- DL manuals

- Yamaha

- Motorcycle

- SR400 2014

- Service Manual

Yamaha SR400 2014 Service Manual

Summary of SR400 2014

Page 1

2014 service manual sr400 sr400e 2rd-28197-e0

Page 3

Eas20040 sr400 sr400e service manual ©2013 by yamaha motor co., ltd. First edition, november 2013 all rights reserved. Any reproduction or unauthorized use without the written permission of yamaha motor co., ltd. Is expressly prohibited..

Page 4: Important

Eas20071 important this manual was produced by the yamaha motor company, ltd. Primarily for use by yamaha dealers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one man- ual. Therefore, anyone who uses this book to perform maintenance and repairs on y...

Page 5: How to Use This Manual

Eas20091 how to use this manual this manual is intended as a handy, easy-to-read reference book for the mechanic. Comprehensive explanations of all installation, removal, disassembly, assembly, repair and check procedures are laid out with the individual steps in sequential order. • the manual is di...

Page 6: Symbols

Eas20101 symbols the following symbols are used in this manual for easier understanding. Tip the following symbols are not relevant to every vehicle. Symbol definition symbol definition serviceable with engine mounted gear oil filling fluid molybdenum disulfide oil lubricant brake fluid special tool...

Page 7: General Information

General information 1 specifications 2 periodic checks and adjustments 3 chassis 4 engine 5 fuel system 6 electrical system 7 troubleshooting 8 eas20110 table of contents.

Page 9: General Information

1 2 3 4 5 6 7 8 9 general information identification .............................................................................................1-1 vehicle identification number ......................................................1-1 model label......................................................

Page 10: Identification

Identification 1-1 eas20130 identification eas20140 vehicle identification number the vehicle identification number “1” is stamped into the right side of the steering head pipe. Eas20150 model label the model label “1” is affixed to the frame under the rider seat. This information will be needed to ...

Page 11: Features

Features 1-2 eas20170 features eas2rd1001 outline of the fi system the main function of a fuel supply system is to provide fuel to the combustion chamber at the optimum air-fuel ratio in accordance with the engine operating conditions and the atmospheric temperature. In the conventional carburetor s...

Page 12: Features

Features 1-3 eas2rd1003 fi system the fuel pump delivers fuel to the fuel injector via the fuel filter. The pressure regulator maintains the fuel pressure that is applied to the fuel injector at a certain level. Accordingly, when the energizing signal from the ecu energizes the fuel injector, the fu...

Page 13: Features

Features 1-4 eas2rd1002 fuel line chart 1 a b 2 5 6 3 4 1. Fuel tank 2. Fuel cock 3. Fuel pump case 4. Fuel pump 5. Fuel injector 6. Pressure regulator a. Feeding side b. Return side.

Page 14: Important Information

Important information 1-5 eas20180 important information eas20190 preparation for removal and disassembly 1. Before removal and disassembly, remove all dirt, mud, dust and foreign material. 2. Use only the proper tools and cleaning equip- ment. Refer to “special tools” on page 1-12. 3. When disassem...

Page 15: Important Information

Important information 1-6 manufacturer marks or numbers are visible. When installing oil seals, lubricate the oil seal lips with a light coat of lithium-soap-based grease. Oil bearings liberally when installing, if appropriate. Notice eca13300 do not spin the bearing with compressed air because this...

Page 16: Basic Service Information

Basic service information 1-7 eas30380 basic service information eas30390 quick fasteners rivet type 1. Remove: • quick fastener tip to remove the quick fastener, push its pin with a screwdriver, then pull the fastener out. 2. Install: • quick fastener tip to install the quick fastener, push its pin...

Page 17: Basic Service Information

Basic service information 1-8 the battery, be sure to disconnect the nega- tive battery lead first, then the positive bat- tery lead. If a tool or similar item contacts the vehicle while only the negative battery lead is connected, a spark could be generated, which is extremely dangerous. Tip if a b...

Page 18: Basic Service Information

Basic service information 1-9 tip when resetting the ecu by turning the main switch to “off”, be sure to wait approximately 5 seconds before turning the main switch back to “on”. Checking the electrical system tip before checking the electrical system, make sure that the battery voltage is at least ...

Page 19: Basic Service Information

Basic service information 1-10 notice eca16790 when disconnecting a connector, do not pull the leads. Hold both sections of the connec- tor securely, and then disconnect the con- nector. 2. Check: • lead • coupler • connector moisture dry with an air blower. Rust/stains connect and disconnect se...

Page 20: Basic Service Information

Basic service information 1-11 5. Check: • resistance tip the resistance values shown were obtained at the standard measuring temperature of 20 c (68 f). If the measuring temperature is not 20 c (68 f), the specified measuring conditions will be shown. Pocket tester 90890-03112 analog pocket tes...

Page 21: Special Tools

Special tools 1-12 eas20260 special tools the following special tools are necessary for complete and accurate tune-up and assembly. Use only the appropriate special tools as this will help prevent damage caused by the use of inappropriate tools or improvised techniques. Special tools, part numbers o...

Page 22: Special Tools

Special tools 1-13 valve spring compressor 90890-01253 5-17, 5-22 ring nut wrench 90890-01268 spanner wrench yu-01268 4-46 crankshaft installer pot 90890-01274 installing pot yu-90058 5-54 crankshaft installer bolt 90890-01275 bolt yu-90060 5-54 adapter (m12) 90890-01278 adapter #3 yu-90063 5-54 spa...

Page 23: Special Tools

Special tools 1-14 piston pin puller set 90890-01304 piston pin puller yu-01304 5-24 t-handle 90890-01326 t-handle 3/8" drive 60 cm long ym-01326 4-39, 4-41 fork seal driver weight 90890-01367 replacement hammer ym-a9409-7 4-41, 4-42 fork seal driver attachment (ø35) 90890-01369 replacement 35 mm ym...

Page 24: Special Tools

Special tools 1-15 compression gauge 90890-03081 engine compression tester yu-33223 5-1 pocket tester 90890-03112 analog pocket tester yu-03112-c 1-10, 1-11, 7-57, 7-58, 7-59, 7-63, 7-64, 7-65, 7-66, 7-67, 7-68, 7-69, 7-70, 7-71, 7-72 pressure gauge 90890-03153 pressure gauge yu-03153 6-12 digital c...

Page 25: Special Tools

Special tools 1-16 test harness s– pressure sensor 5s7 (3p) 90890-03211 test harness s– pressure sensor 5s7 (3p) yu-03211 7-71 test harness– lean angle sensor (3p) 90890-03213 test harness– lean angle sensor (3p) yu-03213 7-67 valve guide remover & installer set (ø8.0) 90890-04014 valve guide remove...

Page 26: Special Tools

Special tools 1-17 ignition checker 90890-06754 oppama pet–4000 spark checker ym-34487 7-66 digital tachometer 90890-06760 digital tachometer yu-39951-b 3-7 vacuum/pressure pump gauge set 90890-06945 pressure/vacuum tester yb-35956-b 6-12 yamaha bond no. 1215 90890-85505 (three bond no.1215®) 5-11, ...

Page 27: Specifications

1 2 3 4 5 6 7 8 9 specifications general specifications .........................................................................2-1 engine specifications .............................................................................2-2 chassis specifications ............................................

Page 28: General Specifications

General specifications 2-1 eas20280 general specifications model model 2rd1 (eur) 2rd4 (aus) dimensions overall length 2085 mm (82.1 in) overall width 750 mm (29.5 in) overall height 1095 mm (43.1 in) seat height 785 mm (30.9 in) wheelbase 1410 mm (55.5 in) ground clearance 130 mm (5.12 in) minimum ...

Page 29: Engine Specifications

Engine specifications 2-2 eas20290 engine specifications engine engine type air cooled 4-stroke, sohc displacement 399 cm 3 cylinder arrangement single cylinder bore stroke 87.0 67.2 mm (3.43 2.65 in) compression ratio 8.50 : 1 standard compression pressure (at sea level) 1050 kpa/700 r/min (1...

Page 30: Engine Specifications

Engine specifications 2-3 camshaft drive system chain drive (right) camshaft lobe dimensions lobe height (intake) 38.860–38.960 mm (1.5299–1.5339 in) limit 38.850 mm (1.5295 in) base circle diameter (intake) 32.170–32.270 mm (1.2665–1.2705 in) limit 32.160 mm (1.2661 in) lobe height (exhaust) 38.890...

Page 31: Engine Specifications

Engine specifications 2-4 limit 43.00 mm (1.69 in) installed length (intake) 38.00 mm (1.50 in) installed length (exhaust) 38.00 mm (1.50 in) spring rate k1 (intake) 16.40 n/mm (1.67 kgf/mm, 93.64 lbf/in) spring rate k2 (intake) 20.80 n/mm (2.12 kgf/mm, 118.77 lbf/in) spring rate k1 (exhaust) 16.40 ...

Page 32: Engine Specifications

Engine specifications 2-5 2nd ring ring type taper end gap (installed) 0.30–0.50 mm (0.0118–0.0197 in) limit 0.80 mm (0.0315 in) ring side clearance 0.030–0.070 mm (0.0012–0.0028 in) limit 0.150 mm (0.0059 in) oil ring end gap (installed) 0.20–0.90 mm (0.0079–0.0354 in) crankshaft crank assembly wid...

Page 33: Engine Specifications

Engine specifications 2-6 fuel pump pump type electrical fuel injector model/quantity 4c8/1 throttle body type/quantity 34ehs/1 id mark 2rd1 00 throttle position sensor resistance 1.75–3.25 k (l-b/l) idling condition engine idling speed 1200–1400 r/min plug seat temperature 170.0–190.0 c (338.00–3...

Page 34: Chassis Specifications

Chassis specifications 2-7 eas20300 chassis specifications chassis frame type semi double cradle caster angle 27.70 trail 111 mm (4.4 in) front wheel wheel type spoke wheel rim size 18 1.85 rim material aluminum wheel travel 150 mm (5.9 in) radial wheel runout limit 1.0 mm (0.04 in) lateral wheel ...

Page 35: Chassis Specifications

Chassis specifications 2-8 brake disc thickness limit 4.5 mm (0.18 in) brake disc runout limit (as measured on wheel) 0.15 mm (0.0059 in) brake pad lining thickness (inner) 6.2 mm (0.24 in) limit 0.8 mm (0.03 in) brake pad lining thickness (outer) 6.2 mm (0.24 in) limit 0.8 mm (0.03 in) master cylin...

Page 36: Chassis Specifications

Chassis specifications 2-9 spring preload adjusting positions minimum 1 standard 1 maximum 5 swingarm swingarm end free play limit (radial) 1.0 mm (0.04 in) swingarm end free play limit (axial) 0.5 mm (0.02 in) drive chain type/manufacturer 428hvs/daido number of links 130 drive chain slack 30.0–40....

Page 37: Electrical Specifications

Electrical specifications 2-10 eas20310 electrical specifications voltage system voltage 12 v ignition system ignition system tci advancer type digital ignition timing (b.T.D.C.) 10.0 1300 r/min engine control unit model/manufacturer tbdfl5/denso ignition coil minimum ignition spark gap 6.0 mm (0....

Page 38: Electrical Specifications

Electrical specifications 2-11 engine trouble warning light 12 v, 1.7 w 1 horn horn type plane quantity 1 maximum amperage 3.0 a coil resistance 1.19–1.25 turn signal/hazard relay relay type full transistor built-in, self-canceling device no turn signal blinking frequency 75–95 cycles/min fuel sen...

Page 39: Tightening Torques

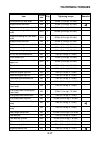

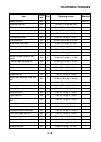

Tightening torques 2-12 eas20320 tightening torques eas20331 general tightening torque specifications this chart specifies tightening torques for stan- dard fasteners with a standard iso thread pitch. Tightening torque specifications for special com- ponents or assemblies are provided for each chapt...

Page 40: Tightening Torques

Tightening torques 2-13 eas20340 engine tightening torques item thread size q’ty tightening torque remarks cylinder head cover bolt m6 3 10 nm (1.0 m·kgf, 7.2 ft·lbf) tappet cover bolt m6 3 10 nm (1.0 m·kgf, 7.2 ft·lbf) exhaust tappet cover bolt (right side of the vehicle) m6 1 10 nm (1.0 m·kgf, 7.2...

Page 41: Tightening Torques

Tightening torques 2-14 timing chain tensioner cap m30 1 18 nm (1.8 m·kgf, 13 ft·lbf) rocker arm shaft lock washer bolt m6 2 10 nm (1.0 m·kgf, 7.2 ft·lbf) decomp cam bolt m6 1 7 nm (0.7 m·kgf, 5.1 ft·lbf) timing chain guide bolt (exhaust side) m6 2 8 nm (0.8 m·kgf, 5.8 ft·lbf) oil pump cover bolt m6...

Page 42: Tightening Torques

Tightening torques 2-15 muffler and frame bracket bolt m8 1 20 nm (2.0 m·kgf, 14 ft·lbf) frame muffler bracket nut m8 1 30 nm (3.0 m·kgf, 22 ft·lbf) muffler bracket and frame bolt m12 1 60 nm (6.0 m·kgf, 43 ft·lbf) air induction system pipe bolt (cylinder head side) m6 2 10 nm (1.0 m·kgf, 7.2 ft·lbf...

Page 43: Tightening Torques

Tightening torques 2-16 eas20350 chassis tightening torques throttle position sensor screw m5 2 3.5 nm (0.35 m·kgf, 2.5 ft·lbf) intake air pressure sensor screw m5 1 3.5 nm (0.35 m·kgf, 2.5 ft·lbf) o 2 sensor m18 1 45 nm (4.5 m·kgf, 33 ft·lbf) intake air temperature sensor screw m5 1 2.5 nm (0.25 m·...

Page 44: Tightening Torques

Tightening torques 2-17 oil drain bolt (oil tank side) m8 1 16 nm (1.6 m·kgf, 12 ft·lbf) engine mount front bolt m8 4 35 nm (3.5 m·kgf, 25 ft·lbf) engine mounting nut (front side) m10 1 64 nm (6.4 m·kgf, 46 ft·lbf) engine mounting nut (front lower side) m10 1 60 nm (6.0 m·kgf, 43 ft·lbf) engine moun...

Page 45: Tightening Torques

Tightening torques 2-18 lower ring nut m25 1 — see tip. Steering stem nut m22 1 110 nm (11 m·kgf, 80 ft·lbf) rollover valve clamp bolt m5 1 3.8 nm (0.38 m·kgf, 2.8 ft·lbf) fuel cock screw m6 2 7 nm (0.7 m·kgf, 5.1 ft·lbf) fuel tank bolt m8 1 16 nm (1.6 m·kgf, 12 ft·lbf) fuel sender screw m6 2 7 nm (...

Page 46: Tightening Torques

Tightening torques 2-19 tip lower ring nut 1. First, tighten the lower ring nut to 38 nm (3.8 m·kgf, 27 ft·lbf) with a torque wrench, then loosen the ring nut completely. 2. Retighten the lower ring nut to 18 nm (1.8 m·kgf, 13 ft·lbf). Brake pedal adjusting bolt lock- nut m6 1 7 nm (0.7 m·kgf, 5.1 f...

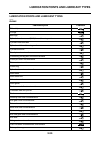

Page 47: 2-20

Lubrication points and lubricant types 2-20 eas20360 lubrication points and lubricant types eas20370 engine lubrication point lubricant oil seal lips o-rings bearings cylinder head cover nut (m10) thread, bearing surface cylinder head stud bolt cylinder nut thread, bearing surface cylinder stud bolt...

Page 48: 2-21

Lubrication points and lubricant types 2-21 eas20380 chassis clutch housing spacer inner circumference push lever shaft outer circumference transmission sliding portion, wheel gear and pinion gear inner surface, end surface shift fork guide bar outer circumference, end surface shift drum bearing shi...

Page 49: 2-22

Lubrication points and lubricant types 2-22 speedometer gear o-ring and sliding part rear brake camshaft mating surfaces, shaft rear brake shoe plate pin pivot rear wheel oil seal lip rear wheel axle rear wheel drive hub brake caliper piston seal master cylinder inside brake caliper piston dust seal...

Page 50: 2-23

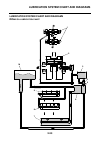

Lubrication system chart and diagrams 2-23 eas20390 lubrication system chart and diagrams eas20400 engine oil lubrication chart 1 2 3 4 5 7 8 6 9 10

Page 51: 2-24

Lubrication system chart and diagrams 2-24 1. Rocker arm shaft 2. Crankshaft 3. Oil filter element 4. Check ball 5. Oil feed pump 6. Scavenging pump 7. Oil strainer 8. Drive axle 9. Main axle 10. Oil tank (frame).

Page 52: 2-25

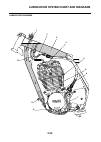

Lubrication system chart and diagrams 2-25 eas20410 lubrication diagrams 1 2 4 5 6 4 8 10 3 7 9.

Page 53: 2-26

Lubrication system chart and diagrams 2-26 1. Engine oil level gauge 2. Breather hose 3. Oil tank 4. Union bolt 5. Oil delivery pipe clamp 6. Oil delivery pipe 7. Oil pipe 8. Oil hose 1 9. Oil drain bolt (oil tank side) 10. Oil hose 2.

Page 54: 2-27

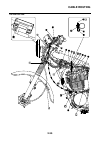

Lubrication system chart and diagrams 2-27 1 3 2.

Page 55: 2-28

Lubrication system chart and diagrams 2-28 1. Oil hose 2 2. Scavenging pump 3. Oil drain bolt (crankcase side) a. To oil tank.

Page 56: 2-29

Lubrication system chart and diagrams 2-29 1 2 3 4 5 8 10 9 a b b a 6 7.

Page 57: 2-30

Lubrication system chart and diagrams 2-30 1. Crankshaft 2. Oil filter element 3. Check ball 4. Oil feed pump 5. Oil strainer 6. Oil pipe 7. Oil delivery pipe 8. Rocker arm (exhaust side) 9. Camshaft 10. Rocker arm (intake side) a. From oil tank.

Page 58: 2-31

Lubrication system chart and diagrams 2-31 2 4 c c 3 1.

Page 59: 2-32

Lubrication system chart and diagrams 2-32 1. Clutch push lever shaft 2. Main axle 3. Oil pump 4. Drive axle a. To oil tank.

Page 60: Cable Routing

Cable routing 2-33 eas20430 cable routing right side view.

Page 61: Cable Routing

Cable routing 2-34 1. Rear brake light switch 2. Rear brake light switch lead 3. Throttle position sensor coupler 4. Fuel sender lead 5. Fuel tank 6. Oil hose 2 7. O 2 sensor coupler 8. Right handlebar switch lead 9. Front brake light switch lead 10. Throttle cable 11. Brake hose 12. Tachometer cabl...

Page 62: Cable Routing

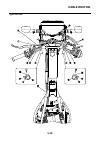

Cable routing 2-35 left side front view.

Page 63: Cable Routing

Cable routing 2-36 1. Speedometer cable 2. Clutch cable 3. Decompression cable 4. Left handlebar switch lead 5. Ignition coil 6. Wire harness 7. Spark plug lead 8. Throttle cable (decelerator) 9. Throttle cable (accelerator) 10. Engine temperature sensor 11. Fuel tank breather hose 12. Ground lead a...

Page 64: Cable Routing

Cable routing 2-37 left side rear view.

Page 65: Cable Routing

Cable routing 2-38 1. Breather hose 2. Oil hose 2 3. Intake air temperature sensor lead 4. Rear brake light switch coupler 5. Optional coupler 6. Fuel pump relay lead, headlight relay (on/off) lead (white tape) 7. Diode 1 8. Fuel pump lead 9. Fuel pump coupler 10. Fuel sender lead 11. Isc (idle spee...

Page 66: Cable Routing

Cable routing 2-39 upper front view.

Page 67: Cable Routing

Cable routing 2-40 1. Clutch cable 2. Decompression cable 3. Brake hose 4. Throttle cable 5. Front brake light switch lead 6. Right handlebar switch lead 7. Left handlebar switch lead 8. Clutch switch lead 9. Handlebar a. Fasten the right handlebar switch lead and front brake light switch lead with ...

Page 68: Cable Routing

Cable routing 2-41 upper rear view.

Page 69: Cable Routing

Cable routing 2-42 1. Rear brake light switch lead 2. Fuse box 3. Rear left turn signal light lead 4. Tail/brake light lead 5. Rear right turn signal light lead 6. Joint coupler 7. Battery lead 8. Hook-and-loop fastener 1 9. Hook-and-loop fastener 2 a. Route the rear brake light switch lead to the r...

Page 70: Cable Routing

Cable routing 2-43 headlight.

Page 71: Cable Routing

Cable routing 2-44 1. Meter lead 2. Clutch switch lead 3. Headlight coupler 4. Left handlebar switch lead 5. Front left turn signal light lead 6. Main switch lead 7. Auxiliary light lead 8. Front right turn signal light lead 9. Right handlebar switch lead 10. Front brake light switch lead 11. Clamp ...

Page 72: Cable Routing

Cable routing 2-45 handle.

Page 73: Cable Routing

Cable routing 2-46 1. Tachometer cable 2. Speedometer cable 3. Clutch cable 4. Decompression cable 5. Wire harness 6. Brake hose 7. Throttle cable a. Route the speedometer cable to the front of the lower bracket. B. Fasten the brake hose with the clamp. C. Route the tachometer cable to the upper rig...

Page 74: Cable Routing

Cable routing 2-47 fuel tank breather hose.

Page 75: Cable Routing

Cable routing 2-48 1. Fuel tank 2. Fuel hose (fuel tank–fuel pump case) 3. Fuel cock 4. Fuel sender 5. Fuel tank breather hose 2 6. Clamp 7. Rollover valve 8. Fuel tank breather hose 1 9. Tank stopper 10. Damper 11. Pump case breather hose (fuel pump case–fuel tank) 12. Fuel hose (fuel pump–fuel rai...

Page 76: Cable Routing

Cable routing 2-49 fuel pump case.

Page 77: Cable Routing

Cable routing 2-50 1. Fuel tank 2. Pump case breather hose (fuel pump case–fuel tank) 3. Fuel pump case 4. Fuel hose (fuel pump–fuel rail) 5. Fuel hose (fuel tank–fuel pump case) 6. Fuel cock 7. Fuel pump case box a. Insert the pump case breather hose (fuel pump case–fuel tank) to the base of the fu...

Page 78: Cable Routing

Cable routing 2-51 throttle body (upper view).

Page 79: Cable Routing

Cable routing 2-52 1. Fuel pump case box 2. Breather hose 3. Pressure regulator 4. Fuel pipe 5. Fuel hose (pressure regulator–fuel pipe) 6. Fuel hose (fuel pipe–fuel tank) a. Avoid contact of the end of the breather hose with the damper. B. Install the breather hose to the air filter case holder. C....

Page 80: Cable Routing

Cable routing 2-53 throttle body (side view).

Page 81: Cable Routing

Cable routing 2-54 1. Fuel tank 2. Fuel hose (pressure regulator–fuel tank) 3. Pressure regulator 4. Air filter case 5. Battery box 6. Oil separator 7. Air filter case drain hose 8. Oil hose 2 9. Breather hose 10. Clamp 11. Stator coil assembly lead 12. Crankcase a. Dispose the fuel hose (pressure r...

Page 82: Cable Routing

Cable routing 2-55 air induction system solenoid.

Page 83: Cable Routing

Cable routing 2-56 1. Air cut-off valve 2. Air induction system hose (air filter case–air cut-off valve) 3. Air induction system hose (air cut-off valve–air induction system pipe) 4. Air induction system pipe a. Point the end of the clamp downward. B. A 0 to 5 mm (0 to 0.2 in) gap is allowed to be p...

Page 84: Cable Routing

Cable routing 2-57.

Page 85

1 2 3 4 5 6 7 8 9 periodic checks and adjustments periodic maintenance .............................................................................3-1 introduction ........................................................................................3-1 periodic maintenance chart for the emission...

Page 86

Adjusting the rear brake light switch ..................................3-24 checking and lubricating the cables .....................................3-24 checking the throttle grip.........................................................3-24 checking and charging the battery...........................

Page 87: Periodic Maintenance

Periodic maintenance 3-1 eas20450 periodic maintenance eas20460 introduction this chapter includes all information necessary to perform recommended checks and adjustments. If followed, these preventive maintenance procedures will ensure more reliable vehicle operation, a lon- ger service life and re...

Page 88: Periodic Maintenance

Periodic maintenance 3-2 5 * front brake • check operation, fluid level and vehicle for fluid leakage. • adjust brake lever free play. • replace brake pads. Whenever worn to the limit 6 * rear brake • check operation and adjust brake pedal free play. • replace brake shoes. Whenever worn to the limit...

Page 89: Periodic Maintenance

Periodic maintenance 3-3 tip • air filter • this model’s air intake system is equipped with a disposable oil-coated paper element. The air filter element cannot be cleaned with compressed air, it must be replaced. • the air filter element needs to be replaced more frequently when riding in unusually...

Page 90: Periodic Maintenance

Periodic maintenance 3-4 eas21030 checking the fuel line the following procedure applies to all of the fuel, vacuum and breather hoses. 1. Remove: • seat • side cover (left) refer to “general chassis” on page 4-1. • fuel tank refer to “fuel tank” on page 6-1. 2. Check: • fuel hose (fuel tank–fuel pu...

Page 91: Periodic Maintenance

Periodic maintenance 3-5 refer to “general chassis” on page 4-1. Eas20690 checking the spark plug 1. Remove: • spark plug cap 2. Remove: • spark plug notice eca13330 before removing the spark plug, blow away any dirt accumulated in the spark plug well with compressed air to prevent it from falling i...

Page 92: Periodic Maintenance

Periodic maintenance 3-6 c. A position where the ac magneto “t” mark matches the crankcase alignment mark is the compression top dead center (tdc). D. Measure the valve clearance with a thickness gauge “1”. Out of specification adjust. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 4. Adjust: • valve clearance ...

Page 93: Periodic Maintenance

Periodic maintenance 3-7 • crankcase cover (left) refer to “generator” on page 5-46. • fuel tank refer to “fuel tank” on page 6-1. • seat refer to “general chassis” on page 4-1. 7. Adjust: • decompression lever free play refer to “adjusting the decompres- sion lever free play” on page 3-11. Eas2rd10...

Page 94: Periodic Maintenance

Periodic maintenance 3-8 d. Press the “up” button and select the co ad- justment mode “co”. E. Select “co”, and then press the “mode” but- ton. F. Check that “c1” appears on the lcd display of the fi diagnostic tool. G. Start the engine. Tip make an adjustment after the battery is fully charged. H. ...

Page 95: Periodic Maintenance

Periodic maintenance 3-9 4. Install: • fuel tank refer to “fuel tank” on page 6-1. • seat refer to “general chassis” on page 4-1. Eas2rd1009 checking the air induction system 1. Check: • air induction system refer to “checking the air induction system” on page 6-18. Eas2rd1008 checking the oil separ...

Page 96: Periodic Maintenance

Periodic maintenance 3-10 eas20870 adjusting the clutch lever free play 1. Check: • clutch lever free play “a” out of specification adjust. 2. Adjust: • clutch lever free play ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Loosen the locknut “1”. B. Turn the adjusting bolt “2” in direction “a” or “b” until t...

Page 97: Periodic Maintenance

Periodic maintenance 3-11 eas2rd1007 adjusting the decompression lever free play 1. Fully turn the handle to the left. 2. Remove: • spark plug cap • spark plug 3. Remove: • crankcase cover (left) refer to “generator” on page 5-46. 4. Turn the ac magneto counterclockwise and align the “t” mark “a” of...

Page 98: Periodic Maintenance

Periodic maintenance 3-12 below the minimum level mark “a” add the specified brake fluid to the proper level. Warning ewa13090 • use only the designated brake fluid. Other brake fluids may cause the rubber seals to deteriorate, causing leakage and poor brake performance. • refill with the same typ...

Page 99: Periodic Maintenance

Periodic maintenance 3-13 1. Operate the brake. 2. Check: • front brake pad “1” wear indicator grooves “2” almost disap- peared replace the brake pads as a set. Refer to “front brake” on page 4-17. Eas21220 adjusting the rear drum brake 1. Check: • brake pedal position (distance “a” from the top o...

Page 100: Periodic Maintenance

Periodic maintenance 3-14 notice eca13520 after adjusting the brake pedal position and free play, make sure there is no brake drag. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 5. Adjust: • rear brake light switch refer to “adjusting the rear brake light switch” on page 3-24. Eas21310 checking the rear brake sh...

Page 101: Periodic Maintenance

Periodic maintenance 3-15 with the specified brake fluid. B. Install the brake master cylinder reservoir di- aphragm. C. Connect a clear plastic hose “1” tightly to the bleed screw “2”. D. Place the other end of the hose into a con- tainer. E. Slowly apply the brake lever several times. F. Fully pul...

Page 102: Periodic Maintenance

Periodic maintenance 3-16 eas21650 checking the tires the following procedure applies to both of the tires. 1. Check: • tire pressure out of specification regulate. Warning ewa13180 • the tire pressure should only be checked and regulated when the tire temperature equals the ambient air temperatur...

Page 103: Periodic Maintenance

Periodic maintenance 3-17 warning ewa14080 • do not use a tubeless tire on a wheel de- signed only for tube tires to avoid tire fail- ure and personal injury from sudden deflation. • when using a tube tire, be sure to install the correct tube. • always replace a new tube tire and a new tube as a set...

Page 104: Periodic Maintenance

Periodic maintenance 3-18 eas21390 adjusting the drive chain slack notice eca13550 a drive chain that is too tight will overload the engine and other vital parts, and one that is too loose can skip and damage the swing- arm or cause an accident. Therefore, keep the drive chain slack within the speci...

Page 105: Periodic Maintenance

Periodic maintenance 3-19 vehicle is used in dusty areas. This vehicle has a drive chain with small rubber o-rings between each side plate. Steam clean- ing, high-pressure washing, certain solvents, and the use of a coarse brush can damage these o-rings. Therefore, use only kerosene to clean the dri...

Page 106: Periodic Maintenance

Periodic maintenance 3-20 ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 5. Install: • upper bracket refer to “steering head” on page 4-44. Eas2rd1024 lubricating the steering head 1. Lubricate: • upper bearing • lower bearing • bearing race eas2rd1025 checking the chassis fasteners make sure that all nuts, bolts...

Page 107: Periodic Maintenance

Periodic maintenance 3-21 3. Hold the vehicle upright and apply the front brake. 4. Check: • front fork operation push down hard on the handlebar several times and check if the front fork rebounds smoothly. Rough movement repair. Refer to “front fork” on page 4-37. Eas2rd1036 checking the rear sho...

Page 108: Periodic Maintenance

Periodic maintenance 3-22 notice eca13361 • engine oil also lubricates the clutch and the wrong oil types or additives could cause clutch slippage. Therefore, do not add any chemical additives or use engine oils with a grade of “cd” or higher and do not use oils labeled “energy conserving ii”. • do ...

Page 109: Periodic Maintenance

Periodic maintenance 3-23 ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 7. Install: • oil drain bolt gasket • oil drain bolt (oil tank side) “1” • oil drain bolt gasket • oil drain bolt (crankcase side) “2” 8. Fill: • oil tank (with the specified amount of the recom- mended engine oil) 9. Install: • engine oil l...

Page 110: Periodic Maintenance

Periodic maintenance 3-24 d. Start the engine after solving the problem(s) and make sure that oil seeps out. E. Tighten the oil check bolt to specification. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ eas2rd1037 checking the front brake light switch refer to “electrical components” on page 7-51. Eas21330 adjus...

Page 111: Periodic Maintenance

Periodic maintenance 3-25 4. Adjust: • throttle grip free play ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ throttle body side a. Loosen the locknut “1” on the decelerator ca- ble. B. Turn the adjusting nut “2” in direction “a” or “b” to take up any slack on the decelerator cable. C. Loosen the locknut “3” on t...

Page 112: Periodic Maintenance

Periodic maintenance 3-26 2. Disconnect: • headlight coupler “1” 3. Remove: • headlight bulb cover “2” 4. Unhook: • headlight bulb holder “1” 5. Remove: • headlight bulb “2” warning ewa13320 since the headlight bulb gets extremely hot, keep flammable products and your hands away from the bulb until ...

Page 113: Periodic Maintenance

Periodic maintenance 3-27 ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 1 a b.

Page 114: Periodic Maintenance

Periodic maintenance 3-28.

Page 115: Chassis

1 2 3 4 5 6 7 8 9 chassis general chassis........................................................................................4-1 removing the side covers ..............................................................4-4 installing the side covers.....................................................

Page 116

Assembling the front fork legs ...............................................4-40 installing the front fork legs .................................................4-42 steering head...........................................................................................4-44 removing the lower brac...

Page 117: General Chassis

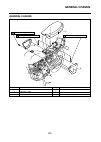

General chassis 4-1 eas21830 general chassis removing the seat and side covers order job/parts to remove q’ty remarks 1 seat 1 2 side cover (right) 1 3 side cover (left) 1 unlock using the key. 1 2 3 7 nm (0.7 m • kgf, 5.1 ft • ibf) 16 nm (1.6 m • kgf, 12 ft • ibf) 16 nm (1.6 m • kgf, 12 ft • ibf).

Page 118: General Chassis

General chassis 4-2 removing the battery and battery box order job/parts to remove q’ty remarks seat 1 battery band 1 2 clamp 1 remove the battery lead. 3 battery connector 1 4 battery 1 5 battery box 1 1 3 4 2 5 7 nm (0.7 m • kgf, 5.1 ft • ibf) 7 nm (0.7 m • kgf, 5.1 ft • ibf).

Page 119: General Chassis

General chassis 4-3 removing the electrical components order job/parts to remove q’ty remarks seat side cover (left) fuel pump case refer to “fuel tank” on page 6-1. 1 pump case box 1 2 fuel hose (fuel pump–fuel rail) 1 remove from the pump case box. 3 lean angle sensor coupler 1 disconnect. 4 ecu c...

Page 120: General Chassis

General chassis 4-4 eas2rd1010 removing the side covers 1. Remove: • bolt “1” • side cover (right) “2” 2. Remove: • side cover (left) “1” tip insert the key into the lock release cylinder and unlock by turning it clockwise “a”. Eas2rd1030 installing the side covers 1. Install: • side cover (right) “...

Page 121: Front Wheel

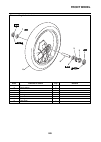

Front wheel 4-5 eas21870 front wheel removing the front wheel and brake disc order job/parts to remove q’ty remarks 1 speedometer cable 1 2 axle holder nut 2 loosen. 3 wheel axle nut 1 4 washer 1 5 collar 1 6 wheel axle 1 7 front wheel assembly 1 8 speedometer gear unit assembly 1 9 brake disc 1 lt ...

Page 122: Front Wheel

Front wheel 4-6 disassembling the front wheel order job/parts to remove q’ty remarks 1 oil seal 1 2 clutch retainer 1 3 meter clutch 1 4 oil seal 1 5 bearing 1 6 spacer 1 7 bearing 1 8 front wheel 1 1 2 3 4 5 6 7 8.

Page 123: Front Wheel

Front wheel 4-7 eas21890 removing the front wheel 1. Stand the vehicle on a level surface. Warning ewa13120 securely support the vehicle so that there is no danger of it falling over. Tip place the vehicle on a suitable stand so that the front wheel is elevated. 2. Loosen: • axle holder nut 3. Remov...

Page 124: Front Wheel

Front wheel 4-8 ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Clean the outside of the front wheel hub. B. Remove the oil seals “1” with a flathead screwdriver. Tip to prevent damaging the wheel, place a rag “2” between the screwdriver and the wheel surface. C. Remove the wheel bearings “3” with a gener- al b...

Page 125: Front Wheel

Front wheel 4-9 f. Repeat steps (c) through (e) several times until all the marks come to rest at the same spot. G. The spot where all the marks come to rest is the front wheel’s heavy spot “x”. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 3. Adjust: • front wheel static balance ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼...

Page 126: Front Wheel

Front wheel 4-10 4. Tighten: • wheel axle nut • axle holder nut “1” notice eca14140 before tightening the wheel axle nut, push down hard on the handlebar(s) several times and check if the front fork rebounds smooth- ly. Tip • make sure that an arrow of the axle holder points toward the front “a”. • ...

Page 127: Rear Wheel

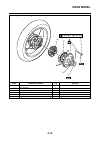

Rear wheel 4-11 eas22020 rear wheel removing the rear wheel and rear brake order job/parts to remove q’ty remarks 1 adjusting nut 1 2 pin 1 3 compression spring 1 4 nut/washer 1/1 5 locknut/adjusting bolt 2/2 loosen. 6 wheel axle nut/washer 1/1 7 wheel axle 1 8 spacer 1 9 chain puller (left)/chain p...

Page 128: Rear Wheel

Rear wheel 4-12 removing the rear wheel sprocket order job/parts to remove q’ty remarks 1 circlip 1 2 hub dust seal 1 3 hub stopper 2 4 rear wheel sprocket 1 5 drive hub 1 6 drive hub damper 6 1 2 3 4 5 6 26 nm (2.6 m • kgf, 19 ft • ibf) lt.

Page 129: Rear Wheel

Rear wheel 4-13 disassembling the rear wheel order job/parts to remove q’ty remarks 1 bearing 1 2 spacer 1 3 flange spacer 1 4 oil seal 1 5 bearing 1 6 bearing 1 1 2 3 4 5 6.

Page 130: Rear Wheel

Rear wheel 4-14 eas22060 removing the rear wheel (drum) 1. Stand the vehicle on a level surface. Warning ewa13120 securely support the vehicle so that there is no danger of it falling over. Tip place the vehicle on a suitable stand so that the rear wheel is elevated. 2. Remove: • brake rod “1” • ten...

Page 131: Rear Wheel

Rear wheel 4-15 refer to “checking the front wheel” on page 4-7. Eas22120 checking and replacing the rear wheel sprocket 1. Check: • rear wheel sprocket more than 1/4 tooth “a” wear replace the drive sprocket, the rear wheel sprocket and the drive chain as a set. Bent teeth replace the drive spr...

Page 132: Rear Wheel

Rear wheel 4-16 3. Install: • rear wheel • drive chain • chain puller (left/right) • toothed spacer • wheel axle • wheel axle nut 4. Adjust: • drive chain slack refer to “adjusting the drive chain slack” on page 3-18. 5. Tighten: • wheel axle nut 6. Install: • tension bar • brake rod 7. Adjust: • br...

Page 133: Front Brake

Front brake 4-17 eas22210 front brake removing the front brake pads order job/parts to remove q’ty remarks 1 brake hose holder 1 2 caliper support bolt 2 3 caliper assembly 1 4 brake pad/shim 2/2 5 pad support 2 6 pad spring 1 s s 27 nm (2.7 m • kgf, 20 ft • ibf) 10 nm (1.0 m • kgf, 7.2 ft • ibf) 1 ...

Page 134: Front Brake

Front brake 4-18 removing the front brake master cylinder order job/parts to remove q’ty remarks brake fluid drain. Refer to “bleeding the hydraulic brake system” on page 3-14. 1 rearview mirror (right) 1 2 brake lever/compression spring 1/1 3 front brake light switch 1 4 brake master cylinder reser...

Page 135: Front Brake

Front brake 4-19 disassembling the front brake master cylinder order job/parts to remove q’ty remarks 1 master cylinder kit 1 bf bf s 1.

Page 136: Front Brake

Front brake 4-20 removing the front brake caliper order job/parts to remove q’ty remarks brake fluid drain. Refer to “bleeding the hydraulic brake system” on page 3-14. 1 brake hose holder 1 2 union bolt 1 3 gasket 2 4 brake hose 1 5 caliper support bolt 2 6 caliper assembly 1 7 caliper bracket 1 s ...

Page 137: Front Brake

Front brake 4-21 disassembling the front brake caliper order job/parts to remove q’ty remarks 1 brake caliper piston 2 2 brake caliper piston dust seal 2 3 brake caliper piston seal 2 4 bleed screw 1 5 brake caliper cylinder 1 6 nm (0.6 m • kgf, 4.3 ft • ibf) 1 1 2 3 3 4 5 bf bf s s.

Page 138: Front Brake

Front brake 4-22 eas22221 introduction warning ewa14101 disc brake components rarely require disas- sembly. Therefore, always follow these pre- ventive measures: • never disassemble brake components un- less absolutely necessary. • if any connection on the hydraulic brake system is disconnected, the...

Page 139: Front Brake

Front brake 4-23 d. Measure the brake disc runout. E. If out of specification, repeat the adjustment steps until the brake disc runout is within specification. F. If the brake disc runout cannot be brought within specification, replace the brake disc. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 6. Install: • f...

Page 140: Front Brake

Front brake 4-24 c. Tighten the bleed screw. D. Install the shims “4” onto each brake pad “5”. E. Install pad spring, pad supports “6”, and brake pads. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 5. Install: • brake caliper “1” • caliper support bolt “2” 6. Check: • brake fluid level below the minimum level ma...

Page 141: Front Brake

Front brake 4-25 ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Blow compressed air into the brake hose joint opening “a” to force out the pistons from the brake caliper. Warning ewa13560 • cover the brake caliper pistons with a rag. Be careful not to get injured when the pis- tons are expelled from the brake ...

Page 142: Front Brake

Front brake 4-26 and brake caliper piston seals. Eas22420 installing the front brake caliper 1. Install: • brake caliper “1” (temporarily) • gasket “2” • brake hose “3” • union bolt “4” warning ewa2rd1011 proper brake hose routing is essential to in- sure safe vehicle operation. Refer to “cable rout...

Page 143: Front Brake

Front brake 4-27 7. Check: • brake lever operation soft or spongy feeling bleed the brake sys- tem. Refer to “bleeding the hydraulic brake system” on page 3-14. Eas22490 removing the front brake master cylinder tip before removing the front brake master cylinder, drain the brake fluid from the ent...

Page 144: Front Brake

Front brake 4-28 4. Check: • brake hose cracks/damage/wear replace. Eas22520 assembling the front brake master cylinder warning ewa13520 • before installation, all internal brake com- ponents should be cleaned and lubricated with clean or new brake fluid. • never use solvents on internal brake com...

Page 145: Front Brake

Front brake 4-29 is already in the system. Mixing brake fluids may result in a harmful chemical reaction, leading to poor brake performance. • when refilling, be careful that water does not enter the brake master cylinder reser- voir. Water will significantly lower the boil- ing point of the brake f...

Page 146: Rear Brake

Rear brake 4-30 eas22550 rear brake disassembling the rear brake order job/parts to remove q’ty remarks 1 brake shoe kit 1 2 brake camshaft lever 1 3 indicator plate 1 4 oil seal 1 5 brake camshaft 1 6 camshaft shim 1 2 1 3 4 5 6 9 nm (0.9 m • kgf, 6.5 ft • ibf) f f.

Page 147: Rear Brake

Rear brake 4-31 eas2rd1031 disassembling the rear brake shoe plate 1. Remove: • brake shoe kit “1” 2. Remove: • brake camshaft lever “1” • indicator plate “2” • brake camshaft “3” eas22681 checking the rear brake shoes 1. Check: • brake shoe lining glazed areas repair. Sand the glazed areas with c...

Page 148: Rear Brake

Rear brake 4-32 ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Install the brake camshaft so its punch mark is positioned as shown. B. Align the projection “a” on the indicator plate with the notch “b” in the brake camshaft. C. Check that the brake shoes are properly po- sitioned. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲...

Page 149: Handlebar

Handlebar 4-33 eas22840 handlebar removing the handlebar order job/parts to remove q’ty remarks 1 rearview mirror 2 2 band 2 3 front brake light switch 1 4 master cylinder holder 1 5 master cylinder assembly 1 6 right handlebar switch 1 7 throttle cable 1, 2 1/1 8 throttle grip 1 9 clutch cable 1 10...

Page 150: Handlebar

Handlebar 4-34 removing the handlebar order job/parts to remove q’ty remarks 17 handlebar 1 18 washer plain 2 19 lower handlebar holder 2 20 cover 2 7 nm (0.7 m • kgf, 5.1 ft • ibf) 23 nm (2.3 m • kgf, 17 ft • ibf) 32 nm (3.2 m • kgf, 23 ft • ibf) 17 19 19 20 20 7 nm (0.7 m • kgf, 5.1 ft • ibf) 2.3 ...

Page 151: Handlebar

Handlebar 4-35 eas22860 removing the handlebar 1. Stand the vehicle on a level surface. Warning ewa13120 securely support the vehicle so that there is no danger of it falling over. 2. Remove: • handlebar grip “1” tip blow compressed air between the left handlebar and the handlebar grip, and graduall...

Page 152: Handlebar

Handlebar 4-36 master cylinder” on page 4-28. Warning ewa13720 make sure the throttle grip operates smooth- ly. Tip the mating surfaces of the right handlebar switch should be perpendicular to the mating surfaces of the master cylinder holder. 5. Install: • lever holder “1” tip align the mating surf...

Page 153: Front Fork

Front fork 4-37 eas22950 front fork removing the front fork legs order job/parts to remove q’ty remarks front wheel refer to “front wheel” on page 4-5. 1 brake caliper 1 2 front fender 1 3 holder stay 1 except for aus. 4 right reflector 1 for aus. 5 left reflector 1 for aus. 6 upper bracket pinch bo...

Page 154: Front Fork

Front fork 4-38 disassembling the front fork legs order job/parts to remove q’ty remarks 1 cap 1 2 dust boot 1 3 cap bolt 1 4 o-ring 1 5 spring seat 1 6 fork spring 1 7 axle holder 1 8 damper rod assembly bolt 1 9 dust seal 1 10 oil seal clip 1 11 inner tube 1 12 oil seal 1 13 washer 1 14 slide meta...

Page 155: Front Fork

Front fork 4-39 eas22970 removing the front fork legs the following procedure applies to both of the front fork legs. 1. Stand the vehicle on a level surface. Warning ewa13120 securely support the vehicle so that there is no danger of it falling over. Tip place the vehicle on a suitable stand so tha...

Page 156: Front Fork

Front fork 4-40 4. Remove: • inner tube ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Hold the front fork leg horizontally. B. Securely clamp the brake caliper bracket in a vise with soft jaws. C. Separate the inner tube from the outer tube by pulling the inner tube forcefully but careful- ly. Notice eca2rd10...

Page 157: Front Fork

Front fork 4-41 –piston metal –oil seal –dust seal • before assembling the front fork leg, make sure all of the components are clean. 1. Install: • slide metal “1” • piston metal “2” • damper rod assembly “3” • oil lock piece “4” notice eca2rd1016 allow the damper rod to slide slowly down the inner ...

Page 158: Front Fork

Front fork 4-42 5. Install: • oil seal clip “1” tip adjust the oil seal clip so that it fits into the outer tube’s groove. 6. Install: • dust seal “1” (with the fork seal driver weight) 7. Fill: • front fork leg (with the specified amount of the recom- mended fork oil) tip • while filling the front ...

Page 159: Front Fork

Front fork 4-43 front fork legs. 1. Install: • front fork leg temporarily tighten the upper and lower bracket pinch bolts. Tip make sure the inner tube is flush with the top of the upper bracket. 2. Tighten: • lower bracket pinch bolt “1” • cap bolt “2” tip tighten the cap bolt with a 17 mm (0.67 in...

Page 160: Steering Head

Steering head 4-44 eas23090 steering head removing the headlight unit, meter assembly, and turn signal lights order job/parts to remove q’ty remarks handlebar refer to “handlebar” on page 4-33. 1 headlight unit assembly 1 2 wirings in headlight body disconnect. 3 headlight body 1 4 front right turn ...

Page 161: Steering Head

Steering head 4-45 removing the lower bracket order job/parts to remove q’ty remarks front fork leg refer to “front fork” on page 4-37. Handlebar refer to “handlebar” on page 4-33. Headlight, meter assembly 1 steering stem nut 1 2 washer 1 3 upper bracket 1 4 lock washer 1 5 upper ring nut 1 6 rubbe...

Page 162: Steering Head

Steering head 4-46 eas23110 removing the lower bracket 1. Stand the vehicle on a level surface. Warning ewa13120 securely support the vehicle so that there is no danger of it falling over. 2. Remove: • upper ring nut • lower ring nut tip remove the ring nut “2” with the ring nut wrench “1”. Warning ...

Page 163: Steering Head

Steering head 4-47 • lower bracket (along with the steering stem) bends/cracks/damage replace. Eas23140 installing the steering head 1. Lubricate: • upper bearing • lower bearing • bearing race 2. Install: • lower ring nut “1” • rubber washer “2” • upper ring nut “3” • lock washer “4” refer to “ch...

Page 164: 4-48

Rear shock absorber assembly and swingarm 4-48 eas2rd1027 rear shock absorber assembly and swingarm removing the rear shock absorber assembly and swingarm order job/parts to remove q’ty remarks rear wheel refer to “rear wheel” on page 4-11. 1 grab bar 1 2 rear right footrest 1 3 rear shock absorber ...

Page 165: 4-49

Rear shock absorber assembly and swingarm 4-49 eas23220 removing the rear shock absorber assemblies 1. Stand the vehicle on a level surface. Warning ewa13120 securely support the vehicle so that there is no danger of it falling over. Tip place the vehicle on a suitable stand so that the rear wheel i...

Page 166: 4-50

Rear shock absorber assembly and swingarm 4-50 ing the swingarm from side to side. C. If the swingarm side play is out of specifica- tion, check the spacers and bearings. D. Check the swingarm vertical movement “b” by moving the swingarm up and down. If swingarm vertical movement is not smooth or if...

Page 167: 4-51

Rear shock absorber assembly and swingarm 4-51 3. Calculate the thrust clearance. Out of specification adjust the shim. 4. If the standard clearance is not met, put the adjusting shim “1” to cause the thrust clear- ance (size “a”–“b”) to fall within the specified range. Tip put each shim in the le...

Page 168: 4-52

Rear shock absorber assembly and swingarm 4-52 4. Adjust: • drive chain slack refer to “adjusting the drive chain slack” on page 3-18 drive chain slack 30.0–40.0 mm (1.18–1.57 in).

Page 169: Chain Drive

Chain drive 4-53 eas23400 chain drive eas23420 removing the drive chain 1. Stand the vehicle on a level surface. Warning ewa13120 securely support the vehicle so that there is no danger of it falling over. Tip place the vehicle on a suitable stand so that the rear wheel is elevated. 2. Remove: • rea...

Page 170: Chain Drive

Chain drive 4-54 notice eca2rd1006 this vehicle has a drive chain with small rub- ber o-rings “1” between the drive chain side plates. Steam cleaning, high-pressure wash- ing, certain solvents, and the use of a coarse brush can damage these o-rings. ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 3. Check: • o-rin...

Page 171: Chain Drive

Chain drive 4-55 4. Adjust: • drive chain slack refer to “adjusting the drive chain slack” on page 3-18. Notice eca13550 a drive chain that is too tight will overload the engine and other vital parts, and one that is too loose can skip and damage the swing- arm or cause an accident. Therefore, keep ...

Page 172: Chain Drive

Chain drive 4-56.

Page 173: Engine

1 2 3 4 5 6 7 8 9 engine engine inspection .....................................................................................5-1 measuring the compression pressure.....................................5-1 engine removal .................................................................................

Page 174

Installing the clutch.....................................................................5-33 kickstarter ..............................................................................................5-36 checking the kickstarter ............................................................5-38 inst...

Page 175: Engine Inspection

Engine inspection 5-1 eas2rd1039 engine inspection eas20720 measuring the compression pressure the following procedure applies to checking and adjusting the compression pressure. Tip insufficient compression pressure will result in a loss of performance. 1. Measure: • valve clearance out of specific...

Page 176: Engine Removal

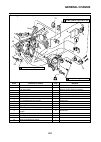

Engine removal 5-2 eas23711 engine removal removing the exhaust pipe and muffler order job/parts to remove q’ty remarks seat refer to “general chassis” on page 4-1. Fuel tank refer to “fuel tank” on page 6-1. Engine oil drain. Refer to “changing the engine oil” on page 3-22. 1 o 2 sensor coupler 1 d...

Page 177: Engine Removal

Engine removal 5-3 disconnecting the cables, leads, and hoses order job/parts to remove q’ty remarks air induction system refer to “air induction system” on page 6-15. Throttle body refer to “throttle body” on page 6-9. 1 drive sprocket cover 1 2 nut 1 3 lock washer 1 straighten the tab of the lock ...

Page 178: Engine Removal

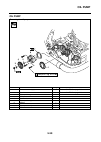

Engine removal 5-4 removing the engine order job/parts to remove q’ty remarks 1 rear brake light switch holder 1 2 engine mount rear 1 3 collar 1 4 engine mount front (right) 1 5 engine mount front (left) 1 6 engine mount upper 1 7 engine 1 1 2 3 4 5 6 7 60 nm (6.0 m • kgf, 43 ft • ibf) 64 nm (6.4m ...

Page 179: Engine Removal

Engine removal 5-5 eas23720 installing the engine 1. Install: • engine mount front “1” • engine mounting bolt/nut (front side) “2” • engine mounting bolt/nut (front lower side) “3” • engine mounting bolt/nut (rear lower side) “4” • engine mount rear “5” • engine mounting bolt/nut (rear side) “6” • e...

Page 180: Cylinder Head

Cylinder head 5-6 eas24100 cylinder head removing the cylinder head and camshaft order job/parts to remove q’ty remarks engine refer to “engine removal” on page 5-2. 1 spark plug 1 2 engine temperature sensor 1 3 exhaust tappet cover 1 4 intake tappet cover 1 5 oil delivery pipe 1 6 cylinder head co...

Page 181: Cylinder Head

Cylinder head 5-7 eas24130 removing the cylinder head 1. Remove: • crankcase cover (left) refer to “generator” on page 5-46. 2. Align: • “t” mark “a” on the ac magneto (with the match mark “b” on the crankcase) ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Turn the ac magneto counterclockwise. B. When the pis...

Page 182: Cylinder Head

Cylinder head 5-8 7. Remove: • cylinder head “1” tip • loosen the bolts and nuts in the proper se- quence. • loosen each bolt and nut 1/2 of a turn at a time. After all of the bolts and nuts are fully loosened, remove them. Eas24160 checking the cylinder head 1. Eliminate: • combustion chamber carbo...

Page 183: Cylinder Head

Cylinder head 5-9 3. Check: • rocker arm and rocker arm shaft oil passage obstruction blow out with compressed air. Eas23870 checking the timing chain and camshaft sprocket 1. Check: • timing chain damage/stiffness replace the timing chain, camshaft sprocket, and crankshaft sprocket as a set. 2....

Page 184: Cylinder Head

Cylinder head 5-10 3. Tighten: • cylinder head nut • cylinder head bolt tip • lubricate the cylinder head nuts with engine oil. • tighten the cylinder head bolts and nuts in two stages. 4. Install: • camshaft “1” 5. Align: • “t” mark “a” on the ac magneto ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Turn the...

Page 185: Cylinder Head

Cylinder head 5-11 • timing chain tensioner locknut “2” 9. Turn: • crankshaft (several turns counterclockwise) 10.Check: • “t” mark “a” align the ac magneto “t” mark with the mark “b” on the crankcase. Not aligned reinstall the camshaft sprock- et. Refer to the installation steps above. 11.Tighten...

Page 186: Cylinder Head

Cylinder head 5-12 tip do not allow any sealant to come into contact with the oil gallery. 17.Install: • cylinder head cover assembly tip tighten the bolts and nuts in a crisscross pattern in two to three stages. 18.Measure: • valve clearance out of specification adjust. Refer to “adjusting the va...

Page 187: Rocker Arms

Rocker arms 5-13 eas2rd1012 rocker arms removing the rocker arms and rocker arm shaft order job/parts to remove q’ty remarks engine refer to “engine removal” on page 5-2. Cylinder head refer to “cylinder head” on page 5-6. 1 locknut/adjuster 2/2 2 lock washer 2 3 rocker arm shaft (intake) 1 4 rocker...

Page 188: Rocker Arms

Rocker arms 5-14 eas2rd1040 removing the rocker arms and rocker arm shafts 1. Remove: • lock washer “1” tip straighten the lock washer tab and remove the bolt “2”. 2. Remove: • intake rocker arm shaft “1” • intake rocker arm “2” • exhaust rocker arm shaft • exhaust rocker arm tip remove the rocker a...

Page 189: Rocker Arms

Rocker arms 5-15 5. Calculate: • rocker-arm-to-rocker-arm-shaft clearance tip calculate the clearance by subtracting the rock- er arm shaft outside diameter from the rocker arm inside diameter. Out of specification replace. Eas2rd1013 checking the cylinder head cover, tappet cover, and viewer plug...

Page 190: Valves and Valve Springs

Valves and valve springs 5-16 eas24270 valves and valve springs removing the valves and valve springs order job/parts to remove q’ty remarks engine refer to “engine removal” on page 5-2. Cylinder head, camshaft refer to “cylinder head” on page 5-6. 1 valve cotter 4 2 valve spring retainer 2 3 valve ...

Page 191: Valves and Valve Springs

Valves and valve springs 5-17 eas24280 removing the valves the following procedure applies to all of the valves and related components. Tip before removing the internal parts of the cylinder head (e.G., valves, valve springs, valve seats), make sure the valves properly seal. 1. Check: • valve sealin...

Page 192: Valves and Valve Springs

Valves and valve springs 5-18 2. Replace: • valve guide tip to ease valve guide removal and installation, and to maintain the correct fit, heat the cylinder head to 100 c (212 f) in an oven. ▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼ a. Remove the valve guide with the valve guide remover “1”. B. Install the...

Page 193: Valves and Valve Springs

Valves and valve springs 5-19 eas24300 checking the valve seats the following procedure applies to all of the valves and valve seats. 1. Eliminate: • carbon deposits (from the valve face and valve seat) 2. Check: • valve seat pitting/wear replace the cylinder head. 3. Measure: • valve seat width “...

Page 194: Valves and Valve Springs

Valves and valve springs 5-20 tip for the best lapping results, lightly tap the valve seat while rotating the valve back and forth be- tween your hands. E. Apply a fine lapping compound to the valve face and repeat the above steps. F. After every lapping procedure, be sure to clean off all of the la...

Page 195: Valves and Valve Springs

Valves and valve springs 5-21 3. Measure: • valve spring tilt “a” out of specification replace the valve spring. Eas24340 installing the valves the following procedure applies to all of the valves and related components. 1. Deburr: • valve stem end (with an oil stone) 2. Lubricate: • valve stem “1...

Page 196: Valves and Valve Springs

Valves and valve springs 5-22 4. Install: • valve cotter “1” tip install the valve cotters by compressing the valve spring with the valve spring compressor “2”. 5. To secure the valve cotters onto the valve stem, lightly tap the valve tip with a soft-face hammer. Notice eca13800 hitting the valve ti...

Page 197: Cylinder and Piston

Cylinder and piston 5-23 eas24350 cylinder and piston removing the cylinder and piston order job/parts to remove q’ty remarks engine refer to “engine removal” on page 5-2. Cylinder head refer to “cylinder head” on page 5-6. 1 timing chain guide (intake side) 1 2 cylinder/o-ring 1/1 3 dowel pin 2 4 c...

Page 198: Cylinder and Piston

Cylinder and piston 5-24 eas24380 removing the piston 1. Remove: • piston pin clip “1” • piston pin “2” • piston “3” notice eca13810 do not use a hammer to drive the piston pin out. Tip • before removing the piston pin clip, cover the crankcase opening with a clean rag to prevent the piston pin clip...

Page 199: Cylinder and Piston

Cylinder and piston 5-25 b. If out of specification, rebore or replace the cylinder, and replace the piston and piston rings as a set. C. Measure piston skirt diameter “d” “a” with a micrometer. D. If out of specification, replace the piston and piston rings as a set. E. Calculate the piston-to-cyli...

Page 200: Cylinder and Piston

Cylinder and piston 5-26 3. Measure: • piston ring end gap out of specification replace the piston ring. Tip the oil ring expander spacer’s end gap cannot be measured. If the oil ring rail’s gap is exces- sive, replace all three piston rings. Eas24440 checking the piston pin 1. Check: • piston pin...

Page 201: Cylinder and Piston

Cylinder and piston 5-27 • 2nd ring “4” • top ring “5” tip be sure to install the 2nd ring so that the manu- facturer’s mark “n” faces up. 2. Install: • piston “1” • piston pin “2” • piston pin clip “3” tip • apply engine oil the piston pin. • make sure that the arrow mark “a” on the piston points t...

Page 202: Clutch

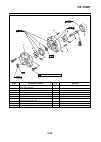

Clutch 5-28 eas25061 clutch removing the kick crank and right crankcase cover order job/parts to remove q’ty remarks engine oil drain. Refer to “changing the engine oil” on page 3-22. Front right footrest refer to “engine removal” on page 5-2. 1 oil filter cover 1 2 oil filter element 1 3 kick crank...

Page 203: Clutch

Clutch 5-29 removing the clutch assembly order job/parts to remove q’ty remarks crankcase cover (right) 1 nut 1 2 conical washer 1 3 holder 1 4 primary drive gear 1 5 straight key 1 6 clutch spring 6 7 pressure plate 1 8 push rod 2 1 9 friction plate 8 10 clutch plate 7 11 nut/belleville washer 1/1 ...

Page 204: Clutch

Clutch 5-30 removing the push lever shaft order job/parts to remove q’ty remarks drive sprocket cover clutch cable clutch assembly 1 locknut/gasket 1/1 2 adjuster 1 3 push lever shaft 1 4 torsion spring 1 5 washer 1 6 oil seal 1 1 2 3 4 5 6 18 nm (1.8 m • kgf, 13 ft • ibf) e.

Page 205: Clutch

Clutch 5-31 eas25070 removing the clutch 1. Loosen: • primary drive gear nut “1” tip insert aluminum plate “a” between the primary drive gear “2” and clutch housing “3”, and loosen the primary drive gear nut. 2. Remove: • pressure plate “1” tip remove the clutch spring by loosening the clutch spring...

Page 206: Clutch

Clutch 5-32 eas25140 checking the clutch springs the following procedure applies to all of the clutch springs. 1. Check: • clutch spring damage replace the clutch springs as a set. 2. Measure: • clutch spring free length “a” out of specification replace the clutch springs as a set. Eas25150 chec...

Page 207: Clutch

Clutch 5-33 2. Measure: • push rod 1 bending limit out of specification replace. Eas25200 checking the primary drive gear 1. Check: • primary drive gear damage/wear replace the primary drive gear and primary driven gear (clutch housing) as a set. Excessive noise during operation replace the pr...

Page 208: Clutch

Clutch 5-34 4. Lubricate: • friction plate • clutch plate (with the recommended lubricant) 5. Install: • friction plate • clutch plate tip first, install a friction plate and then alternate be- tween a clutch plate and a friction plate. 6. Install: • bearing • oil seal • washer • torsion spring “1” ...

Page 209: Clutch

Clutch 5-35 ▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲ 10.Adjust: • clutch lever free play refer to “adjusting the clutch lever free play” on page 3-10. 11.Install: • drive sprocket cover 12.Install: • dowel pin • crankcase cover gasket • crankcase cover (right) drive sprocket cover bolt 10 nm (1.0 m·kgf, 7.2...

Page 210: Kickstarter

Kickstarter 5-36 eas24820 kickstarter removing the kickstarter order job/parts to remove q’ty remarks crankcase cover (right) refer to “clutch” on page 5-28. Clutch refer to “clutch” on page 5-28. 1 kick pinion gear 1 2 circlip/washer 1/1 3 kick idle gear 1 4 kickstarter assembly 1 5 washer 1 6 wash...

Page 211: Kickstarter

Kickstarter 5-37 disassembling the kickstarter order job/parts to remove q’ty remarks 1 circlip/spring cover 1/1 2 compression spring 1 3 ratchet wheel 1 4 circlip/spacer 1/1 5 torsion spring 1 6 spring cover 1 7 circlip/washer 1/1 8 kick gear 1 9 washer 1 10 circlip 1 11 kick axle assembly 1 m e 1 ...

Page 212: Kickstarter

Kickstarter 5-38 eas24850 checking the kickstarter 1. Check: • kick pinion gear “1” • kick idle gear “2” damage/wear replace. 2. Check: • torsion spring “1” compression spring “2” damage/wear replace. Eas24880 installing the kickstarter 1. Install: • ratchet wheel “1” • compression spring “2” • ...

Page 213: Oil Pump

Oil pump 5-39 eas24911 oil pump removing the oil pump order job/parts to remove q’ty remarks crankcase cover (right) refer to “clutch” on page 5-28. Clutch refer to “clutch” on page 5-28. 1 oil pump drive gear 1 2 circlip 1 3 plate washer 1 4 oil pump driven gear 1 5 washer 1 6 oil pump assembly 1 7...

Page 214: Oil Pump

Oil pump 5-40 disassembling the oil pump order job/parts to remove q’ty remarks 1 oil pump cover 1 2 feed side outer rotor 1 3 feed side inner rotor 1 4 dowel pin 1 5 scavenger side outer rotor 1 6 pump shaft 1 7 dowel pin 1 8 scavenger side inner rotor 1 9 dowel pin 2 10 oil pump housing 1 e 1 2 3 ...

Page 215: Oil Pump

Oil pump 5-41 eas24940 removing the oil pump 1. Drain: • engine oil (completely from the crankcase and oil tank) refer to “changing the engine oil” on page 3-22. 2. Remove: • clutch assembly refer to “clutch” on page 5-28. 3. Remove: • oil pump drive gear “1” • oil pump driven gear “2” • oil pump as...

Page 216: Oil Pump

Oil pump 5-42 • oil pump shaft (with the recommended lubricant) 2. Install: • oil pump housing “1” • oil seal “2” • feed side outer rotor “3” • oil pump shaft “4” • scavenger side inner rotor “5” • feed side inner rotor “6” • scavenger side outer rotor “7” • oil pump cover “8” tip align the groove i...

Page 217: Shift Shaft

Shift shaft 5-43 eas25410 shift shaft removing the shift shaft and stopper lever order job/parts to remove q’ty remarks clutch refer to “clutch” on page 5-28. 1 circlip 1 2 stopper lever assembly 1 3 circlip 1 4 washer 1 5 shift shaft assembly 1 6 torsion spring 1 8 nm (0.8 m • kgf, 5.8 ft • ibf) 1 ...

Page 218: Shift Shaft

Shift shaft 5-44 eas2rd1014 removing the shift shaft 1. Remove: • circlip “1” • stopper lever assembly “2” • circlip (left side of the crankcase) • shift shaft assembly tip remove the shift lever “a” by pressing down. Eas25420 checking the shift shaft 1. Check: • shift shaft “1” bends/damage/wear ...

Page 219: Shift Shaft

Shift shaft 5-45 4. Check: • shift lever 3 match mark “a” shift the gear into 2nd and check for align- ment with the match mark “b” in the shift drum. Not aligned adjust. Tip loosen the locknut “1” and adjust with the ad- juster “2”. 1 2 a 1 2 b a.

Page 220: Generator

Generator 5-46 eas24480 generator removing the stator coil assembly order job/parts to remove q’ty remarks drive sprocket cover refer to “engine removal” on page 5-2. 1 crankcase cover (left) 1 2 gasket 1 3 ac magneto 1 4 holder 1 5 oil pipe 1 remove only the upper bolt. 6 rectifier/regulator couple...

Page 221: Generator

Generator 5-47 eas24490 removing the generator 1. Remove: • ac magneto nut “1” • washer tip while holding the ac magneto with the rotor holding tool “2”, loosen the nut. 2. Remove: • ac magneto “1” (with the flywheel puller “2”.) • woodruff key tip make sure the flywheel puller is centered over the ...

Page 222: Crankcase

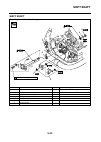

Crankcase 5-48 eas25540 crankcase separating the crankcase order job/parts to remove q’ty remarks engine refer to “engine removal” on page 5-2. Cylinder head refer to “cylinder head” on page 5-6. Cylinder, piston refer to “cylinder and piston” on page 5-23. Clutch refer to “clutch” on page 5-28. Kic...

Page 223: Crankcase

Crankcase 5-49 disassembling the crankcase order job/parts to remove q’ty remarks 10 bearing 1 10 10 nm (1.0 m • kgf, 7.2 ft • ibf) 12 nm (1.2 m • kgf, 8.7 ft • ibf) 12 nm (1.2 m • kgf, 8.7 ft • ibf) 30 nm (3.0 m • kgf, 22 ft • ibf) 7 nm (0.7 m • kgf, 5.1 ft • ibf) lt 7 nm (0.7 m • kgf, 5.1 ft • ibf...

Page 224: Crankcase

Crankcase 5-50 eas25570 disassembling the crankcase 1. Remove: • timing chain • oil strainer cover • oil strainer 2. Remove: • crankcase bolt • stay “1” tip loosen each bolt 1/4 of a turn at a time, in stag- es and in a crisscross pattern. After all of the bolts are fully loosened, remove them. 3. R...

Page 225: Crankcase

Crankcase 5-51 3. Install: • dowel pin 4. Install: • crankcase bolt • stay “1” tip tighten the bolts in stages and in a crisscross pattern. 5. Install: • oil strainer • oil strainer cover • timing chain crankcase bolt 12 nm (1.2 m·kgf, 8.7 ft·lbf) t r . . 1.

Page 226: Crankshaft Assembly

Crankshaft assembly 5-52 eas25970 crankshaft assembly removing the crankshaft assembly order job/parts to remove q’ty remarks separate the crankcase. Refer to “crankcase” on page 5-48. 1 crankshaft assembly 1 2 oil seal 1 3 bearing 1 e e e 1 2 3.

Page 227: Crankshaft Assembly

Crankshaft assembly 5-53 eas26000 removing the crankshaft assembly 1. Remove: • crankshaft assembly “1” notice eca2rd1005 do not tap the crankshaft directly with a hammer, etc. Tip • remove the crankshaft assembly with the crankcase separating tool “2”. • install the crankcase separating tool to the...

Page 228: Crankshaft Assembly

Crankshaft assembly 5-54 eas26210 installing the crankshaft assembly 1. Install: • crankshaft assembly “1” tip install the crankshaft assembly with the crank- shaft installer pot “2”, crankshaft installer bolt “3”, adapter (m12) “4”, and spacer “5”. 2. Install: • crankshaft assembly notice eca13970 ...

Page 229: Transmission

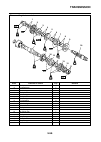

Transmission 5-55 eas26241 transmission removing the transmission, shift drum assembly, and shift forks order job/parts to remove q’ty remarks separate the crankcase. Refer to “crankcase” on page 5-48. 1 stopper cam assembly 1 2 shift fork guide bar 1 1 3 shift fork guide bar 2 1 4 shift drum assemb...

Page 230: Transmission

Transmission 5-56 disassembling the transmission order job/parts to remove q’ty remarks 1 circlip/washer 1/1 2 1st wheel gear 1 3 4th wheel gear 1 4 circlip/washer 1/1 5 3rd wheel gear 1 6 circlip/washer 1/1 7 5th wheel gear 1 8 circlip/washer 1/1 9 2nd wheel gear 1 10 drive axle 1 11 circlip/washer...

Page 231: Transmission

Transmission 5-57 eas26250 removing the transmission 1. Remove: • stopper cam assembly 2. Remove: • drive axle assembly “1” • main axle assembly “2” tip remove the drive axle assembly and the main axle assembly simultaneously. Eas26260 checking the shift forks the following procedure applies to all ...

Page 232: Transmission

Transmission 5-58 eas26300 checking the transmission 1. Measure: • main axle runout (with a centering device and dial gauge “1”) out of specification replace the main axle. 2. Measure: • drive axle runout (with a centering device and dial gauge “1”) out of specification replace the drive axle. 3...

Page 233: Transmission

Transmission 5-59 eas26320 installing the shift forks and shift drum assembly 1. Install: • shift drum “1” • shift fork 1 (c) “2” • shift fork 3 (l) “3” • shift fork 2 (r) “4” • shift fork guide bar 1 “5” • shift fork guide bar 2 “6” • drive axle assembly “7” • main axle assembly “8” 2. Install: • s...

Page 234: Transmission

Transmission 5-60

Page 235: Fuel System

1 2 3 4 5 6 7 8 9 fuel system fuel tank......................................................................................................6-1 removing the fuel tank ...................................................................6-4 removing the fuel pump case ....................................

Page 236: Fuel Tank

Fuel tank 6-1 eas26620 fuel tank removing the fuel tank breather hose and rollover valve order job/parts to remove q’ty remarks engine protector refer to “engine removal” on page 5-2. 1 clamp 1 1 2 rollover valve clamp 1 3 clamp 2 1 4 plastic locking tie 1 5 fuel tank breather hose 1 1 6 rollover va...

Page 237: Fuel Tank

Fuel tank 6-2 removing the fuel tank order job/parts to remove q’ty remarks seat refer to “general chassis” on page 4-1. Side cover (left) refer to “general chassis” on page 4-1. Turn the fuel cock to “off”. 1 fuel hose (fuel tank–fuel pump case) 1 disconnect the connection at the fuel cock side. 2 ...

Page 238: Fuel Tank

Fuel tank 6-3 removing the fuel pump case order job/parts to remove q’ty remarks side cover (left) refer to “general chassis” on page 4-1. Turn the fuel cock to “off”. 1 fuel hose (fuel tank–fuel pump case) 1 disconnect the connection at the fuel cock side. 2 holder 1 3 pump case breather hose (fuel...

Page 239: Fuel Tank

Fuel tank 6-4 eas26630 removing the fuel tank warning ewa2rd1010 gasoline is very flammable and dangerous. While handling gasoline, keep it away from an open flame as well as a spark or any other source of high heat. Tip before removing the fuel hose, blow away any dirt accumulated around the hose w...

Page 240: Fuel Tank

Fuel tank 6-5 i. Remove the clamp “1” and disconnect the fuel sender coupler “2”. J. Remove the fuel tank bolt “1”. K. Disconnect the fuel hose (pressure regula- tor–fuel tank) “1” at the fuel tank side. L. Remove the fuel tank. Tip be sure to place the fuel tank horizontally. Place the fuel tank so...

Page 241: Fuel Tank

Fuel tank 6-6 tip • repeating main switch turning “on” and turn- ing “off” allows the fuel in the fuel pump case to be sent to the fuel tank. • even after this operation, a small amount of fuel remains in the fuel pump case. C. Start the engine with the fuel cock in the “off” position and keep idlin...

Page 242: Fuel Tank

Fuel tank 6-7 eas2rd1018 checking the rollover valve 1. Check: • rollover valve cracks/damage replace. Tip • check that air flows smoothly only in the direc- tion of the arrow shown in the illustration. • the rollover valve must be in an upright posi- tion when checking the airflow. Eas26670 check...

Page 243: Fuel Tank

Fuel tank 6-8 3. Install: • side cover (left) • seat refer to “general chassis” on page 4-1. Eas2rd1035 installing the fuel pump case 1. Install: • fuel hose • fuel pump coupler • fuel pump case notice eca2rd1013 • when installing the fuel hose, make sure that it is securely connected, and that the ...

Page 244: Throttle Body

Throttle body 6-9 eas26970 throttle body removing the throttle body order job/parts to remove q’ty remarks seat refer to “general chassis” on page 4-1. Side cover (left) refer to “general chassis” on page 4-1. Fuel tank refer to “fuel tank” on page 6-1. 1 throttle cable 2 2 fuel hose (fuel pump–fuel...

Page 245: Throttle Body

Throttle body 6-10 removing the throttle body order job/parts to remove q’ty remarks 12 cover 1 13 fuel hose (pressure regulator–fuel tank) 1 2.0 nm (0.20 m • kgf, 1.5 ft • ibf) 12 13 10 nm (1.0 m • kgf, 7.2 ft • ibf) 3.0 nm (0.30 m • kgf, 2.2 ft • ibf).

Page 246: Throttle Body

Throttle body 6-11 disassembling the throttle body order job/parts to remove q’ty remarks 1 fuel rail/pressure regulator assembly 1 2 fuel injector 1 3 intake air pressure sensor 1 4 hose 1 5 throttle position sensor 1 1 2 3 4 5 3.5 nm (0.35 m • kgf, 2.5 ft • ibf) 3.5 nm (0.35 m • kgf, 2.5 ft • ibf).

Page 247: Throttle Body

Throttle body 6-12 eas26980 checking the injector 1. Check: • injector damage replace. 2. Check: • injector resistance refer to “checking the fuel injec- tor” on page 7-72. Eas27000 checking the pressure regulator 1. Check: • pressure regulator damage replace. Eas27010 checking the pressure regu...

Page 248: Throttle Body

Throttle body 6-13 special care. • never subject the throttle position sensor to strong shocks. If the throttle position sensor is dropped, replace it. 1. Check: • throttle position sensor refer to “checking the throttle po- sition sensor” on page 7-70. 2. Adjust: • throttle position sensor angle ▼▼...

Page 249: Throttle Body

Throttle body 6-14.

Page 250: Air Induction System

Air induction system 6-15 eas27040 air induction system 1 2 3 4 5 1 2 3 4 5.

Page 251: Air Induction System

Air induction system 6-16 1. Air filter case 2. Air induction system hose (air filter case–air cut-off valve) 3. Air cut-off valve 4. Air induction system hose (air cut-off valve–air induction system pipe) 5. Air induction system pipe.

Page 252: Air Induction System

Air induction system 6-17 removing the air cut-off valve assembly order job/parts to remove q’ty remarks 1 air induction system solenoid coupler 1 disconnect. 2 air induction system hose (air filter case–air cut-off valve) 1 remove from the air filter case side 3 air cut-off valve 1 4 air induction ...

Page 253: Air Induction System

Air induction system 6-18 eas27060 checking the air induction system air injection the air induction system burns unburned ex- haust gases by injecting fresh air (secondary air) into the exhaust port, reducing the emission of hydrocarbons. When there is negative pressure at the exhaust port, the ree...

Page 254: Air Induction System

Air induction system 6-19.

Page 255: Electrical System

1 2 3 4 5 6 7 8 9 electrical system ignition system ..........................................................................................7-1 circuit diagram ...................................................................................7-1 engine stopping due to sidestand operation............

Page 256

Checking the speed sensor .........................................................7-70 checking the throttle position sensor ................................7-70 checking the air induction system solenoid .......................7-71 checking the intake air pressure sensor .............................

Page 258: Ignition System

Ignition system 7-1 eas27090 ignition system eas27100 circuit diagram 21w 5w 60w 55w 30a 7.5a 7.5a 10a 15a ru n off on off n l r on off hi lo j10 j09 j19 j18 1.7w 1.7w 1.7w 1.7w 1.7w 1.7w 1.7w j04 j17 4w 21w 21w 21w 21w j06 j05 j03 7.5a j08 on p off lock j16 j01 15a j14 j13 j02 off on j07 h20 h21 r1...

Page 259: Ignition System

Ignition system 7-2 1. Crankshaft position sensor 2. Neutral switch 5. Battery 6. Main fuse 7. Main switch 10.Ignition fuse 14.Right handlebar switch 16.Engine stop switch 19.Sidestand switch 20.Clutch switch 21.Diode 1 24.Ecu (engine control unit) 25.Ignition coil 26.Spark plug 30.Lean angle sensor...

Page 260: Ignition System

Ignition system 7-3 eas32020 engine stopping due to sidestand operation when the engine is running and the transmission is in gear, the engine will stop if the sidestand is moved down. This is because the electric current from the ecu does not flow to the ignition coil or in- jector when the neutral...

Page 261: Ignition System

Ignition system 7-4 1. Battery 2. Main fuse 3. Main switch 4. Ignition fuse 5. Engine stop switch 6. Ignition coil 7. Spark plug 8. Ecu (engine control unit) 9. Sidestand switch 10.Diode 1 11.Neutral switch 12.Negative battery lead 13.Frame ground.

Page 262: Ignition System

Ignition system 7-5 eas27131 troubleshooting the ignition system fails to operate (no spark or intermittent spark). Tip • before troubleshooting, remove the following part(s): 1. Seat 2. Side cover (left) 3. Fuel tank 4. Crankcase cover (left) 5. Drive sprocket cover 1. Check the fuses. (main and ig...

Page 263: Ignition System

Ignition system 7-6 9. Check the engine stop switch. Refer to “checking the switches” on page 7-55. Ng replace the right handlebar switch. Ok 10.Check the neutral switch. Refer to “checking the switches” on page 7-55. Ng replace the neutral switch. Ok 11.Check the sidestand switch. Refer to “che...

Page 264: Charging System