- DL manuals

- Yamaha

- Scooter

- Vino YJ50RN

- Service Manual

Yamaha Vino YJ50RN Service Manual

Summary of Vino YJ50RN

Page 1

Yj50rn servicemanual lit-11616-14-50 5ly-28197-e0

Page 2

Eas00001 yj50rn service manual ©2000 by yamaha motor corporation, u.S.A. First edition, december, 2000 all rights reserved. Any reproduction or unauthorized use without the written permission of yamaha motor corporation, u.S.A. Is expressly prohibited. Printed in u.S.A. P/n lit-11616-14-50

Page 3: Notice

Eas00002 notice this manual was produced by the yamaha motor company, ltd. Primarily for use by yamaha deal- ers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manual. Therefore, anyone who uses this book to perform maintenance and repairs on yama...

Page 4: How to Use This Manual

Eas00007 how to use this manual this manual is intended as a handy, easy-to-read reference book for the mechanic. Comprehensive explanations of all installation, removal, disassembly, assembly, repair and check procedures are laid out with the individual steps in sequential order. 1 the manual is di...

Page 5: Gen

Eas00009 symbols the following symbols are not relevant to every vehicle. Symbols 1 to 8 indicate the subject of each chapter. 1 general information 2 specifications 3 periodic checks and adjustments 4 engine 5 carburetor(s) 6 chassis 7 electrical system 8 troubleshooting symbols 9 to f indicate the...

Page 6: Table of Contents

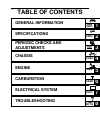

Eas00011 table of contents general information gen info 1 specifications spec 2 periodic checks and adjustments chk adj 3 chassis chas 4 engine eng 5 carburetion carb 6 electrical system elec 7 troubleshooting trbl shtg 8 – +.

Page 7: Memo

Memo.

Page 8: Contents

Contents chapter 1 general information scooter identification..........................................................................1-1 vehicle identification number .....................................................1-1 model code...................................................................

Page 9: Chapter 3

Chapter 3 periodic checks and adjustments introduction..............................................................................................3-1 periodic maintenance and lubrication intervals ....................3-1 side covers and footrest board .................................................

Page 10: Chapter 4

Chapter 4 chassis front wheel and brake ........................................................................4-1 checking the front wheel ............................................................4-5 checking the speedometer gear unit.......................................4-6 checking the brake...

Page 11: Chapter 5

Chapter 5 engine engine removal.........................................................................................5-1 installing the engine .......................................................................5-3 cylinder head, cylinder and piston ...............................................

Page 12: Chapter 6

Crankcase ................................................................................................5-37 disassembling the crankcase ....................................................5-39 checking the crankcase ..............................................................5-39 checking the b...

Page 13: Chapter 8

Starter motor ........................................................................................7-17 checking the starter motor .....................................................7-19 assembling the starter motor .................................................7-20 charging system ............

Page 14

Overheating ...............................................................................................8-3 engine .....................................................................................................8-3 fuel system ....................................................................

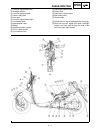

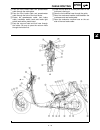

Page 15: Gen

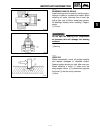

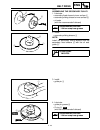

1 - 1 gen info eas00015 general information scooter identification eas00017 vehicle identification number the vehicle identification number 1 is stamped into the frame. 1 eas00018 model code the model code label 1 is affixed to the loca- tion shown in the figure. Record the informa- tion on this lab...

Page 16: Gen

1 - 2 gen info important information eas00020 important information preparation for removal and disassembly 1. Before removal and disassembly, remove all dirt, mud, dust and foreign material. 2. Use only the proper tools and cleaning equipment. Refer to “special tools”. 3. When disassembling, always...

Page 17: Gen

1 - 3 gen info important information eas00024 bearings and oil seals install bearings and oil seals so that the manu- facturer’s marks or numbers are visible. When installing oil seals, lubricate the oil seal lips with a light coat of lithium soap base grease. Oil bearings liberally when installing,...

Page 18: Gen

1 - 4 gen info important information eas00026 checking the connections check the leads, couplers, and connectors for stains, rust, moisture, etc. 1. Disconnect: • lead • coupler • connector 2. Check: • lead • coupler • connector moisture → dry with an air blower. Rust/stains → connect and disconnect...

Page 19: Gen

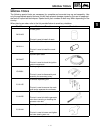

1 - 5 gen info eas00027 special tools the following special tools are necessary for complete and accurate tune-up and assembly. Use only the appropriate special tools as this will help prevent damage caused by the use of inappropri- ate tools or improvised techniques. Special tools, part numbers or ...

Page 20: Gen

1 - 6 gen info yu-01701 sheave holder this tool is used to hold the clutch hous- ing when removing or installing the clutch housing nut. Yu-03112 pocket tester this tool is used to check the electrical system. Yu-33223 compression gauge this tool is used to measure engine compression. Yu-33975 steer...

Page 21: Gen

1 - 7 gen info acc-1100-15-01 quick gasket ® this sealant is used to seal to mating surfaces (e.G., crankcase mating sur- faces). Tool no. Tool name/function illustration special tools 1.

Page 22: Spec

2 - 1 spec specifications general specifications item standard limit model code 5ly1 ---- dimensions overall length 1,630 mm (64.1 in) ---- overall width 630 mm (24.8 in) ---- overall height 1,030 mm (40.5 in) ---- seat height 715 mm (28.1 in) ---- wheelbase 1,150 mm (45.3 in) ---- minimum ground cl...

Page 23: Spec

2 - 2 spec engine specifications engine specifications item standard limit engine engine type air-cooled, 2-stroke ---- induction system reed valve ---- displacement 49 cm 3 ---- cylinder arrangement forward inclined single cylinder ---- bore × stroke 40.0 × 39.2 mm (1.57 × 1.54 in) ---- compression...

Page 24: Spec

2 - 3 spec engine specifications piston piston-to-cylinder clearance 0.03 ~ 0.05 mm (0.0012 ~ 0.0020 in) 0.10 mm (0.0039 in) diameter d 39.952 ~ 39.969 mm (1.5729 ~ 1.5736 in) ---- height h 5 mm (0.2 in) ---- oversize 1st ---- ---- oversize 2nd ---- ---- piston pin bore (in the piston) diameter 10.0...

Page 25: Spec

2 - 4 spec engine specifications crankshaft width a 37.90 ~ 37.95 mm (1.492 ~ 1.494 in) ---- max. Runout c ---- 0.03 mm (0.0012 in) big end side clearance d 0.35 ~ 0.75 mm (0.0138 ~ 0.0295 in) 1.0 mm (0.0394 in) big end radial clearance e 0.004 ~ 0.017 mm (0.00016 ~ 0.00067 in) ---- small end free p...

Page 26: Spec

2 - 5 spec engine specifications carburetor model (manufacturer) × quantity y14p/1 (teikei) × 1 ---- throttle cable free play (at the flange of the throttle grip) 1.5 ~ 3.5 mm (0.06 ~ 0.14 in) ---- id mark 5ly1 00 ---- main jet #64 ---- main air jet 2.0 ---- jet needle 3soc-3/5 ---- needle jet 2.090...

Page 27: Spec

2 - 6 spec chassis specifications chassis specifications item standard limit frame frame type steel tube underbone ---- caster angle 25° ---- trail 71 mm (2.8 in) ---- front wheel wheel type panel wheel ---- rim size 10 × 2.15 ---- material steel ---- wheel travel 60 mm (2.36 in) ---- wheel runout m...

Page 28: Spec

2 - 7 spec chassis specifications front brake brake type drum brake ---- operation right-hand operation ---- brake lever free play (at lever end) 10 ~ 20 mm (0.39 ~ 0.79 in) ---- dram brake type leading, trailing ---- brake drum inside diameter 110 mm (4.33 in) 110.5 mm (4.35 in) lining thickness 4 ...

Page 29: Spec

2 - 8 spec chassis specifications rear suspension suspension type unit swing ---- rear shock absorber assembly type coil spring/oil damper ---- rear shock absorber assembly travel 45 mm (1.77 in) ---- spring free length 173.5 mm (6.83 in) 170.0 mm (6.69 in) installed length 166.5 mm (6.56 in) ---- s...

Page 30: Spec

2 - 9 spec electrical specifications electrical specifications item standard limit system voltage 12 v ---- ignition system ignition system type dc.Cdi ---- ignition timing 14° btdc at 5,000 r/min ---- advancer type fixed ---- pickup coil resistance/color 248 ~ 372 Ω /w/l–w/r ---- cdi unit model (ma...

Page 31: Spec

2 - 10 spec electrical specifications electric starting system system type constant mesh ---- starter motor model (manufacturer) 5bm (yamaha) ---- power output 0.14 kw ---- brush overall length 6.1 mm (0.24 in) 0.9 mm (0.04 in) spring force 2.32 ~ 3.48 n (236.5 ~ 355.0 gf, 8.35 ~ 12.53 oz) ---- arma...

Page 32: Spec

2 - 11 spec conversion table/ general tightening torque specifications eas00028 conversion table all specification data in this manual are listed in si and metric units. Use this table to convert metric unit data to imperial unit data. Conversion table eas00030 general tightening torque specificatio...

Page 33: Spec

2 - 12 spec tightening torques tightening torques engine tightening torques part to be tightened part name thread size q’ty tightening torque remarks nm m·kgf ft·lb spark plug m14 1 20 2.0 14 cylinder head nut m7 4 14 1.4 10 cylinder head stud bolt m7 4 10 1.0 7 air shroud screw m6 2 7 0.7 5.1 air s...

Page 34: Spec

2 - 13 spec tightening torques chassis tightening torques part to be tightened thread size tightening torque remarks nm m·kgf ft·lb engine mounting: engine mounting bolt/nut m12 84 8.4 61 rear shock absorber and engine m8 15 1.5 11 engine bracket and frame m10 46 4.6 33 tail reinforcement m6 10 1.0 ...

Page 35: Spec

2 - 14 spec lubrication points and lubricant types lubrication points and lubricant types engine lubrication point symbol oil seal lips ls o-rings ls bearings e piston surface e piston pin e cylinder e transmission case (bearing) lt right crankcase (bearing retainer) lt autolube pump ls starter whee...

Page 36: Spec

2 - 15 spec lubrication points and lubricant types chassis lubrication point symbol oil seal lips ls o-rings ls bearings ls speedometer drive gear ls front brake camshaft ls front brake cable ls throttle cable ls tube guide (throttle grip) inner surface ls upper steering stem ring nut ls upper beari...

Page 37: Spec

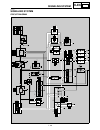

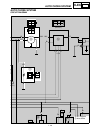

2 - 16 spec cable routing cable routing 1 front brake cable 2 rear brake cable 3 front turn signal leads 4 fuel level gauge coupler 5 flasher relay 6 horn lead 7 throttle cable 8 main switch 9 fuel gauge 0 speedometer cable È push the brake cable flange in until it contacts the lever holder. É faste...

Page 38: Spec

2 - 17 spec cable routing 1 front turn signal leads (left) 2 headlight coupler 3 fuel level gauge coupler 4 flasher relay lead 5 horn lead 6 front turn signal leads (right) 7 front brake cable 8 speedometer cable 9 battery 0 rectifier/regulator coupler a cdi unit lead coupler b fuel overflow hose c ...

Page 39: Spec

2 - 18 spec cable routing Ê pass the front brake cable and speedometer cable through the cable guide. Ë pass the front brake cable and speedometer cable through the hole of the front fender. Ì fasten the speedometer cable, front brake cable, handlebar switch leads and brake light switch leads with a...

Page 40: Spec

2 - 19 spec cable routing 1 tail/brake light coupler 2 oil level switch lead 3 battery leads 4 battery 5 starter motor coupler 6 ac magneto coupler 7 auto choke coupler 8 headlight coupler 9 front turn signal leads 0 horn lead a main switch lead b flasher relay lead c ignition coil lead d spark plug...

Page 41: Spec

2 - 20 spec cable routing È fasten the wire harness with a plastic locking tie. É fasten the wire harness, throttle cable and rear brake cable with plastic locking tie. Ê fasten the main switch lead with a plastic lock- ing tie. Ë fasten the wire harness with a plastic locking tie. Ì pass the wire h...

Page 42: Spec

2 - 21 spec cable routing 1 ignition coil lead 2 ignition coil 3 battery 4 starter relay 5 oil hose 6 oil level switch lead 7 ac magneto lead 8 fuel sender lead 9 tail/brake light lead 0 rear turn signal leads a cdi unit b vacuum hose c rectifier/regulator d fuel hose e auto choke lead f oil deliver...

Page 43: Spec

2 - 22 spec cable routing È fasten the wire harness at the white tape marker with a plastic locking tie. É pass the spark plug lead through the bottom cowling guide. Ê pass the starter motor lead under the engine bracket and engine mount spacer, and then through the hole of the cover. Ë fasten the w...

Page 44: Chk

3 - 1 chk adj eas00036 periodic checks and adjustments introduction this chapter includes all information necessary to perform recommended checks and adjustments. If followed, these preventive maintenance procedures will ensure more reliable vehicle operation, a longer service life and reduce the ne...

Page 45: Chk

3 - 2 chk adj eau00479 note: the air filter needs more frequent service if you are riding in unusually wet or dusty areas. Eau03903 note: from 6,000 mi (9,000 km) or 18 months, repeat the maintenance intervals starting from 2,000 mi (3,000 km) or 6 months. Periodic maintenance and lubrication 3.

Page 46: Chk

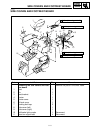

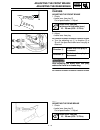

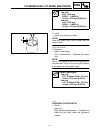

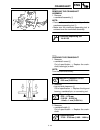

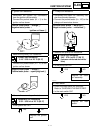

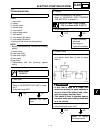

3 - 3 chk adj side covers and footrest board eas00038 side covers and footrest board 6 3 9 18 8 11 13 15 10 12 14 4 16 17 2 1 5 7 7 t r . . 15 nm (1.5 m • kg, 11 ft • ib) t r . . 10 nm (1.0 m • kg, 7.2 ft • ib) t r . . 7 nm (0.7 m • kg, 5.1 ft • ib) t r . . 12 nm (1.2 m • kg, 8.7 ft • ib) 11 order j...

Page 47: Chk

3 - 4 chk adj side covers and footrest board 6 3 9 18 8 11 13 15 10 12 14 4 16 17 2 1 5 7 7 t r . . 15 nm (1.5 m • kg, 11 ft • ib) t r . . 10 nm (1.0 m • kg, 7.2 ft • ib) t r . . 7 nm (0.7 m • kg, 5.1 ft • ib) t r . . 12 nm (1.2 m • kg, 8.7 ft • ib) 11 order job/part q’ty remarks 12 rear turn signal...

Page 48: Chk

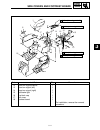

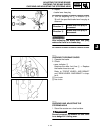

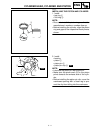

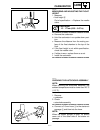

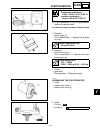

3 - 5 chk adj front panel and leg shield eas00040 front panel and leg shield 1 9 2 3 4 5 7 13 6 8 10 11 12 order job/part q’ty remarks removing the front panel and leg shield remove the parts in the order listed. Footrest board refer to “side covers and foot- rest board”. 1 headlight cover 1 2 headl...

Page 49: Chk

3 - 6 chk adj front panel and leg shield 1 9 2 3 4 5 7 13 6 8 10 11 12 order job/part q’ty remarks 11 fuel level gauge 1 12 main switch cover 1 13 leg shield 1 for installation, reverse the removal procedure. 3.

Page 50: Chk

3 - 7 chk adj adjusting the engine idling speed eas00053 adjusting the engine idling speed note: @ prior to adjusting the engine idling speed, the carburetor should be adjusted properly, the air filter element should be clean, and the engine should have adequate compression. 1. Start the engine and ...

Page 51: Chk

3 - 8 chk adj adjusting the engine idling speed/ adjusting the throttle cable free play 6. Adjust: • throttle cable free play a refer to “adjusting the throttle cable free play”. Throttle cable free play (at the flange of the throttle grip) 1.5 ~ 3.5 mm (0.06 ~ 0.14 in) eas00058 adjusting the thrott...

Page 52: Chk

3 - 9 chk adj bleeding the autolube pump note: the autolube pump and delivery lines must be bled on the following occasions. • setting up a new scooter out of the crate. • whenever the oil tank has run dry. • whenever any portion of the engine oil sys- tem is disconnected. 1. Remove: • center cover ...

Page 53: Chk

3 - 10 chk adj note: • check the bleed screw gasket, and if dam- aged, replace with a new one. • place a oil pan under the autolube pump to catch oil. ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲▲▲ 5. Install: • air shroud refer to “generator and autolube pump” in chapter 5. • footrest board • si...

Page 54: Chk

3 - 11 chk adj checking the spark plug/ measuring the compression pressure 4. Check: • electrodes 1 damage/wear → replace the spark plug. • insulator 2 abnormal color → replace the spark plug. Normal color is medium-to-light tan. 5. Clean: • spark plug (with a spark plug cleaner or wire brush) 6. Me...

Page 55: Chk

3 - 12 chk adj measuring the compression pressure caution: @ before removing the spark plug, use com- pressed air to blow away any dirt accumu- lated in the spark plug well to prevent it from falling into the cylinder. 5. Install: • compression gauge 1 compression gauge yu-33223 1 6. Measure: • comp...

Page 56: Chk

3 - 13 chk adj measuring the compression pressure/ checking the engine oil level d. If the compression pressure is below the minimum specification, squirt a few drops of oil into the cylinder and measure again. Refer to the following table. ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲▲▲ 7. Instal...

Page 57: Chk

3 - 14 chk adj 3. Remove: • oil tank cover refer to “side covers and footrest- board”. • oil tank cap 1 4. Fill: • engine oil make sure the engine oil is at the specified level. Fill with oil as necessary. Recommended oil yamalube 2-cycle oil or 2-stroke engine oil replacing the transmission oil 1. ...

Page 58: Chk

3 - 15 chk adj 5. Remove: • transmission oil drain bolt 1 • gasket 1 6. Drain: • transmission oil (completely from the transmission case) 7. Check: • o-ring damage → replace. 8. Install: • gasket 1 • transmission oil drain bolt 2 new 1 2 new t r . . 18 nm (1.8 m · kg, 13 ft · lb) 9. Fill: • crankcas...

Page 59: Chk

3 - 16 chk adj cleaning the air filter element eas00089 cleaning the air filter element note: @ on the bottom of the air filter case is a check hose 1 . If dust or water or both collects in this hose, clean the air filter element and air filter case. 1. Remove: • footrest board refer to “side covers...

Page 60: Chk

3 - 17 chk adj cleaning the air filter element/ checking the carburetor joint/ checking the fuel and vacuum hoses 6. Install: • air filter element • air filter case cover caution: @ never operate the engine without the air fil- ter element installed. Unfiltered air will cause rapid wear of engine pa...

Page 61: Chk

3 - 18 chk adj checking the fuel and vacuum hoses/ checking the crankcase breather hose/ checking the exhaust system 2. Check: • vacuum hose 1 • fuel hoses 2 cracks/damage → replace. Loose connection → connect properly. 3. Install: • side cover (left) refer to “side covers and footrest board”. Eas00...

Page 62: Chk

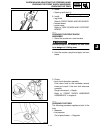

3 - 19 chk adj adjusting the front brake/ adjusting the rear brake eas00109 chassis adjusting the front brake 1. Check: • brake lever free play a out of specification → adjust. Brake lever free play (at the end of the brake lever) 10 ~ 20 mm (0.39 ~ 0.79 in) 2. Adjust: • brake lever free play ▼▼▼ ▼ ...

Page 63: Chk

3 - 20 chk adj adjusting the rear brake/ checking the brake shoes/ checking and adjusting the steering head 2. Adjust: • brake lever free play ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ a. Turn the adjusting nut 1 in direction a or b until the specified brake lever free play is obtained. Caut...

Page 64: Chk

3 - 21 chk adj checking and adjusting the steering head note: @ place the scooter on a suitable stand so that the front wheel is elevated. 2. Check: • steering head grasp the bottom of the front fork legs and gently rock the front fork. Binding/looseness → adjust the steering head. 3. Remove: • cent...

Page 65: Chk

3 - 22 chk adj checking and adjusting the steering head/ checking the front shock absorber/ checking the tires 5. Install: • steering shaft bolt 5 6. Install: • leg shield refer to “front panel and leg shield”. • footrest board • center cover refer to “side covers and footrest board”. 5 t r . . 42 n...

Page 66: Chk

3 - 23 chk adj checking the tires warning @ • the tire pressure should only be checked and regulated when the tire temperature equals the ambient air temperature. • the tire pressure and the suspension must be adjusted according to the total weight (including cargo, rider and acces- sories) and the ...

Page 67: Chk

3 - 24 chk adj checking the tires warning @ • do not use a tubeless tire on a wheel designed only for tube tires to avoid tire failure and personal injury from sudden deflation. • when using tube tires, be sure to install the correct tube. • always replace a new tube tire and a new tube as a set. • ...

Page 68: Chk

3 - 25 chk adj checking the tires/checking the wheels rear tire warning @ new tires have a relatively low grip on the road surface until they have been slightly worn. Therefore, approximately 100 km should be traveled at normal speed before any high-speed riding is done. Note: @ for tires with a dir...

Page 69: Chk

3 - 26 chk adj checking and lubricating the cables/ lubricating the levers/lubricating the centerstand eas00170 checking and lubricating the cables the following procedure applies to all of the cable sheaths and cables. Warning @ damaged cable sheaths may cause the cable to corrode and interfere wit...

Page 70: Chk

3 - 27 chk adj checking and charging the battery eas00179 electrical system checking and charging the battery warning @ batteries generate explosive hydrogen gas and contain electrolyte which is made of poisonous and highly caustic sulfuric acid. Therefore, always follow these preventive measures: •...

Page 71: Chk

3 - 28 chk adj checking and charging the battery note: @ since mf batteries are sealed, it is not possi- ble to check the charge state of the battery by measuring the specific gravity of the electro- lyte. Therefore, the charge of the battery has to be checked by measuring the voltage at the battery...

Page 72: Chk

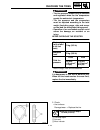

3 - 29 chk adj checking and charging the battery b. Check the charge of the battery, as shown in the charts and the following example. Example c. Open-circuit voltage = 12.0 v d. Charging time = 6.5 hours e. Charge of the battery = 20 ~ 30% ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲▲▲ 5. Charge...

Page 73: Chk

3 - 30 chk adj checking and charging the battery • if the battery becomes hot to the touch at any time during the charging process, disconnect the battery charger and let the battery cool before reconnecting it. Hot batteries can explode! • as shown in the following illustration, the open-circuit vo...

Page 74: Chk

3 - 31 chk adj charging method using a variable voltage charger checking and charging the battery.

Page 75: Chk

3 - 32 chk adj charging method using a constant voltage charger checking and charging the battery 3.

Page 76: Chk

3 - 33 chk adj 6. Install: • battery 7. Connect: • battery lead coupler (to the battery terminals) 8. Check: • battery terminals dirt → clean with a wire brush. Loose connection → connect properly. 9. Lubricate: • battery terminal 10.Install: • battery box refer to “engine removal” in chapter 5. • c...

Page 77: Chk

3 - 34 chk adj checking the fuse eas00181 checking the fuse caution: @ to avoid a short circuit, always set the main switch to “off” when checking or replacing a fuse. 1. Remove: • center cover refer to “side covers and footrest board”. • battery refer to “engine removal” in chapter 5. 2. Check: • c...

Page 78: Chk

3 - 35 chk adj checking the fuse/replacing the headlight warning @ never use a fuse with an amperage rating other than that specified. Improvising or using a fuse with the wrong amperage rat- ing may cause extensive damage to the electrical system, cause the lighting and ignition systems to malfunct...

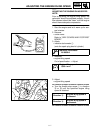

Page 79: Chk

3 - 36 chk adj replacing the headlight bulb/ adjusting the headlight beam 6. Install: • headlight bulb secure the new headlight bulb with the headlight bulb holder. Caution: @ avoid touching the glass part of the head- light bulb to keep it free from oil, otherwise the transparency of the glass, the...

Page 80: Chk

3 - 37 chk adj adjusting the headlight beam 2. Adjust: • headlight beam (horizontally) ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ a. Turn the adjusting knob 2 in direction a or b . ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲▲▲ direction a headlight beam moves to the right. Direction b hea...

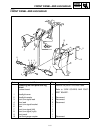

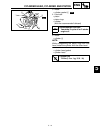

Page 81: Chas

4 - 1 chas eas00517 chassis front wheel and brake 6 9 7 3 4 2 8 1 5 t r . . 48 nm (4.8 m • kg, 35 ft • ib) order job/part q’ty remarks removing the front wheel and brake remove the parts in the order listed. Note: @ place the scooter on a suitable stand so that the front wheel is elevated. 1 speedom...

Page 82: Chas

4 - 2 chas front wheel and brake 6 9 7 3 4 2 8 1 5 t r . . 48 nm (4.8 m • kg, 35 ft • ib) order job/part q’ty remarks 8 front brake shoe plate 1 9 spacer 1 for installation, reverse the removal procedure..

Page 83: Chas

4 - 3 chas front wheel and brake 1 2 4 3 5 6 ls ls new order job/part q’ty remarks disassembling the front wheel remove the parts in the order listed. 1 oil seal 1 refer to “checking the front wheel”. 2 wheel bearing (right) 1 3 spacer 1 4 collar 1 5 wheel bearing (left) 1 6 dust seal 1 for assembly...

Page 84: Chas

4 - 4 chas front wheel and brake 1 2 0 5 4 9 7 new new a 8 6 t r . . 4 nm (0.4 m • kg, 2.9 ft • ib) ls ls 3 order job/part q’ty remarks disassembling the front brake shoe plate remove the parts in the order listed. 1 brake shoe 2 2 brake shoe spring (pin side) 1 3 brake shoe spring (brake camshaft s...

Page 85: Chas

4 - 5 chas front wheel and brake eas00525 checking the front wheel 1. Check: • wheel axle roll the wheel axle on a flat surface. Bends → replace. Warning @ do not attempt to straighten a bent wheel axle. 2. Check: • tire • front wheel damage/wear → replace. Refer to “checking the tires” and “checkin...

Page 86: Chas

4 - 6 chas front wheel and brake 5. Replace: • oil seal • wheel bearings ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ a. Clean the outside of the front wheel hub. B. Remove the oil seal 1 with a flat-head screwdriver. Note: @ to prevent damaging the wheel, place a rag 2 between the screwdriver ...

Page 87: Chas

4 - 7 chas front wheel and brake eas00536 checking the brake the following procedure applies to all of the brake shoes. 1. Check: • brake shoe lining glazed areas → repair. Sand the glazed areas with course sandpa- per. Note: @ after sanding the glazed areas, clean the brake shoe with a cloth. 2. Me...

Page 88: Chas

4 - 8 chas front wheel and brake eas00537 assembling the brake shoe plate 1. Install: • brake camshaft 1 • spring • brake shoe wear indicator 2 • brake camshaft lever 3 ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ a. Align the projection on the brake shoe wear indicator with the notch in the br...

Page 89: Chas

4 - 9 chas front wheel and brake 5. Tighten: • wheel axle nut warning @ make sure the brake cable is routed prop- erly. Caution: @ before tightening the wheel axle nut, push down hard on the handlebar several times and check if the front fork rebounds smoothly. T r . . 48 nm (4.8 m · kg, 35 ft · lb)...

Page 90: Chas

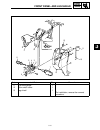

4 - 10 chas rear wheel and brake eas00551 rear wheel and brake 1 2 3 4 5 6 t r . . 105 nm (10.5 m • kg, 75 ft • lb) t r . . 28 nm (2.8 m • kg, 20 ft • ib) t r . . 13 nm (1.3 m • kg, 9.4 ft • ib) new order job/part q’ty remarks removing the rear wheel and brake remove the parts in the order listed. N...

Page 91: Chas

4 - 11 chas rear wheel and brake 1 2 3 4 5 0 9 8 7 a ls ls new 6 new t r . . 7 nm (0.7 m • kg, 5.1 ft • ib) order job/part q’ty remarks removing the rear brake shoe plate remove the parts in the order listed. 1 adjusting nut 1 2 rear brake cable 1 3 pin 1 4 brake shoe 2 5 brake shoe spring (pin side...

Page 92: Chas

4 - 12 chas rear wheel and brake eas00565 checking the rear wheel 1. Check: • rear wheel refer to “checking the front wheel”. 2. Check: • tire • rear wheel damage/wear → replace. Refer to “checking the tires” and “checking the wheels” in chapter 3. 3. Measure: • radial wheel runout • lateral wheel r...

Page 93: Chas

4 - 13 chas rear wheel and brake 3. Measure: • brake drum inside diameter a out of specification → replace the wheel. 4. Check: • brake drum inner surface oil deposits → clean. Remove the oil with a rag soaked in lacquer thinner or solvent. Scratches → repair. Lightly and evenly polish the scratches...

Page 94: Chas

4 - 14 chas rear wheel and brake eas00573 installing the brake shoes 1. Install: • brake camshaft lever 1 note: @ • align the punch mark a in the brake cam- shaft with the mark b on the brake camshaft lever. • lubricate the brake camshaft and pin with lithium soap base grease. Warning @ after instal...

Page 95: Chas

4 - 15 chas front shock absorber assemblies eas00647 front shock absorber assemblies order job/part q’ty remarks removing the front shock absorber assemblies remove the parts in the order listed. The following procedure applies to both of the front shock absorbers. Front panel refer to “front panel ...

Page 96: Chas

4 - 16 chas front shock absorber assemblies checking the front shock absorber assemblies the following procedure applies to both front shock absorber assemblies. 1. Check: • front shock absorber rod bends/damage → replace the front shock absorber assembly. • front shock absorber oil leaks → replace ...

Page 97: Chas

4 - 17 chas handlebar eas00664 handlebar order job/part q’ty remarks removing the handlebar switches and handlebar grips remove the parts in the order listed. Center cover refer to “side covers and foot- rest board” in chapter 3. 1 rear view mirror (left/right) 2 2 front brake cable 1 3 rear brake c...

Page 98: Chas

4 - 18 chas handlebar order job/part q’ty remarks 7 left handlebar switch 1 refer to “installing the handle- bar”. 8 upper handlebar holder 2 9 handlebar 1 10 handlebar grip 1 refer to “removing the handle- bar”. For installation, reverse the removal procedure..

Page 99: Chas

4 - 19 chas handlebar eas00666 removing the handlebar 1. Stand the scooter on a level surface. Warning @ securely support the scooter so that there is no danger of it falling over. 2. Remove: • handlebar grip 1 note: @ blow compressed air between the handlebar and the handlebar grip, and gradually p...

Page 100: Chas

4 - 20 chas handlebar eas00671 installing the handlebar 1. Stand the scooter on a level surface. Warning @ securely support the scooter so that there is no danger of it falling over. 2. Install: • handlebar 1 • upper handlebar holders 2 caution: @ • first, tighten the bolts on the front side of the ...

Page 101: Chas

4 - 21 chas handlebar 4. Install: • throttle grip • throttle cable note: @ lubricate the inside of the throttle grip with a thin coat of lithium soap base grease and install it onto the handlebar. 5. Install: • right handlebar switch 1 warning @ make sure the throttle grip operates smoothly. Note: @...

Page 102: Chas

4 - 22 chas steering head steering head order job/part q’ty remarks removing the lower handlebar holder remove the parts in the order listed. Footrest board refer to “side covers and foot- rest board” in chapter 3. Front panel/leg shield refer to “front panel and leg shield” in chapter 3. Front shoc...

Page 103: Chas

4 - 23 chas steering head order job/part q’ty remarks removing the fork remove the parts in the order listed. 1 cover 1 2 upper steering stem ring nut 1 3 upper race 1 4 fork 1 5 upper bearing 1 6 lower bearing 1 7 upper bearing outer race 1 8 lower bearing outer race 1 for installation, reverse the...

Page 104: Chas

4 - 24 chas steering head eas00680 removing the fork 1. Stand the scooter on a level surface. Warning @ securely support the scooter so that there is no danger of it falling over. 2. Remove: • upper steering stem ring nut 1 • upper race 2 note: @ hold the upper race with the steering nut wrench (45 ...

Page 105: Chas

4 - 25 chas steering head 3. Replace: • bearings • bearing races ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ a. Remove the bearing races from the steering head pipe with a long rod 1 and hammer. B. Install new bearing races. Caution: @ if the bearing race is not installed properly, the steerin...

Page 106: Chas

4 - 26 chas rear shock absorber assembly eas00685 rear shock absorber assembly t r . . 30 nm (3.0 m • kg, 22 ft • ib) t r . . 15 nm (1.5 m • kg, 11 ft • ib) 1 order job/part q’ty remarks removing the rear shock absorber assembly remove the parts in the order listed. Side cover (left) refer to “side ...

Page 107: Chas

4 - 27 chas rear shock absorber assembly eas00692 removing the rear shock absorber assembly 1. Stand the scooter on a level surface. Warning @ securely support the scooter so that there is no danger of it falling over. Note: @ place the scooter on a suitable stand so that the rear wheel is elevated....

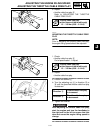

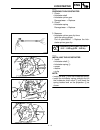

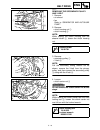

Page 108: Eng

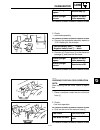

5 - 1 eng engine engine removal 5 6 7 13 16 8 2 11 12 10 15 14 9 4 3 t r . . 84 nm (8.4 m • kg, 61 ft • ib) t r . . 15 nm (1.5 m • kg, 11 ft • ib) t r . . 28 nm (2.8 m • kg, 20 ft • ib) t r . . 11 nm (1.1 m • kg, 8.0 ft • ib) t r . . 13 nm (1.3 m • kg, 9.4 ft • ib) 1 new order job/part q’ty remarks ...

Page 109: Eng

5 - 2 eng engine removal 5 6 7 13 16 8 2 11 12 10 15 14 9 4 3 t r . . 84 nm (8.4 m • kg, 61 ft • ib) t r . . 15 nm (1.5 m • kg, 11 ft • ib) t r . . 28 nm (2.8 m • kg, 20 ft • ib) t r . . 11 nm (1.1 m • kg, 8.0 ft • ib) t r . . 13 nm (1.3 m • kg, 9.4 ft • ib) 1 new order job/part q’ty remarks 10 adju...

Page 110: Eng

5 - 3 eng engine removal eas00192 installing the engine 1. Install: • engine mounting bolt/nut 1 • bolt (rear shock absorber-lower) 2 2. Install: • kickstarter crank • muffler • bolts • exhaust pipe bolts t r . . 84 nm (8.4 m · kg, 61 ft · lb) t r . . 15 nm (1.5 m · kg, 11 ft · lb) t r . . 11 nm (1....

Page 111: Eng

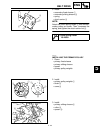

5 - 4 eng cylinder head, cylinder and piston cylinder head, cylinder and piston 9 10 8 12 11 7 8 4 5 3 6 1 13 2 t r . . 14 nm (1.4 m • kg, 10 ft • ib) t r . . 20 nm (2.0 m • kg, 14 ft • ib) t r . . 13 nm (1.3 m • kg, 9.4 ft • ib) t r . . 28 nm (2.8 m • kg, 20 ft • ib) new new new new new e e e order...

Page 112: Eng

5 - 5 eng cylinder head, cylinder and piston 9 10 8 12 11 7 8 4 5 3 6 1 13 2 t r . . 14 nm (1.4 m • kg, 10 ft • ib) t r . . 20 nm (2.0 m • kg, 14 ft • ib) t r . . 13 nm (1.3 m • kg, 9.4 ft • ib) t r . . 28 nm (2.8 m • kg, 20 ft • ib) new new new new new e e e order job/part q’ty remarks 10 bearing 1...

Page 113: Eng

5 - 6 eng cylinder head, cylinder and piston eas00253 removing the cylinder and piston 1. Remove: • piston pin clip 1 • piston pin 2 • piston 3 caution: @ do not use a hammer to drive the piston pin out. Note: @ before removing the piston pin clip, cover the crankcase opening with a clean rag to pre...

Page 114: Eng

5 - 7 eng cylinder head, cylinder and piston ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ a. Place a straightedge 1 and a thickness gauge 2 across the cylinder head. B. Measure the warpage. C. If the limit is exceeded, resurface the cylin- der head as follows. D. Place a 400 ~ 600 grit wet sand...

Page 115: Eng

5 - 8 eng cylinder head, cylinder and piston b. If out of specification, rebore or replace the cylinder, and replace the piston and piston rings as a set. C. Measure piston skirt diameter “p” with the micrometer. A 5 mm (0.20 in) from the bottom edge of the pis- ton d. If out of specification, repla...

Page 116: Eng

5 - 9 eng cylinder head, cylinder and piston piston ring side clearance top ring 0.03 ~ 0.05 mm (0.0012 ~ 0.0020 in) : 0.10 mm (0.0039 in) 2nd ring 0.03 ~ 0.05 mm (0.0012 ~ 0.0020 in) : 0.10 mm (0.0039 in) 2. Install: • piston ring (into the cylinder) note: @ level the piston ring in the cylinder wi...

Page 117: Eng

5 - 10 eng cylinder head, cylinder and piston 2. Measure: • piston pin outside diameter a out of specification → replace the piston pin. Piston pin outside diameter 9.996 ~ 10.000 mm (0.3935 ~ 0.3937 in) : 9.976 mm (0.3928 in) 3. Measure: • piston pin bore diameter (in the piston) 1 out of specifica...

Page 118: Eng

5 - 11 eng cylinder head, cylinder and piston eas00267 installing the piston and cylinder 1. Install: • top ring 1 • 2nd ring 2 note: @ • be sure to install the piston rings so that the manufacturer’s marks or numbers face up. • before installing the cylinder, align the piston ring end gaps to the r...

Page 119: Eng

5 - 12 eng 3. Install: • cylinder gasket 1 4. Lubricate: • piston • piston rings • cylinder (with the recommended lubricant) 5. Install: • cylinder 2 note: @ while compressing the piston rings with one hand, install the cylinder with the other hand. • cylinder head gasket • cylinder head recommended...

Page 120: Eng

5 - 13 eng kickstarter eas00338 kickstarter sheaves cover 6 4 6 5 3 2 1 t r . . 11 nm (1.1 m • kg, 8.0 ft • ib) order job/part q’ty remarks removing the sheave cover remove the parts in the order listed. Air filter case assembly refer to “carburetor” in chapter 6. Transmission oil drain. 1 kickstart...

Page 121: Eng

5 - 14 eng kickstarter 5 6 2 1 7 3 4 ls new order job/part q’ty remarks disassembling the kickstarter shaft remove the parts in the order listed. 1 kickstarter pinion gear 1 2 kickstarter pinion gear clip 1 3 circlip 1 4 washer 1 5 kickstarter shaft 1 6 kickstarter spring 1 7 spacer 1 for assembly, ...

Page 122: Eng

5 - 15 eng kickstarter eas00339 checking the kickstarter 1. Check: • kickstarter shaft • kickstarter pinion gear damage/wear → replace. 2. Check: • kickstarter spring damage/wear → replace. 3. Measure: • kickstarter pinion gear clip force (with the spring gauge) out of specification → replace the ki...

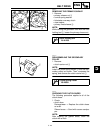

Page 123: Eng

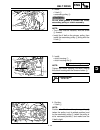

5 - 16 eng belt drive eas00316 belt drive new 16 4 3 1 2 5 6 7 8 9 10 11 12 15 14 13 t r . . 30 nm (3.0 m • kg, 22 ft • ib) t r . . 40 nm (4.0 m • kg, 29 ft • ib) order job/part q’ty remarks removing the v-belt, primary and secondary pulley remove the parts in the order listed. Sheaves cover refer t...

Page 124: Eng

5 - 17 eng belt drive new 16 4 3 1 2 5 6 7 8 9 10 11 12 15 14 13 t r . . 30 nm (3.0 m • kg, 22 ft • ib) t r . . 40 nm (4.0 m • kg, 29 ft • ib) order job/part q’ty remarks 11 collar 1 12 primary sliding sheave 1 13 slider 1 14 cam 1 15 primary pulley weight 6 16 gasket 1 for installation, reverse the...

Page 125: Eng

5 - 18 eng belt drive ls ls ls new 3 2 1 3 new 8 new 7 9 6 0 9 5 4 t r . . 50 nm (5.0 m • kg, 36 ft • ib) order job/part q’ty remarks disassembling the secondary pulley remove the parts in the order listed. 1 clutch carrier nut 1 2 clutch carrier 1 3 clutch spring 2 4 spring 1 5 spring seat 1 6 pin ...

Page 126: Eng

5 - 19 eng belt drive eas00318 removing the secondary pulley and v-belt 1. Remove: • air shroud • fan refer to “generator and autolube pump”. 2. Remove: • clutch housing nut 1 • clutch housing 2 note: @ while holding the clutch housing with the sheave holder 3 , loosen the clutch housing nut. Sheave...

Page 127: Eng

5 - 20 eng belt drive eas00317 removing the primary sheave 1. Remove: • primary sheave nut 1 • conical spring washer • kickstarter one-way clutch • claw washer • primary fixed sheave 2 note: @ while holding the generator rotor with the rotor holding tool 3 , loosen the primary sheave nut. Rotor hold...

Page 128: Eng

5 - 21 eng belt drive 2. Measure: • clutch shoe thickness out of specification → replace the clutch shoes as a set. Clutch shoe thickness 4.0 mm (0.157 in) : 1.0 mm (0.039 in) 3. Check: • clutch housing inside diameter a out of specification → replace the clutch housing. Clutch housing inside diamet...

Page 129: Eng

5 - 22 eng belt drive eas00320 checking the v-belt 1. Check: • v-belt 1 cracks/damage/wear → replace. Grease/oil → check the primary and sec- ondary pulleys. 2. Measure: • v-belt width a out of specification → replace. V-belt width 16.6 mm (0.65 in) : 15.0 mm (0.59 in) 1 eas00321 checking the primar...

Page 130: Eng

5 - 23 eng belt drive eas00324 assembling the secondary pulley 1. Lubricate: • secondary fixed sheave’s inner surface 1 • secondary sliding sheave’s inner surface 2 • oil seals (with the recommended lubricant) 2. Install: • secondary sliding sheave 1 note: @ install the secondary sliding sheave onto...

Page 131: Eng

5 - 24 eng belt drive 5. Install: • secondary fixed sheave 1 • secondary sliding sheave 2 • spring • clutch carrier 3 note: @ attach the clutch spring holder 4 onto the sec- ondary pulley as shown. Then, compress the spring, and tighten the clutch carrier nut 5 . Clutch spring holder ys-28891 4 3 5 ...

Page 132: Eng

5 - 25 eng belt drive 4. Install: • washer 7 • primary fixed sheave 8 • claw washer 9 • kickstarter one-way clutch 0 • conical spring washer a • primary sheave nut b note: • install the conical spring washer a as shown in the illustration. • while holding the generator rotor with the rotor holding t...

Page 133: Eng

5 - 26 eng belt drive 2. Install: • v-belt 1 • secondary pulley 2 caution: @ do not allow grease to contact the v-belt, secondary pulley or clutch assembly. Note: @ • the v-belt must be installed, with the arrow 3 forward. • install the v-belt on the primary pulley, then install the secondary pulley...

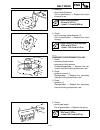

Page 134: Eng

5 - 27 eng starter clutch and starter motor starter clutch and starter motor m ls ls new t r . . 13 nm (1.3 m • kg, 9.4 ft • ib) t r . . 8 nm (0.8 m • kg, 5.8 ft • ib) 8 9 2 3 2 1 4 5 6 7 order job/part q’ty remarks removing the starter clutch and starter motor remove the parts in the order listed. ...

Page 135: Eng

5 - 28 eng starter clutch and starter motor eas00351 checking the starter clutch 1. Check: • starter clutch rollers 1 • starter clutch spring caps 2 • starter clutch springs 3 damage/wear → replace. 1 2 3 2. Check: • starter wheel gear 1 burrs/chips/roughness/wear → replace the defective part(s). 3....

Page 136: Eng

5 - 29 eng starter clutch and starter motor 2. Install: • starter wheel gear 1 • starter clutch assembly 2 note: @ install the starter clutch assembly 1 while turning the starter wheel gear 2 clockwise. 2 1.

Page 137: Eng

5 - 30 eng transmission eas00419 transmission 8 6 5 4 7 11 1 2 3 3 9 new new new g g ls lt lt new t r . . 9 nm (0.9 m • kg, 6.5 ft • ib) t r . . 18 nm (1.8 m • kg, 13 ft • ib) 10 order job/part q’ty remarks removing the transmission remove the parts in the order listed. Transmission oil drain. Rear ...

Page 138: Eng

5 - 31 eng transmission 8 6 5 4 7 11 1 2 3 3 9 new new new g g ls lt lt new t r . . 9 nm (0.9 m • kg, 6.5 ft • ib) t r . . 18 nm (1.8 m • kg, 13 ft • ib) 10 order job/part q’ty remarks 9 circlip 1 10 bearing 1 11 oil seal 1 for installation, reverse the removal procedure..

Page 139: Eng

5 - 32 eng transmission eas00425 checking the transmission 1. Check: • drive axle • main axle • secondary drive gear damage/wear → replace. 2. Check: • bearing rough movement → replace. 3. Check: • secondary drive gear movement rough movement → replace the defective part. 4. Check: • circlips bends/...

Page 140: Eng

5 - 33 eng generator and autolube pump generator and autolube pump stator coil assembly 3 4 7 1 8 6 2 t r . . 38 nm (3.8 m • kg, 27 ft • ib) new 5 order job/part q’ty remarks removing the stator coil assembly remove the parts in the order listed. Center cover, side cover (right) and footrest board r...

Page 141: Eng

5 - 34 eng generator and autolube pump autolube pump t r . . 6 nm (0.6 m • kg, 4.3 ft • ib) 2 1 6 8 9 5 3 4 3 new new new ls 7 order job/part q’ty remarks removing the autolube pump remove the parts in the order listed. Stator coil assembly refer to “generator and autol- ube pump”. 1 spark plug cap ...

Page 142: Eng

5 - 35 eng generator and autolube pump eas00346 removing the generator 1. Remove: • generator rotor nut 1 • washer note: @ while holding the generator rotor 2 with the rotor holding tool 3 , loosen the generator rotor nut. Rotor holding tool yu-01235 3 1 2 2. Remove: • generator rotor 1 (with the fl...

Page 143: Eng

5 - 36 eng generator and autolube pump eas00354 installing the generator 1. Install: • gasket 1 • woodruff key • generator rotor 2 • washer • generator rotor nut note: @ • clean the tapered portion of the crankshaft and the generator rotor hub. • when installing the generator rotor, make sure the wo...

Page 144: Eng

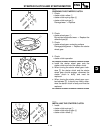

5 - 37 eng crankcase crankcase t r . . 7 nm (0.7 m • kg, 5.1 ft • ib) t r . . 9 nm (0.9 m • kg, 6.5 ft • ib) t r . . 11 nm (1.1 m • kg, 8.0 ft • ib) ls lt lt 7 7 8 9 10 11 4 3 2 1 6 5 (6) new new new order job/part q’ty remarks separating the crankcase remove the parts in the order listed. Rear whee...

Page 145: Eng

5 - 38 eng crankcase t r . . 7 nm (0.7 m • kg, 5.1 ft • ib) t r . . 9 nm (0.9 m • kg, 6.5 ft • ib) t r . . 11 nm (1.1 m • kg, 8.0 ft • ib) ls lt lt 7 7 8 9 10 11 4 3 2 1 6 5 (6) new new new order job/part q’ty remarks 1 cover 1 2 intake manifold 1 3 reed valve assembly 1 4 valve seat gasket 1 5 bear...

Page 146: Eng

5 - 39 eng crankcase eas00385 disassembling the crankcase 1. Remove: • crankcase screws 1 note: @ loosen each screw 1/4 of a turn at a time, in stages and in a crisscross pattern. After all of the screws are fully loosened, remove them. 2. Remove: • right crankcase 1 caution: @ tap on one side of th...

Page 147: Eng

5 - 40 eng crankcase eas00401 checking the bearings and oil seals 1. Check: • bearings clean and lubricate the bearings, then rotate the inner race with your finger. Rough movement → replace. 2. Check: • oil seals damage/wear → replace. Checking the reed valve 1. Measure: • reed valve bending a out ...

Page 148: Eng

5 - 41 eng eas00416 assembling the crankcase 1. Apply: • sealant (onto the crankcase mating surfaces) note: @ do not allow any sealant to come into contact with the oil gallery. 2. Install: • dowel pins 1 quick gasket ® acc-1100-15-01 1 1 3. Install: • left crankcase 1 (onto the right crankcase) use...

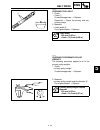

Page 149: Eng

5 - 42 eng crankshaft eas00381 crankshaft 3 2 1 2 4 3 e e e new new ls ls order job/part q’ty remarks removing the crankshaft remove the parts in the order listed. Engine assembly refer to “engine removal”. Crankcase separate. Refer to “crankcase”. 1 crankshaft 1 2 bearing 2 3 oil seal 1 4 crankcase...

Page 150: Eng

5 - 43 eng crankshaft eas00388 removing the crankshaft assembly 1. Remove: • crankshaft assembly 1 note: @ • remove the crankshaft assembly with the crankcase separating tool 2 . • make sure the crankcase separating tool is centered over the crankshaft assembly. Crankcase separating tool yu-01135 1 ...

Page 151: Eng

5 - 44 eng crankshaft 4. Check: • bearing cracks/damage/wear → replace. Eas00408 installing the crankshaft 1. Install: • crankshaft installing tool 2. Install: • crankshaft assembly 4 (to the left crankcase 5 ) caution: @ to avoid scratching the crankshaft and to ease the installation procedure, lub...

Page 152: Carb

6 - 1 carb carburetion carburetor 2 1 3 4 5 6 7 9 10 8 order job/part q’ty remarks removing the carburetor remove the parts in the order listed. Center cover, side cover (left) and foot- rest board refer to “side covers and foot- rest board” in chapter 3. 1 air filter case assembly 1 2 clip 1 3 auto...

Page 153: Carb

6 - 2 carb carburetor 1 4 5 3 2 e d c b a 0 9 6 8 7 order job/part q’ty remarks disassembling the carburetor remove the parts in the order listed. Note: @ before disassembling the carburetor, make sure to note the number of times the pilot air screw is turned out from the seated position to its set ...

Page 154: Carb

6 - 3 carb carburetor 1 4 5 3 2 e d c b a 0 9 6 8 7 order job/part q’ty remarks 8 o-ring 1 9 float pivot pin 1 0 float 1 a needle valve 1 b main jet 1 c needle jet 1 d pilot jet 1 e carburetor body 1 for assembly, reverse the disassembly procedure..

Page 155: Carb

6 - 4 carb carburetor eas00485 checking the carburetor note: before disassembling the carburetor, make sure to note the number of times the pilot air screw is turned out from the seated position to its set position. 1. Check: • carburetor body • float chamber • jet housing cracks/damage → replace. 2...

Page 156: Carb

6 - 5 carb carburetor 7. Check: • throttle valve 1 damage/scratches/wear → replace. 1 8. Check: • jet needle kit 1 • needle jet 2 • main jet 3 • pilot jet 4 bends/damage/wear → replace. Obstruction → clean. Blow out the jets with compressed air. 1 2 3 4 9. Check: • throttle valve movement insert the...

Page 157: Carb

6 - 6 carb carburetor 2. Install: • needle valve 1 • float 2 • float pivot pin 3 • screw 4 2 3 4 1 3. Install: • float chamber 1 1 4. Install: • starter plunger kit 5. Install: • throttle valve • jet needle holder • jet needle kit note: align the groove of the throttle valve with the projection of t...

Page 158: Carb

6 - 7 carb carburetor eas00499 measuring and adjusting the float height 1. Measure: • float height a out of specification → replace the needle valve. ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ a. Remove the carburetor. B. Hold the carburetor in an upside down posi- tion. C. Measure the distan...

Page 159: Carb

6 - 8 carb carburetor ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲▲▲ starter plunger opens. Perform step (3). Starter plunger closes. Replace the auto- choke assembly. 3. Check: • autochoke assembly ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ a. Connect the autochoke assembly leads to a 12....

Page 160: Elec

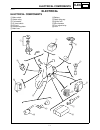

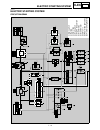

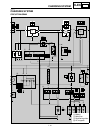

7 - 1 – + elec eas00729 electrical electrical components 1 main switch 2 starter relay 3 fuel sender 4 oil level switch 5 cdi unit 6 rectifier/regulator 7 main fuse 8 battery 9 spark plug cap 0 ignition coil a wire harness b turn signal relay c horn 1 c b a 0 9 8 7 6 5 4 3 2 electrical components.

Page 161: Elec

7 - 2 – + elec switches eas00730 switches checking switch continuity check each switch for continuity with the pocket tester. If the continuity reading is incor- rect, check the wiring connections and if nec- essary, replace the switch. Caution: @ never insert the tester probes into the cou- pler te...

Page 162: Elec

7 - 3 – + elec checking the switches eas00731 checking the switches check each switch for damage or wear, proper connections, and also for continuity between the ter- minals. Refer to “checking switch continuity”. Damage/wear → repair or replace. Improperly connected → properly connect. Incorrect co...

Page 163: Elec

7 - 4 – + elec checking the switches 1 front brake light switch 2 turn signal switch 3 dimmer switch 4 horn switch 5 main switch 6 rear brake light switch 7 start switch 8 engine stop switch 9 main fuse 7.

Page 164: Elec

7 - 5 – + elec checking the bulbs and bulb sockets eas00733 checking the bulbs and bulb sockets check each bulb and bulb socket for damage or wear, proper connections, and also for con- tinuity between the terminals. Damage/wear → repair or replace the bulb, bulb socket or both. Improperly connected...

Page 165: Elec

7 - 6 – + elec checking the bulbs and bulb sockets checking the condition of the bulbs the following procedure applies to all of the bulbs. 1. Remove: • bulb warning @ since the headlight bulb gets extremely hot, keep flammable products and your hands away from the bulb until it has cooled down. Cau...

Page 166: Elec

7 - 7 – + elec checking the bulbs and bulb sockets checking the condition of the bulb sockets the following procedure applies to all of the bulb sockets. 1. Check: • bulb socket (for continuity) (with the pocket tester) no continuity → replace. Note: @ check each bulb socket for continuity in the sa...

Page 167: Elec

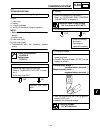

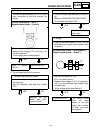

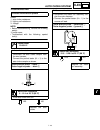

7 - 8 – + elec ignition system eas00734 ignition system circuit diagram off on r br gy br gy r gy br r r w 1 23 o o b cd b r r r b b b b b br b l /w l /y y /r w y /r y /r w /l w /l r r r r g /y r l /w 4 y /r wb r r l /wr g /y r rr b r 5 67 8 9 l /y l /w l /w b l /y l /w l /w b l /w b l /w b br g b g...

Page 168: Elec

7 - 9 – + elec ignition system eas00736 troubleshooting check: 1. Main fuse 2. Battery 3. Spark plug 4. Ignition spark gap 5. Spark plug cap resistance 6. Ignition coil resistance 7. Pickup coil resistance 8. Main switch 9. Engine stop switch 10.Wiring (of the entire ignition system) note: @ • befor...

Page 169: Elec

7 - 10 – + elec eas00742 no yes eas00744 yes no 4. Ignition spark gap • disconnect the spark plug cap from the spark plug. • connect the ignition checker/dynamic spark tester 1 as shown. 2 spark plug cap • set the main switch to “on”. • measure the ignition spark gap a . • crank the engine by pushin...

Page 170: Elec

7 - 11 – + elec eas00746 yes no eas00748 yes no eas00749 yes no 6. Ignition coil resistance • disconnect the ignition coil connectors from the ignition coil terminals. • connect the pocket tester ( Ω × 1) to the ignition coil as shown. Positive tester probe → orange 1 negative tester probe → ignitio...

Page 171: Elec

7 - 12 – + elec eas00750 yes no eas00754 yes no 9. Engine stop switch • check the engine stop switch for continu- ity. Refer to “checking the switches”. • is the engine stop switch ok? Replace the right handlebar switch. 10.Wiring • check the entire ignition system’s wiring. Refer to “circuit diagra...

Page 172: Elec

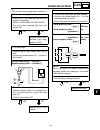

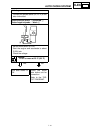

7 - 13 – + elec electric starting system eas00755 electric starting system circuit diagram off on r br gy br gy r gy br r r w 1 23 o o b cd b r r r b b b b b br b l /w l /y y /r w y /r y /r w /l w /l r r r r g /y r l /w 4 y /r wb r r l /wr g /y r rr b r 5 67 8 9 l /y l /w l /w b l /y l /w l /w b l /...

Page 173: Elec

7 - 14 – + elec electric starting system eas00757 troubleshooting check: 1. Main fuse 2. Battery 3. Starter motor 4. Starter relay 5. Main switch 6. Engine stop switch 7. Start switch 8. Front brake light switch 9. Rear brake light switch 10.Wiring (of the entire starting system) note: @ • before tr...

Page 174: Elec

7 - 15 – + elec eas00761 yes no eas00749 yes no eas00750 yes no eas00764 yes no yes no 4. Starter relay • remove the starter relay from the wire harness. • connect the pocket tester ( Ω × 1) and bat- tery (12 v) to the starter relay coupler as shown. Negative battery terminal → green/yellow 1 positi...

Page 175: Elec

7 - 16 – + elec yes no eas00766 yes no 9. Rear brake light switch • check the rear light switch for continuity. Refer to “checking the switches” • is the rear brake light switch ok? Replace the rear brake light switch. 10.Wiring • check the entire starting system’s wiring. Refer to “circuit diagram”...

Page 176: Elec

7 - 17 – + elec starter motor eas00767 starter motor order job/part q’ty remarks removing the starter motor remove the parts in the order listed. Air shroud refer to “cylinder head, cylinder and piston” in chapter 5. 1 starter motor coupler 1 2 starter motor assembly 1 for installation, reverse the ...

Page 177: Elec

7 - 18 – + elec eas00768 1 2 3 4 5 6 ls new order job/part q’ty remarks disassembling the starter motor remove the parts in the order listed. 1 o-ring 1 2 starter motor yoke 1 3 armature assembly 1 4 gasket 2 5 brush holder 1 6 starter motor cover 1 for assembly, reverse the disassembly procedure. S...

Page 178: Elec

7 - 19 – + elec starter motor eas00769 checking the starter motor 1. Check: • commutator dirt → clean with 600-grit sandpaper. 2. Measure: • commutator diameter a out of specification → replace the starter motor. Commutator wear limit 14.8 mm (0.58 in) 3. Measure: • mica undercut a out of specificat...

Page 179: Elec

7 - 20 – + elec starter motor b. If any resistance is out of specification, replace the starter motor. ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲▲▲ armature coil commutator resistance 1 0.065 ~ 0.079 Ω at 20 °c (68 °f) insulation resistance 2 above 1 m Ω at 20 °c (68 °f) 5. Measure: • brush len...

Page 180: Elec

7 - 21 – + elec charging system eas00773 charging system circuit diagram r br gy br gy r r r w 2 3 o b r r r b b b b b br b l/w l/y y/r w y/r y/r w/l w/l r r r r g/y r l/w 4 y/r w b r r l/w r g/y r r r b r 5 6 7 8 9 l/y l/w l/w b l/y l/w l/w b l/w b l/w b w/l b w y/r w w/l w/r y/r a a (black) 0 b a ...

Page 181: Elec

7 - 22 – + elec eas00774 troubleshooting check: 1. Main fuse 2. Battery 3. Charging voltage 4. Wiring (of the entire charging system) note: @ • before troubleshooting, remove the following part(s): 1) center cover 2) side cover (left) 3) side cover (right) • troubleshoot with the following special t...

Page 182: Elec

7 - 23 – + elec no yes eas00779 yes no note: @ make sure the battery is fully charged. • is the charging voltage within specifica- tion? The charging circuit is ok. 4. Wiring • check the wiring connections of the entire charging system. Refer to “circuit diagram”. • is the charging system’s wiring p...

Page 183: Elec

7 - 24 – + elec lighting system eas00780 lighting system circuit diagram off on r br gy br gy r gy br r r w 1 23 o o b cd b r r r b b b b b br b l /w l /y y /r w y /r y /r w /l w /l r r r r g /y r l /w 4 y /r wb r r l /wr g /y r rr b r 5 67 8 9 l /y l /w l /w b l /y l /w l /w b l /w b l /w b br g b ...

Page 184: Elec

7 - 25 – + elec eas00782 troubleshooting check: 1. Main fuse 2. Battery 3. Main switch 4. Dimmer switch 5. Wiring (of the entire charging system) note: @ • before troubleshooting, remove the following part(s): 1) center cover 2) side cover (left) 3) side cover (right) 4) tail cover 5) headlight cove...

Page 185: Elec

7 - 26 – + elec eas00787 yes no eas00788 checking the lighting system 1. The headlight and the high beam indicator light fail to come on. Yes no yes no 5. Wiring • check the entire lighting system’s wiring. Refer to “circuit diagram”. • is the lighting system’s wiring properly connected and without ...

Page 186: Elec

7 - 27 – + elec eas00776 yes no eas00789 2. The meter light fails to come on. Yes no yes no eas00790 3. The tail/brake light fails to come on. Yes no 4. Source coil resistance • disconnect the stator coil assembly cou- pler from the wire harness. • connect the pocket tester ( Ω × 1) to the source co...

Page 187: Elec

7 - 28 – + elec yes no 2. Voltage • connect the pocket tester (dc 20 v) to the tail/brake light coupler (wire harness side) as shown. Positive tester probe → blue 1 negative tester probe → black 2 • set the main switch to “on”. • measure the voltage (12 v) of blue 1 on the tail/brake light coupler (...

Page 188: Elec

7 - 29 – + elec eas00793 signaling system circuit diagram off on r br gy br gy r gy br r r w 1 23 o o b cd b r r r b b b b b br b l /w l /y y /r w y /r y /r w /l w /l r r r r g /y r l /w 4 y /r wb r r l /wr g /y r rr b r 5 67 8 9 l /y l /w l /w b l /y l /w l /w b l /w b l /w b br g b g br b w /l b w...

Page 189: Elec

7 - 30 – + elec 1 main switch 2 battery 3 main fuse e rear brake light switch f front brake light switch g tail/brake light h oil level gauge i diode j turn signal relay k horn m horn switch o turn signal switch p rear turn signal light q front turn signal light t oil level warning light w turn sign...

Page 190: Elec

7 - 31 – + elec eas00794 troubleshooting check: 1. Main fuse 2. Battery 3. Main switch 4. Wiring (of the entire signaling system) note: @ • before troubleshooting, remove the following part(s): 1) center cover 2) side cover (left) 3) side cover (right) 4) tail cover 5) headlight cover 6) front panel...

Page 191: Elec

7 - 32 – + elec eas00796 checking the signaling system 1. The horn fails to sound. Yes no yes no no yes 1. Horn switch • check the horn switch for continuity. Refer to “checking the switches”. • is the horn switch ok? Replace the left han- dlebar switch. 2. Voltage • connect the pocket tester (dc 20...

Page 192: Elec

7 - 33 – + elec yes no eas00798 2. The tail/brake light fails to come on. Yes no yes no yes no 4. Voltage • connect the pocket tester (dc 20 v) to the horn connector at the pink terminal as shown. Positive tester probe → pink 1 negative tester probe → ground • set the main switch to “on”. • measure ...

Page 193: Elec

7 - 34 – + elec eas00799 3. The turn signal light, turn signal indicator light or both fail to blink. Yes no yes no yes no 1. Turn signal indicator light bulb and socket • check the turn signal light bulb and socket for continuity. Refer to “checking the switches”. • are the turn signal light bulb a...

Page 194: Elec

7 - 35 – + elec yes no yes no 4. Voltage • connect the pocket tester (dc 20 v) to the turn signal relay coupler (wire harness side) as shown. Positive tester probe → brown/white 1 negative tester probe → ground • set the main switch to “on”. • set the turn signal switch to “ ” or “ ”. • measure the ...

Page 195: Elec

7 - 36 – + elec eas00802 5. The oil level warning light fails to come on. Yes no yes no yes no 1. Oil level warning light bulb and socket • check the oil level warning light bulb and socket for continuity. Refer to “checking the switches”. • are the oil level warning light bulb and socket ok? Replac...

Page 196: Elec

7 - 37 – + elec yes no eas00803 6. The fuel level indicator light fails to come on. Yes no eas00804 yes no 4. Voltage • connect the pocket tester (dc 20 v) to the meter assembly coupler (wire harness side) as shown. Positive tester probe → gray 1 negative tester probe → black 2 • set the main switch...

Page 197: Elec

7 - 38 – + elec yes no yes no 3. Fuel level gauge • set the main switch to “on”. • move the float up 1 or down 2 . • check that the fuel level gauge needle moves to “f” or “e”. Note: before reading the fuel level meter, leave the float in one position (either up or down) for at least three minutes. ...

Page 198: Elec

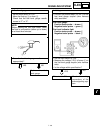

7 - 39 – + elec auto choke system auto choke system circuit diagram o o b b br b l/w l/y w y/r y/r w/l w/l r w/l b w y/r w w/l w/r y/r lack) 0 b a b b b y/r (black) (black) (black) b o l/w br b w/l l/y f br br gy b b j br gy/b gy br/w 0 ac magneto a auto choke.

Page 199: Elec

7 - 40 – + elec troubleshooting check: 1. Auto choke resistance 2. Lighting coil resistance 3. Voltage note: @ • before troubleshooting, remove the following part(s): 1) center cover • troubleshoot with the following special tool(s). Yes no yes no the auto choke fails to operate pocket tester yu-031...

Page 200: Elec

7 - 41 – + elec yes no 3. Voltage • connect the pocket tester (ac 20 v) to the auto choke lead. Tester positive probe → yellow/red 1 tester negative probe → black 2 • set the main switch to “on”. • start the engine and accelerate to about 3,000 r/min • check the voltage. Voltage 12.8 v or more at 20...

Page 201: Trbl

8 - 1 trbl shtg eas00845 troubleshooting note: @ the following guide for troubleshooting does not cover all the possible causes of trouble. It should be helpful, however, as a guide to basic troubleshooting. Refer to the relative procedure in this man- ual for checks, adjustments, and replacement of...

Page 202: Trbl

8 - 2 trbl shtg incorrect engine idling speed/poor medium- and-high-speed performance/faulty clutch eas00847 incorrect engine idling speed engine air filter • clogged air filter element fuel system carburetor • faulty starter plunger • loose or clogged pilot jet • loose or clogged pilot air jet • da...

Page 203: Trbl

8 - 3 trbl shtg overheating/poor braking performance/ unstable handling eas00854 overheating engine cylinder head and piston • heavy carbon buildup engine oil and transmission oil • incorrect oil level • incorrect oil viscosity • inferior oil quality fuel system carburetor • incorrect main jet setti...

Page 204: Trbl

8 - 4 trbl shtg faulty lighting or signaling system eas00866 faulty lighting or signaling system headlight does not light • wrong headlight bulb • too many electrical accessories • hard charging • incorrect connection • improperly grounded circuit • poor contacts (main switch) • burnt-out headlight ...

Page 205

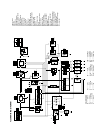

Yamaha motor co., ltd. 2500 shingai iwata shizuoka japan printed in u.S.A..

Page 206

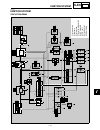

Yj50rn wiring diagram 1 main s witch 2 battery 3 ma in fu se 4 rectifier/regulator 5 right handlebar switch 6 start sw itch 7 engine stop sw itch 8 starte r re lay 9 starte r motor 0 ac m agn eto a auto choke b cd i unit c ignition c o il d spark plug e rear brake light switch f front brake light sw...