- DL manuals

- Yamaha

- Boat

- VX110 Sport

- Service Manual

Yamaha VX110 Sport Service Manual

Summary of VX110 Sport

Page 1

Service manual vx110 sport waverunner f1k-28197-1h-11 lit-18616-02-91 *lit186160291* vx110 deluxe.

Page 2: Notice

E notice this manual has been prepared by yamaha primarily for use by yamaha dealers and their trained mechanics when performing maintenance procedures and repairs to yamaha equipment. It has been written to suit the needs of persons who have a basic understanding of the mechanical and electrical co...

Page 3: How to Use This Manual

E how to use this manual manual format all of the procedures in this manual are organized in a sequential, step-by-step format. The informa- tion has been compiled to provide the mechanic with an easy to read, handy reference that contains comprehensive explanations of all disassembly, repair, assem...

Page 4

E important information in this service manual particularly important information is distinguished in the following ways. The safety alert symbol means attention! Become alert! Your safety is involved! Warning failure to follow warning instructions could result in severe injury or death to the machi...

Page 5

E how to use this manual 1 to help identify parts and clarify procedure steps, there are exploded diagrams at the start of each removal and disassembly section. 2 numbers are given in the order of the jobs in the exploded diagram. 3 symbols indicate parts to be lubricated or replaced (see “symbols”)...

Page 6: Gen

E a50001-1-4 symbols symbols 1 to 9 are designed to indicate the content of a chapter. 1 general information 2 specifications 3 periodic inspection and adjustment 4 fuel system 5 power unit 6 jet pump unit 7 electrical system 8 hull and hood 9 trouble analysis symbols 0 to e indicate specific data. ...

Page 7: Index

E index general information 1 gen info specifications 2 spec periodic inspection and adjustment 3 insp adj fuel system 4 fuel power unit 5 powr jet pump unit 6 jet pump electrical system 7 elec hull and hood 8 hull hood trouble analysis 9 trbl anls – + a30000-0

Page 9: Gen

E gen info 1 2 3 4 5 6 7 8 9 chapter 1 general information identification numbers ......................................................................... 1-1 primary l.D. Number ........................................................................... 1-1 engine serial number ......................

Page 10: Gen

1-1 e gen info identification numbers a60700-0* identification numbers primary l.D. Number the primary l.D. Number is stamped on a label attached to the inside of the engine compart- ment. Starting primary l.D. Number: f1k: 800101 engine serial number the engine serial number is stamped on a label a...

Page 11: Gen

1-2 e gen info safety while working safety while working to prevent and accident or injury and to ensure quality service, follow the safety proce- dures provided below. Fire prevention gasoline is highly flammable. Keep gasoline and all flammable products away from heat, sparks, and open flames. Ven...

Page 12: Gen

1-3 e gen info safety while working under normal conditions, the lubricants men- tioned in this manual should not harm or be hazardous to your skin. However, you should follow these precautions to minimize any risk when working with lubricants. 1. Maintain good standards of personal and industrial h...

Page 13: Gen

1-4 e gen info safety while working 3. Non-reusable parts always use new gaskets, seals, o-rings, oil seals, cotter pins, circlips, etc., when installing or assembling parts. Disassembly and assembly 1. Use compressed air to remove dust and dirt during disassembly. 2. Apply engine oil to the contact...

Page 14: Gen

1-5 e gen info special service tools special service tools using the correct special service tools recom- mended by yamaha, will aid the work and enable accurate assembly and tune-up. Impro- visations and using improper tools can dam- age the equipment. Note: • for u.S.A. And canada, use part number...

Page 15: Gen

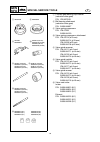

1-6 e gen info special service tools 0 compression gauge extension p/n. 90890-06582 a cylinder gauge set p/n. Yu-03017 90890-06759 b compression gauge p/n. Yu-33223-1 90890-03160 c peak voltage adapter p/n. Yu-39991 d peak voltage adapter b p/n. 90890-03172 e spark checker p/n. Ym-34487 ignition tes...

Page 16: Gen

1-7 e gen info special service tools k yamaha diagnostic system p/n. 60v-85300-02-00 l yamaha diagnostic system p/n. 60v-ws853-03 l 60v-ws853-03 k 60v-85300-02-00 removal and installation 1 oil filter wrench p/n. Yb-01426 90890-01426 2 coupler wrench p/n. Yw-06551 90890-06551 3 sheave holder p/n. Ys...

Page 17: Gen

1-8 e gen info special service tools 7 forward gear bearing cup installer (reduction drive gear) p/n. Yb-06276-b 8 ball bearing attachment (reduction drive gear) p/n. 90890-06657 9 valve spring compressor p/n. Ym-01253 90890-04019 0 valve spring compressor attachment p/n. Ym-04114 (ø19 mm) 90890-041...

Page 18: Gen

1-9 e gen info special service tools e valve seat cutter holder p/n. 90890-06811 (ø4.0 mm) 90890-06812 (ø4.5 mm) f neway valve seat cutter kit p/n. Ym-91044 g piston ring compressor p/n. Ym-08037 90890-05158 h drive shaft holder (impeller) p/n. Yb-06151 drive shaft holder 5 (impeller) p/n. 90890-065...

Page 19: Gen

1-10 e gen info special service tools p outer race installer—forward gear (jet pump oil seal and reduction drive gear) p/n. Yb-06085 q ball bearing attachment (jet pump oil seal and reduction drive gear) p/n. 90890-06631 r driver handle—large (intermediate shaft, jet pump, and reduction drive gear) ...

Page 21: Spec

E spec 1 2 3 4 5 6 7 8 9 chapter 2 specifications general specifications ....................................................................... 2-1 maintenance specifications ............................................................... 2-3 engine ....................................................

Page 22: Spec

2-1 e spec general specifications general specifications item unit model vx110 sport vx110 deluxe model code hull f1k engine/jet 6d3 dimensions length mm (in) 3,220 (126.8) width mm (in) 1,170 (46.1) height mm (in) 1,150 (45.3) dry weight kg (lb) 325 (716) maximum capacity person/kg (lb) 3/240 (530)...

Page 23: Spec

2-2 e spec pon*: pump octane number = (motor octane number + research octane number)/2 ron*: research octane number fuel and oil fuel type regular unleaded gasoline minimum fuel rating pon* 86 ron* 90 fuel tank capacity l (us gal, imp gal) 60 (15.9, 13.2) engine oil type 4-stroke motor oil engine oi...

Page 24: Spec

2-3 e spec maintenance specifications maintenance specifications engine item unit model vx110 sport vx110 deluxe cylinder head warpage limit mm (in) 0.1 (0.004) compression pressure *1 kpa (kgf/cm 2 , psi) 1,150 (11.5, 164) cylinder bore size mm (in) 76.000–76.015 (2.9921–2.9927) taper limit mm (in)...

Page 25: Spec

2-4 e spec maintenance specifications valve face width b intake mm (in) 1.91–2.64 (0.0752–0.1039) exhaust mm (in) 1.91–2.64 (0.0752–0.1039) valve seat width c intake mm (in) 0.90–1.10 (0.0354–0.0433) exhaust mm (in) 0.90–1.10 (0.0354–0.0433) valve margin thickness d intake mm (in) 0.85–1.15 (0.0335–...

Page 26: Spec

2-5 e spec maintenance specifications piston pins outside diameter mm (in) 16.991–17.000 (0.6689–0.6693) wear limit mm (in) 16.986 (0.6687) piston ring top ring type barrel dimension (b × t) mm (in) 0.90 × 2.75 (0.04 × 0.11) end gap (installed) mm (in) 0.32–0.44 (0.0126–0.0173) ring groove clearance...

Page 27: Spec

2-6 e spec maintenance specifications jet pump unit hull and hood fuel pump pump type electrical fuel pressure kpa (kgf/cm 2 , psi) 320–327 (3.2–3.3, 46–47) oil filter oil filter type cartridge type oil pump oil pump type trochoid rotor tip clearance (scavenge pump) mm (in) 0.09–0.15 (0.0035–0.0059)...

Page 28: Spec

2-7 e spec maintenance specifications electrical item unit model vx110 sport vx110 deluxe battery type fluid capacity v/ah 12/19 specific gravity 1.28 ecm unit (b/r – r/y, b/w – r/y, b/y – r/y, b/g – r/y) output peak voltage lower limit @cranking (loaded) v 90 @2,000 r/min (loaded) v 130 @3,500 r/mi...

Page 29: Spec

2-8 e spec maintenance specifications starter motor type constant mesh output kw 0.8 rating seconds 30 brush length mm (in) 12.5 (0.49) wear limit mm (in) 6.5 (0.26) commutator undercut mm (in) 0.7 (0.03) limit mm (in) 0.2 (0.01) commutator diameter mm (in) 28.0 (1.10) limit mm (in) 27.0 (1.06) star...

Page 30: Spec

2-9 e spec maintenance specifications *1: the figures are for reference only. Accelerator position sensor resis- tance *1 @ throttle lever fully closed sensor 1 k Ω 0.50–0.90 sensor 2 k Ω 0.35–10.50 @ throttle lever fully opened sensor 1 k Ω 3.75–4.35 sensor 2 k Ω 3.60–4.50 cam position sensor outpu...

Page 31: Spec

2-10 e spec tightening torques tightening torques specified torques part to tightened part name thread size q’ty tightening torque remarks refer to page n•m kgf•m ft•lb fuel system retainer/fuel pump module 1st nut — 9 3.2 0.32 2.3 4-1 2nd 6.4 0.64 4.6 fuel filler neck/rubber seal nut — 1 5.9 0.59 4...

Page 32: Spec

2-11 e spec tightening torques oil separator 1st bolt m6 2 3.7 0.37 2.7 572 lt 5-12 2nd 7.6 0.76 5.5 ground lead box bolt m6 3 7.6 0.76 5.5 572 lt 5-12 oil tank 1st bolt m10 5 15 1.5 11 572 lt 5-12 2nd 39 3.9 28 plastic tie/collar 1st bolt m6 1 3.7 0.37 2.7 5-12 2nd 7.6 0.76 5.5 oil tank 1st nut — 2...

Page 33: Spec

2-12 e spec tightening torques washer/pickup coil lead and lighting coil lead bolt m5 1 4.9 0.49 3.5 242 lt 5-36 pickup coil bolt m5 2 4.9 0.49 3.5 242 lt 5-36 holder (wiring harness) bolt m6 2 14 1.4 10 242 lt 5-36 lighting coil bolt m6 3 14 1.4 10 242 lt 5-36 spark plug — — 4 13 1.3 9.4 5-41 ignit...

Page 34: Spec

2-13 e spec tightening torques jet pump unit steering cable joint nut — 1 6.8 0.68 4.9 242 lt 6-3 ride plate bolt m8 4 17 1.7 12 572 lt 6-1 intake grate bolt m6 2 7.6 0.76 5.5 242 lt 6-1 m10 40 4.0 29 speed sensor screw m5 4 3.7 0.37 2.7 242 lt 6-1 jet pump unit assembly bolt m6 1 7.8 0.78 5.6 572 l...

Page 35: Spec

2-14 e spec tightening torques shift cable locknut (deluxe model only) nut — 1 3.8 0.38 2.7 572 lt 8-23 steering cable locknut (steering column side) nut — 1 6.5 0.65 4.7 8-23 steering cable locknut (jet pump side) nut — 1 6.8 0.68 4.9 572 lt 8-23 steering cable seal nut — 1 5.9 0.59 4.3 8-23 steeri...

Page 36: Spec

2-15 e spec tightening torques electrical fuse box nut — 2 17 1.7 12 7-2 fuse box bracket nut — 4 15 1.5 11 7-2 ecm bolt m6 4 4.0 0.4 2.9 572 lt 7-7 bracket 1st bolt m8 2 8.8 0.88 6.4 572 lt 7-7 2nd 18 1.8 13 slant detection switch tapping screw ø6 2 3.9 0.39 2.8 7-2 rectifier/regulator bolt m8 2 4....

Page 37: Spec

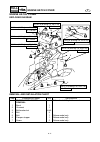

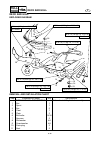

2-16 e spec cable and hose routing cable and hose routing k e 2 1 3 4 5 6 7 8 9 0 d c a b Ê È É 1 2 5 6 7 6 j a a h i g f 0 6 2 7 k-k j-j i-i h-h g-g a-a b-b c-c d-d e-e f-f b b c c e e f f d d i i i i g g h h k k j j a a b b 1 fuel tank breather hose 2 steering cable 3 throttle cable 4 fuse box 5 s...

Page 38: Spec

2-17 e spec cable and hose routing k e 2 1 3 4 5 6 7 8 9 0 d c a b Ê È É 1 2 5 6 7 6 j a a h i g f 0 6 2 7 k-k j-j i-i h-h g-g a-a b-b c-c d-d e-e f-f b b c c e e f f d d i i i i g g h h k k j j a a b b È fasten the speed sensor lead, fuel sender lead, wiring harness, and antenna lead (deluxe model ...

Page 39: Spec

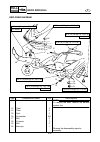

2-18 e spec cable and hose routing 1 2 Ð Ò Ó Õ Î Í Ì È É È É Ñ Ô 3 4 567 8 4 b o p 5 n c d a 0 9 h-h e f g h i p g g-g a b d f c e j j m c f i i e d b a a Ï Ð h h g g j k 0 q l Ê Ë 1 multifunction meter 2 handlebar switch lead 3 buzzer 4 shift cable (deluxe model only) 5 fuel hose 6 relay assembly 7...

Page 40: Spec

2-19 e spec cable and hose routing 1 2 Ð Ò Ó Õ Î Í Ì È É È É Ñ Ô 3 4 567 8 4 b o p 5 n c d a 0 9 h-h e f g h i p g g-g a b d f c e j j m c f i i e d b a a Ï Ð h h g g j k 0 q l Ê Ë m water separator n electric fuel pump o oil separator breather hose (to air intake duct) p wiring harness q cooling wa...

Page 41: Spec

2-20 e spec cable and hose routing 1 2 Ð Ò Ó Õ Î Í Ì È É È É Ñ Ô 3 4 567 8 4 b o p 5 n c d a 0 9 h-h e f g h i p g g-g a b d f c e j j m c f i i e d b a a Ï Ð h h g g j k 0 q l Ê Ë Ï to ventilation socket Ð to fuel tank Ñ point the arrow on the cover toward the fuel tank. Ò fasten the fuel hose with...

Page 42: Spec

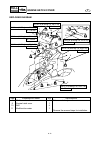

2-21 e spec cable and hose routing a b c d 2 4 2 5 6 7 8 3 2 2 8 Ñ Ê Ó Ò Ê Ê Í É Ë f-f e-e 2 1 2 2 2 2 2 Õ È Ð Ô Î Ì Ï f f e e d c a b 2 1 cooling water inlet hose 2 cooling water hose 3 cooling water outlet hose 4 flushing hose 5 cylinder head breather hose 6 oil separator breather hose (to oil tan...

Page 43: Spec

2-22 e spec cable and hose routing a b c d 2 4 2 5 6 7 8 3 2 2 8 Ñ Ê Ó Ò Ê Ê Í É Ë f-f e-e 2 1 2 2 2 2 2 Õ È Ð Ô Î Ì Ï f f e e d c a b 2 Í fasten the oil separator breather hose (to air intake duct) and cooling water hose with a holder. Î face the ends of the hose clamp towards the starboard (right)...

Page 44: Spec

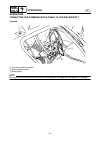

2-23 e spec cable and hose routing 1 3 9 0 a c b 8 8 4 5 6 7 2 e d f È É Í Ê Ë Ì a-a a a Î 1 oil separator breather hose (to air intake duct) 2 wiring harness 3 ignition coil lead #1 4 ignition coil lead #2 5 ignition coil lead #3 6 ignition coil lead #4 7 cam position sensor 8 ignition coil 9 ecm 0...

Page 45: Spec

2-24 e spec cable and hose routing 1 3 9 0 a c b 8 8 4 5 6 7 2 e d f È É Í Ê Ë Ì a-a a a Î Ì to generator Í fasten the thermoswitch (exhaust) lead at the protective sleeve, the oil pressure switch lead at the corrugated tube, and the wiring harness at the tape on the harness with a plastic tie. Î 60...

Page 46: Spec

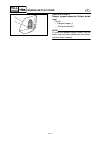

2-25 e spec cable and hose routing d-d a-a b-b 0 8 5 c-c 9 5 Ú Ù É È Ð d d 5 6 a a 1 2 7 3 4 Î Ó Ò ÌÑ Ñ Ì Ñ Ì Ì Ë Ë Ê Ø × Ö Ô Õ Í Ï c c b b 1 ignition coil 2 fuel rail 3 fuel injector coupler 4 throttle body assembly coupler 5 wiring harness 6 engine temperature sensor lead 7 sensor assembly (intake...

Page 47: Spec

2-26 e spec cable and hose routing d-d a-a b-b 0 8 5 c-c 9 5 Ú Ù É È Ð d d 5 6 a a 1 2 7 3 4 Î Ó Ò ÌÑ Ñ Ì Ñ Ì Ì Ë Ë Ê Ø × Ö Ô Õ Í Ï c c b b Ð insert the plastic tie completely into the hole in the engine hanger. Ñ fasten the wiring harness to a bracket on the fuel rail with a plastic tie. Ò fasten t...

Page 49: Insp

E insp adj 1 2 3 4 5 6 7 8 9 chapter 3 periodic inspection and adjustment maintenance interval chart .............................................................. 3-1 periodic service ....................................................................................... 3-2 control system ...........

Page 50: Insp

3-1 e insp adj maintenance interval chart maintenance interval chart the following chart should be considered strictly as a guide to general maintenance intervals. Depending on operating conditions, the intervals of maintenance should be changed. *1: after every use maintenance interval initial ther...

Page 51: Insp

3-2 e insp adj control system periodic service control system steering column inspection 1. Inspect: • steering column excessive play → replace the steering column. Refer to “steering column” in chapter 8. Inspection steps: • move the handlebar up and down and back and forth. • check the excessive p...

Page 52: Insp

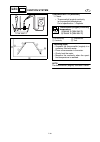

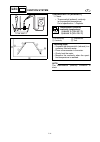

3-3 e insp adj control system 2. Adjust: • steering cable joint (steering column end) note: adjust the cable joint at the jet pump end. Refer to “remote control cables and speed sensor lead” in chapter 8. Adjustment steps: • set the control grip to the neutral posi- tion. • loosen the locknut 1. • d...

Page 53: Insp

3-4 e insp adj control system throttle cable inspection and adjustment note: before adjusting the throttle lever free play, check the trolling speed. 1. Measure: • throttle lever free play a out of specification → adjust. • throttle cable length b out of specification → adjust. Note: • check that th...

Page 54: Insp

3-5 e insp adj control system warning after adjusting the free play, turn the han- dlebar to the right and left and make sure that the trolling speed does not increase. E. Install the handlebar cover. T r . . Lower handlebar cover screw: 3.7 n • m (0.37 kgf • m, 2.7 ft • lb) loctite 242 upper handle...

Page 55: Insp

3-6 e insp adj control system • turn out the cable joint nine times a to extend the cable 7 mm (0.28 in) from the aligned position. Warning the cable joint must be screwed in more than 8 mm (0.31 in). • connect the cable joint and tighten the locknut. T r . . Locknut: 3.8 n • m (0.38 kgf • m, 2.7 ft...

Page 56: Insp

3-7 e insp adj fuel system fuel system warning when removing fuel system parts, wrap them in a cloth and take care that no fuel spills into the engine compartment. Fuel line inspection 1. Inspect: • fuel pump filter clog/contaminants → clean. Refer to “fuel tank and fuel pump module” in chapter 4. •...

Page 57: Insp

3-8 e insp adj fuel system/power unit water separator inspection 1. Inspect: • water separator 1 water accumulation → drain. Note: to drain the water, remove the drain plug. Power unit valve clearance adjustment the following procedure applies to all of the valves. Note: • valve clearance adjustment...

Page 58: Insp

3-9 e insp adj power unit 3. Measure: • valve clearance out of specification → adjust. Valve clearance (cold): intake valve: 0.11–0.20 mm (0.0043–0.0079 in) exhaust valve: 0.25–0.34 mm (0.0098–0.0134 in) measurement steps: • turn the drive coupling counterclockwise, and then check if cylinder #1 is ...

Page 59: Insp

3-10 e insp adj power unit 4. Remove: • timing chain tensioner cap bolt 1 • gasket 1 5. Turn the timing chain tensioner rod fully clockwise with a thin screwdriver 1. Note: make sure that the tensioner rod has been fully turned clockwise. 1 6. Remove: • intake camshaft caps • exhaust camshaft caps •...

Page 60: Insp

3-11 e insp adj power unit 7. Adjust: • valve clearance adjustment steps: • remove the valve lifter 1 and the valve pad 2. Note: • cover the timing chain opening with a rag to prevent the valve pad from falling into the crankcase. • note the position of each valve lifter 3 and valve pad 4 so that th...

Page 61: Insp

3-12 e insp adj power unit note: the new valve pad number is only an approximation. The valve clearance must be measured again and the above steps should be repeated if the measurement is still incorrect. • install the new valve pad 5 and the valve lifter 6. Note: • lubricate the valve pad with moly...

Page 62: Insp

3-13 e insp adj power unit intake exhaust measured clearance original valve pad number 120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240 0.00–0.02 120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 0.03–0.07 120 1...

Page 63: Insp

3-14 e insp adj power unit 8. Remove: • dial gauge • dial gauge stand • dial gauge needle 9. Install: • all removed parts note: for installation, reverse the removal proce- dure. Engine oil level check 1. Check: • engine oil level checking steps: caution: • when checking the engine oil level on wate...

Page 64: Insp

3-15 e insp adj power unit • place the watercraft in a horizontal posi- tion or launch the watercraft. • remove the seat. • remove the oil tank filler cap 1 and check for oil on the dipstick 2. • if there is no oil on the dipstick, pour enough oil so that the tip of the dipstick comes into contact w...

Page 65: Insp

3-16 e insp adj power unit • remove the oil tank filler cap again and check that the oil level is between the minimum level mark a and maximum level mark b on the dipstick. • if the engine oil is below the minimum level mark b, add sufficient oil of the rec- ommended type to raise it to the correct ...

Page 66: Insp

3-17 e insp adj power unit 2. Remove: • oil tank filler cap 1 3. Insert the tube of an oil changer into the oil filler hole. 4. Operate the oil changer to extract the oil. 5. If the oil filter is also to be replaced, per- form the following procedure. 6. Pour the specified amount of the recom- mende...

Page 67: Insp

3-18 e insp adj power unit 7. Fill: • oil tank (with the specified amount of the recom- mended engine oil) caution: when starting the engine make sure the dipstick is securely fitted into the oil tank. 8. Install: • oil tank filler cap recommended oil: sae 10w-30, 20w-40, 20w-50 api se, sf, sg, sh, ...

Page 68: Insp

3-19 e insp adj power unit 5. Remove the air filter element and check it for dirt and oil. Replace the air filter ele- ment if there is any oil buildup. Caution: • do not start the engine with the air filter case removed, otherwise the engine could be damaged. • if cleaning the air filter element, u...

Page 69: Insp

3-20 e insp adj power unit spark plug inspection 1. Remove: • ignition coils caution: be careful not to get any foreign sub- stances or water in spark plug hole. 2. Inspect: • electrodes 1 damage/wear → replace. • insulator color 2 distinctly different color → check the engine condition. Color guide...

Page 70: Insp

3-21 e insp adj power unit 5. Tighten: • spark plug note: • before installing the spark plug, clean the gasket surface and spark plug surface. Also, it is suggested to apply a thin film of anti- seize compound to the spark plug threads to prevent thread seizure. • if a torque wrench is not available...

Page 71: Insp

3-22 e insp adj electrical electrical battery inspection warning battery electrolyte is poisonous and dan- gerous, causing severe burns, etc. Electro- lyte contains sulfuric acid. Avoid contact with skin, eyes or clothing. Antidotes external: flush with water. Internal: drink large quantities of wat...

Page 72: Insp

3-23 e insp adj electrical 1. Remove: • bands • battery negative lead 1 • battery positive lead 2 • battery • battery breather hose 3 warning • when removing the battery, disconnect the negative lead first. • remove the battery to prevent acid loss during turning the watercraft on its side for the i...

Page 73: Insp

3-24 e insp adj electrical 3. Inspect: • specific gravity out of specification → charge. 4. Install: • filler caps caution: before installation, rinse off any fluid from the battery box and battery and make sure that the battery is dry before installing it. Specific gravity at 20 °c (68 °f): 1.28 ch...

Page 74: Insp

3-25 e insp adj jet pump unit jet pump unit impeller inspection 1. Check: • impeller 1 damage/wear → replace. Nicks/scratches → file or grind. 2. Measure: • impeller-to-housing clearance a out of specification → replace. Maximum impeller-to-housing clearance: 0.35–0.45 mm (0.0138–0.0177 in) measurem...

Page 75: Insp

3-26 e insp adj bilge pump/general bilge pump bilge strainer inspection 1. Inspect: • bilge strainer 1 contaminants → clean. Cracks/damage → replace. 1 general drain plug inspection 1. Inspect: • drain plugs cracks/damage → replace. • o-rings cracks/wear → replace. • screw threads contaminants → cle...

Page 76: Insp

3-27 e insp adj general 2. Lubricate: • nozzle pivot shaft • steering cable (nozzle end) recommended grease: yamaha marine grease, yamaha grease a (water resistant grease) 3. Lubricate: • steering cable • steering cable joint note: disconnect the joints and apply a small amount of grease. Recommende...

Page 77: Fuel

E fuel 1 2 3 4 5 6 7 8 9 chapter 4 fuel system fuel tank and fuel pump module...................................................... 4-1 exploded diagram ............................................................................. 4-1 removal and installation chart .....................................

Page 78: Fuel

4-1 e fuel fuel tank and fuel pump module fuel tank and fuel pump module exploded diagram removal and installation chart step procedure/part name q’ty service points fuel tank removal follow the left “step” for removal. Storage compartment panel refer to “front hood” in chapter 8. Ventilation hose f...

Page 79: Fuel

4-2 e fuel fuel tank and fuel pump module exploded diagram step procedure/part name q’ty service points 3 fuel tank breather hose 1 note: make sure that the inner seal of the coupler is installed properly before connecting the coupler. 4 fuel sender coupler 1 5 fuel pump module coupler 1 6 cover 1 7...

Page 80: Fuel

4-3 e fuel fuel tank and fuel pump module exploded diagram step procedure/part name q’ty service points 12 hose clamp 2 13 fuel filler hose 1 14 nut 1 15 fuel filler neck 1 16 rubber seal 1 17 fuel tank belt 2 18 fuel tank assembly 1 reverse the removal steps for installation. 7 10 11 3 2 1 18 17 12...

Page 81: Fuel

4-4 e fuel fuel tank and fuel pump module service points fuel hose disconnection 1. Disconnect: • fuel hose refer to “fuel injection system”. Fuel pump module removal 1. Remove: • nuts • retainer note: loosen the nuts in the sequence shown. 2 3 8 7 5 1 2 3 8 7 5 1 4 4 9 6 6 2. Remove: • fuel pump mo...

Page 82: Fuel

4-5 e fuel fuel tank and fuel pump module fuel sender inspection refer to “fuel control system” in chapter 7. Fuel tank inspection 1. Inspect: • fuel tank cracks/damage → replace. Fuel hose inspection refer to “fuel injection system”. Fuel pump filter inspection 1. Inspect: • fuel pump filter 1 clog...

Page 83: Fuel

4-6 e fuel fuel pump module installation 1. Tighten: • nuts note: tighten the nuts in the sequence shown. Fuel hose connect refer to “fuel injection system”. T r . . Fuel pump module nut: 1st: 3.2 n • m (0.32 kgf • m, 2.3 ft • lb) 2nd: 6.4 n • m (0.64 kgf • m, 4.6 ft • lb) 2 3 8 7 5 1 8 7 2 3 5 9 4 ...

Page 84: Fuel

4-7 e fuel fuel injection system fuel injection system exploded diagram removal and installation chart step procedure/part name q’ty service points fuel injection system removal follow the left “step” for removal. 1 cam position sensor coupler 1 2 fuel injector coupler 4 3 sensor assembly coupler 1 ...

Page 85: Fuel

4-8 e fuel fuel injection system exploded diagram step procedure/part name q’ty service points 10 fuel hose 1 11 clamp 2 12 hose screw clamp 1 13 screw 2 14 screw 4 15 air filter case cover 1 16 air intake duct 1 17 air intake hose 1 18 gasket 1 19 air filter element 1 20 bolt 4 17 n • m (1.7 kgf • ...

Page 86: Fuel

4-9 e fuel fuel injection system exploded diagram step procedure/part name q’ty service points 21 air filter case 1 22 collar 4 23 grommet 4 24 bolt 2 25 intake assembly 1 26 bolt 2 27 throttle cable 1 28 nut 2 29 accelerator position sensor 1 30 nut 4 31 bracket 2 reverse the removal steps for inst...

Page 87: Fuel

4-10 e fuel throttle body assembly and intake manifold throttle body assembly and intake manifold exploded diagram removal and installation chart step procedure/part name q’ty service points throttle body assembly and intake manifold disassembly follow the left “step” for disassembly. 1 bolt 4 2 was...

Page 88: Fuel

4-11 e fuel throttle body assembly and intake manifold exploded diagram step procedure/part name q’ty service points 8 gasket 4 9 fuel injector 4 10 o-ring 4 11 screw 2 12 sensor assembly 1 13 o-ring 1 14 clamp 4 15 clamp 4 16 intake manifold joint 4 reverse the disassembly steps for assembly. 8 × 1...

Page 89: Fuel

4-12 e fuel throttle body assembly and intake manifold service points fuel hose clamps removal 1. Remove: • fuel hose clamps caution: if the fuel hose clamps are removed with- out cutting the joint first, the fuel hose will be damaged. Hose clamps installation 1. Install: • fuel hose clamps warning ...

Page 90: Fuel

4-13 e fuel caution: • do not rotate the quick connector tab 1 past the stopper position, otherwise it could be damaged. • when the fuel hoses are disconnected, quickly remove the retainer 2 from the quick connector, otherwise the retainer could be lost. 2. Disconnect the fuel hose 1 from the fuel p...

Page 91: Fuel

4-14 e fuel throttle body assembly and intake manifold fuel hose installation (replacing with new fuel hose) 1. Install: • fuel hose 1 note: • to install the fuel hose, be sure to align the white mark a of the fuel hose with the checker tab 2 of the quick connector. • when replacing the fuel hose wi...

Page 92: Fuel

4-15 e fuel throttle body assembly and intake manifold fuel injectors inspection note: do not remove the throttle body assembly. 1. Check: • fuel injectors dirt/residue → clean. Damage → replace. 2. Measure: • fuel injectors resistance out of specification → replace. 3. Check the operation of the fu...

Page 93: Fuel

4-16 e fuel throttle body assembly and intake manifold intake assembly installation 1. Install: • intake screw clamp • intake manifold joint • intake assembly note: • install the intake screw clamp in the direction shown in the illustration, making sure to align the indentation in the clamp with the...

Page 94: Fuel

4-17 e fuel throttle body assembly and intake manifold air filter case assembly installation 1. Install: • air intake duct 1 • air intake hose 2 • air filter case cover note: align the projections a on the air intake duct and air intake hose with the projections b on the air filter case cover as sho...

Page 95: Fuel

4-18 e fuel 5. Remove: • fuel pressure gauge • fuel pressure gauge adapter note: to disconnect the fuel pressure gauge adapter, follow the procedures for disconnect- ing a fuel hose. (refer to “fuel hose discon- nection”.) 6. Connect: • fuel hose refer to “fuel hose connection”. Throttle body assemb...

Page 97: Powr

E powr 1 2 3 4 5 6 7 8 9 chapter 5 power unit engine unit .................................................................................................. 5-1 exploded diagram ............................................................................. 5-1 removal and installation chart ............

Page 98: Powr

E powr generator and starter motor ....................................................... 5-33 exploded diagram ........................................................................... 5-33 removal and installation chart ............................................. 5-33 service points ............

Page 99: Powr

E powr connecting rods and pistons .......................................................... 5-80 exploded diagram ........................................................................... 5-80 removal and installation chart .............................................. 5-80 service points ........

Page 100: Powr

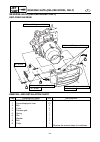

5-1 e powr engine unit engine unit exploded diagram removal and installation chart step procedure/part name q’ty service points engine unit removal follow the left “step” for removal. Engine oil drain. Refer to “power unit” in chapter 3. Storage compartment panel refer to “front hood” in chapter 8. ...

Page 101: Powr

5-2 e powr engine unit exploded diagram step procedure/part name q’ty service points 3 bolt 2 4 air filter case assembly 1 5 bolt 1 6 ecm and rectifier/regulator assembly 1 7 clamp/cooling water hose 1/1 cooling water pilot outlet 8 clamp/cooling water hose 1/1 cooling water inlet 9 clamp/cooling wa...

Page 102: Powr

5-3 e powr engine unit exploded diagram *: as required. Step procedure/part name q’ty service points 13 bolt/washer 4/4 14 shim * 15 engine unit 1 reverse the removal steps for installation. 14 10 10 2 1 13 3 4 11 15 12 8 7 9 6 5 2nd 18 n • m (1.8 kgf • m, 13 ft • ib) 1st 8.8 n • m (0.88 kgf • m, 6....

Page 103: Powr

5-4 e powr engine unit service points compression pressure measurement the following procedure applies to all of the cylinders. Note: insufficient compression pressure will result in a loss of performance. 1. Measure: • valve clearance out of specification → adjust. Refer to “power unit” in chapter ...

Page 104: Powr

5-5 e powr engine unit 5. Measure: • compression pressure out of specification → refer to steps (b) and (c). 6. Install: • spark plug minimum compression pressure (reference data): 1,150 kpa (11.5 kgf/cm 2 , 164 psi) measurement steps: a. With the throttle wide open, crank the engine until the readi...

Page 105: Powr

5-6 e powr engine unit 7. Install: • ignition coils t r . . Ignition coils bolt: 7.6 n • m (0.76 kgf • m, 5.5 ft • lb) loctite 572 engine unit removal 1. Remove: • engine unit removal steps: caution: lift the engine unit carefully trying not to hit it on the deck or letting it fall hard on the hull....

Page 106: Powr

5-7 e powr engine unit coupling clearance inspection 1. Measure: • clearance a • clearance b out of specification → adjust. Note: measure the clearances with a straightedge and thickness gauge. Clearance a: 0–0.5 mm (0–0.020 in) clearance b: 2–4 mm (0.079–0.157 in) 2. Adjust: • clearance a and b adj...

Page 107: Powr

5-8 e powr exhaust pipes 1 and 2 exhaust pipes 1 and 2 exploded diagram removal and installation chart step procedure/part name q’ty service points exhaust pipes 1 and 2 removal follow the left “step” for removal. Engine unit refer to “engine unit”. È for cooling water pilot outlet on port side É fr...

Page 108: Powr

5-9 e powr exhaust pipes 1 and 2 exploded diagram step procedure/part name q’ty service points 7 bolt 1 note: tighten the bolts in the sequence indicated. 8 bolt 1 9 bolt 2 10 collar 1 7 10 9 8 É È 6th 15 n • m (1.5 kgf • m, 11 ft • ib) 2nd 2.0 n • m (0.2 kgf • m, 1.4 ft • ib) 10th 39 n • m (3.9 kgf...

Page 109: Powr

5-10 e powr exploded diagram step procedure/part name q’ty service points 11 exhaust pipe 2 1 12 bolt 3 13 exhaust pipe end 1 14 gasket 2 15 silencer 1 16 inner exhaust joint 1 17 outer exhaust joint 1 18 bolt 2 19 bolt 2 20 exhaust pipe 1 1 21 gasket 1 22 dowel pin 2 reverse the removal steps for i...

Page 110: Powr

5-11 e powr exhaust manifold exhaust manifold exploded diagram removal and installation chart step procedure/part name q’ty service points exhaust manifold removal follow the left “step” for removal. Exhaust pipes 1 and 2 refer to “exhaust pipes 1 and 2”. 1 clamp/cooling hose 2/1 È to cylinder block...

Page 111: Powr

5-12 e powr oil tank oil tank exploded diagram removal and installation chart step procedure/part name q’ty service points oil tank removal follow the left “step” for removal. Engine unit refer to “engine unit”. Intake assembly refer to “fuel injection system” in chapter 4. 1 clamp/cooling water hos...

Page 112: Powr

5-13 e powr oil tank exploded diagram step procedure/part name q’ty service points 9 oil separator 1 10 clamp/breather hose 1/1 Ê to air intake pipe 11 clamp/breather hose 1/1 Ë from cylinder head cover mark a 12 clamp/cooling water hose 1/1 Ì from cooling water inlet 13 bolt 1 14 collar 1 15 band 1...

Page 113: Powr

5-14 e powr oil tank exploded diagram step procedure/part name q’ty service points 20 nut 2 21 bolt 5 22 oil tank 1 23 oil tank stay 1 24 pin 2 25 o-ring 4 26 connector 2 reverse the removal steps for installation. Ì lt 572 lt 572 lt 572 lt 572 lt 572 lt 572 23 19 25 24 26 25 21 16 17 15 14 12 20 22...

Page 114: Powr

5-15 e powr oil tank exploded diagram removal and installation chart step procedure/part name q’ty service points oil tank disassembly follow the left “step” for disassembly. 1 bolt/washer 2/2 2 bracket/grommet 2/2 3 oil tank filler cap 1 4 packing 1 5 bolt 8 6 oil tank cover 1 7 gasket 1 8 bolt 9 9...

Page 115: Powr

5-16 e powr oil tank exploded diagram step procedure/part name q’ty service points 11 bolt 3 12 baffle plate 1 13 bolt 2 14 oil strainer 1 15 bolt 24 16 oil cooler cover 2 17 gasket 2 18 screw 1 19 anode 1 20 oil tank 1 reverse the disassembly steps for assembly. E e e e 7 10 9 8 15 16 17 20 2 1 19 ...

Page 116: Powr

5-17 e powr oil tank service points oil tank removal 1. Remove: • oil tank note: loosen the oil tank bolts and nuts in the sequence shown. 3 5 9 7 6 4 2 1 8 2. Remove: • oil tank cover • gasket note: loosen the oil tank cover bolts in the sequence shown. 1 2 6 7 3 4 8 5 3. Remove: • oil breather pla...

Page 117: Powr

5-18 e powr oil tank 4. Remove: • oil cooler covers • gaskets note: loosen the oil cooler cover bolts in the sequence shown. 8 1 9 12 7 6 5 11 10 3 4 2 oil strainer inspection 1. Check: • oil strainer 1 damage → replace. Contaminants → clean. Oil tank installation 1. Install: • gaskets • oil cooler ...

Page 118: Powr

5-19 e powr 2. Install: • gasket • oil breather plate note: tighten the oil breather plate bolts in the sequence shown. T r . . Oil breather plate bolt: 1st: 1.9 n • m (0.19 kgf • m, 1.4 ft • lb) 2nd: 4.4 n • m (0.44 kgf • m, 3.2 ft • lb) 8 9 3 4 5 6 7 2 1 3. Install: • gasket • oil tank cover note:...

Page 119: Powr

5-20 e powr oil tank 4. Install: • oil tank note: tighten the oil tank nuts and bolts in the sequence shown. T r . . Bolt 1: 1st: 15 n • m (1.5 kgf • m, 11 ft • lb) 2nd: 39 n • m (3.9 kgf • m, 28 ft • lb) loctite 572 nut 2, bolt 3: 1st: 2.0 n • m (0.2 kgf • m, 1.4 ft • lb) 2nd: 15 n • m (1.5 kgf • m...

Page 120: Powr

5-21 e powr oil pump oil pump exploded diagram removal and installation chart step procedure/part name q’ty service points oil pump assembly removal follow the left “step” for removal. Oil tank refer to “oil tank”. 1 drain plug/washer 1/1 drain engine oil. 2 bolt 6 3 bolt 2 4 bolt 2 5 oil pump assem...

Page 121: Powr

5-22 e powr oil pump exploded diagram step procedure/part name q’ty service points 8 bolt 2 9 strainer 1 reverse the removal steps for installation. 2nd 28 n • m (2.8 kgf • m, 20 ft • ib) 1st 15 n • m (1.5 kgf • m, 11 ft • ib) 8 × 112 mm 6 × 25 mm 10 n • m (1.0 kgf • m, 7.2 ft • ib) 2nd 7.6 n • m (0...

Page 122: Powr

5-23 e powr oil pump service points oil strainer inspection 1. Check: • oil strainer 1 damage → replace. Contaminants → clean. 1 oil pump installation 1. Install: • oil pump assembly note: align the projection a on the oil pump shaft with the slit b on the oil pump driven gear shaft. T r . . Oil pum...

Page 123: Powr

5-24 e powr reduction drive gear reduction drive gear exploded diagram removal and installation chart step procedure/part name q’ty service points reduction drive gear removal follow the left “step” for removal. Generator cover refer to “generator and starter motor”. Oil pump refer to “oil pump”. 1 ...

Page 124: Powr

5-25 e powr reduction drive gear exploded diagram step procedure/part name q’ty service points 6 reduction drive gear case assembly 1 7 gasket 1 8 pin 2 9 circlip 2 10 reduction drive gear 1 11 washer 2 12 drive coupling 1 reverse the removal steps for installation. 8 8 9 11 10 11 9 7 3 2 4 12 5 4 6...

Page 125: Powr

5-26 e powr reduction drive gear exploded diagram removal and installation chart *1 : epnoc grease ap #0 step procedure/part name q’ty service points reduction drive gear disassembly follow the left “step” for disassembly. 1 oil pump drive shaft 1 2 drive shaft 1 3 collar 1 4 oil seal 2 5 circlip 1 ...

Page 126: Powr

5-27 e powr reduction drive gear exploded diagram *1 : epnoc grease ap #0 step procedure/part name q’ty service points 9 circlip 1 10 bearing 1 11 reduction drive gear case 1 reverse the disassembly steps for assembly. E e e e 3 4 8 6 5 10 9 1 * 1 a a * 1 e 2 11 7 * 1 not reusable not reusable.

Page 127: Powr

5-28 e powr reduction drive gear service points drive coupling removal 1. Remove: • reduction drive gear housing 2. Remove: • drive coupling 1 note: while holding the drive shaft 2 with the rotor holder 3, loosen the drive coupling with the coupler wrench 4. Coupler wrench: yw-06551/90890-06551 univ...

Page 128: Powr

5-29 e powr reduction drive gear 2. Remove: • circlip • reduction drive gear bearing È for usa and canada É for worldwide slide hammer and adapters: yb-06096 stopper guide plate: 90890-06501 bearing puller assembly: 90890-06535 stopper guide stand: 90890-06538 È É oil pump drive shaft inspection 1. ...

Page 129: Powr

5-30 e powr reduction drive gear bearing installing 1. Install: • reduction drive gear bearing note: install the reduction driver gear bearing using a press. Driver handle—large: yb-06071 driver rod ls: 90890-06606 outer race installer—forward gear: yb-06085 ball bearing attachment: 90890-06631 2. I...

Page 130: Powr

5-31 e powr reduction drive gear 3. Install: • collar • rear bearing note: • install the front bearing using a press. • before installing the rear bearing, hold both the inner and outer races of the front bearing in place as shown with a pipe that is at least 40 mm (1.57 in) long and has an outer di...

Page 131: Powr

5-32 e powr reduction drive gear drive shaft installation 1. Install: • drive shaft • collar note: press the into the reduction drive gear case using a pipe that is more than 30 mm (1.18 in) long, and which has an outer diameter of approximately 35 mm (1.97 in) and an inner diameter of approximately...

Page 132: Powr

5-33 e powr generator and starter motor generator and starter motor exploded diagram removal and installation chart step procedure/part name q’ty service points generator cover and flywheel magneto removal follow the left “step” for removal. Engine unit refer to “engine unit”. 1 nut/washer 1/1 2 sta...

Page 133: Powr

5-34 e powr generator and starter motor exploded diagram step procedure/part name q’ty service points 8 pickup coil coupler 1 9 bolt 6 10 bolt 2 11 generator cover 1 12 dowel pin 2 13 gasket 1 14 idle gear shaft 1 15 idle gear 1 16 bolt/washer 1/1 17 flywheel magneto 1 18 bolt 6 4 3 2 1 5 7 8 9 11 1...

Page 134: Powr

5-35 e powr generator and starter motor exploded diagram step procedure/part name q’ty service points 19 starter clutch 1 20 starter gear 1 21 woodruff key 1 reverse the removal steps for installation. 4 3 2 1 5 7 8 9 11 13 12 18 16 17 19 20 21 15 14 a a e e e lt 572 lt 572 a a a a 8 × 30 mm 18 n • ...

Page 135: Powr

5-36 e powr generator and starter motor exploded diagram removal and installation chart step procedure/part name q’ty service points generator disassembly follow the left “step” for disassembly. 1 bolt/washer 1/1 2 bolt 2 3 pickup coil 1 note: there washer hold the pickup coil lead. Make sure to not...

Page 136: Powr

5-37 e powr generator and starter motor exploded diagram step procedure/part name q’ty service points 5 holder 1 6 bolt 3 7 lighting coil 1 reverse the disassembly steps for assembly. 1 7 6 3 2 4 5 lt 242 lt 242 lt 242 lt 242 14 n • m (1.4 kgf • m, 10 ft • ib) 6 × 14 mm 4.9 n • m (0.49 kgf • m, 3.5 ...

Page 137: Powr

5-38 e powr generator and starter motor service points flywheel magneto removal 1. Remove: • flywheel magneto bolt 1 • washer note: while holding the flywheel magneto 2 with the sheave holder 3, loosen the flywheel magneto bolt. Sheave holder: ys-01880-a/90890-01701 2. Remove: • flywheel magneto 1 •...

Page 138: Powr

5-39 e powr generator and starter motor 2. Check: • starter clutch 1 • starter gear 2 burrs/chips/roughness/wear → replace the defective part(s). 3. Check: • starter clutch gear’s contacting surfaces a damage/pitting/wear → replace the starter clutch gear. 1 2 a 4. Check: • starter clutch operation ...

Page 139: Powr

5-40 e powr generator and starter motor flywheel magneto installation 1. Install: • woodruff key • flywheel magneto • washer • flywheel magneto bolt note: • clean the tapered portion of the crankshaft and the flywheel magneto hub. • when installing the flywheel magneto, make sure the woodruff key is...

Page 140: Powr

5-41 e powr camshafts camshafts exploded diagram removal and installation chart step procedure/part name q’ty service points cylinder head cover removal follow the left “step” for removal. 1 bolt 4 2 ignition coil 4 3 spark plug 4 4 clamp/breather hose 1/1 È to oil tank paint mark a 5 bolt 1 6 cam p...

Page 141: Powr

5-42 e powr camshafts exploded diagram step procedure/part name q’ty service points 9 bolt 1 10 cooling water pipe 1 11 o-ring 1 12 bolt 6 13 rubber mount 6 14 cylinder head cover 1 15 cylinder head cover gasket 1 16 timing chain guide (top side) 1 reverse the removal steps for installation. E 4 6 5...

Page 142: Powr

5-43 e powr camshafts exploded diagram removal and installation chart step procedure/part name q’ty service points camshaft removal follow the left “step” for removal. Cylinder head cover reduction drive gear case refer to “reduction drive gear”. Note: when removing camshafts it is not neces- sary t...

Page 143: Powr

5-44 e powr camshafts exploded diagram step procedure/part name q’ty service points 6 timing chain tensioner 1 7 timing chain tensioner gasket 1 8 timing chain guide (exhaust side) 1 9 bolt 18 10 intake camshaft cap 3 11 dowel pin 6 12 bolt 10 13 exhaust camshaft cap 3 14 dowel pin 6 15 intake camsh...

Page 144: Powr

5-45 e powr camshafts exploded diagram step procedure/part name q’ty service points 18 exhaust camshaft 1 19 bolt 2 20 exhaust camshaft sprocket 1 21 pin 1 22 timing chain guide (intake side) 1 23 bolt 1 24 plate 1 25 gasket 1 26 pipe 1 27 o-ring 1 reverse the removal steps for installation. M e e e...

Page 145: Powr

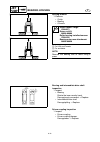

5-46 e powr camshafts service points camshaft removal 1. Install: • dial gauge needle • dial gauge stand 1 (into spark plug hole #1) • dial gauge 2 2. Turn the drive coupling counterclockwise, and then check if cylinder #1 is at tdc of the compression stroke with a dial gauge. Note: tdc on the compr...

Page 146: Powr

5-47 e powr camshafts 5. Remove: • camshaft caps • dowel pins note: loosen the intake and exhaust camshaft cap bolts in the sequence shown. 1 10 7 6 3 2 14 18 15 11 4 10 7 5 2 8 9 4 5 1 12 16 17 13 6 8 9 3 6. Remove: • intake camshaft 1 • exhaust camshaft 2 note: to prevent the timing chain from fal...

Page 147: Powr

5-48 e powr camshafts 3. Measure: • camshaft runout out of specification → replace. Maximum camshaft runout: 0.03 mm (0.0012 in) 4. Measure: • camshaft-journal-to-camshaft-cap clearance out of specification → measure the camshaft journal diameter. Camshaft-journal-to-camshaft- cap clearance: 0.05–0....

Page 148: Powr

5-49 e powr camshafts 5. Measure: • camshaft journal diameter a out of specification → replace the cam- shaft. Within specification → replace the cyl- inder head and the camshaft caps as a set. Camshaft journal diameter: intake: 24.46–24.47 mm (0.9630–0.9634 in) exhaust: 24.44–24.45 mm (0.9622–0.962...

Page 149: Powr

5-50 e powr camshafts camshaft installation 1. Install: • exhaust camshaft sprocket 1 • intake camshaft sprocket 2 (with the special service tool 3) note: install the camshaft sprocket with the punch mark a facing outside. Universal magneto and rotor holder: yu-01235 rotor holder: 90890-01235 t r . ...

Page 150: Powr

5-51 e powr camshafts • install the exhaust and intake camshaft caps. Note: gradually tighten the intake and exhaust camshaft cap bolts in 2–3 steps in the sequence shown. T r . . Camshaft cap bolt: 10 n • m (1.0 kgf • m, 7.2 ft • lb) note: make sure that the punch marks c on the camshafts are align...

Page 151: Powr

5-52 e powr camshafts t r . . Timing chain tensioner bolt: 10 n • m (1.0 kgf • m, 7.2 ft • lb) • remove the screwdriver, make sure the timing chain tensioner rod releases, and then tighten the cap bolt to the specified torque. T r . . Cap bolt: 10 n • m (1.0 kgf • m, 7.2 ft • lb) 4. Turn: • drive co...

Page 152: Powr

5-53 e powr camshafts 7. Install: • cylinder head cover gasket • cylinder head cover note: • apply sealant onto the mating surfaces of the cylinder head cover gasket and cylinder head. • tighten the cylinder head cover bolts stages and in a crisscross pattern. T r . . Cylinder head cover bolt: 12 n ...

Page 153: Powr

5-54 e powr cylinder head cylinder head exploded diagram removal and installation chart step procedure/part name q’ty service points cylinder head removal follow the left “step” for removal. Engine unit refer to “engine unit”. Intake assembly refer to “fuel injection system” in chapter 4. Exhaust pi...

Page 154: Powr

5-55 e powr cylinder head exploded diagram step procedure/part name q’ty service points 4 nut/washer 2/2 5 nut/washer 3/3 6 nut/washer 5/5 7 cylinder head 1 8 cylinder head gasket 1 9 dowel pin 2 reverse the removal steps for installation. E e e e 2 4 1 8 5 5 7 9 3 6 6 lt 271 2nd 121 ± 5˚ 1st 20 n •...

Page 155: Powr

5-56 e powr cylinder head service points cylinder head removal 1. Remove: • cylinder head bolts 1 2. Remove: • cylinder head nuts note: loosen the cylinder head nuts in the sequence shown. Cylinder head inspection 1. Eliminate: • combustion chamber carbon deposits (with a rounded scraper) note: do n...

Page 156: Powr

5-57 e powr cylinder head 3. Measure: • cylinder head warpage out of specification → replace the cyl- inder head. Cylinder head warpage limit: 0.1 mm (0.004 in) measurement steps: • place a straightedge 1 and a thickness gauge 2 across the cylinder head. • measure the warpage. • if the limit is exce...

Page 157: Powr

5-58 e powr cylinder head 2. Tighten: • cylinder head bolts 1 note: lubricate the cylinder head bolts with engine oil. T r . . Cylinder head bolt: 10 n • m (1.0 kgf • m, 7.2 ft • lb).

Page 158: Powr

5-59 e powr valves and valve springs valves and valve springs exploded diagram removal and installation chart step procedure/part name q’ty service points valves and valve springs removal follow the left “step” for removal. Cylinder head refer to “cylinder head”. 1 intake valve lifter 12 2 intake va...

Page 159: Powr

5-60 e powr valves and valve springs exploded diagram step procedure/part name q’ty service points 10 exhaust valve lifter 8 11 exhaust valve pad 8 12 exhaust valve cotter 16 13 exhaust valve upper spring seat 8 14 exhaust valve spring 8 15 exhaust valve stem seal 8 16 exhaust valve lower spring sea...

Page 160: Powr

5-61 e powr valves and valve springs service points valve removal 1. Remove: • valve lifter 1 • valve pad 2 note: make a note of the position of each valve lifter and valve pad so that they can be reinstalled in their original place. 2. Remove: • valve cotters 1 note: remove the valve cotters by com...

Page 161: Powr

5-62 e powr valves and valve springs valve spring inspection 1. Measure: • valve spring free length a out of specification → replace the valve spring. 2. Measure: • valve spring tilt a out of specification → replace the valve spring. Valve spring free length: intake valve spring: 38.90 mm (1.53 in) ...

Page 162: Powr

5-63 e powr valves and valve springs 4. Measure: • valve stem diameter a out of specification → replace the valve. Valve stem diameter a: intake valve: 3.975–3.990 mm (0.1565–0.1571 in) exhaust valve: 4.465–4.480 mm (0.1758–0.1764 in) 5. Measure: • valve stem runout out of specification → replace th...

Page 163: Powr

5-64 e powr valves and valve springs valve guide inspection note: before checking the valve guide make sure that the valve stem diameter is within specifi- cation. 1. Measure: • valve guide inside diameter a 2. Calculate the valve stem-to-valve guide clearance as follows. Replace the valve guide if ...

Page 164: Powr

5-65 e powr valves and valve springs 2. Install the new valve guide 2 by striking the special service tool from the camshaft side until the valve guide clip 3 contacts the cylinder head. Note: apply engine oil to the surface of the new valve guide. Valve guide remover: intake (ø4.0 mm): ym-04111/908...

Page 165: Powr

5-66 e powr valves and valve springs valve seat inspection 1. Eliminate carbon deposits from the valve with a scraper. 2. Apply a thin, even layer of mechanic’s blueing dye (dykem) onto the valve seat. 3. Lap the valve slowly on the valve seat with a valve lapper (commercially available) as shown. 4...

Page 166: Powr

5-67 e powr valves and valve springs valve seat reface 1. Reface the valve seat with the valve seat cutter. 2. Cut the surface of the valve seat with a 45° cutter by turning the cutter clockwise until the valve seat face has become smooth. A slag or rough surface caution: do not over cut the valve s...

Page 167: Powr

5-68 e powr valves and valve springs 4. Use a 60° cutter to adjust the contact width of the bottom edge of the valve seat. B previous contact width 60˚ b 5. Use a 45° cutter to adjust the contact width of the valve seat to specification. B previous contact width c specified contact width 45˚ b c 6. ...

Page 168: Powr

5-69 e powr valves and valve springs 9. Apply a thin, even layer of lapping com- pound onto the valve seat, and then lap the valve using a valve lapper (commer- cially available). Caution: do not get the lapping compound on the valve stem and valve guide. 10. After every lapping procedure, be sure t...

Page 169: Powr

5-70 e powr valves and valve springs 2. Compress the valve spring, and then install the valve cotter 1 using a thin screwdriver with a small amount of grease applied to it. Valve spring compressor: ym-01253/90890-04019 valve spring compressor attachment: (for the intake valve): ym-04114/90890-04114 ...

Page 170: Powr

5-71 e powr crankcase crankcase exploded diagram removal and installation chart step procedure/part name q’ty service points oil pan and crankcase removal follow the left “step” for removal. Engine unit refer to “engine unit”. Intake assembly refer to “fuel injection system” in chapter 4. Exhaust pi...

Page 171: Powr

5-72 e powr crankcase exploded diagram step procedure/part name q’ty service points reduction drive gear case refer to “reduction drive gear”. Cylinder head refer to “camshafts”. 1 timing chain 1 2 engine temperature sensor 1 3 washer 1 4 bolt 2 5 thermoswitch (engine) 1 6 oil pressure switch 1 7 bo...

Page 172: Powr

5-73 e powr crankcase exploded diagram step procedure/part name q’ty service points 11 anode 1 12 bolt 15 13 oil pan 1 14 gasket 1 15 bolt 2 16 bolt 1 17 bolt 7 18 bolt/washer 10/10 19 lower crankcase 1 20 dowel pin 2 21 dowel pin/o-ring 1/1 reverse the removal steps for installation. 6 21 20 20 11 ...

Page 173: Powr

5-74 e powr crankcase exploded diagram removal and installation chart step procedure/part name q’ty service points oil pipe and oil filter bolt removal follow the left “step” for removal. Crankshaft refer to “crankshaft”. 1 bolt 1 2 oil pipe 1 3 o-ring 2 4 oil filter bolt 1 5 lower crankcase 1 rever...

Page 174: Powr

5-75 e powr crankcase service points crankcase disassembly 1. Remove: • oil pan bolts note: • loosen each bolt 1/4 of a turn at a time, in stages and in a crisscross pattern. After all of the bolts are fully loosened, remove them. • loosen the bolts in decreasing numerical order (refer to the number...

Page 175: Powr

5-76 e powr crankcase 4. Remove: • dowel pins crankcase inspection 1. Thoroughly wash the crankcase halves in a mild solvent. 2. Thoroughly clean all the gasket surfaces and crankcase mating surfaces. 3. Check: • crankcase cracks/damage → replace. • oil delivery passages obstruction → blow out with ...

Page 176: Powr

5-77 e powr crankcase crankcase assembly 1. Lubricate: crankshaft journal bearings (with the recommended lubricant) 2. Apply: • threebond 1280b (onto the crankcase mating surfaces) note: do not allow any sealant to come into contact with the oil gallery or crankshaft journal bear- ings. Recommended ...

Page 177: Powr

5-78 e powr crankcase 5. Tighten: • crankcase bolts 1–0 note: • do not reuse crankcase bolts 1–0. • the tightening procedure of crankcase bolts 1–0 is angle controlled, therefore tighten the bolts using the following procedure. Tightening steps: • tighten the bolts in the order of the num- bers on t...

Page 178: Powr

5-79 e powr crankcase caution: • do not use a torque wrench to tighten the bolt to the specified angle. • tighten the bolt until it is at the speci- fied angle. Note: when using a hexagonal bolt, note that the angle from one corner to another is 60°. 6. Tighten: • crankcase bolts a–j note: tighten t...

Page 179: Powr

5-80 e powr connecting rods and pistons connecting rods and pistons exploded diagram removal and installation chart step procedure/part name q’ty service points connecting rods and pistons removal follow the left “step” for removal. Crankcase separate refer to “crankcase”. 1 nut 8 2 connecting rod c...

Page 180: Powr

5-81 e powr connecting rods and pistons exploded diagram step procedure/part name q’ty service points 8 bolt 8 9 big end upper bearing 4 10 top ring 4 11 2nd ring 4 12 oil ring 4 reverse the removal steps for installation. E e e e 1 2 3 10 11 12 4 5 6 8 7 9 2nd 120 ± 5˚ 1st 20 n • m (2.0 kgf • m, 14...

Page 181: Powr

5-82 e powr connecting rods and pistons service points connecting rod and piston removal the following procedure applies to all of the connecting rods and pistons. 1. Remove: • connecting rod cap 1 • big end bearings note: identify the position of each big end bearing so that it can be reinstalled i...

Page 182: Powr

5-83 e powr connecting rods and pistons cylinder and piston inspection the following procedure applies to all of the cylinders and pistons. 1. Check: • piston wall • cylinder wall vertical scratches → replace the cylin- der, and the piston and piston rings as a set. 2. Measure: • piston-to-cylinder ...

Page 183: Powr

5-84 e powr connecting rods and pistons • if out of specification, replace the piston and piston rings as a set. • calculate the piston-to-cylinder clearance with the following formula. Piston-to-cylinder clearance = cylinder bore “c” – piston skirt diameter “p” piston-to-cylinder clearance: 0.10–0....

Page 184: Powr

5-85 e powr connecting rods and pistons 2. Install: • piston ring (into the cylinder) note: level the piston ring in the cylinder with the piston crown. A 5 mm (0.2 in) 3. Measure: • piston ring end gap out of specification → replace the pis- ton ring. Note: the oil ring expander spacer’s end gap ca...

Page 185: Powr

5-86 e powr connecting rods and pistons piston pin inspection the following procedure applies to all of the piston pins. 1. Check: • piston pin bluediscoloration/grooves → replace the piston pin and then check the lubri- cation system. 2. Measure: • piston pin outside diameter a out of specification...

Page 186: Powr

5-87 e powr connecting rods and pistons connecting rod inspection 1. Measure: • big end oil clearance out of specification → replace the big end bearings. Big end oil clearance: 0.016–0.040 mm (0.0006–0.0016 in) measurement steps: the following procedure applies to all of the connecting rods. Cautio...

Page 187: Powr

5-88 e powr connecting rods and pistons note: • do not move the connecting rod or crank- shaft until the clearance measurement has been completed. • lubricate the bolts threads and nut seats with molybdenum disulfide grease. • make sure the “y” mark c on the con- necting rod faces towards the front ...

Page 188: Powr

5-89 e powr connecting rods and pistons for example, if the connecting rod “p 1 ” and the crankshaft web “p 1 ” numbers are “5” and “1” respectively, then the bearing size for “p 1 ” is: bearing size of p 1 : “p 1 ” (connecting rod) – “p 1 ” (crankshaft web) 5 – 1 = 4 (green) bearing color code 1 br...

Page 189: Powr

5-90 e powr connecting rods and pistons 3. Offset: • piston ring end gaps a top ring, oil ring expander spacer b 2nd ring, lower oil ring rail c upper oil ring rail È exhaust side b c a È 90 ˚ 45˚ 90˚ 4. Lubricate: • piston • piston rings • cylinder (with the recommended lubricant) recommended lubri...

Page 190: Powr

5-91 e powr connecting rods and pistons 7. Install: • big end bearings • connecting rod assembly 1 (into the cylinder and onto the crankshaft pin) • connecting rod cap (onto the crankshaft pin) note: • align the projections on the big end bearings with the notches in the connecting rods and connecti...

Page 191: Powr

5-92 e powr connecting rods and pistons 9. Tighten: • connecting rod nuts warning • replace the connecting rod bolts and nuts with new ones. • clean the connecting rod bolts and nuts. Note: the tightening procedure of the connecting rod nuts is angle controlled, therefore tighten the nuts using the ...

Page 192: Powr

5-93 e powr crankshaft crankshaft exploded diagram removal and installation chart step procedure/part name q’ty service points crankshaft removal follow the left “step” for removal. Crankcase separate refer to “crankcase”. Connecting rod caps refer to “connecting rods and pistons”. 1 crankshaft 1 2 ...

Page 193: Powr

5-94 e powr crankshaft service points crankshaft removal 1. Remove: • crankshaft 1 • crankshaft journal lower bearings (from the lower crankcase) • crankshaft journal upper bearings (from the upper crankcase) note: identify the position of each crankshaft journal bearing so that it can be reinstalle...

Page 194: Powr

5-95 e powr crankshaft caution: do not interchange the crankshaft journal bearings. To obtain the correct crankshaft journal oil clearance and prevent engine damage, the crankshaft journal bearings must be installed in their original positions. Measurement steps: • clean the crankshaft journal beari...

Page 195: Powr

5-96 e powr crankshaft • tighten the bolts to specification in the order of the numbers on the crankcase. Refer to “crankcase assembly”— “crankcase”. • remove the lower crankcase and the crankshaft journal lower bearings. • measure the compressed plastigauge width c on each crankshaft journal. If th...

Page 196: Powr

5-97 e powr crankshaft crankshaft installation 1. Install: • crankshaft journal upper bearings (into the upper crankcase) • crankshaft journal lower bearings (into the lower crankcase) note: • align the projections a on the crankshaft journal upper bearings with the notches b in the upper crankcase....

Page 197: Powr

5-98 e powr cooling water hose cooling water hose exploded diagram removal and installation chart step procedure/part name q’ty service points cooling water hose removal follow the left “step” for removal. Exhaust manifold refer to “exhaust manifold”. 1 clamp/cooling water hose 1/1 È to cylinder blo...

Page 198: Powr

5-99 e powr cooling water hose exploded diagram step procedure/part name q’ty service points 4 joint 1 5 clamp/cooling water hose 1/1 Ê to oil tank 6 clamp/cooling water hose 1/1 Ë from transom plate 7 joint 1 reverse the removal steps for installation. 1 4 3 2 3 7 5 6 È É Ê Ë a 2 3 4 1.

Page 199: Jet

E jet pump 1 2 3 4 5 6 7 8 9 chapter 6 jet pump unit intake grate and ride plate ............................................................... 6-1 exploded diagram ............................................................................. 6-1 removal and installation chart ........................

Page 200: Jet

6-1 e jet pump intake grate and ride plate exploded diagram removal and installation chart step procedure/part name q’ty service points intake grate, ride plate, and intake duct removal follow the left “step” for removal. 1 bolt 2 2 bolt 2 3 intake grate 1 4 screw 4 5 speed sensor 1 note: route the ...

Page 201: Jet

6-2 e jet pump intake grate and ride plate exploded diagram step procedure/part name q’ty service points 6 bolt 4 7 ride plate 1 reverse the removal steps for installation..

Page 202: Jet

6-3 e jet pump jet pump unit jet pump unit exploded diagram removal and installation chart step procedure/part name q’ty service points jet pump unit removal follow the left “step” for removal. 1 shift cable joint 1 deluxe model only 2 bilge hose 1 3 nut/washer 1/2 4 steering cable joint 1 5 hose cl...

Page 203: Jet

6-4 e jet pump jet pump unit exploded diagram step procedure/part name q’ty service points 9 collar 2 10 bolt 2 11 rubber plate 2 12 bolt 1 13 bolt 2 14 bolt 4 15 jet pump unit assembly 1 16 dowel pin 2 reverse the removal steps for installation. 8 × 24 mm 14 n • m (1.4 kgf • m, 10 ft • ib) 6 × 22 m...

Page 204: Jet

6-5 e jet pump reverse gate (deluxe model only) reverse gate (deluxe model only) exploded diagram removal and installation chart step procedure/part name q’ty service points reverse gate removal follow the left “step” for removal. 1 hose clamp/spout hose 1/1 2 bolt 2 3 collar 2 4 reverse gate 1 5 sp...

Page 205: Jet

6-6 e jet pump jet thrust nozzle, impeller duct, and impeller housing 1 jet thrust nozzle, impeller duct, and impeller housing 1 exploded diagram removal and installation chart step procedure/part name q’ty service points jet thrust nozzle, impeller duct, and impeller housing 1 removal follow the le...

Page 206: Jet

6-7 e jet pump jet thrust nozzle, impeller duct, and impeller housing 1 exploded diagram step procedure/part name q’ty service points 10 bolt 4 11 water inlet cover 1 12 packing 1 13 water inlet strainer 1 14 packing 1 reverse the removal steps for installation. 10 × 125 mm 40 n • m (4.0 kgf • m, 29...

Page 207: Jet

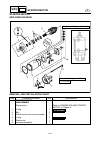

6-8 e jet pump impeller duct and drive shaft impeller duct and drive shaft exploded diagram removal and installation chart *1: epnoc grease ap #0 step procedure/part name q’ty service points impeller duct and drive shaft disassembly follow the left “step” for disassembly. 1 bolt 3 2 cap 1 3 o-ring 1...

Page 208: Jet

6-9 e jet pump impeller duct and drive shaft exploded diagram *1: epnoc grease ap #0 step procedure/part name q’ty service points 8 oil seal 1 9 rear bearing 1 10 spacer 1 11 front bearing 1 12 impeller duct 1 reverse the disassembly steps for assembly. Not reusable not reusable not reusable.

Page 209: Jet

6-10 e jet pump impeller duct and drive shaft service points drive shaft removal 1. Remove: • impeller note: hold the impeller duct assembly in a vise between two aluminum plates a. Crankshaft holder: yb-06552 crankshaft holder 20: 90890-06552 a a 2. Remove: • drive shaft 1 note: remove the drive sh...

Page 210: Jet

6-11 e jet pump impeller duct and drive shaft 4. Remove: • oil seals note: remove the oil seals using a flat head screw- driver. 5. Remove: • front bearing note: remove the front bearing using a press. Driver handle—large: yb-06071 driver rod l3: 90890-06652 bearing housing needle bearing remover: y...

Page 211: Jet

6-12 e jet pump impeller duct and drive shaft drive shaft installation 1. Install: • oil seals driver handle—large: yb-06071 driver rod ls: 90890-06606 outer race installer—forward gear: yb-06085 ball bearing attachment: 90890-06634 distance a: 4.6 ± 0.2 mm (0.18 ± 0.01 in) 2. Install: • rear bearin...

Page 212: Jet

6-13 e jet pump impeller duct and drive shaft 5. Install: • front bearing note: press the spacer and the front bearing using a pipe that is more than 60 mm (2.36 in) long and that has an inner diameter more than 26 mm (1.02 in). 6. Install: • drive shaft (with front bearing spacer and rear bearing) ...

Page 213: Jet

6-14 e jet pump 8. Install: • impeller note: hold the impeller duct assembly in a vise between two aluminum plates a. T r . . Impeller: 75 n • m (7.5 kgf • m, 54 ft • lb) loctite 572 crankshaft holder: yb-06552 crankshaft holder 20: 90890-06552 a a impeller duct and drive shaft.

Page 214: Jet

6-15 e jet pump transom plate and hoses transom plate and hoses exploded diagram removal and installation chart step procedure/part name q’ty service points transom plate and hoses removal follow the left “step” for removal. Exhaust system refer to “exhaust system” in chapter 8. Jet pump unit assemb...

Page 215: Jet

6-16 e jet pump transom plate and hoses exploded diagram step procedure/part name q’ty service points 6 bilge strainer 1 7 nut/washer 2/2 8 nut/washer 2/2 9 transom plate 1 10 bilge hose 2 1 reverse the removal steps for installation..

Page 216: Jet

6-17 e jet pump transom plate and hoses service points bilge strainer inspection refer to “jet pump unit” in chapter 3. Bilge hose inspection 1. Inspect: • bilge hoses cracks/damage/wear → replace. Cooling water hose inspection 1. Inspect: • cooling water hoses cracks/damage/wear → replace..

Page 217: Jet

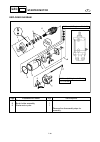

6-18 e jet pump bearing housing bearing housing exploded diagram removal and installation chart step procedure/part name q’ty service points bearing housing removal follow the left “step” for removal. Engine unit refer to “engine unit” in chapter 5. 1 rubber coupling 1 2 bolt 4 3 intermediate housin...

Page 218: Jet

6-19 e jet pump bearing housing exploded diagram removal and installation chart step procedure/part name q’ty service points bearing housing disassembly follow the left “step” for disassembly. 1 driven coupling 1 2 washer 1 3 damper 1 4 intermediate drive shaft 1 5 circlip 1 not reusable.

Page 219: Jet

6-20 e jet pump bearing housing exploded diagram step procedure/part name q’ty service points 6 oil seal 1 7 bearing 1 8 oil seal 1 9 oil seal 1 10 bearing housing 1 reverse the disassembly steps for assembly. Not reusable not reusable not reusable not reusable.

Page 220: Jet

6-21 e jet pump bearing housing service points driven coupling removal and installation 1. Remove and install: • driven coupling note: • install the driven coupling using the same special tools that were used for removal. • check that the drive shaft holder and inter- mediate drive shaft are properl...

Page 221: Jet

6-22 e jet pump bearing housing bearing removal 1. Remove: • circlip • bearing • oil seals È for usa and canada É for worldwide note: remove the bearing and oil seals using a press. Driver handle—large: yb-06071 driver rod ls: 90890-06606 roller bearing installer/remover: yb-06432 bearing outer race...

Page 222: Jet

6-23 e jet pump bearing housing bearing and oil seals installation 1. Install: • oil seals • bearing note: install the bearing using a press. Driver handle—large: yb-06071 driver rod ls: 90890-06606 outer race installer—forward gear: yb-06085 ball bearing attachment: 90890-06631 distance a: 14.2 ± 0...

Page 223: Jet

6-24 e jet pump bearing housing intermediate drive shaft installation 1. Install: • intermediate drive shaft note: install the intermediate drive shaft using a press. Distance a: 56.8 ± 0.2 mm (2.24 ± 0.01 in) a.

Page 225: Elec

E – + elec 1 2 3 4 5 6 7 8 9 chapter 7 electrical system electrical components........................................................................ 7-1 fuse box....................................................................................................... 7-2 exploded diagram ...............

Page 226: Elec

E – + elec fuel control system ........................................................................... 7-31 wiring diagram ................................................................................. 7-31 electric fuel pump ......................................................................

Page 227: Elec

E – + elec indication system .................................................................................. 7-48 wiring diagram ................................................................................. 7-48 fuse ...............................................................................

Page 228: Elec

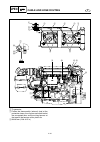

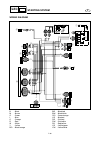

7-1 e – + elec electrical components electrical components o n m l k j i h g f e d c b a 0 9 1 2 3 4 5 6 7 8 1 thermoswitch (engine) 2 fuse box 3 slant detection switch 4 starter motor 5 engine temperature sensor 6 spark plugs and ignition coils 7 cam position sensor 8 battery 9 speed sensor 0 senso...

Page 229: Elec

7-2 e – + elec fuse box fuse box exploded diagram removal and installation chart step procedure/part name q’ty service points fuse box removal follow the left “step” for removal. 1 nut/washer 2/2 2 wiring harness 1 note: disconnect all couplers. 3 fuse box 1 4 fuse box cap 1 5 gasket 1 6 fuse 10 7 t...

Page 230: Elec

7-3 e – + elec fuse box exploded diagram step procedure/part name q’ty service points 9 bracket 1 10 rubber mount 1 11 main and fuel pump relay 1 12 electronic control throttle valve relay 1 13 tapping screw 2 14 slant detection switch 1 15 bolt 6 16 fuse box cover 1 17 nut 6 18 gasket 1 19 tapping ...

Page 231: Elec

7-4 e – + elec fuse box exploded diagram step procedure/part name q’ty service points 20 plate 1 21 bolt 2 22 cover 2 23 positive battery lead 1 24 starter motor lead 1 with white tape 25 starter relay 1 26 grommet 1 27 bolt 3 28 wiring harness 1 red 29 wiring harness 1 brown 30 3 10 10 20 30 3 10 1...

Page 232: Elec

7-5 e – + elec fuse box exploded diagram step procedure/part name q’ty service points 30 wiring harness 1 black 31 holder 2 32 pipe 1 33 battery 1 34 battery box 1 35 nut 4 36 holder 1 reverse the removal steps for installation. 30 3 10 10 20 30 3 10 10 20 6 × 25 mm 6 × 20 mm 6 × 10 mm 6 × 8 mm 6 × ...

Page 233: Elec

7-6 e – + elec fuse box 1 2 6 5 4 3 1 positive battery lead 2 starter motor lead (white tape) 3 starter relay 4 wiring harness (black) 5 wiring harness (brown) 6 wiring harness (red).

Page 234: Elec

7-7 e – + elec ecm and rectifier/regulator ecm and rectifier/regulator exploded diagram removal and installation chart step procedure/part name q’ty service points ecm and rectifier/ regulator removal follow the left “step” for removal. 1 wiring harness 1 note: disconnect all couplers. 2 bolt 2 3 re...

Page 235: Elec

7-8 e – + elec ecm and rectifier/regulator exploded diagram step procedure/part name q’ty service points 8 bolt 2 9 bracket 1 10 grommet 2 11 collar 2 reverse the removal steps for installation. 2nd 18 n • m (1.8 kgf • m, 13 ft • ib) 1st 8.8 n • m (0.88 kgf • m, 6.4 ft • ib) 8 × 35 mm 6 × 30 mm 4.0 ...

Page 236: Elec

7-9 e – + elec electrical analysis electrical analysis inspection caution: • all measuring instruments should be han- dled with special care. Damaged or mis- handled instruments will not measure properly. • on an instrument powered by dry batter- ies, check the battery’s voltage periodi- cally and r...

Page 237: Elec

7-10 e – + elec electrical analysis low resistance measurement note: • when measuring a resistance of 10 Ω or less using a digital tester, the correct measure- ment cannot be obtained because of the tester’s internal resistance. • to obtain the correct value, subtract the internal resistance from th...

Page 238: Elec

7-11 e – + elec electrical analysis peak voltage adapter note: • throughout this chapter the part numbers of the specified peak voltage adapters have been omitted. Refer to the following part numbers. • the peak voltage adapter should be used with a digital tester. • when measuring the peak voltage,...

Page 239: Elec

7-12 e – + elec ignition system ignition system wiring diagram 10a 10a 3a 30a 20a w br b r free push b w free push br br free push b w w br br br br r w b/w b/o b/o b/o b/r p/r p/r w/b p/w p/w b/o l/b b/w b/r b/o p/w p/r w w w l r y g o o w g g b w g g o o l g w y w g/o w/b r/y y/g b l p b w p/w b/g...

Page 240: Elec

7-13 e – + elec ignition system wiring diagram 10a 10a 3a 30a 20a w br b r free push b w free push br br free push b w w br br br br r w b/w b/o b/o b/o b/r p/r p/r w/b p/w p/w b/o l/b b/w b/r b/o p/w p/r w w w l r y g o o w g g b w g g o o l g w y w g/o w/b r/y y/g b l p b w p/w b/g b/y y/w l/r b/r...

Page 241: Elec

7-14 e – + elec ignition system ignition spark warning • when checking the spark gap, do not touch any of the connections of the spark checker/ignition tester lead wires. • when performing the spark gap test, take special care not to let sparks leak out of the removed spark plug cap. • when performi...

Page 242: Elec

7-15 e – + elec ignition system ignition system peak voltage warning when checking the electrical components, do not touch any of the connections of the digital tester lead wires. Note: • if there is no spark, or the spark is weak, continue with the ignition system test. • if a good spark is obtaine...

Page 243: Elec

7-16 e – + elec ignition system 2. Measure: • pickup coil output peak voltage below specification → replace the pickup coil. Above specification → replace the ecm. Note: to crank the engine, connect the engine shut- off cord (lanyard) to the engine shut-off switch, and then press the start switch an...

Page 244: Elec

7-17 e – + elec note: to crank the engine, connect the engine shut- off cord (lanyard) to the engine shut-off switch, and then press the start switch and engine stop switch simultaneously. 4. Measure: • rectifier/regulator output voltage below specification → replace the recti- fier/regulator. Note:...

Page 245: Elec

7-18 e – + elec ignition coil 1. Measure: • primary coil resistance out of specification → replace. Note: when measuring a resistance of 10 Ω or less using a digital tester, the correct measurement cannot be obtained because of the tester’s internal resistance. Refer to “low resistance measurement”....

Page 246: Elec

7-19 e – + elec ignition system engine temperature sensor 1. Measure: • engine temperature sensor resistance (at the specified temperature) out of specification → replace. Engine temperature sensor resistance: 20 °c (68 °f): 54.2–69.0 k Ω 100 °c (212 °f): 3.12–3.48 k Ω measurement steps: • suspend t...

Page 247: Elec

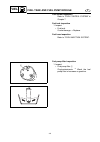

7-20 e – + elec ignition system thermoswitch (engine) 1. Check: • thermoswitch (engine) continuity (at the specified temperature) out of specification → replace. 1 no continuity È temperature 2 continuity É time note: the thermoswitch (engine) connector is blue. Thermoswitch (engine) continuity temp...

Page 248: Elec

7-21 e – + elec thermoswitch (exhaust) 1. Check: • thermoswitch (exhaust) continuity (at the specified temperature) out of specification → replace. 1 no continuity È temperature 2 continuity É time note: the thermoswitch (exhaust) connector is black. Thermoswitch (exhaust) continuity temperature: a ...

Page 249: Elec

7-22 e – + elec ignition system main and fuel pump relay 1. Check: • main and fuel pump relay continuity faulty → replace. Checking steps: • connect the tester leads to the main and fuel pump relay terminals 5 and 6 or 7. • connect terminals 2 or 3 to the positive battery terminal. • connect termina...

Page 250: Elec