- DL manuals

- Yamaha

- Motorcycle

- Scorpio

- Service Manual

Yamaha Scorpio Service Manual

Summary of Scorpio

Page 1

Scorpio ( sx-4 ) servicemanual a winanda fairyanto's collection nanda@jogjalandrover.Org fairyanto@gmail.Com yamaha_scorpio@yahoogroups.Com 5bp-f8197-b0

Page 2

Service manual scorpio © 2006 oleh yamaha motor co., ltd. Edisi kedua, agustus 2006 dialih bahasakan oleh : technical publication yamaha indonesia motor manufacturing di cetak di indonesia.

Page 3: Pendahuluan

Pendahuluan service manual ini dibuat oleh yamaha motor company, ltd. Dan dialih bahasakan oleh, technical publication yamaha indonesia diharapkan dapat dipakai oleh teknisi bengkel dan dealer yamaha kami menyadari bahwa tidak mungkin menjelaskan seluruh pelajaran teknik perbaikan sepeda motor dalam...

Page 4

Teknik membaca cepat buku petunjuk susunan buku petunjuk buku ini terdiri dari beberapa bab utama yang didalamnya terdapat beberapa judul (lihat "simbol") judul pertama 1 : bab yang disertai simbol, terletak disudut kanan atas, pada setiap halaman. Judul kedua 2 : judul ini adalah judul bagian bab y...

Page 5: Gen

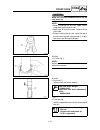

Simbol (sesuai illustrasi) illustrasi simbol 1 hingga 8 merupakan simbol di setiap bab, yang menggambarkan isi dari setiap bab. 1 informasi umum 2 spesifikasi 3 perawatan berkala dan pelumasan 4 membongkar mesin 5 karburator 6 rangka/chassis 7 kelistrikan/electrical 8 cara mengatasi masalah/troubles...

Page 6: Daftar Isi

Daftar isi informasi umum gen info 1 spesifikasi spec 2 perawatan berkala dan penyetelan insp adj 3 membongkar mesin eng 4 carburator carb 5 rangka/chassis chas 6 kelistrikan elec 7 troubleshooting trbl shtg 8 – +.

Page 7: Gen

Gen info bab 1. Informasi umum identifikasi sepeda motor ............................................................... 1-1 nomor rangka ................................................................................ 1-1 nomor mesin ....................................................................

Page 8: Gen

Gen info.

Page 9: Gen

1 - 1 gen info yp100000 informasi umum identifikasi sepeda motor yp100020 nomor rangka/chasis nomor rangka 1 tercetak pada rangka di bagian down tube eb100030 nomor mesin nomor mesin ( 2) tercetak pada crankcase mesin sebelah kanan. Catatan: bentuk dan spesifikasi sewaktu-waktu dapat berubah tanpa p...

Page 10: Gen

1 - 2 gen info informasi penting eb101000 informasi penting prosedur persiapan membongkar 1. Bersihkan dari debu, dan kotoran yang menempel pada sepeda motor 2. Pergunakan peralatan yang tepat dan bersih 3. Lihat bagian “ special tools” 4. Komponen yang telah dibongkar, tempatkan dalam kondisi teran...

Page 11: Gen

1 - 3 gen info eb101030 lock washers/plates dan cotter pins 1. Ganti lock washers/plates dan cotter pin setelah dibuka. Tekuk lock washer plat, di bagian yang rata pada bagian mur, setelah mur dikencang- sesuai spesifikasi pengencangan. Eb101040 bearing dan seal oil pasang bearing dan seal oli denga...

Page 12: Gen

1 - 4 gen info informasi penting eb801000 memeriksa sistim penyambungan bersihkan debu dan kotoran yang terdapat pada pada connector. 1. Lepaskan: • connector 2. Semprot dengan udara bertekanan. 3. Pasang dan cabut connector dua atau tiga kali pemasangan 4. Tarik kabel untuk memeriksa, agar kabel ti...

Page 13: Gen

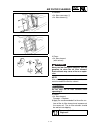

1 - 5 gen info special tools eb102000 special tools the following special tools are necessary for complete and accurate tune-up and assembly. Use only the appropriate special tools; this will help prevent damage caused by the use of inappropriate tools or improvised techniques. When placing an order...

Page 14: Gen

1 - 6 gen info special tools 90890-01362 flywheel puller alat ini digunakan untuk melepas magnet weight 90890-01367 attachment 90890-01368 fork seal driver weight fork seal driver attachment (ø33) alat ini digunakan untuk memasang seal oli dan seal debu pada fork depan. 90890-01403 steering nut wren...

Page 15: Gen

1 - 7 gen info special tools 90890-04086 universal clutch holder alat ini digunakan untuk menahan clutch boss, pada saat memasang dan melepas baut clutch boss nut. 90890-06754 ignition checker alat ini digunakan untuk memeriksa komponen sistim pengapian. Nomor tool nama tool gambar illustrasi.

Page 16: Spec

Spec bab 2. Spesifikasi spesifikasi umum ................................................................................. 2-1 spesifikasi perawatan ..................................................................... 2-4 mesin ..........................................................................

Page 17: Spec

Spec.

Page 18: Spec

2 - 1 spec spesifikasi umum spesifikasi spesifikasi umum model sx-4 kode model : 5bp1 dimensi: panjang 2.020 mm lebar 770 mm tinggi 1.090 mm tinggi tempat duduk 770 mm jarak sumbu roda 1.295 mm jarak ketanah 165 mm berat: dengan oli dan bahan bakar terisi penuh 131 kg kemampuan berbelok : 2.100 mm m...

Page 19: Spec

2 - 2 spec spesifikasi umum busi : tipe/pabrik pembuat d8ea/ngk atau x24es-u/denso gap 0.6 ~ 0.7 mm tipe kopling : basah, multiple-disc transmisi : sistim reduksi primary spur gear perbandingan reduksi primary 74/24 (3.083) sistim reduksi secondary rantai penggerak perbandingan reduksi secondary 44/...

Page 20: Spec

2 - 3 spec general specifications shock absorber: front shock absorber coil spring, oil damper rear shock absorber coil spring, oil damper wheel travel: front wheel travel 140 mm rear wheel travel 100 mm electrical: ignition system cdi generator system a.C. Magneto generator battery type or model gm...

Page 21: Spec

2 - 4 spec maintenance specifications maintenance specifications engine model sx-4 cylinder head: warp limit lines indicate straight edge measurement. Cylinder: bore size/measuring point 70.000 ~ 70.018 mm 40 mm wear limit camshaft: drive method chain drive (right) camshaft outside dia. 24.96 ~ 24.9...

Page 22: Spec

2 - 5 spec maintenance specifications value dimensions: “a” head dia. In. 33.9 ~ 34.1 mm ex. 28.4 ~ 28.6 mm “b” face width in. 2.26 mm ex. 2.26 mm “c” seat width in. 0.9 ~ 1.1 mm ex. 0.9 ~ 1.1 mm “d” margin thickness in. 0.8 ~ 1.2 mm ex. 0.8 ~ 1.2 mm stem outside dia. In. 5.975 ~ 5.990 mm ex. 5.960 ...

Page 23: Spec

2 - 6 spec maintenance specifications tilt limit in. Ex. Direction of winding inner in. Counterclockwise ex. Counterclockwise outer in. Clockwise ex. Clockwise piston: piston-to-cylinder clearance 0.020 ~ 0.025 mm piston size “d” 69.977 ~ 69.996 mm measuring point “h” 4 mm piston ring: top ring: typ...

Page 24: Spec

2 - 7 spec maintenance specifications crankshaft: crank width “a” 69.25 ~ 69.30 mm runout limit “b” big end side clearance “c” 0.35 ~ 0.85 mm clutch: friction plate: thickness 2.9 ~ 3.1 mm quantity 6 pcs. Wear limit clutch plate: thickness 1.5 ~ 1.7 mm quantity 5 pcs. Warp limit clutch spring: free ...

Page 25: Spec

2 - 8 spec maintenance specifications fuel level 2.7 ~ 4.7 mm below the float chamber line engine idling speed 1,350 ~ 1,450 r/min lubrication system: oil filter type paper and wire mesh type oil pump type: trochoid type tip clearance 0.15 mm side clearance 0.04 ~ 0.09 mm model sx-4.

Page 26: Spec

2 - 9 spec maintenance specifications lubrication chart: model sx-4 oil cleaner pin with hole crankshaft cylinder head camshaft oil pump main axle drive axle oil strainer oil pan.

Page 27: Spec

2 - 10 spec maintenance specifications tightening torque part to be tightened part name thread size q’ty tightening torque remarks nm m·kg camshaft sprocket cover bolt m6 2 10 1.0 tappet cover bolt m55 2 18 1.8 cylinder head flange bolt m8 4 22 2.2 e bolt m8 2 20 2.0 cylinder head (exhaust pipe) stu...

Page 28: Spec

2 - 11 spec maintenance specifications pickup coil bolt m6 2 7 0.7 starter motor bolt m6 2 10 1.0 kick crank bolt m8 1 20 2.0 kick racket wheel guide bolt m6 2 10 1.0 use lock washer part to be tightened part name thread size q’ty tightening torque remarks nm m·kg.

Page 29: Spec

2 - 12 spec maintenance specifications chassis item sx-4 steering system: steering bearing type angular bearing front suspension: front fork travel 140 mm fork spring free length 391.5 mm spring rate: k1 0.75 kg/mm k2 1.0 kg/mm stroke k1 0 ~ 95 mm k2 95 ~ 140 mm optional spring no. Oil capacity 252 ...

Page 30: Spec

2 - 13 spec maintenance specifications front disc brake: disc brake type single disc outside diameter × thickness 267 × 4 brake pad lining thickness 5.3 mm master cylinder inside diameter 11 mm caliper cylinder inside diameter 26.99 mm 22.22 mm recommended fluid dot 3 or 4 rear drum brake: type lead...

Page 31: Spec

2 - 14 spec maintenance specifications tightening torque note: 1. First, tighten the ring nut approximately 48 nm (4.8 m • kg) by using the torque wrench, then loosen the ring nut one turn. 2. Retighten the ring nut 18 nm (1.8 m • kg). Part to be tightened thread size tightening torque remarks nm m·...

Page 32: Spec

2 - 15 spec maintenance specifications electrical item sx-4 voltage: 12 v ignition system: ignition timing (b.T.D.C.) 5° at 1,450 r/min advancer type electrical cdi: pickup coil resistance (color) 248 ~ 372 Ω at 20°c (red - white) source coil resistance 688 ~ 1,032 Ω at 20°c (brown - green) cdi. Uni...

Page 33: Spec

2 - 16 spec maintenance specifications horn: type/quantity plain type × 2 model/manufacturer 5bp/imasen maximum amperage 1.5 a flasher relay: type condenser type model/manufacturer 3rs/denso self cancelling device no flasher frequency 75 ~ 95 cycle/min wattage 10 w × 2 + 3.4 w starting circuit cut-o...

Page 34: Spec

2 - 17 spec general torque specifications this chart specifies torque for standard fasten- ers with standard i.S.O. Pitch threads. Torque specifications for special components or assemblies are included in the applicable sections of this book. To avoid warpage, tighten multifastener assemblies in a ...

Page 35: Spec

2 - 18 spec lubrication points and lubricant type lubrication points and lubricant type engine lubrication symbol lubricant type oil seal lip ls lithium-soap base grease o-ring ls lithium-soap base grease bearing e engine oil cylinder head bolt/washer e engine oil rocker shaft m molybdeum disulfide ...

Page 36: Spec

2 - 19 spec lubrication points and lubricant type chassis lubrication symbol lubricant type steering bearing (upper/lower) ls lithium-soap base grease wheel bearing/axle ls lithium-soap base grease front wheel oil seal (right/left) ls lithium-soap base grease rear wheel oil seal ls lithium-soap base...

Page 37: Spec

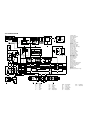

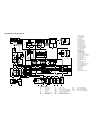

2 - 20 spec cable routing 1 tachometer cable 2 brake hose 3 brake hose holder 4 wire harness 5 air vent hose 6 starting motor lead 7 battery negative lead 8 battery positive lead 9 rear brake switch lead 0 taillight lead a fuel sender lead b breather hose c air vent hose d throttle cable e clutch ca...

Page 38: Spec

2 - 21 spec Î to fuel tank Ï clamp the throttle cable and clutch cable. Turn the clamp end to inside of motorcycle. Ð clamp the throttle cable and clutch cable. Ñ insert the air vent hose into the frame. Ò clamp the wire harness and turn the clamp end to inside of motorcycle. Ó clamp the magneto lea...

Page 39: Spec

2 - 22 spec 1 clutch cable 2 breather hose 3 fuel tank over flow hose 4 magneto lead 5 battery breather hose 6 carburetor over flow hose 7 fuel tank over flow hose 8 speedometer cable 9 wire harness 0 pick-up coil lead a magneto lead b fuel tank over flow hose È install the horn lead (long side) to ...

Page 40

2 - 23.

Page 41: Insp

Insp adj bab 3. Parawatan berkala dan penyetelan pendahuluan ........................................................................................... 3-1 perawatan berkala/pelumasan .................................................... 3-1 tempat duduk/jok ............................................

Page 42: Insp

Insp adj electrical ............................................................................................. 3-28 battery inspection ..................................................................... 3-28 fuse inspection ..........................................................................

Page 43: Insp

3 - 1 insp adj introduction/periodic maintenance/ lubrication periodic inspection and adjustment introduction this chapter includes all information necessary to perform recommended inspections and adjust- ments. These preventive maintenance procedures, if followed, will ensure more reliable vehicle ...

Page 44: Insp

3 - 2 insp adj periodic maintenance/lubrication *since these items require special tools, data and technical skills, have a yamaha dealer perform the service. Note: ● the air filter needs more frequent service if you are riding in unusually wet or dusty areas. ● hydraulic brake systems ● after disas...

Page 45: Insp

3 - 3 insp adj seat/side cover/fuel tank seat 1.Install: ● seat 1 note: insert the projection a on the front of the seat into the seat holder b as shown. Side cover 1.Remove: ● seat 2.Remove: ● side covers (left and right) note: remove screws a and knob b , and then pull the side cover off as shown....

Page 46: Insp

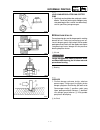

3 - 4 insp adj valve clearance adjustment engine valve clearance adjustment note: valve clearance adjustment should be made with the engine cool, at room temperature. When the valve clearance is to be measured or adjusted, the piston must be at top dead center (t.D.C) on the compression stroke. 1.Re...

Page 47: Insp

3 - 5 insp adj valve clearance adjustment/ idling speed adjustment ● measure the valve clearance by using a feeler gauge. Out of specification → adjust clearance. ***************************************************** 5.Adjust: ● valve clearance ***************************************************** a...

Page 48: Insp

3 - 6 insp adj idling speed adjustment/ throttle cable adjustment 3.Check: ● engine idling speed out of specification → adjust. 4.Adjust: ● engine idle speed ***************************************************** adjustment steps: ● turn the pilot screw 1 until it is lightly seated. ● turn the pilot ...

Page 49: Insp

3 - 7 insp adj throttle cable adjustment 2.Adjust: ● throttle cable free play ***************************************************** adjustment steps: carburetor side ● loosen the locknut 1 . ● turn the adjusting nut 2 in or out until the specified throttle cable free play is obtained. ● tighten the ...

Page 50: Insp

3 - 8 insp adj spark plug inspection/ compression pressure measurement eb303040 spark plug inspection 1.Check: ● spark plug type incorrect → replace. Standard spark plug: d8ea (ngk), x24es-u (denso) 2.Inspect: ● electrode 1 wear/damage → replace. ● insulator 2 abnormal color → replace. Normal color ...

Page 51: Insp

3 - 9 insp adj compression pressure measurement/ engine oil level inspection 5.Measure: ● compression pressure if it exceeds the maximum pressure allowed → inspect the cylinder head, valve surfaces and piston crown for carbon deposits. If it is below the minimum pressure → squirt a few drops of oil ...

Page 52: Insp

3 - 10 insp adj engine oil level inspection/ engine oil replacement 3.Check: ● engine oil level the engine oil level should be between the minimum level mark a and maximum level mark b . Below the minimum level mark → add the recommended engine oil to the proper level. Caution: do not allow foreign ...

Page 53: Insp

3 - 11 insp adj engine oil replacement 5.If the oil filter element is also to be replaced, perform the following procedure. ***************************************************** replacement steps: ● remove the oil filter element cover 1 and oil filter element 2 . ● check the o-rings 3 and replace th...

Page 54: Insp

3 - 12 insp adj engine oil replacement/ clutch adjustment 10.Start the engine, warm it up for several min- utes, and then turn it off. 11.Check: ● engine (for engine oil leaks) 12.Check: ● engine oil level refer to the “engine oil level inspec- tion” section. 13.Check: ● engine oil pressure ********...

Page 55: Insp

3 - 13 insp adj clutch adjustment/ air filter cleaning 2.Adjust: ● clutch cable free play ***************************************************** adjustment steps: handlebar side ● loosen the locknut 1 . ● turn the adjusting bolt 2 in or out until the specified clutch cable free play is obtained. ● ti...

Page 56: Insp

3 - 14 insp adj air filter cleaning 3.Remove: ● air filter case cover 1 ● air filter element 2 4.Clean: ● air filter element (with solvent) warning never use low flash point solvents, such as gasoline, to clean the air filter element. Such solvents may cause a fire or an explo- sion. Note: after cle...

Page 57: Insp

3 - 15 insp adj air filter cleaning/carburetor joint inspection/fuel line inspection 7.Install: ● air filter element ● air filter case cover caution: never operate the engine without the air fil- ter element installed. Unfiltered air will cause rapid wear of engine parts and may damage the engine. O...

Page 58: Insp

3 - 16 insp adj exhaust system inspection exhaust system inspection 1.Inspect: ● exhaust pipe 1 ● muffler 2 cracks/damage/leak → repair or replace. ● exhaust pipe joint 3 ● gasket 4 damage/leak → repair or replace. 2.Tighten: ● muffler and exhaust pipe t r . . Nuts (exhaust pipe joint) 5 : 18 nm (1....

Page 59: Insp

3 - 17 insp adj chassis front brake adjustment 1.Check: ● brake lever free play a out of specification → adjust. 2.Adjust: ● brake lever free play ***************************************************** adjustment steps: ● loosen the locknut 1 . ● turn the adjuster 2 in or out until the speci- fied fr...

Page 60: Insp

3 - 18 insp adj brake fluid level inspection/ air bleeding (hydraulic brake system) brake fluid level inspection 1.Stand the motorcycle on a level surface. Note: when inspecting the brake fluid level, make sure the motorcycle is upright. 2.Inspect: ● brake fluid level brake fluid level is below the ...

Page 61: Insp

3 - 19 insp adj air bleeding (hydraulic brake system)/ brake hose inspection i. Repeat steps (e) to (h) until all the air bub- bles have disappeared from the bake fluid. Note: when bleeding the brake system, make sure that there is always enough brake fluid in the brake fluid reservoir, before apply...

Page 62: Insp

3 - 20 insp adj rear brake adjustment rear brake adjustment 1.Check: ● brake pedal position (distance a from the top of the rider footrest to the top of the brake pedal) out of specification → adjust. 2.Adjust: ● brake pedal position ***************************************************** adjustment s...

Page 63: Insp

3 - 21 insp adj rear brake adjustment/brake shoe inspection/brake light switch adjustment 4.Adjust: ● brake pedal free play ***************************************************** adjustment steps: ● turn the adjuster 1 in or out until the speci- fied free play is obtained. Caution: make sure that the...

Page 64: Insp

3 - 22 insp adj drive chain slack adjustment warning ● securely support the motorcycle so that there is no danger of it falling over. ● stand the motorcycle on its centerstand. 1.Check: ● drive chain slack a out of specification → adjust. 2.Adjust: ● drive chain slack *******************************...

Page 65: Insp

3 - 23 insp adj tire inspection/ steering head inspection tire inspection 1.Measure: ● tire inflation pressure out of specification → adjust. * load is the total weight of the cargo, rider, pas- senger and accessories. Basic weight (with oil and full fuel tank) 131 kg maximum load* 180 kg cold tire ...

Page 66: Insp

3 - 24 insp adj steering head inspection 3.Check: ● handlebar assembly grasp the handlebar and gently rock the steering. Looseness → adjust the handlebar. ● steering assembly bearings grasp the bottom of the lower front fork tubes and gently rock the fork assembly. Looseness → adjust the steering he...

Page 67: Insp

3 - 25 insp adj steering head inspection/ rear shock absorber inspection ● check the steering head for looseness or binding by turning the front fork all the way in both directions. If any binding is felt, remove the lower bracket and inspect the upper and lower bearings. Refer to the “steering head...

Page 68: Insp

3 - 26 insp adj wheel inspection/spoke inspection and tightening/cable inspection wheel inspection 1.Inspect: ● wheels damage/bends → replace. Note: always balance the wheel when a tire or wheel has been changed or replaced. Warning ● never attempt even small repairs to the wheel. ● ride conservativ...

Page 69: Insp

3 - 27 insp adj lubrication lubrication cables 1.Check: ● cable operation unsmooth operation → lubricate. Note: hold cable end high and apply several drops of lubricant to cable. 2.Apply the grease to the throttle cable end and cable guide groove at inside of throttle housing 1 . Level/pedal 1.Lubri...

Page 70: Insp

3 - 28 insp adj battery inspection electrical battery inspection warning battery electrolyte is dangerous. It con- tains sulfuric acid which is poisonous and highly caustic. Always follow these preventive measures: ● avoid bodily contact with electrolyte as it can cause severe burns and permanent ey...

Page 71: Insp

3 - 29 insp adj battery inspection 4.Inspect: ● electrolyte level electrolyte level should be between the upper 1 and lower 2 level marks. Electro- lyte level is too low → add electrolyte to proper level. Caution: refill with distilled water only. Tap water contains minerals which are harmful to a b...

Page 72: Insp

3 - 30 insp adj battery inspection ● specific gravity readings after a long, slow charge indicate that one cell is charged lower than the rest. ● warpage or buckling of plates or insulators is evident. ***************************************************** 7.Connect: ● breather hose (battery) be sure...

Page 73: Insp

3 - 31 insp adj fuse inspection fuse inspection 1.Remove: ● side cover (right) refer to the “side cover” section. 2.Remove: ● fuse 1 3.Inspect: ● fuse defective → replace. Blown fuse (new) → inspect circuit. Note: install new fuse of proper amperage. 4.Replace: ● blown fuse *************************...

Page 74: Insp

3 - 32 insp adj headlight beam adjustment/ headlight bulb replacement headlight beam adjustment 1.Remove: ● holding screw 1 ● headlight unit 2 2.Adjust: ● headlight beam (vertical) ***************************************************** headlight beam adjustment steps: ● loosen the bolt (headlight bod...

Page 75: Insp

3 - 33 insp adj headlight bulb replacement 3.Install: ● bulb (new) secure the new bulb with the bulb holder. Caution: avoid touching glass part of bulb. Also keep it free from oil otherwise, transpar- ency of glass, bulb life and illuminous flux will be adversely affected. If oil gets on bulb, clean...

Page 76: Eng

Eng chapter 4. Engine overhaul engine removal ...................................................................................... 4-1 engine oil .......................................................................................... 4-1 exhaust pipe assembly ......................................

Page 77: Eng

Eng generator ............................................................................................. 4-36 crankcase cover (left) removal .......................................... 4-37 generator rotor removal ..................................................... 4-38 starter clutch inspection...

Page 78: Eng

4 - 1 eng engine removal engine overhaul engine removal note: it is not necessary to remove the engine in order to remove the following components. ● cylinder head ● cylinder ● piston ● clutch ● kickstarter shaft and shift shaft ● oil pump ● generator 1.Remove: ● seat ● fuel tank refer to the “seat,...

Page 79: Eng

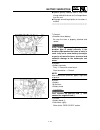

4 - 2 eng engine removal 2.Loosen: ● bolt 1 (exhaust pipe joint) 3.Remove: ● nuts 1 (exhaust pipe) 4.Remove: ● exhaust pipe assembly 5.Remove: ● bolts (muffler) ● nut (muffler) ● muffler 1 left footrest bracket 1.Remove: ● bolt (shift pedal) ● bolts (left footrest bracket) ● left footrest bracket 1 ...

Page 80: Eng

4 - 3 eng engine removal 2.Remove: ● lock washer 1 ● drive sprocket 2 3.Loosen: ● rear wheel axle nut ● locknuts ● drive chain adjuster nuts carburetor 1.Remove: ● carburetor refer to the “carburetor” section in chapter 5. Wire, cable and tube 1.Remove: ● spark plug lead cap 1 ● ignition coil 2 2.St...

Page 81: Eng

4 - 4 eng engine removal 5.Remove: ● neutral switch lead 1 ● generator lead coupler 2 ● generator leads 3 starter motor 1.Remove: ● starter motor refer to the “electric starting sys- tem” in chapter 7. Engine 1.Remove: ● engine mounting bracket 1 2.Remove: ● rear upper mounting bolt 1 ● front mounti...

Page 82: Eng

4 - 5 eng engine installation engine installation engine assembly warning securely support the motorcycle so there is no danger of it falling over when install- ing engine. 1.Install: ● engine assembly ● rear lower mounting bolt ● rear upper mounting bolt 2.Install: ● front mounting bolt 3.Install: ...

Page 83: Eng

4 - 6 eng engine installation 2.Install: ● tachometer cable ● breather hose 3.Install: ● clutch cable 4.Install: ● ignition coil ● spark plug lead cap carburetor 1.Install: ● carburetor refer to the “carburetor” section in chapter 5. Drive chain 1.Install: ● drive chain ● drive sprocket ● lock washe...

Page 84: Eng

4 - 7 eng exhaust assembly 1.Install: ● muffler ● nut (muffler) ● bolts (muffler) 2.Install: ● exhaust pipe 3.Tighten: ● bolt (exhaust pipe joint) 4.Tighten: ● nuts ● bolts t r . . Nuts (exhaust pipe): 18 nm (1.8 m • kg) bolt (exhaust pipe joint): 20 nm (2.0 m • kg) bolts (muffler) 30 nm (3.0 m • kg...

Page 85: Eng

4 - 8 eng engine installation 3.Adjust: ● throttle cable free play ● clutch lever free play refer to the “throttle cable adjust- ment”, “clutch adjustment” section in chapter 3. 4.Adjust: ● drive chain slack refer to the “drive chain slack adjustment” section in chapter 3. Throttle cable free play: ...

Page 86: Eng

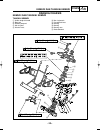

4 - 9 eng cylinder head cylinder head 1 o-ring 2 tappet cover 3 o-ring 4 camshaft sprocket cover 5 plate 6 cam chain tensioner 7 gasket 8 camshaft sprocket 9 gasket 0 dowel pin a cylinder head b spark plug c timing chain guide (exhaust side).

Page 87: Eng

4 - 10 eng cylinder head cylinder head removal note: prior to remove the cylinder head, remove the seat, fuel tank and air scoop, and drain the engine oil. 1.Remove: ● exhaust pipe assembly refer to the “engine removal” section in chapter 3. 2.Remove: ● carburetor refer to the “carburetor” section i...

Page 88: Eng

4 - 11 eng note: tdc on compression stroke check: ● both rocker arms must have a valve clearance when the “l” mark a on the flywheel is aligned with the slit b on the crankcase cover. ● if not, give the crankshaft one counter clock- wise turn to meet above condition. ********************************...

Page 89: Eng

4 - 12 eng cylinder head 12.Remove: ● dowel pins 1 ● gasket (cylinder head) 2 ● timing chain guide (exhaust side) 3 cylinder head inspection 1.Eliminate: ● carbon deposits (from combustion chambers) use a rounded scraper. Note: do not use a sharp instrument to avoid damag- ing or scratching: ● spark...

Page 90: Eng

4 - 13 eng cylinder head timing chain tensioner inspection 1.Check: ● timing chain tensioner cracks/damage/rough movement → replace. *********************************************** a. Lightly press the timing chain tensioner rod into the timing chain tensioner housing by hand. Note: while pressing t...

Page 91: Eng

4 - 14 eng cylinder head cylinder head instalation 1.Install: ● cylinder 2.Install: ● camshaft sprocket ● timing chain ● washer ● bolt (camshaft sprocket) *********************************************** camshaft sprocket installing steps (rear cylinder): ● turn the crankshaft counter clockwise with ...

Page 92: Eng

4 - 15 eng cylinder head *********************************************** timing chain tension installation steps: ● turn the stopper clockwise. ● hold the stopper with the bolt 1 . ● install the tensioner with a new gasket into the cylinder. *********************************************** 4.Tighten:...

Page 93: Eng

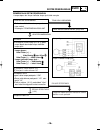

4 - 16 eng camshaft and rocker arms camshaft and rocker arms 1 locknut 2 valve adjuster 3 rocker arm 4 rocker arm shaft (exhaust) 5 rocker arm shaft (intake) 6 o-ring 7 bearing 8 camshaft 9 plate.

Page 94: Eng

4 - 17 eng camshaft and rocker arms rocker arm and camshaft removal note: prior to remove the rocker arm and camshaft, remove the cylinder head. 1.Loosen: ● locknut 1 ● valve adjuster 2 2.Remove ● stopper plate 3 3.Remove: ● camshaft 1 ● bearing 2 note: remove the camshaft and collar by using 10 mm ...

Page 95: Eng

4 - 18 eng camshaft and rocker arms yp402052 camshaft inspection 1.Inspect: ● cam lobes pitting/scratches/blue discoloration → replace. 2.Measure: ● cam lobes length a and b . Out of specification → replace. Cam lobes length: intake: a 36.52 ~ 36.62 mm b 30.201 ~ 30.301 mm exhaust: a 36.564 ~ 36.664...

Page 96: Eng

4 - 19 eng camshaft and rocker arms ● inspect the surface condition of the rocker arm shafts. ● pitting/scratches/blue discoloration → replace or check lubrication. ● measure the inside diameter of the rocker arm holes. Out of specification → replace. ● measure the outside diameter of the rocker arm...

Page 97: Eng

4 - 20 eng camshaft and rocker arms 3.Lubricate: ● camshaft 1 camshaft: molybdenum disulfide grease camshaft bearing: engine oil 4.Install: ● plate 1 ● bolts 2 t r . . 8 nm (0.8 m • kg).

Page 98: Eng

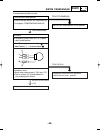

4 - 21 eng valves and valve springs valves and valve springs 1 valve cotter 2 upper spring seat 3 lower spring seat 4 oil seal 5 inner valve spring 6 outer valve spring 7 valve.

Page 99: Eng

4 - 22 eng valves and valve springs valve and valve springs removal note: ● prior to remove the valves, remove the cylin- der head, rocker arm and camshaft. ● before removing the internal parts (valve, valve spring, valve seat etc.) of the cylinder head, the valve sealing should be checked. 1.Check:...

Page 100: Eng

4 - 23 eng valves and valve springs 2.Attach: ● valve spring compressor 1 valve spring compressor: 90890-04019 3.Remove: ● valve cotters 1 ● upper spring seat 2 ● outer valve spring 3 ● inner valve spring 4 ● oil seal 5 ● lower spring seat 6 ● valve 7 note: ● identify each part position very careful...

Page 101: Eng

4 - 24 eng valves and valve springs yp****** valves and valve springs inspection 1.Measure: ● valve stem diameter a out of specification → replace . Yp402010 2.Measure: ● runout (valve stem) out of specification → replace. Yp402030 3.Measure: ● free length (valve spring) a out of specification → rep...

Page 102: Eng

4 - 25 eng valves and valve springs 6.Inspect: ● spring contact face wear/pitting/scratches → replace. 7.Measure: ● valve guide inside diameter out of specification → replace. Yp402010 8.Measure: out of specification → replace the valve guide. Valve guide inside diameter: intake: 6.000 ~ 6.012 mm ex...

Page 103: Eng

4 - 26 eng valves and valve springs 3.Measure: ● valve seat width a out of specification → reface the valve seat. *********************************************** measurement steps: ● apply mechanic’s blueing dye (dykem) 1 to the valve face. ● install the valve into the cylinder head. ● press the val...

Page 104: Eng

4 - 27 eng valves and valve springs ● install the valve into the cylinder head. ● turn the valve unit the valve face and valve seat are evenly polished, then clean off all compound. Note: for best lapping results, lightly tap the valve seat while rotating the valve back and forth between your hand. ...

Page 105: Eng

4 - 28 eng valves and valve springs 4.Install: ● valve cotters 1 note: install the valve cotters while compressing the valve spring with a valve spring compressor 2 . 5.Secure the valve cotters onto the valve stem by tapping lightly with a piece of wood. Caution: do not hit so much as to damage the ...

Page 106: Eng

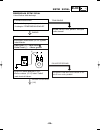

4 - 29 eng cylinder and piston cylinder and piston 1 oil delivery pipe 2 cylinder 3 o-ring 4 gasket 5 o-ring 6 dowel pin 7 piston 8 piston rings 9 piston pin clip 0 piston pin.

Page 107: Eng

4 - 30 eng cylinder and piston piston removal note: prior to remove the cylinder, remove the cylin- der head, carburetor joint and exhaust pipe. 1.Remove: ● oil delivery pipe 1 2.Remove: ● cylinder 1 ● o-ring 2 ● dowel pin 3 ● gasket 4 (cylinder) ● o-ring 5 3.Remove: ● piston pin clip 1 note: before...

Page 108: Eng

4 - 31 eng cylinder and piston 5.Remove: ● piston rings 1 note: when removing a piston rings, open the end gap with your fingers and lift the other side of the ring over the piston crown. Yp402100 cylinder inspection 1.Measure: ● cylinder bore out of specification → rebore or replace. Note: ● measur...

Page 109: Eng

4 - 32 eng cylinder and piston yp****** piston and piston pin inspection 1.Measure: ● piston skirt diameter out of specification → replace. A 4.0 mm form the piston bottom edge 2.Calculate: ● piston-to cylinder-clearance refer to the “cylinder” section for cylinder bore measurement. Out of specifica...

Page 110: Eng

4 - 33 eng cylinder and piston yp402111 piston rings inspection 1.Measure: ● side clearance out of specification → replace the piston and the piston rings as a set. Note: eliminate the carbon deposits from the piston ring grooves and piston rings before measur- ing the side clearance. Side clearance...

Page 111: Eng

4 - 34 eng cylinder and piston eb404184 piston rings, piston and cylinder installation 1.Install: ● top ring 1 ● 2nd ring 2 ● oil ring 3 note: ● make sure to install the piston rings so that the manufacture’s marks or numbers are located on the upper side of the rings. ● lubricate the pistons and pi...

Page 112: Eng

4 - 35 eng 5.Lubricate: ● piston outer surface ● piston ring ● cylinder inner surface engine oil 6.Install: ● cylinder 1 note: ● install the cylinder with one hand while com- pressing the piston rings with the other hand. ● pass the timing chain and timing chain guide (exhaust side) through the timi...

Page 113: Eng

4 - 36 eng generator generator 1 drive sprocket cover 2 cover 3 o-ring 4 crankcase cover (left) 5 gasket 6 dowel pin 7 stator assembly 8 pickup coil 9 generator rotor 0 starter clutch a starter clutch gear b bearing c starter clutch idle gear #2 d starter clutch idle gear #1.

Page 114: Eng

4 - 37 eng generator crankcase cover (left) removal note: prior to remove the crankcase cover (left), remove the shift pedal and drain the engine oil. 1.Remove: ● fuel tank refer to the “fuel tank” section in chap- ter 3. 2.Remove: ● left footrest bracket refer to the “left footrest bracket” section...

Page 115: Eng

4 - 38 eng generator generator rotor removal 1.Remove: ● bolt 1 note: ● do not touch the projection a when install- ing the sheave holder. ● loosen the nut while holding the generator rotor with sheave holder 2 . 2.Remove: ● generator rotor 1 use a flywheel puller 2 sheave holder: 90890-01701 flywhe...

Page 116: Eng

4 - 39 eng generator eas00351 starter clutch inspection 1.Check: ● starter clutch idle gear #1 1 ● starter clutch idle gear #2 2 ● starter clutch gear 3 burrs/chips/roughness/wear → replace the defective part(-s). 2.Check: ● starter clutch gear’s contacting surfaces a damage/pitting/wear → replace t...

Page 117: Eng

4 - 40 eng generator 2.Install: ● woodruff key 1 ● generator rotor 2 ● washer 3 ● bolt 4 use the sheave holder 5 note: ● before installing the generator rotor, clean the outside of the crankshaft and inside of the generator rotor. ● when installing the generator rotor, make sure the woodruff key is ...

Page 118: Eng

4 - 41 eng 3.Install: ● crankcase cover (left) note: tighten the bolts (crankcase cover-left) in a crisscross pattern. M6 × 40 mm bolts: 1 ~ 6 m6 × 30 mm bolts: 7 ~ 9 t r . . Bolts (crankcase cover-left): 7 nm (0.7 m • kg) 4.Install: ● neutral switch lead 1 5.Install: ● starter clutch idle gear #1 ●...

Page 119: Eng

4 - 42 eng clutch clutch 1 crankcase cover (right) 2 gasket 3 dowel pin 4 compression spring 5 pressure plate 6 push plate 7 push rod #1 8 clutch plate 9 friction plate (#1) 0 cushion spring a friction plate (#2) b clutch boss c thrust washer d clutch housing e ball f push rod #2 g push lever assemb...

Page 120: Eng

4 - 43 eng clutch crankcase cover (right) removal note: prior to remove the crankcase cover (right), drain the engine oil. 1.Remove: ● oil filter cover 1 ● oil filter 2 ● o-ring 3 (filter cover) ● o-ring 4 2.Remove: ● oil delivery pipe 1 3.Remove: ● kick starter 1 4.Remove: ● crankcase cover (right)...

Page 121: Eng

4 - 44 eng clutch clutch removal 1.Remove: ● bolts (clutch springs) ● clutch springs 2.Remove: ● pressure plate 1 ● friction plate (#1) 2 (5 pcs) ● friction plate (#2) 3 (1 pcs) ● clutch plate 4 (5 pcs) ● cushion spring 5 ● push plate 6 ● push rod (#1) 7 ● ball 8 ● push rod (#2) 9 3.Straighten: ● lo...

Page 122: Eng

4 - 45 eng clutch 5.Remove: ● nut 1 (clutch boss) ● lock washer 2 ● clutch boss 3 ● thrust washer 4 ● clutch housing 5 6.Remove: ● nut 1 (primary drive gear) ● lock washer 2 ● crow washer 3 ● primary drive gear 4 ● collar 5 ● straight key 6 t402181 clutch inspection 1.Inspect: ● friction plate (#1, ...

Page 123: Eng

4 - 46 eng clutch 5.Inspect: ● compression springs damage → replace the compression springs as a set. 6.Measure: ● free length (compression spring) a out of specification → replace the clutch springs as a set. Free length (clutch spring): 34.9 mm 7.Inspect: ● push rod (#2) wear/crack/damage → replac...

Page 124: Eng

4 - 47 eng clutch 11.Inspect: ● clutch boss splines scoring/wear/damage → replace clutch boss assembly. 12.Inspect: ● oil filter cracks/damage → replace. Contamination → clean the flushing oil. T****** clutch installation 1.Install: ● straight key ● collar 1 ● primary drive gear 2 ● crow washer 3 ● ...

Page 125: Eng

4 - 48 eng clutch 4.Install: ● friction plate (#1) 1 (3 pcs) ● clutch plate 2 (3 pcs) ● cushion spring 3 ● friction plate (#2) 4 ● clutch plate 5 (2 pcs) ● friction plate (#1) 6 (2 pcs) ● push rod (#2) 7 ● ball 8 ● push rod (#1) 9 ● push plate 0 note: install the clutch plates and friction plates al...

Page 126: Eng

4 - 49 eng 7.Tighten ● screw (push lever axle) t r . . Screw: 12 nm (1.2 m • kg) 8.Install: ● dowel pins 1 ● gasket 2 new 9.Install: ● crankcase cover (right) m6 × 55 mm bolt: 1 m6 × 50 mm bolts: 2 ~ 4 m6 × 35 mm bolt: 5 m6 × 25 mm bolts: 6 ~ c t r . . Bolts (crankcase cover-right): 10 nm (1.0 m • k...

Page 127: Eng

4 - 50 eng kick starter and shift shaft kick starter and shift shaft 1 kick shaft 2 kick segment gear 3 kick pinion gear 4 kick spring 5 kick crank 6 shift shaft assembly 7 stopper lever.

Page 128: Eng

4 - 51 eng kick starter and shift shaft kick shaft and shift shaft removal note: prior to remove the kick shaft, remove the clutch assembly. 1.Remove: ● clutch housing refer to the “clutch removal” section. 2.Remove: ● shift pedal refer to the “left footrest bracket” section. 3.Remove: ● circlip 1 ●...

Page 129: Eng

4 - 52 eng kick starter and shift shaft 2.Inspect: ● kick spring wear/crack → replace. T402200 shift shaft inspection 1.Inspect: ● stopper lever roller turns roughly → replace. Bends/damage → replace. 2.Inspect: ● stopper lever spring wear/damage → replace. 3.Inspect: ● shift shaft assembly ● shift ...

Page 130: Eng

4 - 53 eng kick starter and shift shaft kick shaft assembling 1.Install: ● kick shaft 1 ● kick segment gear 2 ● ratchet gear 3 note: align the punch mark of kick shaft a to the kick segment gear b . Shift shaft and kick starter installation 1.Install: ● stopper lever assembly 1 t r . . Bolt (stopper...

Page 131: Eng

4 - 54 eng oil pump oil pump 1 oil pump assembly 2 oil pump gear 3 circlip 4 gasket 5 oil strainer.

Page 132: Eng

4 - 55 eng oil pump oil pump removal note: prior to remove the oil pump, remove the clutch assembly. 1.Remove: ● oil strainer 1 ● circlip 2 ● oil pump gear 3 ● oil pump assembly 4 ● gasket 5 note: do not remove the screw, to avoid disassem- bling oil pump. T402140 oil pump inspection 1.Measure: ● ti...

Page 133: Eng

4 - 56 eng oil pump 2.Inspect: ● oil stainer cracks/damage → replace. Contamination → clean the flushing oil. Oil pump installation 1.Install: ● gasket 1 ● oil pump assembly 2 ● oil pump gear 3 ● circlip 4 ● oil strainer 5 t r . . Bolt (oil pump): 6 nm (0.6 m • kg).

Page 134: Eng

4 - 57 eng crankcase and crankshaft crankcase and crankshaft 1 crankcase (left) 2 crankcase (right) 3 dowel pin 4 crank shaft assembly 5 bearing 6 timing chain drive sprocket 7 timing chain 8 timing chain guide (intake side) 9 drain bolt 0 gasket.

Page 135: Eng

4 - 58 eng crankcase and crankshaft crankcase separating note: prior to separate the crankcase, remove the engine and remove the cylinder head, cylinder, generator, clutch, kick axle, shift shaft and oil pump. 1.Remove: ● timing chain 1 ● timing chain guide (intake side) 2 ● timing chain drive sproc...

Page 136: Eng

4 - 59 eng crankcase and crankshaft 4.Remove: ● crankshaft 1 use a crankcase separating tool 2 . Crankcase separating tool: 90890-01135 t****** crankshaft inspection 1.Measure: ● crankshaft runout 1 out of specification → replace crankshaft and/or bearing. Note: measure the crankshaft runout with th...

Page 137: Eng

4 - 60 eng crankcase and crankshaft 5.Inspect: ● crankshaft journal clogged → blow out the journal with com- pressed air. Eas00401 bearings and oil seals inspection 1.Check: ● bearings clean and lubricate the bearings, then rotate the inner race with your finger. Rough movement → replace. 2.Check: ●...

Page 138: Eng

4 - 61 eng crankcase and crankshaft 3.Check: ● timing chain guide (exhaust side) ● timing chain guide (intake side) damage/wear → replace the defective part(-s). Crankshaft installation 1.Install: ● crankshaft into the crankcase (right) note: hold the connecting rod 1 at top dead center with one han...

Page 139: Eng

4 - 62 eng crankcase and crankshaft 4.Tighten: ● crankcase bolts note: ● tighten the crankcase bolts in stages and in a crisscross pattern. ● install a copper washer on bolts 1 , 2 , 3 . M6 × 70 mm bolts: 1 ~ 3 m6 × 60 mm bolts: 4 , 5 m6 × 55 mm bolts: 6 ~ 8 m6 × 45 mm bolts: 9 ~ b 5.Install: ● neut...

Page 140: Eng

4 - 63 eng transmission transmission 1 main axle/1st pinion gear 2 3rd/4th pinion gear 3 5th pinion gear 4 2nd pinion gear 5 drive axle 6 1st wheel gear 7 3rd wheel gear 8 4th wheel gear 9 5th wheel gear 0 2nd wheel gear a drive sprocket b shift drum assembly c shift fork “l” d shift fork “c” e shif...

Page 141: Eng

4 - 64 eng transmission transmission removal note: prior to remove the transmission, separate the crankcase. 1.Remove: ● dowel pin ● guide bar 1 ● shift fork “r” 2 ● shift fork “c” ● shift fork “l” 3 ● shift drum assembly 4 note: note the position of each part. Pay particular attention to the locati...

Page 142: Eng

4 - 65 eng transmission 3.Inspect: ● shift fork “l” 1 ● shift fork “c” 2 ● shift fork “r” 3 ● shift fork guide bar 4 ● shift drum assembly 5 ● pin 6 roll the shift fork guide bar on a flat surface. Bends → replace. Warning do not attempt to straighten a bent shift fork guide bar. 4.Check: ● shift fo...

Page 143: Eng

4 - 66 eng transmission 3.Check: ● transmission gears blue discoloration/pitting/wear → replace the defective gear(s). ● transmission gear dogs cracks/damage/rounded edges → replace the defective gear(s). 4.Check: ● transmission gear engagement (each pinion gear to its respective wheel gear) incorre...

Page 144: Eng

4 - 67 eng transmission transmission installation 1.Install: ● transmission gears assembly 1 ● shift drum assembly 2 ● shift fork “l” 3 ● shift fork “c” ● shift fork “r” 4 into the crankcase (right) ● guide bar 5 note: facing the mark on shift fork down ward. 2.Check: ● shifter operation unsmooth op...

Page 145: Carb

Carb chapter 5. Carburetion carburetor ............................................................................................. 5-1 removal ............................................................................................. 5-2 disassembly ................................................

Page 146: Carb

Carb.

Page 147: Carb

5 - 1 carb carburetor carburetion carburetor 1 vacuum chamber cover 2 piston valve spring 3 jet needle set 4 pilot screw set 5 piston valve 6 starter plunger assembly 7 needle jet 8 pilot jet 9 throttle stop screw set 0 gasket a main jet b needle valve assembly c needle valve holder d drain hose e f...

Page 148: Carb

5 - 2 carb carburetor removal warning gasoline is highly flammable. Avoid spilling fuel on the hot engine. 1.Remove: ● fuel tank refer to the “fuel tank” section in chapter 3. 2.Remove: ● battery refer to the “battery inspection” sec- tion in chapter 3. 3.Remove: ● drive chain guard 1 4.Remove: ● ba...

Page 149: Carb

5 - 3 carb 6.Remove: ● air filter case 1 7.Drain: ● loosen the drain screw 1 and drain the gas- oline 8.Loosen: ● lock nut 2 (throttle cable) 9.Remove: ● throttle cable 3 10.Loosen: ● screw 1 (carburetor joint) 11.Remove: ● carburetor 1 disassembly 1.Remove: ● vacuum chamber cover 1 2.Remove: ● pist...

Page 150: Carb

5 - 4 carb carburetor 3.Remove: ● jet needle set 1 4.Remove: ● pilot screw set 1 5.Remove: ● float chamber cover 1 ● gasket 6.Remove: ● float pivot pin 1 ● float 2 ● needle valve 3 7.Remove: ● needle valve holder 1.

Page 151: Carb

Carb 5 - 5 carburetor 8.Remove: ● main jet 1 ● washer 2 ● needle jet 3 ● pilot jet 4 9.Remove: ● starter plunger assembly 1 inspection 1.Inspect: ● carburetor body ● fuel passage contamination → clean as indicated. ***************************************************** carburetor cleaning steps: ● wa...

Page 152: Carb

5 - 6 carb carburetor 4.Inspect: ● piston valve 1 cracks → replace. ● rubber diaphragm 2 tears → replace. ● jet needle 3 bend → replace. Note: if you suspect the piston valve has been dam- aged, check the component for cracks by pouring gasoline into the valve. If it leaks, replace with a new piston...

Page 153: Carb

5 - 7 carb carburetor assembly to assemble the carburetor reverse the disas- sembly procedures. Note the following points. Note: ● before reassembling wash all parts in clean gasoline. ● always use a new gasket. 1.Install: ● jet needle set to piston valve assembly note: be sure to install the jet ne...

Page 154: Carb

5 - 8 carb carburetor 3.Install: ● needle jet to carburetor note: be sure to insert the slot a onto the projection b . 4.Install: ● needle valve holder t r . . Screw (float valve holder): 2 nm (0.2 m • kg) 5.Install: ● float chamber cover 1 t r . . Screw (float chamber cover): 5 nm (0.5 m • kg) 6.In...

Page 155: Carb

5 - 9 carb carburetor installation reverse the “removal” procedure. Note the following points: 1.Install: ● carburetor note: be sure to insert the projection a into the slot b of carburetor joint. 2.Adjust: ● engine idle speed refer to the “idling speed adjust- ment” section in chapter 3. Engine idl...

Page 156: Carb

5 - 10 carb carburetor fuel level adjustment 1.Measure: ● fuel level a out of specification → adjust. ***************************************************** fuel level measurement and adjustment steps: ● place the motorcycle on a level surface. ● use centerstand to ensure that the carbure- tor is pos...

Page 157: Chas

Chas chapter 6. Chassis front wheel and brake disc ............................................................ 6-1 front wheel removal .................................................................. 6-2 front wheel disassembly .......................................................... 6-2 front ...

Page 158: Chas

Chas rear shock absorber and swingarm ........................................ 6-41 rear shock absorber and swingarm removal ............... 6-42 rear shock absorber inspection ......................................... 6-43 swingarm inspection ...........................................................

Page 159: Chas

6 - 1 chas front wheel and brake disc chassis front wheel and brake disc 1 front wheel axle 2 collar 3 oil seal 4 bearing 5 spacer 6 meter clutch 7 speedometer gear unit 8 brake disc.

Page 160: Chas

6 - 2 chas front wheel and brake disc front wheel removal warning securely support the motorcycle so there is no danger of it falling over. 1.Place the motorcycle on level place. 2.Remove: ● speedometer cable 1 ● front wheel axle nut 2 3.Remove: ● front wheel axle 1 ● collar 2 ● speedometer gear uni...

Page 161: Chas

6 - 3 chas front wheel and brake disc t700021 front wheel inspection 1.Inspect: ● front wheel axle (by rolling it on a flat surface) bends → replace. Warning do not attempt to straighten a bent axle. 2.Inspect: ● front tire wear/damage → replace. Refer to the “tire inspection” section in chapter 3. ...

Page 162: Chas

6 - 4 chas front wheel and brake disc 5.Measure: ● front wheel runout over the specified limits → replace. 6.Inspect: ● front wheel bearings bearings allow free play in the wheel hub or the wheel does not turn smoothly → replace. ● oil seals wear/damage → replace. 7.Inspect: ● collar grooved wear → ...

Page 163: Chas

6 - 5 chas front wheel and brake disc front wheel assembly 1.Install: ● bearing 1 ● spacer ● bearing ● oil seal note: ● apply the lithium soap base grease on the bearing and oil seal lip when installing. ● use a socket that matches the outside diam- eter of the race of the bearing. ● always use a ne...

Page 164: Chas

6 - 6 chas front wheel and brake disc 3.Tighten: ● front wheel axle nut note: be sure that the projection (torque stopper) a of the gear unit housing is positioned correctly. T r . . 58 nm (5.8 m • kg) 4.Connect: ● speedometer cable.

Page 165: Chas

6 - 7 chas rear wheel and rear brake rear wheel and rear brake 1 drive chain puller 2 brake camshaft lever 3 brake shoe wear indicator 4 spacer 5 brake shoe plate 6 brake camshaft 7 brake shoe 8 oil seal 9 bearing 0 spacer a rear wheel clutch hub damper b rear wheel clutch hub c driven sprocket d co...

Page 166: Chas

6 - 8 chas rear wheel and rear brake rear wheel removal 1.Remove: ● adjuster 1 ● brake rod 2 ● tension bar 3 note: depress the brake pedal to remove the brake rod. 2.Loosen: ● rear wheel axle nut 1 ● locknuts ● drive chain adjuster nuts 3.Remove: ● rear wheel axle nut 1 ● rear wheel axle 2 ● washers...

Page 167: Chas

6 - 9 chas rear wheel and rear brake 4.Inspect: ● rear wheel clutch hub damper wear/damage → replace. Rear brake inspection 1.Inspect: ● brake shoes glazed parts → sand with coarse sandpa- per. Note: after using the sandpaper, clean of the pol- ished particles with a cloth. 2.Measure: ● brake shoe t...

Page 168: Chas

6 - 10 chas rear wheel and rear brake 6.Inspect: ● brake shoe plate 1 cracks/damage → replace. ● brake camshaft 2 ● camshaft hole 3 scratches/excessive wear → replace. T****** brake shoe plate assembly 1.Install: ● brake camshaft 1 ● brake shoe wear indicator 2 **************************************...

Page 169: Chas

6 - 11 chas rear wheel and rear brake t701032 rear wheel installation reverse the “removal” procedure. Note the following points. 1.Install: ● brake shoe plate assembly ● rear wheel assembly note: make sure that the slot in the rear wheel clutch hub damper fits over the tab on the rear wheel clutch ...

Page 170: Chas

6 - 12 chas front brake front brake front brake caliper 1 brake caliper 2 brake pad 3 brake pad spring 4 retaining bolt 5 brake caliper piston 6 brake caliper piston seal 7 bleed screw kit 8 brake caliper bolt.

Page 171: Chas

6 - 13 chas front brake master cylinder 1 brake master cylinder 2 brake master cylinder kit 3 reservoir diaphragm 4 reservoir cap 5 master cylinder holder 6 brake hose 7 union bolt 8 copper washer.

Page 172: Chas

6 - 14 chas front brake caution: disc brake components rarely require dis- assembly. Do not: ● disassemble components unless abso- lutely necessary; ● use solvents on internal brake compo- nents; ● use spent brake fluid for cleaning; (use only clean brake fluid) ● allow brake fluid to come in contac...

Page 173: Chas

6 - 15 chas front brake 5.Install: ● brake pads ● brake pads springs *********************************************** installation steps: ● connect a suitable hose 1 tightly to the brake caliper bleed screw 2 . Put the other end of this hose into an open container. ● loosen the brake caliper bleed sc...

Page 174: Chas

6 - 16 chas front brake eas00619 front brake caliper removal note: before disassembling the brake caliper, drain the brake fluid from the entire brake system. 1.Remove: ● union bolt 1 ● copper washers 2 ● brake hose note: put the end of the brake hose into a container and pump out the brake fluid ca...

Page 175: Chas

6 - 17 chas front brake eas00633 front brake caliper inspection 1.Check: ● brake caliper pistons 1 rust/scratches/wear → replace the brake caliper. Piston assembly. ● brake caliper cylinders 2 scratches/wear → replace the brake cali- per. ● brake caliper 3 cracks/damage → replace ● brake fluid deliv...

Page 176: Chas

6 - 18 chas front brake 1.Install: ● brake caliper 1 (temporarily) ● copper washers 2 ● brake hose 3 ● union bolt 4 warning proper brake hose routing is essential to insure safe motorcycle operation. Refer to the “cable routing” section. Caution: when installing the brake hose onto the brake caliper...

Page 177: Chas

6 - 19 chas front brake ● when refilling, be careful that water does not enter the reservoir. Water will signifi- cantly lower the boiling point of the brake fluid and could cause vapor lock. Caution: brake fluid may damage painted surfaces and plastic parts. Therefore, always clean up any spilt bra...

Page 178: Chas

6 - 20 chas front brake eas00588 master cylinder removal note: before removing the front brake master cylin- der, drain the brake fluid from the entire brake system. 1.Remove: ● brake lever/compression spring ● brake switch 1 2.Remove: ● union bolt 2 ● copper washers ● brake hose 3 note: to collect ...

Page 179: Chas

6 - 21 chas front brake 3.Check: ● brake fluid reservoir 1 cracks/damage → replace. ● reservoir diaphragm 2 cracks/damage → replace. 4.Check: ● brake hose 1 cracks/damage/wear → replace. Eas00598 master cylinder installation warning ● before installation, all internal brake com- ponents should be cl...

Page 180: Chas

6 - 22 chas front brake 2.Install: ● copper washers 1 ● brake hose 2 ● union bolt 3 warning proper brake hose routing is essential to insure safe motorcycle operation. Refer to the “cable routing” section. Note: ● while holding the brake hose, tighten the union bolt as shown. ● turn the handlebar to...

Page 181: Chas

6 - 23 chas front brake 4.Bleed: ● brake system refer to the “air bleeding (hydraulic brake system)” section in chapter 3. 5.Check: ● brake fluid level below the minimum level mark a → add the recommended brake fluid to the proper level. Refer to the “brake fluid level inspection” section in chapter...

Page 182: Chas

6 - 24 chas front fork front fork 1 cap bolt 2 o-ring 3 spacer 4 spring seat 5 fork spring 6 rebound spring 7 damper rod 8 oil lock piece 9 inner tube 0 dust seal a oil seal clip b oil seal c outer tube.

Page 183: Chas

6 - 25 chas front fork eas00649 front fork removal the following procedure applies to both of the front fork legs. 1.Stand the motorcycle on a level surface. Warning securely support the motorcycle so that there is no danger of it falling over. 2.Remove: ● front wheel refer to the “front wheel and b...

Page 184: Chas

6 - 26 chas front fork 2.Drain: ● fork oil 3.Remove: ● dust seal 1 ● oil seal clip 2 (with a flat-head screwdriver) caution: do not scratch the inner tube. 4.Remove: ● damper rob bolt ● copper washer note: while holding the damper rod with the damper rod holder 1 and t-handle 2 , loosen the damper r...

Page 185: Chas

6 - 27 chas front fork eas00657 front fork inspection the following procedure applies to both of the front fork legs. 1.Check: ● inner tube 1 ● outer tube 2 bends/damage/scratches → replace. Warning do not attempt to straighten a bent inner tube as this may dangerously weaken it. 2.Measure: ● spring...

Page 186: Chas

6 - 28 chas front fork note: ● when assembling the front fork leg, be sure to replace the following parts: -oil seal -dust seal ● before assembling the front fork leg, make sure that all of the components are clean. 1.Install: ● damper rod 1 ● oil lock piece 2 caution: allow the damper rod to slide ...

Page 187: Chas

6 - 29 chas front fork caution: make sure that the numbered side of the oil seal faces up. Note: ● before installing the oil seal, apply lithium soap base grease onto its lips. ● apply fork oil onto the outer surface of the inner tube. ● before installing the oil seal, cover the top of the front for...

Page 188: Chas

6 - 30 chas front fork note: ● while filling the front fork leg, keep it upright. ● after filling, slowly pump the front fork leg up and down to distribute the fork oil. ● be sure to stroke the inner tube slowly because the for oil may spurt out. 8.Install: ● spring 1 ● spring seat 2 ● spacer 3 ● ca...

Page 189: Chas

6 - 31 chas front fork 2.Tighten: ● lower bracket pinch bolt 1 ● handle crown pinch bolt 2 ● cap bolt 3 warning make sure that the brake hoses are routed properly. 3.Install: ● front fender ● collars ● bolts (front fender) 4.Install: ● front wheel refer to the “front wheel and brake disc” section. T...

Page 190: Chas

6 - 32 chas steering head and handlebar steering head and handlebar handlebar 1 grip end 2 throttle grip 3 handlebar 4 throttle cable 5 clutch cable.

Page 191: Chas

6 - 33 chas steering head and handlebar steering head 1 handlebar holder 2 bolt cap 3 lock washer 4 upper ring nut 5 rubber washer 6 lower ring nut 7 ball race cover 8 bearing 9 bearing 0 bearing race a lower bracket.

Page 192: Chas

6 - 34 chas steering head and handlebar handlebar removal 1.Remove: ● handlebar switch 1 (left) 2.Remove: ● grip end 1 (left) ● handlebar grip 2 (left) ● clutch cable 3 ● clutch lever holder 4 note: before removing the clutch lever holder 4 , remove the clutch switch leads and clutch cable. 3.Remove...

Page 193: Chas

6 - 35 chas steering head and handlebar 6.Remove: ● bolt cap 1 ● handlebar holders 2 7.Remove: ● handlebar steering head removal warning securely support the motorcycle so there is no danger of its falling over. 1.Place the motorcycle on the centerstand and place a suitable stand under the engine to...

Page 194: Chas

6 - 36 chas steering head and handlebar 4.Remove: ● front wheel ● front fork refer to the “front wheel and front fork removal” section. Note: it is not necessary to remove the cap bolts when removing front fork. 5.Remove: ● handle crown 1 ● upper ring nut 2 ● rubber washer ● lower ring nut 3 use the...

Page 195: Chas

6 - 37 chas steering head and handlebar 3.Remove: ● ball race cover 1 ● bearing race 2 ● bearing 3 *********************************************** bearing race replacement steps: ● remove the bearing race on the lower bracket using the floor chisel 4 and the hammer as shown. ● install the new bearin...

Page 196: Chas

6 - 38 chas steering head and handlebar 2.Install: ● bearing (lower) onto the bearing race. ● lower bracket warning support the lower bracket until it is secured. ● bearing (upper) ● bearing race (upper) ● bearing race cover ● ring nuts 3.Tighten: ● ring nut refer to the “steering head inspec- tion”...

Page 197: Chas

6 - 39 chas steering head and handlebar handlebar installation 1.Install: ● speedometer assembly ● handlebar 1 ● handlebar holders 2 ● bolt cap 3 note: ● punch mark 1 should be flush with upper bracket when installing the handlebar. ● arrow marks 2 should be pointed toward when installing handlebar ...

Page 198: Chas

6 - 40 chas warning it should have 1 ~ 3 mm when installing throttle grip end. 4.Adjust: ● throttle cable free play refer to the “throttle cable free play adjustment” section in chapter 3. T r . . Bolt (throttle grip end): 23 nm (2.3 m • kg) throttle cable free play: 3 ~ 5 mm steering head and handl...

Page 199: Chas

6 - 41 chas rear shock absorber and swingarm rear shock absorber and swingarm 1 rear shock absorber 2 bush 3 swingarm 4 bearing 5 dust cover 6 bush 7 drive chain guide 8 relay arm 9 bush 0 oil seal a collar b connecting arm c bush d oil seal e collar.

Page 200: Chas

6 - 42 chas rear shock absorber and swingarm eas00703 rear shock absorber and swingarm removal 1.Stand the motorcycle on a level surface. Warning securely support the motorcycle so that there is no danger of it falling over. 2.Remove: ● air filter case refer to the “carburetor” section in chapter 5....

Page 201: Chas

6 - 43 chas rear shock absorber and swingarm eas00696 rear shock absorber inspection 1.Inspect: ● rear shock absorber rod bends/damage → replace the rear shock absorber assembly. ● rear shock absorber gas leaks/oil leaks → replace the rear shock absorber assembly. ● spring damage/wear → replace the ...

Page 202: Chas

6 - 44 chas rear shock absorber and swingarm 4.Inspect: ● dust covers 1 ● bush 2 damage/wear → replace. ● bearings 3 damage/pitting → replace. Ec574210 relay arm inspection 1.Inspect: ● bushs 1 ● collar 2 free play exists/unsmooth revolution/rust → replace bush and collar as a set. 2.Inspect: ● oil ...

Page 203: Chas

6 - 45 chas rear shock absorber and swingarm 3.Measure: ● 10 link length a (drive chain) out of specification → replace the drive chain. Note: ● tighten the drive chain with a finger before measuring. ● 10 link length is the distance between the inside edge of roller 1 and a as shown. ● 10 link leng...

Page 204: Chas

6 - 46 chas rear shock absorber and swingarm t***** rear wheel clutch hub inspection 1.Inspect: ● rear wheel clutch hub wear/damage/cracks → replace. T****** driven sprocket assembly 1.Install: ● driven sprocket 1 ● lock washers 2 ● bolts 3 note: tighten the bolts in a crisscross pattern. New t r . ...

Page 205: Chas

6 - 47 chas rear shock absorber and swingarm 2.Install: ● bush 1 ● bearings 2 ● chain guide 3 ● collar (chain guide) 4 ● bolt (chain guide) 5 ● dust covers 6 (to the swingarm). 3.Install: ● collar 1 ● bushes 2 ● oil seals 3 (to the relay arm). 4.Install: ● collars 1 ● bushes 2 ● oil seals 3 (to the ...

Page 206: Chas

6 - 48 chas rear shock absorber and swingarm 6.Install: ● connecting arm 1 ● bolt (connecting arm-swingarm) 2 ● washer 3 ● nut (connecting arm-swingarm) 4 note: apply the lithium soap-base grease on the bolt. 7.Install: ● swingarm 1 ● pivot shaft 2 ● washer ● nut note: ● apply the lithium soap-base ...

Page 207: Elec

– + elec chapter 7. Electrical electrical components ..................................................................... 7-1 switches ................................................................................................... 7-3 checking switch continuity ....................................

Page 208: Elec

– + elec.

Page 209: Elec

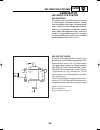

7 - 1 – + elec electrical components electrical electrical components 1 fuel sender 2 starting circuit cut-off relay 3 rectifier/regulator 4 rear brake switch 5 starter relay 6 battery 7 main switch.

Page 210: Elec

7 - 2 – + elec electrical components 1 ignition coil 2 flasher relay 3 cdi unit 4 neutral switch 5 horn.

Page 211: Elec

7 - 3 – + elec switches eas0010 switches checking switch continuity check each switch for continuity with the pocket tester. If the continuity reading is incorrect, check the wiring connections and if necessary, replace the switch. Caution: never insert the tester probes into the cou- pler terminal ...

Page 212: Elec

7 - 4 – + elec checking the switches eas00731 checking the switches check each switch for damage or wear, proper connections, and also for continuity between the ter- minals. Refer to the “checking switch continuity” section. Damage/wear → repair or replace the switch. Improperly connected → properl...

Page 213: Elec

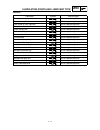

7 - 5 – + elec checking the switches 1 clutch switch 2 pass switch 3 horn switch 4 dimmer switch 5 turn switch 6 main switch 7 lights switch 8 front brake switch 9 engine stop switch 0 start switch a fuse b rear brake switch c neutral switch.

Page 214: Elec

7 - 6 – + elec checking of bulbs checking of bulbs (for headlight, tail/blake light, flasher light, meter light, etc.) to determine the condition of a bulb check for continuity at the bulb terminal. Kinds of bulbs the bulbs used in motorcycles can be classi- fied by shape of socket and use. A and b ...

Page 215: Elec

7 - 7 – + elec checking of bulbs 2.Check for continuity at the bulb terminals. ***************************************************** checking steps: ● set the pocket tester selector to “ Ω × 1”. ● connect the tester leads to the respective bulb terminals. Take for example a 3-termi- nal bulb as show...

Page 216: Elec

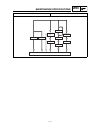

7 - 8 – + elec ignition system circuit diagram 9 lock off on g b 1 r br b r b br b / w b / w x y 10a y /r b w l /w r /w z [ (green) 2 wb ry / r w b y /r b y w 3 r bw ob r b / wg 4 6 5 l / yr / w sb br off on off ru n p (green) (green) b g o dg ch (blue) (blue) ch dg sb br g l b g l sb br b 9 r l n h...

Page 217: Elec

7 - 9 – + elec ignition system troubleshooting procedure check; 1.Spark plug 2.Ignition spark gap 3.Spark plug cap resistance 4.Ignition coil resistance 5.Main switch 6.Engine stop switch 7.Source coil resistance 8.Pickup coil resistance 9.Wiring connection (ignition system) note: ● remove the follo...

Page 218: Elec

7 - 10 – + elec ignition system c0ntinuity out of specification 2.Ignition spark gap ● disconnect the spark plug cap from the spark plug. ● connect the ignition checker 1 between cylinder head and spark plug cap 2 , and set the specified spark gap 3 . ● turn the main switch to “on”, then apply clutc...

Page 219: Elec

7 - 11 – + elec ignition system c0ntinuity 4.Ignition coil resistance ● disconnect the ignition coil lead (orange) from the wire harness. ● connect the pocket tester to the ignition coil. Primary coil: ( Ω × 1) tester (+) lead → orange 1 terminal tester (–) lead → ignition coil base 2 secondary coil...

Page 220: Elec

7 - 12 – + elec ignition system c0ntinuity 7.Source coil resistance ● disconnect the cdi magneto coupler from the wire harness. ● connect the pocket tester ( Ω × 100) to the source coil. Tester (+) lead → brown 1 terminal tester (–) lead → green 2 terminal * meets specification 3 cdi magneto ● measu...

Page 221: Elec

7 - 13 – + elec electric starting system electric starting system circuit diagram 9 lock off on g b 1 r br b r b br b / w b / w x y 10a y /r b w l /w r /w z [ (green) 2 wb ry / r w b y /r b y w 3 r bw ob r b / wg 4 6 5 l / yr / w sb br off on off ru n p (green) (green) b g o dg ch (blue) (blue) ch d...

Page 222: Elec

7 - 14 – + elec electric starting system starting circuit operation the starting circuit on this model consist of the starter motor, starter relay, and the relay unit (starting circuit cut-off relay). If the engine stop switch and the main switch are both closed, the starter motor can operate only i...

Page 223: Elec

7 - 15 – + elec electric starting system troubleshooting procedure check; 1.Fuse 2.Battery 3.Starter motor 4.Starter relay 5.Starting circuit cut-off relay (relay assembly) 6.Main switch 7.Engine stop switch 8.Neutral switch 9.Clutch switch 10.Start switch 11.Wiring connection (electric starting sys...

Page 224: Elec

7 - 16 – + elec electric starting system c0ntinuity c0ntinuity 3.Starter motor ● connect the battery positive terminal 1 and starter motor cable 2 using the jumper lead 3 . ● check the starter motor operation. * * warning ● a wire for the jumper lead must have the equivalent capacity as that of the ...

Page 225: Elec

7 - 17 – + elec electric starting system c0ntinuity continuity 5.Starting circuit cut-off relay ● disconnect the relay lead coupler from the wire harness. ● connect the pocket tester ( Ω × 1) and bat- tery (12 v) to relay. Step 1: battery (+) lead → brown terminal 1 battery (–) lead → sky blue termi...

Page 226: Elec

7 - 18 – + elec electric starting system c0ntinuity correct 8.Neutral switch ● check the neutral switch for continuity. Refer to the “checking the switches” section. * incorrect replace neutral switch. Correct 9.Clutch switch ● check the clutch switch for continuity. Refer to the “checking the switc...

Page 227: Elec

7 - 19 – + elec electric starting system starter motor 1 brush 2 armature 3 o-ring 4 o-ring a brush length limit: 3.5 mm b commutator wear limit: 21 mm c mica under cut: 1.5 mm d armature coil resistance: 0 Ω at 20°c.

Page 228: Elec

7 - 20 – + elec electric starting system removal 1.Remove: ● carburetor refer to the “carburetor” section in chapter 5. 2.Remove: ● clutch cable refer to the “wire, cable and tube” section in chapter 4. 3.Disconnect: ● starter motor lead 1 4.Remove: ● starter motor 2 5.Remove: ● bolts (starter motor...

Page 229: Elec

7 - 21 – + elec electric starting system 3.Measure: ● mica undercut b out of specification → scrape the mica to proper value use a hacksaw blade can be ground to fit. Note: the mica insulation of the commutator must be undercut to ensure proper operation of com- mutator. Mica undercut: 1.5 mm 4.Insp...

Page 230: Elec

7 - 22 – + elec electric starting system 6.Measure: ● brush spring pressure fatigue/out of specification → replace as a set. Brush spring pressure: 560 ~ 840 g 7.Inspect ● bearing ● oil seal ● o-ring wear/damage → replace. Assembly reverse the “removal” procedure. Note the following points. 1.Instal...

Page 231: Elec

7 - 23 – + elec electric starting system 2.Install ● armature 1 3.Install: ● o-ring 1 ● starter motor yoke 2 4.Install ● starter motor assembly note: align the groove a on the starter motor assembly with the groove b on the housing. 5.Install: ● o-ring 1 ● screw warning always use a new o-ring. 6.In...

Page 232: Elec

7 - 24 – + elec electric starting system installation 1.Install: ● starter motor 1 ● starter motor lead 2 t r . . Bolt (starter motor): 10 nm (1.0 m • kg).

Page 233: Elec

7 - 25 – + elec charging system charging system circuit diagram 9 lock off on g b 1 r br b r b br b / w b / w x y 10a y /r b w l /w r /w z [ (green) 2 wb ry / r w b y /r b y w 3 r bw ob r b / wg 4 6 5 l / yr / w sb br off on off ru n p (green) (green) b g o dg ch (blue) (blue) ch dg sb br g l b g l ...

Page 234: Elec

7 - 26 – + elec charging system troubleshooting procedure check; 1.Fuse 2.Battery 3.Charging voltage 4.Charging coil resistance 5.Wiring connection (charging system) note: ● remove the following parts before troubleshooting. 1)side cover (right) 2)seat 3)fuel tank ● use the following special tools i...

Page 235: Elec

7 - 27 – + elec charging system c0ntinuity 3.Charging voltage ● connect the indicative tachometer to the spark plug lead. ● connect the pocket tester (dc 20 v) to the battery. Tester (+) lead → battery (+) terminal 1 tester (–) lead → battery (–) terminal 2 * out of specification ● start the engine....

Page 236: Elec

7 - 28 – + elec lighting system lighting system circuit diagram 9 lock off on g b 1 r br b r b br b / w b / w x y 10a y /r b w l /w r /w z [ (green) 2 wb ry / r w b y /r b y w 3 r bw ob r b / wg 4 6 5 l / yr / w sb br off on off ru n p (green) (green) b g o dg ch (blue) (blue) ch dg sb br g l b g l ...

Page 237: Elec

7 - 29 – + elec lighting system troubleshooting procedure check; 1.Lighting coil resistance 2.Lights switch 3.Dimmer switch 4.Pass switch 5.Wiring connection (entire lighting system) note: ● remove the following parts before troubleshooting. 1)side cover (right) 2)headlight unit 3)seat ● use the fol...

Page 238: Elec

7 - 30 – + elec lighting system c0ntinuity correct 3.Dimmer switch ● check the dimmer switch for continuity. Refer to the “checking the switches” section. * incorrect dimmer switch is faulty, replace handlebar switch (left). Correct 4.Pass switch ● check the pass switch for continuity. Refer to the ...

Page 239: Elec

7 - 31 – + elec lighting system lighting system check 1.Headlight and high beam indicator light do not come on. Continuity 1.Bulb and bulb socket ● check the bulb and bulb socket for continu- ity. Refer to the “checking of bulbs” sec- tion. No continuity bulb and/or bulb socket are faulty, replace. ...

Page 240: Elec

7 - 32 – + elec lighting system 2.Meter light does not come on. Continuity 1.Bulb and bulb socket ● check the bulb and bulb socket for continu- ity. Refer to the “checking of bulbs” sec- tion. No continuity bulb and/or bulb socket are faulty, replace. Meets specifi- cation (12 v) 2.Voltage ● connect...

Page 241: Elec

7 - 33 – + elec lighting system 3.Taillight does not come on continuity 1.Bulb and bulb socket ● check the bulb and bulb socket for continu- ity. Refer to the “checking the switches” section. No continuity bulb and/or bulb socket are faulty, replace. Meets specifi- cation (12 v) 2.Voltage ● connect ...

Page 242: Elec

7 - 34 – + elec signaling system signaling system circuit diagram 9 lock off on g b 1 r br b r b br b / w b / w x y 10a y /r b w l /w r /w z [ (green) 2 wb ry / r w b y /r b y w 3 r bw ob r b / wg 4 6 5 l / yr / w sb br off on off ru n p (green) (green) b g o dg ch (blue) (blue) ch dg sb br g l b g ...

Page 243: Elec

7 - 35 – + elec signaling system 1 main switch 9 horn 0 flasher relay a front brake switch b rear brake switch d horn switch h turn signal switch j tail/black light k rear turn signal light l front turn signal light o neutral switch p fuel sender r fuel gauge u neutral indicator light v turn indicat...

Page 244: Elec

7 - 36 – + elec signaling system troubleshooting procedure check; 1.Fuse 2.Battery 3.Main switch 4.Wiring connection (entire signal system) note: ● remove the following parts before troubleshooting. 1)side cover (right) 2)headlight unit 3)seat 4)fuel tank ● use the following special tool (s) in this...

Page 245: Elec

7 - 37 – + elec signaling system c0ntinuity correct 3.Main switch ● check the main switch for continuity. Refer to the “checking the switches” section. * incorrect main switch is faulty, replace it. Correct 4.Wiring connection ● check the entire signal system for connec- tions. Refer to the “wiring ...

Page 246: Elec

7 - 38 – + elec signaling system signal system check 1.Horn does not sound. Correct 1.Horn switch ● check the horn switch for continuity. Refer to the “checking the switches” section. Incorrect horn switch is faulty, replace handlebar switch (left). Meets specifi- cation (12 v) 2.Voltage ● connect t...

Page 247: Elec

7 - 39 – + elec signaling system c0ntinuity horn is not sounded 3.Horn ● disconnect the “pink” lead at the horn ter- minal. ● connect a jumper lead 1 to the horn termi- nal and ground the jumper lead. ● turn the main switch to “on”. * horn is sounded horn is good. Meets specifi- cation (12 v) 4.Volt...

Page 248: Elec

7 - 40 – + elec signaling system 2.Brake light does not come on. Continuity 1.Bulb and bulb socket ● check the bulb and bulb socket for continu- ity. Refer to the “checking of bulbs” sec- tion. No continuity bulb and/or bulb socket are faulty, replace. Correct 2.Brake switch ● check the brake switch...

Page 249: Elec

7 - 41 – + elec signaling system 3.Flasher light and/or turn indicator light do not blink. Continuity 1.Bulb and bulb socket ● check the bulb and bulb socket for continu- ity. Refer to the “checking of bulbs” sec- tion. No continuity bulb and/or bulb socket are faulty, replace. Correct 2.Turn signal...

Page 250: Elec

7 - 42 – + elec signaling system c0ntinuity meets specifi- cation (12 v) 4.Voltage ● connect the pocket tester (dc 20 v) to the flasher relay. Tester (+) lead → brown/white 1 terminal tester (–) lead → frame ground ● turn the main switch to “on”. ● check for voltage (12 v) on the “brown/ white” lead...

Page 251: Elec

7 - 43 – + elec signaling system 4.Natural indicator light does not come on. Continuity 1.Bulb and bulb socket ● check the bulb and bulb socket for continu- ity. Refer to the “checking of bulbs” sec- tion. No continuity bulb and/or bulb socket are faulty, replace. Correct 2.Neutral switch ● check th...

Page 252: Elec

7 - 44 – + elec signaling system 5.Fuel meter does not operate. 1.Fuel sender ● remove the fuel sender 1 from the fuel tank. ● connect the pocket tester to the fuel sender coupler. Tester (+) lead → green 2 terminal tester (–) lead → black 3 terminal both meet specification ● check the fuel sender f...

Page 253: Elec

7 - 45 – + elec signaling system c0ntinuity moves 3.Fuel meter ● move the float to “up 1 ” or “down 2 ”. ● turn the main switch to “on”. ● check the fuel meter needle moves “full” or “empty”. * note: before reading the meter, stay put the float for more than three minutes respectively at “up” or “do...

Page 254: Trbl

Trbl shtg chapter 8. Troubleshooting troubleshooting .................................................................................. 8-1 electrical system ........................................................................ 8-1 compression system .................................................

Page 255: Trbl

Trbl shtg.

Page 256: Trbl

8 - 1 trbl shtg troubleshooting troubleshooting troubleshooting electrical system.

Page 257: Trbl

8 - 2 trbl shtg troubleshooting compression system.

Page 258: Trbl

8 - 3 trbl shtg troubleshooting intake and exhaust system.

Page 259