- DL manuals

- Yamaha

- Snowmobiles

- VX500SXBC

- Service Manual

Yamaha VX500SXBC Service Manual

Summary of VX500SXBC

Page 1

Supplementary service manual.

Page 2: Foreword

Caution: note: foreword this supplementary service manual has been prepared to introduce new service and new data for the vx500sxbc, vx700erc. For complete information, on service proce- dures, it is necessary to use this supplemen- tary service manual together with following manual: vt500a, vt600a,...

Page 3

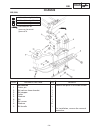

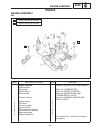

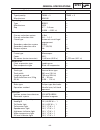

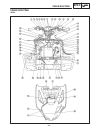

1 3 5 7 9 17 20 2 4 8 18 6 23 26 19 21 22 24 25 14 15 16 11 12 13 oe031 illustrated symbols (refer to the illustration) illustrated symbols 1 to 9 are designed as thumb tabs to indicate the chapter’s number and content. 1 general information 2 periodic inspection and adjustment 3 chassis 4 power tra...

Page 4

Contents general information 1 . . . . . . . . . . . . . . Machine identification 1 . . . . . . . . . Frame serial number 1 . . . . . . . Engine serial number 1 . . . . . . . Important information 1 . . . . . . . . Loctite 1 . . . . . . . . . . . . . . . . . . . . . . Power train 2 . . . . . . . . ....

Page 5: Gen

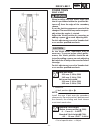

–1– 500 700 machine identification/important information gen info note: 1e001 general information machine identification frame serial number the frame serial number 1 is located on the right-hand side of the frame (just below the front of the seat). Engine serial number the engine serial number 1 is...

Page 6: Insp

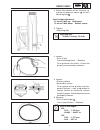

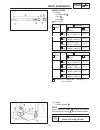

–2– drive v-belt insp adj caution: note: power train drive v-belt when installing the new v-belt, make sure that it is positioned within the specified dis- tances 1 from the edge of the secondary sheave. If not, the clutch engagement speed will be changed. The machine may move unexpect- edly when th...

Page 7: Insp

–3– drive v-belt insp adj 2. Adjust the position of the v-belt by re- moving or adding a spacer 1 on each adjusting bolt 2 . V-belt height adjustment to move v-belt up: add spacer to move v-belt down: reduce spacer 3. Tighten: sadjusting bolt adjusting bolt: 10 nm (1.0 m skg, 7.2 ftslb) 4. Inspect: ...

Page 8: Insp

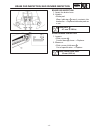

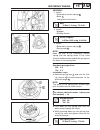

–4– brake pad inspection/slid runner inspection insp adj brake pad inspection 1. Apply the brake lever. 2. Inspect: sbrake pad wear indicator 1 nearly contacts the brake disc ! Replace the brake pads as a set. Wear limit a : 4.7 mm (0.185 in) slide runner inspection 1. Inspect: sslide runner 1 crack...

Page 9: Insp

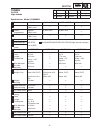

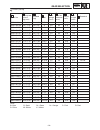

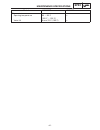

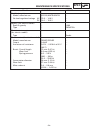

–5– clutch insp adj a b c d e f g h i j k l m n o p q r s t u v w x z y a b d tuning clutch high altitude w white s silver l blue p pink r red o orange y yellow g green specifications model: vx500sxb elevation x 3,500 ft 3,000 x 5,000 ft 4,500 x 7,000 ft 6,500 x 10,000 ft idle speed approx. 1,600 r ...

Page 10: Insp

–6– clutch insp adj a b c d e f g h i j k l m n o p q r s t u v w x z y a b see maintenance specifications (high altitude settings) d w white s silver l blue p pink r red o orange y yellow g green specifications model: vx700er elevation x 3,500 ft 3,000 x 5,000 ft 4,500 x 7,000 ft 6,500 x 10,000 ft ...

Page 11: Insp

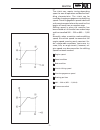

–7– clutch insp adj 2e331 the clutch may require tuning depending upon the area of operation and desired han- dling characteristics. The clutch can be tuned by changing engagement and shifting speed. Clutch engagement speed is defined as the engine speed where the machine first begins to move from a...

Page 12: Insp

–8– gear selection insp adj note: a b c d e f g driven gear drive gear b a gear selection the reduction ratio of the driven gear to the drive gear must be set according to the snow conditions. If there are many rough surfaces or unfavorable snow conditions, the drive / driven gear ratio should be in...

Page 13: Insp

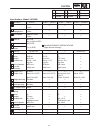

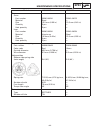

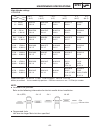

–9– gear selection insp adj a b c d e f g a sheave seat b a b c 3 secondary spring parts no. Spring rate n smm/rad (kgmm / rad) no. Of coils color wire gauge (mm) free length (mm) standard 90508-500b1 6003 (613) 5.2 brown 5.0 75 90508-536a9 7147 (729) 5.5 red 5.3 75 vx500 90508-556a2 8314 (848) 5.5 ...

Page 14: Insp

–10– gear selection insp adj a e h b c d f g i 6 primary spring parts no. Spring rate n / mm (kg / mm) preload (kg) color wire gauge (mm) outside diameter (mm) no. Of coils free length (mm) standard 90501-481j1 9.8 (1.0) 196.1 (20) s-b-s 4.8 60 5.16 85.4 90501-487g8 14.7 (1.5) 147 (15) g 4.8 60 4.19...

Page 15: Insp

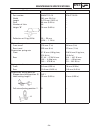

–11– front suspension insp adj caution: a caution: front suspension spring preload (700) 1. Adjust: sturn the adjusting ring 1 to the proper position. Spring adjuster position 1 2 3 4 5 preload softer z ! Harder standard 1 be sure that the left and right spring preload is the same. Spring preload (5...

Page 16: Insp

–12– a b rear suspension insp adj caution: note: a b rear suspension stopper band 1. Adjust: sstopper band tension be sure that the left and right length is the same. This adjustment affects the handling charac- teristics of the machine. Adjustment steps: s loosen the locknut 1 . S turn the adjustin...

Page 17: Insp

–13– a b rear suspension insp adj a a b b spring preload (500) 1. Adjust: sturn the spring seat 1 in or out. Spring seat distance standard shorter z ! Longer preload harder z ! Softer length (front) max. Min. 172 mm 182 mm 192 mm (6.77 in) (7.17 in) (7.56 in) length (rear) max. Min. 302 mm 312 mm 32...

Page 18: Chas

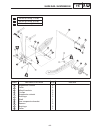

–14– ski chas order job name / part name q’ty remarks 1 2 3 4 5 6 7 8 9 ski removal cotter pin ski column lower bracket ski stopper collar washers ski ski runner washers ski handle 1 1 1 1 6 1 1 6 1 remove the parts in the order below. For installation, reverse the removal procedure. 10 nm (1.0 m sk...

Page 19: Chas

–15– ski/front suspension chas inspection 1. Inspect: sski 1 sski runner 2 sski column lower bracket 3 sski handle 4 sski stopper 5 wear / cracks/ damage ! Replace. Smounting bolt 6 scollar 7 wear / damage ! Replace. Front suspension this shock absorber contains highly com- pressed nitrogen gas. Bef...

Page 20: Chas

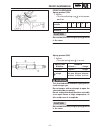

–16– front suspension chas c a h i f b d h i c a h i f b e h i note: installation 1. Install: scontrol rod 1 snut 2 sjoint 3 a set length left hand model set length (mm) set angle ( _) vx500 upper 460.2 ± 0.5 mm (18.11 ± 0.0197 in) 94 ± 1 lower 458.7 ± 0.5 mm (18.059 ± 0.0197 in) 94 ± 1 vx700 upper ...

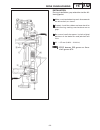

Page 21: Powr

–17– secondary sheave powr tr note: note: assembly 1. Install: ssecondary sheave spring 1 sbolts 2 (along with the shims) bolt: 10 nm (1.0 m skg, 7.2 ftslb) 2. Install: sstopper ssliding sheave screw (stopper): 6.5 nm (0.65 m skg, 4.6 ftslb) 3. Install: ssecondary sheave spring 1 sspring seat 2 hook...

Page 22: Powr

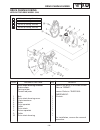

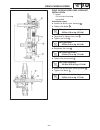

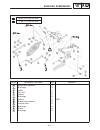

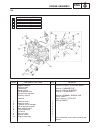

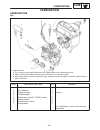

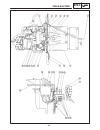

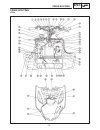

–18– order job name / part name q’ty remarks 1 2 3 4 5 6 7 8 9 10 drive chain housing removal brake caliper parking brake tension adjuster bolt drive chain housing cover chain tensioner roller drive sprocket collar drive chain driven sprocket collar drive chain housing 1 1 1 1 1 1 1 1 1 1 remove the...

Page 23: Powr

–19– drive chain housing powr tr installation during installation, pay attention to the fol- lowing point: a make sure that the bearing seals face towards the drive chain, as shown. B properly install the rubber seal onto the drive chain housing, making sure that these are no gaps. C be sure to inst...

Page 24: Powr

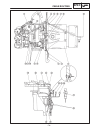

–20– drive chain housing powr tr drive chain housing and jackshaft installation 1. Install: sdrive chain housing sjackshaft installation steps: d install the drive chain housing 1 . D tighten the bolts 2 . Bolt (drive chain housing): 48 nm (4.8 m skg, 35 ftslb) d temporarily tighten the nuts 3 . D t...

Page 25: Powr

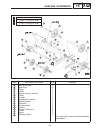

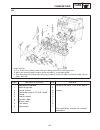

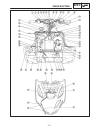

–21– order job name / part name q’ty remarks 1 2 3 4 5 6 7 8 9 drive chain housing removal battery battery bracket brake caliper parking brake tension adjuster joints shift rod shift lever assembly lever joints lever rod bolt drive chain housing cover washer 2 1 1 1 2 1 1 1 1 remove the parts in the...

Page 26: Powr

–22– order job name / part name q’ty remarks 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 reverse drive gear spring chain tensioner roller collar spring journal reverse driven gear washer forward driven sprocket collar counter gear drive sprocket drive chain collar washer plate shaft dri...

Page 27: Powr

–23– drive chain housing/jackshaft powr tr installation during installation, pay attention to the fol- lowing point: a properly install the rubber seal onto the drive chain housing, making sure that these are no gaps. B make sure that the bearing seals face towards the drive chain, as shown. C be su...

Page 28: Powr

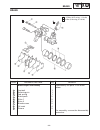

–24– order job name / part name q’ty remarks brake caliper disassembly cap bolt retaining pin pad spring brake pads shim 1 shim 2 bleed screws oil seals pistons 1 1 1 2 2 2 2 4 2 disassembly the parts in the order below. For assembly, reverse the disassembly procedure. 1 2 3 4 5 6 7 8 9 1.5 nm (0.15...

Page 29: Powr

–25– brake powr tr caution: note: note: disc brake components rarely require disas- sembly. Do not: d disassemble components unless abso- lutely necessary. D use solvents on internal brake compo- nents. D use contaminated brake fluid for clean- ing. Use only clean brake fluid. D allow brake fluid to...

Page 30: Powr

–26– brake powr tr note: 2. Install: sbrake pads spad spring installation steps: sconnect a suitable hose 1 tightly to the caliper bleed screw 2 . Put the other end of this hose into an open container. Sloosen the caliper bleed screw and push the pistons into the caliper with the finger. Stighten th...

Page 31: Powr

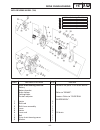

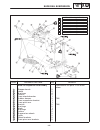

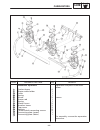

–27– order job name / part name q’ty remarks 1 2 3 4 slide rail suspension removal tension adjuster blind caps bolts washer slide rail suspension 2 6 2 1 remove the parts in the order below. Loosen. For installation, reverse the removal procedure. 71 nm (7.1 m skg, 51 ftslb) a : slide rail suspensio...

Page 32: Powr

–28– order job name / part name q’ty remarks slide rail suspension disassembly stopper bands hooks bushings collars front shock absorber rubber damper front suspension bracket front pivot arm bracket bushings shaft bushings collars suspension wheels collar wheel brackets front pivot arm brackets 2 2...

Page 33: Powr

–29– order job name / part name q’ty remarks suspension wheels collar wheel brackets circlips suspension wheels bushings shaft rear suspension bracket spacers bushings collar 2 2 2 2 2 2 1 1 2 2 1 24 nm (2.4 m skg, 17 ftslb) a : 49 nm (4.9 m skg, 35 ftslb) b : 71 nm (7.1 m skg, 50 ftslb) c : 18 19 2...

Page 34: Powr

–30– order job name / part name q’ty remarks rear shock absorber bushings collar pull rod collars bushings collars suspension wheels control rods bushings screw bushings 1 2 1 2 4 4 2 2 2 2 2 2 (700) 49 nm (4.9 m skg, 35 ftslb) a : 71 nm (7.1 m skg, 50 ftslb) b : 29 30 31 32 33 34 35 36 37 38 39 40 ...

Page 35: Powr

–31– order job name / part name q’ty remarks rear pivot arm bushings collar collar rear pivot arm bracket collar circlips suspension wheels wheel bracket rear axle guide wheels collars tension adjusters collar collar sliding frames 1 2 1 1 1 1 2 2 1 1 3 2 2 1 1 2 for assembly, reverse the disassembl...

Page 36: Powr

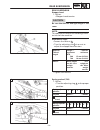

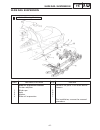

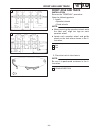

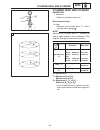

–32– a b 102 mm (4.0157 in) 123 mm (4.84 in) 102 mm (4.0157 in) 43.1 mm (1.70 in) 27 mm (1.06 in) 201.4 mm (7.93 in) 60 mm (2.36 in) 123 mm (4.84 in) 132.6 mm (5.22 in) 164.1 mm (6.46 in) 60 mm (2.36 in) 132.6 mm (5.22 in) 164.1 mm (6.46 in) 201.4 mm (7.93 in) 111.9 mm (5.22 in) 39 mm (1.535 in) 39 ...

Page 37: Eng

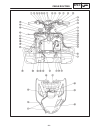

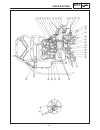

–33– order job name / part name q’ty remarks 1 2 3 4 5 6 7 8 engine removal exhaust pipe carburetor recoil starter water pump primary sheave coolant hose oil hoses oil pump cable vacuum hose cdi magneto couplers thermo sensor coupler spark plug caps engine assembly 1 2 1 1 2 1 2 1 remove the parts i...

Page 38: Eng

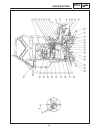

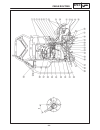

–34– order job name / part name q’ty remarks 1 2 3 4 5 6 7 8 9 10 engine removal exhaust pipe carburetor recoil starter cdi magneto rotor frame cross member primary sheave coolant coolant hose 1 coolant hose 2 thermo sensor coupler cdi magneto couplers rear bracket right oil pump cable oil hoses vac...

Page 39: Eng

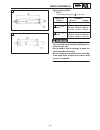

–35– c cylinder head and cylinder eng note: cylinder head and cylinder inspection 1. Measure: spiston-to-cylinder clearance measurement steps: 1st step: smeasure the cylinder bore “c” with a cylinder bore gauge 1 . Measure the cylinder bore “c” parallel to, and at right angles to the crankshaft. The...

Page 40: Eng

–36– p cylinder head and cylinder eng 2nd step: smeasure the piston skirt diameter “p” with a micrometer from distance a . A 500: 25 mm (0.98 in) 700: 15 mm (0.59 in) from the piston bottom edge. Piston size p standard 500: 67.930 x 67.935 mm (2.6745 x 2.6746 in) 700: 70.425 x 70.430 mm (2.7727 x 2....

Page 41: Cool

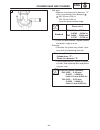

–37– heat exchanger cool 1 2 cooling system heat exchanger 1. Measure: sfiller cap opening pressure cap opens at pressure below the speci- fied pressure ! Replace. Cap opening pressure: 95 x 125 kpa (0.95 x 1.25 kg/cm 2 , 13.58 x 17.87 psi) measurement steps: d attach the cooling system tester (9089...

Page 42: Carb

–38– order job name / part name q’ty remarks 1 2 3 4 5 6 7 carburetors removal air chamber clamp screws throttle cable carburetor switch (t.O.R.S.) leads starter cable fuel delivery hoses carburetors 1 4 1 2 1 2 1 remove the parts in the order below. Loosen for installation, reverse the removal proc...

Page 43: Carb

–39– order job name / part name q’ty remarks 1 2 3 4 5 6 7 8 9 carburetors removal spark plug caps clamp screws carburetor switch (t.O.R.S.) leads clamp coolant hoses throttle cable starter cable fuel hoses carburetors 3 6 2 1 3 1 1 3 1 remove the parts in the order below. Loosen for installation, r...

Page 44: Carb

–40– order job name / part name q’ty remarks carburetor separation coolant hoses starter cable holder collar spring screw starter rod spring starter levers breather hoses top covers gaskets throttle shaft connecting screws connecting plate (upper) connecting plate (lower) 4 1 1 1 3 1 1 3 3 3 3 3 1 1...

Page 45: Carb

–41– carburetors carb note: assembly 1. Measure: sfloat height a out of specification ! Adjust. Float height: 500 22.3 ± 2.0 mm (0.878 ± 0.080 in) 700 13.3 ± 2.0 mm (0.524 ± 0.080 in) measurement and adjustment steps: shold the carburetor in an upside down position. Smeasure the distance between the...

Page 46: Spec

–42– general specifications spec specifications general specifications model vx500sxb vx700er model code number: 8ct 8dy dimensions: overall length overall width overall height 2,760 mm (108.7 in) 1,170 mm (46.1 in) 1,085 mm (42.7 in) z 1,200 mm (47.2 in) 1,300 mm (51.2 in) weight: 222 kg (488 lb) 2...

Page 47: Spec

–43– general specifications spec model vx500sxb vx700er carburetor: type / quantity manufacturer tm36 2 mikuni tm33 3 z spark plug: type manufacturer gap br9es ngk 0.7 x 0.8 mm (0.028 x 0.031 in) z z z transmission: primary reduction system primary reduction ratio clutch type secondary reduction sys...

Page 48: Spec

–44– maintenance specifications spec a maintenance specifications engine model vx500sxb vx700er cylinder head: volume (with spark plug) 500 700 23.3 x 23.9 cm 3 * lines indicate straight edge measurement. 22.9 x 23.5 cm 3 z z cylinder: material bore size aluminum alloy with dispersion coating 68.00 ...

Page 49: Spec

–45– maintenance specifications spec 500 700 model vx500sxb vx700er crankshaft: crank width “a” crank width “b” crankshaft deflection “c” : c 1 500: c 2 , c 3 500: c 4 700: c 2 x c 5 700: c 6 measuring points: 1 measuring points: 2 connecting rod big end side clearance “d” connecting rod small end f...

Page 50: Spec

–46– maintenance specifications spec model vx500sxb vx700er carburetor: type / quantity manufacturer i.D. Mark main jet (m.J) main air jet (m.A.J) pilot jet (p.J) jet needle (j.N) needle jet (n.J) pilot air jet (p.A.J) pilot outlet (p.O) bypass (b.P.I) pilot screw (p.S) throttle valve (th.V) valve s...

Page 51: Spec

–47– maintenance specifications spec model vx500sxb vx700er thermostat: opening temperature valve lift 50 x 55_c (122 _f x 132_f) 8 mm / 70 _c (159_f) z z.

Page 52: Spec

–48– maintenance specifications spec power train model vx500sxb vx700er transmission: type range of ratio engagement r / min shift r / min sheave center distance “a” sheave offset “b” v-belt automatic 3.8 x 1.0 : 1 4,000 ± 200 r/min 7,800 ± 250 r/min 267 x 270 mm (10.52 x 10.62 in) 13.5 x 16.5 mm (0...

Page 53: Spec

–49– maintenance specifications spec model vx500sxb vx700er rivet: outer part number material size quantity hole quantity inner part number material size quantity hole quantity 90261-06034 steel 13.9 mm (0.55 in) 3 pcs 3 pcs 90261-06028 aluminum 10.3mm (0.40in) 3 pcs 3 pcs 90261-06015 z 10.3 mm (0.4...

Page 54: Spec

–50– maintenance specifications spec model vx500sxb vx700er track: part number width length pitch number of links height “b” deflection at 10 kg (22 lb) 8ab-47110-10 381 mm (15.0 in) 3,072 mm (120.9 in) 64 mm (2.52 in) 48 16 mm (0.63 in) 25 x 30 mm (0.98 x 1.18 in) 8ch-47110-00 z z z z z z slide rai...

Page 55: Spec

–51– maintenance specifications spec model vx500sxb vx700er shock absorber: damping force front extension compression rear extension compression 3,320n ± 460n/0.3m/s 1,110n ± 225n/0.3m/s 1,950n ± 264n/0.3m/s 1,380n ± 235n/0.3m/s 720 n ± 150n/0.3m/s 1,020 n ± 210n/0.3m/s 2,206 n ± 657n/0.3m/s 726 n ±...

Page 56: Spec

–52– maintenance specifications spec chassis model vx500sxb vx700er frame: frame material seat height luggage box location aluminum 685 mm (26.8 in) rear side of seat z 730 mm (28.7 in) z steering: lock-to-lock angle (left) (right) ski alignment toe-out size caster angle 29.6 _ (r ski) 34.8_ (l ski)...

Page 57: Spec

–53– maintenance specifications spec electrical model vx500sxb vx700er voltage: 12 v z ignition system: ignition timing (b.T.D.C.) advanced timing (b.T.D.C.) advanced type 16 _ at 1.600 r/min 18 _ at 4.500 r/min electrical type 18 _ at 1.500 r/min 24 _ at 4.500 r/min z ignition coil: model / manufac...

Page 58: Spec

–54– maintenance specifications spec model vx500sxb vx700er rectifier / regulator: model / manufacturer no load regulated voltage ac dc 8cr-00 / matsushita 13.8 x 14.8 v 14.0 x 15.0 v z z z battery: (for electric model) specific gravity type – – 1.280 gm18z-3a electric starter system: (for electric ...

Page 59: Spec

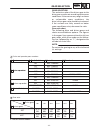

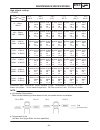

–55– maintenance specifications spec tempera- ture altitude note: jn: 2 (std) jn: 1.5 jn: 1 jn: 0.5 clip 0.4 mm shim high altitude settings vx500sxb – 40 _c – 29 _c – 18 _c – 7 _c 4 _c 15 _c (– 40 _f) (– 20 _f) (0 _f) (20 _f) (40 _f) (60 _f) 0 x 100 m (0 x 330 ft) mj#155 jn-2.0 mj#153.8 jn-2.0 mj#15...

Page 60: Spec

–56– maintenance specifications spec tempera- ture altitude note: jn: 2 (std) jn: 1.5 jn: 1 jn: 0.5 clip 0.4 mm shim high altitude settings vx700er – 40 _c – 29 _c – 18 _c – 7 _c 4 _c 15 _c (– 40 _f) (– 20 _f) (0 _f) (20 _f) (40 _f) (60 _f) 0 x 100 m (330 ft) mj#1 #148.8 mj#2#3 #147.5 pj #45.0 jn 3....

Page 61: Spec

–57– maintenance specifications spec tightening torque: parts to be tightened tightening torque remarks parts to be tightened nm m skg ft slb remarks crankcase (first) crankcase (final) engine bracket (front) and frame 500 engine bracket (front) and frame 700 engine bracket damper (front) engine bra...

Page 62: Spec

–58– maintenance specifications spec parts to be tightened tightening torque remarks parts to be tightened nm m skg ftslb remarks sliding frame and slide runner slide rail suspension mounting bolt rear pivot arm and bracket shock absorber and rear pivot arm rear pivot arm and rod rear suspension bra...

Page 63: Spec

–59– maintenance specifications spec.

Page 64: Spec

–60– cable routing spec cable routing.

Page 65: Spec

–61– cable routing spec 1 oil pump cable 2 throttle cable 3 fasten the wire harness. Do not fasten the throttle cable and oil pump cable. 4 fasten the throttle cable and oil pump cable with a plastic clamp. Route the cable along the side of the handle holder. 5 thumb warmer coupler 6 engine stop swi...

Page 66: Spec

–62– cable routing spec.

Page 67: Spec

–63– cable routing spec 35 to the conduction 36 voltage regulator 37 rectifire regulator 38 fasten the wire harness with a plastic clamp. 39 rectifire regulator (ecc model) 40 brake hose holder 41 fasten the wire harness with a plastic clamp. 42 to reverse gear 43 fasten the wire harness, fuel breat...

Page 68: Spec

–64– cable routing spec 30 _.

Page 69: Spec

–65– cable routing spec 1 wire lead (electrical starter model) 2 carburetor switch coupler 3 fasten the throttle cable and oil pump cable with a plastic clamp. 4 air temperature sensor coupler (ecc model) 5 coolant hose 6 starter relay lead 7 starter relay sub lead (electrical starter model) 8 faste...

Page 70: Spec

–66– 30 _ cable routing spec.

Page 71: Spec

–67– cable routing spec 32 solenoid coupler (ecc model) 33 ignition coil 34 carburetor heating lever 35 coolant hose 36 speedometer cable 37 fasten the throttle cable, water temperature sensor lead, carburetor switch lead and solenoid lead with a plastic clamp. 38 water temperature sensor coupler 39...

Page 72: Spec

–68– cable routing spec.

Page 73: Spec

–69– cable routing spec 1 make sure that the oil tank cap and oil breather hose do not touch each other. 2 route the fuel breather hose along the upper of the main harness. 3 route the oil breather hose along the upper of the main harness. 4 install the tail / brake light lead behind the instrument ...

Page 74: Spec

–70– cable routing spec cable routing.

Page 75: Spec

–71– cable routing spec 1 oil pump cable 2 throttle cable 3 do not fasten the throttle cable and oil pump wire with a plastic clamp. 4 thumb warmer coupler 5 engine stop switch coupler 6 holder 7 grip warmer coupler 8 brake light switch coupler 9 head light switch coupler 10 fasten the oil breather ...

Page 76: Spec

–72– cable routing spec.

Page 77: Spec

–73– cable routing spec 37 dc back buzzer (reverse model) 38 voltage regulator 39 rectifier regulator 40 dc back buzzer coupler 41 fasten the wire harness with a plastic clamp. 42 brake hose holder 43 fasten the wire harness with a plastic clamp. 44 to reverse gear 45 fasten the wire harness, fuel b...

Page 78: Spec

–74– cable routing spec.

Page 79: Spec

–75– cable routing spec 1 fasten the carburetor switch, water temperature sensor lead, coolant hose, wire lead and battery negative lead with a plastic clamp. 2 clamp 3 fasten the ignition coil and starter cable with a plastic clamp. 4 fasten the wire lead, battery negative lead and coolant hose wit...

Page 80: Spec

–76– cable routing spec.

Page 81: Spec

–77– cable routing spec 1 wire harness 2 50 mm (1.97 in) 3 make sure that the oil tank cap and oil breather hose do not touch each other. 4 route the fuel breather hose along the upper of the main harness. 5 route the oil breather hose along the upper of the main harness. 6 install the tail / brake ...

Page 82

1 cdi magneto 2 rectifier / regulator 3 starter relay / fuse 4 battery 5 starter motor 6 main switch 7 engine stop switch 8 throttle switch 9 carburetor switch 10 cdi unit 11 ignition coil 12 spark plug 13 water temp sensor 14 voltage regulator 15 variable resistor 16 thumb warmer 17 grip warmer 18 ...

Page 83

1 cdi magneto 2 rectifier / regulator 3 starter relay / fuse 4 battery 5 starter motor 6 main switch 7 engine stop switch 8 throttle switch 9 carburetor switch 10 cdi unit 11 ignition coil 12 spark plug 13 water temp sensor 14 voltage regulator 15 variable resistor 16 thumb warmer 17 grip warmer 18 ...

Page 84

Printed in usa (ੑ) printed on recycled paper.