- DL manuals

- Yamaha

- Boat

- WaveRunner VX 700

- Service Manual

Yamaha WaveRunner VX 700 Service Manual

Summary of WaveRunner VX 700

Page 1

Service manual waverunner f2v-28197-zn-11 vx 700 vx 700 (f2v).

Page 2: Preface

Preface this manual has been prepared by yamaha primarily for use by yamaha dealers and their trained mechanics when performing maintenance procedures and repairs to yamaha equipment. It has been written to suit the needs of persons who have a basic understanding of the mechanical and electrical con...

Page 3: Contents

Contents general information gen info specification spec maintenance mnt fuel system fuel power unit powr jet pump unit jet pump electrical system elec hull and hood hull hood troubleshooting trbl shtg appendix – + 1 2 3 4 5 6 7 8 9 a.

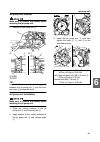

Page 5: Gen

Gen info 1 general information safety while working ..................................................... 1-1 rotating part............................................................................... 1-1 hot part........................................................................................

Page 6: Gen

1-1 gen info general information safety while working to prevent an accident or injury and to pro- vide quality service, observe the following safety procedures. Rotating part • hands, feet, hair, jewelry, clothing, per- sonal flotation device straps, and so on, can become entangled with internal ro...

Page 7

1-2 1 ventilation • gasoline vapor and exhaust gas are heavier than air and extremely poisonous. If gasoline vapor or exhaust gas is inhaled in large quantities, it may cause loss of con- sciousness and death within a short time. • when test running an engine indoors (for example, in a water tank) m...

Page 8: Gen

1-3 gen info general information handling of heat gun • improper handling of a heat gun may result in burns. For information on the proper han- dling of the heat gun, see the operation manual issued by the manufacturer. • when using a heat gun, keep it away from the gasoline and oil, to prevent a fi...

Page 9

1-4 1 disassembly and assembly • use compressed air to remove dust and dirt during disassembly. • apply engine oil to the contact surfaces of moving parts before assembly. • install bearings so that the bearing identifi- cation mark is facing in the direction indi- cated in the installation procedur...

Page 10: Gen

1-5 gen info general information how to use this manual manual format the format of this manual has been designed to make service procedures clear and easy to under- stand. Use the information below as a guide for effective and quality service. • parts are shown and detailed in an exploded diagram a...

Page 11

1-6 1 abbreviation the following abbreviations are used in this service manual. Abbreviation description bow bow end cdi capacitor discharge ignition ex exhaust in intake nmma national marine manufacturers association pon pump octane number port port side ron research octane number stbd starboard si...

Page 12: Gen

1-7 gen info general information adhesive, lubricant, sealant, and thread locking agent symbol symbols in an exploded diagram or illustration indicate the grade of lubricant and the lubrication points. Symbols in an exploded diagram or illustration indicate the type of adhesive, sealant, or thread l...

Page 13: Special Service Tool

1-8 1 special service tool special service tools with yamaha part numbers (90890-*****) are distributed by the parts division. Digital tachometer 90890-06760 compression gauge 90890-03160 flywheel holder 90890-06522 flywheel puller 90890-06521 coupler wrench 90890-06425 driver rod l3 90890-06652 nee...

Page 14: Gen

1-9 gen info general information stopper guide stand 90890-06538 driver rod ls 90890-06606 ball bearing attachment 90890-06631 crankshaft holder 20 90890-06552 bearing outer race attachment 90890-06628 drive shaft holder 5 90890-06519 digital circuit tester 90890-03174 peak voltage adapter b 90890-0...

Page 15: Model Feature

1-10 1 model feature identification number primary i.D. Number the primary i.D. Number is stamped on a label attached to the inside of the engine compartment. 1 model name 2 hull type 3 primary i.D. Number engine serial number the engine serial number is stamped on a label attached to the engine uni...

Page 16: Gen

1-11 gen info general information — memo —.

Page 17: Spec

Spec 1 2 3 4 5 6 7 8 9 a specification model data .......................................................................... 2-1 model code ................................................................................. 2-1 dimension and weight ........................................................

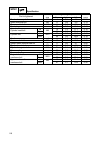

Page 18: Spec

2-1 spec specification model data model code dimension and weight performance power unit item unit model vx 700 hull f2v engine/jet 6cp/6cp item unit model vx 700 length mm (in) 3220 (126.8) width mm (in) 1170 (46.1) height mm (in) 1160 (45.7) dry weight kg (lb) 283 (624) maximum capacity person/ kg...

Page 19

2-2 1 2 3 4 5 6 7 8 9 a drive unit fuel and oil requirement battery requirement item unit model vx 700 jet pump type axial flow, single stage impeller rotation counterclockwise (viewed from rear) transmission constant mesh 1-speed jet thrust nozzle horizontal angle degree 24 + 24 trim system — jet t...

Page 20: Spec

2-3 spec specification fuel system technical data fuel system power unit technical data power unit cylinder head assy. Item unit model vx 700 carburetor manufacturer mikuni model × quantity bn38 × 2 type floatless id mark 62t03f/03r main jet (mj) 120 (front), 130 (rear) main nozzle (mn) mm (in) 2.5 ...

Page 21

2-4 1 2 3 4 5 6 7 8 9 a crank case assy. Item unit model vx 700 cylinder bore mm (in) 81.000–81.020 (3.1890–3.1898) bore wear limit mm (in) 81.100 (3.1929) taper limit mm (in) 0.080 (0.0031) out-of-round limit mm (in) 0.050 (0.0020) piston diameter mm (in) 80.922–80.941 (3.1859–3.1866) measuring poi...

Page 22: Spec

2-5 spec specification jet pump unit technical data jet pump unit electrical technical data ignition system item unit model vx 700 impeller housing inside diameter mm (in) 155.35–155.45 (6.116–6.120) impeller-to-housing clearance mm (in) 0.35–0.45 (0.014–0.018) clearance limit mm (in) 0.60 (0.024) i...

Page 23

2-6 1 2 3 4 5 6 7 8 9 a charging system control system item unit model vx 700 charge coil output peak voltage at cranking (unloaded) v 180 at cranking (loaded) v 20 at 1500 r/min (loaded) v 210 at 3500 r/min (loaded) v 150 resistance (*1) at 20 °c (68 °f) Ω 497.7–608.3 lighting coil output peak volt...

Page 24: Spec

2-7 spec specification starting system meter system item unit model vx 700 fuse rating main v/a 12/10 starter motor type constant mesh output kw 0.8 cranking time limit seconds 30 commutator diameter mm (in) 27.0–28.0 (1.06–1.10) commutator undercut (*1) mm (in) 0.2–0.7 (0.008–0.028) brush length mm...

Page 25: Specified Tightening Torque

2-8 1 2 3 4 5 6 7 8 9 a specified tightening torque fuel system power unit part to tightened screw size tightening torque see page n·m kgf·m ft·lb fuel cock knob screw ø4 2 0.2 1.5 4-1 fuel cock assy./washer nut — 5 0.5 3.7 4-1 choke knob screw ø3 2 0.2 1.5 4-3 choke knob nut — 2 0.2 1.5 4-3 oil fil...

Page 26: Spec

2-9 spec specification reed valve assy. Bolt m5 4 0.4 3.0 5-14 intake manifold bolt m6 8 0.8 5.9 5-14 thermoswitch bolt m6 8 0.8 5.9 5-16 spark plug — 25 2.5 18.4 5-16 cylinder head bolt 1st m8 15 1.5 11.1 5-16 2nd 29 2.9 21.4 5-16 cylinder bolt 1st m10 22 2.2 16.2 5-18 2nd 39 3.9 28.8 5-18 anode sc...

Page 27

2-10 1 2 3 4 5 6 7 8 9 a jet pump unit electrical system part to tightened screw size tightening torque see page n·m kgf·m ft·lb intake grate bolt m6 8 0.8 5.9 6-1 m10 40 4.0 29.5 6-1 ride plate bolt m8 17 1.7 12.5 6-1 cover screw ø5 4 0.4 3.0 6-1 steering cable joint nut — 6.8 0.68 4.9 6-2 jet pump...

Page 28: Spec

2-11 spec specification hull and hood part to tightened screw size tightening torque see page n·m kgf·m ft·lb upper handlebar cover screw ø4 1 0.1 0.7 8-1 ø5 1 0.1 0.7 8-1 lower handlebar cover screw ø6 4 0.4 3.0 8-1 grip end bolt m5 1 0.1 0.7 8-2 left handlebar switch assy. Screw ø5 3 0.3 2.2 8-2 t...

Page 29: General Tightening Torque

2-12 1 2 3 4 5 6 7 8 9 a general tightening torque this chart indicates the tightening torques for standard fasteners with a standard iso thread pitch. Tightening torque specifications for special components and assemblies are provided in the applicable sections of this manual. To prevent warpage, t...

Page 30: Spec

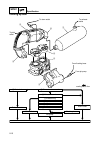

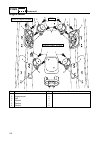

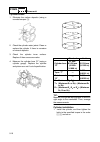

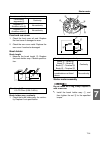

2-13 spec specification cooling system 3 1 4 5 6 7 2 1 exhaust manifold 3 cylinder head 6 exhaust outer cover 1 flushing hose jet pump 7 water lock exhaust outlet 5 exhaust chamber water to stern outlet to exhaust outlet to pilot outlet 4 exhaust ring 2 cylinder block pilot outlet stern outlet from ...

Page 31: Cable and Hose Routing

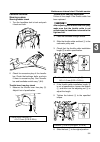

2-14 1 2 3 4 5 6 7 8 9 a cable and hose routing starboard bow view 1 positive battery cable 2 battery breather hose 3 flushing hose 4 bilge hose 5 cooling water pilot outlet hose 6 choke cable 7 oil tank breather hose 8 buzzer lead 9 multifunction meter lead 0 left handlebar switch lead a fuel level...

Page 32: Spec

2-15 spec specification top view 1 positive battery cable 2 battery breather hose 3 flushing hose 4 bilge hose 5 cooling water pilot outlet hose 6 choke cable 7 oil tank breather hose 8 buzzer lead 9 multifunction meter lead 0 left handlebar switch lead a fuel level sensor lead b fuel tank breather ...

Page 33

2-16 1 2 3 4 5 6 7 8 9 a m fuel hose n fuel reservoir hose o negative battery cable 8 a 6 c 7 d g i h 1 2 j f 4 o 5 e l 0 m k n 9 3 b cable and hose routing.

Page 34: Spec

2-17 spec specification port view 1 positive battery cable 2 battery breather hose 3 flushing hose 4 bilge hose 5 cooling water pilot outlet hose 6 choke cable 7 oil tank breather hose 8 buzzer lead 9 multifunction meter lead 0 left handlebar switch lead a fuel level sensor lead b fuel tank breather...

Page 35

2-18 1 2 3 4 5 6 7 8 9 a m fuel hose n fuel reservoir hose o negative battery cable 9 0 8 7 6 5 g l h i 1 2 4 3 j o k e f b m n d a c cable and hose routing.

Page 36: Spec

2-19 spec specification — memo —.

Page 37: Mnt

Mnt 1 2 3 4 5 6 7 8 9 a maintenance maintenance interval chart ................................................ 3-1 periodic service.................................................................. 3-2 steering system.......................................................................... 3-2 ste...

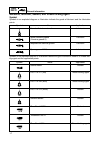

Page 38: Mnt

3-1 mnt maintenance maintenance interval chart the following chart should be considered strictly as a guide to general maintenance intervals. Depending on operating conditions, the maintenance intervals should be changed. Maintenance interval initial thereafter every page 10 hours 50 hours 100 hours...

Page 39: Periodic Service

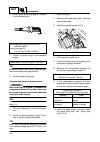

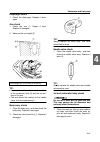

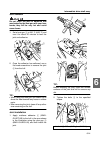

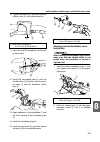

3-2 1 2 3 4 5 6 7 8 9 a periodic service steering system steering master check 1. Turn the handlebar lock to lock and push it back and forth. 2. Check for excessive play of the handle- bar. Check the bushings, bolts, and nuts if there is excessive play. See “handle- bar and handlebar switch assy.” (...

Page 40: Mnt

3-3 mnt maintenance 7. Remove the upper handlebar cover. See “steering pad and handlebar cover” (8- 1). 8. Slide the rubber cover 4 away from the throttle lever, and then loosen the locknut 5. 9. Turn the adjuster 6 in or out until the specified free play b is obtained. 10. Tighten the locknut 5. 11...

Page 41

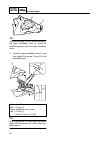

3-4 1 2 3 4 5 6 7 8 9 a water separator check 1. Check the water separator 1. Drain the water if water has accumulated. 2. Check the o-ring of the drain plug. Replace the o-ring if cracked or dam- aged. See “water separator check” (8- 21). Tip: to drain water from the water separator, loosen the dra...

Page 42: Mnt

3-5 mnt maintenance 4. Measure the spark plug gap b. Replace if out of specification. 5. Tighten the spark plugs to the specified torque. Tip: before installing a spark plug, clean the gas- ket surface and spark plug surface. 6. Install the spark plug caps. Compression pressure measurement when star...

Page 43

3-6 1 2 3 4 5 6 7 8 9 a engine oil level check do not allow the oil tank to become com- pletely empty. If the oil tank becomes empty the oil injection pump must be bled to ensure proper oil flow, otherwise engine damage may occur. See “oil pump air bleeding” (4-18). Make sure that debris or water do...

Page 44: Mnt

3-7 mnt maintenance nut and bolt check 1. Check the engine, deck, and hull for loose bolts and nuts. Tighten if loose. See “specified tightening torque” (2-8). Jet pump unit impeller check make sure to remove the battery before checking the jet pump unit. 1. Remove the jet pump unit. See “jet pump u...

Page 45

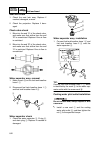

3-8 1 2 3 4 5 6 7 8 9 a 3. Disconnect the steering cable joint 2 from the ball joint 3. 4. Turn the steering cable joint 2 in or out to adjust distances a and b. Warning! The steering cable joint must be screwed in more than 8 mm (0.31 in) c. 5. Connect the steering cable joint 2 to the ball joint 3...

Page 46: Mnt

3-9 mnt maintenance be careful not to place the battery on its side. Make sure to remove the battery from the battery compartment when adding battery electrolyte or charging the battery. When checking the battery, make sure the breather hose is connected to the battery and not obstructed. 1. Disconn...

Page 47

3-10 1 2 3 4 5 6 7 8 9 a tip: remove the bilge strainer case 1 by pushing the hooks on the bilge strainer inward. 3. Install the bilge strainer case 1. Drain plug check 1. Check the o-ring of each drain plug. Replace if cracked or damaged. See “drain plug check” (8-29). Lubrication points throttle c...

Page 48: Mnt

3-11 mnt maintenance tip: disconnect the joint and apply a small amount of grease. Recommended lubricant: yamaha grease a.

Page 49: Fuel

Fuel 1 2 3 4 5 6 7 8 9 a fuel system fuel cock and fuel filter ..................................................... 4-1 fuel filter check .......................................................................... 4-2 fuel cock check......................................................................

Page 50: Fuel

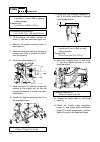

4-1 fuel fuel system fuel cock and fuel filter no. Part name q’ty remarks 1 screw 1 m4 × 7 mm 2 fuel cock knob 1 3 nut 1 4 washer 1 5 fuel cock assy. 1 6 fuel hose 3 7 holder 1 8 fuel filter 1 9 fuel hose 1 1 2 7 8 9 3 4 5 6 (out) (on) (res) 2 n • m (0.2 kgf • m, 1.5 ft • ib) 5 n • m (0.5 kgf • m, 3...

Page 51

4-2 1 2 3 4 5 6 7 8 9 a fuel filter check see “fuel system” (3-3). Fuel cock check before checking the fuel system, remove the battery, and then remove the fuel filler cap to reduce any pressure inside the fuel tank. 1. Check the fuel cock. Replace if there is rough movement. Fuel cock and fuel filt...

Page 52: Fuel

4-3 fuel fuel system choke cable no. Part name q’ty remarks 1 screw 1 m3 × 6 mm 2 knob 1 3 friction adjusting nut 1 4 nut 1 5 choke cable 1 2 3 5 4 1 2 n • m (0.2 kgf • m, 1.5 ft • ib) 2 n • m (0.2 kgf • m, 1.5 ft • ib).

Page 53: Oil Tank

4-4 1 2 3 4 5 6 7 8 9 a oil tank no. Part name q’ty remarks 1 clamp 1 2 nut 1 3 oil filler neck 1 4 rubber seal 1 5 tank belt 1 6 oil level sensor coupler 1 7 oil level sensor 1 8 oil filter 1 9 damper 1 10 clamp 1 11 oil filler hose 1 12 breather hose 1 13 oil hose 1 14 oil tank 1 15 damper 1 2 1 3...

Page 54: Fuel

4-5 fuel fuel system oil line check 1. Clean the oil filter, and then check the oil filter. Replace if frayed or teared. 2. Check the rubber seal. Replace if cracked or worn. 3. Check the hoses. Replace if cracked or damaged. 4. Check the oil tank filler cap. Replace if cracked or damaged. Oil level...

Page 55: Fuel Tank

4-6 1 2 3 4 5 6 7 8 9 a fuel tank no. Part name q’ty remarks oil tank see “oil tank” (4-4). Engine unit see “engine unit” (5-1). 1 clamp 2 2 nut 1 3 fuel filler neck 1 4 rubber seal 1 5 fuel filler hose 1 6 fuel tank breather hose 1 7 check valve 1 8 fuel tank breather hose 1 9 fuel level sensor cou...

Page 56: Fuel

4-7 fuel fuel system check valve check 1. Blow into the end a of the check valve, and make sure that airflow from the end b is unrestricted. Replace if the air flow is restricted. 2. Blow into the end b of the check valve, and make sure that airflow from the end a is restricted. Replace if the air f...

Page 57: Carburetor Unit

4-8 1 2 3 4 5 6 7 8 9 a carburetor unit no. Part name q’ty remarks fuel cock knob turn the fuel cock knob to “off”. 1 bolt 6 m5 × 56 mm 2 cover 1 3 flame arrester 2 4 band 2 not reusable 5 oil delivery hose 2 2 6 bolt 1 m6 × 14 mm 7 bolt 1 m6 × 12 mm 8 holder 1 9 washer 1 10 bolt 6 m6 × 20 mm 11 fla...

Page 58: Fuel

4-9 fuel fuel system no. Part name q’ty remarks 16 throttle cable 1 a: 13–15 mm (0.51–0.59 in) 17 band 3 not reusable 18 fuel hose 1 19 pulse hose 1 20 fuel reservoir hose 1 21 nut 4 22 carburetor assy. 1 23 gasket 1 not reusable 1 n·m (0.1 kgf·m, 0.7 ft·ib) 7 9 8 6 5 4 14 17 19 18 17 22 17 20 23 16...

Page 59

4-10 1 2 3 4 5 6 7 8 9 a choke cable and throttle cable installation 1. Install the choke cable 1 and throttle cable 2, and then tighten the nuts to the specified torque. 2. Adjust the throttle lever free play. See “steering system” (3-2). Carburetor assy. Check 1. Adjust the trolling speed. See “po...

Page 60: Fuel

4-11 fuel fuel system carburetor and fuel pump no. Part name q’ty remarks carburetor assy. See “carburetor unit” (4-8). 1 screw 4 m5 × 30 mm 2 cover 1 3 fuel pump gasket 1 not reusable 4 fuel pump diaphragm 1 5 o-ring 1 6 fuel pump diaphragm body 1 7 bushing 2 8 valve seat 2 9 diaphragm 1 10 packing...

Page 61

4-12 1 2 3 4 5 6 7 8 9 a no. Part name q’ty remarks 16 idle adjusting screw 1 17 spring 1 18 washer 1 19 high speed screw 2 20 o-ring 2 not reusable 21 washer 2 22 spring 2 23 low speed screw 2 24 o-ring 2 not reusable 25 washer 2 26 spring 2 27 washer 2 28 screw 8 m5 × 12 mm 29 cover 2 30 diaphragm...

Page 62: Fuel

4-13 fuel fuel system no. Part name q’ty remarks 32 arm 2 33 pin 2 34 screw 2 m3 × 6 mm 35 plate 2 36 needle valve assy. 2 37 screw 4 m4 × 11 mm 38 body assy. 2 39 gasket 2 not reusable 40 main jet 2 carburetor 1 (r): #130 carburetor 2 (f): #120 41 pilot jet 2 #67.5 42 carburetor assy. 1 1 43 carbur...

Page 63

4-14 1 2 3 4 5 6 7 8 9 a diaphragm check 1. Check the diaphragm. Replace if dam- aged. Arm check 1. Check the arm 1. Repair if bent. Replace if damaged. 2. Measure the arm height a. Tip: • measure the distance between the surface of the carburetor body b and the top sur- face of the arm. • the arm s...

Page 64: Fuel

4-15 fuel fuel system tip: before disassembling the carburetor, make sure to note the number of times the speed screw is turned in from its set position to the seated position. Fuel pump check 1. Check the fuel pump gasket, diaphragm, fuel pump diaphragm, fuel pump dia- phragm body, and valve seat. ...

Page 65

4-16 1 2 3 4 5 6 7 8 9 a carburetor assy. Check 1. Adjust the trolling speed. See “power unit” (3-4). Carburetor and fuel pump.

Page 66: Fuel

4-17 fuel fuel system oil pump no. Part name q’ty remarks 1 band 1 2 oil hose 1 3 hose clamp 2 4 oil delivery hose 1 1 85 mm (3.35 in) 5 oil delivery hose 1 1 70 mm (2.76 in) 6 bolt 2 m6 × 35 mm 7 oil pump 1 8 gasket 1 not reusable 9 hose clamp 4 10 check valve 2 11 oil delivery hose 2 1 210 mm (8.2...

Page 67

4-18 1 2 3 4 5 6 7 8 9 a oil pump check • if the oil delivery hoses are not full of oil, fill them up. • after installing the oil injection system, bleed the system of any air. 1. Clean the oil pump, and then check the oil pump. Replace if damaged or worn. Oil hose check • if the oil delivery hoses ...

Page 68: Powr

Powr power unit engine unit.......................................................................... 5-1 engine mount ..................................................................... 5-3 engine unit removal.................................................................... 5-4 engine mount ch...

Page 69

1 2 3 4 5 6 7 8 9 a crankcase ......................................................................... 5-30 crankcase check...................................................................... 5-32 crankcase installation .............................................................. 5-32 crankshaf...

Page 70: Powr

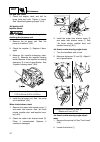

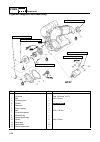

5-1 powr power unit engine unit no. Part name q’ty remarks storage compartment panel see “front hood” (8-8). Positive and negative battery lead see “electrical box” (7-2). 1 coupler 3 2 plastic tie 7 3 plastic tie 1 4 nut/washer 2/2 5 electrical box 1 6 band/cooling water hose 1/1 È cooling water pi...

Page 71

5-2 1 2 3 4 5 6 7 8 9 a *: as required. No. Part name q’ty remarks 14 bolt/collar 2/2 m6 × 25 mm 15 coupling cover 1 16 bolt/washer 4/4 m8 × 35 mm 17 shim * 18 engine unit 1 11 7 9 18 11 12 13 10 2 17 1 6 16 8 15 14 5 4 3 14 lt 572 lt lt 271 5 n·m (0.5 kgf·m, 3.7 ft·ib) 8 n·m (0.8 kgf·m, 5.9 ft·ib) ...

Page 72: Powr

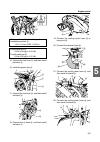

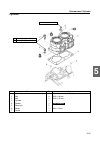

5-3 powr power unit engine mount no. Part name q’ty remarks 1 bolt 8 m8 × 35 mm 2 engine mount 4 3 bolt 4 4 bracket 1 5 bracket 1 6 bracket 2 bow 17 n·m (1.7 kgf·m, 12.5 ft·ib) 17 n·m (1.7 kgf·m, 12.5 ft·ib) 1 1 2 4 6 2 2 6 1 3 1 2 3 5 1.

Page 73

5-4 1 2 3 4 5 6 7 8 9 a engine unit removal before removing the engine, make sure to take adequate measures to protect the deck opening from damage. 1. Disconnect the negative battery cable, and then disconnect the positive battery cable. 2. Remove the service lid. 3. Disconnect the multifunction me...

Page 74: Powr

5-5 powr power unit 11. Remove the band e, and then discon- nect the fuel hose f. Tip: when removing the fuel hose, remove the fuel filler cap to reduce any pressure inside the fuel tank. 12. Remove the band g, and then discon- nect the fuel hose h. 13. Remove the fuel hose h from the plastic ties i...

Page 75

5-6 1 2 3 4 5 6 7 8 9 a 19. Suspend the engine unit using an engine hangers, and then separate the unit from the engine mounts and move it forward to disconnect the coupling. Notice: when removing the engine unit, take care to avoid causing damage to the hull liner and deck opening. Engine mount che...

Page 76: Powr

5-7 powr power unit 5. Lift the engine unit slightly, remove the shims 4, and then lower the engine unit. 6. Remove the engine mounting bolts 2 and washer 3. 7. Separate the engine unit from the engine mounts and move it forward to discon- nect the coupling. 8. Install the rubber damper 5. 9. Instal...

Page 77

5-8 1 2 3 4 5 6 7 8 9 a 15. Connect the fuel hose a, and then install the band b. 16. Install the plastic ties c. 17. Connect the fuel hose d, and then install the band e. 18. Connect the oil hose f, and then install the band g. 19. Connect the cooling water hose h to hose joint i. 20. Connect the e...

Page 78: Powr

5-9 powr power unit 23. Install the fuse box assy. O, and then tighten the nuts p to the specified torque. 24. Install the band q. 25. Install the plastic ties r. 26. Connect the multifunction meter couplers s, and then install the plastic ties t. 27. Install the service lid. 28. Connect the positiv...

Page 79: Exhaust Ring

5-10 1 2 3 4 5 6 7 8 9 a exhaust ring no. Part name q’ty remarks 1 band/pilot water hose 2/1 2 clamp 2 3 clamp 1 4 bolt 2 m8 × 75 mm 5 bolt 2 m8 × 115 mm 6 exhaust ring 1 7 dowel pin 2 8 gasket 1 not reusable 9 clamp 1 10 joint 1 11 exhaust joint 1 2 n·m (0.2 kgf·m, 1.5 ft·ib) 2 n·m (0.2 kgf·m, 1.5 ...

Page 80: Powr

5-11 powr power unit exhaust chamber assy. No. Part name q’ty remarks exhaust ring see “exhaust ring” (5-10). 1 clamp/exhaust hose 1/1 2 band 4 not reusable 3 joint 1 4 hose 1 5 hose 1 6 bolt 2 m10 × 35 mm 7 bolt 4 m10 × 45 mm 8 muffler stay 1 9 bolt 2 m10 × 35 mm 10 exhaust chamber assy. 1 2 n·m (0...

Page 81: Exhaust Chamber

5-12 1 2 3 4 5 6 7 8 9 a exhaust chamber no. Part name q’ty remarks 1 bolt 6 m6 × 70 mm 2 exhaust outer cover 1 1 3 gasket 1 not reusable 4 exhaust inner cover 1 5 rubber seal 1 6 gasket 1 not reusable 7 bolt 6 m6 × 25 mm 8 exhaust outer cover 2 1 9 gasket 1 not reusable 10 exhaust chamber 1 8 n·m (...

Page 82: Powr

5-13 powr power unit muffler no. Part name q’ty remarks exhaust chamber see “exhaust chamber assy.” (5-11). 1 clamp/cooling water hose 1/1 È cooling water inlet 2 bolt 8 m10 × 35 mm 3 muffler 1 4 gasket 1 not reusable lt 271 lt 271 4 3 1 2 È 21 n·m (2.1 kgf·m, 15.5 ft·ib) 39 n·m (3.9 kgf·m, 28.8 ft·...

Page 83: Reed Valves

5-14 1 2 3 4 5 6 7 8 9 a reed valves no. Part name q’ty remarks carburetor assy. See “carburetor unit” (4-8). 1 bolt 2 m6 × 16 mm 2 plate 1 3 bolt 8 m6 × 25 mm 4 bolt 3 m6 × 35 mm 5 intake manifold 1 6 screw 4 m5 × 15 mm 7 reed valve assy. 2 8 plate 1 9 gasket 2 not reusable 10 screw 16 m3 × 8 mm 11...

Page 84: Powr

5-15 powr power unit reed valve check 1. Check the reed valves. Replace if cracked or damaged. 2. Measure the valve warpage a. Replace if out of specification. 3. Measure the valve stopper height b. Replace if out of specification. Valve warpage limit: 0.2 mm (0.01 in) valve stopper height: 8.8–9.2 ...

Page 85: Cylinder Head

5-16 1 2 3 4 5 6 7 8 9 a cylinder head no. Part name q’ty remarks exhaust chamber assy. See “exhaust chamber assy.” (5-11). 1 bolt 2 m6 × 16 mm 2 thermoswitch 1 3 spark plug 2 4 bolt 10 m8 × 50 mm 5 cylinder head 1 6 gasket 1 25 n·m (2.5 kgf·m, 18.4 ft·ib) 15 n·m (1.5 kgf·m, 11.1 ft·ib) 29 n·m (2.9 ...

Page 86: Powr

5-17 powr power unit cylinder head check do not use a sharp instrument to avoid damaging or scratching the cylinder head or spark plug bore threads. 1. Eliminate the carbon deposits (using a rounded scraper 1). 2. Check the cylinder head water jacket. Clean or replace the cylinder head if there is c...

Page 87: Cylinder

5-18 1 2 3 4 5 6 7 8 9 a cylinder no. Part name q’ty remarks cylinder head see “cylinder head” (5-16). 1 bolt 4 m10 × 40 mm 2 bolt 2 m10 × 55 mm 3 cylinder 1 4 gasket 1 not reusable 5 dowel pin 2 6 screw 1 m4 × 12 mm 7 anode 1 3 n·m (0.3 kgf·m, 2.2 ft·ib) 22 n·m (2.2 kgf·m, 16.2 ft·ib) 39 n·m (3.9 k...

Page 88: Powr

5-19 powr power unit cylinder check 1. Eliminate the carbon deposits (using a rounded scraper 1). 2. Check the cylinder water jacket. Clean or replace the cylinder if there is corrosion or mineral deposits. 3. Check the cylinder inner surface. Replace if there are score marks. 4. Measure the cylinde...

Page 89

5-20 1 2 3 4 5 6 7 8 9 a cylinder bolt: 1st: 22 n·m (2.2 kgf·m, 16.2 ft·lb) 2nd: 39 n·m (3.9 kgf·m, 28.8 ft·lb) 6 2 3 5 1 4 cylinder.

Page 90: Powr

5-21 powr power unit pistons no. Part name q’ty remarks cylinder see “cylinder” (5-18). 1 piston pin clip 4 not reusable 2 piston pin 2 3 piston 2 a arrow mark 4 washer 4 5 bearing 2 6 piston ring 4.

Page 91

5-22 1 2 3 4 5 6 7 8 9 a piston pin clip removal and installation tip: before removing or installing the piston pin clip, cover the crankcase opening with a clean rag to prevent the piston pin clip from falling into the crankcase. Piston check 1. Eliminate the carbon deposits (from the piston crown ...

Page 92: Powr

5-23 powr power unit piston pin and bearing check 1. Check the piston pins and bearings. Replace if there are signs of heat discol- oration. 2. Measure the piston pin outside diameter (using a micrometer 1). Replace if out of specification. 3. Insert the piston pin into the piston, and then check th...

Page 93

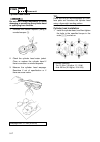

5-24 1 2 3 4 5 6 7 8 9 a tip: • install the piston with the arrow a facing towards the exhaust port. • do not align the open end of the clip with the piston pin slot b. Pistons.

Page 94: Powr

5-25 powr power unit flywheel magneto and base assy. No. Part name q’ty remarks engine unit see “engine unit” (5-1). Oil pump see “oil pump” (4-17). 1 bolt 7 m6 × 25 mm 2 flywheel cover 1 3 gasket 1 not reusable 4 dowel pin 2 5 drive coupling 1 6 bolt 1 m10 × 32 mm 7 flywheel magneto 1 8 woodruff ke...

Page 95

5-26 1 2 3 4 5 6 7 8 9 a no. Part name q’ty remarks 14 bolt 2 m6 × 16 mm 15 starter motor 1 5 n·m (0.5 kgf·m, 3.7 ft·ib) 8 n·m (0.8 kgf·m, 5.9 ft·ib) 8 n·m (0.8 kgf·m, 5.9 ft·ib) 18 n·m (1.8 kgf·m, 13.3 ft·ib) 36 n·m (3.6 kgf·m, 26.6 ft·ib) 74 n·m (7.4 kgf·m, 54.6 ft·ib) 1207d 1207d flywheel magneto...

Page 96: Powr

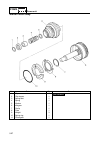

5-27 powr power unit starter clutch assy. No. Part name q’ty remarks 1 clip 1 not reusable 2 clip stopper 1 3 spring seat 1 4 spring 1 5 washer 1 6 idle gear 1 7 circlip 1 8 plate 1 9 weight 3 10 spring ring 1 11 pinion gear 1.

Page 97

5-28 1 2 3 4 5 6 7 8 9 a drive coupling removal and installation 1. Remove the drive coupling. Tip: install the drive coupling with the same spe- cial service tools that were used for removal. Flywheel magneto removal and installation 1. Remove the flywheel magneto bolt. Tip: install the bolt with t...

Page 98: Powr

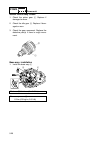

5-29 powr power unit starter clutch assy. Check 1. Check the pinion gear 1. Replace if damaged or worn. 2. Check the idle gear 2. Replace if dam- aged or worn. 3. Check the gear movement. Replace the defective part(s) if there is rough move- ment. Base assy. Installation 1. Install the base assy 1. ...

Page 99: Crankcase

5-30 1 2 3 4 5 6 7 8 9 a crankcase no. Part name q’ty remarks base assy. And starter motor see “flywheel magneto and base assy.” (5-25). Pistons see “pistons” (5-21). 1 bolt 1 m10 × 35 mm 2 bolt 1 m10 × 65 mm 3 bolt 1 m10 × 70 mm 4 bolt 1 m10 × 80 mm 5 engine bracket 1 6 bolt 3 m10 × 70 mm 7 engine ...

Page 100: Powr

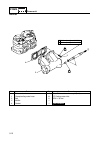

5-31 powr power unit no. Part name q’ty remarks 13 crankshaft assy. 1 14 upper crankcase 1 23 n·m (2.3 kgf·m, 17.0 ft·ib) 52 n·m (5.2 kgf·m, 38.4 ft·ib) 1 2 15 n·m (1.5 kgf·m, 11.1 ft·ib) 27 n·m (2.7 kgf·m, 19.9 ft·ib) 1 2 23 n·m (2.3 kgf·m, 17.0 ft·ib) 52 n·m (5.2 kgf·m, 38.4 ft·ib) 1 2.

Page 101

5-32 1 2 3 4 5 6 7 8 9 a crankcase check 1. Check the mating surfaces. Replace the crankcase if scratched. Crankcase installation 1. Apply the gasket maker (to the crank- case mating surfaces). Tip: before applying gasket maker, clean the crankcase mating surfaces. 2. Install the crankshaft. Tip: • ...

Page 102: Powr

5-33 powr power unit crankshaft no. Part name q’ty remarks crankcase see “crankcase” (5-30). 1 oil seal 1 not reusable 2 bearing 1 3 oil seal 1 2 not reusable 4 drive shaft collar 1 5 bearing clip 1 6 bearing 2 1 7 crankshaft assy. 1 7 5 6 4.

Page 103

5-34 1 2 3 4 5 6 7 8 9 a crankshaft check 1. Measure the crank width a. Replace if out of specification. 2. Measure deflection b (using a dial gauge). Replace if out of specification. 3. Measure big end side clearance c (using a thickness gauge). Replace if out of specification. 4. Measure small end...

Page 104: Powr

5-35 powr power unit — memo —.

Page 105: Jet

Jet pump 1 2 3 4 5 6 7 8 9 a jet pump unit intake grate and ride plate................................................. 6-1 jet pump unit...................................................................... 6-2 jet pump unit removal ................................................................ 6...

Page 106: Jet

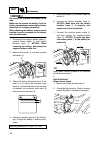

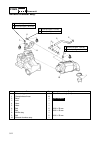

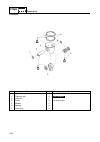

6-1 jet pump jet pump unit intake grate and ride plate no. Part name q’ty remarks 1 bolt 2 m6 × 30 mm 2 bolt 2 m10 × 25 mm 3 intake grate 1 4 screw 4 m5 × 12 mm 5 cover 1 6 bolt 4 m8 × 35 mm 7 ride plate 1 4 n·m (0.4 kgf·m, 3.0 ft·ib) 8 n·m (0.8 kgf·m, 5.9 ft·ib) 17 n·m (1.7 kgf·m, 12.5 ft·ib) 40 n·...

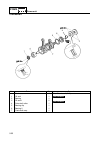

Page 107: Jet Pump Unit

6-2 1 2 3 4 5 6 7 8 9 a jet pump unit no. Part name q’ty remarks 1 band/bilge hose 1 2 nut/washer 1/2 3 steering cable joint 1 4 clamp/spout hose 2/1 5 bolt 4 m6 × 22 mm 6 collar 4 7 nut 2 8 collar 2 9 bolt 2 m6 × 25 mm 10 rubber plate 2 11 bolt 1 m6 × 30 mm 12 bolt 2 m8 × 18 mm 13 bolt 4 m10 × 45 m...

Page 108: Jet

6-3 jet pump jet pump unit no. Part name q’ty remarks 17 washer 2 18 gasket 2 19 bracket 1 10 6 5 4 2 15 2 11 lt 572 lt 572 lt 572 lt 572 lt 242 lt 271 lt 3 16 17 18 16 17 18 19 13 1 9 12 7 8 14 4 1 n·m (0.1 kgf·m, 0.7 ft·ib) 2 n·m (0.2 kgf·m, 1.5 ft·ib) 6.8 n·m (0.68 kgf·m, 4.9 ft·ib) 7 n·m (0.7 kg...

Page 109

6-4 1 2 3 4 5 6 7 8 9 a jet pump unit removal make sure to remove the battery before removing the jet pump unit. 1. Remove the jet pump unit 1. È stbd É port tip: insert a flat-head screwdriver into the gaps a between the jet pump unit 1 and the tran- som plate 2 to separate them. Jet pump unit inst...

Page 110: Jet

6-5 jet pump jet pump unit jet thrust nozzle, impeller duct, and impeller housing no. Part name q’ty remarks 1 bolt 2 m8 × 25 mm 2 collar 2 3 jet thrust nozzle 1 4 bolt 4 m10 × 125 mm 5 bracket 1 6 nozzle 1 7 impeller duct assy. 1 8 impeller housing 1 1 9 pin 2 10 bolt 4 m6 × 35 mm 11 water inlet co...

Page 111

6-6 1 2 3 4 5 6 7 8 9 a impeller duct and drive shaft *: epnoc grease ap #0 no. Part name q’ty remarks 1 bolt 3 m6 × 20 mm 2 cap 1 3 o-ring 1 not reusable 4 cap 1 5 impeller 1 6 drive shaft 1 7 oil seal 1 not reusable 8 oil seal 1 not reusable 9 rear bearing 1 not reusable 10 spacer 1 11 front beari...

Page 112: Jet

6-7 jet pump jet pump unit drive shaft removal 1. Remove the impeller. Tip: hold the impeller duct assy. In a vise between two aluminum plates a. 2. Remove the drive shaft 1. Tip: remove the drive shaft using a press. 3. Remove the rear bearing. 4. Remove the oil seals. Tip: remove the oil seals usi...

Page 113

6-8 1 2 3 4 5 6 7 8 9 a impeller housing check 1. Measure the impeller housing inside diameter a. Replace if out of specifica- tion. Drive shaft check 1. Check the drive shaft. Replace if cracked or damaged. 2. Measure the drive shaft runout. Replace if out of specification. Drive shaft installation...

Page 114: Jet

6-9 jet pump jet pump unit 5. Install the front bearing. Tip: press the spacer and the front bearing using a pipe of the proper size [more than 60 mm (2.36 in) long and that has an inner diameter more than 24 mm (0.94 in)]. 6. Install the drive shaft. (with front bearing spacer and rear bearing) tip...

Page 115: Transom Plate and Hoses

6-10 1 2 3 4 5 6 7 8 9 a transom plate and hoses no. Part name q’ty remarks exhaust system see “exhaust system” (8-23). Jet pump unit assy. See “jet pump unit” (6-2). 1 clamp 1 2 bilge hose 1 1 3 clamp 1 4 cooling water hose 1 cooling water inlet 5 bilge strainer 1 6 nut/washer 2/2 7 nut/washer 2/2 ...

Page 116: Jet

6-11 jet pump jet pump unit bilge strainer check see “hull and hood” (3-9). Bilge hose check 1. Check the bilge hoses. Replace if cracked or damaged. Cooling water hose check 1. Check the cooling water hoses. Replace if cracked or damage..

Page 117: Bearing Housing

6-12 1 2 3 4 5 6 7 8 9 a bearing housing no. Part name q’ty remarks engine unit see “engine unit” (5-1). 1 rubber coupling 1 2 bolt 4 m8 × 48 mm 3 intermediate housing cover 1 4 clamp 2 5 intermediate drive shaft assy. 1 6 rubber hose 1 7 bolt 3 m6 × 14 mm 8 joint 1 2 3 4 6 5 1 lt 271 7 7 7 8 4 n·m ...

Page 118: Jet

6-13 jet pump jet pump unit intermediate drive shaft assy. No. Part name q’ty remarks 1 driven coupling 1 2 washer 1 3 damper 1 4 intermediate drive shaft extension 1 5 intermediate drive shaft 1 6 circlip 1 not reusable 7 oil seal 1 not reusable 8 bearing 1 not reusable 9 oil seal 1 not reusable 10...

Page 119

6-14 1 2 3 4 5 6 7 8 9 a joint removal do not touch the joint or adhesive that was heated by the heat gun with your bare hands; they will be very hot and could cause burns. 1. Set a heat gun 1 to 350 °c (662 °f) and use it for about 20 minutes to heat the joint and adhesive. 2. Once the adhesive has...

Page 120: Jet

6-15 jet pump jet pump unit tip: • remove any adhesive that is protruding in or around the hole for the intermediate drive shaft. • after installing the joint, allow the adhesive to harden for at least 24 hours before plac- ing the watercraft in the water. Driven coupling removal and installation 1....

Page 121

6-16 1 2 3 4 5 6 7 8 9 a tip: remove the bearing and oil seals using a press. Driven coupling check 1. Check the driven coupling and driven coupling damper. Replace if damaged or worn. Bearing and oil seals installation 1. Install the oil seals and bearing. Tip: install the bearing using a press. 2....

Page 122: Jet

6-17 jet pump jet pump unit tip: fit a wrench into the notches in the interme- diate drive shaft extension. Intermediate drive shaft extension: 36 n·m (3.6 kgf·m, 26.6 ft·lb).

Page 123: Elec

Elec – + 1 2 3 4 5 6 7 8 9 a electrical system electrical components ....................................................... 7-1 electrical box ...................................................................... 7-2 electrical analysis ................................................................

Page 124: Elec

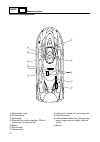

7-1 elec electrical system – + electrical components 1 multifunction meter 2 oil level sensor 3 spark plugs 4 electrical box (rectifier regulator, cdi unit, starter relay, and ignition coil) 5 battery 6 starter motor 7 thermoswitch 8 lighting coil, pickup coil, and charge coil 9 fuel level sensor 0 ...

Page 125: Electrical Box

7-2 1 2 3 4 5 6 7 8 9 a electrical box no. Part name q’ty remarks 1 nut/washer 2/2 2 electrical box cap 1 3 screw 14 ø6 × 24 mm 4 electrical box cover 1 5 gasket 1 6 screw 2 ø6 × 16 mm 7 wiring harness 1 electrical box to thermoswitch 8 wiring harness 1 electrical box to multifunction meter and hand...

Page 126: Elec

7-3 elec electrical system – + no. Part name q’ty remarks 16 positive battery cable 1 starter relay to positive battery terminal 17 starter relay 1 18 screw 2 ø6 × 16 mm 19 holder 1 20 rectifier regulator 1 21 screw 2 ø6 × 30 mm 22 spark plug wire 1/spark plug cap 1/1 23 spark plug wire 2/spark plug...

Page 127

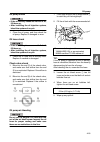

7-4 1 2 3 4 5 6 7 8 9 a 1 cdi unit 2 rectifier regulator 3 spark plug wires 4 ignition coil 5 starter relay 6 fuse holder È to base assy. É to multifunction meter, engine start switch, and engine stop switch Ê to thermoswitch Ë to positive battery terminal Ì to starter motor b : black br : brown g :...

Page 128: Elec

7-5 elec electrical system – + electrical analysis to measure the peak voltage when measuring the peak voltage, do not touch any of the connections of the digital tester probes. • when testing the voltage between the terminals of an electrical component with the digital tester, do not allow any of t...

Page 129

7-6 1 2 3 4 5 6 7 8 9 a ignition coil resistance 1. Measure the primary coil resistance. 2. Replace the ignition coil if out of specifi- cation. 3. Measure the secondary coil resistance. 4. Replace the ignition coil if out of specifi- cation. Cdi unit cdi unit output peak voltage 1. Measure the cdi ...

Page 130: Elec

7-7 elec electrical system – + [k Ω] È tester lead + É tester lead - “ ” mark: the needle swings toward zero once, and then returns to the home position. Tip: • the resistance values will vary from tester to tester, especially with electronic digital testers. For some testers, the polarity of the le...

Page 131

7-8 1 2 3 4 5 6 7 8 9 a pickup coil pickup coil output peak voltage 1. Measure the pickup coil output peak volt- age. 2. Measure the pickup coil resistance if below specification. Tip: • to crank the engine, connect the engine shut-off cord to the engine shut-off switch, and then push the engine sta...

Page 132: Elec

7-9 elec electrical system – + charging system lighting coil lighting coil output peak voltage 1. Disconnect the lighting coil connectors. 2. Measure the lighting coil output peak voltage. 3. Measure the lighting coil resistance if below specification. Tip: to crank the engine, connect the engine sh...

Page 133: Starting System

7-10 1 2 3 4 5 6 7 8 9 a [k Ω] È tester lead + É tester lead - tip: • the resistance values will vary from tester to tester, especially with electronic digital testers. For some testers, the polarity of the leads is reversed. • the “ ∞ ” mark indicates no continuity. Starting system fuse 1. Check th...

Page 134: Elec

7-11 elec electrical system – + starter relay 1. Connect the tester leads between the starter relay terminals 1 and 2. 2. Connect the positive battery lead to the terminal a, and the negative battery lead to the terminal b. 3. Check the continuity between the starter relay terminals 1 and 2. 4. Repl...

Page 135: Starter Motor

7-12 1 2 3 4 5 6 7 8 9 a starter motor no. Part name q’ty remarks 1 o-ring 1 not reusable 2 bolt 2 m5 × 114 mm 3 front cover assy. 1 4 o-ring 2 not reusable 5 washer set 1 6 rear cover assy. 1 7 armature 1 8 brush holder assy. 1 9 starter motor yoke 1 6 n·m (0.6 kgf·m, 4.4 ft·ib) a a a a 6 5 2 9 4 4...

Page 136: Elec

7-13 elec electrical system – + starter motor operation 1. Hold the starter motor in a vise using alu- minum plates on both sides. 2. Connect the positive battery cable to the starter motor terminal bolt. 3. Connect the negative battery cable to the starter motor body, and then check the starter mot...

Page 137

7-14 1 2 3 4 5 6 7 8 9 a front and rear cover 1. Check the front cover oil seal. Replace the front cover if damaged or worn. 2. Check the rear cover metal. Replace the rear cover if cracked or damaged. Brush holder brush length 1. Measure the brush length a. Replace the brush holder assy. If below s...

Page 138: Elec

7-15 elec electrical system – + tip: • install the spacer 2 so that the notch b in the spacer is facing in the direction of the arrow. • align the protrusion c on the brush holder with the notch d on the starter motor yoke. Indication system multifunction meter multifunction meter appearance 1. Chec...

Page 139

7-16 1 2 3 4 5 6 7 8 9 a 3. Replace the fuel level sensor if out of specification. 4. Replace the multifunction meter if the fuel level sensor resistance is within specification. Engine overheat warning indicator 1. Check the thermoswitch if engine over- heat warning indicator does not come on. See ...

Page 140: Hull

Hull hood hull and hood steering pad and handlebar cover ................................... 8-1 handlebar and handlebar switch assy. ............................ 8-2 left handlebar switch assy. And throttle lever assy. ...... 8-3 throttle cable removal..................................................

Page 141

1 2 3 4 5 6 7 8 9 a deck and hull .................................................................... 8-25 rear section...................................................................... 8-27 drain plug check....................................................................... 8-29 spout insta...

Page 142: Hull

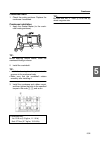

Hull hood hull and hood 8-1 steering pad and handlebar cover no. Part name q’ty remarks 1 screw 2 ø4 × 10 mm 2 screw 4 ø5 × 16 mm 3 upper handlebar cover 1 4 steering pad 1 5 screw 4 ø6 × 14 mm 6 lower handlebar cover 1 5 2 6 4 1 1 3 1 n·m (0.1 kgf·m, 0.7 ft·ib) 1 n·m (0.1 kgf·m, 0.7 ft·ib) 4 n·m (0...

Page 143

8-2 1 2 3 4 5 6 7 8 9 a handlebar and handlebar switch assy. No. Part name q’ty remarks 1 bolt 2 m5 × 35 mm 2 grip end 2 3 handlebar grip 2 4 corrugated tube 1 5 throttle cable 1 6 screw 2 ø5 × 25 mm 7 left handlebar switch assy. 1 8 bolt 2 m5 × 25 mm 9 throttle lever assy. 1 10 bolt 4 m8 × 45 mm 11...

Page 144: Hull

Hull hood hull and hood 8-3 left handlebar switch assy. And throttle lever assy. No. Part name q’ty remarks 1 left handlebar switch assy. 1 2 engine shut-off cord 1 3 stop button assy. 1 4 start button assy. 1 5 screw 2 6 throttle lever assy. 1 7 e-ring 1 8 washer 2 9 shaft 1 10 lever 1 11 spring 1 ...

Page 145

8-4 1 2 3 4 5 6 7 8 9 a throttle cable removal 1. Remove the corrugated tube 1. 2. Remove the throttle cable 2. Notice: make sure to remove the throttle cable seal a. Handlebar check 1. Check the handlebar. Replace if bent, cracked, or damaged. Left handlebar switch assy. Check 1. Check the left han...

Page 146: Hull

Hull hood hull and hood 8-5 tip: • do not route the left handlebar switch lead 1 and throttle cable 3 between the han- dlebar 5 and the steering master 4. • the upper handlebar holder 6 should be installed with the punch mark e facing down. • tighten the bolts 7 so that there is clear- ance between ...

Page 147

8-6 1 2 3 4 5 6 7 8 9 a 10. Tighten the locknut b, and then slide the rubber cover c to its original position. 11. Insert the seal m completely into the slot in the bracket. 12. Install the corrugated tube d onto the throttle cable 3, and then route the throt- tle cable 3 and left handlebar switch l...

Page 148: Hull

Hull hood hull and hood 8-7 tip: if the steering pad 3 is not installed securely, the upper handlebar cover 4 cannot be installed properly onto the lower handlebar cover. 3. Install the upper handlebar cover 4, and then tighten the screws 5 and 6 to the specified torque. Tip: align the portions a on...

Page 149: Front Hood

8-8 1 2 3 4 5 6 7 8 9 a front hood no. Part name q’ty remarks 1 nut 4 2 washer 4 3 left mirror 1 4 left mirror spacer 1 5 right mirror 1 6 right mirror spacer 1 7 bolt 2 m5 × 20 mm 8 hood lock assy. 1 9 screw 8 ø5 × 15 mm 10 front hood 1 11 nut 2 12 washer 2 13 bolt 2 m6 × 95 mm 14 ventilator cover ...

Page 150: Hull

Hull hood hull and hood 8-9 no. Part name q’ty remarks 17 hinge assy. 1 18 rivet 5 19 service lid 1 12 17 11 13 18 19 15 7 9 16 5 2 2 1 1 6 8 10 3 4 14 2 n·m (0.2 kgf·m, 1.5 ft·ib) 7 n·m (0.7 kgf·m, 5.2 ft·ib) 7 n·m (0.7 kgf·m, 5.2 ft·ib) 7 n·m (0.7 kgf·m, 5.2 ft·ib) 4 n·m (0.4 kgf·m, 3.0 ft·ib).

Page 151

8-10 1 2 3 4 5 6 7 8 9 a service lid installation 1. Install the service lid 1, and then insert a rivet completely in the holes in both the service lid 1 and inner hull 2. 2. Push in the rivet pin 3 until it clicks and is flush with the top of the rivet. 3. When removing a rivet, push the rivet pin ...

Page 152: Hull

Hull hood hull and hood 8-11 multifunction meter and engine hatch cover no. Part name q’ty remarks seat assy. See “seat and handgrip” (8-18). 1 glove box 1 2 lock 1 3 hinge pin 2 4 center console box lid 1 5 damper 2 6 nut 6 7 bolt 4 m6 × 18 mm 8 bolt 4 m6 × 29 mm 9 bolt 4 m6 × 29 mm 10 plastic tie ...

Page 153

8-12 1 2 3 4 5 6 7 8 9 a no. Part name q’ty remarks 16 lid lock hook 1 17 nut 2 18 revet 1 19 plug 1 6 6 6 9 8 19 18 14 13 11 15 7 12 5 5 7 3 3 2 4 17 16 8 1 10 5 n·m (0.5 kgf·m, 3.7 ft·ib) 5 n·m (0.5 kgf·m, 3.7 ft·ib) 4 n·m (0.4 kgf·m, 3.0 ft·ib) multifunction meter and engine hatch cover.

Page 154: Hull

Hull hood hull and hood 8-13 steering master assy. No. Part name q’ty remarks 1 buzzer coupler 1 2 steering cable joint 1 3 bolt 1 m6 × 18 mm 4 cable stopper 1 5 bolt 4 m8 × 30 mm 6 steering master assy. 1 7 rivet 2 not reusable 8 cable stopper bracket 1 9 grommet 1 5 6 7 n·m (0.7 kgf·m, 5.2 ft·ib) ...

Page 155: Steering Master

8-14 1 2 3 4 5 6 7 8 9 a steering master no. Part name q’ty remarks 1 bolt/plate 1/1 m8 × 50 mm 2 nut 1 3 steering arm assy. 1 4 nut 1 5 ball joint 1 6 arm 1 7 steering shaft assy. 1 8 bushing 1 9 band 2 not reusable 10 buzzer 1 11 bolt 2 m5 × 16 mm 12 bracket 1 13 bolt 4 m6 × 25 mm 14 case assy. 1 ...

Page 156: Hull

Hull hood hull and hood 8-15 shift lever assy. Check 1. Check the shift lever assy. Replace if cracked or damaged. Notice: do not disassemble the shift lever assy. Bushing check 1. Check the bushing. Replace if cracked, damaged, or worn. Steering arm assy. Installation 1. Install the steering arm as...

Page 157: Steering Cable

8-16 1 2 3 4 5 6 7 8 9 a steering cable no. Part name q’ty remarks service lid see “front hood” (8-8). Seat assy. See “seat and handgrip” (8-18). Ride plate/rubber plate see “intake grate and ride plate” (6-1). 1 steering cable joint 1 2 bolt 1 m6 × 18 mm 3 steering cable stopper 1 4 plastic tie 3 5...

Page 158: Hull

Hull hood hull and hood 8-17 steering cable installation (steering master end) if a cable becomes damaged, replace it. Never attempt to repair damaged cable. 1. Install the steering cable 1 and steering cable stopper 2, and then tighten the bolt 3 to the specified torque. Tip: install the steering c...

Page 159: Seat and Handgrip

8-18 1 2 3 4 5 6 7 8 9 a seat and handgrip no. Part name q’ty remarks 1 seat assy. 1 2 bolt 2 m6 × 40 mm 3 seat lock assy. 1 4 packing 1 not reusable 5 nut 1 6 washer 1 7 projection 1 8 washer 1 9 nut 4 10 washer 4 11 bolt 4 m8 × 30 mm 12 handgrip 1 3 1 11 2 4 7 8 12 10 9 6 5 5 n·m (0.5 kgf·m, 3.7 f...

Page 160: Hull

Hull hood hull and hood 8-19 ventilation hose and water separator no. Part name q’ty remarks oil filler neck see “oil tank” (4-4). Fuel filter see “fuel cock and fuel filter” (4-1). 1 rivet 6 not reusable 2 induction box 2 3 band 2 not reusable 4 ventilation hose 2 5 grommet 2 6 nut 2 7 seat holder ...

Page 161

8-20 1 2 3 4 5 6 7 8 9 a no. Part name q’ty remarks 15 rivet 2 not reusable 16 ventilation socket 1 17 ventilation pipe 1 18 plastic tie 1 19 nut 1 20 seal 1 not reusable 21 clamp 1 22 cooling water pilot outlet 1 23 cooling water hose 1 È to exhaust joint 24 plastic tie 1 25 band 1 not reusable 26 ...

Page 162: Hull

Hull hood hull and hood 8-21 seat lock check 1. Check the seat lock assy. Replace if cracked, damaged, or worn. 2. Check the projection. Replace if dam- aged. Check valve check 1. Blow into the end “a” of the check valve, and make sure that airflow from the end “b” is unrestricted. Replace if the ai...

Page 163

8-22 1 2 3 4 5 6 7 8 9 a tip: align the projection a with the slit b. Ventilation hose installation 1. Install the grommets 1. Tip: make sure that the grommet 1 is properly seated in the hole in the inner hull 2. 2. Install the ventilation hoses 3. Tip: • make sure to route the ventilation hose (por...

Page 164: Hull

Hull hood hull and hood 8-23 exhaust system no. Part name q’ty remarks ride plate see “intake grate and ride plate” (6-1). 1 band 1 2 clamp 3 3 water lock 1 4 band 1 not reusable 5 rubber hose 1 6 bolt 3 m5 × 20 mm 7 exhaust outlet 1 8 band 1 not reusable 9 hose 1 10 seal 1 not reusable 5 4 10 2 7 9...

Page 165

8-24 1 2 3 4 5 6 7 8 9 a exhaust system check 1. Check the rubber hoses. Replace if burned, cracked, or damaged. 2. Check the water lock. Replace if cracked, damaged, or leaked. Exhaust system.

Page 166: Hull

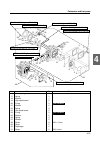

Hull hood hull and hood 8-25 deck and hull no. Part name q’ty remarks fuel cock assy. See “fuel cock and fuel filter” (4-1). Choke cable see “choke cable” (4-3). 1 bolt 2 m6 × 20 mm 2 bow eye 1 3 nut 4 4 washer 4 5 bolt 2 m6 × 25 mm 6 front protector 1 7 bolt 2 m6 × 25 mm 8 rivet 9 not reusable 9 re...

Page 167

8-26 1 2 3 4 5 6 7 8 9 a no. Part name q’ty remarks 15 collar 10 16 sponson 2 17 rivet 2 not reusable 18 fuel cock cover 1 19 rivet 2 not reusable 20 choke cover 1 1 2 7 5 19 6 11 4 4 3 12 3 13 17 10 16 15 14 8 9 8 7 n·m (0.7 kgf·m, 5.2 ft·ib) 13 n·m (1.3 kgf·m, 9.6 ft·ib) 15 n·m (1.5 kgf·m, 11.1 ft...

Page 168: Hull

Hull hood hull and hood 8-27 rear section no. Part name q’ty remarks water lock see “exhaust system” (8-23). Flushing hose see “transom plate and hoses” (6-10). 1 nut 2 2 bracket 1 3 plate 2 4 ski tow 1 5 clamp 1 6 spout hose 1 7 nut 1 8 spout 1 9 nut 4 10 plate 4 11 packing 2 not reusable 12 stern ...

Page 169

8-28 1 2 3 4 5 6 7 8 9 a no. Part name q’ty remarks 15 screw 4 ø5 × 25 mm 16 packing 2 not reusable 17 drain plug 2 5 8 7 15 9 10 12 10 11 4 3 1 2 3 17 16 14 13 2 n·m (0.2 kgf·m, 1.5 ft·ib) 5 n·m (0.5 kgf·m, 3.7 ft·ib) 2 n·m (0.2 kgf·m, 1.5 ft·ib) 15 n·m (1.5 kgf·m, 11.1 ft·ib) 15 n·m (1.5 kgf·m, 11...

Page 170: Hull

Hull hood hull and hood 8-29 drain plug check 1. Check the drain plug 1 and o-ring 2. Replace if cracked or damaged. Spout installation 1. Install the spout 1, and then tighten the nut 2 to the specified torque. 2. Install the hose 3, and then tighten the clamp 4 to the specified torque. Tip: face t...

Page 171: Trbl

Trbl shtg 1 2 3 4 5 6 7 8 9 a troubleshooting engine unit troubleshooting ............................................. 9-1 troubleshooting (engine unit, jet pump unit, charging system)............................. 9-1.

Page 172: Trbl

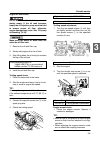

Trbl shtg troubleshooting 9-1 engine unit troubleshooting tip: • before troubleshooting the engine unit, make sure that fresh fuel of the specified type has been used. • check that all wiring connections are properly secured and that they are not rusty or corroded. • check that the engine shut-off c...

Page 173

9-2 1 2 3 4 5 6 7 8 9 a symptom 1: engine will not start (engine cranks). Symptom 2 cause checking step see page throttle valve does not move properly throttle cable installed incorrectly adjust the throttle lever free play. 3-2 throttle valve malfunction check the carburetor. 4-14 discharged batter...

Page 174: Trbl

Trbl shtg troubleshooting 9-3 symptom 1: unstable engine idle speed, poor acceleration, poor performance, or limited engine speed fuel not supplied (all cylinders) fuel leakage check the fuel hose. 3-3 clogged fuel filter replace the fuel filter. 3-3 fuel pump malfunction check the fuel pump onto th...

Page 175

9-4 1 2 3 4 5 6 7 8 9 a symptom 1: high engine idle speed symptom 1: limited engine speed symptom 1: discharged battery compression pres- sure is low compression leakage measure the compression pres- sure. 3-5 check the cylinder head gasket and cylinder head warpage. 5-17 check the piston and piston...

Page 176: Trbl

Trbl shtg troubleshooting 9-5 symptom 1: poor performance symptom 2 cause checking step see page watercraft cannot reach high speeds jet pump unit malfunction check the impeller, impeller duct, and intake grate. 6-6 water entered hull check the drain plugs and o-rings for damage. 8-29 check the cool...

Page 177: Appendix

1 2 3 4 5 6 7 8 9 a appendix wiring diagram ............................................................................ A-1.

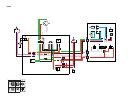

Page 178: Wiring Diagram

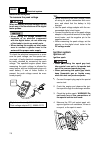

Wiring diagram vx 700 color code 1 thermoswitch b : black 2 base assy. (lighting coil, pickup coil, charge coil) br : brown 3 starter motor g : green 4 oil level sensor l : blue 5 fuel level sensor o : orange 6 multifunction meter p : pink 7 buzzer r : red 8 engine start switch w : white 9 engine sh...

Page 180

Yamaha motor co., ltd. Sep. 2010 – ** × 1 cr (e).

Page 181

Vx700 2 1 4 2 3 1 1 2 2 1 2 1 w br b r set pull 2 1 b c a g r p l l b l b b w/l b w/l b l/r l/b w/l b b g r p b br b w b w r g r p b p b o b r b g g b p p g g g p p o b o b b p b br /w w/r g g b br /w w /r g g b b w w w p o b b b b b b b b b b br /w w /r br /w w /r g g b r r br b w r r r b r r r br ...