- DL manuals

- Yamaha

- Network Card

- SRCP

- User Manual

Yamaha SRCP User Manual

Summary of SRCP

Page 1

User’s manual english e yamaha single-axis robot controller e84-ver. 2.04 srcp.

Page 3: General Contents

I general contents chapter 1 overview ........................................................................................................... 1-1 1-1 features of the srcp series controller ................................................................................... 1-2 1-2 setting up for ...

Page 4

Ii chapter 4 basic operation of the tpb ......................................................................... 4-1 4-1 connecting and disconnecting the tpb ................................................................................. 4-2 4-1-1 connecting the tpb to the srcp controller ..........

Page 5: III

Iii 8-4 robot language description .................................................................................................. 8-6 8-4-1 mova ..........................................................................................................................................................

Page 6

Iv 10-6 using a memory card ........................................................................................................ 10-14 10-6-1 saving controller data to a memory card ................................................................................................... 10-14 10-6-2 l...

Page 7

V chapter 15 specifications ............................................................................................... 15-1 15-1 srcp sereis ..........................................................................................................................15-2 15-1-1 basic specifications...

Page 8: Memo

Vi memo.

Page 9: Chapter 1

1- 1 1 over view chapter 1 overview thank you for purchasing the yamaha single-axis robot controller srcp series (hereafter called "srcp control- ler" or simply "srcp" or "this controller"). This manual describes srcp controller features and operating proce- dures. When used with a yamaha single-axi...

Page 10: 1-1

1- 2 1 over view 1-1 features of the srcp series controller 1-1 features of the srcp series controller the srcp series is a high-performance robot controller using a 32-bit risc chip cpu. When used with a yamaha single-axis phaser series robot, the srcp controller performs posi- tioning tasks of var...

Page 11: 1-2

1- 3 1 over view 1-2 setting up for operation 1-2 setting up for operation the chart below illustrates the basic steps to follow from the time of purchase of this controller until it is ready for use. The chapters of this user's manual are organized according to the operation proce- dures, and allow...

Page 12: 1-3

1- 4 1 over view 1-3 external view and part names 1-3 external view and part names this section explains part names of the srcp controller and tpb along with their functions. Note that the external view and specifications are subject to change without prior notice to the user. 1-3-1 srcp controller ...

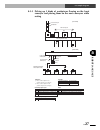

Page 13

1- 5 1 over view 1-3 external view and part names fig. 1-1 exterior of the srcp controller srcp-05 srcp-10, 20 srcp-05a, 10a, 20a 1 2 3 8 9 10 4 5 6 7 1 2 3 8 10 4 5 6 7 11 1 2 3 8 9 10 4 5 6 7 11 11.

Page 14

1- 6 1 over view 1-3 external view and part names fig. 1-2 three-side view of the srcp controller com l n t1 t2 acin1 (pwr) n p u v w pwr (g) esc tpb rob i/o i/o rgen motor err (r) nc nc srcp model. Ser. No. Factory automation equipment made in japan emg 24v 24g srcp 10 dont connect • 200-230v~ 50-6...

Page 15

1- 7 1 over view 1-3 external view and part names 1-3-2 tpb 1. Liquid crystal display (lcd) screen this display has four lines of twenty characters each and is used as a program console. 2. Memory card slot an ic memory card can be inserted here. Be careful not to insert the card upside-down. 3. Con...

Page 16: 1-4

1- 8 1 over view 1-4 system configuration 1-4 system configuration 1-4-1 system configuration the srcp controller can be combined with various peripheral units and optional products to configure a robot system as shown below. * programming box tpb and support software popcom are sold separately. Src...

Page 17: 1-5

1- 9 1 over view 1-5 accessories and options 1-5-1 accessories the srcp robot controller comes with the following accessories. After unpacking, check that all items are included. 1. Ext. Cn connector connector : 733-104 made by wago 1 piece 2. I/o. Cn connector with flat cable (option) connector : x...

Page 18: Memo

1- 10 memo.

Page 19: Chapter 2

2- 1 2 inst alla tion and connection chapter 2 installation and connection this chapter contains precautions that should be observed when installing the controller, as well as procedures and precautions for wiring the controller to the robot and to external equipment..

Page 20: 2-1

2- 2 2 inst alla tion and connection 2-1 installing the srcp controller 2-1 installing the srcp controller 2-1-1 installation method using the l-shaped brackets attached to the top and bottom of the controller, install the controller from the front or rear position. (see fig.1-2 three-side view of t...

Page 21: 2-2

2- 3 2 inst alla tion and connection 2-2 connecting the power supply 2-2 connecting the power supply 2-2-1 power supply no. Of phases single-phase type and item srcp-05 srcp-10 srcp-20 frequency 50/60hz max. Power consumption 400va or less power supply voltage ac200 to 230v ±10% single-phase 50/60hz...

Page 22

2- 4 2 inst alla tion and connection 2-2 connecting the power supply c caution the srcp series controller does not have a power switch. Be sure to provide a power supply breaker (insulation) of the correct specifications that will turn the power on or off to the entire system including the robot con...

Page 23: 2-3

2- 5 2 inst alla tion and connection 2-2 connecting the power supply 2-2-5 installing current control switches when controlling the power on/off of the robot controller from an external device such as a plc, a current control switch (contactor, breaker, etc.) may be used. In this case, the current c...

Page 24: 2-5

2- 6 2 inst alla tion and connection 2-5 connecting to the robot 2-5 connecting to the robot first make sure that the power to the srcp controller is turned off, and then connect the robot cable to the robot i/o connector and motor connector on the front panel of the srcp controller. Fully insert th...

Page 25: 2-6

2- 7 2 inst alla tion and connection 2-6 connecting to the i/o. Cn connector 2-6 connecting to the i/o. Cn connector the i/o. Cn connector is used for connecting the srcp controller to external equipment such as a plc. When using external equipment for i/o control, connect the wiring to the i/o. Cn ...

Page 26: 2-7

2- 8 2 inst alla tion and connection 2-7 connecting to the ext. Cn connector connect an emergency stop circuit and a 24v power supply for i/o control to the ext. Cn connec- tor. Make the necessary wiring hookup (see below) to the mating connector that comes with the srcp controller and then plug it ...

Page 27: 2-8

2- 9 2 inst alla tion and connection 2-8 connecting to the regenerative unit 2-8 connecting to the regenerative unit some types of robots must be connected to a regenerative unit. In such cases, use the interconnection cable to connect the srcp controller to the regenerative unit. Fig. 2-3 connectin...

Page 28: Memo

2- 10 memo.

Page 29: Chapter 3

3- 1 3 i/o interf ace chapter 3 i/o interface the srcp series has i/o interface connectors (ext. Cn and i/o. Cn) as a standard feature. The ext. Cn is used for emergency stop input and 24v power input for i/o control. The i/o. Cn consists of an interlock input, 7 dedicated command inputs, 3 dedicate...

Page 30: 3-1

3- 2 3 i/o interf ace 3-1 i/o signals 3-1 i/o signals the srcp controller has two i/o interface connectors (ext. Cn and i/o. Cn) as a standard feature. The ext. Cn is used for emergency stop input and 24v power input for i/o control. The i/o. Cn is used for interlock signal input, dedicated command ...

Page 31: 3-2

3- 3 3 i/o interf ace 3-2 input signal description 3-2 input signal description input signals consist of 7 dedicated command inputs, 8 general-purpose inputs and interlock signals fed to the i/o. Cn terminal, as well as an emergency stop input fed to the ext. Cn terminal. * di7 functions as the serv...

Page 32

3- 4 3 i/o interf ace 3-2 input signal description ■ absolute point movement command (abs-pt) this command moves the robot to an absolute position specified by a point number at a specified speed along an axis coordinate whose origin is defined as 0. The point number and speed are specified by gener...

Page 33

3- 5 3 i/o interf ace 3-2 input signal description ■ return-to-origin command (org-s) this command returns the robot to its origin position by using stroke-end detection as the origin detection method. N note the magnetic pole is detected simultaneously with return-to-origin operation. Return-to-ori...

Page 34

3- 6 3 i/o interf ace 3-2 input signal description 3-2-2 general-purpose input (di0 to di7) these general-purpose inputs are available to users for handling data input in a program. These inputs are usually connected to sensors or switches. These inputs can also be directly con- nected to a plc outp...

Page 35

3- 7 3 i/o interf ace 3-2 input signal description 3-2-3 service mode input (svce) when the service mode function is enabled, di7 functions as the service mode input (svce). The service mode input is used to notify the srcp controller whether the current state is a "serv- ice mode state". This input...

Page 36: 3-3

3- 8 3 i/o interf ace 3-3 output signal description 3-3 output signal description the output signals consist of 3 dedicated outputs (ready, busy and end), 5 general-purpose outputs, and feedback pulse outputs. In this section, terms "on" and "off" mean the output transis- tors are "on" and "off". 3-...

Page 37

3- 9 3 i/o interf ace 3-3 output signal description 3-3-2 general-purpose output (do0 to do4) these general-purpose outputs are available to users for freely controlling on/off operation in a pro- gram. These outputs are used in combination with an external 24v power supply, to drive loads such as s...

Page 38: 3-4

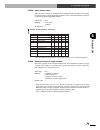

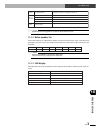

3- 10 3 i/o interf ace 3-4 i/o circuits 3-4 i/o circuits this section provides the srcp controller i/o circuit specifications and examples of how the i/o circuits should be connected. Refer to these specifications and diagrams when connecting to external equipment such as a plc. 3-4-1 i/o circuit sp...

Page 39

3- 11 3 i/o interf ace 3-4 i/o circuits 3-4-2 i/o circuit and connection example i/o circuit and connection example external dc24v power supply push-button npn transistor incandescent lamp solenoid valve input signal photocoupler output signal controller side di do do di 24v 24g fg + - pulse output ...

Page 40: 3-5

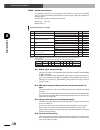

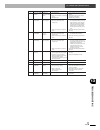

3- 12 3 i/o interf ace 3-5 i/o connection diagram 3-5 i/o connection diagram 3-5-1 connection to plc output unit connection to the mitsubishi © plc ay51 output unit ay51 type output unit srcp series controller external dc 24v power supply + - y00 y01 y02 y03 y04 y05 y06 y07 y08 y09 y0a y0b y0c y0d y...

Page 41

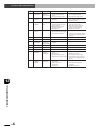

3- 13 3 i/o interf ace 3-5 i/o connection diagram 3-5-2 connection to plc input unit connection to the mitsubishi © plc ax41 input unit ax41 type input unit srcp series controller external dc 24v power supply photocoupler internal circuit x01 x00 x02 x03 x04 x05 x06 x07 dc24v x08 x09 x0a x0b x0c x0d...

Page 42: 3-6

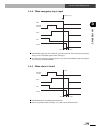

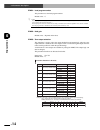

3- 14 3 i/o interf ace 3-6 i/o control timing charts 3-6 i/o control timing charts the following shows typical timing charts for i/o control. Refer to these diagrams when creating a sequence program. 3-6-1 when turning the power on when emergency stop is triggered: ac power supply ready end 300ms or...

Page 43

3- 15 3 i/o interf ace 3-6 i/o control timing charts 3-6-2 when executing a dedicated input command ■ the busy signal turns on when a dedicated command is received. Whether the received com- mand has ended normally can be checked with the end signal status at the point that the busy signal turns off...

Page 44

3- 16 3 i/o interf ace (2)when a command with a short execution time runs and ends normally: (command execution has already ended and the end signal is on before turning off (contact open) the dedicated command input, as in the examples listed below.) • a movement command (abs-pt, inc-pt) for a very...

Page 45

3- 17 3 i/o interf ace (3)when a command cannot be executed from the beginning: (command execution is impossible from the beginning and the end signal does not turn on, as in the examples listed below.) • a movement command (abs-pt, inc-pt) was executed without return-to-origin being com- pleted. • ...

Page 46

3- 18 3 i/o interf ace (4)when command execution cannot be completed: (command execution stops before completion and the end signal does not turn on, as in the examples listed below.) • an interlock or emergency stop was triggered during execution of a dedicated command. • the service mode input was...

Page 47

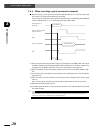

3- 19 3 i/o interf ace 3-6-4 when emergency stop is input ready end busy emg emergency stop 5ms or less 1ms or less dedicated command ■ the ready signal turns off. The busy signal also turns off while a dedicated command is being executed. The end signal remains unchanged. ■ to enable robot operatio...

Page 48

3- 20 3 i/o interf ace 3-6-6 when executing a point movement command ■ when executing a point movement command (abs-pt, inc-pt), the point data and speed data must first be input before inputting the command. The point data and speed data can be specified with di0 to di7 (or di0 to di6 when service ...

Page 49: Chapter 4

4- 1 4 basic opera tion of the tpb chapter 4 basic operation of the tpb the tpb is a hand-held, pendant-type programming box that connects to the srcp controller to edit or run pro- grams for robot operation. The tpb allows interactive user operation on the display screen so that even first-time use...

Page 50: 4-1

4- 2 4 basic opera tion of the tpb 4-1 connecting and disconnecting the tpb 4-1 connecting and disconnecting the tpb 4-1-1 connecting the tpb to the srcp controller c caution do not modify the tpb cable or use any type of relay unit for connecting the tpb to the srcp controller. Doing so might cause...

Page 51

4- 3 4 basic opera tion of the tpb 4-1 connecting and disconnecting the tpb 4-1-2 disconnecting the tpb from the srcp controller to disconnect the tpb from the controller while a program or an i/o dedicated command is being executed, pull out the tpb while holding down the esc switch on the front pa...

Page 52: 4-2

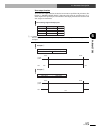

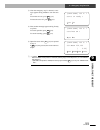

4- 4 4 basic opera tion of the tpb 4-2 basic key operation 4-2 basic key operation 1) selectable menu items are displayed on the 4th line (bottom line) of the tpb screen. Example a is the initial screen that allows you to select the following modes. ↓ ↑ a d c e f2 f2 f3 esc esc esc ↓ ↑ ↑ ↓ [menu] se...

Page 53: 4-3

4- 5 4 basic opera tion of the tpb 4-3 reading the screen 4-3 reading the screen the following explains the basic screen displays and what they mean. 4-3-1 program execution screen the display method slightly differs depending on the version of tpb. [oprt-step] 100 0:31 062:mova 200,100 [ 0.00] 1spd...

Page 54

4- 6 4 basic opera tion of the tpb 4-3-3 point edit screen (teaching playback) [edit-pnt-tch](1)100 p255 = 123.45 [mm] [ 0.00] 1chg 2spd 3s_set4next 5 1 2 3 4 1. Current mode 2. Speed selection number 3. Speed parameter (%) 4. Edit point number 5. Current position 4-3-4 dio monitor screen 1 2 3 4 di...

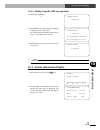

Page 55: 4-4

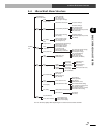

4- 7 4 basic opera tion of the tpb 4-4 hierarchical menu structure power on mod (step edit) ins (step insert) del (step delete) chg (program change) mdi (manual data input) tch (teaching playback) dtch (direct teaching) del (delete) copy (program copy) del (program delete) list (program list) spd (e...

Page 56: 4-5

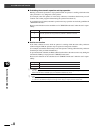

4- 8 4 basic opera tion of the tpb 4-5 restricting key operation by access level 4-5 restricting key operation by access level the tpb key operations can be limited by setting the access levels (operation levels). A person not trained in robot operation might accidentally damage the robot system or ...

Page 57

4- 9 4 basic opera tion of the tpb 4-5 restricting key operation by access level memory card level 0 1 2 3 description all operations are permitted. Loading the parameters and all data to the srcp is prohibited. (point data or program data can be loaded.) loading any data to the srcp is prohibited. ...

Page 58

4- 10 4 basic opera tion of the tpb 4-5 restricting key operation by access level 5) select the item you want to change. To change the access level for editing, press f1 (edit). To change the access level for operation, press f2 (oprt). To change the access level for system-related data, press f3 (s...

Page 59: Chapter 5

5- 1 5 parameters chapter 5 parameters the srcp controller uses a software servo system, so no adjustment of hardware components such as potentiometers or dip switches are required. Instead, the srcp controller uses parameters that can be easily set or changed by the tpb or pc (personal computer). T...

Page 60: 5-1

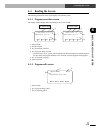

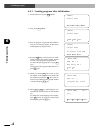

5- 2 5 parameters 5-1 setting the parameters 5-1 setting the parameters 1) on the initial screen, press f3 (sys). [sys-prm-prm1] prm1 = 450 [mm] (+)soft limit range -9999 → 9999 [sys-prm-prm1] prm1 = 450_ [mm] (+)soft limit range -9999 →9999 [sys-prm-prm1] prm0 = 20 robot type read only select menu ...

Page 61: 5-2

5- 3 5 parameters 5-2 parameter description 5-2 parameter description the parameters are described in order below. C caution parameters not displayed on the tpb screen are automatically set or optimized to match the robot type when the robot parameters are initialized. You usually do not have to cha...

Page 62

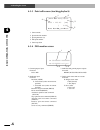

5- 4 5 parameters 5-2 parameter description prm3: payload this specifies the total weight of the workpiece and tool attached to the robot. In cases where this weight varies, enter the maximum payload. Based on this parameter, the controller determines the optimum acceleration speed for the robot, so...

Page 63

5- 5 5 parameters 5-2 parameter description prm7: i/o point movement command speed this parameter sets the movement speed to execute a point movement command (abs- pt, inc-pt) and also determines the number of points that can be used with a point movement command. (see "3-2-2 general-purpose input (...

Page 64

5- 6 5 parameters 5-2 parameter description prm11: no. Of encoder pulses (4 ✕ mode) this parameter indicates the constant that is determined by the linear scale. Default value: depends on robot type. Prm12: lead length this parameter indicates the constant that is determined by the linear scale. Def...

Page 65

5- 7 5 parameters 5-2 parameter description prm18: speed integration gain this sets the speed control gain. Typically, prm17 and prm18 should be input at a ratio of 3 : 2. Generally, the larger the gain, the higher the acceleration will be. However, if the gain is set too high, abnormal oscillation ...

Page 66

5- 8 5 parameters 5-2 parameter description prm24: teaching count data (tpb entry) this is entered in the tpb and cannot be used. Default value: 0 prm25: not used default value: 0 prm26: teaching movement data this parameter is used during movement with a communication command @x+ or @xinc. This is ...

Page 67

5- 9 5 parameters 5-2 parameter description prm32: alarm number output when an alarm is issued, this parameter selects whether the alarm number is to be output as a general-purpose output. When this parameter is set to 1, the alarm number is output as a 5-bit binary signal through do0 to do4. Input ...

Page 68

5- 10 5 pa rameters 5-2 parameter description prm34: system mode selection this parameter specifies the system operation mode. When you want to use the srcp series in operating specifications that differ from normal mode, change this parameter as explained below. This parameter functions are allocat...

Page 69

5- 11 5 pa rameters 5-2 parameter description bit 7: end output sequence setting at command execution completion (supported by ver. 24.32 and later versions): this selects the end output sequence at dedicated command completion. With the standard setting ("0"), the command's execution result is outp...

Page 70

5- 12 5 parameters 5-2 parameter description prm41: i/o point movement command speed 1 this parameter sets the speed at which the robot moves when a point movement command (abs-pt, inc-pt) is executed. The speed set here is the movement speed used in normal mode (service mode disabled) with prm7set ...

Page 71

5- 13 5 parameters 5-2 parameter description prm46: servo status output this parameter selects whether to output the axis servo status as a general-purpose output. When this parameter is set to 1, do3 turns on and off along with servo on/off. Input range: 0 or 1 meaning: 0: does not output the servo...

Page 72

5- 14 5 pa rameters 5-2 parameter description prm51: lead program number this parameter sets the lead program number. Default value: 0 n note the lead program is the program that has been selected as the execution program by the tpb or popcom. (see "9-4 switching the execution program".) the lead pr...

Page 73

5- 15 5 pa rameters 5-2 parameter description zone output function to use the zone output function, the desired zone must be specified with point data. (see chapter 7, "editing point data".) when the robot enters the specified zone, its re- sult is output to the specified port. Point numbers and out...

Page 74

5- 16 5 parameters 5-2 parameter description prm54: magnetic pole detection level default value: depends on the robot. Prm55: magnetic pole position default value: 0 prm56: controller version 2 this parameter reads out the version information (2) on the control software in the con- troller. This is ...

Page 75: Chapter 6

6- 1 6 programming chapter 6 programming in this chapter we will try programming some operations. First, you will learn how to enter a program using the tpb programming box..

Page 76: 6-1

6- 2 6 programming 6-1 basic contents 6-1 basic contents 6-1-1 robot language and point data the srcp controller uses the yamaha robot language that is very similar to basic. It allows you to easily create programs for robot operation. In programs created with the yamaha robot language, the robot po...

Page 77: 6-2

6- 3 6 programming 6-2 editing programs 6-2 editing programs "program editing" refers to operations such as creating a program right after initialization, creating a new program, changing an existing program, and deleting or copying a program. In this section, you will learn the basic procedures for...

Page 78

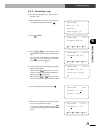

6- 4 6 programming 6-2 editing programs 6-2-1 creating programs after initialization 1) on the initial screen, press f1 (edit). [menu] select menu 1edit2oprt3sys 4mon [edit] select menu 1pgm 2pnt 3utl [edit] select menu 43:cannot find pgm 1pgm 2pnt 3utl [edit-pgm] pgm no = 0 new entry ok ? 1yes 2no ...

Page 79

6- 5 6 programming 6-2 editing programs 7) after selecting the robot language command, enter the operand data. When you press x z + , the cursor moves to op- erand 1, so enter the data with the number keys. (do not press at this point.) while pressing x z + or x z – to move the cur- sor, enter all n...

Page 80

6- 6 6 programming 6-2 editing programs 6-2-2 creating a new program 1) on the initial screen, press f1 (edit). [menu] select menu 1edit2oprt3sys 4mon [edit] select menu 1pgm 2pnt 3utl [edit-pgm] no10 017:mova 254,100 1mod 2ins 3del 4chg [edit-pgm] pgm no = _ (program no) 0 →99 [edit-pgm] pgm no = 1...

Page 81

6- 7 6 programming 6-2 editing programs 6-2-3 adding a step 1) on the initial screen, press f1 (edit). [menu] select menu 1edit2oprt3sys 4mon [edit-pgm] no10 017:mova 254,100 1mod 2ins 3del 4chg [edit-pgm] pgm no = _ (program no) 0 →99 [edit-pgm] pgm no = 10 step no = _ (reg.Steps) 50 [edit-pgm] no1...

Page 82

6- 8 6 programming 6-2 editing programs 7) select f1 to f3 or a robot language com- mand shown on the lower part of each number key. To change the robot language menu display, press f4 (next). To go back to the previous menu display, press the bs key. [edit-pgm] no10 051:jmpf 0 ,10 ,1 (label no) 0 →...

Page 83

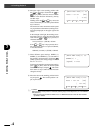

6- 9 6 programming 6-2 editing programs 6-2-4 correcting a step 1) use the same procedure up to step 4 in "6-2-3 adding a step". 2) enter the number of the step you want to cor- rect with the number keys and press . [edit-pgm] pgm no = 10 step no = _ (reg.Steps) 50 [edit-pgm] no10 010:mova 999,100 1...

Page 84

6- 10 6 programming 6-2 editing programs 6-2-5 inserting a step 1) use the same procedure up to step 4 in "6-2-3 adding a step". 2) enter the number of the step where you want to insert a step with the number keys and press . [edit-pgm] pgm no = 10 step no = _ (reg steps) 50 [edit-pgm] no10 010:mova...

Page 85

6- 11 6 programming 6-2 editing programs 6-2-6 deleting a step 1) use the same procedure up to step 4 in "6-2-3 adding a step". 2) enter the number of the step you want to delete with the number keys and press . [edit-pgm] pgm no = 10 step no = _ (reg steps) 50 [edit-pgm] no10 010:mova 999,100 1mod ...

Page 86: 6-3

6- 12 6 programming 6-3 program utility 6-3 program utility 6-3-1 copying a program 1) on the initial screen, press f1 (edit). [menu] select menu 1edit2oprt3sys 4mon [edit] select menu 1pgm 2pnt 3utl [edit-utl] select menu 1copy2del 3list [edit-utl-copy] copy from no = _ (program no) 0 →99 [edit-utl...

Page 87

6- 13 6 programming 6-3 program utility 6) if program data is already registered with the selected program number, a confirmation mes- sage appears. To overwrite the program, press f1 (yes). To cancel, press f2 (no). [edit-utl-copy] copy from no = 0 no99 overwrite ok ? 1yes 2no [edit-utl] select men...

Page 88

6- 14 6 programming 6-3 program utility 6-3-3 viewing the program information 1) use the same procedure up to 2 in "6-3-1 copy- ing a program". 2) press f3 (list). [edit-utl] select menu 1copy2del 3list [edit-utl-list] free 678 steps no 0 57 steps no 1 255 steps [edit-utl] select menu 1copy2del 3lis...

Page 89: Chapter 7

7- 1 7 editing point da ta chapter 7 editing point data there are three methods to enter point data: manual data input (mdi), teaching playback, and direct teaching. Manual data input allows you to directly enter point data with the tpb number keys. Teaching playback moves the robot in manual operat...

Page 90: 7-1

7- 2 7 editing point da ta 7-1 manual data input 7-1 manual data input 1) on the initial screen, press f1 (edit). [edit] select menu 1pgm 2pnt 3utl [edit-pnt] select menu 1mdi 2tch 3dtch4del [menu] select menu 1edit2oprt3sys 4mon [edit-pnt-mdi] p0 = 0.00 [mm] input data[_ ] input data[_ ] 1chg [edit...

Page 91: 7-2

7- 3 7 editing point da ta 7-2 teaching playback 7-2 teaching playback 1) on the initial screen, press f1 (edit). [edit-pnt-tch](1) 50 pn : n = _ (point no) 0 →999 [edit-pnt] select menu 1mdi 2tch 3dtch4del [menu] select menu 1edit2oprt3sys 4mon [edit] select menu 1pgm 2pnt 3utl [edit-pnt-tch](1) 50...

Page 92

7- 4 7 editing point da ta 7-2 teaching playback 6) move the robot to the teaching position with the x z – or x z + keys. Each time the x z – or x z + key is pressed, the robot moves a certain amount in the direction indicated by the key and then stops. Holding down the x z – or x z + key moves the ...

Page 93: 7-3

7- 5 7 editing point da ta 7-3 direct teaching 7-3 direct teaching 1) on the initial screen, press f1 (edit). [edit-pnt-dtch] p0 = 0.00 [mm] [ 0.00] 1chg 2do 3brk [edit-pnt-dtch] pn : n = _ (point no) 0 →999 [edit-pnt-dtch] press emg.Button [edit] select menu 1pgm 2pnt 3utl [menu] select menu 1edit2...

Page 94

7- 6 7 editing point da ta 7-3 direct teaching 7) move the robot to the teaching position by hand. [edit-pnt-dtch] p500 = 19.27 [mm] [ 0.00] [edit-pnt-dtch] servo on ready ? 1yes 2no [edit-pnt] select menu 1mdi 2tch 3dtch4del [edit-pnt-dtch] release emg.Button [edit-pnt-dtch] p500 = 167.24 [mm] [ 16...

Page 95: 7-4

7- 7 7 editing point da ta 7-4 manual control of general-purpose output 7-4 manual control of general-purpose output when performing teaching playback or direct teaching with systems that use a general-purpose output through the i/o interface to operate a gripper or other tools, you may want to chec...

Page 96: 7-5

7- 8 7 editing point da ta 7-5 manual release of holding brake 7-5 manual release of holding brake the holding brake on the vertical type robot can be released. Since the movable part will drop when the brake is released, attaching a stopper to protect the tool tip from being damaged is recommended....

Page 97: 7-6

7- 9 7 editing point da ta 7-6 deleting point data 7-6 deleting point data 1) use the same procedure up to step 2 in "7-1 manual data input". 2) press f4 (del). [edit-pnt] select menu 1mdi 2tch 3dtch4del [edit-pnt-del] del range p100-p_ (point no) 0 →999 [edit-pnt-del] del range p_ -p (point no) 0 →...

Page 98: 7-7

7- 10 7 editing point da ta 7-7 tracing points (moving to a registered data point) 7-7 tracing points (moving to a registered data point) the robot can be moved to the position specified by a registered data point. You can check the input point data by actually moving the robot. 1) use the same proc...

Page 99: Chapter 8

8- 1 8 robot language chapter 8 robot language this chapter explains the robot language. It describes what kind of commands are available and what they mean. The srcp series uses the yamaha robot language. This is an easy-to-learn basic-like programming language. Even a first-time user can easily cr...

Page 100: 8-1

8- 2 8 robot language 8-1 robot language table 8-1 robot language table mova movi movf jmp jmpf jmpb l call do wait timr p p+ p- srvo stop orgn ton toff jmpp mat msel movm jmpc jmpd csel c c+ c- d d+ d- shft moves to point data position. Mova , moves from current position by amount of point data. Mo...

Page 101: 8-2

8- 3 8 robot language 8-2 robot language syntax rules 8-2 robot language syntax rules 8-2-1 command statement format the robot language command statement format for the srcp controller is as follows. When creating a program using the tpb, each command statement can be automatically entered in this f...

Page 102

8- 4 8 robot language 8-2 robot language syntax rules 8-2-2 variables variable are used in a program to hold data. The following variables can be used with the srcp controller. ■ point variable p a point variable can contain a point number. It is used in movement commands such as mova and movi state...

Page 103: 8-3

8- 5 8 robot language 8-3 program function 8-3 program function 8-3-1 multi-task function a multi-task function allows simultaneous executing two or more programs (tasks). The srcp con- troller can execute a maximum of 4 programs at the same time. Since the multi-task function simultaneously execute...

Page 104: 8-4

8- 6 8 robot language 8-4 robot language description 8-4 robot language description 8-4-1 mova function: moves to a point specified by a point number (moves to an absolute position relative to the origin point). Format: mova , example: mova 51, 80 moves to p51 at speed 80. Explanation: this command ...

Page 105

8- 7 8 robot language 8-4 robot language description 8-4-3 movf function: moves until a specified di number input is received. Format: movf example: movf 1, 2, 1 the robot moves toward p1 and stops when di2 turns on. Program ex- ecution then proceeds to the next step. Explanation: this is used when ...

Page 106

8- 8 robot language 8-4 robot language description 8 8-4-5 jmpf function: if the conditional jump input matches the setting value, program execu- tion jumps to a specified label in a specified program. Format: jmpf , , example: jmpf 12, 3, 5 if the conditional jump input is 5, program execution jump...

Page 107

8- 9 8 robot language 8-4 robot language description 8-4-6 jmpb function: jumps to a specified label when a specified general-purpose input or memory input is on or off. Format: jmpb , , example: jmpb 12, 2, 1 jumps to label 12 when di2 input is on. If di2 is off, the program execution proceeds to t...

Page 108

8- 10 robot language 8-4 robot language description 8 8-4-8 call function: calls and executes another program. Format: call , example: call 5, 2 calls program 5 and executes it twice. Program execution then proceeds to the next step. Explanation: when repeating the same operation a number of times, ...

Page 109

8- 11 8 robot language 8-4 robot language description 8-4-10 wait function: waits until a specified general-purpose input or memory input changes to a specified state. Format: wait , example: wait 5, 1 waits until di5 turns on. Explanation: this command adjusts the timing according to the general-pu...

Page 110

8- 12 robot language 8-4 robot language description 8 8-4-12 p function: sets a point variable p. Format: p example: p 200 sets a point variable p to 200. Explanation: the point variable can contain a point number as a variable, which can be from 0 to 999. By using a movement command such as mova wi...

Page 111

8- 13 8 robot language 8-4 robot language description 8-4-15 srvo function: turns the servo on and off. Format: srvo example: srvo 1 this turns the servo on. Srvo 0 this turns the servo off. Explanation: this command is used to prevent an overload on the motor that may occur if the robot is locked m...

Page 112

8- 14 robot language 8-4 robot language description 8 8-4-17 orgn function: performs return-to-origin by using the stroke-end detection method. Format: orgn example: orgn performs return-to-origin by the stroke-end detection method. Explanation: return-to-origin is performed based on return-to-origi...

Page 113

8- 15 8 robot language 8-4 robot language description 8-4-18 ton function: executes a specified task. Format: ton , , example: ton 1,2,0 newly executes program 2 as task 1. Explanation: this command starts multiple tasks and can be used to control the i/o signals in parallel with the axis movement a...

Page 114

8- 16 robot language 8-4 robot language description 8 8-4-20 jmpp function: jumps to a specified label when the axis position relation meets the speci- fied conditions. Format: jmpp , example: jmpp 3,1 jumps to label 3 if the x-axis position is smaller than the point specified with the point variabl...

Page 115

8- 17 8 robot language 8-4 robot language description 8-4-21 mat function: defines the number of rows and columns of the matrix. Format: mat , , example: mat 3, 6, 0 defines a matrix of 3 × 6 on pallet number 0. Explanation: this command defines a matrix for palletizing movement. A palletizing progr...

Page 116

8- 18 robot language 8-4 robot language description 8 8-4-22 msel function: specifies a matrix where the robot moves with a movm statement. Format: msel example: msel 0 points where the robot moves with a movm statement are calculated based on matrix data of pallet number 0. Explanation: this comman...

Page 117

8- 19 8 robot language 8-4 robot language description 8-4-23 movm function: moves to a point on the specified matrix. Format: movm , example: movm 23, 100 moves to the point at row 3, column 7 at speed 100 when a matrix of 5 × 8 is defined by the mat statement. Explanation: this command moves the ro...

Page 118

8- 20 robot language 8-4 robot language description 8 8-4-24 jmpc function: jumps to a specified label when the counter array variable c matches a specified value. Format: jmpc , example: jmpc 5, 100 jumps to label 5 when the counter array variable c is 100. Program execution proceeds to the next st...

Page 119

8- 21 8 robot language 8-4 robot language description 8-4-26 csel function: specifies an array element of the counter array variable c to be used. Format: csel example: csel 1 the counter array variable of element number 1 is used in the subse- quent steps. Explanation: this command designates an ar...

Page 120

8- 22 robot language 8-4 robot language description 8 8-4-28 c+ function: adds a specified value to the counter array variable c. Format: c+ [] example: c+ 100 adds 100 to the counter array variable c. (c ←c+100) c+ adds 1 to the counter array variable c. (c ←c+1) explanation: this command adds a sp...

Page 121

8- 23 8 robot language 8-4 robot language description 8-4-32 d- function: subtracts a specified value from the counter variable d. Format: d- [] example: d- 100 subtracts 100 from the counter variable d. (d ←d-100) d- subtracts 1 from the counter variable d. (d ←d-1) explanation: this command subtra...

Page 122: 8-5

8- 24 8 robot language 8-5 sample programs 8-5 sample programs 8-5-1 moving between two points p1 p2 program comment [no0] 001: l 0 ; label definition 002: mova 1, 100 ; moves to p1 003: mova 2, 100 ; moves to p2 004: timr 100 ; delays for one second 005: jmp 0, 0 : returns to l0 8-5-2 moving at an ...

Page 123

8- 25 8 robot language 8-5 sample programs 8-5-3 positioning 2 points and sending job commands to a plc at each position p1 p2 position at which job 1 is complete position at which job 2 is complete point di1 di2 job 1 completion 1: complete 0: not complete job 2 completion 1: complete 0: not comple...

Page 124

8- 26 8 robot language 8-5 sample programs 8-5-4 robot stands by at p0, and moves to p1 and then to p2 to pick and place a workpiece horizontal direction vertical direction hold ac servo motor air cylinder air chuck actuator di0 di1 di2 upper end limit switch 1: on 0: off lower end limit switch 1: o...

Page 125

8- 27 8 robot language 8-5 sample programs 8-5-5 picking up 3 kinds of workpieces flowing on the front conveyor and placing them on the next conveyors while sorting horizontal direction vertical direction hold ac servo motor air cylinder air chuck actuator di0 di1 di2 di3 di4 upper end limit switch ...

Page 126

8- 28 8 robot language 8-5 sample programs program comment [no1] > 001: l 1 ; label definition 002: jmpb 2, 2, 1 ; jumps to l2 when workpiece a is detected 003: jmpb 3, 3, 1 ; jumps to l3 when workpiece b is detected 004: jmpb 4, 4, 1 ; jumps to l4 when workpiece c is detected 005: jmp 1, 1 ; return...

Page 127

8- 29 8 robot language 8-5 sample programs 8-5-6 switching the program from i/o the srcp series controller does not accept dedicated command inputs for program switching. To switch the program through the i/o, use the program selection signal as a conditional jump input as explained below. The follo...

Page 128

8- 30 8 robot language 8-5 sample programs program comment [no0] 001: l 0 ; label definition 002: wait 7, 1 ; waits for confirmation on of the selected program handshaking 003: do 0, 1 ; program selection start turns on 004: wait 7, 0 ; waits for confirmation off of the selected program 005: jmpf 1,...

Page 129

8- 31 8 robot language 8-5 sample programs 8-5-7 axis movement and i/o multi-task the robot moves between two points and performs multi-task i/o operation in asynchronous mode. General-purpose input/output di0 job status detection do0 job owner's output p0 p1 program comment [no0] 001: ton 1, 1, 0 ;...

Page 130

8- 32 8 robot language 8-5 sample programs 8-5-8 turning on general-purpose outputs during robot movement after a certain time has elapsed point p0 start position p1 target position 3 sec. 3 sec. 3 sec. P0 p1 do0=1 do1=1 do2=1 program comment [no0] 001: l 0 ; label definition 002: mova 0, 100 ; move...

Page 131

8- 33 8 robot language 8-5 sample programs 8-5-9 turning on a general-purpose output during robot movement when it has passed a specified position point p0 start position p1 target position p10 position at do0=1 p11 position at do0=0 p0 p1 do0=1 p10 p11 do0=0 ■ when p1 is nearer to the plus side tha...

Page 132: Memo

8- 34 memo.

Page 133: Chapter 9

9- 1 9 opera ting the robot chapter 9 operating the robot this chapter describes how to actually operate the robot. If the program has already been completed, you will be able to operate the robot by the time you finish reading this chapter. There are two types of robot operation: step and automatic...

Page 134: 9-1

9- 2 9 opera ting the robot 9-1 performing return-to-origin 9-1 performing return-to-origin the stroke-end detection is used as the origin (reference point) detection method. The following explains the procedure to perform return-to-origin using the stroke-end detection. The magnetic pole is detecte...

Page 135

9- 3 9 opera ting the robot 9-1 performing return-to-origin c caution when the service mode function is enabled, the following safety control will function. (see "10-4 service mode function".) • return-to-origin movement speed is limited to 10mm/s or less in "service mode state" when the robot movem...

Page 136: 9-2

9- 4 9 opera ting the robot 9-2 using step operation 9-2 using step operation the following procedure explains how to perform step operation. In the case of a multi-task program, only the task currently selected is executed in step operation. 1) on the initial screen, press f2 (oprt). [menu] select ...

Page 137

9- 5 9 opera ting the robot 9-2 using step operation 7) the screen returns to step 5. Pressing run at this point executes the first step. [oprt-step] 50 0:10 001:mova 999,50 [ 0.00] 1spd 2rset3chg 4next [oprt-step] running ... [oprt-step] 50 0:10 001:mova 999,50 [ 201.11] 1spd 2rset3chg 4next [oprt-...

Page 138

9- 6 9 opera ting the robot 9-2 using step operation 14)the screen returns to step 5, and the process is repeated from that point. [oprt-step] 50 0:10 001:mova 999,50 [ 250.00] 1spd 2rset3chg 4next c caution when the service mode function is enabled, the following safety control will function. (see ...

Page 139: 9-3

9- 7 9 opera ting the robot 9-3 using automatic operation 9-3 using automatic operation the following procedure explains how to perform automatic operation. All the tasks started in a multi-task program are executed by automatic operation. 1) on the initial screen, press f2 (oprt). [oprt-auto] 100 0...

Page 140

9- 8 9 opera ting the robot 9-3 using automatic operation 8) this is the screen displayed while the program is being executed. [oprt-auto] running ··· [oprt-auto] 60:program end [oprt-auto] 50 1:11 010:wait 0 ,1 [ 250.00] 1val 2s_on3chgt4next [oprt-auto] 50 2:12 015:do 1 ,1 [ 250.00] 1val 2s_on3chgt...

Page 141: 9-4

9- 9 9 opera ting the robot 9-4 switching the execution program 9-4 switching the execution program the following procedure explains how to switch the program in automatic operation. Use the same procedure in step operation. The program selected by this procedure will be the lead program to which th...

Page 142: 9-5

9- 10 9 opera ting the robot 9-5 emergency stop function 9-5 emergency stop function there are two ways to trigger emergency stop on the srcp controller. One way is by using the push- button on the tpb. The other is to use the i/o emergency stop input. In either case for safety reasons, a contact b ...

Page 143

9- 11 9 opera ting the robot 9-5 emergency stop function 3) after the emergency stop is released, a mes- sage appears asking whether to turn the servo on. To turn the servo on, press f1 (yes). To leave the servo off , press f2 (no). [oprt-step] 100 0: 7 001:mova 254,100 [ 0.00] 1spd 2rset3chg 4next ...

Page 144: 9-6

9- 12 9 opera ting the robot 9-6 displaying the memory i/o status 9-6 displaying the memory i/o status the memory i/o status can be displayed on the screen. 1) on the initial screen, press f2 (oprt). [menu] select menu 1edit2oprt3sys 4mon [oprt] select menu 1org 2step3auto [oprt-step] 100 0: 0 001:m...

Page 145: 9-7

9- 13 9 opera ting the robot 9-7 displaying the variables the point data variable "p", counter array variable "c" and counter variable "d" values can be dis- played on the tpb screen. 1) on the initial screen, press f2 (oprt). [oprt-step] 100 0: 0 001:mova 254,100 [ 0.00] 1val 2s_on3chgt4next [menu]...

Page 146: Memo

9- 14 memo.

Page 147: Chapter 10

10- 1 10 other opera tions chapter 10 other operations the tpb has many convenient functions in addition to those already covered. For example, memories can be initialized, and options such as memory cards can be used. This chapter will describe these additional functions.

Page 148: 10-1 Initialization

10- 2 10 other opera tions 10-1 initialization 10-1 initialization initializing the programs and points erases all the program data and point data currently stored in the controller. Initializing the parameters resets the parameters to their initial values. 1) on the initial screen, press f3 (sys). ...

Page 149

10- 3 10 other opera tions 10-1 initialization 6) finally, enter the robot payload. Enter the payload with the number keys and then press . [sys-init-prm] robot type : 516 stroke : 400 [mm] weight : 3_ [kg] [sys-init-prm] parameter data initialize ok ? 1yes 2no [sys-init] select menu 1pgm 2pnt 3prm ...

Page 150: 10-2 Dio Monitor Display

10- 4 10 other opera tions 10-2 dio monitor display 10-2 dio monitor display data indicating whether the i/o signals are on or off can be displayed on the screen. The operation procedure is explained below. 10-2-1 display from the monitor menu 1) on the initial screen, press f4 (mon). [menu] select ...

Page 151

10- 5 10 other opera tions 10-2 dio monitor display 10-2-2 display from the dio key operation 1) hold down the dio key. [oprt-auto] running... [oprt-auto] running... Running... [oprt-auto] di 00000000 00000000 do 11100000 o:0 s:1 2) the on/off status of i/o signals is displayed as long as the key is...

Page 152: 10-4 Service Mode Function

10- 6 10 other opera tions 10-4 service mode function 10-4 service mode function the service mode function is explained in this section. The robot operator or others sometimes need to enter the hazardous area in the robot safety enclosure and move the robot to perform maintenance or adjustment while...

Page 153

10- 7 10 other opera tions 10-4 service mode function 10-4-1 safety settings for service mode safety controls that work in "service mode state" are explained in detail below. ■ limiting command input from any device other than tpb when the operator is working within the robot safety enclosure using ...

Page 154

10- 8 10 other opera tions 10-4 service mode function ■ prohibiting the automatic operation and step operation running an automatic operation or step operation while an operator is working within the robot safety enclosure is very dangerous to that operator. (for example, when the operator is in the...

Page 155

10- 9 10 other opera tions 10-4 service mode function 10-4-2 enabling/disabling the service mode function to enable or disable the service mode function, follow these steps. 1) on the initial screen, press f3 (sys). [menu] select menu 1edit2oprt3sys 4mon [sys] select menu 1safe2opt 3utl 4next [sys-s...

Page 156

10- 10 10 other opera tions 10-4 service mode function 7) when writing is complete, the screen returns to step 6. [sys-safe-svce-set] service mode = 1 0:invalid 1:valid n note the password is identical to the srcp controller's version number. For example, if the controller version is 24.00, enter 24...

Page 157

10- 11 10 other opera tions 10-4 service mode function 10-4-3 setting the service mode functions 1) on the initial screen, press f3 (sys). [menu] select menu 1edit2oprt3sys 4mon [sys] select menu 1safe2opt 3utl 4next [sys-safe] password: 24.00_ input password [sys-safe] select menu 1aclv2svce [sys-s...

Page 158

10- 12 10 other opera tions 10-4 service mode function 7) when the setting has been changed, the memory write screen appears. To save the change permanently (retain the change even after the controller power is turned off), press f1 (save). To save the change temporarily (retain the change until the...

Page 159: 10-5 System Utilities

10- 13 10 other opera tions 10-5 system utilities 10-5 system utilities 10-5-1 viewing hidden parameters parameters hidden in the normal state can be viewed. Use extra caution to avoid accidentally changing the parameters when these hidden parameters are displayed. 1) on the initial screen, press f3...

Page 160: 10-6 Using A Memory Card

10- 14 10 other opera tions 10-6 using a memory card 10-6 using a memory card a memory card can be used with the tpb to back up the data in the srcp controller. Refer to "16-1-1 memory card" for the procedure for handling a memory card and for the number of data that can be stored. 10-6-1 saving con...

Page 161

10- 15 10 other opera tions 10-6 using a memory card 7) if data already exists in the area specified in step 5, a confirmation message appears. To overwrite the data in the selected area, press f1 (yes). To change the selected area, press f2 (no). [b.Up-save] area 1 already saved delete ok ? 1yes 2n...

Page 162

10- 16 10 other opera tions 10-6 using a memory card 10-6-2 loading data from a memory card 1) insert the memory card into the tpb. 2) on the initial screen, press f3 (sys). [menu] select menu 1edit2oprt3sys 4mon [sys] select menu 1prm 2b.Up3init [sys-b.Up] select menu 1save2load3fmt 4id [b.Up-load]...

Page 163

10- 17 10 other opera tions 10-6 using a memory card 7) when the load area was selected in step 5, the data load screen appears. Select the data to be loaded. To load the program data, press f1 (pgm). To load the point data, press f2 (pnt). To load the parameter data, press f3 (prm). To load all of ...

Page 164

10- 18 10 other opera tions 10-6 using a memory card 10-6-3 formatting a memory card 1) insert the memory card into the tpb. 2) on the initial screen, press f3 (sys). [menu] select menu 1edit2oprt3sys 4mon [sys] select menu 1prm 2b.Up3init [sys-b.Up] select menu 1save2load3fmt 4id [sys-b.Up] format ...

Page 165

10- 19 10 other opera tions 10-6 using a memory card 10-6-4 viewing the id number for memory card data 1) insert the memory card into the tpb. 2) on the initial screen, press f3 (sys). [menu] select menu 1edit2oprt3sys 4mon [sys] select menu 1prm 2b.Up3init [sys-b.Up] select menu 1save2load3fmt 4id ...

Page 166

10- 20 10 other opera tions 10-7 duty (load factor) monitor 10-7 duty (load factor) monitor the srcp controller has a duty (load factor) monitor to allow you to operate the robot under the most optimal conditions. The duty monitor checks the robot's motor load factor and displays it in percent (%) v...

Page 167

10- 21 10 other opera tions 10-7 duty (load factor) monitor [method 2] 1) add the robot language command "duty 1" to the beginning of the interval in a program in which you want to measure the duty and also add the robot language command "duty 0" to the end of the interval. 005: 006: 007: 008: 009: ...

Page 168

10- 22 10 other opera tions 10-7 duty (load factor) monitor 10-7-1 measuring the duty (load factor) 1) while moving the robot with a pulse train input (pulse train mode) or dedicated command input (normal mode), press f4 (mon) on the tpb initial menu screen to enter mon (monitor) mode. [menu] select...

Page 169

10- 23 10 other opera tions 10-8 using the internal flash rom 10-8 using the internal flash rom when you set parameters using the tpb or popcom (options) or via the rs-232c, the parameter data stored in the ram inside the srcp is rewritten and the robot operates based on this parameter data written ...

Page 170

10- 24 10 other opera tions 10-8 using the internal flash rom 10-8-1 saving the parameter data onto the flash rom n note the internal flash rom can be used when the srcp controller version is 24.10 or later and the tpb version is 12.51 or later. 1) on the initial screen, press f3 (sys). [menu] selec...

Page 171

10- 25 10 other opera tions 10-8 using the internal flash rom 8) a confirmation message appears. To save the parameter data, press f1 (yes). To cancel, press f2 (no). [from-save] save ok ? Id=04.04.10 1yes 2no [from-save] saving ... [from-save] saving is complete 1alod [from-save-alod] auto load = 0...

Page 172

10- 26 10 other opera tions 10-8 using the internal flash rom 10-8-2 manually loading the data from flash rom n note the internal flash rom can be used when the srcp controller version is 24.10 or later and the tpb version is 12.51 or later. 1) on the initial screen, press f3 (sys). [menu] select me...

Page 173

10- 27 10 other opera tions 10-8 using the internal flash rom 8) the screen returns to step 4 when loading is complete. 2load3init [sys-b.Up-from] from : 04.03.01 auto load : invalid 1save c caution when loading the data from the flash rom, make sure that the i/o. Cn connector is disconnected and th...

Page 174

10- 28 10 other opera tions 10-8 using the internal flash rom 10-8-3 initializing the flash rom data n note the internal flash rom can be used when the srcp controller version is 24.10 or later and the tpb version is 12.51 or later. 1) on the initial screen, press f3 (sys). [menu] select menu 1edit2...

Page 175

10- 29 10 other opera tions 10-8 using the internal flash rom 8) the screen returns to step 4 when initializa- tion is complete. After initializing the flash rom, the auto load function is set to "invalid" (disabled). 2load3init [sys-b.Up-from] from : auto load : invalid 1save c caution when initial...

Page 176: Memo

10- 30 memo.

Page 177: Chapter 11

11- 1 11 communica tion with pc chapter 11 communication with pc the srcp controller allows you to edit the program data and point data or control the robot operation using a pc (personal computer) by rs-232c communication instead of using the tpb. This chapter describes how to set the communication...

Page 178

11- 2 11 communica tion with pc 11-1 communication parameter specifications 11-1 communication parameter specifications the communication parameters on the pc should be set as follows. For the setting procedure, refer to the computer operation manual. ■ baud rate 9600 bps ■ data bit length 8 bits ■ ...

Page 179

11- 3 11 communica tion with pc 11-2 communication cable specifications 11-2 communication cable specifications c caution pins 10, 12, 18 and 21 of the controller's connector are specifically used for tpb connection. To avoid possible accidents do not connect other inputs to these pins. When using o...

Page 180

11- 4 11 communica tion with pc 11-3 communication command specifications 11-3 communication command specifications on the srcp controller, a command interface resembling the basic programming language is pro- vided as standard, to facilitate easy communication with a pc. Communication commands are ...

Page 181

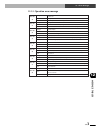

11- 5 11 communica tion with pc 11-4 communication command list 11-4 communication command list no. Operation code operand 1 operand 2 operand 3 command details 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. Org orgn reset run srun srvo x+/x- x...

Page 182

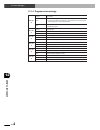

11- 6 11 communica tion with pc 11-4 communication command list no. Operation code operand 1 operand 2 operand 3 command details 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. ?Pos ?No ?Sno ?Tno ?Pno ?Stp ?Mem ?Ver ?Robot ?Clock ?Alm ?Err ?...

Page 183

11- 7 11 communica tion with pc 11-4 communication command list no. Operation code operand 1 operand 2 operand 3 command details 1. 2. 3. 4. 5. 6. 7. 8. 9. Init swi switsk sins sdel smod copy del pdel pgm pnt prm clock alm err program number task number program number program number program number p...

Page 184

11- 8 11 communica tion with pc 11-5 communication command description 11-5-1 robot movements (1)@org @orgn returns the robot to its origin position and outputs the machine reference value when completed correctly. Transmission example : @org c/r l/f ................................ Performs return-...

Page 185

11- 9 11 communica tion with pc (2)@reset this returns the program execution step to the first step of the program selected with the '@swi' statement, and turns all general-purpose outputs (do0 to do4) and memory output off. The "cur- rent position in the program" used as a reference for the relativ...

Page 186

11- 10 11 communica tion with pc 11-5 communication command description (6)@x+, (@x-) @x+ moves the robot to the + side and @x- to the - side based on the following equation. Movement distance = 1 × (prm26/100) (mm) prm26: teaching movement data (%) (7)@xinc, (@xdec) @xinc moves the robot to the + s...

Page 187

11- 11 11 11-5 communication command description communica tion with pc (9)@mova , moves the robot to a position specified by a point number at a specified speed. Point number : this is a number assigned to each point (position data) and can be from 0 to 999 (a total of 1,000 points). Data for the p...

Page 188

11- 12 11 communica tion with pc 11-5 communication command description (11)@movf ,, this command moves the robot toward a position specified by a point number until a specified di input condition is met. When the di condition is met, the robot stops and the command termi- nates. Even if the di cond...

Page 189

11- 13 11 11-5 communication command description communica tion with pc (15)@p sets the point variable p. Point number : this can be any value from 0 to 999. Transmission example : @p 100 c/r l/f ............................... Set the point variable p to 100. Response example : ok c/r l/f c caution...

Page 190

11- 14 11 communica tion with pc 11-5 communication command description (18)@movm , moves the robot to a specified pallet work position at a specified speed. Pallet work position : the pallet work position is a number used to identify each point on a matrix, and can be from 1 to 65025 (=255 × 255). ...

Page 191

11- 15 11 11-5 communication command description communica tion with pc (21)@csel specifies an array element for the counter array variable c to be used. Array element number : this is a number used to designate an array element for the counter array variable c, and can be from 0 to 31. The counter ...

Page 192

11- 16 11 communica tion with pc 11-5 communication command description (26)@d+ [] adds a specified value to the counter variable d. Addition value : this can be any value from 1 to 65535. If this value is omitted, then 1 is added to the counter variable. Transmission example : @d+ c/r l/f ............

Page 193

11- 17 11 11-5 communication command description communica tion with pc 11-5-2 data handling (1)@?Pos reads the current position. Transmission example : @?Pos c/r l/f response example : 321.05 c/r l/f ok c/r l/f (2)@?No reads the current program number. In multi-task operation, this command reads th...

Page 194

11- 18 11 communica tion with pc 11-5 communication command description (6)@?Stp reads the total number of steps in the specified program. Program number : this is a number used to identify each program and can be 0 to 99 (a total of 100). Transmission example : @?Stp 10 c/r l/f .......................

Page 195

11- 19 11 11-5 communication command description communica tion with pc (11) @?Alm [,] displays a specified number of past alarms, starting from a specified history number. A maximum of 100 past alarms can be displayed. This alarm history shows the time (total elapsed time from controller start-up) ...

Page 196

11- 20 11 communica tion with pc 11-5 communication command description (13)@?Emg reads the emergency stop status. Transmission example : @?Emg c/r l/f response example 1 : 0 c/r l/f .......................................... Emergency stop is off. Ok c/r l/f response example 2 : 1 c/r l/f ............

Page 197

11- 21 11 11-5 communication command description communica tion with pc (17)@?Pva reads the point variable p. In multi-task operation, this command reads the program information on the task currently selected. Transmission example : @?Pva c/r l/f response example : 0 c/r l/f ok c/r l/f c caution the...

Page 198

11- 22 11 communica tion with pc 11-5 communication command description (20-1) @?Prm reads the data from a specified parameter. Parameter number : this is a number used to identify each parameter and can be from 0 to 99. Transmission example : @?Prml c/r l/f ............................. Reads the d...

Page 199

11- 23 11 11-5 communication command description communica tion with pc (21-2) @?P , reads multiple point data from the first point number to the second point number. If unregistered points exist, they will be skipped. Point number : this is a number used to identify each point data and can be from ...

Page 200

11- 24 11 communica tion with pc 11-5 communication command description (22-3) @read pnt reads all point data. Transmission example : @read pnt c/r l/f response example : p0=0.00 c/r l/f p1=350.00 c/r l/f p2=196.47 c/r l/f p254=-0.27 c/r l/f ^z (=1ah) ok c/r l/f (22-4) @read prm reads all parameter ...

Page 201

11- 25 11 11-5 communication command description communica tion with pc (22-6) @read dio reads the on/off status of dio. Refer to "4-3-4 dio monitor screen". Transmission example : @read dio c/r l/f response example : d i 00000000 00000000 c/r l/f do 11100000 o:0 s:1 c/r l/f ok c/r l/f (22-7) @read ...

Page 202

11- 26 11 communica tion with pc 11-5 communication command description (23-2) @write pnt writes the point data. The controller will transmit ready when this command is received. Con- firm that ready is received and then transmit the point data. Always transmit ^z (=1ah) at the end of the data. Tran...

Page 203

11- 27 11 11-5 communication command description communica tion with pc (23-4) @write all writes all data (parameters, programs and points) at one time. The controller will transmit ready when this command is received. Confirm that ready is received and then transmit all data. Always transmit ^z (=1...

Page 204

11- 28 11 communica tion with pc 11-5 communication command description (26)@?Csel reads the currently specified element number of the counter array variable c. In multi-task opera- tion, this command reads the program information on the task currently selected. Transmission example : @?Csel c/r l/f...

Page 205

11- 29 11 11-5 communication command description communica tion with pc 11-5-3 utilities (1-1) @init pgm initializes all program data. Transmission example : @init pgm c/r l/f response example : ok c/r l/f (1-2) @init pnt initializes all point data. Transmission example : @init pnt c/r l/f response ...

Page 206

11- 30 11 communica tion with pc 11-5 communication command description (2)@swi this command switches the execution program number. When a program is reset, program execu- tion will always return to the first step of the program selected here. The program is reset when the @swi command is executed. ...

Page 207

11- 31 11 11-5 communication command description communica tion with pc (5)@sdel , deletes a specified step. Program number : this is a number used to identify each program and can be from 0 to 99. Step number : this is a number used to identify each step and can be from 1 to 255. Transmission examp...

Page 208

11- 32 11 communica tion with pc 11-5 communication command description (8)@del deletes a program. Program number : this is a number used to identify each program and can be from 0 to 99. Transmission example : @del 10 c/r l/f ............................ Deletes program no. 10. Response example 1 :...

Page 209: Chapter 12

12- 1 12 message t ables chapter 12 message tables this section lists all of the messages that are displayed on the tpb or sent to the pc (personal computer) to inform the operator of an error in operation or a current status. For a list of the alarm messages displayed if any trouble occurs, refer t...

Page 210: 12-1 Error Messages

12- 2 12 message t ables 12-1 error messages 12-1 error messages 12-1-1 error message specifications the error message transmission format is as follows. : c/r l/f the length of the character string is 17 characters. (spaces are added until the message contains 17 characters.) thus, the character st...

Page 211

12- 3 12 message t ables 12-1 error messages 12-1-3 operation error message error no. 30 error no. 31 error no. 32 error no. 33 error no. 34 error no. 35 error no. 36 error no. 37 error no. 38 message cause action message cause action message cause action message cause action message cause action me...

Page 212

12- 4 12 message t ables 12-1 error messages 12-1-4 program error message error no. 40 error no. 41 error no. 42 error no. 43 error no. 44 error no. 45 message cause action message cause action message cause action message cause action message cause action message cause action stack overflow q seven...

Page 213

12- 5 12 message t ables 12-1 error messages 12-1-5 system error message error no. 50 error no. 51 error no. 52 error no. 53 error no. 54 error no. 56 error no. 57 error no. 59 message cause action message cause action message cause action message cause action message cause action message cause acti...

Page 214: 12-2 Tpb Error Messages

12- 6 12 message t ables 12-2 tpb error messages 12-2 tpb error messages message cause action message cause action message cause action message cause action message cause action message cause action message cause remedy sio error 1. Parity error in data received from controller. 2. Tpb was connected...

Page 215: 12-3 Stop Messages

12- 7 12 message t ables 12-3 stop messages 12-3 stop messages 12-3-1 message specifications the stop message transmission format is as follows. : c/r l/f the length of the character string is 17 characters. (spaces are added until the mes- sage contains 17 characters.) thus, the character string le...

Page 216

12- 8 12 message t ables 12-4 displaying the error history a history of past errors can be displayed. Up to 100 errors can be stored in the controller. 1) on the initial screen, press f3 (sys). [menu] select menu 1edit2oprt3sys 4mon [sys] select menu 1safe2opt 2rec 3utl 4next [sys-utl] select menu 1...

Page 217

12- 9 12 message t ables 12-4 displaying the error history 5) history numbers, time that errors occurred (total elapsed time from controller start-up) and error descriptions are displayed. One screen displays the past 4 errors in the order from the most recent error. Pressing the x z – and x z + key...

Page 218: Memo

12- 10 memo.

Page 219: Chapter 13

13- 1 13 troubleshooting chapter 13 troubleshooting this chapter explains how to take corrective action when a problem or breakdown occurs, by categorizing it into one of two cases depending on whether or not an alarm is output from the controller..

Page 220: 13-1 If A Trouble Occurs

13- 2 13 troubleshooting 13-1 if a trouble occurs 13-1 if a trouble occurs if trouble or breakdown occurs, contact yamaha or your yamaha dealer, providing us with the following information in as much detail as possible. Item what you were using when under what conditions what happened how often desc...

Page 221

13- 3 13 troubleshooting 13-2 alarm and countermeasures 13-2 alarm and countermeasures if the ready signal is turned off except in cases of emergency stop, then an alarm has probably been issued. The status led on the front panel of the controller lights up in red. 13-2-1 alarm specifications ■ if a...

Page 222

13- 4 13 troubleshooting 13-2 alarm and countermeasures 13-2-2 alarm message list action lower the operation duty on the robot or reduce the acceleration parameter, or correct the payload parameter. If the motor armature resistance is too low, contact our sales office or representative. Initialize t...

Page 223

13- 5 13 troubleshooting 13-2 alarm and countermeasures action check whether robot moving parts are locked. Check the motor wire and position signal wire connections. Initialize the parameters. In emergency stop, turn power on and check point data. If part of the data is defective, correct the data....

Page 224

13- 6 13 troubleshooting 13-2 alarm and countermeasures action lower the operation duty on the robot, or install a cooling fan. Check the power supply voltage. If the error occurs frequently, then the lsi is probably defective, so replace the srcp controller. Remove the obstacle or correct the point...

Page 225

13- 7 13 troubleshooting 13-3 troubleshooting for specific symptom 13-3 troubleshooting for specific symptom if any problems develop while the controller is being used, check the items below for the appropriate way to handle them. If the problem cannot be corrected using the steps listed below, plea...

Page 226

13- 8 13 troubleshooting 13-3 troubleshooting for specific symptom items to check • make sure there is no loose parts where the robot is installed. • check whether the motor case is properly grounded. • check that the resistance between the motor case and the controller's fg terminal is 1 ohm or les...

Page 227

13- 9 13 troubleshooting 13-3 troubleshooting for specific symptom 13-3-2 relating to the i/o items to check • check the wiring. • check the operation with the manual instruction of the tpb general-purpose output. (refer to "7-4 manual control of general-purpose output".) • connect the tpb and check...

Page 228

13- 10 13 troubleshooting 13-3 troubleshooting for specific symptom 13-3-3 other items to check • check the signal input (by using a plc monitor, etc.). • check the cable wiring. • try connecting another tpb if available. • check that the tpb version is 12.50 or later. • check whether the wrong cabl...

Page 229

13- 11 13 troubleshooting 13-4 displaying the alarm history 13-4 displaying the alarm history a history of past alarms can be displayed. Up to 100 alarms can be stored in the controller. 1) on the initial screen, press f3 (sys). [menu] select menu 1edit2oprt3sys 4mon [sys] select menu 1safe2opt 2rec...

Page 230

13- 12 13 troubleshooting 5) history numbers, time that alarms occurred (total elapsed time from controller start-up) and alarm descriptions are displayed. One screen displays the past 4 alarms in the order from the most recent alarm. Pressing the x z – and x z + keys displays the hidden items. Pres...

Page 231: Chapter 14

14- 1 14 maintenance and w arranty chapter 14 maintenance and warranty for safety purposes, always turn the power off before starting robot maintenance, cleaning or repairs, etc..

Page 232: 14-1 Warranty

14- 2 14 maintenance and w arranty 14-1 warranty 14-1 warranty the yamaha robot and/or related product you have purchased are warranted against the defects or malfunctions as described below. 14-1-1 warranty description if a failure or breakdown occurs due to defects in materials or workmanship in t...

Page 233

14- 3 14 maintenance and w arranty 14-2 replacing the system backup battery 14-2 replacing the system backup battery if an alarm is issued indicating that the system backup battery voltage is low, replace the battery using the procedure listed below. (1) first, make a backup copy of all necessary da...

Page 234: 14-3 Updating The System

14- 4 14 maintenance and w arranty 14-3 updating the system 14-3 updating the system yamaha may request, on occasion, that you update the system in your equipment. The following steps describe how to update the system. Before updating the system, you must set up a system that allows communications b...

Page 235: Chapter 15

15- 1 15 specifica tions chapter 15 specifications.

Page 236: 15-1 Srcp Sereis

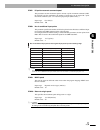

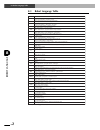

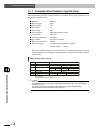

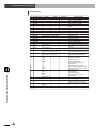

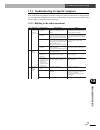

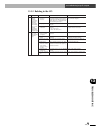

15- 2 15 specifica tions 15-1 srcp sereis 15-1 srcp sereis 15-1-1 basic specifications model specification item srcp-10 srcp-20 srcp-05 basic specifi- cations axis control memory command mode i/o i/o interface normal mode max. Power consumption external dimensions weight no. Of controllable axes con...

Page 237

15- 3 15 specifica tions 15-1 srcp sereis error detection items ambient temperature storage temperature ambient humidity noise immunity peripheral options overcurrent, overload, wire breakage, runaway, etc. 0 to 40 °c -10 to 65 °c 35 to 85%rh (no condensation) conforms to iec61000-4-4 level 2 tpb (v...

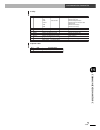

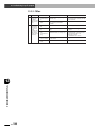

Page 238: 15-2 Tpb

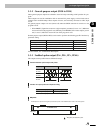

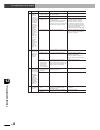

15- 4 15 specifica tions 15-2 tpb 15-2 tpb 15-2-1 basic specifications tpb basic specifications external dimensions weight power consumption power supply cable length serial interface display keyboard emergency stop button auxiliary memory device ambient temperature storage temperature ambient humid...

Page 239

15- 5 15 specifica tions 15-3 regenerative unit (rgu-2) 15-3 regenerative unit (rgu-2) 15-3-1 basic specifications rgu-2 basic specifications external dimensions weight cable length regenerative voltage regenerative stop voltage ambient temperature storage temperature ambient humidity noise immunity...

Page 240: Memo

Memo 15- 6.

Page 241: Chapter 16

16- 1 16 appendix chapter 16 appendix.

Page 242: 16-1 How to Handle Options

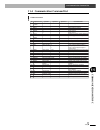

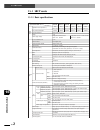

16- 2 16 appendix 16-1 how to handle options 16-1 how to handle options 16-1-1 memory card a memory card (option) can be used with the tpb to back up the srcp controller data. ■ using the memory card 1. Insert the memory card into the tpb as shown in fig. 16-1. 2. Back up the data by referring to se...

Page 243

16- 3 16 appendix 16-1 how to handle options ■ data size that can be saved data size that can be saved on one memory card is as follows: memory card capacity 8kb 64kb 1024kb (1mb) dpb cannot be used. Cannot be used. Tpb ver. 2.18 or earlier tpb ver. 12.50 or later up to 3 units of srcp up to 48 unit...

Page 244

16- 4 16 appendix 16-1-2 popcom communication cable this cable is used to operate the srcp controller from popcom software which runs on a pc and allows easy and efficient robot programming and operation. This popcom cable is different from typical communication cables, so do not use it for other pu...

Page 245: Memo

Memo.

Page 246

Ver. 1.01 ver. 2.00 ver. 2.01 ver. 2.02 ver. 2.03 ver. 2.04 english manual ver. 1.01 is based on japanese manual ver. 1.01. English manual ver. 2.00 is based on japanese manual ver. 3.04. English manual ver. 2.01 is based on japanese manual ver. 3.05. English manual ver. 2.02 is based on japanese ma...