- DL manuals

- Yamaha

- Boat

- SR230 2004

- Service Manual

Yamaha SR230 2004 Service Manual

Summary of SR230 2004

Page 1

Service manual sr230 2004.

Page 2: Preface

Preface this manual has been prepared by yamaha primarily for use by yamaha dealers and their trained mechanics when performing maintenance procedures and repairs to yamaha equipment. It is not possible to put an entire mechanic’s education into one manual, so it is assumed that persons using this b...

Page 3: How To Use This Manual

How to use this manual manual format all of the procedures in this manual are organized in a sequential, step-by-step format. The infor- mation has been compiled to provide the mechanic with an easy-to-read, handy reference that con- tains comprehensive explanations of all disassembly, repair, assem...

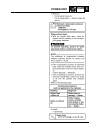

Page 4: How To Read Descriptions

How to read descriptions 1. A disassembly/installation job instruction mainly consists of the exploded diagram 1 1 . 2. The numerical figures represented by the number 2 2 indicates the order of the job steps. 3. The symbols represented by the number 3 3 indicates the contents and notes of the job. ...

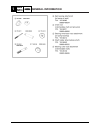

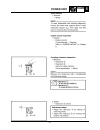

Page 5: Symbols

Symbols symbols 1 to 9 are designed as thumb-tabs to indicate the content of a chapter: general information specifications periodic inspection and adjustment fuel system power unit jet pump unit electrical system hull and deck trouble analysis symbols to indicate specific data: special tool specifie...

Page 6: Index

Index specifications spec general information 1 gen info 2 periodic inspection and adjustment 3 insp adj fuel system 4 fuel power unit 5 powr jet pump 6 jet pump electrical system 7 elec hull and deck 8 hull deck trouble analysis 9 trbl anls.

Page 7: Chapter 1

Chapter 1 general information identification numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 primary i.D. Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 engine serial number . . . . . . . ...

Page 8: Identification Numbers

A60700-0* identification numbers primary i.D. Number the primary i.D. Number is stamped on a label attached to the deck under the rear seat. Engine serial number the engine serial number is stamped on a label attached to the crankcase. Hull identification number (h.I.N.) the h.I.N. Is stamped into t...

Page 9: Safety While Working

Safety while working the procedures given in this manual are those recommended by yamaha to be followed by yamaha dealers and their mechanics. Fire prevention gasoline (petrol) is highly flammable. Petroleum vapor is explosive if ignited. Do not smoke while handling gasoline (petrol), and keep it aw...

Page 10: General Information

3. Avoid skin contact with lubricants; do not, for example, place a soiled wiping-rag in one’s pocket. 4. Hands, and any other part of the body which have been in contact with lubricants or lubricant-contaminated clothing, should be thoroughly washed with hot water and soap as soon as practicable. 5...

Page 11: General Information

Disassembly and assembly 1. Clean parts with solvent and compressed- air on disassembling them. 2. Oil the contact surfaces of moving parts on assembly. 3. After assembly, check that moving parts operate normally. 4. Install bearings with the manufacturer’s markings on the side exposed to view and l...

Page 12: General Information

Special tools use of the correct special tools recommended by yamaha will aid the work and enable accu- rate assembly and tune-up. Improvisations and use of improper tools can cause damage to the equipment. Note: • for u.S.A. And canada, use part numbers starting with “j-”, “yb-”, “ym-”,“ys-”, “yu-”...

Page 13: General Information

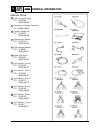

Special tools fuel pressure gauge p/n yb-06766 90890-06786 compression gauge extension p/n 90890-06582 cylinder gauge set p/n yu-03017 90890-06759 compression gauge p/n yu-33223-1 90890-03160 peak voltage adapter p/n yu-39991 90890-03172 spark gap tester p/n ym34487 90890-06754 test harness (2 pins)...

Page 14: General Information

1-7 general information x 1 gen info special tools test harness (3 pins) p/n yb-06769 90890-06769 vacuum/pressure pump gauge set p/n yb-35956-a 90890-06756 yamaha diagnostic system for watercraft p/n lit-ydis1-21-00 yamaha diagnostic system connector for watercraft p/n 60v-ws850-00-00 usb cable p/n ...

Page 15: General Information

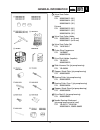

1-8 general information 1 gen info removal and installation tools 1 oil filter wrench p/n yu-38411 90890-01426 2 coupler wrench p/n yw-06551 90890-06551 3 sheave holder p/n ys-01880-a 90890-01701 4 rotor puller p/n ym-01082 90890-01080 5 rotor holder p/n yu-01235 90890-01235 6 valve remover/installe...

Page 16: General Information

1-9 general information x 1 gen info valve seat cutter intake p/n 90890-06813 (60°) 90890-06814 (45°) 90890-06815 (30°) exhaust p/n 90890-06315 (60°) 90890-06312 (45°) 90890-06328 (30°) valve seat cutter holder p/n 90890-06811 (ø4.0 mm) 90890-06812 (ø4.5 mm) valve seat cutter set p/n ym-91043-c pist...

Page 17: General Information

General information 1 gen info 1-10

Page 18: Chapter 2

Chapter 2 specifications general specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 maintenance specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3 engine . . . . . . . . . . . . . . ...

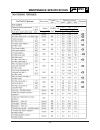

Page 19: General Specifications

General specifications general specifications x 2 2-1 spec jet thrust nozzle trim angle degree +3 impeller pitch degree port 17.3 / stbd. 16.3 1.72 (5.67 ft).

Page 20: General Specifications

2-2 general specifications 2 spec.

Page 21: Maintenance Specifications

2-3 maintenance specifications x 2 spec.

Page 22: Maintenance Specifications

2-4 maintenance specifications 2 spec.

Page 23: Maintenance Specifications

2-5 maintenance specifications x 2 spec.

Page 24: Maintenance Specifications

2-6 maintenance specifications 2 spec port 17.3 stbd. 16.3 marine group 24 dual purpose 675 cca 100 (12/68.4).

Page 25: Maintenance Specifications

2-7 maintenance specifications x 2 spec.

Page 26: Maintenance Specifications

2-8 maintenance specifications 2 spec main (at battery) starter (at each engine) b.

Page 27: Maintenance Specifications

2-9 maintenance specifications x 2 spec 1/4-20 8-32 10-24 part to be tightened.

Page 28: Maintenance Specifications

2-10 maintenance specifications 2 spec tightening torques part to be tightened.

Page 29: Maintenance Specifications

2-11 maintenance specifications x 2 spec tightening torques part to be tightened.

Page 30: Maintenance Specifications

2-12 maintenance specifications 2 spec tightening torques part to be tightened.

Page 31: Maintenance Specifications

2-13 maintenance specifications x 2 spec tightening torques part to be tightened 6 m8 3 20 2.0 14.

Page 32: Maintenance Specifications

2-14 maintenance specifications 2 spec tightening torques thread tightening torque part to be tightened part name size qty n•m kgf•m ft•lb remarks water inlet cover/water inlet bolt m6 43 6.6 0.66 4.8 strainer - impeller duct drive shaft nut - drive shaft nut – 1 69 6.9 50 impeller (left-hand thread...

Page 33: Maintenance Specifications

2-15 maintenance specifications x 2 spec tightening torques thread tightening torque part to be tightened part name size qty n•m kgf•m ft•lb remarks main and fuel pump relay tapping ø6 1 3.9 0.39 2.8 screw rectifier/regulator tapping ø6 2 3.9 0.39 2.8 screw ignition coil - oil tank bolt m6 3 7.6 0.7...

Page 34: Maintenance Specifications

2-16 general torque this chart specifies the torques for tightening standard fasteners with standard clean dry iso threads at room temperature. Torque specifica- tions for special components or assemblies are given in applicable sections of this manual. To avoid causing warpage, tighten multifastene...

Page 35: Maintenance Specifications

2-17 maintenance specifications x 2 spec cable and hose routing.

Page 36: Maintenance Specifications

2-18 maintenance specifications 2 spec cable and hose routing.

Page 37: Maintenance Specifications

2-19 maintenance specifications x 2 spec cable and hose routing.

Page 38: Maintenance Specifications

2-20 maintenance specifications 2 spec cable and hose routing.

Page 39: Maintenance Specifications

2-21 maintenance specifications x 2 spec cable and hose routing.

Page 40: Chapter 3

Chapter 3 periodic inspection and adjustment maintenance interval chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 periodic service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2 control s...

Page 41: Insp

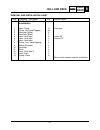

3-1 periodic inspection and adjustment x 3 insp adj.

Page 42: Periodic Service

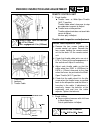

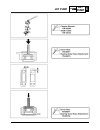

Periodic service control system steering helm inspection 1. Check: ● friction excessively heavy ➔ replace the steering helm unit. 2. Check: ● free play excessive free play ➔ replace the steering helm unit. Steering cable adjustment 1. Measure: ● distance between the center of the steering nozzle joi...

Page 43: Insp

1 cable wheel 2 locknuts 3 throttle cable remote control unit 1. Check throttle: ● throttle lever at wide-open-throttle (w.O.T.) position. Throttle cable wheel, clearance to stop on carburetor incorrect ➔ adjust. ● throttle lever at idle position. Throttle cable wheel does not touch idle screw ➔ adj...

Page 44: Insp

Shift cable inspection and adjustment the cable joints must have more than 8mm (0.31 in) engagement after adjustment is complete. 3. Check: ● mechanical interlock shift lever can move when throttle levers are not in idle position ➔ replace interlock. 4. Check: ● neutral switch refer to the “starting...

Page 45: Insp

3-5 periodic inspection and adjustment x 3 insp adj.

Page 46: Insp

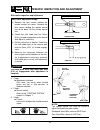

3-6 periodic inspection and adjustment 3 insp adj • valve clearance adjustment should be made on a cold engine at room temperature. • when the valve clearance is to be measured or adjusted, the piston must be at top dead center (tdc) on the compression stroke..

Page 47: Insp

3-7 periodic inspection and adjustment x 3 insp adj.

Page 48: Insp

3-8 periodic inspection and adjustment 3 insp adj.

Page 49: Insp

3-9 periodic inspection and adjustment x 3 insp adj make a note of the position of each valve lifter 3 and valve pad 4 so they can be installed in the correct place. Lowing table:.

Page 50: Insp

3-10 periodic inspection and adjustment 3 insp adj.

Page 51: Insp

3-11 periodic inspection and adjustment x 3 insp adj.

Page 52: Insp

3-12 periodic inspection and adjustment 3 insp adj caution:.

Page 53: Insp

3-13 periodic inspection and adjustment x 3 insp adj caution: place the craft in water, and then.

Page 54: Insp

3-14 periodic inspection and adjustment 3 insp adj if the oil temperature is low, the reading on the dipstick will be low. If the temperature is high, the reading on the dipstick will be high. Do not run the engine for more than 15 sec- onds without supplying water when check- ing the oil level on l...

Page 55: Insp

3-15 periodic inspection and adjustment x 3 insp adj caution:.

Page 56: Insp

3-16 periodic inspection and adjustment 3 insp adj when starting the engine, make sure the dip- stick is securely fitted into the oil tank. Caution:.

Page 57: Insp

3-17 periodic inspection and adjustment x 3 insp adj make sure the air filter element is installed in the filter case properly. If cleaning the air filter element, use cold or lukewarm water and let it air dry complete- ly. Do not use detergent or a solvent to clean the air filter element, or dry it...

Page 58: Insp

3-18 periodic inspection and adjustment 3 insp adj.

Page 59: Insp

3-19 periodic inspection and adjustment x 3 insp adj.

Page 60: Insp

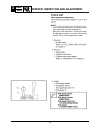

Periodic inspection and adjustment 3 insp adj 3-20 caution: be sure the cap is properly positioned and locked in place. Otherwise, the cap could loosen and be forced out of the access ports by water pressure, causing loss of performance and pos- sible damage. A clean-out cap 1 by pressing release bo...

Page 61: Insp

3-21 periodic inspection and adjustment x 3 insp adj disconnect the bilge strainer from the bilge strainer holder. Bilge pump 1. Remove inspection cover in pump clean-out tray. 2. Inspect: • bilge strainer contaminants → clean. Cracks/damage → replace. Inspection steps: • install the coupling cover..

Page 62: Insp

3-22 periodic inspection and adjustment 3 insp adj.

Page 63: Insp

3-23 periodic inspection and adjustment x 3 insp adj general drain plug inspection 1. Inspect: ● drain plug crack/damage ➔ replace. ● o-ring crack/wear ➔ replace. ● screw threads dirt/sand ➔ clean. Greasing points 1. Apply: ● throttle cable inner wire ● shift control cable ● cable joint ● steering c...

Page 64: Insp

3-24 periodic inspection and adjustment 3 insp adj lubrication points 1. Lubricate: ● throttle cable (throttle body end) note: before lubricating the qsts control cables, remove the qsts cable housing cover. Spray the rust inhibitor into the outer cables, and apply grease to the inner cables. 2. Lub...

Page 65: Insp

Periodic inspection and adjustment x 3 insp adj 4. 3-25.

Page 66: Chapter 4

X chapter 4 fuel system fuel tank and fuel pump module exploded diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 removal and installation chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 service points . . . . . . ...

Page 67: Fuel System

Fuel system x 4 fuel 4-1 28 28 28 28 28 28 28 28 28 1 2 3 4 5 10 12 11 13 16 13 15 18 13 17 19 20 26 25 24 23 27 21 22 14 13 9 8 6 7 29 29 28 30 step procedure / part name q’ty service points fuel tank pump module follow the “step” order for removal. 1 connector, harness 2 2 cover 2 3 screw, machine...

Page 68: Fuel System

4-2 fuel system 4 fuel fuel tank and fuel pump module (cont’d.) 28 28 28 28 28 28 28 28 28 1 2 3 4 5 10 12 11 13 16 13 15 18 13 17 19 20 26 25 24 23 27 21 22 14 13 9 8 6 7 29 29 28 30 step procedure / part name q’ty service points 11 fuel level sender 1 12 gasket 1 13 clamp 4 14 hose, vent 1 15 hose...

Page 69: Fuel System

4-3 fuel system x 4 fuel fuel tank and fuel pump module (cont’d.) 28 28 28 28 28 28 28 28 28 1 2 3 4 5 10 12 11 13 16 13 15 18 13 17 19 20 26 25 24 23 27 21 22 14 13 9 8 6 7 29 29 28 30 step procedure / part name q’ty service points 26 filler cap assembly 1 27 gasket 1 fuel tank note: deck must be c...

Page 70: Fuel System

4-4 fuel system 4 fuel system.” screws loosen the screws in the sequence shown..

Page 71: Fuel System

4-5 fuel system x 4 fuel system.” screws 4.9 nm (0.49 kgf-m) 7.9 nm (0.8 kgf-m).

Page 72: Fuel System

4-6 fuel system 4 fuel.

Page 73: Fuel System

4-7 fuel system x 4 fuel fuel injection system (cont’d.).

Page 74: Fuel System

4-8 fuel system 4 fuel fuel injection system (cont’d.).

Page 75: Fuel System

4-9 fuel system x 4 fuel fuel injection system (cont’d.).

Page 76: Fuel System

4-10 fuel system 4 fuel fuel injection system (cont’d.).

Page 77: Fuel System

4-11 fuel system x 4 fuel fuel injection system (cont’d.).

Page 78: Fuel System

4-12 fuel system 4 fuel fuel injection system (cont’d.) qty.

Page 79: Fuel System

4-13 fuel system x 4 fuel fuel injection system (cont’d.).

Page 80: Fuel System

4-14 fuel system 4 fuel fuel injection system (cont’d.).

Page 81: Fuel System

4-15 fuel system x 4 fuel caution:.

Page 82: Fuel System

4-16 fuel system 4 fuel caution: disconnect the fuel hose 1 directly from the fuel pipe 2 ..

Page 83: Fuel System

4-17 fuel system x 4 fuel caution: if free play is not obtained, disconnect the fuel hose, check the o-ring for damage and that it is properly installed..

Page 84: Fuel System

4-18 fuel system 4 fuel caution:.

Page 85: Fuel System

4-19 fuel system x 4 fuel caution: blow out all passages with compressed air..

Page 86: Fuel System

4-20 fuel system 4 fuel caution: only butterfly valve #2 should be fully closed. The other valves should be halfway closed..

Page 87: Fuel System

4-21 fuel system x 4 fuel.

Page 88: Fuel System

4-22 fuel system 4 fuel caution:.

Page 89: Fuel System

4-23 fuel system x 4 fuel.

Page 90: Fuel System

4-24 fuel system 4 fuel.

Page 91: Fuel System

4-25 fuel system x 4 fuel “fuel hose disconnection.” “fuel hose connection.”) nection.”) connection.”.

Page 96: Power Unit

Power unit x 5 powr 5-1 refer to “engine hatch” in chapter 8..

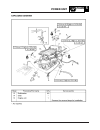

Page 97: Engine Unit

5-2 engine unit exploded diagram power unit 5 powr.

Page 98: Power Unit

5-3 power unit x 5 powr.

Page 99: Power Unit

5-4 power unit 5 powr caution:.

Page 100: Power Unit

5-5 power unit x 5 powr.

Page 101: Power Unit

5-6 power unit 5 powr caution:.

Page 102: Power Unit

5-7 power unit x 5 powr.

Page 103: Power Unit

5-8 power unit 5 powr unit.”.

Page 104: Power Unit

5-9 power unit x 5 powr exhaust pipe 3 (cont’d.).

Page 105: Power Unit

5-10 power unit 5 powr exhaust pipe 3 (cont’d.).

Page 106: Power Unit

5-11 power unit x 5 powr pipe 3.” motor.”.

Page 107: Power Unit

5-12 power unit 5 powr exhaust pipes 1 and 2 (cont’d.).

Page 108: Power Unit

5-13 power unit x 5 powr and 2.”.

Page 109: Power Unit

5-14 power unit 5 powr exhaust manifold (cont’d.).

Page 110: Power Unit

5-15 power unit x 5 powr unit.” “thermostat.”.

Page 111: Power Unit

5-16 power unit 5 powr oil tank (cont’d.).

Page 112: Power Unit

5-17 power unit x 5 powr oil tank (cont’d.).

Page 113: Power Unit

5-18 power unit 5 powr oil tank (cont’d.).

Page 114: Power Unit

5-19 power unit x 5 powr oil tank (cont’d.).

Page 115: Power Unit

5-20 power unit 5 powr oil tank (cont’d.).

Page 116: Power Unit

5-21 power unit x 5 powr oil tank (cont’d.).

Page 117: Power Unit

5-22 power unit 5 powr.

Page 118: Power Unit

5-23 power unit x 5 powr.

Page 119: Power Unit

5-24 power unit 5 powr.

Page 120: Power Unit

5-25 power unit x 5 powr.

Page 121: Power Unit

5-26 power unit 5 powr tank.”.

Page 122: Power Unit

5-27 power unit x 5 powr oil pump (cont’d.).

Page 123: Power Unit

5-28 power unit 5 powr oil pump (cont’d.).

Page 124: Power Unit

5-29 power unit x 5 powr.

Page 125: Power Unit

5-30 power unit 5 powr.

Page 126: Power Unit

5-31 power unit x 5 powr.

Page 127: Power Unit

5-32 power unit 5 powr motor.” pump.”.

Page 128: Power Unit

5-33 power unit x 5 powr reduction drive gear (cont’d.).

Page 129: Power Unit

5-34 power unit 5 powr reduction drive gear (cont’d.).

Page 130: Power Unit

5-35 power unit x 5 powr reduction drive gear (cont’d.).

Page 131: Power Unit

5-36 power unit 5 powr reduction drive gear (cont’d.).

Page 132: Power Unit

5-37 power unit x 5 powr.

Page 133: Power Unit

5-38 power unit 5 powr.

Page 134: Power Unit

5-39 power unit x 5 powr unit.”.

Page 135: Power Unit

5-40 generator and starter motor (cont’d.) power unit 5 powr.

Page 136: Power Unit

5-41 generator and starter motor (cont’d.) power unit x 5 powr.

Page 137: Power Unit

5-42 generator and starter motor (cont’d.) power unit 5 powr make sure not to pinch the pulser coil leads between the washers and projec- tions on the case when installing the bolts. Caution:.

Page 138: Power Unit

5-43 generator and starter motor (cont’d.) power unit x 5 powr.

Page 139: Power Unit

5-44 power unit 5 powr.

Page 140: Power Unit

5-45 power unit x 5 powr.

Page 141: Power Unit

5-46 power unit 5 powr caution: washer. Always replace them with new ones..

Page 142: Power Unit

5-47 power unit x 5 powr.

Page 143: Power Unit

5-48 power unit 5 powr camshafts (cont’d.).

Page 144: Power Unit

5-49 power unit x 5 powr camshafts (cont’d.) gear.”.

Page 145: Power Unit

5-50 power unit 5 powr camshafts (cont’d.).

Page 146: Power Unit

5-51 power unit x 5 powr camshafts (cont’d.).

Page 147: Power Unit

5-52 power unit 5 powr.

Page 148: Power Unit

5-53 power unit x 5 powr.

Page 149: Power Unit

5-54 power unit 5 powr.

Page 150: Power Unit

5-55 power unit x 5 powr.

Page 151: Power Unit

5-56 power unit 5 powr caution:.

Page 152: Power Unit

5-57 power unit x 5 powr.

Page 153: Power Unit

5-58 power unit 5 powr.

Page 154: Power Unit

5-59 power unit x 5 powr tighten the cylinder head cover bolts in a criss- cross pattern..

Page 155: Power Unit

5-60 power unit 5 powr unit.” pipe 3.” and 2.” tank.” “camshafts.”.

Page 156: Power Unit

5-61 cylinder head (cont’d.) power unit x 5 powr.

Page 157: Power Unit

5-62 power unit 5 powr.

Page 158: Power Unit

5-63 power unit x 5 powr.

Page 159: Power Unit

5-64 power unit 5 powr.

Page 160: Power Unit

5-65 power unit x 5 powr head.”.

Page 161: Power Unit

5-66 power unit 5 powr valves and valve springs (cont’d.).

Page 162: Power Unit

5-67 power unit x 5 powr.

Page 163: Power Unit

5-68 power unit 5 powr.

Page 164: Power Unit

5-69 power unit x 5 powr before checking the valve guide, make sure the valve stem diameter is within specifica- tion..

Page 165: Power Unit

5-70 power unit 5 powr.

Page 166: Power Unit

5-71 power unit x 5 powr.

Page 167: Power Unit

5-72 power unit 5 powr.

Page 168: Power Unit

5-73 power unit x 5 powr caution:.

Page 169: Power Unit

5-74 power unit 5 powr.

Page 170: Power Unit

5-75 power unit x 5 powr caution:.

Page 171: Power Unit

5-76 power unit 5 powr.

Page 172: Power Unit

5-77 power unit x 5 powr unit.” pipe 3.” and 2.” motor.” tank.” manifold.”.

Page 173: Power Unit

5-78 power unit 5 powr crancase (cont’d.) pump.” gear.” “camshafts.”.

Page 174: Power Unit

5-79 power unit x 5 powr crancase (cont’d.).

Page 175: Power Unit

5-80 power unit 5 powr crancase (cont’d.).

Page 176: Power Unit

5-81 power unit x 5 powr crancase (cont’d.) “crankshaft.”.

Page 177: Power Unit

5-82 power unit 5 powr tap on one side of the crankcase with a soft-face hammer. Tap only on rein- forced portions of the crankcase, not on the crankcase mating surfaces. Work slowly and carefully and make sure the crankcase halves separate evenly. Caution:.

Page 178: Power Unit

5-83 power unit x 5 powr.

Page 179: Power Unit

5-84 power unit 5 powr.

Page 180: Power Unit

5-85 power unit x 5 powr caution:.

Page 181: Power Unit

5-86 power unit 5 powr.

Page 182: Power Unit

5-87 power unit x 5 powr “crankcase.”.

Page 183: Power Unit

5-88 power unit 5 powr connecting rods and pistons (cont’d.).

Page 184: Power Unit

5-89 power unit x 5 powr caution:.

Page 185: Power Unit

5-90 power unit 5 powr pistons:.

Page 186: Power Unit

5-91 power unit x 5 powr formula:.

Page 187: Power Unit

5-92 power unit 5 powr.

Page 188: Power Unit

5-93 power unit x 5 powr.

Page 189: Power Unit

5-94 power unit 5 powr caution:.

Page 190: Power Unit

5-95 power unit x 5 powr lubricate the bolt threads and nut seats installation.” removal.”.

Page 191: Power Unit

5-96 power unit 5 powr.

Page 192: Power Unit

5-97 power unit x 5 powr.

Page 193: Power Unit

5-98 power unit 5 powr.

Page 194: Power Unit

5-99 power unit x 5 powr procedure.” caution:.

Page 195: Power Unit

5-100 power unit 5 powr “crankcase.” pistons.”.

Page 196: Power Unit

5-101 power unit x 5 powr.

Page 197: Power Unit

5-102 power unit 5 powr caution:.

Page 198: Power Unit

5-103 power unit x 5 powr “crankcase.”.

Page 199: Power Unit

5-104 power unit 5 powr.

Page 200: Power Unit

5-105 power unit x 5 powr fwd.

Page 201: Power Unit

5-106 power unit 5 powr thermostat (cont’d.) fwd.

Page 202: Power Unit

5-107 power unit x 5 powr does not open at 50~60°c (123~.

Page 203: Power Unit

5-108 power unit 5 powr manifold.”.

Page 204: Power Unit

5-109 power unit x 5 powr pressure control valve (cont’d.).

Page 205: Power Unit

5-110 power unit 5 powr pressure control valve (cont’d.).

Page 206: Power Unit

5-111 power unit x 5 powr pressure control valve (cont’d.).

Page 207: Power Unit

5-112 power unit 5 powr.

Page 208: Chapter 6

Chapter 6 jet pump unit intake grating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1 exploded diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1 removal and installation chart...

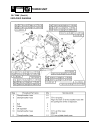

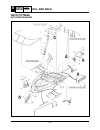

Page 209: Jet Pump

Jet pump x 6 6-1 jet pump intake grating exploded diagram lt 242 lt 242 1 2 3 4 5 lt 242 step procedure / part name q’ty (ea) service points intake grating follow the left “step” order for removal. Removal 1 screw 2 8 x 35mm 2 screw 4 8 x 20mm 3 intake grating 2 port and starboard units 4 screw 12 8...

Page 210: Jet Pump

6-2 jet pump 6 jet pump apply clear silicone as shown before installing duct into hull. Install duct and torque screws to 15nm (1.5m-kg, 11 ft-lb). Fill gaps with silicone fill gaps with silicone.

Page 211: Jet Pump

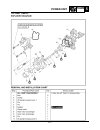

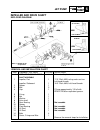

6-3 jet pump x 6 jet pump pump unit exploded diagram step procedure / part name q’ty (ea.) service points pump unit removal follow the “step” order for removal. 1 shift cable joint 1 2 steering cable joint 1 3 bolt (with washer) 4 4 nozzle 1 1 note: may be left on to remove pump as an assembly. 5 do...

Page 212: Jet Pump

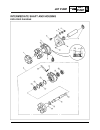

Jet pump 6 jet pump step procedure / part name q’ty (ea) service points reverse gate and nozzle follow the “step” order for removal. Deflector removal 1 bolt (with washer) 2 8 x 20mm 2 collar 2 3 reverse gate 1 4 bolt (with washer) 2 8 x 20mm 5 collar 2 6 nozzle deflector 1 reverse gate disassembly ...

Page 213: Jet Pump

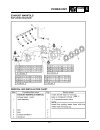

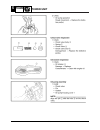

6-5 jet pump x 6 jet pump impeller and drive shaft exploded diagram step procedure / part name q’ty (ea) service points impeller duct and drive follow the “step” order for removal. Shaft assembly 1 impeller, port 1 17.3° pitch, 6b5, csting marks on hex left-hand threads impeller, starboard 1 16.3° p...

Page 214: Jet Pump

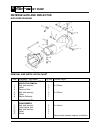

Jet pump 6 jet pump 6-6 jet pump clean-out ports exploded diagram removal and installation chart lt 242 step procedure / part name qty (ea.) service points jet pump clean-out follow the “step” order for removal. Tray removal 1 inspection cover 2 2 clamp, upper 2 access top hose clamps through inner ...

Page 215: Jet Pump

Jet pump x 6 jet pump 6-7.

Page 216: Jet Pump

Jet pump 6 jet pump 6-8 10 11 2.

Page 217: Jet Pump

Jet pump x 6 jet pump 6-9.

Page 218: Jet Pump

Jet pump 6 jet pump 6-10

Page 219: Chapter 7

X chapter 7 electrical system electrical components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 electrical box and ignition coil box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2 exploded diagram . . . . . . . . . . . . ...

Page 220

Thermoswitch (exhaust) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-31 slant detection switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-31 starting system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 221: Electrical System

7-1 electrical system x 7 elec electrical components stereo speaker running light 23 24 1 1 2 2 3 3 4 4 5 5 6 6 7 7 8 8 9 9 bow light fuel pumps fuel sender 19 22 23 23 18 23 23 20 21 24 7 1 2 3 4 10 5 6 17 16 11 15 14 13 12 9 8.

Page 222: Electrical System

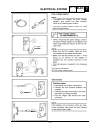

7-2 electrical system 7 elec electrical box and ignition coil box exploded diagram 2 step procedure / part name qty service points electrical box removal follow the left “step” for removal. 1 battery negative lead 1 2 battery positive lead 1 3 bolt 2 4 battery hold down bracket 1 5 battery 1 6 batte...

Page 223: Electrical System

7-3 electrical box and ignition coil box (cont’d.) exploded diagram 2 electrical system x 7 elec step procedure / part name qty service points 9 bolt 4 10 screw 4 11 terminal cover 1 12 gasket 1 not reusable 13 screw 1 14 starter motor lead 1 15 bolt 3 16 cover 1 removal and installation chart.

Page 224: Electrical System

7-4 electrical system 7 elec electrical box and ignition coil box (cont’d.) exploded diagram 2 step procedure / part name q’ty service points 17 gasket 1 not reusable 18 bolt 2 19 ground led 2 20 holder 1 21 coupler 15 note: disconnect all couplers. Reverse the removal steps for installation. Remova...

Page 225: Electrical System

7-5 electrical system x 7 elec electrical box and ignition coil box (cont’d.) exploded diagram.

Page 226: Electrical System

7-6 electrical system 7 elec electrical box and ignition coil box (cont’d.) exploded diagram.

Page 227: Electrical System

7-7 electrical system x 7 elec electrical box and ignition coil box (cont’d.) exploded diagram step procedure / part name q’ty service points 19 tapping screw 1 20 bracket 1 21 joint connector 2 22 tapping screw 1 23 main and fuel pump relay 1 24 tapping screw 2 25 rectifier/regulator 1 reverse the ...

Page 228: Electrical System

7-8 electrical system 7 elec electrical box and ignition coil box (cont’d.) exploded diagram.

Page 229: Electrical System

7-9 electrical system x 7 elec electrical box and ignition coil box (cont’d.) exploded diagram high tension code.

Page 230: Electrical System

7-10 electrical system 7 elec electrical box and ignition coil box (cont’d.).

Page 231: Electrical System

7-11 electrical system x 7 elec throughout this chapter, the digital tester’s part number has been omitted. Refer to the following part number. “o o” indicates a continuity of electricity (e.G., a closed circuit at the respective switch posi- tion)..

Page 232: Electrical System

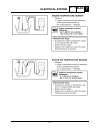

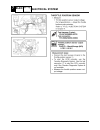

7-12 electrical system 7 elec • when checking the condition of the ignition system, it is vital to know the peak voltage. • cranking speed is dependant on many factors (e.G., fouled or weak spark plugs or a weak battery). If one of these is defective, the peak voltage will be lower than specificatio...

Page 233: Electrical System

7-13 electrical system x 7 elec • throughout this chapter, the peak voltage adaptor’s part number has been omitted. Refer to the following part number. Tests:.

Page 234: Electrical System

7-14 electrical system 7 elec ignition system wiring diagram free push w b free push br b w br p/w p/w p/w r/y b/w b/w o b/o p/g r l/r r/y r/y b/o b/o b/y b/o b/o b/o b/o b/w r b b/o r/y l/r br l y r/y r/y b g/o g/o r/y r/y b/y b/y b/y b/o b/y b/o b/o b/o w/r w/b w b r b/o b/y o p y p r g g g g r b ...

Page 235: Electrical System

7-15 electrical system x 7 elec ignition system wiring diagram free push w b free push br b w br p/w p/w p/w r/y b/w b/w o b/o p/g r l/r r/y r/y b/o b/o b/y b/o b/o b/o b/o b/w r b b/o r/y l/r br l y r/y r/y b g/o g/o r/y r/y b/y b/y b/y b/o b/y b/o b/o b/o w/r w/b w b r b/o b/y o p y p r g g g g r ...

Page 236: Electrical System

7-16 electrical system 7 elec.

Page 237: Electrical System

7-17 electrical system x 7 elec • if there is no spark or the spark is weak, con- tinue with the ignition system test. • if a good spark is obtained, the problem is not with the ignition system but possibly with the spark plug(-s) or another component..

Page 238: Electrical System

7-18 electrical system 7 elec.

Page 239: Electrical System

7-19 electrical system x 7 elec system.”.

Page 240: Electrical System

7-20 electrical system 7 elec measurement.” lanyard clip white black installed o o removed o o.

Page 241: Electrical System

7-21 electrical system x 7 elec.

Page 242: Electrical System

7-22 electrical system 7 elec.

Page 243: Electrical System

7-23 electrical system x 7 elec.

Page 244: Electrical System

7-24 electrical system 7 elec.

Page 245: Electrical System

7-25 electrical system x 7 elec.

Page 246: Electrical System

7-26 electrical system 7 elec.

Page 247: Electrical System

7-27 electrical system x 7 elec fuel control system wiring diagram thermoswitch (exhaust) thermoswitch (engine) 6 7 8 9 10 11 12 13 12 9 10 11 6 7 8 engine temperature sensor intake air temperature sensor intake air pressure sensor throttle position sensor fuel injector oil pressure switch 13.

Page 248: Electrical System

7-28 electrical system 7 elec fuel control system wiring diagram 12 9 10 11 6 7 8 13.

Page 249: Electrical System

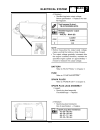

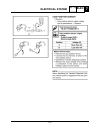

7-29 electrical system x 7 elec 12vdc purple fuel gauge, low fuel led and wiring check 1. Open the fuel hatch and locate the three wire connector for the fuel sensor. Unplug the sensor's connector and turn the starboard key to the “on” position. The gauge should then read below “empty” and the low f...

Page 250: Electrical System

7-30 electrical system 7 elec 2. Put the black lead of a voltmeter on the black/white wire of the harness. Then use the red lead of the voltmeter to measure the voltage on the other two pins. Purple = more than +12 vdc (or close to battery terminal voltage) pink = more than +7 vdc (sensor discon- ne...

Page 251: Electrical System

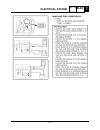

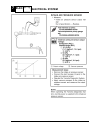

7-31 electrical system x 7 elec 4 3 2 1 8 7 6 5 r/y 7 18 r/y l/r br l y r/y r/y b r/y r/y y r br br br br r/b r/b br r b b r 4 3 2 1 6 r/y r/y r p p o r r r r r r 1 2 3 4 5 6 7 8 b b b 5 br b b b 8 7 off on start set pull br b w br starting system wiring diagram.

Page 252: Electrical System

7-32 electrical system 7 elec key switch 1. Check: • continuity out of specification → → replace. 1. Disconnect switch at harness. 2. Turn key to function to be checked. 3. Check continuity between the indicated wire leads. No continuity → → replace switch assembly. Start continuity brown red/black ...

Page 253: Electrical System

7-33 electrical system x 7 elec.

Page 254: Electrical System

7-34 electrical system 7 elec.

Page 255: Electrical System

7-35 electrical system x 7 elec starter motor (cont’d.).

Page 256: Electrical System

7-36 electrical system 7 elec starter motor (cont’d.).

Page 257: Electrical System

7-37 electrical system x 7 elec.

Page 258: Electrical System

7-38 electrical system 7 elec.

Page 259: Electrical System

7-39 electrical system x 7 elec.

Page 260: Electrical System

7-40 electrical system 7 elec system.” system.” system.”.

Page 261: Electrical System

7-41 electrical system x 7 elec b b b br br br br electric bilge pump wiring diagram b: black br: brown.

Page 262: Electrical System

7-42 electrical system 7 elec.

Page 263: Electrical System

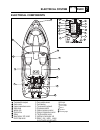

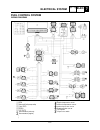

7-43 electrical system x 7 elec main component location exploded diagram 1 2 3 4 5 6 7 8 9 10 11 1. Battery 2. Fuel level sensor 3. Bow light 4. Stern light connector 5. Blower motors 6. Bilge pump 7. Horn 8. Stereo unit 9. Hull harness #3 10. Deck harness 11. 12v outlet and circuit breaker.

Page 264: Electrical System

7-44 electrical system 7 elec switch location wiring diagram 1 2 3 4 5 1. Key switches 2. Lanyard switch 3. Neutral switch 4. Hatch interlock switches 5. Engine harness #2.

Page 265: Electrical System

7-45 electrical system x 7 elec meter panel back view wiring diagram deutsch 6 pin plug 52506 wedge 52508 soc 5251 8 s tb t a ch pwr 2 s tb t a ch 1 s tb l o oil 4 s tb o verhea t 5 s tb check eng. 6 s tb t a ch gnd 3 blue -6" red -6" gra y -6" blue/white -6" ta n/white -6" bla ck -6" st to harness ...

Page 266: Electrical System

7-46 electrical system 7 elec electrical components step procedure / part name qty (ea.) service points meter panel disassembly follow the “step” order for removal. 1 cover, steering wheel 1 2 nut w/washer 1 3 steering wheel 1 4 woodruff key 1 5 nut 2 6 key switch 2 7 screw 3 #8 x 3/4” pth 8 nut w/w...

Page 267: Electrical System

7-47 electrical system x 7 elec switch and component wiring diagram 1 circuit breaker 2 stereo switch 3 courtesy light switch 4 navigation light switch 5 bilge pump switch 6 blower switch 7 horn switch 8 stereo 9 courtesy lead 10 blower motors 11 bilge pump 12 horn 13 stern light 14 bow light 10 11 ...

Page 268: Electrical System

7-48 electrical system 7 elec.

Page 269: Electrical System

7-49 electrical system x 7 elec.

Page 270: Chapter 8

Chapter 8 hull and deck engine compartment layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1 exploded diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1 ventilation system . . . . . . . . . . . . . ...

Page 271

Gunwale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-24 exploded diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-24 removal and installation chart . . . . . . . . . . . ...

Page 272: Hull And Deck

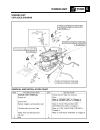

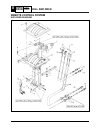

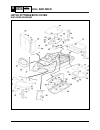

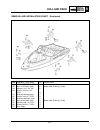

8-1 hull and deck x 8 hull deck engine compartment layout exploded diagram 1 2 3 4 5 6 7 1. Engine 5. Battery 2. Water lock 6. Blowers 3. Jet pump 7. Bilge pump 4. Fuel tank.

Page 273: Hull And Deck

8-2 hull and deck 8 hull deck ventilation system exploded diagram.

Page 274: Hull And Deck

8-3 step procedure / part name q’ty service points ventilation system follow the “step” order for removal. Disassembly 1 hose clamp 11 snap type 2 screw, oval head tapping 28 3 ventilator (white) 5 4 ventilator (black) 2 5 hose, ventilation 3 intake 36” 6 hose, ventilation 2 exhaust 24” 7 hose, vent...

Page 275: Hull And Deck

8-4 hull and deck 8 hull deck cooling system exploded diagram 28 28 29 29 30 27 27 30 25.

Page 276: Hull And Deck

8-5 step procedure / part name q’ty service points cooling system and water lock removal follow the “step” order for removal. 1 band, hose 18 2 2 clip 2 3 hose 1 2 4 joint, hose 1 2 5 clip 2 6 nut 2 7 cap, 1 2 8 joint assy 2 9 band, hose 18 2 10 clip 2 11 hose (l=1250) 2 12 clip 2 13 band, hose 18 2...

Page 277: Steering System

8-6 steering system exploded diagram hull and deck 8 hull deck 1 2 3 4 13 a a a ss ss 11 12 1 2 3 4 5 6 7 8 9 10 note: see removal and installation chart on next page for torque specs and locking agent instructions..

Page 278: Hull And Deck

8-7 step procedure / part name q’ty service points steering helm removal follow the “step” order for removal. 1 cover 1 2 nut 1 1/2"-13, nylon lock, 18 nm (1.8 m-kg, 13 ft-lb) 3 washer 1 1/2" 4 steering wheel 1 5 key 1 6 boot 1 7 screw 2 #8 x 1", 1.8 nm (0.18 m-kg, 1.3 ft-lb) 8 helm, bezel 1 9 screw...

Page 279: Remote Control System

8-8 remote control system exploded diagram hull and deck 8 hull deck.

Page 280: Hull And Deck

8-9 step procedure / part name q’ty service points remote control unit follow the “step” order for removal. Removal 1 throttle lever plugs (red) 2 sets screws face starboard 2 shift lever plugs (black) 1 set screws face starboard 3 screw, oval head 4 4 cover, remote control 1 5 screw, flat head 4 6 ...

Page 281: Engine Hatch

8-10 engine hatch exploded diagram hull and deck 8 hull deck.

Page 282: Hull And Deck

8-11 step procedure / part name q’ty service points engine hatch removal follow the “step” order for removal. And disassembly 1 support, engine hatch 2 support hatch lid before removal. 2 nut, #10-24 nylon lock 4 3 washer, 310 fender 3/4” o.D. 4 4 screw #10-24 x 1” 4 5 bracket, support 2 6 nut, 1/4-...

Page 283: Hatch Fittings/bow Cover

8-12 hatch fittings/bow cover exploded diagram hull and deck 8 hull deck.

Page 284: Hull And Deck

8-13 step procedure / part name q’ty service points bow locker follow the “step” disassembly order for removal. 1 screw, tapping 16 #8 x 5/8” 2 hinge 1 3 hatch 1 4 screw, machine 2 5 latch 1 6 screw, tapping 2 7 catch 1 8 screw 2 #8 x 3/4” 9 cushion 2 10 screw 1 #10 x 1/2” 11 screw 1 #8 x 3/4” 12 ha...

Page 285: Hull And Deck

8-14 hull and deck 8 hull deck seat fittings exploded diagram.

Page 286: Hull And Deck

8-15 hull and deck x 8 hull deck step procedure / part name q’ty service points seat fitting disassembly follow the “step” order for removal. Driver’s bucket seats 1 screw, 1/4-20 x 1/2" 8 2 washer, flat 1/4 x 1" fender 8 3 driver seat assembly 2 4 seat slider 2 5 screw, 1/4-20 x 1 1/4" 12 6 pedesta...

Page 287: Deck Fittings

Deck fittings exploded diagram hull and deck 8 hull deck 8-16.

Page 288: Hull And Deck

8-17 step procedure / part name q’ty service points stern light follow the “step” order for removal. 1 stern light assembly 1 2 lens 1 3 bulb 1 ml1004 obtain locally 4 screw, tapping 3 5 socket assembly 1 6 collar (shim) 1 position so that stern light angles towards stern. Drawing f1c-u268b-00 bow l...

Page 289: Hull And Deck

8-18 hull and deck 8 hull deck deck fittings (continued) exploded diagram step procedure / part name q’ty service points table 39 table 1 optional accy 40 stanchion (table post) short, swim deck 1 330mm, 13 in, optional accy 41 stanchion (table post) long, cockpit 1 622mm, 24.5 in, optional accy 42 ...

Page 290: Hull And Deck

8-19 removal and installation chart (continued) hull and deck x 8 hull deck step procedure / part name q’ty service points bimini top brackets 48 nut, 10-24 nylon lock 8 torque 4nm (0.4m-kg, 3 ft-lb) 49 washer, 10 x 3/4” od 8 50 screw, 10-24 x 1-1/2” poh 4 51 bracket, awning (front) 2 52 screw, 10-2...

Page 291: Hull And Deck

8-20 deck fittings (continued) exploded diagram hull and deck 8 hull deck.

Page 292: Hull And Deck

8-21 hull and deck x 8 hull deck removal and installation chart (continued) step procedure / part name q’ty service points windshield 58 nut, 10-24 nylon lock 4 torque 4nm (0.4m-kg, 3 ft-lb) 59 washer, #10 flat 4 60 screw, 10-24 x 2” pph 4 61 screw, #8 x 3/8” pph- type b 4 62 windshield brace 2 63 w...

Page 293: Hull And Deck

8-22 through hull and drain fittings exploded diagram qty 3 for bilge hose hull and deck 8 hull deck.

Page 294: Hull And Deck

8-23 step procedure / part name q’ty service points through hull and drain follow the “step” order for removal. Fittings 1 drain plug 1 apply silicone to the drain plug assy flange. 2 screw #8 x 3/4 poh 3 3 clamp, hose 2 (sae #24) 1 4 cockpit drain 1 5 scupper drain for cockpit 1 apply clear silicon...

Page 295: Gunwale

8-24 gunwale exploded diagram 1 2 3 4 5 step procedure / part name q’ty service points gunwale follow the “step” order for removal. 1 screw, 310 x 2” poh 2 torque 2 nm (0.2m-kg, 1.5 ft-lb) 2 cover, rub rail joint 1 before installing, apply silicone to the join area. 3 inner gunwale (rubrail insert) ...

Page 296: Hull And Deck

8-25 hull and deck x 8 hull deck hull construction and care the srt1000 hull is built of a material called frp. This is then finished with a very hard product called gelcoat to protect the fiberglass and provide a durable finish. What is frp? Frp stands for fiberglass reinforced plastic. It is a com...

Page 297: Trouble Analysis

Trouble analysis x 9 trbl anls windows ® 95, windows ® 98, windows ® me, windows ® 2000, ® or windows ® xp .......................................... 9-3 updating the database ............................................................ 9-7 engine monitor................................................

Page 298

Operating procedure............................................................................ 9-41 data display item selection.................................................................. 9-42 operating procedure............................................................................ 9-42.

Page 299: Trouble Analysis

9-1 trouble analysis x 9 trbl anls if this software is run on microsoft windows ® 95, windows ® 98, windows ® me, windows ® 2000, or windows ® xp, the information can be displayed in colorful graphics. Also, the software can be operat- ed using either a mouse or a keyboard. 1 2 3 4 5.

Page 300: Trouble Analysis

9-2 trouble analysis 9 trbl anls make sure your computer meets the following requirements before using this software. Rs232c (dsub-9 pin) port, usb portj.

Page 301: Trouble Analysis

Trouble analysis x 9 trbl anls 9-3 installing the yamaha diagnostic system under windows 95, windows 98, windows me, windows 2000, or windows xp 9-2..

Page 302: Trouble Analysis

9-4 trouble analysis 9 trbl anls.

Page 303: Trouble Analysis

9-5 trouble analysis x 9 trbl anls.

Page 304: Trouble Analysis

9-6 trouble analysis 9 trbl anls install the database file before using the yamaha diagnostic system, otherwise, the program will not operate correctly. For installation procedures, refer to “updating the database” on the next page..

Page 305: Trouble Analysis

9-7 trouble analysis x 9 trbl anls after about three seconds, the display will automatically go to the first menu display, or you can click or press any key to go to the first menu. (see fig. 12.).

Page 306: Trouble Analysis

9-8 trouble analysis 9 trbl anls do not click the starting service tool [enter] button or press the enter key on your keyboard until the database has been updated, otherwise, the program will not operate correctly..

Page 307: Trouble Analysis

9-9 trouble analysis x 9 trbl anls.

Page 308: Trouble Analysis

9-10 trouble analysis 9 trbl anls when the database is updated, a confirmation screen is displayed..

Page 309: Trouble Analysis

9-11 trouble analysis x 9 trbl anls.

Page 310: Trouble Analysis

9-12 trouble analysis 9 trbl anls 1 2.

Page 311: Trouble Analysis

9-13 trouble analysis x 9 trbl anls open the yamaha diagnostic system window. (fig. 20) after about three seconds, the display will automatically go to the first menu, or click or press any key to go to the first menu. (see fig. 21.).

Page 312: Trouble Analysis

9-14 trouble analysis 9 trbl anls.

Page 313: Trouble Analysis

9-15 trouble analysis x 9 trbl anls.

Page 314: Trouble Analysis

9-16 trouble analysis 9 trbl anls eight commands appear in the main menu. Select a command in any of the following three ways:.

Page 315: Trouble Analysis

9-17 trouble analysis x 9 trbl anls.

Page 316: Trouble Analysis

9-18 trouble analysis 9 trbl anls.

Page 317: Trouble Analysis

9-19 trouble analysis x 9 trbl anls top..

Page 318: Trouble Analysis

9-20 trouble analysis 9 trbl anls.

Page 319: Trouble Analysis

9-21 trouble analysis x 9 trbl anls.

Page 320: Trouble Analysis

9-22 trouble analysis 9 trbl anls.

Page 321: Trouble Analysis

9-23 trouble analysis x 9 trbl anls ..

Page 322: Trouble Analysis

9-24 trouble analysis 9 trbl anls check that the items deleted are normal in the diagnosis record. If the items remain irregular, they will appear as irregular in the diagnosis record. Even if you try to delete them, they are undeletable..

Page 323: Trouble Analysis

9-25 trouble analysis x 9 trbl anls click the ok button or press the enter key on your keyboard (fig. 35): the selected item is deleted. To cancel deleting the item, click the cancel button or press the esc key on your keyboard..

Page 324: Trouble Analysis

9-26 trouble analysis 9 trbl anls do not use the engine monitor function to check the engine condition while operating a water- craft, otherwise, you could become distracted which could result in a collision. Display..

Page 325: Trouble Analysis

9-27 trouble analysis x 9 trbl anls in the scroll bar or press the up or down (fig. 38). Keyboard.

Page 326: Trouble Analysis

9-28 trouble analysis 9 trbl anls avoid clicking the execute and cancel buttons repeatedly, otherwise, the ecm or pc will not work properly and they could be damaged. Item. Test..

Page 327: Trouble Analysis

9-29 trouble analysis x 9 trbl anls keys on your keyboard (fig. 39). (spark gap tester ym-34487/90890-06754) is needed. Keyboard (fig. 39)..

Page 328: Trouble Analysis

9-30 trouble analysis 9 trbl anls keyboard (fig. 42)..

Page 329: Trouble Analysis

9-31 trouble analysis x 9 trbl anls if the engine is running an error message is displayed, follow the instructions that appear (fig. 44). Instructions in the messages that are displayed (see fig. 43). Instructions that appear in the error message (fig. 45). To stop the stationary test, click the ca...

Page 330: Trouble Analysis

9-32 trouble analysis 9 trbl anls selected (fig. 46). Displayed (fig. 47)..

Page 331: Trouble Analysis

9-33 trouble analysis x 9 trbl anls keyboard (fig. 48). Make sure that there is fuel in the fuel tank, otherwise, an error will occur and the test cannot be per- formed. Keyboard (fig. 48)..

Page 332: Trouble Analysis

9-34 trouble analysis 9 trbl anls keyboard (fig. 49)..

Page 333: Trouble Analysis

9-35 trouble analysis x 9 trbl anls selected (fig. 51). Do not test the same cylinder three or more times, otherwise, the spark plug insulator could be damaged. Make sure there is fuel in the fuel tank, otherwise, an error will occur and the test cannot be performed. Caution:.

Page 334: Trouble Analysis

9-36 trouble analysis 9 trbl anls select the test to be performed, then click the select button or press the enter key on your keyboard (fig. 52). Make sure the engine is not running..

Page 335: Trouble Analysis

9-37 trouble analysis x 9 trbl anls keyboard (fig. 53). Selected (fig. 54)..

Page 336: Trouble Analysis

9-38 trouble analysis 9 trbl anls avoid clicking the execute and cancel buttons repeatedly, otherwise, the ecm or pc will not work properly and they could be damaged..

Page 337: Trouble Analysis

9-39 trouble analysis x 9 trbl anls for the first ten seconds, operate all four cylinders, then stop one cylinder for five seconds. For the last five seconds, operate all four cylinders. Keyboard (fig. 55). Keyboard (fig. 55). Keyboard (fig. 56)..

Page 338: Trouble Analysis

9-40 trouble analysis 9 trbl anls if the engine is not running, an error message is displayed. Follow the instructions that appear (fig. 57). Displayed (fig. 56). Appear (fig. 58)..

Page 339: Trouble Analysis

9-41 trouble analysis x 9 trbl anls board (fig. 59). Press the enter key on your keyboard. The window of the selected item is displayed (fig. 59)..

Page 340: Trouble Analysis

9-42 trouble analysis 9 trbl anls bar (fig. 60). Displayed (see fig. 61)..

Page 341: Trouble Analysis

9-43 trouble analysis x 9 trbl anls axis (fig. 61). Value at the time the enter key on your keyboard was pressed in the monitor item selection..

Page 342: Trouble Analysis

9-44 trouble analysis 9 trbl anls (fig. 62). Although the engine is running, the displayed time refers to the added hours until the data logger starts..

Page 343: Trouble Analysis

9-45 trouble analysis x 9 trbl anls displayed (fig. 63)..

Page 344: Trouble Analysis

9-46 trouble analysis 9 trbl anls (fig. 65)..

Page 345: Trouble Analysis

9-47 trouble analysis x 9 trbl anls programs (fig. 66). (fig. 67)..

Page 346: Trouble Analysis

9-48 trouble analysis 9 trbl anls button (see figs. 68~70)..

Page 347: Trouble Analysis

9-49 trouble analysis x 9 trbl anls.

Page 348: Trouble Analysis

9-50 trouble analysis 9 trbl anls test,.

Page 349: Trouble Analysis

9-51 trouble analysis x 9 trbl anls display (fig. 73). Slider (fig. 74). ..

Page 350: Trouble Analysis

9-52 trouble analysis 9 trbl anls button (see figs. 75~76)..

Page 351: Trouble Analysis

9-53 trouble analysis x 9 trbl anls consulted:.

Page 352: Trouble Analysis

9-54 trouble analysis 9 trbl anls.

Page 353: Trouble Analysis

9-55 trouble analysis x 9 trbl anls.

Page 354

Lit-18616-02-52 ©2003 yamaha motor corporation, u.S.A. Printed in u.S.A..