- DL manuals

- Yamaha

- Motorcycle

- ROAD STAN XV17ASC

- Supplementary Service Manual

Yamaha ROAD STAN XV17ASC Supplementary Service Manual

Summary of ROAD STAN XV17ASC

Page 1

Lit-11616-17-09 4wm-28197-e1 xv17as(c) xv17ass(c) xv17ats(c) supplementary service manual.

Page 2: Foreword

Foreword this supplementary service manual has been prepared to introduce new service and data for the xv17as(c)/xv17ass(c)/xv17ats(c). For complete service information procedures it is neces- sary to use this supplementary service manual together with the following manual. Xv16al/xv16alc/xv16atl/xv...

Page 3: Notice

Eas00003 notice this manual was produced by the yamaha motor company, ltd. Primarily for use by yamaha dealers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manual. Therefore, anyone who uses this book to perform maintenance and repairs on yamaha...

Page 4: How to Use This Manual

Eas00007 how to use this manual this manual is intended as a handy, easy-to-read reference book for the mechanic. Comprehensive explanations of all installation, removal, disassembly, assembly, repair and check procedures are laid out with the individual steps in sequential order. 1 the manual is di...

Page 5: Gen

Symbols the following symbols are not relevant to every vehicle. Symbols 1 to 8 indicate the subject of each chapter. 1 general information 2 specifications 3 periodic checks and adjustments 4 chassis 5 engine 6 carburetor 7 electrical system 8 troubleshooting symbols 9 to f indicate the following. ...

Page 6: Contents

Contents specifications ............................................................................................1 general specifications ..................................................................1 engine specifications ........................................................................

Page 7

Carburetor ...............................................................................................71 air induction system ......................................................................71 air induction system diagrams .............................................71 xv17as(c)/xv17ass(c...

Page 8: Spec

– 1 – spec specifications general specifications item standard limit model code 5vn1 (xv17a for usa) 5vn2 (xv17a for california) 5vn6 (xv17a for cdn) 5vr1 (xv17as for usa) 5vr2 (xv17as for california) 5vr3 (xv17as for cdn) 5vp1 (xv17at for usa) 5vp2 (xv17at for california) 5vp3 (xv17at for cdn) 5vp4...

Page 9: Spec

– 2 – spec engine specifications engine specifications item standard limit engine engine type air-cooled, 4-stroke, ohv ---- displacement 1,670 cm 3 ---- cylinder arrangement v-type 2-cylinder ---- bore × stroke 97 × 113 mm (3.82 × 4.45 in) ---- compression ratio 8.36 : 1 ---- engine idling speed 85...

Page 10: Spec

– 3 – spec engine specifications camshaft exhaust cam dimensions measurement a 38.236 ~ 38.336 mm (1.5054 ~ 1.5093 in) 38.136 mm (1.5014 in) measurement b 32.013 ~ 32.113 mm (1.2604 ~ 1.2643 in) 31.913 mm (1.2564 in) rocker arms, rocker arm shafts rocker arm inside diameter 18.000 ~ 18.018 mm (0.708...

Page 11: Spec

– 4 – spec engine specifications pistons piston-to-cylinder clearance 0.025 ~ 0.050 mm (0.001 ~ 0.002 in) 0.15 mm (0.006 in) diameter d 96.960 ~ 96.975 mm (3.8173 ~ 3.8179 in) ---- height h 5 mm (0.20 in) ---- piston pin bore (in the piston) diameter 22.004 ~ 22.015 mm (0.8663 ~ 0.8667 in) 22.045 mm...

Page 12: Spec

– 5 – spec engine specifications transmission transmission type constant mesh, 5-speed ---- primary reduction system spur gear ---- primary reduction ratio 72/47 (1.532) ---- secondary reduction system belt drive ---- secondary reduction ratio 35/32 × 70/32 (2.393) ---- operation left-foot operation...

Page 13: Spec

– 6 – spec chassis specifications chassis specifications item standard limit front wheel wheel type cast wheel spoke wheel (xv17a for cdn) ---- ---- rim size 16m/c × mt3.00 ---- material aluminum steel (xv17a for cdn) ---- ---- wheel travel 140 mm (5.51 in) ---- wheel runout maximum radial wheel run...

Page 14: Spec

– 7 – spec chassis specifications front tire tire type tubeless with tube (xv17a for cdn) ---- ---- size 130/90–16m/c 67h ---- model (manufacturer) usa cdn g703 n (bridgestone) (xv17a/xv17as) g703 (bridgestone) (xv17at) g703 f (bridgestone) (xv17a) d404fl (dunlop) (xv17a) g703 n (bridgestone) (xv17a...

Page 15: Spec

– 8 – spec chassis specifications front brakes brake type dual-disc brake ---- operation right-hand operation ---- brake lever free play (lever end) 2 ~ 5 mm (0.08 ~ 0.20 in) ---- recommended fluid dot 4 ---- brake discs diameter × thickness 298 × 5 mm (11.7 × 0.20 in) ---- minimum thickness ---- 4....

Page 16: Spec

– 9 – spec chassis specifications drive belt model (manufacturer) ubd-0681 ---- drive belt slack (on a sidestand) 6 ~ 8 mm (0.24 ~ 0.31 in) ---- drive belt slack (on a suitable stand) 7 ~ 9 mm (0.28 ~ 0.35 in) ---- item standard limit.

Page 17: Spec

– 10 – spec electrical specifications electrical specifications item standard limit system voltage 12 v ---- ignition system ignition system type transistorized coil ignition (digital) ---- ignition timing 10° btdc at 900 r/min ---- advancer type throttle position sensor and electrical ---- pickup c...

Page 18: Spec

– 11 – spec tightening torques tightening torques engine tightening torques item fastener thread size q’ty tightening torque remarks nm m · kgf ft · lb cylinder head nut m12 8 60 6.0 43 rocker arm base bolt m8 4 24 2.4 17 rocker arm base bolt m6 8 10 1.0 7.2 front cylinder camshaft end cover bolt m5...

Page 19: Spec

– 12 – spec tightening torques chassis tightening torques item thread size tightening torque remarks nm m · kgf ft · lb upper bracket and inner tube m6 18 1.8 13 handlebar holder (lower) and handlebar holder (upper) m8 28 2.8 20 throttle cable adjusting nut and locknut m6 4 0.4 2.9 engine mounting: ...

Page 20: Spec

– 13 – spec cable routing eb206000 cable routing 1 right handlebar switch lead 2 throttle cables 3 brake hoses 4 clutch cable 5 left handlebar switch lead 6 air induction system vacuum hose 7 rectifier/regulator 8 rear brake light switch lead È to engine É route the rear brake light switch lead in f...

Page 21: Spec

– 14 – spec cable routing 1 rectifier/regulator lead 2 rear brake light switch lead 3 wire harness 4 seat lock cable 5 throttle position sensor coupler 6 carburetor heater coupler 7 air induction system vacuum hose 8 fuel pump lead 9 spark plug cap #1 0 spark plug cap #3 a horn b horn lead c starter...

Page 22: Spec

– 15 – spec cable routing È fasten the rectifier/regulator lead and rear brake light switch lead with the plastic holders. É pass the left handlebar switch lead through the left brake hose guide and the right handlebar switch lead through the right brake hose guide under the upper bracket. Ê fasten ...

Page 23: Spec

– 16 – spec cable routing Ð fasten the horn lead and starter motor lead to the frame with the plastic locking tie. Ñ fasten the starter motor lead with the plastic holders. Ò fasten the clutch cable with the plastic holders. Ó to air cut-off valve Ô to engine Õ fasten the throttle position sensor le...

Page 24: Spec

– 17 – spec cable routing 1 wire harness 2 spark plug cap #1 3 fuel sender lead 4 negative battery lead 5 positive battery lead 6 tail/brake light lead 7 starter relay 8 thermo switch 9 starter motor lead 0 fuel tank breather hose a horn b pickup coil lead c sidestand switch lead d horn lead e decom...

Page 25: Spec

– 18 – spec cable routing È to fuel sender É fasten the wire harness and seat lock cable to the frame with the plastic band. Ê fasten the wire harness, fuel sender lead and seat lock cable with the plastic locking tie. Ë fasten the wire harness and all leads that branch off from the wire harness wit...

Page 26: Spec

– 19 – spec cable routing Ò fasten the speed sensor lead, decompression solenoid lead, pickup coil lead, neutral switch lead, stator coil lead, sidestand switch lead, and horn lead with the plastic holder. Ó fasten the starter motor lead, sidestand switch lead, and horn lead to the frame with the pl...

Page 27: Spec

– 20 – spec cable routing 1 turn signal relay 2 relay unit 3 battery 4 oil tank breather hose 5 fuel tank breather hose 6 meter assembly lead 7 throttle cables 8 right handlebar switch lead 9 main switch lead 0 spark plug cap #4 a spark plug cap #2 b rear brake light switch lead c sidestand switch c...

Page 28: Spec

– 21 – spec cable routing È fasten the fuel tank breather hose with the plas- tic holder. É fasten the throttle cables and fuel tank breather hose with the plastic holder. Ê fasten the throttle cables with the plastic holder. Ë to stator coil Ì to decompression solenoid Í to fuel tank Î to wire harn...

Page 29: Spec

– 22 – spec cable routing 1 left handlebar switch lead 2 throttle cables 3 right handlebar switch lead 4 fuel tank breather hose 5 oil tank breather hose 6 relay unit 7 turn signal relay 8 tail/brake light and rear turn signal light sub-wire harness coupler 9 thermo switch 0 fuse box a fuel sender l...

Page 30: Spec

– 23 – spec cable routing È fasten the left handlebar switch lead with the plastic holders. É fasten the right handlebar switch lead with the plastic holders. Ê to engine Ë fasten the wire harness with the plastic holder. Ì align the yellow tape on the wire harness with the hole in battery box, as s...

Page 31: Spec

– 24 – spec cable routing evaporative emission control system (for california) 1 compensator 2 compensator breather hose 3 3-way-joint-to-compensator hose 4 main switch 5 fuel tank breather hose 6 rollover valve 7 rollover-valve-to-3-way-joint hose 8 surge-tank-to-3-way-joint hose 9 3-way joint 0 3-...

Page 32: Spec

– 25 – spec cable routing È fasten the 3-way-joint-to-compensator hose with the plastic holder. É to solenoid valve Ê fasten the compensator breather hose and 3- way-joint-to-compensator hose with the plastic holder. Ë fasten the compensator breather hose with the plastic holder. Ì fasten the clutch...

Page 33: Spec

– 26 – spec cable routing 1 carburetor-to-surge-tank hose 2 3-way-joint-to-surge-tank hose 3 surge tank 4 surge-tank-to-3-way-joint hose 5 carburetor-to-charcoal-canister hose 6 solenoid valve 7 3-way-joint 1 2 3 4 5 6 7 2 1 3 a b a b.

Page 34: Chk

– 27 – chk adj eas00036 periodic checks and adjustments introduction this chapter includes all information necessary to perform recommended checks and adjustments. If followed, these preventive maintenance procedures will ensure more reliable vehicle operation, a longer service life and reduce the n...

Page 35: Chk

– 28 – chk adj general maintenance and lubrication chart * since these items require special tools, data and technical skills, have a yamaha dealer perform the ser- vice. 5 * brake hoses • check for cracks or damage. √ √ √ √ √ • replace. (see note.) every 4 years 6 * wheels • check runout and for da...

Page 36: Chk

– 29 – chk adj general maintenance and lubrication chart note: from 24000 mi (37000 km) or 36 months, repeat the maintenance intervals starting from 8000 mi (13000 km) or 12 months. Note: ● the air filter needs more frequent service if you are riding in unusually wet or dusty areas. ● hydraulic brak...

Page 37: Chk

– 30 – chk adj seats and side covers seats and side covers order job/part q’ty remarks removing the seats and side covers remove the parts in the order listed. 1 rider seat 1 2 passenger seat 1 3 left side cover 1 4 right side cover 1 for installation, reverse the removal pro- cedure..

Page 38: Chk

– 31 – chk adj fuel tank eas00040 fuel tank 1 2 1 6 5 3 4 t r . . 7 nm (0.7 m • kg, 5.1 ft • ib) order job/part q’ty remarks removing the fuel tank remove the parts in the order listed. Rider seat refer to “seats and side covers”. 1 meter assembly 1 2 meter assembly coupler 2 disconnect. 3 fuel tank...

Page 39: Chas

– 32 – chas eas00514 chassis front wheel and brake discs order job/part q’ty remarks removing the front wheel and brake discs remove the parts in the order listed. Note: place the motorcycle on a suitable stand so that the front wheel is elevated. 1 reflector (left and right) 2 2 brake caliper (left...

Page 40: Chas

– 33 – chas rear wheel, brake disc and rear wheel pulley eas00550 rear wheel, brake disc and rear wheel pulley order job/part q’ty remarks removing the rear wheel remove the parts in the order listed. Note: place the motorcycle on a suitable stand so that the rear wheel is elevated. Rear fender asse...

Page 41: Chas

– 34 – chas rear wheel, brake disc and rear wheel pulley order job/part q’ty remarks 7 right adjusting plate 1 8 left adjusting plate 1 9 rear wheel axle 1 10 rear wheel 1 11 collar (left and right) 2 12 brake caliper bracket 1 for installation, reverse the removal pro- cedure..

Page 42: Chas

– 35 – chas front and rear brakes eas00577 front and rear brakes front brake pads 3 2 2 6 6 5 4 1 t r . . 6 nm (0.6 m • kg, 4.3 ft • ib) t r . . 40 nm (4.0 m • kg, 29 ft • ib) 7 7 order job/part q’ty remarks removing the front brake pads remove the parts in the order listed. The following procedure ...

Page 43: Chas

– 36 – chas front and rear brakes eas00580 replacing the front brake pads the following procedure applies to both brake calipers. Note: _ when replacing the brake pads, it is not neces- sary to disconnect the brake hose or disas- semble the brake caliper. 1. Remove: • brake caliper bolts 1 • brake c...

Page 44: Chas

– 37 – chas front and rear brakes 5. Install: • brake pad shims (onto the brake pads) • brake pads • brake pad spring note: _ always install new brake pads and a new brake pad spring as a set. ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ a. Connect a clear plastic hose 1 tightly to the bleed sc...

Page 45: Chas

– 38 – chas front and rear brakes eas00586 rear brake master cylinder order job/part q’ty remarks removing the rear brake master cyl- inder remove the parts in the order listed. Brake fluid drain. 1 brake fluid reservoir cover 1 2 brake fluid reservoir cap 1 3 brake fluid reservoir diaphragm holder ...

Page 46: Chas

– 39 – chas front and rear brakes order job/part q’ty remarks 11 left footrest assembly 1 12 cotter pin 1 13 pin 1 14 brake master cylinder 1 for installation, reverse the removal pro- cedure..

Page 47: Chas

– 40 – chas front and rear brakes eas00613 front brake calipers 4 3 6 5 5 t r . . 40 nm (4.0 m • kg, 29 ft • ib) new t r . . 30 nm (3.0 m • kg, 22 ft • ib) 1 2 order job/part q’ty remarks removing the front brake calipers remove the parts in the order listed. The following procedure applies to both ...

Page 48: Chas

– 41 – chas front and rear brakes eas00615 7 6 7 8 7 4 6 4 7 3 2 1 new new new new t r . . 6 nm (0.6 m • kg, 4.3 ft • ib) 5 5 order job/part q’ty remarks disassembling the front brake calipers remove the parts in the order listed. The following procedure applies to both of the front brake calipers. ...

Page 49: Chas

– 42 – chas front and rear brakes eas00625 disassembling the front brake calipers the following procedure applies to both of the brake calipers. Note: _ before disassembling the brake caliper, drain the brake fluid from the entire brake system. 1. Remove: • union bolt 1 • copper washers 2 • brake ho...

Page 50: Chas

– 43 – chas front and rear brakes eas00633 checking the front brake calipers recommended brake component replacement schedule brake pads if necessary piston seals every two years brake hoses every four years brake fluid every two years and whenever the brake is disassem- bled 1. Check: • brake calip...

Page 51: Chas

– 44 – chas front and rear brakes eas00638 assembling and installing the front brake calipers the following procedure applies to both of the brake calipers. Warning _ • before installation, all internal brake com- ponents should be cleaned and lubricated with clean or new brake fluid. • never use so...

Page 52: Chas

– 45 – chas front and rear brakes 4. Fill: • brake master cylinder reservoir (with the specified amount of the recom- mended brake fluid) warning _ • use only the designated brake fluid. Other brake fluids may cause the rubber seals to deteriorate, causing leakage and poor brake performance. • refil...

Page 53: Chas

– 46 – chas front and rear brakes 7. Check: • brake lever operation soft or spongy feeling → bleed the brake system. Refer to “bleeding the hydraulic brake system” in chapter 3. (manual no.: 4wm-28197-e0).

Page 54: Chas

– 47 – chas handlebar eas00664 handlebar order job/part q’ty remarks removing the handlebar remove the parts in the order listed. 1 rear view mirror (left and right) 2 2 plastic clamp 4 3 front brake light switch connector 2 disconnect. 4 brake master cylinder holder 1 5 brake master cylinder 1 6 ri...

Page 55: Chas

– 48 – chas handlebar order job/part q’ty remarks 12 left handlebar switch 1 13 handlebar grip 1 14 clutch cable 1 disconnect. 15 clutch lever holder 1 16 cable guide 1 17 upper handlebar holder 1 18 handlebar 1 19 lower handlebar holder 1 for installation, reverse the removal pro- cedure..

Page 56: Chas

– 49 – chas rear shock absorber and swingarm rear shock absorber and swingarm order job/part q’ty remarks removing the rear shock absorber and swingarm remove the parts in the order listed. Rear wheel refer to “rear wheel, brake disc and rear wheel pulley”. 1 adjusting bolt 1 2 locknut 1 3 mud guard...

Page 57: Chas

– 50 – chas rear shock absorber and swingarm order job/part q’ty remarks 11 pivot shaft 1 12 rear shock absorber and swingarm assembly 1 for installation, reverse the removal pro- cedure..

Page 58: Chas

– 51 – chas rear shock absorber and swingarm order job/part q’ty remarks removing the rear shock absorber and swingarm remove the parts in the order listed. 1 self-locking nut/washer/bolt 1/1/1 bolt = 53 mm (2.19 in) 2 self-locking nut/washer/bolt 1/1/1 bolt = 124 mm (4.88 in) 3 connecting arm 2 4 o...

Page 59: Chas

– 52 – chas rear shock absorber and swingarm order job/part q’ty remarks 11 spacer/bearing 1/1 12 swingarm 1 13 dust cover 2 14 spacer 1 15 bearing 2 for installation, reverse the removal pro- cedure..

Page 60: Chas

– 53 – chas drive belt and drive pulley drive belt and drive pulley order job/part q’ty remarks removing the drive belt and drive pulley remove the parts in the order listed. Rear wheel refer to “rear wheel, brake disc and rear wheel pulley”. Rear shock absorber and swingarm assembly refer to “rear ...

Page 61: Eng

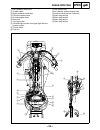

– 54 – eng engine rocker arms, push rods and valve lifters 9 8 6 5 4 2 5 4 3 4 5 5 4 5 9 5 3 4 5 4 4 5 5 3 5 8 7 t r . . 10 nm (1.0 m • kg, 7.2 ft • ib) new new 3 1 quick gasket ® quick gasket ® order job/part q’ty remarks removing cylinder head covers remove the parts in the order listed. Engine le...

Page 62: Eng

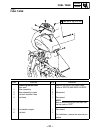

– 55 – eng rocker arms, push rods and valve lifters 10 11 8 9 10 11 7 10 11 10 11 8 9 3 5 6 6 4 5 1 2 1 e e e e e e e t r . . 24 nm (2.4 m • kg, 17 ft • ib) t r . . 10 nm (1.0 m • kg, 7.2 ft • ib) t r . . 20 nm (2.0 m • kg, 14 ft • ib) new new 7 6 order job/part q’ty remarks removing the push rods a...

Page 63: Eng

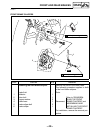

– 56 – eng rocker arms, push rods and valve lifters 2 3 1 2 7 6 4 5 2 1 3 2 7 e e t r . . 10 nm (1.0 m • kg, 7.2 ft • ib) t r . . 10 nm (1.0 m • kg, 7.2 ft • ib) e e e e order job/part q’ty remarks removing the valve lifters remove the parts in the order listed. 1 push rod cover 2 2 o-ring 4 3 seal ...

Page 64: Eng

– 57 – eng rocker arms, push rods and valve lifters installing the rocker arms and push rods the following procedure applies to both cylin- ders. 1. Install: • rocker arms 1 • rocker arm shafts 2 (onto rocker arm base) note: the thread hole a of the rocker arm shaft must face to the outside. 2. Inst...

Page 65: Eng

– 58 – eng rocker arms, push rods and valve lifters c. Install the rocker arm base bolts. Note: tighten the rocker arm base bolts in stages and in a crisscross pattern. Bolts 1: m6, = 40 mm (1.57 in) bolts 2: m6, = 30 mm (1.18 in) bolts 3: m8, = 70 mm (2.76 in) ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ...

Page 66: Eng

– 59 – eng clutch eas00274 clutch order job/part q’ty remarks removing the clutch remove the parts in the order listed. Clutch cover refer to “clutch” in chapter 5. (manual no.: 4wm-28197-e0) generator rotor cover refer to “generator and starter clutch” in chapter 5. (manual no.: 4wm-28197-e0) 1 clu...

Page 67: Eng

– 60 – eng clutch order job/part q’ty remarks 10 friction plate 1 11 clutch damper spring 1 12 clutch damper spring seat 1 13 clutch boss 1 14 thrust washer 1 15 clutch housing 1 16 circlip 1 17 oil pump drive gear 1 18 dowel pin 1 19 spacer 1 20 pickup coil rotor 1 21 primary drive gear 1 22 straig...

Page 68: Eng

– 61 – eng clutch installing the clutch boss nut 1. Install: • washer • clutch boss nut 1 note: • install the washer on the main axle with the “out” mark facing away from the motorcy- cle. • lock the threads on the clutch boss nut by staking them with a drift punch at the point aligned with the groo...

Page 69: Eng

– 62 – eng generator and starter clutch eas00343 generator and starter clutch order job/part q’ty remarks removing the generator rotor remove the parts in the order listed. Generator cover refer to “generator and starter clutch” in chapter 5. (manual no.: 4wm-28197-e0) 1 starter clutch idle gear sha...

Page 70: Eng

– 63 – eng crankshaft and connecting rods crankshaft and connecting rods eas00398 checking the crankshaft and connecting rods 1. Measure: • crankshaft runout out of specification → replace the crank- shaft. 2. Check: • crankshaft journal surfaces • crankshaft pin surfaces • bearing surfaces scratche...

Page 71: Eng

– 64 – eng crankshaft and connecting rods b. Install the big end upper bearing into the connecting rod and the big end lower bear- ing into the connecting rod cap. Note: align the projections a on the big end bear- ings with the notches b in the connecting rod and connecting rod cap. C. Put a piece ...

Page 72: Eng

– 65 – eng crankshaft and connecting rods warning when a bolt is tightened more than the specified angle, do not loosen them and then retighten them. Replace the bolt with a new one and per- form the procedure again. Caution: • do not use a torque wrench to tighten the bolt to the specified angle. •...

Page 73: Eng

– 66 – eng crankshaft and connecting rods 4. Select: • big end bearings (p 1 ~ p 2 ) note: • the numbers a stamped into the crankshaft web and the numbers b on the connecting rods are used to determine the replacement big end bearing sizes. • “p 1 ” ~ “p 2 ” refer to the bearings shown in the cranks...

Page 74: Eng

– 67 – eng crankshaft and connecting rods 6. Measure: • crankshaft journal bearing inside diameter a out of specification → replace the crank- case assembly. Note: measure the inside diameter of each crank- shaft journal bearing at two places. Crankshaft journal bearing inside diameter 50.01 ~ 50.03...

Page 75: Eng

– 68 – eng crankshaft and connecting rods 2. Lubricate: • crankshaft pins • big end bearings • connecting rod inner surface (with the recommended lubricant) recommended lubricant engine oil 3. Install: • big end bearings • connecting rods • connecting rod caps (onto the crankshaft pins) note: • alig...

Page 76: Eng

– 69 – eng crankshaft and connecting rods ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ a. Tighten the connecting rod bolts to the specified torque. B. Tighten the connecting rod bolts further to reach the specified angle 90° ~ 120°. Warning when a bolt is tightened more than the specified angle...

Page 77: Eng

– 70 – eng transmission transmission order job/part q’ty remarks disassembling the main axle assem- bly remove the parts in the order listed. Main axle assembly refer to “transmission” in chapter 5. (manual no.: 4wm-28197-e0) 1 circlip 1 2 washer 1 3 5th pinion gear 1 4 2nd/3rd pinion gear 1 5 circl...

Page 78: Carb

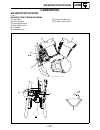

– 71 – carb carburetor air induction system eas00509 air induction system diagrams 1 reed valve 2 air cut-off valve 3 front cylinder head 4 rear cylinder head 5 air cleaner 6 carburetor joint È to the carburetor joint É to the air cut-off valve 5 4 3 1 2 6 È È 1 2 É a a air induction system.

Page 79: Carb

– 72 – carb air induction system order job/part q’ty remarks removing the air induction system remove the parts in the order listed. Fuel tank refer to “fuel tank” fuel pump refer to “carburetor” in chapter 6. (manual no.: 4wm-28197-e0) 1 reed valve case to rear cylinder head hose 1 1 2 reed valve c...

Page 80: Carb

– 73 – carb air induction system order job/part q’ty remarks 7 reed valve case to front cylinder head pipe 1 8 rectifier/regulator coupler 1 disconnect. 9 rectifier/regulator 1 10 air filter bracket 1 11 air filter 1 12 air filter cover 1 13 air filter hose 1 14 air cut-off valve to air filter hose ...

Page 81: Carb

– 74 – carb air induction system order job/part q’ty remarks 20 air cut-off valve to reed valve cover hose 1 21 reed valve cover 1 22 reed valve case 1 23 reed valve base 1 24 reed valve stopper 2 25 reed valve 2 for installation, reverse the removal pro- cedure..

Page 82

Yamaha motor co., ltd. 2500 shingai iwata shizuoka japan printed in u.S.A..

Page 83

Xv17as(c)/xv17ass(c)/xv17ats(c) wiring diagram sb l/r b w w w w w w w w w l y b y l b/l o p b/w l/y w b/l o r/b sb/w r/b l l/b l/r l/g l/y sb l/w b/y b/l y l b/l y l o r/g r b b r b b r/w r/w r r l b b r (black) (black) l/b br/l l/y r l/b br/l l/y l/b l/y br/l br br/l r/w br/l r/y br/l br/y g b y w ...