- DL manuals

- Yamaha

- Offroad Vehicle

- RAPTOR YFM125RA

- Service Manual

Yamaha RAPTOR YFM125RA Service Manual - General Chassis

GENERAL CHASSIS

4-5

EAS2PA1401

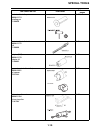

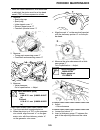

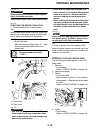

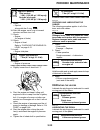

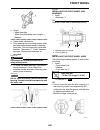

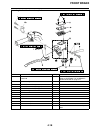

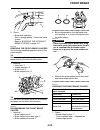

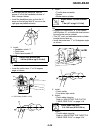

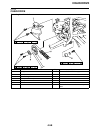

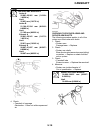

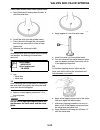

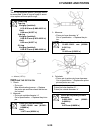

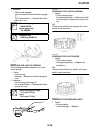

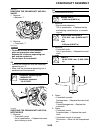

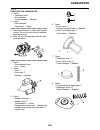

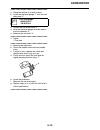

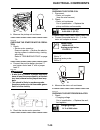

REMOVING THE FRONT PANEL

1. Remove:

• Quick fasteners “1”

2. Remove

• Front panel

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Pull the panel upward as shown, and then

remove the socket “1” (together with the

bulb) by pulling it out.

b. Pull the panel downward, and then remove

the panel by pulling it as shown.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

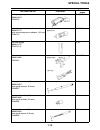

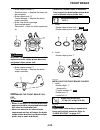

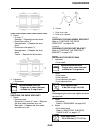

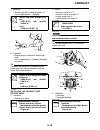

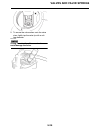

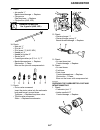

EAS2PA1402

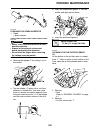

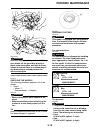

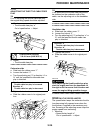

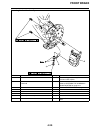

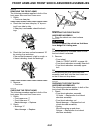

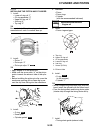

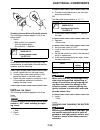

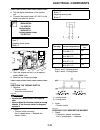

INSTALLING THE FRONT PANEL

1. Install:

• Front panel

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Place the panel in its original position, and

then install the socket “1” (together with the

bulb) by pushing it in.

ECA2PA1401

When installing the panel, be sure not to

pinch the cables or wires.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

2. Install:

• Quick fasteners

Summary of RAPTOR YFM125RA

Page 1

Service manual yfm125ra 2011 2pa-28197-10 lit-11616-24-36.

Page 2

Eas20050 yfm125ra service manual ©2010 by yamaha motor corporation, u.S.A. First edition, may 2010 all rights reserved. Any reproduction or unauthorized use without the written permission of yamaha motor corporation, u.S.A. Is expressly prohibited. Printed in u.S.A. P/n lit-11616-24-36.

Page 3

Eas20071 important this manual was produced by the yamaha motor company, ltd. Primarily for use by yamaha deal- ers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manual. Therefore, anyone who uses this book to perform maintenance and repairs on y...

Page 4

Eas20091 how to use this manual this manual is intended as a handy, easy-to-read reference book for the mechanic. Comprehensive explanations of all installation, removal, disassembly, assembly, repair and check procedures are laid out with the individual steps in sequential order. • the manual is di...

Page 5

Eas30370 symbols the following symbols are used in this manual for easier understanding. Tip the following symbols are not relevant to every vehicle. Symbol definition symbol definition serviceable with engine mounted gear oil filling fluid molybdenum disulfide oil lubricant brake fluid special tool...

Page 7: Table of Contents

1 2 3 4 5 6 7 8 eas20110 table of contents general information specifications periodic checks and adjustments chassis engine fuel system electrical system troubleshooting.

Page 9: General Information

1 general information identification .......................................................................................... 1-1 vehicle identification number................................................... 1-1 model label ..........................................................................

Page 10: Identification

Identification 1-1 eas20130 identification eas20140 vehicle identification number the vehicle identification number “1” is stamped into the left side of the frame. Eas20150 model label the model label “1” is affixed to the air filter case cover. This information will be needed to order spare parts..

Page 11: Important Information

Important information 1-2 eas20180 important information eas20190 preparation for removal and disas- sembly 1. Before removal and disassembly, remove all dirt, mud, dust and foreign material. 2. Use only the proper tools and cleaning equipment. Refer to “special tools” on page 1-9. 3. When disassemb...

Page 12: Important Information

Important information 1-3 eas20231 bearings and oil seals install bearings “1” and oil seals “2” so that the manufacturer marks or numbers are visible. When installing oil seals, lubricate the oil seal lips with a light coat of lithium-soap-based grease. Oil bearings liberally when installing, if ap...

Page 13: Basic Service Information

Basic service information 1-4 eas30380 basic service information eas30390 quick fasteners rivet type 1. Remove: • quick fastener tip to remove the quick fastener, push its pin with a screwdriver, then pull the fastener out. 2. Install: • quick fastener tip to install the quick fastener, push its pin...

Page 14: Basic Service Information

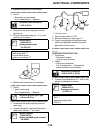

Basic service information 1-5 eas30402 electrical system electrical parts handling eca16600 never disconnect a battery lead while the engine is running; otherwise, the electrical components could be damaged. Eca16751 when disconnecting the battery leads from the battery, be sure to disconnect the ne...

Page 15: Basic Service Information

Basic service information 1-6 eca16620 handle electrical components with special care, and do not subject them to strong shocks. Eca16630 electrical components are very sensitive to and can be damaged by static electricity. Therefore, never touch the terminals and be sure to keep the contacts clean....

Page 16: Basic Service Information

Basic service information 1-7 checking the connections check the leads, couplers, and connectors for stains, rust, moisture, etc. 1. Disconnect: • lead • coupler • connector eca16780 • when disconnecting a coupler, release the coupler lock, hold both sections of the coupler securely, and then discon...

Page 17: Basic Service Information

Basic service information 1-8 5. Check: • continuity (with the pocket tester) tip • if there is no continuity, clean the terminals. • when checking the wire harness, perform steps (1) to (3). • as a quick remedy, use a contact revitalizer available at most part stores. Pocket tester 90890-03112 anal...

Page 18: Special Tools

Special tools 1-9 eas20260 special tools the following special tools are necessary for complete and accurate tune-up and assembly. Use only the appropriate special tools as this will help prevent damage caused by the use of inappropri- ate tools or improvised techniques. Special tools, part numbers ...

Page 19: Special Tools

Special tools 1-10 crankshaft installer pot 90890-01274 installing pot yu-90058 5-65 crankshaft installer bolt 90890-01275 bolt yu-90060 5-65 adapter (m12) 90890-01278 adapter #3 yu-90063 5-65 spacer (crankshaft installer) 90890-04081 pot spacer ym-91044 5-65 piston pin puller set 90890-01304 piston...

Page 20: Special Tools

Special tools 1-11 tappet adjusting tool 90890-01311 six piece tappet set ym-a5970 3-6 flywheel puller 90890-01362 heavy duty puller yu-33270-b 5-50 sheave holder 90890-01701 primary clutch holder ys-01880-a 5-50, 5-51, 5-52 thickness gauge 90890-03180 feeler gauge set yu-26900-9 3-5, 5-36 digital c...

Page 21: Special Tools

Special tools 1-12 valve spring compressor 90890-04019 ym-04019 5-19, 5-24 valve spring compressor attachment 90890-04114 valve spring compressor adapter 19.5 mm ym-04114 5-19, 5-24 fuel level gauge 90890-01312 ym-01312-a 6-10 universal clutch holder 90890-04086 ym-91042 5-35, 5-38 valve guide remov...

Page 22: Special Tools

Special tools 1-13 valve lapper 90890-04101 valve lapping tool ym-a8998 5-22 axle nut wrench (46 mm) 90890-01498 rear axle nut wrench 46 mm ym-37134 4-14, 4-15 ignition checker 90890-06754 opama pet-4000 spark checker ym-34487 7-39 digital tachometer 90890-06760 yu-39951-b 3-6, 7-41 yamaha bond no. ...

Page 23: Specifications

2 specifications general specifications ...................................................................... 2-1 engine specifications..........................................................................2-4 chassis specifications...................................................................

Page 24: General Specifications

General specifications 2-1 eas29110 general specifications model model 2pa1 (usa) 2pa2 (can) 2pa3 (aus, nzl) dimensions overall length 1610 mm (63.4 in) overall width 1018 mm (40.1 in) overall height 1010 mm (39.8 in) seat height 715 mm (28.1 in) wheelbase 1110 mm (43.7 in) ground clearance 85 mm (3...

Page 25: General Specifications

General specifications 2-2 clutch type wet, multiple-disc transmission primary reduction system helical gear primary reduction ratio 68/20 (3.400) secondary reduction system chain drive secondary reduction ratio 48/14 (3.429) transmission type constant mesh 5-speed operation left foot operation 1st ...

Page 26: General Specifications

General specifications 2-3 spring/shock absorber type coil spring/oil damper wheel travel 190 mm (7.5 in) rear suspension type swingarm spring/shock absorber type coil spring/gas-oil damper wheel travel 200 mm (7.9 in) electrical system ignition system cdi charging system ac magneto battery model yt...

Page 27: Engine Specifications

Engine specifications 2-4 eas29120 engine specifications cylinder head volume 15.20–15.60 cm³ (0.93–0.95 cu.In) warpage limit 0.03 mm (0.0012 in) cylinder bore 54.024–54.056 mm (2.1269–2.1282 in) wear limit 54.156 mm (2.1321 in) camshaft drive system chain drive (left) camshaft lobe dimensions intak...

Page 28: Engine Specifications

Engine specifications 2-5 valve, valve seat, valve guide valve clearance (cold) intake 0.08–0.12 mm (0.0032–0.0047 in) exhaust 0.10–0.14 mm (0.0039–0.0055 in) valve dimensions valve head diameter a (intake) 25.90–26.10 mm (1.0197–1.0276 in) valve head diameter a (exhaust) 21.90–22.10 mm (0.8622–0.87...

Page 29: Engine Specifications

Engine specifications 2-6 free length (exhaust) 47.06 mm (1.85 in) limit 44.71 mm (1.76 in) installed length (intake) 25.60 mm (1.01 in) installed length (exhaust) 25.60 mm (1.01 in) spring rate k1 (intake) 8.01 n/mm (0.82 kgf/mm, 45.74 lbf/in) spring rate k2 (intake) 9.33 n/mm (0.95 kgf/mm, 53.27 l...

Page 30: Engine Specifications

Engine specifications 2-7 2nd ring ring type taper dimensions (b × t) 1.00 × 2.10 mm (0.04 × 0.08 in) end gap (installed) 0.30–0.45 mm (0.012–0.018 in) limit 0.55 mm (0.0217 in) ring side clearance 0.020–0.060 mm (0.0008–0.0024 in) limit 0.120 mm (0.0047 in) oil ring dimensions (b × t) 2.00 × 2.25 m...

Page 31: Engine Specifications

Engine specifications 2-8 shifting mechanism shift mechanism type shift drum and guide bar shift fork thickness 4.76–4.89 mm (0.1874–0.1925 in) carburetor id mark 2pa1 00 (usa, can) 2pa1 10 (aus, nzl) main jet #123.8 main air jet #110 jet needle 5dh54-1 (usa, can) 5dh72-2 (aus, nzl) needle jet p-0m ...

Page 32: Chassis Specifications

Chassis specifications 2-9 eas29130 chassis specifications front suspension shock absorber travel 90.7 mm (3.57 in) spring free length 248.5 mm (9.78 in) spring rate k1 23.00 n/mm (2.35 kgf/mm, 131.33 lbf/in) spring stroke k1 0.0–90.7 mm (0.00–3.57 in) optional spring available no spring preload adj...

Page 33: Chassis Specifications

Chassis specifications 2-10 brake pad lining thickness (inner) 4.5 mm (0.18 in) limit 1.0 mm (0.04 in) brake pad lining thickness (outer) 4.5 mm (0.18 in) limit 1.0 mm (0.04 in) master cylinder inside diameter 12.7 mm (0.50 in) caliper cylinder inside diameter 32.03 mm (1.26 in) recommended fluid do...

Page 34: Electrical Specifications

Electrical specifications 2-11 eas29140 electrical specifications system voltage system voltage 12 v ignition system ignition timing (b.T.D.C.) 7.0 °/1600 r/min advanced timing (b.T.D.C.) 32.5 °/9400 r/min advancer type digital cdi pickup coil resistance 248.0–372.0 Ω (r–w) cdi unit model/manufactur...

Page 35: Electrical Specifications

Electrical specifications 2-12 carburetor warmer resistance 5.6–8.4 Ω at 25 °c (77 °f) circuit breaker circuit breaker type fuse fuse fuse 15.0 a reserve 15.0 a.

Page 36: Tightening Torques

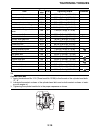

Tightening torques 2-13 eas20320 tightening torques eas20331 general tightening torque specifi- cations this chart specifies tightening torques for stan- dard fasteners with a standard iso thread pitch. Tightening torque specifications for spe- cial components or assemblies are provided for each cha...

Page 37: Tightening Torques

Tightening torques 2-14 eas20340 engine tightening torques item thread size q’ty tightening torque remarks cylinder head bolt m8 4 22 nm (2.2 m·kgf, 16 ft·lbf) see tip cylinder head bolt m6 2 10 nm (1.0 m·kgf, 7.2 ft·lbf) see tip yamaha bond no.1215 (three bond no.1215®) oil check bolt m6 1 7 nm (0....

Page 38: Tightening Torques

Tightening torques 2-15 tip cylinder head bolt 1. Apply yamaha bond no.1215 (three bond no.1215®) to the threads of the cylinder head bolts “5”, “6”. 2. Lubricate the contact surfaces of the cylinder head bolts and on both contact surfaces of wash- ers with engine oil. 3. Tightening the cylinder hea...

Page 39: Tightening Torques

Tightening torques 2-16 eas20350 chassis tightening torques item thread size q’ty tightening torque remarks engine bracket (upper side) and frame bolt m8 2 33 nm (3.3 m·kgf, 24 ft·lbf) engine bracket (upper side) and engine nut m8 1 40 nm (4.0 m·kgf, 29 ft·lbf) engine bracket (front side) and engine...

Page 40: Tightening Torques

Tightening torques 2-17 steering knuckle and front brake caliper bracket bolt m8 4 28 nm (2.8 m·kgf, 20 ft·lbf) front brake disc and front wheel hub bolt m8 8 28 nm (2.8 m·kgf, 20 ft·lbf) rear axle and rear wheel hub nut m14 2 120 nm (12 m·kgf, 87 ft·lbf) rear brake caliper and brake cali- per brack...

Page 41: Tightening Torques

Tightening torques 2-18 tip rear axle pinch bolt tightening the rear axle pinch bolts in the proper sequence as shown. Rear brake fluid reservoir, cover and frame bolt m6 1 7 nm (0.7 m·kgf, 5.1 ft·lbf) front bumper and frame bolt m8 4 31 nm (3.1 m·kgf, 22 ft·lbf) front fender stay and frame bolt m6 ...

Page 42: Tightening Torques

Tightening torques 2-19.

Page 43

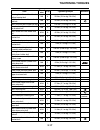

Lubrication points and lubricant types 2-20 eas20360 lubrication points and lubricant types eas20370 engine lubrication point lubricant oil seal lips bearings cylinder head bolt seats and washers camshaft sprocket cover o-ring tappet cover o-rings connecting rod big end thrust surface piston pin cyl...

Page 44

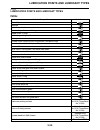

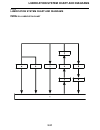

Lubrication system chart and diagrams 2-21 eas20390 lubrication system chart and diagrams eas20400 engine oil lubrication chart.

Page 45

Lubrication system chart and diagrams 2-22 1. Oil pan 2. Oil strainer 3. Oil pump 4. Rotary filter 5. Cylinder head 6. Camshaft 7. Crankshaft 8. Drive axle 9. Main axle.

Page 46

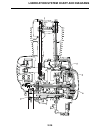

Lubrication system chart and diagrams 2-23 eas20410 lubrication diagrams.

Page 47

Lubrication system chart and diagrams 2-24 1. Camshaft 2. Rotary filter 3. Oil pump 4. Oil strainer 5. Push lever shaft.

Page 48

Lubrication system chart and diagrams 2-25.

Page 49

Lubrication system chart and diagrams 2-26 1. Camshaft 2. Rotary filter 3. Crankshaft 4. Main axle 5. Drive axle.

Page 50: Cable Routing

Cable routing 2-27 eas20430 cable routing handlebar (top view).

Page 51: Cable Routing

Cable routing 2-28 1. Brake hose 2. Throttle cable 3. Plastic band 4. Parking brake cable 5. Clutch cable a. Pass the brake hose and throttle cable through the guide of the handlebar protec- tor. Pass the throttle cable behind the brake hose. B. Clamp the front brake light switch lead at the bends o...

Page 52: Cable Routing

Cable routing 2-29 frame (right side view).

Page 53: Cable Routing

Cable routing 2-30 1. Neutral indicator light lead 2. Front brake light switch lead 3. Main switch lead 4. Headlight lead 5. Brake hose 6. Starter motor lead 7. Battery negative lead 8. Parking brake cable 9. Rear brake light switch lead 10.Carburetor warmer lead 11.Air vent hose 12.Crankcase breath...

Page 54: Cable Routing

Cable routing 2-31 rear brake (right side view).

Page 55: Cable Routing

Cable routing 2-32 1. Rear brake reservoir 2. Rear brake light switch 3. Clip 4. Rear brake reservoir hose 5. Rear brake master cylinder 6. Parking brake cable 7. Parking brake cable adjusting nut 8. Brake hose 9. Rear brake caliper 10.Swingarm a. Make sure that the end of the clip is facing downwar...

Page 56: Cable Routing

Cable routing 2-33 frame (left side view).

Page 57: Cable Routing

Cable routing 2-34 1. Spring 2. Adjusting screw 3. Washer 4. Adjusting nut 5. Rectifier/regulator 6. Clutch switch lead 7. Handlebar switch lead 8. Rectifier/regulator lead 9. Wire harness 10.Neutral switch lead 11.Drain hose 12.Clamp 13.Screw 14.Collar 15.Headlight 16.Spring nut 17.Headlight stay 1...

Page 58: Cable Routing

Cable routing 2-35 rear frame (left side view).

Page 59: Cable Routing

Cable routing 2-36 1. Air vent hose 2. Clamp 3. Starter motor lead 4. Ac magneto lead 5. Carburetor overflow hose 6. Frame 7. Seat pad 8. Wire harness 9. Battery negative lead 10.Rear brake light switch lead 11.Carburetor warmer lead 12.Side cover 13.Crankcase breather hose 14.Air filter joint 15.En...

Page 60: Cable Routing

Cable routing 2-37 front fender (top view).

Page 61: Cable Routing

Cable routing 2-38 1. Neutral indicator light 2. Main switch lead coupler 3. Main switch lead 4. Headlight lead 5. Main switch 6. Front brake light switch lead 7. Throttle cable 8. Air vent hose 9. Clutch switch lead 10.Handlebar switch lead 11.Parking brake cable 12.Clutch cable 13.Front fender 14....

Page 62: Cable Routing

Cable routing 2-39 frame (top view).

Page 63: Cable Routing

Cable routing 2-40 1. Main switch lead 2. Headlight lead 3. Neutral indicator light lead 4. Front brake light switch lead 5. Clutch cable 6. Parking brake cable 7. Throttle cable 8. Brake fluid reservoir 9. Rear brake light switch lead 10.Air vent hose 11.Carburetor warmer lead 12.Starter motor lead...

Page 64: Cable Routing

Cable routing 2-41 air filter case (top view).

Page 65: Cable Routing

Cable routing 2-42 1. Tool kit 2. Air filter case 3. Tail/brake light 4. Tail/brake light lead 5. Battery 6. Starter relay lead 7. Starter relay 8. Battery positive lead 9. Battery negative lead 10.Ac magneto coupler 11.Starter motor lead a. Clamp the tail/brake light lead. B. Do not clamp. C. Set t...

Page 66: Cable Routing

Cable routing 2-43.

Page 67

3 periodic checks and adjustments periodic maintenance ......................................................................... 3-1 introduction .................................................................................... 3-1 periodic maintenance chart for the emission control system..........

Page 68

Replacing the headlight bulb .................................................3-25 adjusting the headlight beam ................................................3-26.

Page 70: Periodic Maintenance

Periodic maintenance 3-1 eas20450 periodic maintenance eas20460 introduction this chapter includes all information necessary to perform recommended checks and adjustments. If followed, these preventive maintenance procedures will ensure more reliable vehicle operation, a longer service life and redu...

Page 71: Periodic Maintenance

Periodic maintenance 3-2 eas2pa1302 general maintenance and lubrication chart tip • for atvs not equipped with an odometer or an hour meter, follow the month maintenance inter- vals. • for atvs equipped with an odometer or an hour meter, follow the km (mi) or hours maintenance intervals. However, ke...

Page 72: Periodic Maintenance

Periodic maintenance 3-3 tip • some maintenance items need more frequent service if you are riding in unusually wet, dusty, sandy or muddy areas, or at full-throttle. • hydraulic brake service • regularly check and, if necessary, correct the brake fluid level. • every two years replace the internal ...

Page 73: Periodic Maintenance

Periodic maintenance 3-4 eas21030 checking the fuel line the following procedure applies to all of the fuel and breather hoses. 1. Check: • fuel hose “1” • fuel tank breather hose “2” cracks/damage → replace. Loose connection → connect properly. Eca14940 make sure the fuel tank breather hose is rout...

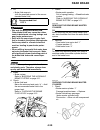

Page 74: Periodic Maintenance

Periodic maintenance 3-5 • when the valve clearance is to be measured or adjusted, the piston must be at top dead center (tdc) on the compression stroke. 1. Remove: • spark plug cap • spark plug • intake tappet cover “1” • exhaust tappet cover “2” • camshaft sprocket cover “3” 2. Remove: • timing ma...

Page 75: Periodic Maintenance

Periodic maintenance 3-6 c. Turn the adjusting screw “3” in direction “a” or “b” until the specified valve clearance is obtained. • hold the adjusting screw to prevent it from moving and tighten the locknut to specification. D. Measure the valve clearance again. E. If the valve clearance is still ou...

Page 76: Periodic Maintenance

Periodic maintenance 3-7 4. Adjust: • engine idling speed ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Turn the pilot screw “1” in until it is lightly seated. (aus, nzl) b. Turn the pilot screw out the specified num- ber of turns. (aus, nzl) c. Turn the throttle stop screw “1” in direction “a” or “b” until the...

Page 77: Periodic Maintenance

Periodic maintenance 3-8 eas28970 cleaning the spark arrester 1. Clean: • spark arrester ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ warning ewa14680 • select a well-ventilated area free of com- bustible materials. • always let the exhaust system cool before performing this operation. • do not start the engine w...

Page 78: Periodic Maintenance

Periodic maintenance 3-9 3. Remove: • wing bolt “1” • air filter element “2” • air filter element frame “3” eca2pa1301 • never operate the engine without the air filter element installed. • unfiltered air will cause rapid wear of engine parts and may damage the engine. • operating the engine without...

Page 79: Periodic Maintenance

Periodic maintenance 3-10 tip make sure its sealing surface matches the sealing surface of the case so there is no air leak. 10. Install: • air filter case cover 11. Install: • seat refer to “general chassis” on page 4-1. Eas20870 adjusting the clutch cable free play 1. Check: • clutch cable free pl...

Page 80: Periodic Maintenance

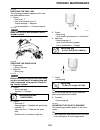

Periodic maintenance 3-11 eas21350 bleeding the hydraulic brake sys- tem warning ewa13100 bleed the hydraulic brake system when- ever: • the system is disassembled. • a brake hose is loosened, disconnected or replaced. • the brake fluid level is very low. • brake operation is faulty. Tip • be carefu...

Page 81: Periodic Maintenance

Periodic maintenance 3-12 warning ewa13110 after bleeding the hydraulic brake system, check the brake operation. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ eas21240 checking the brake fluid level 1. Place the vehicle on a level surface. Tip when checking the brake fluid level, make sure that the top of the brak...

Page 82: Periodic Maintenance

Periodic maintenance 3-13 eas29190 adjusting the brake pedal 1. Check: • brake pedal height “a” out of specification → adjust. Tip the brake pedal height “a” is measured from the root of the foot rest “a” to the brake pedal surface “b”. 2. Adjust: • rear brake pedal height ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼...

Page 83: Periodic Maintenance

Periodic maintenance 3-14 3. Check: • brake hose clamp loose → tighten the clamp bolt. 4. Hold the vehicle upright and apply the brake several times. 5. Check: • brake hose brake fluid leakage → replace the dam- aged hose or pipe. Refer to “front brake” on page 4-17. 6. Install: • front fender • sea...

Page 84: Periodic Maintenance

Periodic maintenance 3-15 warning ewa4d3f003 after this adjustment is performed, lift the rear wheels off the ground by placing a block under the engine, and spin the rear wheels to ensure there is no brake drag. If any brake drag is noticed perform the above steps again. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲...

Page 85: Periodic Maintenance

Periodic maintenance 3-16 • use no more than the following pressures when seating the tire beads. • front 250 kpa (2.5 kgf/cm², 36 psi) • rear 250 kpa (2.5 kgf/cm², 36 psi) higher pressures and fast inflation may cause a tire to burst. Inflate the tires very slowly and carefully. Maximum loading lim...

Page 86: Periodic Maintenance

Periodic maintenance 3-17 eas2pa1305 checking the wheel hub bearings refer to “checking the front wheel hubs” on page 4-7. Eas2pa1306 checking and lubricating the swin- garm pivots refer to “swingarm” on page 4-55. Eas2pa1307 lubricating the upper and lower arm pivots refer to “front arms and front ...

Page 87: Periodic Maintenance

Periodic maintenance 3-18 ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ eas21440 lubricating the drive chain the drive chain consists of many interacting parts. If the drive chain is not maintained prop- erly, it will wear out quickly. Therefore, the drive chain should be serviced, especially when the vehicle is u...

Page 88: Periodic Maintenance

Periodic maintenance 3-19 ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ eas4d3f006 checking the rear shock absorber assembly 1. Place the vehicle on a level surface. 2. Check: • rear shock absorber rod • rear shock absorber • spring refer to “checking the rear shock absorber assembly” on page 4-54. 3. Check: • ope...

Page 89: Periodic Maintenance

Periodic maintenance 3-20 eas2pa1310 lubricating the steering shaft refer to “steering stem” on page 4-46. Eas29280 checking the steering system 1. Place the vehicle on a level surface. 2. Check: • steering assembly bushings move the handlebar up and down, and back and forth. Excessive play → replac...

Page 90: Periodic Maintenance

Periodic maintenance 3-21 ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 3. Adjust: • toe-in warning ewa14910 • be sure that both tie-rods are turned the same amount. If not, the vehicle will drift right or left even though the handlebar is positioned straight. This may lead to mis- handling and an accident. • afte...

Page 91: Periodic Maintenance

Periodic maintenance 3-22 3. Check: • engine oil level the engine oil level should be between the minimum level mark “a” and maxi- mum level mark “b”. Below the minimum level mark → add the recommended engine oil to the proper level. Tip do not screw the dipstick “1” in when checking the oil level. ...

Page 92: Periodic Maintenance

Periodic maintenance 3-23 9. Install: • dipstick (along with the o-ring ) 10. Start the engine, warm it up for several minutes, and then turn it off. 11. Check: • engine (for engine oil leaks) 12. Check: • engine oil level refer to “checking the engine oil level” on page 3-21. 13. Install: • engine ...

Page 93: Periodic Maintenance

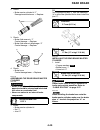

Periodic maintenance 3-24 eas20660 adjusting the throttle cable free play tip prior to adjusting the throttle cable free play, the engine idling speed should be adjusted. 1. Check: • throttle cable free play “a” out of specification → adjust. 2. Adjust: • throttle cable free play ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼...

Page 94: Periodic Maintenance

Periodic maintenance 3-25 2. Adjust: • speed limiter length ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Loosen the locknut “1”. B. Turn the adjusting screw “2” in or out until the specified speed limiter length is obtained. C. Tighten the locknut. Warning ewa14880 • particularly for a beginner rider, the spee...

Page 95: Periodic Maintenance

Periodic maintenance 3-26 tip • remove them from the right side of the vehi- cle. • push the headlight bulb holder inward, turn it counterclockwise and remove the defective bulb. Warning ewa13320 since the headlight bulb gets extremely hot, keep flammable products and your hands away from the bulb u...

Page 96: Periodic Maintenance

Periodic maintenance 3-27.

Page 97: Chassis

4 chassis general chassis.................................................................................... 4-1 removing the front panel........................................................... 4-5 installing the front panel ......................................................... 4-5 front whe...

Page 98

Rear brake ............................................................................................4-30 introduction ..................................................................................4-35 checking the rear brake disc .................................................4-35 replacing...

Page 99

Chain drive .............................................................................................4-58 removing the drive chain ..........................................................4-59 checking the drive chain ..........................................................4-59 checking the d...

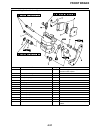

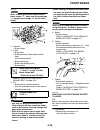

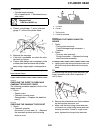

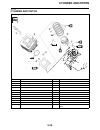

Page 100: General Chassis

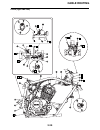

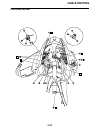

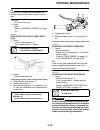

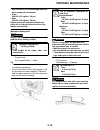

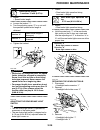

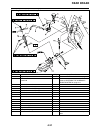

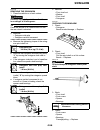

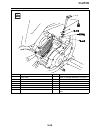

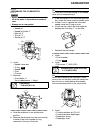

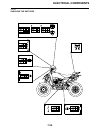

General chassis 4-1 eas21830 general chassis removing the seat, front fender and headlight order job/parts to remove q’ty remarks 1 seat 1 tip pull back the seat lock lever, than pull up on the rear of the seat. 2 front panel 1 3 main switch coupler 1 disconnect. 4 wire harness clamp 1 5 fuel tank c...

Page 101: General Chassis

General chassis 4-2 removing the foot protectors and engine skid plate order job/parts to remove q’ty remarks 1 left foot protector 1 2 right foot protector 1 3 engine skid plate 1 for installation, reverse the removal proce- dure..

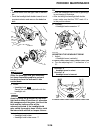

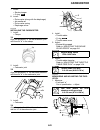

Page 102: General Chassis

General chassis 4-3 removing the rear fender and air filter case order job/parts to remove q’ty remarks seat/front fender refer to “general chassis” on page 4-1. 1 rear fender 1 2 battery cover 1 3 negative battery lead 1 4 positive battery lead 1 5 battery 1 6 tail/brake light lead 3 disconnect. 7 ...

Page 103: General Chassis

General chassis 4-4 removing the rear fender and air filter case order job/parts to remove q’ty remarks 14 license bracket 1 can 15 rear reflector 1 can 16 air filter case 1 17 left side cover 1 18 rear side reflector 2 can for installation, reverse the removal proce- dure..

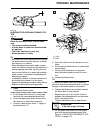

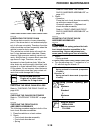

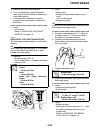

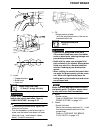

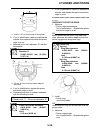

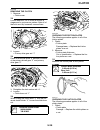

Page 104: General Chassis

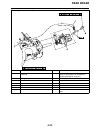

General chassis 4-5 eas2pa1401 removing the front panel 1. Remove: • quick fasteners “1” 2. Remove • front panel ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Pull the panel upward as shown, and then remove the socket “1” (together with the bulb) by pulling it out. B. Pull the panel downward, and then remove th...

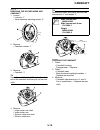

Page 105: Front Wheel

Front wheel 4-6 eas21870 front wheel removing the front wheel and brake discs order job/parts to remove q’ty remarks the following procedure applies to both of the front wheels. 1 cotter pin 1 2 axle nut 1 3 front wheel 1 4 brake disc guard (outer) 1 5 brake caliper assembly 1 6 wheel hub 1 7 collar...

Page 106: Front Wheel

Front wheel 4-7 eas21890 removing the front wheels the following procedure applies to both of the front wheels. 1. Place the vehicle on a level surface. Warning ewa13120 securely support the vehicle so that there is no danger of it falling over. Tip place the vehicle on a suitable stand so that the ...

Page 107: Front Wheel

Front wheel 4-8 2. Check: • wheel bearings wheel hub play/wheel turns roughly → replace. ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Clean wheel hub exterior. B. Drive bearing out by pushing spacer aside and tapping around perimeter of bearing inner race. Use soft metal drift punch and hammer. The spacer “1” ...

Page 108: Front Wheel

Front wheel 4-9 eas29420 installing the front wheels the following procedure applies to both of the front wheels. 1. Install: • brake disc guard (outer) 2. Install: • front wheel front wheel nut 45 nm (4.5 m·kgf, 33 ft·lbf).

Page 109: Rear Wheel

Rear wheel 4-10 eas22020 rear wheel removing the rear wheel order job/parts to remove q’ty remarks 1 rear wheel 2 2 cotter pin 2 3 axle nut 2 4 wheel hub 2 for installation, reverse the removal proce- dure..

Page 110: Rear Wheel

Rear wheel 4-11 eas22040 removing the rear wheels 1. Place the vehicle on a level surface. Warning ewa13120 securely support the vehicle so that there is no danger of it falling over. Tip place the vehicle on a suitable stand so that the rear wheel is elevated. 2. Remove: • rear wheels eas29430 chec...

Page 111

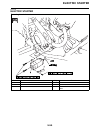

Rear axle and rear axle hub 4-12 eas29470 rear axle and rear axle hub removing the rear axle and rear axle hub order job/parts to remove q’ty remarks rear wheels/rear wheel hubs refer to “rear wheel” on page 4-10. 1 rear axle ring nut set bolt 2 2 rear axle ring nut 1 3 conical spring washer 1 4 bra...

Page 112

Rear axle and rear axle hub 4-13 removing the rear axle and rear axle hub order job/parts to remove q’ty remarks 11 rear axle pinch bolt 4 loosen. Refer to “adjusting the drive chain slack” on page 3-17. 12 rear axle hub 1 13 bearing/oil seal 2/2 14 spacer 1 for installation, reverse the removal pro...

Page 113

Rear axle and rear axle hub 4-14 eas29490 removing the rear axle 1. Place the vehicle on a level surface. 2. Remove: • rear axle ring nut set bolts “1” 3. Loosen: • rear axle ring nut “2” tip • apply the brake pedal so that the rear axle does not turn when loosening the nut. • use the axle nut wrenc...

Page 114

Rear axle and rear axle hub 4-15 eas2pa1403 checking the rear axle hub 1. Check: • rear axle hub cracks/damage → replace. Eas29510 checking the rear wheel sprocket 1. Check: • rear wheel sprocket refer to “checking the drive sprocket” on page 4-60. Eas2pa1404 checking the sprocket bracket 1. Check: ...

Page 115

Rear axle and rear axle hub 4-16.

Page 116: Front Brake

Front brake 4-17 eas22210 front brake removing the front brake pads order job/parts to remove q’ty remarks the following procedure applies to both of the front brake calipers. Front wheel refer to “front wheel” on page 4-6. 1 brake pad retaining bolt 2 2 brake pad 2 3 brake pad spring 1 4 brake pad ...

Page 117: Front Brake

Front brake 4-18 removing the front brake master cylinder order job/parts to remove q’ty remarks brake fluid drain. Refer to “bleeding the hydraulic brake system” on page 3-11. 1 front brake light switch connector 2 disconnect. 2 brake fluid reservoir cap 1 3 brake fluid reservoir diaphragm plate 1 ...

Page 118: Front Brake

Front brake 4-19 disassembling the front brake master cylinder order job/parts to remove q’ty remarks 1 brake master cylinder kit 1 2 brake master cylinder body 1 for assembly, reverse the disassembly pro- cedure..

Page 119: Front Brake

Front brake 4-20 removing the front brake calipers order job/parts to remove q’ty remarks the following procedure applies to both of the front brake calipers. Brake fluid drain. Refer to “bleeding the hydraulic brake system” on page 3-11. Front wheel refer to “front wheel” on page 4-6. 1 union bolt ...

Page 120: Front Brake

Front brake 4-21 disassembling the front brake calipers order job/parts to remove q’ty remarks the following procedure applies to both of the front brake calipers. 1 brake pad retaining bolt 2 2 brake pad 2 3 brake pad spring 1 4 brake pad shim 1 5 dust plug 1 6 slide pin bolt 1 7 boot 1 8 brake cal...

Page 121: Front Brake

Front brake 4-22 eas22221 introduction warning ewa14101 disc brake components rarely require dis- assembly. Therefore, always follow these preventive measures: • never disassemble brake components unless absolutely necessary. • if any connection on the hydraulic brake system is disconnected, the ent...

Page 122: Front Brake

Front brake 4-23 d. Measure the brake disc deflection. E. If out of specification, repeat the adjust- ment steps until the brake disc deflection is within specification. F. If the brake disc deflection cannot be brought within specification, replace the brake disc. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 6. ...

Page 123: Front Brake

Front brake 4-24 5. Check: • brake lever operation soft or spongy feeling → bleed the brake system. Refer to “bleeding the hydraulic brake system” on page 3-11. Eas22300 removing the front brake calipers the following procedure applies to both of the brake calipers. Tip before removing the brake cal...

Page 124: Front Brake

Front brake 4-25 • brake caliper cylinder “2” scratches/wear → replace the brake cal- iper assembly. • brake caliper body “3” cracks/damage → replace the brake caliper assembly. • brake fluid delivery passage (brake caliper body) obstruction → blow out with compressed air. Warning ewa13601 whenever ...

Page 125: Front Brake

Front brake 4-26 eca14170 when installing the brake hose onto the brake caliper “1”, make sure the brake pipe “a” passes notch-shape “b” on the brake caliper. 2. Remove: • brake caliper 3. Install: • brake pads • brake pad shim (brake caliper piston side) (onto the brake pad) • brake pad spring • br...

Page 126: Front Brake

Front brake 4-27 2. Remove: • union bolt • copper washers • brake hose tip to collect any remaining brake fluid, place a container under the master cylinder and the end of the brake hose. Eas22500 checking the front brake master cylinder 1. Check: • brake master cylinder “1” damage/scratches/wear → ...

Page 127: Front Brake

Front brake 4-28 2. Install: • copper washers • brake hose • union bolt warning ewa13530 proper brake hose routing is essential to insure safe vehicle operation. Refer to “cable routing” on page 2-27. Tip • while holding the brake hose, tighten the union bolt as shown. • turn the handlebar to the le...

Page 128: Front Brake

Front brake 4-29 6. Check: • brake lever operation soft or spongy feeling → bleed the brake system. Refer to “bleeding the hydraulic brake system” on page 3-11..

Page 129: Rear Brake

Rear brake 4-30 eas22550 rear brake removing the rear brake pads order job/parts to remove q’ty remarks 1 brake pad retaining bolt 2 2 lock washer 1 3 brake pad 2 4 brake pad spring 1 for installation, reverse the removal proce- dure..

Page 130: Rear Brake

Rear brake 4-31 removing the rear brake master cylinder order job/parts to remove q’ty remarks right foot protector refer to “general chassis” on page 4-1. Brake fluid drain. Refer to “bleeding the hydraulic brake system” on page 3-11. 1 brake fluid reservoir cover 1 2 brake fluid reservoir cap 1 3 ...

Page 131: Rear Brake

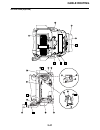

Rear brake 4-32 disassembling the rear brake master cylinder order job/parts to remove q’ty remarks 1 pin 1 2 joint 1 3 brake master cylinder kit 1 4 brake master cylinder 1 for assembly, reverse the disassembly pro- cedure..

Page 132: Rear Brake

Rear brake 4-33 removing the rear brake caliper order job/parts to remove q’ty remarks brake fluid drain. Refer to “bleeding the hydraulic brake system” on page 3-11. 1 parking brake cable 1 disconnect. 2 union bolt 1 3 copper washer 2 4 brake hose 1 disconnect. 5 brake caliper assembly 1 for instal...

Page 133: Rear Brake

Rear brake 4-34 disassembling the rear brake caliper order job/parts to remove q’ty remarks 1 spring 1 2 locknut 1 loosen. 3 adjusting bolt 1 4 parking brake arm 1 5 brake pad retaining bolt 2 6 lock washer 1 7 brake pad 2 8 brake pad spring 1 9 slide pin bolt 1 10 brake caliper bracket 1 11 boot 2 ...

Page 134: Rear Brake

Rear brake 4-35 eas22561 introduction warning ewa14101 disc brake components rarely require dis- assembly. Therefore, always follow these preventive measures: • never disassemble brake components unless absolutely necessary. • if any connection on the hydraulic brake system is disconnected, the enti...

Page 135: Rear Brake

Rear brake 4-36 b. Loosen the bleed screw and push the brake caliper pistons into the brake caliper with your finger. C. Tighten the bleed screw. D. Install the brake pads and a brake pad spring. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 3. Install: • lock washer “1” • brake pad retaining bolts “2” 4. Bend the...

Page 136: Rear Brake

Rear brake 4-37 ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Blow compressed air into the brake hose joint opening “a” to force out the piston from the brake caliper. Warning ewa13550 • cover the brake caliper piston with a rag. Be careful not to get injured when the pis- ton is expelled from the brake caliper...

Page 137: Rear Brake

Rear brake 4-38 1. Install: • brake caliper piston seal “1” • brake caliper piston dust seal “2” 2. Install: • brake caliper piston “1” 3. Install: • parking brake arm “1” 4. Measure: • parking brake arm to parking brake bracket distance “a” out of specification → adjust. Eas22670 installing the rea...

Page 138: Rear Brake

Rear brake 4-39 4. Fill: • brake fluid reservoir (with the specified amount of the recom- mended brake fluid) warning ewa13090 • use only the designated brake fluid. Other brake fluids may cause the rubber seals to deteriorate, causing leakage and poor brake performance. • refill with the same type ...

Page 139: Rear Brake

Rear brake 4-40 2. Check: • brake master cylinder kit “1” damage/scratches/wear → replace. 3. Check: • brake fluid reservoir “1” cracks/damage → replace. • brake fluid reservoir diaphragm “2” cracks/damage → replace. 4. Check: • brake hose cracks/damage/wear → replace. Eas22730 assembling the rear b...

Page 140: Rear Brake

Rear brake 4-41 2. Install: • brake fluid reservoir hose “1” tip install the brake fluid reservoir hose with the white paint mark “a” facing up as shown. 3. Fill: • brake fluid reservoir (with the specified amount of the recom- mended brake fluid) warning ewa13090 • use only the designated brake flu...

Page 141: Handlebar

Handlebar 4-42 eas22840 handlebar removing the handlebar order job/parts to remove q’ty remarks 1 handlebar protector 1 2 band 3 3 front brake light switch 1 4 brake master cylinder/bracket 1/1 5 throttle lever assembly/bracket 1/1 6 spacer 1 7 clutch switch 1 8 parking brake lever 1 9 clutch lever/...

Page 142: Handlebar

Handlebar 4-43 eas22860 removing the handlebar 1. Remove: • clutch switch “1” tip push the fastener when removing the clutch switch out of the clutch lever holder. 2. Remove: • handlebar grip “1” tip blow compressed air between the left handle- bar and the handlebar grip, and gradually push the grip...

Page 143: Handlebar

Handlebar 4-44 tip • before applying the adhesive, wipe off grease or oil on the handlebar surface “a” with a lacquer thinner. • install the handlebar grips so that the “l” arrow on the left grip and “r” arrow on the right grip are placed vertically. 3. Install: • handlebar switch “1” • clutch lever...

Page 144: Handlebar

Handlebar 4-45 throttle cable free play 2.0–4.0 mm (0.08–0.16 in).

Page 145: Steering Stem

Steering stem 4-46 eas29540 steering stem removing the steering stem order job/parts to remove q’ty remarks front fender refer to “general chassis” on page 4-1. 1 lock washer 1 2 bracket 1 3 steering stem bushing 2 4 spacer 2 5 oil seal 2 6 steering stem 1 7 bushing 2 for installation, reverse the r...

Page 146: Steering Stem

Steering stem 4-47 eas29560 checking the steering stem 1. Check: • steering stem “1” bends → replace. Warning ewa15030 do not attempt to straighten a bent stem; this may dangerously weaken the stem. 2. Check: • oil seals “1” • steering stem bushings “2” wear/damage → replace. 3. Check: • o-rings “1”...

Page 147

Tie-rods and steering knuckles 4-48 eas29660 tie-rods and steering knuckles removing the tie-rods and steering knuckles order job/parts to remove q’ty remarks the following procedure applies to both of the tie-rods and steering knuckles. Front wheel refer to “front wheel” on page 4-6. Front brake ca...

Page 148

Tie-rods and steering knuckles 4-49 eas29670 removing the steering knuckles the following procedure applies to both of the steering knuckles. 1. Remove: • steering knuckle “1” tip use a general puller to separate the ball joints “2” from the steering knuckle “1”. Eas29680 checking the tie-rods the f...

Page 149

Front arms and front shock absorber assemblies 4-50 eas29710 front arms and front shock absorber assemblies removing the front arms and front shock absorber assemblies order job/parts to remove q’ty remarks the following procedure applies to both of the front upper arms, front lower arms, and front ...

Page 150

Front arms and front shock absorber assemblies 4-51 eas29720 removing the front arms the following procedure applies to both of the front upper arms and front lower arms. 1. Check: • front arm free play ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Check the front arm side play “a” by mov- ing it from side to s...

Page 151

Front arms and front shock absorber assemblies 4-52 eas29770 checking the front arm ball joints the following procedure applies to each of the front arm ball joints. 1. Check: • ball joint damage/pitting → replace the front arm. Free play → replace the front arm. Turns roughly → replace the front ar...

Page 152

Rear shock absorber assembly 4-53 eas23160 rear shock absorber assembly removing the rear shock absorber assembly order job/parts to remove q’ty remarks seat/rear fender/air filter case refer to “general chassis” on page 4-1. 1 rear shock absorber assembly 1 for installation, reverse the removal pro...

Page 153

Rear shock absorber assembly 4-54 eas23170 handling the rear shock absorber warning ewa13750 this rear shock absorber contains highly compressed nitrogen gas. Before handling the rear shock absorber, read and make sure you understand the following informa- tion. The manufacturer cannot be held respo...

Page 154: Swingarm

Swingarm 4-55 eas23330 swingarm removing the swingarm order job/parts to remove q’ty remarks rear axle hub refer to “rear axle and rear axle hub” on page 4-12. Rear shock absorber assembly refer to “rear shock absorber assembly” on page 4-53. 1 plate 1 2 swingarm end cover 1 3 pivot shaft nut/washer...

Page 155: Swingarm

Swingarm 4-56 eas23340 removing the swingarm 1. Place the vehicle on a level surface. Warning ewa13120 securely support the vehicle so that there is no danger of it falling over. Tip place the vehicle on a suitable stand so that the rear wheel is elevated. 2. Measure: • swingarm side play • swingarm...

Page 156: Swingarm

Swingarm 4-57 eas23380 installing the swingarm 1. Lubricate: • bearings • spacer • oil seals 2. Install: • bearings “1” • spacer “2” • oil seals • dust covers tip inject the bearing with the character stamp turned outward. 3. Install: • pivot shaft 4. Install: • rear shock absorber assembly • rear a...

Page 157: Chain Drive

Chain drive 4-58 eas23400 chain drive removing the drive chain order job/parts to remove q’ty remarks swingarm refer to “swingarm” on page 4-55. 1 drive sprocket cover 1 2 drive chain guide 1 3 drive sprocket lock plate 1 4 drive sprocket 1 5 drive chain 1 for installation, reverse the removal proce...

Page 158: Chain Drive

Chain drive 4-59 eas23410 removing the drive chain 1. Place the vehicle on a level surface. Warning ewa13120 securely support the vehicle so that there is no danger of it falling over. Tip place the vehicle on a suitable stand so that the rear wheel is elevated. 2. Remove: • swingarm refer to “swing...

Page 159: Chain Drive

Chain drive 4-60 ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 3. Check: • o-rings “1” damage → replace the drive chain. • drive chain rollers “2” damage/wear → replace the drive chain. • drive chain side plates “3” damage/wear → replace the drive chain. Cracks → replace the drive chain. 4. Lubricate: • drive chai...

Page 160: Chain Drive

Chain drive 4-61 eca13550 a drive chain that is too tight will overload the engine and other vital parts, and one that is too loose can skip and damage the swingarm or cause an accident. Therefore, keep the drive chain slack within the speci- fied limits..

Page 161: Engine

5 engine engine removal ...................................................................................... 5-1 installing the engine .................................................................... 5-4 installing the muffler and exhaust pipe.............................. 5-4 cylinder head......

Page 162

Oil pump ...................................................................................................5-40 checking the oil pump ................................................................5-42 checking the rotary filter.......................................................5-42 assembling...

Page 164: Engine Removal

Engine removal 5-1 eas23711 engine removal removing the exhaust pipe and muffler order job/parts to remove q’ty remarks 1 muffler clamp 1 loosen. 2 muffler 1 3 muffler gasket 1 4 spark arrester 1 5 gasket 1 6 exhaust pipe 1 7 exhaust pipe protector 1 8 gasket 1 for installation, reverse the removal ...

Page 165: Engine Removal

Engine removal 5-2 * yamaha bond no.1215 (three bond no.1215®) disconnecting the leads and hoses order job/parts to remove q’ty remarks carburetor refer to “carburetor” on page 6-3. Drive sprocket refer to “chain drive” on page 4-58. 1 spark plug cap 1 disconnect. 2 crankcase breather hose 1 disconn...

Page 166: Engine Removal

Engine removal 5-3 removing the engine order job/parts to remove q’ty remarks 1 engine mounting bolt (front) 1 2 engine bracket (left and right) 2 3 engine mounting bolt (upper) 1 4 engine bracket (upper) 1 5 engine mounting bolt (rear upper) 1 6 engine mounting bolt (rear lower) 1 7 engine 1 for in...

Page 167: Engine Removal

Engine removal 5-4 eas23720 installing the engine 1. Install: • engine mounting bolt (rear lower side) “1” • engine mounting bolt (rear upper side) “2” • engine bracket bolts (upper side) “3” • engine mounting bolt (upper side) “4” • engine brackets (front side) “5” “6” • engine mounting bolt (front...

Page 168: Engine Removal

Engine removal 5-5 3. Install: • muffler gasket “1” (to muffler) 4. Install: • gasket “1” • spark arrester “2” (to muffler) 5. Install: • muffler clamp tip slide the clamp onto the end of the muffler and insert the projection “a” of the clamp into a slot “b” in the muffler. Tighten the clamp after i...

Page 169: Cylinder Head

Cylinder head 5-6 eas24100 cylinder head * yamaha bond no.1215 (three bond no.1215®) removing the cylinder head order job/parts to remove q’ty remarks spark plug cap refer to “engine removal” on page 5-1. Fuel tank refer to “fuel tank” on page 6-1. Carburetor refer to “carburetor” on page 6-3. 1 eng...

Page 170: Cylinder Head

Cylinder head 5-7 * yamaha bond no.1215 (three bond no.1215®) removing the cylinder head order job/parts to remove q’ty remarks 11 plate 1 12 gasket 1 13 cylinder head gasket 1 14 dowel pin 2 for installation, reverse the removal proce- dure..

Page 171: Cylinder Head

Cylinder head 5-8 eas24130 removing the cylinder head 1. Align: • “i” mark “a” on the generator rotor (with the stationary pointer “b” on the generator rotor cover) ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Turn the crankshaft counterclockwise. B. When the piston is at tdc on the compres- sion stroke, align...

Page 172: Cylinder Head

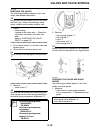

Cylinder head 5-9 3. Measure: • cylinder head warpage out of specification → resurface the cyl- inder head. ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Place a straightedge “1” and a thickness gauge “2” across the cylinder head. B. Measure the warpage. C. If the limit is exceeded, resurface the cylin- der hea...

Page 173: Cylinder Head

Cylinder head 5-10 ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 3. Check: • timing chain tensioner cap bolt • timing chain tensioner rod damage/wear → replace the timing chain tensioner assembly. Eas24230 installing the cylinder head 1. Install: • dowel pins • cylinder head gasket 2. Install: • cylinder head • wa...

Page 174: Cylinder Head

Cylinder head 5-11 eca13740 do not turn the crankshaft when installing the camshaft sprocket to avoid damage or improper valve timing. Tip • when installing the camshaft sprocket, be sure to keep the timing chain as tight as pos- sible on the exhaust side. • align the projection “e” on the camshaft ...

Page 175: Cylinder Head

Cylinder head 5-12 9. Tighten: • camshaft sprocket bolts eca13750 be sure to tighten the camshaft sprocket bolts to the specified torque to avoid the possibility of the bolts coming loose and damaging the engine. 10. Measure: • valve clearance out of specification → adjust. Refer to “adjusting the v...

Page 176: Camshaft

Camshaft 5-13 eas23730 camshaft removing the rocker arms and camshaft order job/parts to remove q’ty remarks intake tappet cover/exhaust tappet cover refer to “cylinder head” on page 5-6. Camshaft sprocket refer to “cylinder head” on page 5-6. 1 locknut/valve clearance adjusting screw 2/2 loosen. 2 ...

Page 177: Camshaft

Camshaft 5-14 eas23770 removing the rocker arms and camshaft 1. Loosen: • locknuts “1” • valve clearance adjusting screws “2” 2. Remove: • camshaft retainer “1” 3. Remove: • camshaft “1” tip screw 8 mm (0.31 in) bolt “2” into the threaded end of the camshaft and then pull out the cam- shaft. 4. Remo...

Page 178: Camshaft

Camshaft 5-15 4. Check: • camshaft oil passage obstruction → blow out with compressed air. Eas23880 checking the rocker arms and rocker arm shafts the following procedure applies to all of the rocker arms and rocker arm shafts. 1. Check: • rocker arms damage/wear → replace. 2. Check: • rocker arm sh...

Page 179: Camshaft

Camshaft 5-16 5. Measure: • rocker arm shaft outside diameter “a” out of specification → replace. 6. Calculate: • rocker-arm-to-rocker-arm-shaft clear- ance out of specification → replace the defec- tive part(s). Tip calculate the clearance by subtracting the rocker arm shaft outside diameter from t...

Page 180: Camshaft

Camshaft 5-17 4. Install: • camshaft “1” tip screw 8 mm (0.31 in) bolt “2” into the threaded end of the camshaft and then install the cam- shaft. 5. Install: • camshaft retainer “1” camshaft retainer bolt 10 nm (1.0 m·kgf, 7.2 ft·lbf) loctite®.

Page 181: Valves And Valve Springs

Valves and valve springs 5-18 eas24270 valves and valve springs removing the valves and valve springs order job/parts to remove q’ty remarks cylinder head refer to “cylinder head” on page 5-6. Rocker arm/camshaft refer to “camshaft” on page 5-13. 1 valve cotter 4 2 valve spring retainer 2 3 valve sp...

Page 182: Valves And Valve Springs

Valves and valve springs 5-19 eas24280 removing the valves the following procedure applies to all of the valves and related components. Tip before removing the internal parts of the cylin- der head (e.G., valves, valve springs, valve seats), make sure the valves properly seal. 1. Check: • valve seal...

Page 183: Valves And Valve Springs

Valves and valve springs 5-20 2. Replace: • valve guide tip to ease valve guide removal and installation, and to maintain the correct fit, heat the cylinder head to 100 °c (212 °f) in an oven. ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Remove the valve guide with the valve guide remover “1”. B. Install the n...

Page 184: Valves And Valve Springs

Valves and valve springs 5-21 ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 3. Eliminate: • carbon deposits (from the valve face and valve seat) 4. Check: • valve face pitting/wear → grind the valve face. • valve stem end mushroom shape or diameter larger than the body of the valve stem → replace the valve. 5. Mea...

Page 185: Valves And Valve Springs

Valves and valve springs 5-22 ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Apply mechanic’s blueing dye (dykem) “b” onto the valve face. B. Install the valve into the cylinder head. C. Press the valve through the valve guide and onto the valve seat to make a clear impression. D. Measure the valve seat width. T...

Page 186: Valves And Valve Springs

Valves and valve springs 5-23 h. Install the valve into the cylinder head. I. Press the valve through the valve guide and onto the valve seat to make a clear impression. J. Measure the valve seat width “c” again. If the valve seat width is out of specification, reface and lap the valve seat. ▲▲▲▲▲▲▲...

Page 187: Valves And Valve Springs

Valves and valve springs 5-24 eas24340 installing the valves the following procedure applies to all of the valves and related components. 1. Deburr: • valve stem end (with an oil stone) 2. Lubricate: • valve stem “1” • valve stem seal “2” (with the recommended lubricant) 3. Install: • valve stem sea...

Page 188: Valves And Valve Springs

Valves and valve springs 5-25 5. To secure the valve cotters onto the valve stem, lightly tap the valve tip with a soft- face hammer. Eca13800 hitting the valve tip with excessive force could damage the valve..

Page 189: Cylinder And Piston

Cylinder and piston 5-26 eas24350 cylinder and piston removing the cylinder and piston order job/parts to remove q’ty remarks cylinder head refer to “cylinder head” on page 5-6. 1 timing chain guide (exhaust side) 1 2 cylinder 1 3 cylinder gasket 1 4 dowel pin 2 5 piston pin clip 2 6 piston pin 1 7 ...

Page 190: Cylinder And Piston

Cylinder and piston 5-27 eas24380 removing the piston 1. Remove: • piston pin clips “1” • piston pin “2” • piston “3” eca13810 do not use a hammer to drive the piston pin out. Tip • before removing the piston pin clip, cover the crankcase opening with a clean rag to pre- vent the piston pin clip fro...

Page 191: Cylinder And Piston

Cylinder and piston 5-28 b. If out of specification, rebore or replace the cylinder, and replace the piston and piston rings as a set. C. Measure piston skirt diameter “d” with the micrometer. D. If out of specification, replace the piston and piston rings as a set. E. Calculate the piston-to-cylind...

Page 192: Cylinder And Piston

Cylinder and piston 5-29 tip the oil ring expander spacer’s end gap cannot be measured. If the oil ring rail’s gap is exces- sive, replace all three piston rings. Eas24440 checking the piston pin 1. Check: • piston pin blue discoloration/grooves → replace the piston pin and then check the lubrica- t...

Page 193: Cylinder And Piston

Cylinder and piston 5-30 eas24450 installing the piston and cylinder 1. Install: • lower oil ring rail “1” • oil ring expander “2” • upper oil ring rail “3” • 2nd ring “4” • top ring “5” tip be sure to install the piston rings so that the manufacturer’s mark or number face up. 2. Install: • piston “...

Page 194: Clutch

Clutch 5-31 eas25061 clutch removing the clutch cover order job/parts to remove q’ty remarks engine oil drain. Refer to “changing the engine oil” on page 3-22. Starter motor refer to “electric starter” on page 5- 54. 1 battery negative lead 1 disconnect. 2 clutch cover 1 3 clutch cover gasket 1 4 do...

Page 195: Clutch

Clutch 5-32 removing the clutch order job/parts to remove q’ty remarks 1 clutch spring 4 2 pressure plate 1 3 locknut/washer 1/1 4 short clutch push rod 1 5 clutch push rod holder 1 6 ball 1 7 friction plate 4 8 clutch plate 3 9 primary drive gear nut 1 10 washer 1 11 clutch boss nut 1 12 lock washe...

Page 196: Clutch

Clutch 5-33 removing the clutch order job/parts to remove q’ty remarks 14 thrust washer 1 15 clutch housing 1 16 plate washer 1 17 primary drive gear 1 18 straight key 1 for installation, reverse the removal proce- dure..

Page 197: Clutch

Clutch 5-34 removing the push lever order job/parts to remove q’ty remarks clutch cable refer to “engine removal” on page 5-1. Short clutch push rod refer to “clutch” on page 5-31. 1 clutch push lever 1 2 clutch push lever spring 1 3 circlip 1 4 oil seal 1 for installation, reverse the removal proce...

Page 198: Clutch

Clutch 5-35 eas25070 removing the clutch 1. Remove: • clutch cover tip loosen each bolt 1/4 of a turn at a time, in stages and in a crisscross pattern. After all of the bolts are fully loosened, remove them. 2. Loosen: • primary drive gear nut “1” tip place an aluminum plate “a” between the teeth of...

Page 199: Clutch

Clutch 5-36 2. Measure: • clutch plate warpage (with a surface plate and thickness gauge “1”) out of specification → replace the clutch plates as a set. Eas25140 checking the clutch springs the following procedure applies to all of the clutch springs. 1. Check: • clutch spring damage → replace the c...

Page 200: Clutch

Clutch 5-37 eas25191 checking the clutch push lever and clutch push rod 1. Check: • short clutch push rod “1” • ball “2” • clutch push lever “3” cracks/damage/wear → replace the defective part(s). Eas25200 checking the primary drive gear and primary driven gear 1. Check: • primary drive gear “1” • p...

Page 201: Clutch

Clutch 5-38 5. Bend the lock washer tab “a” along a flat side of the nut. 6. Tighten: • primary drive gear nut “1” tip place an aluminum plate “a” between the teeth of the primary drive gear “2” and primary driven gear “3”. 7. Lubricate: • friction plates (with the recommended lubricant) 8. Install:...

Page 202: Clutch

Clutch 5-39 ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 11. Install: • clutch cover tip tighten the clutch cover bolts in the proper tightening sequence as shown. 12. Install: • battery negative lead “1” tip • when installing the battery negative lead, clearance “a” between the top end of the bat- tery negative ...

Page 203: Oil Pump

Oil pump 5-40 eas24911 oil pump removing the oil pump order job/parts to remove q’ty remarks clutch housing/primary drive gear refer to “clutch” on page 5-31. 1 rotary filter 1 2 oil pump drive gear 1 3 oil pump assembly/oil pump driven gear 1 4 oil pump gasket 1 5 oil strainer 1 for installation, r...

Page 204: Oil Pump

Oil pump 5-41 * when replacing any of parts, replace the oil pump assembly. Disassembling the oil pump order job/parts to remove q’ty remarks 1 circlip 1 2 washer 1 3 conical spring washer 1 4 oil pump driven gear 1 5 pin 1 6 washer 1 7 oil pump housing cover 1 8 pin 1 9 oil pump shaft 1 10 oil pump...

Page 205: Oil Pump

Oil pump 5-42 eas24960 checking the oil pump 1. Check: • oil pump drive gear • oil pump driven gear • oil pump housing • oil pump housing cover cracks/damage/wear → replace the defective part(s). 2. Measure: • inner-rotor-to-outer-rotor-tip clearance “a” • outer-rotor-to-oil-pump-housing clear- ance...

Page 206: Oil Pump

Oil pump 5-43 2. Install: • oil pump outer rotor • oil pump inner rotor “1” • oil pump shaft • pin “2” • oil pump housing cover tip when installing the inner rotor, align the pin in the oil pump shaft with the groove “a” in the inner rotor. 3. Install: • washer • pin “1” • oil pump driven gear “2” •...

Page 207: Oil Pump

Oil pump 5-44.

Page 208: Shift Shaft

Shift shaft 5-45 eas25410 shift shaft removing the shift shaft and stopper lever order job/parts to remove q’ty remarks right footrest refer to “rear brake” on page 4-30. Clutch assembly refer to “clutch” on page 5-31. 1 shift pedal 1 2 shift shaft 1 3 circlip 1 4 shift shaft spring 1 5 shift shaft ...

Page 209: Shift Shaft

Shift shaft 5-46 eas25420 checking the shift shaft 1. Check: • shift shaft “1” • shift lever “2” bends/damage/wear → replace. • shift lever spring “3” • shift shaft spring stopper damage/wear → replace. Eas25430 checking the stopper lever 1. Check: • stopper lever “1” bends/damage → replace. Roller ...

Page 210: Shift Shaft

Shift shaft 5-47 tip hook the end of the shift shaft spring onto the shift shaft spring stopper “2”. 4. Install: • oil seal • shift pedal “1” tip • lubricate the oil seal lips with lithium-soap- based grease. • install the shift pedal as shown in the illustra- tion. • for the installation heights of...

Page 211

Generator and starter clutch 5-48 eas2pa1513 generator and starter clutch * yamaha bond no.1215 (three bond no.1215®) ** when replacing any of parts, replace the pickup coil/stator coil assembly. Removing the generator and starter clutch order job/parts to remove q’ty remarks engine oil drain. Refer...

Page 212

Generator and starter clutch 5-49 * yamaha bond no.1215 (three bond no.1215®) ** when replacing any of parts, replace the pickup coil/stator coil assembly. Removing the generator and starter clutch order job/parts to remove q’ty remarks 11 generator rotor 1 12 starter clutch assembly 1 13 starter cl...

Page 213

Generator and starter clutch 5-50 eas2pa1505 removing the generator rotor 1. Remove: • generator rotor cover tip loosen each bolt 1/4 of a turn at a time, in stages and in a crisscross pattern. After all of the bolts are fully loosened, remove them. 2. Remove: • generator rotor nut “1” • washer tip ...

Page 214

Generator and starter clutch 5-51 eas2pa1507 checking the stator coil assembly 1. Check: • stator coil • pickup coil damage → replace the stator coil assembly. Eas2pa1508 checking the starter clutch 1. Check: • starter clutch rollers “1” • starter clutch spring caps “2” • starter clutch springs “3” ...

Page 215

Generator and starter clutch 5-52 eas2pa1510 installing the generator rotor 1. Install: • starter clutch idle gear shaft “1” (to the left crankcase) • starter clutch idle gear • starter clutch idle gear holder 2. Install: • woodruff key • generator rotor • washer • generator rotor nut tip • clean th...

Page 216

Generator and starter clutch 5-53 5. Install: • stator coil • stator coil lead holder • pickup coil 6. Install: • dowel pin • generator rotor cover gasket • generator rotor cover tip tighten the generator rotor cover bolts in the proper tightening sequence as shown. 7. Install: • neutral switch lead...

Page 217: Electric Starter

Electric starter 5-54 eas24780 electric starter removing the starter motor order job/parts to remove q’ty remarks 1 starter motor lead 1 disconnect. 2 starter motor 1 for installation, reverse the removal proce- dure..

Page 218: Electric Starter

Electric starter 5-55 * when replacing any of parts, replace the starter motor assembly. Disassembling the starter motor order job/parts to remove q’ty remarks 1 starter motor front cover 1 2 lock washer 1 3 shim 1 4 circlip 1 5 starter motor rear cover 1 6 brush set 1 7 armature assembly 1 8 starte...

Page 219: Electric Starter

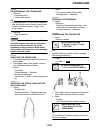

Electric starter 5-56 eas24791 checking the starter motor 1. Check: • commutator dirt → clean with 600 grit sandpaper. 2. Measure: • commutator diameter “a” out of specification → replace the starter motor. 3. Measure: • mica undercut “a” out of specification → scrape the mica to the proper measurem...

Page 220: Electric Starter

Electric starter 5-57 6. Measure: • brush spring force out of specification → replace the brush springs as a set. 7. Check: • gear teeth damage/wear → replace the starter motor. 8. Check: • bearing • oil seal damage/pitting → replace the starter motor. Eas24800 assembling the starter motor 1. Instal...

Page 221: Crankcase

Crankcase 5-58 eas25540 crankcase * yamaha bond no.1215 (three bond no.1215®) separating the crankcase order job/parts to remove q’ty remarks engine refer to “engine removal” on page 5-1. Cylinder head refer to “cylinder head” on page 5-6. Cylinder/piston refer to “cylinder and piston” on page 5-26....

Page 222: Crankcase

Crankcase 5-59 * yamaha bond no.1215 (three bond no.1215®) separating the crankcase order job/parts to remove q’ty remarks 5 right crankcase 1 6 left crankcase 1 7 dowel pin 2 for installation, reverse the removal proce- dure. 10 nm (1.0 m kgf, 7.2 ft ibf) t r ..

Page 223: Crankcase

Crankcase 5-60 separating the crankcase order job/parts to remove q’ty remarks crankshaft/balancer shaft refer to “crankshaft assembly” on page 5-63. Transmission refer to “transmission” on page 5-66. 1 oil seal 1 2 bearing retainer 1 3 bearing 7 for installation, reverse the removal proce- dure..

Page 224: Crankcase

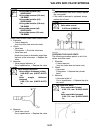

Crankcase 5-61 eas25570 disassembling the crankcase 1. Remove: • crankcase bolts • clutch cable holder tip • loosen each bolt 1/4 of a turn at a time and after all the bolts are loosened, remove them. • loosen the bolts in stages, using a criss- cross pattern. 2. Remove: • right crankcase eca13900 t...

Page 225: Crankcase

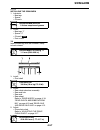

Crankcase 5-62 5. Install: • clutch cable holder • crankcase bolts tip apply sealant to the threads of the crankcase bolts. 6. Tighten: • crankcase bolts tip tighten each bolt 1/4 of a turn at a time, in stages and in the proper sequence as shown. • m6 × 45 mm bolts: “1”–“4”, “7”–“9”, “11”– “13” • m...

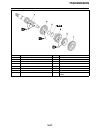

Page 226: Crankshaft Assembly

Crankshaft assembly 5-63 eas25970 crankshaft assembly removing the crankshaft and balancer order job/parts to remove q’ty remarks crankcase separate. Refer to “crankcase” on page 5-58. 1 balancer 1 2 crankshaft 1 for installation, reverse the removal proce- dure..

Page 227: Crankshaft Assembly

Crankshaft assembly 5-64 eas2pa1514 removing the crankshaft and bal- ancer 1. Remove: • balancer “1” 2. Remove: • crankshaft “1” eca2pa1501 • to protect the end of the crankshaft, place an appropriate sized socket between the crankcase separating tool bolt and the crankshaft. • do not tap on the cra...

Page 228: Crankshaft Assembly

Crankshaft assembly 5-65 eas26120 checking the balancer 1. Check: • balancer gear damage/wear → replace the balancer gear assembly. 2. Check: • balancer shaft cracks/damage/wear → replace the bal- ancer shaft. Dirt → clean. Eas26210 installing the crankshaft assem- bly 1. Install: • crankshaft “1” t...

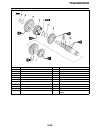

Page 229: Transmission

Transmission 5-66 eas26241 transmission removing the transmission, shift drum assembly, and shift forks order job/parts to remove q’ty remarks crankcase separate. Refer to “crankcase” on page 5-58. 1 long shift fork guide bar 1 2 short shift fork guide bar 1 3 shift fork-r 1 4 shift fork-l 1 5 shift...

Page 230: Transmission

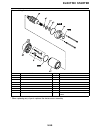

Transmission 5-67 disassembling the main axle order job/parts to remove q’ty remarks 1 5th pinion gear 1 2 2nd pinion gear 1 3 3rd pinion gear 1 4 circlip 1 5 washer 1 6 4th pinion gear 1 7 main axle/1st pinion gear 1 for assembly, reverse the disassembly pro- cedure..

Page 231: Transmission

Transmission 5-68 disassembling the drive axle order job/parts to remove q’ty remarks 1 5th wheel gear 1 2 2nd wheel gear 1 3 circlip 1 4 washer 1 5 1st wheel gear 1 6 4th wheel gear 1 7 circlip 1 8 washer 1 9 3rd wheel gear 1 10 drive axle 1 for assembly, reverse the disassembly pro- cedure..

Page 232: Transmission

Transmission 5-69 eas26250 removing the transmission 1. Remove: • long shift fork guide bar “1” • short shift fork guide bar “2” • shift drum “3” • shift fork-r “4” • shift fork-l “5” • shift fork-c “6” • transmission “7” eas26260 checking the shift forks the following procedure applies to all of th...

Page 233: Transmission

Transmission 5-70 2. Measure: • drive axle runout (with a centering device and dial gauge “1”) out of specification → replace the drive axle. 3. Check: • transmission gears blue discoloration/pitting/wear → replace the defective gear(s). • transmission gear dogs cracks/damage/rounded edges → replace...

Page 234: Transmission

Transmission 5-71 eas26320 installing the shift forks and shift drum 1. Install: • transmission “1” • shift fork-c “2” • shift fork-l “3” • shift fork-r “4” • shift drum “5” • short shift fork guide bar “6” • long shift fork guide bar “7” tip the embossed marks on the shift forks should face towards...

Page 235: Fuel System

6 fuel system fuel tank .................................................................................................. 6-1 removing the fuel tank ................................................................ 6-2 checking the fuel cock .............................................................

Page 236: Fuel Tank

Fuel tank 6-1 eas26620 fuel tank removing the fuel tank order job/parts to remove q’ty remarks seat refer to “general chassis” on page 4-1. Front fender refer to “general chassis” on page 4-1. 1 fuel hose (fuel cock side) 1 disconnect. 2 fuel tank 1 3 fuel cock 1 4 drain hose 1 disconnect. 5 fuel ta...

Page 237: Fuel Tank

Fuel tank 6-2 eas26630 removing the fuel tank 1. Extract the fuel in the fuel tank through the fuel tank cap with a pump. 2. Remove: • fuel hose (fuel cock side) eca14700 although the fuel has been removed from the fuel tank be careful when removing the fuel hoses, since there may be fuel remain- in...

Page 238: Carburetor

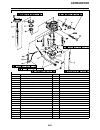

Carburetor 6-3 eas26730 carburetor removing the carburetor order job/parts to remove q’ty remarks seat refer to “general chassis” on page 4-1. Front fender refer to “general chassis” on page 4-1. Rear fender refer to “general chassis” on page 4-1. Air filter case refer to “general chassis” on page 4...

Page 239: Carburetor

Carburetor 6-4 disassembling the carburetor order job/parts to remove q’ty remarks 1 drain hose 1 2 throttle stop screw 1 3 diaphragm cover 1 4 piston valve spring 1 5 piston valve 1 6 ring 1 7 piston valve diaphragm 1 8 jet needle set 1 9 diaphragm cover 1 10 diaphragm spring 1 11 coasting enricher...

Page 240: Carburetor

Carburetor 6-5 disassembling the carburetor order job/parts to remove q’ty remarks 21 main jet 1 22 needle jet holder 1 23 needle jet 1 24 pilot jet 1 25 starter jet 1 26 pilot screw set 1 aus, nzl tip before disassembling the carburetor, make sure to note the number of times the pilot screw is turn...

Page 241: Carburetor

Carburetor 6-6 eas26770 checking the carburetor 1. Check: • carburetor body • float chamber cracks/damage → replace. 2. Check: • fuel passages obstruction → clean. ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Wash the carburetor in a petroleum-based solvent. Do not use any caustic carburetor cleaning solution....

Page 242: Carburetor

Carburetor 6-7 9. Check: • jet needle “1” bends/wear/damage → replace. • clip groove free play/wear → replace. • clip position (aus, nzl) 10. Check: • main jet “1” • pilot jet “2” • pilot screw “3” (aus, nzl) • needle jet “4” • needle jet holder “5” • starter jet “6” • coasting enricher jet (p. A. J...

Page 243: Carburetor

Carburetor 6-8 eas26810 assembling the carburetor eca14110 • before assembling the carburetor, wash all of the parts in a petroleum-based sol- vent. • always use a new gasket. 1. Install: • needle jet • needle jet holder “1” • main jet “2” • pilot jet “3” • starter jet “4” 2. Install: • needle valve...

Page 244: Carburetor

Carburetor 6-9 7. Install: • starter plunger • o-ring 8. Install: • piston valve (along with the diaphragm) • jet needle set • piston valve spring • diaphragm cover eas26890 installing the carburetor 1. Install: • clamps tip align the projection “a” on the carburetor joint with the slot “b” in the c...

Page 245: Carburetor

Carburetor 6-10 ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Stand the vehicle on a level surface. B. Install the fuel level gauge “1” onto the fuel drain pipe “2”. C. Loosen the fuel drain screw “3”. D. Hold the fuel level gauge vertically next to the float chamber “4”. E. Measure the fuel level “a”. ▲▲▲▲▲▲▲▲...

Page 246: Carburetor

Carburetor 6-11.

Page 247: Electrical System

7 electrical system ignition system....................................................................................... 7-1 circuit diagram................................................................................ 7-1 troubleshooting ............................................................

Page 248: Ignition System

Ignition system 7-1 eas27090 ignition system eas27100 circuit diagram.

Page 249: Ignition System

Ignition system 7-2 1. Pickup coil 4. Main switch 5. Battery 8. Fuse 9. Cdi unit 10.Ignition coil 11.Spark plug 22.Left handlebar switch 24.Engine stop switch.

Page 250: Ignition System

Ignition system 7-3 eas27131 troubleshooting the ignition system fails to operate (no spark or intermittent spark). Tip • before troubleshooting, remove the following part(s): 1. Seat 2. Front panel 3. Front fender 4. Rear fender 5. Left side cover ng → ok ↓ ng → ok ↓ ng → ok ↓ ok → ng ↓ ng → ok ↓ n...

Page 251: Ignition System

Ignition system 7-4 ng → ok ↓ ng → ok ↓ ng → ok ↓ 8. Check the main switch. Refer to “checking the switches” on page 7-29. Replace the main switch. 9. Check the engine stop switch. Refer to “checking the switches” on page 7-29. Replace the left handlebar switch. 10.Check the entire ignition system’s...

Page 252: Electric Starting System

Electric starting system 7-5 eas27160 electric starting system eas27170 circuit diagram.

Page 253: Electric Starting System

Electric starting system 7-6 4. Main switch 5. Battery 6. Starter relay 7. Starter motor 8. Fuse 12.Diode 1 14.Clutch switch 15.Starting circuit cut-off relay 22.Left handlebar switch 24.Engine stop switch 25.Start switch 28.Neutral switch.

Page 254: Electric Starting System

Electric starting system 7-7 eas27180 starting circuit cut-off system operation if the engine stop switch is set to “ ” and the main switch is set to “on” (both switches are closed), the starter motor can only operate if at least one of the following conditions is met: • the transmission is in neutr...

Page 255: Electric Starting System

Electric starting system 7-8 a. When the transmission is in neu- tral b. When the clutch lever is pulled to the handlebar 1. Battery 2. Fuse 3. Main switch 4. Engine stop switch 5. Starting circuit cut-off relay 6. Clutch switch 7. Neutral switch 8. Start switch 9. Starter relay 10.Starter motor.

Page 256: Electric Starting System

Electric starting system 7-9 eas27190 troubleshooting the starter motor fails to turn. Tip • before troubleshooting, remove the following part(s): 1. Seat 2. Front panel 3. Front fender 4. Rear fender 5. Left side cover ng → ok ↓ ng → ok ↓ ok → ng ↓ ng → ok ↓ ng → ok ↓ ng → ok ↓ ng → ok ↓ 1. Check t...

Page 257: Electric Starting System

Electric starting system 7-10 ng → ok ↓ ng → ok ↓ ng → ok ↓ ng → ok ↓ ng → ok ↓ ng → ok ↓ 8. Check the engine stop switch. Refer to “checking the switches” on page 7-29. Replace the left handlebar switch. 9. Check the diode 1. Refer to “checking the diode” on page 7-38. Replace the diode 1. 10.Check...

Page 258: Charging System

Charging system 7-11 eas27200 charging system eas27210 circuit diagram.

Page 259: Charging System

Charging system 7-12 2. Stator coil 3. Rectifier/regulator 5. Battery 8. Fuse.

Page 260: Charging System

Charging system 7-13 eas27230 troubleshooting the battery is not being charged. Tip • before troubleshooting, remove the following part(s): 1. Seat 2. Front panel 3. Front fender 4. Rear fender 5. Left side cover ng → ok ↓ ng → ok ↓ ng → ok ↓ ng → ok ↓ ng → ok ↓ 1. Check the fuse. Refer to “checking...

Page 261: Charging System

Charging system 7-14.

Page 262: Lighting System

Lighting system 7-15 eas27240 lighting system eas27250 circuit diagram.

Page 263: Lighting System

Lighting system 7-16 4. Main switch 5. Battery 8. Fuse 21.Tail/brake light 22.Left handlebar switch 23.Dimmer switch 26.Headlight relay 27.Headlight.

Page 264: Lighting System