- DL manuals

- Yamaha

- Offroad Vehicle

- Vector RS90GTZ

- Owner's Manual

Yamaha Vector RS90GTZ Owner's Manual

Summary of Vector RS90GTZ

Page 1

Owner’s manual rs90gtz rs90ltgtz 8ja-28199-10 lit-12628-02-91 esu10012 read this manual carefully before operating this vehicle. Dic183.

Page 2

Esu10041 read this manual carefully before operating this vehicle. This manual should stay with this vehicle if it is sold. U8ja10e0.Book page 1 tuesday, may 19, 2009 2:37 pm.

Page 3: Introduction

Introduction esu10121 congratulations on your purchase of a yamaha snowmobile. This model is the result of yamaha’s vast experience in the produc- tion of fine sporting and touring snowmobiles. It represents the high degree of craftsmanship and reliability that have made yamaha a lead- er in these f...

Page 4

Important manual information esu10151 particularly important information is distin- guished in this manual by the following nota- tions. This is the safety alert symbol. It is used to alert you to potential personal injury haz- ards. Obey all safety messages that follow this symbol to avoid possible...

Page 5: Contents

Contents location of the important labels ..... 1 safety information ............................ 5 description ........................................ 7 control functions ............................ 10 main switch .................................. 10 throttle lever .................................

Page 6: Contents

Contents troubleshooting ............................. 74 storage ............................................ 78 specifications ................................. 80 consumer information.................... 82 identification number records ....... 82 vehicle emission control information label .........

Page 7

Location of the important labels 1 esu10215 read and understand all of the labels on your vehicle. They contain important information for safe and proper operation of your vehicle. Never remove any labels from your vehicle. If a label becomes difficult to read or comes off, a replacement label is av...

Page 8

Location of the important labels 2 attention 8et-2815k-10 tune-up specifications engine 1.Spark plug 2.Spark plug gap 3.Idle speed specifications de la mise au point moteur 1.Type de bougie 2.Ecartement des Électrodes 3.RÉgime de ralenti cr8e(ngk) 0.7 ~ 0.8 mm (0.028 ~ 0.031 in) 1300 ± 100 r/min cr8...

Page 9

Location of the important labels 3 8fr-77763-e0 • c m v s s • c anada • n s v a c • t r a n s p o r t 506 this spark ignition system meets all requirements of the canadian interference causing equipment regulations. Ce système d’allumage par étincelle de véhicule respecte toutes les exigences du règ...

Page 10

Location of the important labels 4 jumper cable connection leads • for connecting procedures, refer to owner’s manual. Fils de branchement des cbles de dÉmarrage • effectuer le branchement des câbles de démarrage conformément aux instructions du manuel du propriétaire. 8fa-e0 8fa-2389c-e0 11 12 u8ja...

Page 11: Safety Information

Safety information 5 esu10183 as the vehicle’s owner, you are responsible for the safe and proper operation of your snowmobile. When you ride your snowmo- bile, you must know and use the following for your safety. Severe injury or death may result if you ignore any of the following. Before you opera...

Page 12: Safety Information

Safety information 6 ● many surfaces such as ice and hardpacked snow require much longer stopping distanc- es. Be alert, plan ahead and begin deceler- ating early. The best braking method on most surfaces is to release the throttle and apply the brake gently—not suddenly. Avoid carbon monoxide poiso...

Page 13: Description

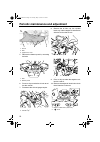

Description 7 esu10260 1,2,3 4 5,6,7 8,9 10 11 12 13 14 1,2,3 rs90gt rs90ltgt 4 5,6,7 8,9 10 11 12 13 14 1. Battery 2. Main fuse 3. Air filter 4. Oil filler cap 5. Fuse box 6. Coolant reservoir 7. Coolant recovery tank 8. Storage compartment 9. Tool kit 10. Tail/brake light 11. Slide rail suspension...

Page 14: Description

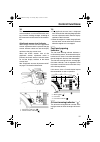

Description 8 fhi e lo 1 2 3 4 5 9 8 6 7 10 11 12 13 14 16 17 19 21 23 25 15 18 20 22 24 26 27 1. Brake lever 2. Parking brake lever 3. Grip/thumb warmer adjustment switch 4. Engine stop switch 5. Throttle lever 6. Main switch 7. Shift lever 8. Auxiliary dc jack 9. Helmet shield heater jack 10. Head...

Page 15: Description

Description 9 tip ● the snowmobile you have purchased may differ slightly from those shown in the figures of this manual. ● design and specifications are subjected to change without notice. U8ja10e0.Book page 9 tuesday, may 19, 2009 2:37 pm.

Page 16: Control Functions

Control functions 10 esu10292 main switch the main switch controls the ignition and lighting systems. The various positions are described below. Off the ignition circuit is switched off. The key can be removed only in this position. On the ignition circuit is switched on. Start the starting circuit ...

Page 17: Control Functions

Control functions 11 tip if the t.O.R.S. Is activated, the warning light and self-diagnosis warning indicator will flash, and the two-digit code “84” will be displayed in the meter display. If this occurs, have a yamaha dealer check the system as soon as possible. Esu13395 multi-function meter unit ...

Page 18: Control Functions

Control functions 12 odometer and tripmeter modes push the “select” button to switch the dis- play between the odometer mode “odo” and the tripmeter modes “trip a” and “trip b” in the following order: odo → trip a → trip b → odo if the fuel level warning indicator and warning light come on (see page...

Page 19: Control Functions

Control functions 13 been reached), the tripmeter must be reset af- ter the oil change for the next periodic oil change to be indicated at the correct time. In that case, reset the oil change tripmeter as follows. 1. Push the “select” button until “odo” is displayed, then push the “reset” button for...

Page 20: Control Functions

Control functions 14 esu10472 low coolant temperature indi- cator light “ ” the low coolant temperature indicator light comes on when the coolant temperature is low and informs the rider that the snowmobile should be warmed up. After the engine is started, warm it up until the indicator light goes o...

Page 21: Control Functions

Control functions 15 tip the snowmobile must be stopped on a level surface to obtain an accurate fuel meter read- ing, since the reading changes according to the movement and inclination of the snowmo- bile. Grip/thumb warmer level indicator when the grip warmer side of the grip/thumb warmer adjustm...

Page 22: Control Functions

Control functions 16 if the oil level warning indicator and the warn- ing light come on, place the snowmobile on a level surface and allow it to idle for one minute. If the oil level warning indicator and the warn- ing light go off, the engine oil level is sufficient, however it is getting low. Add ...

Page 23: Control Functions

Control functions 17 esu10531 engine stop switch “ ” the engine stop switch is used to stop the en- gine in an emergency. Simply push the stop switch to stop the engine. To start the engine, pull the stop switch and proceed with starting the engine. (see page 30 for engine starting procedures.) duri...

Page 24: Control Functions

Control functions 18 esu10692 auxiliary dc jack the auxiliary dc jack is located in the front panel and can be used for accessories. Tip the auxiliary dc jack cannot be used if the engine is not running. To use the auxiliary dc jack 1. Start the engine. 2. Open the auxiliary dc jack cap, and then in...

Page 25: Control Functions

Control functions 19 esu13520 brake lever the snowmobile is stopped by braking the en- tire drive system. Squeeze the brake lever towards the handle- bar grip to stop the snowmobile. Tip when the brake lever is operated, the brake light will illuminate. The brake lever is equipped with a position ad...

Page 26: Control Functions

Control functions 20 notice ecs00072 do not use the shift lever while the snow- mobile is moving, otherwise the drive train could be damaged. Esu10722 shroud and covers securely fasten the shroud and covers before operating the snowmobile. (see page 42 for removal and installation procedures.) 1. Sh...

Page 27: Control Functions

Control functions 21 esu13312 drive guard warning ews00401 ● coming in contact with the rotating v- belt or clutch parts can cause severe in- jury or death. Never run the engine with the drive guard removed. ● make sure that the drive guard is tight- ened securely before operating the snowmobile to ...

Page 28: Control Functions

Control functions 22 esu10760 v-belt holders keep a spare v-belt for emergency use by placing it into the v-belt holders provided. Notice ecs00180 make sure that the v-belt is installed se- curely in the holders. Esu10810 storage compartment open the storage compartment to store the tool kit, spare ...

Page 29: Control Functions

Control functions 23 3. Wipe up any spilled fuel immediately. 4. Be sure the fuel tank cap is closed se- curely by turning it clockwise. Warning ews00680 gasoline is poisonous and can cause inju- ry or death. Handle gasoline with care. Never siphon gasoline by mouth. If you should swallow some gasol...

Page 30: Control Functions

Control functions 24 warning ews00151 read and understand the following infor- mation before handling shock absorbers that contain highly pressurized nitrogen gas. ● do not tamper with or attempt to open the cylinder assemblies. ● do not subject the shock absorbers to an open flame or other high hea...

Page 31: Control Functions

Control functions 25 esu10926 adjusting the damping forces of the front shock absorbers warning ews00740 the damping forces of the left and right shock absorbers must be adjusted to the same settings. Uneven settings can cause poor handling and loss of stability. Compression damping force the compre...

Page 32: Control Functions

Control functions 26 to increase the spring preload and thereby harden the suspension, turn the adjusting ring in direction (a). To decrease the spring pre- load and thereby soften the suspension, turn the adjusting ring in direction (b). Tip the spring preload can be further adjusted by changing th...

Page 33: Control Functions

Control functions 27 to the control rod, and that it is tightly fitted on the locknut and against the control rod adjuster. [ecs00323] tip use the special wrench in the owner’s tool kit to make this adjustment. 2. Loosen the locknut. 3. To increase weight transfer, turn the ad- juster in direction (...

Page 34: Pre-Operation Checks

Pre-operation checks 28 esu11071 inspect your vehicle each time you use it to make sure the vehicle is in safe operating condition. Always follow the inspection and maintenance procedures and schedules described in the owner’s manual. Warning ews00191 failure to inspect or maintain the vehicle prope...

Page 35: Pre-Operation Checks

Pre-operation checks 29 drive track • check the deflection. • adjust if necessary. • check for wear and damage. • if necessary, have a yamaha dealer replace track. 64 slide runners • check for wear and damage. • if necessary, have yamaha dealer replace slide runners. 64 steering • check for excessiv...

Page 36: Operation

Operation 30 esu13500 read the owner’s manual carefully to be- come familiar with all controls. If there is a control or function you do not understand, ask your yamaha dealer. Warning ews00201 failure to familiarize yourself with the con- trols can lead to loss of control, which could cause an acci...

Page 37: Operation

Operation 31 4. Warm up the engine until it runs smooth- ly. 5. Be sure the low coolant temperature indi- cator light has gone out before operation. (see page 14 for detailed information about the indicator light.) esu11310 break-in there is never a more important period in the life of your engine t...

Page 38: Operation

Operation 32 pay particular attention to the safety informa- tion on page 5. Please read all warning and notice labels on your snowmobile. Also, read the snowmobil- er’s safety handbook that is supplied with your snowmobile. Learning to ride your snowmobile before you ride, always perform the pre-op...

Page 39: Operation

Operation 33 improper riding techniques such as abrupt throttle changes, excessive braking, incorrect body movements, or too much speed for the sharpness of the turn may cause the snow- mobile to tip. If your snowmobile begins to tip while turning, lean more into the turn to regain balance. If neces...

Page 40: Operation

Operation 34 traversing a slope warning ews00251 driving across the face of a slope (“side- hilling”) can lead to overturn or loss of control if proper techniques are not used. Follow these instructions to reduce your risk of an accident. Do not try steeper or more difficult inclines until you have ...

Page 41: Operation

Operation 35 ● sand ● rocks ● grass ● bare pavement other surfaces that should be avoided for the sake of drive track and slide runner life are: ● glare ice surfaces ● snow mixed with a lot of dirt and sand all of the above surfaces have one thing in common in regard to drive track and slide run- ne...

Page 42: Operation

Operation 36 esu11393 driving warning ews00300 be sure to read the “safety informa- tion” section on page 5 and the “riding your snowmobile” section on page 31 carefully before operating the snowmo- bile. Tip make sure that the engine is warmed up enough before riding. Warning ews00310 ● make sure t...

Page 43: Operation

Operation 37 3. Squeeze the throttle lever slowly to start out. 4. Turn the handlebar in the desired direc- tion. 5. Squeeze the brake lever to stop the snowmobile. 6. Apply the parking brake by moving the parking brake lever to the left. Esu11411 stopping the engine ● turn the main switch to the of...

Page 44

Periodic maintenance and adjustment 38 esu11451 periodic inspection, adjustment, and lubrication will keep your snowmobile in the safest and most efficient condition possible. Safety is an obligation of the vehicle owner/operator. The most important points of vehicle inspection, adjustment, and lubr...

Page 45

Periodic maintenance and adjustment 39 * valve clearance • check and adjust valve clear- ance when engine is cold. Every 40000 km (25000 mi) 50 * crankcase breather system • check breather hose for cracks or damage. • replace if necessary. — * fuel line • check fuel hose for cracks or damage. • repl...

Page 46

Periodic maintenance and adjustment 40 esu11563 general maintenance and lubrication chart item remarks initial every page 1 month or 800 km (500 mi) (40 hr) seasonally or 4000 km (2500 mi) (200 hr) engine oil • change (warm engine before draining). 50 * engine oil filter car- tridge • replace. Every...

Page 47

Periodic maintenance and adjustment 41 tip brake system: ● after disassembling the master cylinder or caliper cylinder, always change the brake fluid. Regularly check the brake fluid level and add fluid if necessary. ● replace the oil seals of the master cylinder and caliper cylinder every two years...

Page 48

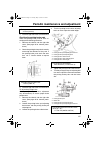

Periodic maintenance and adjustment 42 esu11741 tool kit the service information included in this man- ual and the tools provided in the owner’s tool kit are intended to assist you in the perfor- mance of preventive maintenance and minor repairs. However, additional tools such as a torque wrench may...

Page 49

Periodic maintenance and adjustment 43 to install a side cover 1. Fit the projection on the rear of the side cover into the hole in the fuel tank cover. 2. Fit the projections on the side cover into the slots as shown. 3. Tighten the fasteners. 4. Install the shroud. Top cover to remove the top cove...

Page 50

Periodic maintenance and adjustment 44 5. Lift up the rear of the top cover, discon- nect the main switch coupler, and then remove the cover. To install the top cover 1. Connect the main switch coupler. 2. Place the top cover in the original posi- tion, making sure to fit the projections on the cove...

Page 51

Periodic maintenance and adjustment 45 esu11782 checking the spark plugs the spark plug is an important engine compo- nent and is easy to inspect. The condition of the spark plug can indicate the condition of the engine. Check the coloration on the white porcelain insulator around the center electro...

Page 52

Periodic maintenance and adjustment 46 esu12911 adjusting the throttle cable free play 1. Place the snowmobile on a level surface and apply the parking brake. 2. Remove the shroud, the left and right side covers, and the top cover. (see page 42 for removal procedures.) 3. Remove the headlight unit b...

Page 53

Periodic maintenance and adjustment 47 9. Fit the weatherstrip on the headlight unit into the recess in the top of the air filter case cover. 10. Install the headlight unit bolts, and then tighten them to the specified torque. 11. Install the top cover, the left and right side covers, and the shroud...

Page 54

Periodic maintenance and adjustment 48 the t.O.R.S. Will be activated and the engine speed will be limited to less than the clutch engagement speed. (see page 80 for the clutch engagement speed.) warning! If the engine speed does not decrease to less than the clutch engagement speed, stop the engine...

Page 55

Periodic maintenance and adjustment 49 5. Lift up the air filter element frame and check the air filter element. If there is any snow on the air filter element, remove the element, brush off the snow, and then in- stall the air filter element. 6. Place the air filter element frame in the original po...

Page 56

Periodic maintenance and adjustment 50 because there is less air as altitude increases. Less air means less oxygen available for combustion. Your snowmobile utilizes an electronic fuel in- jection system that delivers the optimal air/fu- el ratio required by the engine. Therefore, the fuel injection...

Page 57

Periodic maintenance and adjustment 51 ● after operating the snowmobile, allow the engine to idle for at least 10 seconds before turning it off. 3. Remove the shroud and the right side cover. (see page 42 for removal proce- dures.) 4. Disconnect the oil level gauge coupler. Notice: disconnect the oi...

Page 58

Periodic maintenance and adjustment 52 5. Remove the bottom panel by removing the bolts. 6. Place an oil pan under the oil tank to col- lect the used oil. 7. Disconnect the oil level gauge coupler. 8. Remove the oil filler cap, the cylinder head cap, and the engine oil drain bolt to drain the oil fr...

Page 59

Periodic maintenance and adjustment 53 tip ● a “ ” mark is stamped on the crankcase near the engine oil drain bolt. ● dispose of used oil according to local regu- lations. ● skip steps 10–12 if the oil filter cartridge is not being replaced. 11. Remove the oil filter cartridge with an oil filter wre...

Page 60

Periodic maintenance and adjustment 54 gine oil drain bolts, the cylinder head cap, and the oil filler cap are installed correct- ly. 19. Turn the engine off, and then connect the oil level gauge coupler. Notice: if oil is leaking or the oil level warning indica- tor comes on when the engine is run-...

Page 61

Periodic maintenance and adjustment 55 ant as soon as possible, otherwise the cooling system will not be protected against frost and corrosion. If water has been added to the coolant, have a yamaha dealer check the antifreeze content of the coolant as soon as pos- sible, otherwise the effectiveness ...

Page 62

Periodic maintenance and adjustment 56 5. Start the engine, allow it to idle for several minutes, and then turn it off. 6. Check the coolant level in the coolant reservoir. If it is not full, remove the cool- ant reservoir cap, fill the reservoir with the recommended coolant, and then install the ca...

Page 63

Periodic maintenance and adjustment 57 have a yamaha dealer make this adjust- ment. 1. Place the snowmobile on a level surface and apply the parking brake. 2. Remove the shroud and the left side cov- er, and then remove the drive guard. (see pages 21 and 42 for removal proce- dures.) 3. Remove the s...

Page 64

Periodic maintenance and adjustment 58 8. If the v-belt position is incorrect, adjust it by removing or adding a spacer on each v-belt position adjusting bolt. 9. Tighten the v-belt position adjusting bolts. 10. Install the v-belt over the primary sheave assembly. 11. Rotate the secondary sliding sh...

Page 65

Periodic maintenance and adjustment 59 14. Install the drive guard, and then install the left side cover and the shroud. Esu12104 drive chain housing to check the drive chain housing oil level 1. Place the snowmobile on a level surface and apply the parking brake. 2. Remove the shroud and the right ...

Page 66

Periodic maintenance and adjustment 60 6. Install the right side cover and the shroud. To adjust the chain tension 1. Remove the shroud and the right side cover. (see page 42 for removal proce- dures.) 2. Loosen the locknut. 3. Turn the chain tension adjusting bolt clockwise until it is finger tight...

Page 67

Periodic maintenance and adjustment 61 4. Install the right side cover and the shroud. Checking the parking brake pads check the parking brake pads for wear ac- cording to the following procedure. 1. Remove the shroud and the right side cover. (see page 42 for removal proce- dures.) 2. Check the par...

Page 68

Periodic maintenance and adjustment 62 7. Tighten the parking brake pad adjusting bolt locknut. 8. Install the right side cover and the shroud. Checking the brake fluid level warning ews00460 be careful that water does not enter the master cylinder when refilling. Water will significantly lower the ...

Page 69

Periodic maintenance and adjustment 63 notice ecs00560 avoid scratching the skis when loading and unloading the snowmobile, when riding in areas with little or no snow, or on sharp edges such as concrete, curbs, etc. This will wear or damage the skis. To align the skis 1. Turn the handlebar so the s...

Page 70

Periodic maintenance and adjustment 64 esu13570 drive track and slide runners drive track warning ews00480 a broken track, track fittings or debris thrown by the drive track could be danger- ous to an operator or bystanders. Observe the following precautions: ● do not allow anyone to stand behind th...

Page 71

Periodic maintenance and adjustment 65 3. If the deflection is incorrect, adjust the drive track. Adjusting the drive track 1. Loosen the rear axle nut. 2. Lift the rear of the snowmobile onto a suit- able stand to raise the drive track off the ground. 3. Start the engine and rotate the drive track ...

Page 72

Periodic maintenance and adjustment 66 shifted to left 5. Adjust the drive track deflection to speci- fication. Notice: the right and left ad- justing bolts should be turned an equal amount. [ecs00970] 6. Tighten the locknuts to their specified torque. 7. Recheck alignment and deflection. If nec- es...

Page 73

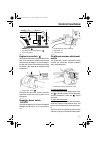

Periodic maintenance and adjustment 67 rs90gt rs90ltgt esu12221 replacing a headlight bulb 1. Remove the top cover. (see page 42 for removal procedures.) 2. Remove the screws, and then remove the headlight access panel. 1. Lubrication point 1. Throttle cable end 1. Lubrication point 1 1. Lubrication...

Page 74

Periodic maintenance and adjustment 68 3. Disconnect the headlight coupler. 4. Remove the bulb holder cover. 5. Unhook the bulb holder by pushing it in, then clockwise. 6. Remove the bulb. 7. Install the new bulb, and then hook the bulb holder onto the headlight unit. Notice: keep oil and your hands...

Page 75

Periodic maintenance and adjustment 69 2. Use a phillips screwdriver to turn the headlight beam adjusting screw and ad- just the headlight beams. To lower the headlight beams, turn the headlight beam adjusting screw in direction (a). To raise the headlight beams, turn the head- light beam adjusting ...

Page 76

Periodic maintenance and adjustment 70 dealer charge your battery. Using a con- ventional battery charger will damage the battery. ● do not charge the battery quickly. Esu12952 replacing a fuse warning ews00550 be sure to use the specified fuse. A wrong fuse could cause electrical system dam- age or...

Page 77

Periodic maintenance and adjustment 71 7. Slide the oil tank breather hose clamp away from the air filter case, and then dis- connect the oil tank breather hose. 8. Lift up the air filter case, disconnect the isc (idle speed control) unit inlet hose and cylinder head breather hose from the case, and...

Page 78

Periodic maintenance and adjustment 72 12. Connect the negative battery lead by in- stalling the bolt. 13. Install the battery cover, and then hook the battery band onto the holder. 14. Install the air filter case by reversing the removal steps. 15. Place the headlight unit in the original po- sitio...

Page 79

Periodic maintenance and adjustment 73 17. Install the headlight unit bolts, and then tighten them to the specified torque. 18. Install the top cover, the left and right side covers, and the shroud. Tip if the fuse immediately blows again, ask a yamaha dealer to inspect the snowmobile. 1. Weatherstr...

Page 80: Troubleshooting

Troubleshooting 74 esu12384 engine turns over but does not start 1. Fuel system ● no fuel supplied to combustion cham- ber • no fuel in tank: supply fuel. ↓ • clogged fuel line: clean fuel line. ↓ • clogged injector: ask a yamaha dealer to inspect. ● fuel supplied to combustion chamber • flooded eng...

Page 81: Troubleshooting

Troubleshooting 75 ● be sure to pull the lead covers back over the terminals completely. If the termi- nals are exposed, they could come into contact with the frame or a metal part of the snowmobile and this can cause elec- trical system damage or a fire haz- ard. Notice ecs00650 use the connecting ...

Page 82: Troubleshooting

Troubleshooting 76 7. Pull the black (–) connecting lead cover to expose the terminal through the slit in the cover, and then connect the black (–) jumper cable to the black (–) connecting lead. 8. Start the engine. 9. Disconnect the black (–) jumper cable from the black (–) connecting lead, and the...

Page 83: Troubleshooting

Troubleshooting 77 v-belt twists ● improper v-belt: replace with the correct v- belt. ● incorrect v-belt clutch offset: ask a yamaha dealer to inspect. ● loose or broken engine mount(s): ask a yamaha dealer to inspect. V-belt slips or becomes extremely hot ● oily or dirty v-belt or primary and secon...

Page 84: Storage

Storage 78 esu12433 long-term storage requires some preventive procedures to guard against deterioration. Cleaning thoroughly clean the snowmobile, inside and out, to remove the corrosive salts and acids that can accumulate. Use yamaha mud, grease, and engine cleaner, or an equivalent product, to lo...

Page 85: Storage

Storage 79 surface protection apply a coat of wax to painted surfaces. Apply suitable protectants to the exterior of the en- gine, drive track, and to other metal, plastic, and rubber parts. Battery remove the battery from the snowmobile. Store it in a cool, dry place that is above 0 °c (32 °f), but...

Page 86: Specifications

Specifications 80 esu12468 dimensions: overall length: rs90gt 2805 mm (110.4 in) rs90ltgt 3000 mm (118.1 in) overall width: 1225 mm (48.2 in) overall height: 1160 mm (45.7 in) dry weight: rs90gt 260.0 kg (573 lb) rs90ltgt 268.0 kg (591 lb) ski stance: 1086 mm (42.8 in) engine: type: liquid cooled 4-...

Page 87: Specifications

Specifications 81 fuel tank capacity: 35.6 l (9.41 us gal, 7.83 imp.Gal) engine oil quantity: with oil filter cartridge replacement: 3.3 l (3.49 us qt, 2.90 imp.Qt) without oil filter cartridge replacement: 3.1 l (3.28 us qt, 2.73 imp.Qt) total amount: 4.0 l (4.23 us qt, 3.52 imp.Qt) brake: type: hy...

Page 88: Consumer Information

Consumer information 82 esu12480 identification number records record the frame serial number, engine serial number (primary id), and key identification number in the spaces provided for assistance when ordering spare parts from a yamaha dealer. Also, record and keep the id numbers in a separate pla...

Page 89: Consumer Information

Consumer information 83 esu13460 vehicle emission control infor- mation label the vehicle emission control information la- bel is affixed at the location in the illustration. This label shows specifications related to ex- haust emissions as required by federal law, state law and environment canada. ...

Page 90: Consumer Information

Consumer information 84 esu12500 yamaha motor corporation, u.S.A. Snowmobile limit- ed warranty yamaha motor corporation, u.S.A. Hereby warrants that new yamaha snowmobiles purchased from an autho- rized yamaha snowmobile dealer in the continental united states will be free from defects in material ...

Page 91: Consumer Information

Consumer information 85 yamaha motor corporation, u.S.A. Makes no other warranty of any kind, expressed or implied. All implied war- ranties of merchantability and fit- ness for a particular purpose which exceed the obligations and time lim- its stated in this warranty are hereby disclaimed by yamah...

Page 92: Consumer Information

Consumer information 86 q. What responsibility does my dealer have under this warranty? A. Each yamaha snowmobile dealer is expected to: 1. Completely set up every new machine before sale. 2. Explain the operation, maintenance, and warranty requirements to your satisfaction at the time of sale, and ...

Page 93: Consumer Information

Consumer information 87 esu12510 yamaha extended service (y.E.S.) u8ja10e0.Book page 87 tuesday, may 19, 2009 2:37 pm.

Page 94: Index

Index a air filter, checking..................................... 48 auxiliary dc jack ...................................... 18 b battery...................................................... 69 brake and parking brake .......................... 60 brake lever .........................................

Page 95: Index

Index v valve clearance........................................ 50 v-belt........................................................ 56 v-belt holders ........................................... 22 vehicle emission control information label ...................................................... 83 u8ja...

Page 96

A5-tate_blank.Fm page 1 friday, may 16, 2003 9:00 am.

Page 97

A5-tate_blank.Fm page 1 friday, may 16, 2003 9:00 am.

Page 98

Yamaha motor co., ltd. Printed on recycled paper printed in japan 2009.05-0.5 ×1 cr esu12520 dic183.