- DL manuals

- Yamaha

- Offroad Vehicle

- WOLVERINE YFM45FXV

- Supplementary Service Manual

Yamaha WOLVERINE YFM45FXV Supplementary Service Manual - – 24 –

– 24 –

CHK

ADJ

PERIODIC MAINTENANCE AND LUBRICATION CHART

(For Europe)

NOTE:

• The air filter needs more frequent service if you are riding in unusually wet or dusty areas.

• Hydraulic brake service

• Regularly check and, if necessary, correct the brake fluid level.

• Every two years replace the internal components of the brake master cylinders and calipers, and

change the brake fluid.

• Replace the brake hoses every four years and if cracked or damaged.

19 * Steering system

• Check operation and repair or replace if damaged.

• Check toe-in and adjust if necessary.

√

√

√

√

√

20 * Engine mount

• Check for cracks or other damage, and replace if nec-

essary.

√

√

√

21 * Axle boots

• Check for cracks or other damage, and replace if nec-

essary.

Before each ride.

22 * Carburetor

• Check starter (choke) operation and correct if neces-

sary.

• Check engine idling speed and adjust if necessary.

√

√

√

√

23 *

Crankcase

breather system

• Check breather hose for cracks or other damage, and

replace if necessary.

√

√

√

24

Engine oil

• Change.

• Check ATV for oil leakage, and correct if necessary.

√

√

√

√

25

Engine oil filter

cartridge

• Replace.

√

√

√

26 * Engine oil strainer • Clean.

√

√

√

27

Differential gear oil

• Change.

• Check ATV for oil leakage, and correct if necessary.

√

√

28

Final gear oil

• Change.

• Check ATV for oil leakage, and correct if necessary.

√

√

29

Cooling system

• Check coolant level and ATV for coolant leakage, and

correct if necessary.

√

√

√

√

√

• Replace coolant.

Every 2 years

30 *

Moving parts and

cables

• Lubricate.

√

√

√

√

31 *

Drive select lever

safety system

cable

• Check operation and adjust or replace if necessary.

√

√

√

32 *

Throttle lever

housing and cable

• Check operation and correct if necessary.

• Check throttle cable free play and adjust if necessary.

• Lubricate throttle lever housing and cable.

√

√

√

√

√

33 * Exhaust system

• Check for leakage and replace gasket(s) if necessary.

• Check for looseness and tighten all screw clamps and

joints if necessary.

√

√

√

34 *

Front and rear

brake switches

• Check operation and correct if necessary.

√

√

√

√

√

35 *

Lights and

switches

• Check operation and correct if necessary.

• Adjust headlight beams.

√

√

√

√

√

NO.

ITEM

CHECK OR MAINTENANCE

JOB

INITIAL

EVERY

Whichever

comes first

month

1

3

6

6

12

km (mi)

320

(200)

1200

(750)

2400

(1500)

2400

(1500)

4800

(3000)

hours

20

75

150

150

300

Summary of WOLVERINE YFM45FXV

Page 1

Yfm45fxv supplementary service manual 3c2-f8197-e0

Page 2: Foreword

Foreword this supplementary service manual has been prepared to introduce new service and data for the yfm45fxv. For complete service information procedures it is necessary to use this supplementary service manual together with the following manual. Yfm45far/yfm450far service manual: 5nd2-ae1 yfm45f...

Page 3: Notice

Eb001000 notice this manual was produced by the yamaha motor company primarily for use by yamaha dealers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manual, so it is assumed that anyone who uses this book to perform maintenance and repairs on y...

Page 4: How to Use This Manual

Eb002000 how to use this manual manual organization this manual consists of chapters for the main categories of subjects. (see “illustrated symbols”) 1st title 1: this is the title of the chapter with its symbol in the upper right corner of each page. 2nd title 2: this title indicates the section of...

Page 5: Illustrated Symbols

Eb003000 illustrated symbols illustrated symbols 1 to 0 are printed on the top right of each page and indicate the subject of each chapter. 1 general information 2 specifications 3 periodic checks and adjustments 4 engine 5 cooling system 6 carburetion 7 drive train 8 chassis 9 electrical 0 troubles...

Page 6: Contents

Contents general information ................................................................................ 1 vehicle identification......................................................................... 1 vehicle identification number.................................................. 1 model la...

Page 7

Middle gear........................................................................................... 58 middle driven shaft .................................................................... 58 cooling system...........................................................................................

Page 8: – 1 –

– 1 – gen info general information vehicle identification vehicle identification number the vehicle identification number 1 is stamped into the left side of the frame. Model label the model label 1 is affixed to the frame. This information will be needed to order spare parts. Vehicle identification.

Page 9: – 2 –

– 2 – spec specifications general specifications item standard model code: 3c21 (for usa) 3c22 (for cdn) 3c23 (for europe) dimensions: overall length 1,978 mm (77.9 in) overall width 1,063 mm (41.9 in) overall height 1,095 mm (43.1 in) seat height 840 mm (33.1 in) wheelbase 1,233 mm (48.5 in) minimu...

Page 10: – 3 –

– 3 – spec general specifications transmission: primary reduction system v-belt secondary reduction system shaft drive secondary reduction ratio 39/24 × 24/18 × 33/9 (7.944) transmission type v-belt automatic operation left hand operation single speed automatic 2.55 ~ 0.75 : 1 sub transmission ratio...

Page 11: – 4 –

– 4 – spec maintenance specifications maintenance specifications engine item standard limit air filter oil grade: yamaha foam air filter oil or other quality foam air filter oil ---- carburetor: i. D. Mark 5ndc 00 ---- main jet (m.J) #131.3 ---- main air jet (m.A.J) #50 ---- jet needle (j.N) 5ep13-5...

Page 12: – 5 –

– 5 – spec maintenance specifications tightening torques chassis part to be tightened part name thread size q’ty tightening torque remarks nm m·kg ft·lb oil seal retainer screw m5 2 7 0.7 5.1 lt access cover bolt m6 4 10 1.0 7.2 thermo switch — m18 1 7 0.7 5.1 stopper lever shaft bolt m6 1 10 1.0 7....

Page 13: – 6 –

– 6 – spec maintenance specifications tightening torques electrical brake lever and brake pedal: rear brake lever free play (pivot) 0.5 ~ 2 mm (0.02 ~ 0.08 in) ---- brake pedal height 67 ~ 77 mm (2.64 ~ 3.03 in) ---- throttle lever free play 3 ~ 5 mm (0.12 ~ 0.20 in) ---- part to be tightened thread...

Page 14: – 7 –

– 7 – spec coolant flow diagrams coolant flow diagrams 1 radiator 2 thermo switch 2 3 fan motor È to coolant reservoir.

Page 15: – 8 –

– 8 – spec coolant flow diagrams 1 radiator 2 thermostat.

Page 16: – 9 –

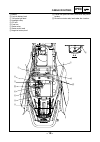

– 9 – spec cable routing cable routing 1 on-command four-wheel drive switch 2 on-command four-wheel drive switch lead 3 throttle cable 4 handlebar switch lead 5 handlebar switch 6 rear brake switch lead 7 starter cable 8 rear brake cable 9 front brake hose 0 front brake light switch lead a main swit...

Page 17: – 10 –

– 10 – spec cable routing È fasten the on-command four-wheel drive switch lead and front brake light switch lead behind the handlebar with the plastic bands. É fasten the starter cable, handlebar switch lead, and rear brake switch lead behind the handlebar with a plastic band. Ê fasten the handlebar...

Page 18: – 11 –

– 11 – spec cable routing 1 auxiliary dc jack (optional) 2 headlight lead 3 headlight coupler a-a a a 1 2 2 3.

Page 19: – 12 –

– 12 – spec cable routing 1 starter cable 2 fuel tank breather hose 3 fuel hose 4 cylinder head breather hose 5 carburetor drain hose 6 radiator outlet hose 7 coolant reservoir breather hose 8 coolant reservoir hose 9 sub-wire harness 1 0 differential gear case breather hose a thermo switch 2 È inse...

Page 20: – 13 –

– 13 – spec cable routing Í fasten the sub-wire harness 1 and differential gear case breather hose with a plastic band. Î fasten the sub-wire harness 1, differential gear case breather hose, coolant reservoir hose, and coolant reservoir breather hose with a plastic band. Ï 7 ~ 17 mm (0.28 ~ 0.67 in)...

Page 21: – 14 –

– 14 – spec cable routing 1 fuel hose 2 cylinder head breather hose 3 final drive gear case breather hose 4 negative battery lead 5 starter motor lead 6 wire harness 7 tail/brake light lead 8 air filter case check hose 9 water pump breather hose 0 speed sensor lead a a.C. Magneto lead b radiator out...

Page 22: – 15 –

– 15 – spec cable routing È fasten the final drive gear case breather hose and wire harness with a plastic band. É fasten the starter motor lead, final drive gear case breather hose, and wire harness with a plastic band. Ê fasten the wire harness with the plastic bands. Ë fasten the tail/brake light...

Page 23: – 16 –

– 16 – spec cable routing 1 wire harness 2 throttle cable 3 spark plug lead 4 radiator inlet hose 5 main switch 6 rear brake fluid reservoir hose 7 rear brake cable 8 rear brake light switch lead 9 select lever control cable 0 rear brake hose a ignition coil b sub-wire harness 3 È fasten the select ...

Page 24: – 17 –

– 17 – spec cable routing 1 auxiliary dc jack connectors (optional) 2 front brake hose 3 throttle cable 4 float chamber air vent hose 5 wire harness 6 final drive gear case breather hose 7 rear brake cable 8 starter cable 9 headlight leads 0 front brake light switch coupler a on-command four-wheel d...

Page 25: – 18 –

– 18 – spec cable routing È fasten the wire harness with the plastic bands. É fasten the float chamber air vent hose with the plastic holders. Ê route the headlight lead under the couplers. Ë pass the hoses through the holes in the air duct bracket. The end of each hose should extend approximately 2...

Page 26: – 19 –

– 19 – spec cable routing 1 battery 2 positive battery lead 3 tail/brake light lead 4 headlight relay 5 cdi unit 6 fuse box 7 starter relay 8 starter motor lead 9 negative battery lead È fasten the positive battery lead with the plastic holders. É route the starter relay lead under the fuse box. A-a...

Page 27: – 20 –

– 20 – spec cable routing 1 final drive gear case breather hose 2 rear brake hose 3 air filter case check hose È fasten the final drive gear case breather hose with the plastic holder. É fasten the rear brake hose with the plastic hold- ers. Ê pass the rear brake hose through the hose guides. È É 1 ...

Page 28: – 21 –

– 21 – chk adj eb300000 periodic checks and adjustments introduction this chapter includes all information necessary to perform recommended checks and adjustments. These preventive maintenance procedures, if followed, will ensure more reliable vehicle operation and a longer service life. The need fo...

Page 29: – 22 –

– 22 – chk adj general maintenance and lubrication chart (for cdn) general maintenance and lubrication chart (for cdn) note: • recommended brake fluid: dot 4 • brake fluid replacement: • when disassembling the master cylinders or calipers, replace the brake fluid. Normally check the brake fluid leve...

Page 30: – 23 –

– 23 – chk adj periodic maintenance and lubrication chart (for europe) periodic maintenance and lubrication chart (for europe) note: • for atvs not equipped with an odometer or an hour meter, follow the month maintenance inter- vals. • for atvs equipped with an odometer or an hour meter, follow the ...

Page 31: – 24 –

– 24 – chk adj periodic maintenance and lubrication chart (for europe) note: • the air filter needs more frequent service if you are riding in unusually wet or dusty areas. • hydraulic brake service • regularly check and, if necessary, correct the brake fluid level. • every two years replace the int...

Page 32: – 25 –

– 25 – chk adj seat, fenders and fuel tank seat, fenders and fuel tank seat 2 3 1 t r . . 7 nm (0.7 m • kg, 5.1 ft • ib) t r . . 7 nm (0.7 m • kg, 5.1 ft • ib) order job/part q’ty remarks removing the seat remove the parts in the order below. 1 seat 1 note: pull rearward on the seat lock lever, loca...

Page 33: – 26 –

– 26 – chk adj seat, fenders and fuel tank front guard and front fender t r . . 7 nm (0.7 m • kg, 5.1 ft • ib) 10 11 8 7 9 4 5 4 5 6 3 1 2 (8) (6) (6) t r . . 34 nm (3.4 m • kg, 24 ft • ib) t r . . 7 nm (0.7 m • kg, 5.1 ft • ib) t r . . 7 nm (0.7 m • kg, 5.1 ft • ib) order job/part q’ty remarks remo...

Page 34: – 27 –

– 27 – chk adj seat, fenders and fuel tank rear guard and rear fender 2 5 4 3 8 7 9 (6) 6 1 t r . . 34 nm (3.4 m • kg, 24 ft • ib) (6) order job/part q’ty remarks removing the rear fender remove the parts in the order below. Seat refer to “seat”. Fuel tank cover refer to “front guard and front fende...

Page 35: – 28 –

– 28 – chk adj seat, fenders and fuel tank 2 5 4 3 8 7 9 (6) 6 1 t r . . 34 nm (3.4 m • kg, 24 ft • ib) (6) order job/part q’ty remarks 8 wire harness 1 9 rear fender 1 for installation, reverse the removal pro- cedure..

Page 36: – 29 –

– 29 – chk adj seat, fenders and fuel tank fuel tank 7 3 4 2 6 6 5 6 1 t r . . 10 nm (1.0 m • kg, 7.2 ft • ib) t r . . 10 nm (1.0 m • kg, 7.2 ft • ib) order job/part q’ty remarks removing the fuel tank remove the parts in the order below. Seat refer to “seat”. Front fender refer to “front guard and ...

Page 37: – 30 –

– 30 – chk adj seat, fenders and fuel tank 7 3 4 2 6 6 5 6 1 t r . . 10 nm (1.0 m • kg, 7.2 ft • ib) t r . . 10 nm (1.0 m • kg, 7.2 ft • ib) order job/part q’ty remarks 6 plastic band 4 7 rubber cover 1 for installation, reverse the removal pro- cedure..

Page 38: – 31 –

– 31 – chk adj footrest boards footrest boards order job/part q’ty remarks removing the footrest boards remove the parts in the order below. 1 left footrest board 1 2 right footrest board 1 3 footrest board bracket 4 for installation, reverse the removal pro- cedure..

Page 39: – 32 –

– 32 – chk adj adjusting the rear brake chassis adjusting the rear brake warning always adjust both the brake pedal and the rear brake lever whenever adjusting the rear brake. 1. Check: • rear brake lever free play a out of specification → adjust. Rear brake lever free play 0.5 ~ 2.0 mm (0.02 ~ 0.08...

Page 40: – 33 –

– 33 – chk adj adjusting the rear brake c. Loosen the locknut 4. D. Turn the adjusting bolt 5 until the brake pedal height is within the specified limits. E. Tighten the locknut 4. Note: when adjusting the brake pedal height make sure the locknut-to-adjusting bolt clearance a does not exceed 6 mm (0...

Page 41: – 34 –

– 34 – chk adj adjusting the select lever control cable and shift rod adjusting the select lever control cable and shift rod 1 neutral 2 forward 3 reverse 4 park 5 control cable 6 select lever shift rod warning before moving the select lever, bring the vehicle to a complete stop and return the throt...

Page 42: – 35 –

– 35 – chk adj adjusting the select lever control cable and shift rod f. Check that locknuts 3 are tightened cor- rectly. G. If the operation of the select lever is incor- rect, adjust the select lever control cable 4 with the adjuster 5. Select lever shift rod: a. Make sure the select lever is in n...

Page 43: – 36 –

– 36 – chk adj adjusting the headlight beams/ changing the headlight bulbs electrical ebs00122 adjusting the headlight beams 1. Adjust: • headlight beam (vertically) ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ a. Turn the adjusting bolt 1 in direction a or b. ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲...

Page 44: – 37 –

– 37 – chk adj changing the headlight bulbs 3. Install: • bulb secure the new bulb with the headlight unit. Caution: avoid touching the glass part of the bulb. Keep it free from oil; otherwise, the trans- parency of the glass, life of the bulb, and luminous flux will be adversely affected. If oil ge...

Page 45: – 38 –

– 38 – eng engine engine removal select lever unit and coolant reservoir order job/part q’ty remarks removing the select lever unit and coolant reservoir remove the parts in the order below. Engine oil drain. Refer to “changing the engine oil” in chapter 3. (manual no.: 5nd2-ae1) front fender/rear f...

Page 46: – 39 –

– 39 – eng engine removal order job/part q’ty remarks 1 shift arm 1 2 select lever shift rod 1 3 select lever unit 1 4 coolant reservoir breather hose 1 5 coolant reservoir hose 1 6 coolant reservoir 1 for installation, reverse the removal pro- cedure..

Page 47: – 40 –

– 40 – eng engine removal air ducts, muffler and exhaust pipe order job/part q’ty remarks removing the air ducts, muffler and exhaust pipe remove the parts in the order below. 1 air duct assembly 1 (upper) 1 2 air duct assembly 1 (lower) 1 3 muffler 1 4 exhaust pipe stay 1 5 exhaust pipe/gasket 1/1 ...

Page 48: – 41 –

– 41 – eng engine removal hoses and leads order job/part q’ty remarks removing the hoses and leads remove the parts in the order below. Water pump inlet hose refer to “water pump” in chapter 5. (manual no.: 5nd2-ae1) 1 cylinder head breather hose 1 2 spark plug lead 1 3 thermo switch 1 lead 1 4 star...

Page 49: – 42 –

– 42 – eng engine removal installing the muffler and exhaust pipe 1. Install: • exhaust pipe 1 • exhaust pipe stay 2 • muffler 3 note: do not fully tighten the bolts and nuts. 2. Tighten: • exhaust pipe nut 4 • muffler bolt (front side) 5 • muffler bolt (rear side) 6 • exhaust pipe stay bolt (drive ...

Page 50: – 43 –

– 43 – eng cylinder head cylinder head order job/part q’ty remarks removing the cylinder head remove the parts in the order below. Fuel tank/rubber cover/front fender/air filter case refer to “seat, fenders and fuel tank”. Air duct assembly 1 (upper and lower)/ exhaust pipe/muffler refer to “engine ...

Page 51: – 44 –

– 44 – eng cylinder head order job/part q’ty remarks 3 cylinder head breather hose 1 4 camshaft sprocket cover/o-ring 1/1 5 tappet cover/o-ring 2/2 6 thermo switch 1 lead 1 disconnect. 7 timing chain tensioner cap bolt 1 refer to “removing the cylinder head” and “installing the cylin- der head”. 8 t...

Page 52: – 45 –

– 45 – eng cylinder head removing the cylinder head 1. Align: • “t” mark 1 (with stationary pointer) ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼ ▼▼▼ ▼ ▼▼▼ a. Turn the crankshaft counterclockwise with a wrench. B. Align the “t” mark 1 on the rotor with the stationary pointer 2 on the a.C. Magneto cover. ...

Page 53: – 46 –

– 46 – eng cylinder head 5. Remove: • cylinder head note: • loosen the 6 mm bolts first. • working in a crisscross pattern, loosen each 10-mm bolt 1/4 of a turn. After all the bolts are loosened, remove them. Installing the cylinder head 1. Install: • cylinder head • bolt (m10) • bolt (m6) note: • l...

Page 54: – 47 –

– 47 – eng cylinder head note: be sure the “i” mark 5 on the camshaft sprocket is aligned with the match mark 2 on the cylinder head. F. Force the camshaft clockwise and counter- clockwise to remove timing chain slack. G. Insert a screwdriver into the timing chain tensioner hole and push the timing ...

Page 55: – 48 –

– 48 – eng cylinder head 4. Tighten: • camshaft sprocket bolt 1 note: when tightening the bolt, use a wrench 2 to hold the collar. 5. Check: • camshaft sprocket “i” mark • rotor “t” mark out of alignment → adjust. T r . . 60 nm (6.0 m · kg, 43 ft · lb).

Page 56: – 49 –

– 49 – eng a.C. Magneto a.C. Magneto order job/part q’ty remarks removing the a.C. Magneto remove the parts in the order below. Engine oil drain. Refer to “changing the engine oil” in chapter 3. (manual no.: 5nd2-ae1) seat refer to “seat, fenders and fuel tank”. Left footrest board refer to “footres...

Page 57: – 50 –

– 50 – eng a.C. Magneto order job/part q’ty remarks 7 pickup coil 1 8 stator assembly 1 9 rotor 1 refer to “removing the a.C. Mag- neto” and “installing the a.C. Magneto”. 10 starter wheel gear 1 11 woodruff key 1 12 washer 1 13 starter idle gear shaft 1 14 washer/bearing 1/1 15 starter idle gear 1 ...

Page 58: – 51 –

– 51 – eng a.C. Magneto removing the a.C. Magneto 1. Remove: • collar 1 note: when loosening the rotor bolt, use a wrench 2 to hold the collar. 1 2 2. Remove: • a.C. Magneto cover • gasket • dowel pins note: working in a crisscross pattern, loosen each bolt 1/4 of a turn. Remove them after all of th...

Page 59: – 52 –

– 52 – eng a.C. Magneto 3. Install: • dowel pins • gasket • a.C. Magneto cover note: • when installing the a.C. Magneto cover, use a long rod to hold the rotor in position from the outside. This will make assembly easier. Be careful not to damage the oil seal. • tighten the bolts in stages, using a ...

Page 60: – 53 –

– 53 – eng crankcase crankcase starter motor, timing chain and oil filter order job/part q’ty remarks removing the starter motor, timing chain and oil filter remove the parts in the order below. Engine assembly refer to “engine removal” in chapter 4. (manual no.: 5nd2-ae1) cylinder head refer to “cy...

Page 61: – 54 –

– 54 – eng crankcase order job/part q’ty remarks 1 oil pump drive gear/straight key 1/1 refer to “removing the oil pump drive gear” and “installing the oil pump drive gear” in chapter 4. (manual no.: 5nd2-ae1) 2 oil pump driven gear 1 3 timing chain guide 1 4 timing chain 1 5 starter motor/o-ring 1/...

Page 62: – 55 –

– 55 – eng crankcase order job/part q’ty remarks 13 bearing cover/gasket 1/1 14 oil delivery pipe 1 15 oil strainer cover/o-ring 1/1 16 compression spring 1 17 oil strainer 1 for installation, reverse the removal pro- cedure..

Page 63: – 56 –

– 56 – eng transmission transmission order job/part q’ty remarks removing the transmission remove the parts in the order below. Crankcase separation refer to “crankcase” in chapter 4. (manual no.: 5nd2-ae1) 1 driven sprocket 1 2 chain 1 3 guide bar 1 4 shift fork 1 5 spring 1 6 clutch dog 1 7 low wh...

Page 64: – 57 –

– 57 – eng transmission order job/part q’ty remarks 11 shift cam 1 12 middle drive gear 1 13 stopper wheel 1 14 stopper lever 1 15 stopper lever shaft 1 16 spacer 1 for installation, reverse the removal pro- cedure..

Page 65: – 58 –

– 58 – eng middle gear middle gear middle driven shaft order job/part q’ty remarks removing the middle driven shaft remove the parts in the order below. Crankcase separation refer to “crankcase” in chapter 4. (manual no.: 5nd2-ae1) 1 circlip 2 refer to “removing the middle driven shaft” and “install...

Page 66: – 59 –

– 59 – eng middle gear order job/part q’ty remarks 9 damper cam 1 10 spring 1 11 gear coupling 1 12 front drive shaft coupling 1 13 bearing retainer 1 14 middle driven shaft 1 for installation, reverse the removal pro- cedure..

Page 67: – 60 –

– 60 – cool cooling system radiator 8 (4) 5 6 7 1 4 2 9 3 t r . . 7 nm (0.7 m • kg, 5.1 ft • ib) t r . . 8 nm (0.8 m • kg, 5.8 ft • ib) order job/part q’ty remarks removing the radiator remove the parts in the order below. Front guard/front fender/headlights/ front grill refer to “seat, fenders and ...

Page 68: – 61 –

– 61 – cool radiator 8 (4) 5 6 7 1 4 2 9 3 t r . . 7 nm (0.7 m • kg, 5.1 ft • ib) t r . . 8 nm (0.8 m • kg, 5.8 ft • ib) order job/part q’ty remarks 8 fan motor 1 9 thermo switch 2 1 for installation, reverse the removal pro- cedure..

Page 69: – 62 –

– 62 – driv drive train front constant velocity joints and differential gear order job/part q’ty remarks removing the front constant veloc- ity joints and differential gear remove the parts in the order below. Engine skid plate/front fender refer to “seat, fenders and fuel tank”. Differential gear o...

Page 70: – 63 –

– 63 – driv front constant velocity joints and differential gear order job/part q’ty remarks 3 differential gear case breather hose 1 disconnect. 4 differential gear assembly 1 5 front drive shaft 1 6 compression spring 1 7 front drive shaft coupling 1 for installation, reverse the removal pro- cedu...

Page 71: – 64 –

– 64 – driv front constant velocity joints and differential gear order job/part q’ty remarks disassembling the constant velocity joints remove the parts in the order below. 1 circlip 1 2 boot band 2 refer to “assembling the front constant velocity joints”. 3 boot band 2 4 dust boot 2 5 circlip 1 6 d...

Page 72: – 65 –

– 65 – driv front constant velocity joints and differential gear order job/part q’ty remarks disassembling the differential gear remove the parts in the order below. 1 gear motor/o-ring 1/1 2 four-wheel drive switch 1 3 dust seal 1 4 circlip 1 5 coupling gear/bearing/circlip 1/1/1 6 stopper bolt/sha...

Page 73: – 66 –

– 66 – driv front constant velocity joints and differential gear order job/part q’ty remarks c shim (right) d circlip/bearing 1/1 e drive pinion gear 1 f differential gear case 1 for assembly, reverse the disassembly procedure..

Page 74: – 67 –

– 67 – driv front constant velocity joints and differential gear disassembling the differential gear 1. Remove: • differential gear unit 1 caution: the differential gear unit is assembled into a proper unit at the factory by means of specialized equipment. Do not attempt to disassemble this unit. Di...

Page 75: – 68 –

– 68 – driv front constant velocity joints and differential gear checking the differential gear 1. Check: • gear teeth pitting/galling/wear → replace drive pinion gear and differential gear unit as a set. • bearings pitting/damage → replace. • oil seal • o-ring damage → replace. 2. Check: • drive sh...

Page 76: – 69 –

– 69 – driv front constant velocity joints and differential gear b. Install the dust boots. C. Install the dust boot bands. Note: • the new boot bands may differ from the orig- inal ones. • the dust boots should be fastened with the dust boot bands 3 at the grooves in the joint shaft. ▲▲▲ ▲ ▲ ▲▲▲ ▲ ...

Page 77: – 70 –

– 70 – driv front constant velocity joints and differential gear 3. Check: • differential gear assembly operation unsmooth operation → replace the differ- ential gear assembly. Insert the double off-set joint into the differ- ential gear, and turn the gear back and forth. Measuring and adjusting the...

Page 78: – 71 –

– 71 – driv front constant velocity joints and differential gear 5. Measure: • gear lash gently rotate the gear coupling from engagement to engagement . Note: measure the gear lash at four positions. Rotate the shaft 90° each time. Differential gear lash 0.10 ~ 0.50 mm (0.004 ~ 0.020 in) adjusting d...

Page 79: – 72 –

– 72 – driv front constant velocity joints and differential gear c. If it is necessary to reduce by more than 0.1 mm (0.004 in): increase right shim thickness by 0.1 mm (0.004 in) for every 0.1 mm of left shim decrease. ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲ ▲▲▲ ▲ ▲▲▲ ring gear shim (left and right...

Page 80: – 73 –

– 73 – driv rear axle/final drive gear and drive shaft rear axle/final drive gear and drive shaft order job/part q’ty remarks removing the rear axle, final drive gear assembly and drive shaft remove the parts in the order below. Final gear oil drain. Refer to “changing the final gear oil” in chapter...

Page 81: – 74 –

– 74 – chas chassis front and rear wheels front wheels order job/part q’ty remarks removing the front wheels remove the parts in the order below. Place the vehicle on a level surface. Warning securely support the vehicle so there is no danger of it falling over. 1 front wheel 1 refer to “installing ...

Page 82: – 75 –

– 75 – chas front and rear wheels order job/part q’ty remarks 6 wheel hub 1 7 brake disc 1 for installation, reverse the removal pro- cedure..

Page 83: – 76 –

– 76 – chas front and rear wheels rear wheels order job/part q’ty remarks removing the rear wheels remove the parts in the order below. Place the vehicle on a level surface. Warning securely support the vehicle so there is no danger of it falling over. 1 rear wheel 2 refer to “installing the wheel” ...

Page 84: – 77 –

– 77 – chas front and rear wheels order job/part q’ty remarks 8 brake disc 1 refer to “installing the rear brake disc”. 9 brake disc guard 1 for installation, reverse the removal pro- cedure..

Page 85: – 78 –

– 78 – chas front and rear wheels installing the rear brake disc 1. Install: • brake disc 1 note: • make sure that the “out” mark on the brake disc faces the brake disc bracket 2. • apply locking agent (loctite ® ) to the threads of brake disc bolts. T r . . 28 nm (2.8 m · kg, 20 ft · lb).

Page 86: – 79 –

– 79 – chas front and rear brakes front and rear brakes rear brake master cylinder order job/part q’ty remarks removing the rear brake master cyl- inder remove the parts in the order below. Front fender refer to “seat, fenders and fuel tank”. Brake fluid drain. 1 brake fluid reservoir cap 1 2 brake ...

Page 87: – 80 –

– 80 – chas front and rear brakes order job/part q’ty remarks 10 brake cable 1 disconnect. 11 bracket 1 12 brake master cylinder 1 13 hose joint 1 14 brake pedal 1 15 select lever control cable 1 disconnect. 16 rear brake light switch 1 17 bracket 1 18 brake master cylinder bracket 1 for installatio...

Page 88: – 81 –

– 81 – chas steering system steering system steering stem order job/part q’ty remarks removing the steering stem remove the parts in the order below. Handlebar refer to “handlebar” in chapter 8. (manual no.: 5nd2-ae1) seat/front fender refer to “seat, fenders and fuel tank”. Radiator refer to “radia...

Page 89: – 82 –

– 82 – chas steering system order job/part q’ty remarks 8 steering stem nut 1 9 pitman arm 1 10 steering stem 1 11 oil seal 1 12 bearing retainer 1 refer to “removing the bearing retainer” and “installing the bearing retainer” in chapter 8. (manual no.: 5nd2-ae1) 13 bearing 1 14 oil seal 1 for insta...

Page 90: – 83 –

– 83 – chas steering system tie rod and steering knuckle order job/part q’ty remarks removing the tie rod and steering knuckle remove the parts in the order below. Front fender refer to “seat, fenders and fuel tank”. Front wheel/brake disc refer to “front and rear wheels”. 1 tie rod 1 refer to “inst...

Page 91: – 84 –

– 84 – chas steering system order job/part q’ty remarks 8 steering knuckle 1 refer to “removing the steering knuckle” in chapter 8. (manual no.: 5nd2-ae1) 9 oil seal 1 10 oil seal 1 11 bearing 2 12 spacer 1 13 circlip 1 14 rubber boot 1 15 ball joint 1 for installation, reverse the removal pro- cedu...

Page 92: – 85 –

– 85 – chas front arms and front shock absorbers front arms and front shock absorbers order job/part q’ty remarks removing the front arms and front shock absorbers remove the parts in the order below. Engine skid plate/front fender refer to “seat, fenders and fuel tank”. Front wheel/brake disc refer...

Page 93: – 86 –

– 86 – chas front arms and front shock absorbers order job/part q’ty remarks 5 nut 1 refer to “removing the front arms” and “installing the front arms and front shock absorber” in chapter 8. (manual no.: 5nd2-ae1) 6 nut 1 7 bolt/nut 2/2 8 front lower arm/bushing 1/2 9 nut/bolt 2/2 10 front shock abs...

Page 94: – 87 –

– 87 – chas rear shock absorber and swingarm rear shock absorber and swingarm order job/part q’ty remarks removing the rear shock absorber and swingarm remove the parts in the order below. Rear wheel hubs/brake disc refer to “front and rear wheels”. Rear brake caliper/brake hose refer to “front and ...

Page 95: – 88 –

– 88 – chas rear shock absorber and swingarm order job/part q’ty remarks 7 rear axle housing 1 refer to “installing the rear axle housing” in chapter 8. (manual no.: 5nd2-ae1) 8 nut/bolt 2/2 refer to “removing the swing- arm” in chapter 8. (manual no.: 5nd2-ae1) 9 swingarm/bushing 1/2 10 spring/rubb...

Page 96: – 89 –

– 89 – – + elec eb800000 electrical electrical components 1 main switch 2 front brake light switch 3 rear brake switch 4 thermo switch 1 5 battery 6 tail/brake light 7 headlight relay 8 fuse box 9 main fuse 0 starter relay a cdi unit b rectifier/regulator c reverse switch d park switch e neutral swi...

Page 97: – 90 –

– 90 – – + elec checking the switch checking the switch checking the switch continuity refer to “checking the switch” and check for continuity between lead terminals. Poor connection, no continuity → correct or replace. * the coupler locations are circled. L b y g br l/b (black) 1 4 5 c 6 2 3 r/b r/...

Page 98: – 91 –

– 91 – – + elec checking the switch 1 light switch 2 engine stop switch 3 start switch 4 on-command four-wheel drive switch 5 main switch 6 rear brake light switch 7 front brake light switch 8 rear brake switch 9 four-wheel drive switch 0 reverse switch a park switch b neutral switch c fuse.

Page 99: – 92 –

– 92 – – + elec electric starting system eb803000 electric starting system circuit diagram (black) r /b c lb bl yb r bb b /y b bb c wire harness sub-wire harness 3 b /rl /b b br /w sb r /b b l /bb /r r /b sb br /w br y l l /b gb ws b g /l l/ rb /rw /l g /l sb w w /lb /rl /r w /g r w /rw /g r w /g w ...

Page 100: – 93 –

– 93 – – + elec lighting system eb805000 lighting system circuit diagram (black) r /b c lb bl yb r bb b /y b bb c wire harness sub-wire harness 3 b /rl /b b br /w sb r /b b l /bb /r r /b sb br /w br y l l /b gb ws b g /l l/ rb /rw /l g /l sb w w /lb /rl /r w /g r w /rw /g r w /g w /l w /r rb r r br ...

Page 101: – 94 –

– 94 – – + elec lighting system eb805010 troubleshooting procedure check: 1. Fuses (main, headlight) 2. Battery 3. Main switch 4. Light switch 5. Headlight relay 6. Wiring connections (the entire lighting system) if the headlight and/or taillight fail to come on: note: • remove the following part(s)...

Page 102: – 95 –

– 95 – – + elec lighting system correct 4. Light switch refer to “checking the switch”. * incorrect replace the handlebar switch (left). Continuity 5. Headlight relay • remove the headlight relay from the wire harness. • connect the pocket tester ( Ω × 1) and the battery (12 v) to the headlight rela...

Page 103: – 96 –

– 96 – – + elec signaling system eb806000 signaling system circuit diagram (black) r /b c lb bl yb r bb b /y b bb c wire harness sub-wire harness 3 b /rl /b b br /w sb r /b b l /bb /r r /b sb br /w br y l l /b gb ws b g /l l/ rb /rw /l g /l sb w w /lb /rl /r w /g r w /rw /g r w /g w /l w /r rb r r b...

Page 104: – 97 –

– 97 – – + elec signaling system 3 main switch 4 backup fuse 5 battery 6 main fuse 0 cdi unit c speed sensor e multi-function meter f neutral indicator light g reverse indicator light h park indicator light i four-wheel drive indicator light j coolant temperature warning light k reverse switch l neu...

Page 105: – 98 –

– 98 – – + elec signaling system checking the signaling system eb806024 1. If the indicator lights fail to come on: continuity 1. Neutral switch refer to “checking the switch”. No continuity replace the neutral switch. Continuity 2. Park switch refer to “checking the switch”. No continuity replace t...

Page 106: – 99 –

– 99 – – + elec 2wd/4wd selecting system 2wd/4wd selecting system circuit diagram (black) r /b c lb bl yb r bb b /y b bb c wire harness sub-wire harness 3 b /rl /b b br /w sb r /b b l /bb /r r /b sb br /w br y l l /b gb ws b g /l l/ rb /rw /l g /l sb w w /lb /rl /r w /g r w /rw /g r w /g w /l w /r r...

Page 107: – 100 –

– 100 – – + elec 2wd/4wd selecting system eb803020 troubleshooting procedure check: 1. Fuses (main, four-wheel drive) 2. Battery 3. Main switch 4. On-command four-wheel drive switch 5. Gear motor 6. Wiring connections (the entire 2wd/4wd selecting system) if the gear motor fails to operate: note: • ...

Page 108: – 101 –

– 101 – – + elec 2wd/4wd selecting system correct 4. On-command four-wheel drive switch refer to “checking the switch”. * incorrect replace the on-command four-wheel drive switch. Correct 5. Gear motor • check that the shift fork sliding gear is in the 2wd position. • disconnect the gear motor coupl...

Page 109: – 102 –

– 102 – – + elec 2wd/4wd selecting system eb803028 correct 6. Wiring connections • check the connections of the entire 2wd/ 4wd selecting system. Refer to “circuit diagram”. This circuit is not faulty. * poor connection properly connect the 2wd/4wd selecting system..

Page 110

Yfm45fxv 2006 wiring diagram 1 a.C. Magneto 2 rectifier/regulator 3 main switch 4 backup fuse 5 battery 6 main fuse 7 starter relay 8 starter motor 9 diode 0 cdi unit a ignition coil b spark plug c speed sensor d meter assembly e multi-function meter f neutral indicator light g reverse indicator lig...

Page 111

Yamaha motor co., ltd. 2500 shingai iwata shizuoka japan.

Page 112

Yfm45fxv 2006 wiring diagram yfm45fxv 2006 schÉma de cblage (black) r/b c l b b l y br b b b/y b b b c wire harness sub-wire harness 3 b/r l/b b br/w sb r/b b l/b b/r r/b sb br/w br y l l/b g b w sb g/l l/r b/r w/l g/l sb w w/l b/r l/r w/g r w/r w/g r w/g w/l w/r r br r br/l br r/w br/l r r l/w l/b ...