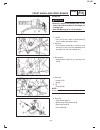

Eng r-127 engine assembly and adjustments 4-55 3. Install : • dowel pins ¿ • gasket (cylinder) À new piston ring, piston and cylinder installation 1. Install in following sequence • expander spacer (oil ring) ¿ • side rails (oil ring) À • 2nd ring Á • top ring note : • make sure to install the pisto...

Page 129

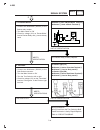

Eng l-128 engine assembly and adjustments 4-56 cylinder head installation 1. Install • dowel pins ¿ new • gasket ( cylinder head) À new • guide stopper#1 Á 4. Install : • piston rings ¿ note : offset the piston rings end gaps as shown. ç top ring end è oil ring end (lower) é oil ring end (upper) ê 2...

Page 130

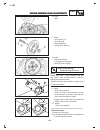

Eng r-129 engine assembly and adjustments 4-57 2. Install : • cylinder head • bolt with washer (cylinder head) note : • apply engine oil onto the bolt thread • tighten the bolts starting with the lowest num- bered one. 3. Install : • cam sprocket À • timing chain ¿ ææææææææææææææææææææææææææææææææææ...

Page 131

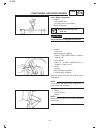

Eng l-130 engine assembly and adjustments 4-58 6. Check : • magneto rotor slit ç third mark in anticlockwise direction. Align with stationary pointer è in the crankcase cover #1 (lh) • cam sprocket “i” mark é align with stationary pointer ê on the cylinder head out of alignment Ÿ adjust 4. Install :...

Page 132

Eng r-131 engine assembly and adjustments 4-59 12. Install • o-ring (intake manifold) • intake manifold ¿ 13. Tighten • bolts (intake manifold) À 11. Install : • timing check plug (with o-ring) ¿ • center plug (with o-ring) À 10.Install : • valve covers (with o-ring) ¿ • cylinder head side cover (wi...

Page 133

Eng l-132 1 engine assembly and adjustments 4-60 14. Install : • spark plug 15. Install : • plug drain engine mounting when remounting the engine, reverse the re- moval procedure. Note the following points : 1. Install : • engine assembly (from the left side of the motorcycle) 2. Install • footrest ...

Page 134

Eng r-133 engine assembly and adjustments 4-61 5. Install : • gasket • exhaust pipe ¿ • bolts exhaust pipe À - 2 nos • bolt (muffler) Á 6. Install : • shift pedal ¿ 7. Tighten : • bolt shift pedal À 8. Install : • stay clutch cable 9. Install • clutch cable • adjust clutch cable free play at lever e...

Page 135

Eng l-134 max min engine assembly and adjustments 4-62 11. Install: • carburetor refer to “carburetor “ section in chapter 5 page no 5-7 12. Tighten: • air filter case screws ¿ 15. Install spark plug cap 16. Fill • crankcase refer to “engine oil replacement” section in chapter 3, page no 3-14 17. Ad...

Page 136

Carb r-135 chapter 5 carburetion carburetor view ................................................................ 5-1 removal ................................................................................... 5-2 disassembly .............................................................................

Page 137

Carb l-136 2 5 1 4 16 17 18 3 6 7 8 9 10 11 15 12 19 21 13 14 20 22 ¿ throttle cable À jet needle assembly Á spring throttle valve plug drain à float chamber body Ä o-ring Å main chamber body Æ float pin Ç float È needle valve assembly É jet main Ê throttle valve Ë nozzle main Ì screw pilot assembly...

Page 138

Carb r-137 removal 1. Remove : • side covers (lh & rh) refer to the “side cover, seat and fuel tank” section in chapter 3, page no 3-3 2. Drain : • fuel (float chamber) note : place a rag under the over flow hose to absorb the spilt fuel. Carburetor 5-2 7. Remove • throttle cable ¿ remove with carbu...

Page 139

Carb l-138 disassembly 1. Open • screws (float chamber) ¿ 4 nos 2. Remove : • float chamber À • seal float chamber Á disassembly note: the following parts can be cleaned and inspected without carburetor disassembly. • throttle valve assembly • starter lever • starter plunger assembly • before disass...

Page 140

Carb r-139 carburetor body 1. Inspect : • cracks/damage Ÿ replace • fuel passages blockage Ÿ clean with petrol and compressed air. • contamination in jet housings Ÿ clean disassembly/inspection 7. Remove : • pilot screw assembly ¿ (spring, washer and ‘o’ ring) • pilot jet À 8. Remove : • cap plunger...

Page 141

Carb l-140 needle valve and valve seat 1. Inspect • needle valve ¿ • valve seat À • o-ring Á damage/wear /blockage Ÿ clean/replace as a set inspection starter assembly 1. Inspect : • starter lever ¿ • cover pluger cap À • cap plunger Á • o-ring • spring plunger à • starter plunger Ä for seat and fre...

Page 142

Carb r-141 assembly reverse the disassembly procedure. 1. Wash • all the parts in clean petroleum based solvent • always use new ‘o’ rings 2. Install : • pilot jet ¿ • pilot screw assembly À assembly 7. Install • seal float chamber ¿ new • float chamber À • screw Á with spring washer (4 nos) 6. Meas...

Page 143

Carb l-142 installation 5-7 installation reverse the “removal” procedure 1. Install : • spring, throttle valve with the throttle cable 2. Install : • throttle valve assembly with carburetor chamber top note : align the slot ç on the throttle valve ¿ with the projection è on the carburetor body. 3. I...

Page 144

Carb r-143 carburetor tuning 8. Adjust : • idling speed by throttle stop screw ¿ 5 5-10 1 2 3 4 turning in Ÿ rpm increases turning out Ÿ rpm decareses engine idling speed : 1300 - 1500 r.P.M. 9. Adjust : • throttle cable free play refer to “throttle cable adjustment” in chapter 3, page no 3-9 carbur...

Page 145

Carb l-144 1 warning caution: do not disturb settings of the carburetor if the engine performance is o.K. • if required, must record the existing set- ting (no. Of turns) of the pilot screw. • to counter check the setting of the pilot screw, follow the ‘co’ adjustement proce- dure. • ensure proper c...

Page 146

Carb r-145 carburetor tuning 5-10 by bending down Ÿ float height increase by lifting up Ÿ float height decrease • otherwise adjust float level by bending the float tang on the float slightly up or down as required. • install the carburetor • recheck the fuel level • adjust float height through float...

Page 147

Chas l-146 chapter 6 chassis front wheel and front brake ...................................... 6-1 front wheel ......................................................................... 6-1 front brake .......................................................................... 6-2 removal ..............

Page 148

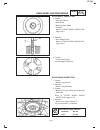

Chas r-147 front wheel ¿ cotter pin À axle nut Á speedometer cable assy. Wheel axle à spacer Ä brake shoe plate assy. Å dust seal/collar Æ front wheel front wheel and front brakes 6-1.

Page 149

Chas l-148 front brake ¿ brake shoe assy. À oil seal Á clutch meter gear drive à lever camshaft Ä indicator plate front wheel and front brakes 6-2 Å camshaft Æ bush Ç plate washer È gear meter É o-ring Ê oil seal.

Page 150

Chas r-149 front wheel and front brakes warning • securely support the motorcycle on the centre stand so that there is no danger of it falling over. • park the motorcycle on a level surface 3. Disconnect • speedometer cable ¿ by removing the clip À 4. Remove • cotter pin ¿ • nut À 5. Lift • front wh...

Page 151

Chas l-150 front wheel inspection : 1. Inspect • front wheel axle (by rolling it on a flat surface) bends Ÿ replace 2. Inspect : • front tyre wear/damage Ÿ replace refer to “tyre inspection” in chapter 3, page no 3-26 • front wheel refer to “wheel inspection” in chapter 3, page no 3-27 3. Check : • ...

Page 152

Chas r-151 5. Measure : • front wheel runout using a height gauge over the specified limits Ÿ correct/replace 6. Inspect : • front wheel bearings bearings allow free play in the wheel hub or the wheel does not turn smoothly Ÿ replace • oil seals wear/damage Ÿ replace 7. Inspect : • collar grooved we...

Page 153

Chas l-152 front wheel and front brakes front brake inspection 1. Inspect : • brake lining surface glazed areas Ÿ replace use coarse sand paper for polishing of brake lining note: after polishing , wipe the polished particles with a cloth. 2. Measure : • brake lining thickness ç out of specification...

Page 154

Chas r-153 front wheel and front brakes 6-7 warning after installing the brake camshaft, remove the excess grease 5. Install : • brake shoe plate assembly ¿ note : make sure that the wheel hub and the speed- ometer gear unit are installed with the two pro- jections ç meshed into the two solts è 6. I...

Page 155

Chas l-154 front wheel installation reverse the “removal” procedure note the following points 1. Lubricate : • axle front wheel • bearings • oil seal (lips) • drive/driven gear (speedometer) front wheel and front brakes 6-8 warning caution: before tightning the wheel axle, stroke the front fork seve...

Page 156

Chas r-155 5 install : • meter cable ¿ • clip À • brake cable Á 6. Check : • front brake for proper operation improper operation Ÿ recheck or disassemble. 7. Adjust • brake lever free play refer to “front brake adjustment” section in chapter 3, page no 3-18 front wheel and front brakes 6-9 warning m...

Page 157

Chas l-156 rear wheel ¿ adjuster À pin Á compressionspring cotter pin à tension bar Ä axle nut Å chain puller Æ driven sprocket axle Ç rear wheel assembly È brake shoe plate assembly É damper Ê bearing Ë spacer/collar Ì bearing rear wheel and rear brake 6-10

Page 158

Chas r-157 rear brake ¿ brake shoe kit À cam lever Á indicator plate camshaft rear wheel and rear brake 6-11.

Page 159

Chas l-158 rear wheel and rear brake 6-12 warning • securely support the motorcycle on centre stand so that there is no danger of it fall- ing over • stand the motorcycle on a level surface removal 1. Remove : • chain cover (upper ¿ and lower À) 2. Loosen • chain adjuster Á 3. Remove : • adjuster (r...

Page 160

Chas r-159 rear wheel and rear brake 6-13 rear wheel inspection 1. Inspect : • axle rear wheel • rear wheel • bearings rear wheel • oil seals refer to “front wheel inspection” page no 6-4 2. Measure : • rear wheel runout refer to “front wheel inspection ” page no 6-4 3. Inspect : • clutch hub damper...

Page 161

Chas l-160 rear wheel and rear brake 6-14 warning always use a new cottor pin rear wheel installation reverse the “removal” procedure 1. Install : • rear wheel assembly • brake shoe plate assembly • spacer with chain adjuster • axle rear wheel note : make sure that the slots in the rear wheel hub da...

Page 162

Chas r-161 drive chain and sprockets ¿ chain case À crankcase cover 3 Á drive sprocket clip chain joint à link plate Ä chain joint Å drive chain Æ nut driven sprocket axle Ç driven sprocket assembly È chain tensioner É circlip Ê oil seal drive chain and sprockets 6-15.

Page 163

Chas l-162 1 3 2 drive chain and sprockets 6-16 5. Remove : • nut (driven sprocket shaft nut) ¿ • driven sprocket À (with sprocket hub) • chain tensioner Á 4. Remove : • chain joint clip ¿ • link plate À • chain joint Á • drive chain warning securely support the motorcycle on centre stand so that th...

Page 164

Chas r-163 drive chain inspection 1. Inspect : • drive chain stiffness stiffness Ÿ clean and lubricate or replace drive chain and sprockets 6-17 4. Clean : • drive chain put it in kerosene and brush off as much dirt as possible. Then remove the drive chain from the ketosene and dry it. 3. Measure : ...

Page 165

Chas l-164 6-18 drive chain and sprockets clutch hub inspection 1. Inspect : clutch hub wear/damage/cracks Ÿ replace driven sprocket and drive chain installation 1. Install : • chain tensioner • driven sprocket axle ¿ with drive sprocket assembly note : align the slot on the swingarm with the flat f...

Page 166

Chas r-165 drive chain and sprockets warning caution: be sure to install the chain joint clip to the di- rection as shown 6-19 3. Install : • drive sprocket • drive chain ¿ • chain joint À • plate Á 4. Install : clip ¿ new 5. Install : • chain case (upper) • chain case (lower) • shift pedal refer to...

Page 167

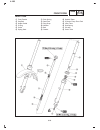

Chas l-166 front fork 6-20 front fork ¿ front fender À cap bolt Á holder cable o ring à collar Ä spring seat Å fork spring Æ seal dust Ç ring snap È washer É bolt Ê gasket Ë spindle taper Ì cylinder comp front fork Í inner tube Î sub spring Ï oil seal Ð outer tube.

Page 168

Chas r-167 front fork 6-21 warning securely support the motorcycle so there is no danger of it falling over front fork disassembly 1. Drain : • fork oil 2. Remove : • spacer ¿ • seat upper À • spring front fork Á 3. Remove : • front wheel • front fender refer to “front wheel removal” section page no...

Page 169

Chas l-168 front fork 6-22 warning caution: never reuse the oil seal 5. Remove : • ring snap • washer • oil seal ¿ using oil seal remover À 4. Remove : • bolt (damper rod) ¿ • washer À • cylinder complete fornt fork • spindle taper • spring sub 3. Loosen : • bolt allen (damper rod) ¿ loosen the bolt...

Page 170

Chas r-169 front fork front fork inspection 1. Inspect : • inner tube bending scratches/bends/damage Ÿ replace 2. Measure : • fork spring length ç over the specified limit Ÿ replace 3. Inspect : • cylinder complete front fork ¿ • piston ring À wear/cracks/damage Ÿ replace • spring sub Á • spindle ta...

Page 171

Chas l-170 front fork 6-24 warning allow the cylinder complete to slide slowly down the inner fork tube until it protrudes from the bottom, being careful not to dam- age the inner fork tube 3. Install : • cylinder complete ¿ • spindle taper À • inner tube Á • outer tube front fork assembly reverse t...

Page 172

Chas r-171 front fork 6-25 warning caution: make sure that the oil seal numbered side faces upward 7. Install : • washer ¿ • ring snap À • dust seal Á 5. Tighten : • bolt (cylinder complete) ¿ holding the cylinder complete with a t-handle À 6. Install : • oil seal ¿ new using tff oil seal installati...

Page 173

Chas l-172 front fork installation reverse the “removal procedure” note the following points 1. Install • front fork • temporarily tighten pinch bolt (underbracket) ¿ note: pull up the inner to until its end flushes with the top of the handle crown then temporarily tighten the bolts (underbracket) 2...

Page 174

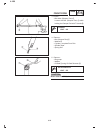

Chas r-173 steering head and handlebar 6-27 steering head and handlebar ¿ holder handle bar lower À holder handlebar upper Á handlebar grip assembly (right) Ã handle crown Ä lock washer Å ring nut (upper) Æ damper rubber Ç ring nut (lower) È ball race cover É under bracket Ê ball race (upper) Ë ball...

Page 175

Chas l-174 1 2 3 4 1 steering head and handlebar 6-28 warning securely support the motorcycle so that there is no danger of it falling over stand the motorcycle on a level surface removal 1. Remove : • band ¿ • brake cable (front) À • clutch cable Á • speedometer cable 2. Remove : switch handle ¿ 3....

Page 176

Chas r-175 steering head and handlebar 6-29 warning securely support the steering shaft so that there is no danger of it falling down warning do not attempt to straighten a bent handle- bar as this may dangerously weaken the handlebar ring nut wrench : ysst - 621 handlebar inspection 1. Inspect : • ...

Page 177

Chas l-176 1 2 steering head and handlebar steering inspection 1. Wash the bearing and ball races with a sol- vent 2. Inspect : • bearing races ¿ • ball races À pitting/damage Ÿ replace ææææææææææææææææææææææææææææææææææ bearing race replacement steps : • remove the ball races on the head pipe us- i...

Page 178

Chas r-177 steering head and handlebar 4. Install : • front fork refer to “front fork” section, page no 6-27 • front fender • front wheel refer to “front wheel” section, page no 6-8 handlebar installation 1. Install : • holder handelbar lower ¿ • handlebar ¿ • upper handlebar holder À note : • apply...

Page 179

Chas l-178 rear shock absorber and swing arm rear shock absorber and swingarm ¿ rear shock absorber À axle nut Á swing arm tension bar à seal guard 6-32.

Page 180

Chas r-179 rear shock absorber and swing arm removal 1. Stand the motorcycle on a level surface. 2. Remove : • side covers (left and right) • seat • cover chaincase • chain case (upper and lower) refer to “side covers, seat, and fuel tank ” section in chapter 3, page no 3-3 3. Remove : • rear wheel ...

Page 181

Chas l-180 rear shock absorber and swing arm inspection 1. Inspect : • swingarm looseness looseness exists Ÿ tighten the pivot shaft nut or replace bushes • swingarm up and down movement unsmooth movement/bending/rough spots Ÿ replace bushes 2. Inspect : • rear shock absorber oil leaks/damage Ÿ repl...

Page 182: R-181

R-181 chapter 7 electrical circuit diagram ................................................................... 7-1 location of electrical components ......................... 7-2 checking of connections ............................................... 7-3 ignition system/charging system circuit diagr...

Page 183

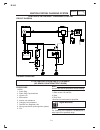

Elec l-182 circuit diagram circuit diagram 7-1.

Page 184

Elec r-183 ¿ main switch À flasher relay assy Á c.D.I. Unit assy battery à fuse Ä stop switch rear Å neutral switch assy Æ rectifier / regulator assy Ç ignition coil assy È spark plug cap É horn Ê spark plug location of electrical components electrical components 7-2.

Page 185

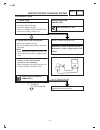

Elec l-184 checking of connections dealing with wire pressed stains, rust, moisture etc. On the connector. 1. Disconnect • connector ¿ 2. Dry each terminal with an air blower 3. Connect and disconnect the connector two or three times. 4. Pull the lead to check that it will not come off. Checking of ...

Page 186

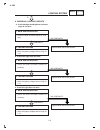

Elec r-185 ignition system/ charging system ignition system and charging system circuit diagram trouble shooting if the ignition system fails to operate. (no spark or intermittent spark) procedure check 1. Spark plug 2. Spark plug cap resistance 3. Ignition coil 4. Main switch 5. Sensor coil resista...

Page 187

Elec l-186 ignition system / charging system procedure steps 1. Spark plug • check the spark plug condition • check the spark plug type • check the spark plug gap • refer to “spark plug inspection“ section in chapter 3, page 3-10 standard spark plug dpr7ea (ngk) out of specification adjust or replac...

Page 188

Elec r-187 ignition system / charging system 3a. Ignition coil resistance (primary) • disconnect the ignition coil connector from the wire harness • connect the multimeter to the ignition coil. • check the primary coil resistance multimeter (+) lead Ÿ orange terminal ¿ multimeter (-) lead Ÿ earth À ...

Page 189

Elec l-188 5. Sensor coil resistance • disconnect the sensor coil coupler from the wiring harness • connect the multimeter ( Ω x 100) to the sensor coil coupler • check the sensor coil resistance mutimeter (+) lead Ÿ blue/yellow terminal ¿ multimeter (-) lead Ÿ green tertminal À replace the sensor c...

Page 190

Elec r-189 7. Rectifier cum regulator unit • check the charging voltage procedure steps • connect the tachometer to spark plug lead • connect the multimeter ( dc 20v) to bat- tery red wire. Measure the battery voltage : 12v if less than specifications, charge the battery • start the engine and accel...

Page 191

Elec l-190 charging system trouble shooting procedure check 1. Fuse 2. Battery 3. Charging voltage 4. Charging coil resistance 5. Wiring system (entire charging system) note : remove the following parts before trouble shoot- ing. 1) side covers (lh ) • use service instruments as specified. 1. Fuse r...

Page 192

Elec r-191 lighting system trouble shooting if the head light, hi beam indicator light, taillight and meter light do not work procedure check 1. Lighting coil resistance 2. Light switch 3. Dimmer switch 4. Lighting voltage 5. Wiring connections (entire lighting system) 6. Check individual lighting c...

Page 193

Elec l-192 lighting system 1. Lighting coil resistance • remove the c.D.I. Magento coupler from the wiring harness • connect the multimeter ( Ω x 1) to the light- ing coil • measure the lighting coil resistance multimeter (+) lead Ÿ yellow terminal ¿ multimeter (-) lead Ÿ black terminal À replace th...

Page 194

Elec r-193 lighting system 5. Wiring connections • check entire lighting system for poor con- nections refer to “wiring diagram” page check the lighting coil resistance out of specification meets specification • repair or replace wireharness poor connections continuity • check the condition of indiv...

Page 195

Elec l-194 lighting system 1. Bulb and bulb socket • check the bulb and bulb socket for continuity. C. If the tail light does not work replace bulb and/or bulb socket. No continuity 2. Lighting voltage • refer the lighting voltage section page no 7-12 continuity 1. Bulb and bulb socket • check the b...

Page 196

Elec r-195 signal system signal system circuit diagram : dc trouble shooting if the flasher light, brake light and indicator lights do not work if the horn does not work procedure check 1. Fuse 2. Battery 3. Main switch 4. Wiring connections (entire lighting system) 5. Check individual lighting circ...

Page 197

Elec l-196 signal system 1. Fuse refer to “fuse inspection section “ in chapter 3, page 3-30 2. Battery • check the battery condition refer to “battery inspection sec- tion” in chapter 3, page 3-28 continuity no continuity replace fuse 3. Main switch • disconnect the main switch coupler from wirehar...

Page 198

Elec r-197 signal system 1. Horn switch • disconnect the handlebar switch coupler from wireharness. • check the continuity between the “pink” and “black” with switch in pressed position. A. If the horn does not work. Replace the switch handle (lh) no continuity 2. Voltage • connect the multimeter (d...

Page 199

Elec l-198 signal system 1. Bulb and bulb sockets • check the bulb and bulb sockets for con- tinuity. B. If the brake light does not work. Replace bulb and/or bulb socket. No continuity continuity replace the brake switch out of specification 3. Voltage • connect the multimeter “dc20v” to bulb socke...

Page 200

Elec r-199 signal system 1. Bulb and bulb socket • check the bulb and bulb socket continuity c. If the flasher light and/or turn indicator light fails to blink. Replace the bulb and/or bulb socket 2. Turn switch • disconnect the handlebar switch (left) cou- pler from wireharness. • check the switch ...

Page 201

Elec l-200 signal system 5. Voltage • connect the multimeter (dc20v) to the bulb socket connector • turn the main switch to ‘on’ • turn the turn switch to left or right • check for voltage (12v) on the “chocolate” lead and “dark green” at the flasher light terminal. At flasher light (lh) multimeter ...

Page 202

Elec r-201 signal system check the connection of the entire signal system. Refer to “circuit diagram” page no 7-14. 1. Bulb and bulb socket • check the bulb and bulb socket for conti- nuity. 2. Neutral switch • disconnect the neutral switch lead. • check the continuity between the switch terminal an...

Page 203: L-202

Chapter 8 trouble shooting starting failure/ hard starting .................................. 8-1 poor idle speed performance ...................................... 8-2 poor medium and high speed performance ............ 8-2 poor speed performance ............................................... 8-3 ...

Page 204

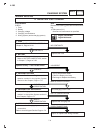

Trbl shtg r-203 starting failure / hard starting note: the following troubleshooting does not cover all the possible causes of trouble. It should be helpful, however, as a guide to troubleshooting. Refer to the related procedure in this manual for inspection, adjustment and replacement of parts. Com...

Page 205

Trbl shtg l-204 poor idle speed performance ignition system spark plug • improper plug gap • worn electrodes • wire between terminals broken • improper heat range • faulty spark plug cap ignition coil • broken or shorted primary /secondary coil • faulty high tension cord • broken ignition coil body ...

Page 206

Trbl shtg r-205 poor speed performance ignition system • dirty spark plug • improper heat range • faulty c.D.I. Unit • faulty sensor coil fuel system • clogged fuel tank cap breather hole • clogged air cleaner element • clogged jet • improperly adjusted fuel level compression system • worn cylinder ...

Page 207

Trbl shtg l-206 faulty gear shifting / overheating faulty gear shifting hard shifting refer to “clutch dragging’’ page no 8-3 shift pedal does not move shift shaft • bent shift shaft shift cam shift fork • groove jammed with impurities • seized shift fork • bent shift fork guide bar transmission • s...

Page 208

Trbl shtg r-207 front fork malfunction / unstable handling front fork malfunction oil leakage • bent damaged or rusty inner tube • damaged or cracked outer tube • damaged oil seal lip. • loose hexagon bolt • damaged cap bolt o-ring • improperly installed oil seal malfunction • bent inner tube • defo...

Page 209

Trbl shtg l-208 faulty signal and lighting system faulty signal and lighting system headlight dim • improper bulb • too many electric accessories • hard charging • faulty rectifier/regulator • faulty battery • improperly connected coupler, connector wire harness • improperly grounded • faulty main s...