- DL manuals

- Yamaha

- Boat

- LS2000

- Service Manual

Yamaha LS2000 Service Manual

Summary of LS2000

Page 1

Ls2000/lx210/ar210 lit-18616-sb-01 1999~2003 all lst1200 (ls2000) models.

Page 160

2000 lst1200y supplementary service manual.

Page 161

Lst1200y supplementary service manual © 2000 yamaha motor corporation, u.S.A. 1st edition, january 2000 all rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, including photocopying and recording, without the written permission of the copyright...

Page 162: Preface

Preface this supplementary service manual has been prepared to introduce new service and data for the lst1200y. For complete service information, it is necessary to use this supplementary service manual together with the following manual: lst1200x service manual: lit-18616-02-06 for what is not ment...

Page 163: Table Of Contents

Table of contents 1 gen info general information identification numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 primary i.D. Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 engi...

Page 164: Table Of Contents

Table of contents 1 gen info jet pump jet pump clean-out ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 exploded diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 removal and installati...

Page 165: Symbols

I symbols symbols 1 to 9 are designed as thumb-tabs to indicate the content of a chapter: general information specifications periodic inspection and adjustment fuel system power unit jet pump unit electrical system hull and deck trouble analysis symbols to indicate specific data: special tool specif...

Page 166: Identification Numbers

A60700-0* identification numbers primary i.D. Number the primary i.D. Number is stamped on a label attached to the deck under the rear seat. Engine serial number the engine serial number is stamped on a label attached to the crankcase. Hull identification number (h.I.N.) the h.I.N. Is stamped into t...

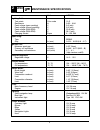

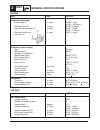

Page 167: Spec

2 model code : lst1200 hull f0r engine 66h dimensions: length 19’6” (5.9 m) width 8’ (2.4 m) draft 18” (.5 m) dry weight 2100 lb. (955 kg) performance: maximum output (each engine) 135hp @ 6750 maximum fuel consumption (w.O.T.) 28.0 gal/hr (106 l/hr) @ 6730rpm cruising range 1.5 hr @ w.O.T. Engine (...

Page 168: Maintenance Specifications

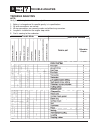

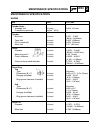

Maintenance specifications engine 3 item unit lst1200 cylinder head: warpage limit in (mm) 0.004” (0.1mm) compression pressure kg/cm 2 (kpa) — cylinder: bore size in (mm) 3.307 ~ 3.308” (84.00 ~ 84.02mm) taper limit in (mm) 0.003” (0.08mm) out of round limit in (mm) 0.002” (0.05mm) wear limit in (mm...

Page 169: Maintenance Specifications

Maintenance specifications 2 spec 4 item unit lst1200 crankshaft assembly: crank width “a” in (mm) 2.439 ~ 2.441” (61.95 ~ 62.00mm) deflection limit “b” in (mm) 0.002” (0.05mm) big end side clearance “c” in (mm) 0.010 ~ 0.030” (0.25 ~ 0.75mm) maximum small end in (mm) 0.08” (2.0mm) axial play “d” ca...

Page 170: Maintenance Specifications

Hull and hood electrical 5 item unit lst1200 free play: throttle lever free play in (mm) 0.16 ~ 0.28” (4 ~ 7mm) choke cable free play in (mm) 0.04 ~ 0.24” (1 ~ 6mm) item unit lst1200 battery: type marine group 24 dual purpose 675cca capacity a•h (v/kc) 100 (12/68.4) ignition timing: ignition timing ...

Page 171: Maintenance Specifications

Maintenance specifications 2 spec 6 item unit lst1200 lighting coil: test points color code g~g resistance Ω 0.56 ~ 0.84 peak voltage (open cranking) v 5.6 (min) peak voltage (closed cranking) v 5.6 (min) peak voltage (2000 rpm) v 23.8 (min) peak voltage (3500 rpm) v 28.1 (min) charging current a/rp...

Page 172: Maintenance Specifications

7 maintenance specifications 2 spec as shown in the illustration below, the pilot water exits the engine from the upper side of the exhaust joint. The cooling water that is used to cool the sides of the muffler exits the engine from the front and back of the cylinder head. Part of the cooling water ...

Page 173: Maintenance Specifications

8 maintenance specifications 2 spec tightening torque specified torque part to be tightened part name size qty nm m•kg ft•lb remarks engine: electric box bolt m8 3 17 1.7 12 electric box cover bolt m6 12 4 0.4 2.9 mounting bolt bolt m8 4 17 1.7 12 reed valve screw m4 24 1 0.1 0.7 exhaust ring bolt m...

Page 174: Tightening Torque

2 9 tightening torque (continued) specified torque part to be tightened part name size qty nm m•kg ft•lb remarks jet unit: mounting bolt bolt m8 2 19 1.9 13.7 impeller housing/duct bolt m8 4 19 1.9 13.7 transom plate bolt m8 4 19 1.9 13.7 intake duct bolt m8 6 19 1.9 13.7 intake grate bolt m8 3 19 1...

Page 175: Maintenance Specifications

General torque this chart specifies the torques for tightening standard fasteners with standard clean dry iso threads at room temperature. Torque specifica- tions for special components or assemblies are given in applicable sections of this manual. To avoid causing warpage, tighten multifastener ass...

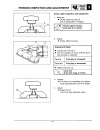

Page 176: Jet Pump Unit

Jet pump unit clean-out cap inspection 1. Remove: ● clean-out cap 1 2. Inspect: ● rubber seal crack/damage ➔ replace. ● locking mechanism wear/damage ➔ replace 3. Install: ● clean-out cap note: ● align the projection of the clean-out cap with the recess of the clean-out opening. ● holding the cap by...

Page 177: Fuel System

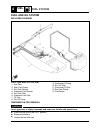

Fuel system 4 fuel 12 fuel and oil system exploded diagram fuel line and oil system 1. Fuel tank 2. Main fuel pickup 3. Port fuel petcock 4. Starboard fuel petcock 5. Port fuel filter 6. Starboard fuel filter 7. Oil tank 8. Port oil pump 9. Starboard oil pump 10. Port oil filter 11. Starboard oil fi...

Page 178: Fuel Tank

Fuel tank exploded diagram removal and installation chart 13 fuel system 4 fuel step procedure / part name qty service points fuel tank removal follow the “step” order for removal. Fuel remove the fuel in the tank. Rear seat base assembly refer to “seat fittings” in chapter 8. 1 hose band 2 2 fuel f...

Page 179: Fuel System

14 fuel system exploded diagram fuel system x 4 fuel.

Page 180: Fuel System

Fuel level sensor inspection refer to the “instrument” section in chapter 7. Fuel tank inspection 1. Inspect: fuel tank cracks/damage → replace. 15 removal and installation chart fuel system 4 fuel step procedure / part name qty service points fuel system disassembly follow the “step” order for remo...

Page 181: Fuel Pump

16 fuel pump exploded diagram fuel system 4 fuel.

Page 182: Fuel System

17 removal and installation chart step procedure / part name qty service points fuel pump disassembly follow the “step” order for removal. Carburetor assembly refer to “carburetor removal.” 1 pump cover 1 2 gasket 1 3 clear diaphragm 1 4 o-ring 1 5 diaphragm body assembly 1 6 check valve 2 7 bushing...

Page 183: Jet Pump Clean-Out Ports

18 jet pump clean-out ports exploded diagram step procedure / part name qty (ea.) service points jet pump clean-out follow the “step” order for removal. Ports removal 1 cap 1 note: follow cap installation instructions in “jet pump unit inspection,” chapter 3. 2 screw 15 3 clean-out tray 1 4 hatch in...

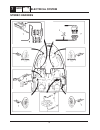

Page 184: Electrical System

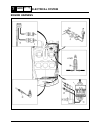

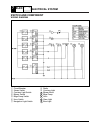

19 electrical system x 7 elec electrical system wiring diagram.

Page 185: Electrical System

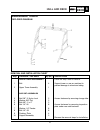

20 electrical system 7 elec hull harness.

Page 186: Electrical System

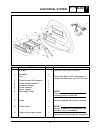

21 electrical system x 7 elec step procedure / part name qty (ea.) service points hull harness #3 follow the “step” order for removal. Replacement 1 battery leads 2 2 blower motor leads 2 3 hull harness to deck harness 1 access: engine compartment connector clean-out tray 1 refer to “jet pump clean-...

Page 187: Engine Harness

22 engine harness electrical system 7 elec.

Page 188: Electrical System

Step procedure / part name qty (ea.) service points engine harness #2 follow the “step” order for removal. Replacement (ea.) battery leads 2 1 engine harness #2 to hatch 1 access: engine compartment switch harness connector remote control assembly 1 refer to “remote control system” in chapter 8 2 ne...

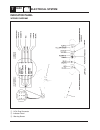

Page 189: Deck Harness

24 deck harness electrical system 7 elec.

Page 190: Electrical System

25 electrical system x 7 elec step procedure / part name qty service points deck harness replacement follow the “step” order for removal. Battery leads 2 1 oil sending unit lead 1 2 stern light socket 2 disconnect leads seat base board refer to “seat fittings” in chapter 8 3 fuel sending unit lead 1...

Page 191: Electrical System

26 electrical system 7 elec stereo harness.

Page 192: Electrical System

27 electrical system x 7 elec step procedure / part name qty service points stereo harness #5 follow the “step” order for removal. Replacement battery leads 2 1 speaker 2 remote control assembly 1 refer to “remote control system” in chapter 8 2 stereo remote keypad connectors 2 3 stereo harness #5 t...

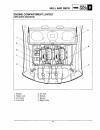

Page 193: Meter Panel Back View

28 meter panel back view wiring diagram electrical system 7 elec 1 starboard tach 2 speedometer 3 port tach 4 fuel gauge 5 horn switch 6 nav lights switch 7 courtesy light switch 8 radio switch 9 bilge switch blower switch 10

Page 194: Electrical System

29 electrical system x 7 elec step procedure / part name qty (ea.) service points meter panel disassembly follow the “step” order for removal. Disconnect wiring 1 set screw 2 2 choke knob 2 3 nut 2 4 choke cable 2 5 nut 2 6 main switch 2 7 nut w/ washer) 8 8 meter panel ass’y 1 9 nut (w/ flat and lo...

Page 195: Switch and Component

30 switch and component wiring diagram 1 circuit breaker 8 radio 2 stereo switch 9 courtesy light 3 courtesy light switch blower motor 4 blower switch bilge pump 5 bilge pump switch horn 6 horn switch stern light 7 navigation light switch bow light electrical system 7 elec 11 12 10 13 14.

Page 196: Electrical System

31 electrical system x 7 elec step procedure / part name qty (ea.) service points stereo follow the “step” order for removal. 1 faceplate 1 2 trim 1 push down gently at the outer edges to release the lower tabs, then lift to remove 3 stereo harness #6 connector 1 4 stereo remote connector 1 5 antenn...

Page 197: Electrical System

32 stereo troubleshooting stereo does not come on. 1 check: ● fuses and breakers ● out of specification ➔ replace 2. Measure voltage to stereo ● out of specification ➔ check switch and wiring disconnect remote keypad and retest replace stereo no sound 1. Check: ● speakers and wiring attenuator butto...

Page 198: Electrical System

Electrical system 33 stereo remote control 1 check: ● fuse 1 2. Measure: ● voltage to remote out of specification ➔ inspect harness. 3. Measure: ● voltage from remote (button depressed) out of specification ➔ replace stereo remote control. Note: the remote control output will be a low voltage. The v...

Page 199: Bimini Top

34 bimini top hull and deck 8 hull deck.

Page 200: Hull and Deck

35 step procedure / part name qty (ea.) service points bimini top follow the “step” order for removal. Place in the stored position refer to owners manual 1 mounting pins 4 2 bimini top assembly 1 3 pivot screw 4 4 bimini canvas 1 5 rivet 12 6 pivot end 6 7 rivet 8 8 coupler 4 9 rivet 4 10 mounting ...

Page 201: Remote Control System

36 remote control system exploded diagram hull and deck 8 hull deck.

Page 202: Hull and Deck

37 removal and installation chart hull and deck x 8 hull deck step procedure / part name qty service points remote control unit follow the “step” order for removal. Removal 1 screw, oval head 4 2 plate, remote control 1 3 washer 4 4 screw, flat head 4 5 clevis pin 4 6 screw, plate 2 7 nut 1 8 plate,...

Page 203: Hatch Fittings

38 hatch fittings exploded diagram hull and deck 8 hull deck.

Page 204: Hull and Deck

39 removal and installation chart hull and deck x 8 hull deck step procedure / part name qty service points ski locker hatch follow the “step” order for removal. Disassembly 1 screw, tapping 12 2 ski locker hatch 1 3 hinge 1 4 screw, pan head 2 5 latch 1 6 screw, tapping 2 7 latch plate 1 clean-out ...

Page 205: Helm Pod Assembly

40 helm pod assembly exploded diagram hull and deck 8 hull deck.

Page 206: Hull and Deck

41 removal and installation chart step procedure / part name qty service points helm pod disassembly follow the “step” order for removal. 1 locker, console 2 2 seal, locker 2 3 rivet (w/ washer) 3 4 fire extinguisher case (w/cap) 1 5 screw 4 6 latch 2 7 seal, windshield 2 8 windshield 2 9 screw (w/ ...

Page 207

2001 lst1200z supplementary service manual.

Page 208

Lst1200z supplementary service manual © 2000 yamaha motor corporation, u.S.A. 1st edition, october 2000 all rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, including photocopying and recording, without the written permission of the copyright...

Page 209: Preface

Preface this supplementary service manual has been prepared to introduce new service and data for the lst1200z. For complete service information, it is necessary to use this supplementary service manual together with the following manual: for what is not mentioned in this manual, please refer to the...

Page 210: Table Of Contents

Table of contents general information symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 identification numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 211: General Information

1 general information 1 gen info symbols symbols 1 to 9 are designed as thumb-tabs to indicate the content of a chapter: general information specifications periodic inspection and adjustment fuel system power unit jet pump unit electrical system hull and deck trouble analysis symbols to indicate spe...

Page 212: Identification Numbers

3 a60700-0* identification numbers primary i.D. Number the primary i.D. Number is stamped on a label attached to the deck under the rear seat. Engine serial number the engine serial number is stamped on a label attached to the crankcase. Hull identification number (h.I.N.) the h.I.N. Is stamped into...

Page 213: Spec

4 2 spec general specifications model code : lst1200 hull f0r engine 66h dimensions: length 19’6” (5.9 m) width 8’ (2.4 m) draft 18” (.5 m) dry weight 2100 lb. (955 kg) performance: maximum output (each engine) 135hp @ 6750 maximum fuel consumption (w.O.T.) 28.0 gal/hr (106 l/hr) @ 6750rpm cruising ...

Page 214: Maintenance Specifications

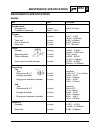

Maintenance specifications engine item unit lst1200 cylinder head: warpage limit in (mm) 0.004” (0.1mm) compression pressure kg/cm 2 (kpa) — cylinder: bore size in (mm) 3.307 ~ 3.308” (84.00 ~ 84.02mm) taper limit in (mm) 0.003” (0.08mm) out of round limit in (mm) 0.002” (0.05mm) wear limit in (mm) ...

Page 215: Spec

6 2 spec general specifications item unit lst1200 crankshaft assembly: crank width “a” in (mm) 2.439 ~ 2.441” (61.95 ~ 62.00mm) deflection limit “b” in (mm) 0.002” (0.05mm) big end side clearance “c” in (mm) 0.010 ~ 0.030” (0.25 ~ 0.75mm) maximum small end in (mm) 0.08” (2.0mm) axial play “d” carbur...

Page 216: Maintenance Specifications

7 hull and hood electrical item unit lst1200 free play: throttle lever free play in (mm) 0.16 ~ 0.28” (4 ~ 7mm) choke cable free play in (mm) 0.04 ~ 0.24” (1 ~ 6mm) item unit lst1200 battery: type marine group 24 dual purpose 675cca capacity a•h (v/kc) 100 (12/68.4) ignition timing: ignition timing ...

Page 217: Spec

8 item unit lst1200 lighting coil: test points color code g~g resistance Ω 0.56 ~ 0.84 peak voltage (open cranking) v 5.5 (min) peak voltage (closed cranking) v 5.5 (min) peak voltage (2000 rpm) v 20 (min) peak voltage (3500 rpm) v 25 (min) charging current a/rpm 6 ~ 8/5, 500 spark plug: type br8hs ...

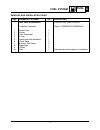

Page 218: Maintenance Interval Chart

9 maintenance interval chart the following chart should be considered strictly as a guide to general maintenance intervals. Depending on operating conditions, the intervals of maintenance may need to be adjusted. *1 flush after every salt water use *2 grease capacity 33.0~35.0 cm 3 (1.11~1.18 oz.) i...

Page 219: Fuel System

10 fuel system 4 fuel fuel and oil system exploded diagram fuel line and oil system 1. Fuel tank 2. Port fuel valve 3. Starboard fuel valve 4. Port fuel filter 5. Starboard fuel filter 6. Oil tank 7. Port oil pump 8. Starboard oil pump 9. Port oil filter 10. Starboard oil filter 11. Fuel return prep...

Page 220: Fuel System

11 fuel system 4 fuel fuel tank exploded diagram removal and installation chart step procedure / part name qty service points fuel tank removal follow the “step” order for removal. Fuel remove the fuel in the tank. Rear seat base assembly refer to “seat fittings” in chapter 8. 1 hose band 2 2 fuel f...

Page 221: Fuel System

12 fuel system 4 fuel fuel system exploded diagram.

Page 222: Fuel System

13 fuel system 4 fuel fuel level sensor inspection refer to the “instrument” section on page 13. Fuel tank inspection 1. Inspect: fuel tank cracks/damage → replace. Removal and installation chart step procedure / part name qty service points fuel system disassembly follow the “step” order for remova...

Page 223: Jet Pump

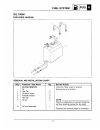

14 jet pump 6 jet pump jet pump clean-out ports exploded diagram removal and installation chart step procedure / part name qty service points jet pump clean-out follow the “step” order for removal. Ports removal 1 cap 2 note: follow cap installation instructions in “jet pump unit inspection,” chptr....

Page 224: Jet Pump

Jet pump x 6 15 jet pump cleanout hatch switch inspection/reinstallation 1. Open the cleanout hatch and remove the black inspection plug below the switches. 2. Measure the set height of the switch and adjust to 1/2” (12.7mm), if necessary. 3. After the switch height is set, reach through the inspect...

Page 225: Stereo Harness

16 stereo harness electrical system 7 elec.

Page 226: Electrical System

17 electrical system x 7 elec step procedure / part name qty service points stereo harness #5 follow the “step” order for removal. Replacement battery leads 2 1 speaker 2 remote control assembly 1 refer to “remote control system” in chapter 8 2 stereo remote keypad connectors 2 3 stereo harness #5 t...

Page 227: Meter Panel Back View

18 meter panel back view wiring diagram 1 2 3 4 5 6 7 8 9 11 10 electrical system 7 elec 1 starboard tach 2 speedometer 3 port tach 4 fuel gauge 5 horn switch 6 nav lights switch 7 courtesy light switch 8 radio switch 9 bilge switch blower switch indicator panel 10 11.

Page 228: Electrical System

19 electrical system x 7 elec step procedure / part name qty (ea.) service points meter panel disassembly follow the “step” order for removal. Disconnect wiring 1 set screw 2 apply loctite #242 2 choke knob 2 3 nut 2 4 choke cable 2 5 nut 2 6 main switch 2 7 nut w/ washer) 8 8 meter panel ass’y 1 9 ...

Page 229: Electrical System

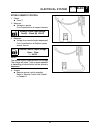

20 electrical system 7 elec indicator panel wiring diagram 1 9 pin plug connector 2 indicator panel 3 warning buzzer.

Page 230: Electrical System

Electrical system x 7 elec indicator panel 1. Check: ● bulbs and buzzer function. Turn the port key switch to the on position. The port engine overheat, low fuel, power on and low oil lights should glow and you will hear 3 beeps from the warning buzzer. The warning lights will go out after a few sec...

Page 231: Electrical System

22 electrical system 7 elec low oil warning 1. Check: ● disconnect the 9-pin indicator connec- tor behind the instrument panel and test according to the table below. ● bulb glows after 1 to 2 minutes and buzzer beeps 5 times. Not working ➔ repair wiring or replace indicator assembly as needed. Note:...

Page 232: Electrical System

23 electrical system x 7 elec oil switch 1. Check: ● continuity out of specification ➔ replace. Fuel gauge 1. Check: ● indication out of specification ➔ replace. Note: the meter should be battery powered for this inspection. Fuel level sensor/ low fuel switch fuel meter indication: leads indication ...

Page 233: Trouble Analysis

Trouble analysis 9 trbl anls trouble analysis note: verify the following before “trouble analysis”: 1. Battery is charged and its specific gravity is in specification. 2. All wire connections are correct. 3. Wiring connections are securely made and without any corrosion. 4. Lanyard is installed on t...

Page 234: Trouble Analysis

Trouble analysis x 9 trbl anls trouble modei items to be checked relative part reference chapter power unit (cont.) o o pilot water hose 5 o o water hose 5 o o water passage 5 jet pump unit o o o duct 6 o impeller 6 o intake screen 6 o bearing 6 o duct intake 6 o o water inlet hose 6 o bilge hose 6 ...

Page 235

© 2000 yamaha motor corporation, usa lit-18616-02-29.

Page 236

2002 lst1200a (a-a) supplementary service manual.

Page 237

Lst1200a (a-a) supplementary service manual © 2001 yamaha motor corporation, u.S.A. 1st edition, october 2001 all rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, including photocopying and recording, without the written permission of the cop...

Page 238: Preface

Preface this supplementary service manual has been prepared to introduce new service and data for the lst1200z. For complete service information, it is necessary to use this supplementary service manual together with the following manual: for what is not mentioned in this manual, please refer to the...

Page 239: Table Of Contents

Table of contents general information symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 identification numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 s...

Page 240: General Information

1 general information 1 gen info symbols symbols 1 to 9 are designed as thumb-tabs to indicate the content of a chapter: general information specifications periodic inspection and adjustment fuel system power unit jet pump unit electrical system hull and deck trouble analysis symbols to indicate spe...

Page 241: Identification Numbers

3 a60700-0* identification numbers primary i.D. Number the primary i.D. Number is stamped on a label attached to the deck under the rear seat. Engine serial number the engine serial number is stamped on a label attached to the crankcase. Hull identification number (h.I.N.) the h.I.N. Is stamped into...

Page 242: Spec

4 2 spec general specifications model code : lst1200 hull f0r engine 66h dimensions: height 52 ” (1.32 m) length 19 ’ 6 ” (5.9 m) width 8’ (2.4 m) draft 18 ” (.5 m) dry weight 2100 lb. (955 kg) performance: maximum output (each engine) 135hp @ 6750 maximum fuel consumption (w.O.T.) 28.0 gal/hr (106 ...

Page 243: Maintenance Specifications

Maintenance specifications engine item unit lst1200 cylinder head: warpage limit in (mm) 0.004 ” (0.1mm) compression pressure kg/cm 2 (kpa) — cylinder: bore size in (mm) 3.307 ~ 3.308” (84.00 ~ 84.02mm) taper limit in (mm) 0.003 ” (0.08mm) out of round limit in (mm) 0.002 ” (0.05mm) wear limit in (m...

Page 244: Spec

6 2 spec general specifications item unit lst1200 crankshaft assembly: crank width “a” in (mm) 2.439 ~ 2.441 ” (61.95 ~ 62.00mm) deflection limit “b” in (mm) 0.002 ” (0.05mm) big end side clearance “c” in (mm) 0.010 ~ 0.030 ” (0.25 ~ 0.75mm) maximum small end in (mm) 0.08 ” (2.0mm) axial play “d” ca...

Page 245: Maintenance Specifications

7 hull and hood electrical item unit lst1200 free play: throttle lever free play in (mm) 0.16 ~ 0.28” (4 ~ 7mm) choke cable free play in (mm) 0.04 ~ 0.24” (1 ~ 6mm) item unit lst1200 battery: type marine group 24 dual purpose 675cca capacity a•h (v/kc) 100 (12/68.4) ignition timing: ignition timing ...

Page 246: Spec

8 item unit lst1200 lighting coil: test points color code g~g resistance Ω 0.56 ~ 0.84 peak voltage (open cranking) v 5.5 (min) peak voltage (closed cranking) v 5.5 (min) peak voltage (2000 rpm) v 20 (min) peak voltage (3500 rpm) v 25 (min) charging current a/rpm 6 ~ 8/5, 500 spark plug: type br8hs ...

Page 247: Maintenance Interval Chart

9 maintenance interval chart the following chart should be considered strictly as a guide to general maintenance intervals. Depending on operating conditions, the intervals of maintenance may need to be adjusted. *1 flush after every salt water use *2 grease capacity 33.0~35.0 cm 3 (1.11~1.18 oz.) i...

Page 248: Stereo Harness

10 stereo harness electrical system 7 elec.

Page 249: Electrical System

11 electrical system x 7 elec step procedure / part name qty service points stereo harness #5 follow the “step” order for removal. Replacement 1 battery leads 2 2 stereo harness #5 to harness 1 leads 3 stereo harness #5 to accessory 2 access: passenger pod outlet leads 4 stereo harness #5 to stereo ...

Page 250: Meter Panel Back View

12 meter panel back view wiring diagram electrical system 7 elec 1 starboard tach 2 speedometer 3 port tach 4 fuel gauge 5 horn switch 6 nav lights switch 7 courtesy light switch 8 radio switch 9 bilge switch blower switch indicator panel 10 11.

Page 251: Electrical System

13 electrical system x 7 elec step procedure / part name qty (ea.) service points meter panel disassembly follow the “step” order for removal. Disconnect wiring 1 set screw 2 apply loctite #242 2 choke knob 2 3 nut 2 4 choke cable 2 5 nut 2 6 main switch 2 7 nut w/ washer) 8 8 meter panel ass’y 1 9 ...

Page 252: Electrical System

14 oil switch 1. Check: ● continuity out of specification ➔ replace. Fuel gauge 1. Check: ● indication out of specification ➔ replace. Note: the meter should be battery powered for this inspection. Fuel level sensor/ low fuel switch fuel meter indication: leads indication pink black “f” o—————o “e” ...

Page 253: Trouble Analysis

15 trouble analysis x 7 elec trouble analysis note: verify the following before “trouble analysis”: 1. Battery is charged and its specific gravity is in specification. 2. All wire connections are correct. 3. Wiring connections are securely made and without any corrosion. 4. Lanyard is installed on t...

Page 254: Trouble Analysis

Trouble analysis 9 trbl anls trouble modei items to be checked relative part reference chapter power unit (cont.) o o pilot water hose 5 o o water hose 5 o o water passage 5 jet pump unit o o o duct 6 o impeller 6 o intake screen 6 o bearing 6 o duct intake 6 o o water inlet hose 6 o bilge hose 6 o ...

Page 255

© 2001 yamaha motor corporation, usa lit-18616-02-41.

Page 256: Ls2000/lx210/ar210

2003 lst1200-b (a-b, b-b, and d-b) supplementary service manual ls2000/lx210/ar210 ls2000/lx210/ar210

Page 257

Lst1200-b (a-b, b-b and d-b) supplementary service manual © 2003 yamaha motor corporation, u.S.A. 1st edition, january 2003 all rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, including photocopying and recording, without the written permiss...

Page 258: Preface

Preface this supplementary service manual has been prepared to introduce new service and data for the 2003 lst1200 models. For complete service information, it is necessary to use this supplementary service manual together with the following manual: for what is not mentioned in this manual, please r...

Page 259: Table Of Contents

Table of contents general information symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 identification numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 s...

Page 260: General Information

1 general information 1 gen info symbols symbols 1 to 9 are designed as thumb-tabs to indicate the content of a chapter: general information specifications periodic inspection and adjustment fuel system power unit jet pump unit electrical system hull and deck trouble analysis symbols to indicate spe...

Page 261: Identification Numbers

3 a60700-0* identification numbers primary i.D. Number the primary i.D. Number is stamped on a label attached to the deck in the engine compart- ment. Engine serial number the engine serial number is stamped on a label attached to the crankcase. Hull identification number (h.I.N.) the h.I.N. Is stam...

Page 262: Spec

4 2 spec general specifications model code : lst1200 hull f0r engine 66h dimensions: height* 54.5 ” (1.38 m) ls/lx, 101.5 ” (2.58 m) ar length 19 ’ 6 ” (5.9 m) width 8’ (2.4 m) draft 18 ” (.5 m) dry weight 2100 lb. (955 kg) performance: maximum output (each engine) 135hp @ 6750 maximum fuel consumpt...

Page 263: Maintenance Specifications

Maintenance specifications engine item unit lst1200 cylinder head: warpage limit in (mm) 0.004 ” (0.1mm) compression pressure kg/cm 2 (kpa) — cylinder: bore size in (mm) 3.307 ~ 3.308” (84.00 ~ 84.02mm) taper limit in (mm) 0.003 ” (0.08mm) out of round limit in (mm) 0.002 ” (0.05mm) wear limit in (m...

Page 264: Spec

6 2 spec general specifications item unit lst1200 crankshaft assembly: crank width “a” in (mm) 2.439 ~ 2.441 ” (61.95 ~ 62.00mm) deflection limit “b” in (mm) 0.002 ” (0.05mm) big end side clearance “c” in (mm) 0.010 ~ 0.030 ” (0.25 ~ 0.75mm) maximum small end in (mm) 0.08 ” (2.0mm) axial play “d” ca...

Page 265: Maintenance Specifications

7 hull and hood electrical item unit lst1200 free play: throttle lever free play in (mm) 0.16 ~ 0.28” (4 ~ 7mm) choke cable free play in (mm) 0.04 ~ 0.24” (1 ~ 6mm) item unit lst1200 battery: type marine group 24 dual purpose 675cca capacity a•h (v/kc) 100 (12/68.4) ignition timing: ignition timing ...

Page 266: Spec

8 item unit lst1200 lighting coil: test points color code g~g resistance Ω 0.56 ~ 0.84 peak voltage (open cranking) v 5.5 (min) peak voltage (closed cranking) v 5.5 (min) peak voltage (2000 rpm) v 20 (min) peak voltage (3500 rpm) v 25 (min) charging current a/rpm 6 ~ 8/5, 500 spark plug: type br8hs ...

Page 267: Maintenance Interval Chart

9 maintenance interval chart the following chart should be considered strictly as a guide to general maintenance intervals. Depending on operating conditions, the intervals of maintenance may need to be adjusted. *1 flush after every salt water use *2 grease capacity 33.0~35.0 cm 3 (1.11~1.18 oz.) i...

Page 268: Stereo Harness

10 stereo harness electrical system 7 elec 4 2 3.

Page 269: Electrical System

11 electrical system x 7 elec step procedure / part name qty service points stereo harness #5 follow the “step” order for removal. Replacement 1 battery leads 2 2 stereo harness #5 to harness 1 access: passenger pod leads 3 stereo harness #5 to accessory 2 for accessory outlet (pur/red and b) outlet...

Page 270: Electrical System

12 meter panel back view – (ls2000/lx210 models) wiring diagram electrical system 7 elec 1 starboard tach 2 speedometer 3 port tach 4 fuel gauge 5 horn switch 6 nav lights switch 7 courtesy light switch 8 radio switch 9 bilge switch blower switch indicator panel 10 11.

Page 271: Electrical System

13 electrical system x 7 elec meter panel back view - ar10 model wiring diagram 1 starboard tach 2 speedometer 3 port tach 4 fuel gauge 5 horn switch 6 nav lights switch 7 courtesy light switch 8 radio switch 9 bilge switch blower switch indicator panel 10 11.

Page 272: Hull And Deck

Hull and deck 14 8 step procedure / part name qty (ea.) service points swimstep removal follow the “step” order for removal. 1 nut 5/16”-18 nylon lock 8 2 washer 5/16” flat 8 3 screw 5/16”-18 x 2-1/4” 8 4 ladder, transom 1 5 platform 1 bracket removal remove cleanout tray for access to bracket faste...

Page 273: Hull And Deck

Hull and deck x 8 15 step procedure / part name qty (ea.) service points upper tower disassembly follow the “step” order for removal. 1 bolt 4 support tower or use an assistant to prevent damage to aluminum tubing. 2 upper tower assembly 1 support assemblies 3 nut 5/8 ” -11 nylon lock 2 access faste...

Page 274: Trouble Analysis

16 trouble analysis note: verify the following before “trouble analysis”: 1. Battery is charged and its specific gravity is in specification. 2. All wire connections are correct. 3. Wiring connections are securely made and without any corrosion. 4. Lanyard is installed on the engine stop switch. 5. ...

Page 275: Trouble Analysis

Trouble analysis x 17 9 trbl anls trouble modei items to be checked relative part reference chapter power unit (cont.) o o pilot water hose 5 o o water hose 5 o o water passage 5 jet pump unit o o o duct 6 o impeller 6 o intake screen 6 o bearing 6 o duct intake 6 o o water inlet hose 6 o bilge hose...

Page 276

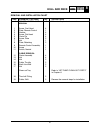

18 12v battery 20a red/black red/black key switch assembly (right) engine shut-off switch shifter (right) cleanout hatch switch (right) red brn brn blk wht red grn brn brn free (off) push (on) brn brn blk wht set pull blk wht brn blk wht wht blk red yel off on start red/blk tachometer (right) gry pu...

Page 277

© 2003 yamaha motor corporation, usa lit-18616-03-41.