- DL manuals

- Yamaha

- Bicycle

- X94 Series

- Service Manual

Yamaha X94 Series Service Manual

Summary of X94 Series

Page 1

Service manual e-bike systems x94 series.

Page 2: How to Use This Manual

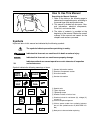

How to use this manual searching for manual contents 1. Refer to the table on the following page to determine the applicable parts according to the model type code and product code. 2. This manual is divided into four parts: gen- eral information, electrical components, drive unit, and service data....

Page 3

List of pa rt ty pes an d includ ed crank p arts acco rdi ng to the model ty pe code and produc t code *1: i n t h e d iag nosis se ct ion , r e fe r to t he a pplicab le pa ges accor d ing t o t h e t y pe o f me te r displa y un it . *2: for the illustrations and contents for di s a s s embling th...

Page 5: General Information

Index general information gen info 1 electrical components elec 2 drive unit drive unit 3 service data service data 4 – +.

Page 6: Contents

Contents chapter 1 general information description ................................................................................................... P1-1 precautions relating to maintenance (1).................................................... P1-2 cleaning and maintenance .........................

Page 7

Diagnosis function .............................................................................. P2-39 speed sensor set ....................................................................................... P2-45 speed sensor inspection ................................................................

Page 8: General Information

1-1 gen info general information description 1. Drive unit 2. Speed sensor set a) magnet sensor spoke type b) pick up 3. È display unit (led type) É display unit (lcd type) a) display (detachable) b) display holder c) switch 4. Battery charger 5. Battery pack (the battery may differ depend- ing on t...

Page 9

1-2 gen info precautions relating to maintenance (1) precautions relating to maintenance (1) cleaning and maintenance notice when washing the bicycle, keep water away from the e-bike system. Water which comes in direct contact with the e-bike system can get inside and reduce performance. Steam clean...

Page 10

1-3 gen info precautions relating to maintenance (1) replacement parts replace gaskets (packing), o-rings, cotter pins, circlips (split rings), lock washers, etc. With new parts. Be sure to use genuine new yamaha parts and recommended parts for oils and greases, including periodic replacement parts ...

Page 11

1-4 gen info precautions relating to maintenance (1) handling the battery pack 1. Use the dedicated battery charger for charging the battery pack. 2. The battery pack is a dedicated e-bike sys- tem battery. If it is connected to a product other than the e-bike system, it will cause a fluid leakage, ...

Page 12

1-5 gen info servicing precautions (2) servicing precautions (2) bearing installation 1. When installing a bearing, the surface with the manufacturer’s mark and the size code should face outward. 2. When striking a bearing into the case, apply a parallel force to the outer race. 3. When striking a b...

Page 13

1-6 gen info precautions relating to maintenance (3) precautions relating to maintenance (3) handling of the torque sensor 1. Keep away from magnets. Do not use magnetized screwdrivers or per- form maintenance near large sources of electric power. 2. Avoid strong mechanical impact. Torque sensors wh...

Page 14

1-7 gen info specialized tools and equipment specialized tools and equipment the appropriate specialized tools must be used for inspection, adjustment, disassembly, and reas- sembly. Maintenance problems and mechanical breakage can be prevented by using the appropriate spe- cialized tools. Lithium s...

Page 15: Electrical Components

2-1 elec – + electrical components electrical component wiring diagram t o ba tter y wire lead 2 b or p w r gy br l b y b r gy w g l sb g b r gy b r l sb r speed sensor t o light displa y unit (lcd type) displa y unit (led type) wire lead 1 wire lead 3 wire lead 5 wire lead 4 y y l w rb w l t o mot ...

Page 16

2-2 elec – + battery pack battery pack battery pack display function by holding down the battery capacity indicator button “ ” on the battery pack, the following items can be checked. Length of time that the button is pushed display item display time details page when pushed normal state: residual b...

Page 17

2-3 elec – + battery pack 3. If the battery capacity indicator lamps [1] and [4] are fast flash simultaneously when the battery capacity indicator button “ ” is pushed or connect the battery charger, see “non-recoverable errors of battery pack”. (p. 2-10) 3 2 1 4 off fast flashing 4. If all four bat...

Page 18

2-4 elec – + battery pack how to check the total number of battery charging cycles check the total number of battery charging cycles as follows: 1. Hold down the battery capacity indicator button “ ” 1 for 20 seconds. 2. The total number of battery charging cycles is indicated by the four battery ca...

Page 19

2-5 elec – + battery pack how to check the absolute battery capacity check the * 1 absolute battery capacity as fol- lows: 1. Hold down the battery capacity indicator button “ ” 1 for 30 seconds. 2. The * 1 absolute battery capacity is indicated by the four battery capacity indicator lamps 2 on the ...

Page 20

2-6 elec – + charging charging e-bike system dedicated battery charger this battery charger 1 is a dedicated battery charger for the e-bike system’s battery pack. 1 3 2 1 4 3 2 1 4 3 2 1 4 3 2 1 4 3 2 1 4 3 2 1 4 charging time preliminary charging when starting charge from a discharged state slow fl...

Page 21

2-7 elec – + charging display on battery capacity indicator lamps while charging some phenomena such as the following may occur while charging the battery pack, depend- ing on the battery pack’s state; however, these are not malfunctions. 1. Charging on stand-by display on the battery capacity indic...

Page 22

2-8 elec – + diagnosis mode diagnosis mode recoverable errors of battery pack or battery charger if the battery pack or battery charger has the errors, the following procedure can be used to access the error diagnosis mode and confirm the details regarding the error of the battery pack or battery ch...

Page 23

2-9 elec – + diagnosis mode list of ba ttery pack /battery ch arger diagnos is items o ff on battery c a pa city indica- tor la mps battery ca pac ity indicator lamps fa ul t de vi ce fa il u re a cti o n 1/3 and 2/4 turn on alter- na tel y ho ld do wn the ba ttery capacity indica to r bu tt o n “ ”...

Page 24

2-10 elec – + diagnosis mode 1/2 and 3/4 turn on alter- na tel y ho ld do wn the ba ttery capacity indica to r bu tt o n “ ” for 10 sec- o nds battery charge r fa ilure overcharg- in g durin g ch ar gi n g rep lace the ba ttery ch arger. The battery pack will return to the n o rma l sta te, afte r t...

Page 25

2-11 elec – + non-recoverable errors of battery pack if the battery pack has the errors, the following procedure can be used to access the error diagnosis mode and confirm the details regarding the error of the battery pack. 1. If there is a non-recoverable errors when the battery capacity indicator...

Page 26

2-12 elec – + diagnosis mode off on fast flashin g batter y ca pa city display la mp battery ca pac ity displa y lamp fa ul t de vi ce fa il u re a cti o n 1 and 4 flash r a pidly ho ld do wn the resi dual ba tt e ry capacity indica to r bu tt o n “ ” for 10 sec- o nds fet fa ilure rep lace the ba t...

Page 27

2-13 elec – + diagnosis mode when the battery pack signal lead wire becomes disconnected although the power to the display unit is turned on, • all of the led displays of the display unit (led type) turn on for 4 seconds, and then the power turns off automatically (led) È • all segments of the displ...

Page 28

2-14 elec – + diagnosis mode temperature protection function if the battery pack’s internal temperature is -20°c or less or 80°c or higher while the battery pack is discharging (during the power assist), the tem- perature protection function of the battery pack operates and the battery pack stops di...

Page 29

2-15 elec – + diagnosis mode over-discharge protection function if the battery pack becomes over-discharged, the over-discharge protection function of the battery pack operates. If the battery capacity indicator button “ ” is pushed at this time, the battery capacity indi- cator lamps do not turn on...

Page 30

2-16 elec – + replace the battery pack the led lamps [1] and [4] are flashing rapidly at the same time. The led lamp [1] is flashing rap- idly. The led lamp [3] is illuminate. The led lamp [3] is illuminate. The led lamps [1]/[2] and [3]/[4] are turn on alternately. If the battery pack does not retu...

Page 31

2-17 elec – + diagnosis function (led type display unit) diagnosis function (led type display unit) display unit’s display when there is an error detects system malfunctions, changes assist operation, and displays the errors as well as performing error code recording. Error displays are indicated by...

Page 32

2-18 elec – + diagnosis function (led type display unit) how drive unit malfunctions are displayed the 3 assist mode lamps 1, the “%” lamp 2, the “km” lamp 3, and the “km/h” lamp 4 will flash alternately, and “er” will be displayed on the function display 5 of the display unit. When the function sel...

Page 33

2-19 elec – + diagnosis function (led type display unit) operating procedures to diagnosis mode this is the mode in which each type of diagno- sis and the content of error codes which are stored when there is an error are displayed. You can switch between speed sensor diagno- sis mode, drive unit di...

Page 34

2-20 elec – + diagnosis function (led type display unit) speed sensor diagnosis mode press the assist mode switch “ ” 1 until the “high” assist mode lamp is illuminated. Press the light switch “ ”. The “high” assist mode lamp flashes rapidly (0.2 second). For more information about the speed sensor ...

Page 35

2-21 elec – + diagnosis function (led type display unit) speed sensor diagnosis mode display method to determine if the controller is correctly rec- ognizing the speed sensor signal, rotate the wheel to which the speed sensor is connected and make sure that the number of rotations of the wheel indic...

Page 36

2-22 elec – + diagnosis function (led type display unit) drive unit diagnosis mode display method you can check the status of or malfunctions in the drive unit. 1. Go into drive unit diagnosis mode. See “operating procedures to diagnosis mode.” confirm that the “std” of the assist mode lamps is flas...

Page 37

2-23 elec – + diagnosis function (led type display unit) 1. Torque sensor reference voltage display a. “10” is displayed in the diagnosis mode dis- play 1 of the display unit. B. Press the function select switch “ ” of the display unit. C. Displayed in units of 0.1 v from 0.0 to 5.0 v in the diagnos...

Page 38

2-24 elec – + diagnosis function (led type display unit) a. “14” is displayed in the diagnosis mode dis- play 1 of the display unit. B. Press the function select switch “ ” button of the display unit. C. The diagnosis data display 2 of the display unit displays the motor output current (%) from “00”...

Page 39

2-25 elec – + diagnosis function (led type display unit) a. “16” is displayed in the diagnosis mode dis- play 1 of the display unit. B. Press the function select switch “ ” of the display unit. C. When there is a malfunction, “e2” (motor) or “e4” (controller) will be displayed on the diagnosis data ...

Page 40

2-26 elec – + diagnosis function (led type display unit) error log check mode display method the three most recent types of error codes which are stored when there is an error are stored and these are displayed in order from the most recent every 10 seconds. 1. Go into error log check mode. See “ope...

Page 41

2-27 elec – + diagnosis function (led type display unit) how to delete the malfunction history 1. While pressing the light switch “ ” 1 dur- ing the error code display, press the assist mode switch power assist decrease 2 and power assist increase 3 to switch. 1 3 2 2. The diagnostic display pattern...

Page 42

2-28 elec – + diagnosis function (lcd type display unit) diagnosis function (lcd type display unit) display unit’s display when there is an error detects system malfunctions, changes assist operation, and displays the errors as well as performing error code recording. Error displays are indicated by...

Page 43

2-29 elec – + diagnosis function (lcd type display unit) how drive unit malfunctions are displayed all segments of the assist mode indicator 1 and all segments of the battery capacity indi- cator 2 will flash alternately, and “er” will be displayed on the speedometer section 3 of the display unit. W...

Page 44

2-30 elec – + diagnosis function (lcd type display unit) operating procedures to diagnosis mode this is the mode in which each type of diagno- sis and the content of error codes which are stored when there is an error are displayed. You can switch between speed sensor diagno- sis mode, drive unit di...

Page 45

2-31 elec – + diagnosis function (lcd type display unit) speed sensor diagnosis mode press the assist mode switch “ ” 1 until the “high” assist mode indicator comes on. Press the light switch “ ” 3. The “high” assist mode indicator flashes rap- idly (0.2 second). For more information about the speed...

Page 46

2-32 elec – + diagnosis function (lcd type display unit) speed sensor diagnosis mode display method to determine if the controller is correctly rec- ognizing the speed sensor signal, rotate the wheel to which the speed sensor is connected and make sure that the number of rotations of the wheel indic...

Page 47

2-33 elec – + diagnosis function (lcd type display unit) drive unit diagnosis mode display method you can check the status of or malfunctions in the drive unit. 1. Go into drive unit in diagnosis mode. See “operating procedures to diagnosis mode.” confirm that the assist mode display is flashing “st...

Page 48

2-34 elec – + diagnosis function (lcd type display unit) 1. Torque sensor reference voltage display a. “10” is displayed in the diagnosis mode dis- play 1 of the display unit. B. Press the function select switch “s” of the display unit. C. Displayed in units of 0.1 v from 0.0 to 5.0 v in the diagnos...

Page 49

2-35 elec – + diagnosis function (lcd type display unit) a. “14” is displayed in the diagnosis mode dis- play 1 of the display unit. B. Press the function select switch “s” of the display unit. C. The diagnosis data display 2 of the display unit displays the motor output current (%) from “0” to “100...

Page 50

2-36 elec – + diagnosis function (lcd type display unit) a. “16” is displayed in the diagnosis mode dis- play 1 of the display unit. B. Press the function select switch “s” of the display unit. C. When there is a malfunction, “e2” (motor) or “e4” (controller) will be displayed on the diagnosis data ...

Page 51

2-37 elec – + diagnosis function (lcd type display unit) error log check mode display method the three most recent types of error codes which are stored when there is an error are stored and these are displayed in order from the most recent every 10 seconds. 1. Go into error log check mode. See “ope...

Page 52

2-38 elec – + diagnosis function (lcd type display unit) how to delete the malfunction history 1. While pressing the light switch “ ” 1 dur- ing the error code display, press the assist mode switch power assist decrease 2 and power assist increase 3 to switch. 2 3 1 fast flashing 2. The diagnostic d...

Page 53

2-39 elec – + diagnosis function (lcd type display unit) dia gnosis function list of error code s and c o rres ponding power a ssist op erations. D isplay pa tte rn fa ul t d e vi ce er ro r cod e s fa ul t d e tai ls power ass is t behavior a n d e rror code rec o rd *r estoration ma x lev e l acti...

Page 54

2-40 elec – + diagnosis function (lcd type display unit) torque s e n- sor 23 abno rma l vo ltage . (detected du ri ng runn ing / w ith sl ight voltage r ise) powe r assist will stop afte r determine the error. Error c o de will record. 2 1. P e rf or m the torque sen s or re f- eren ce v o ltage a ...

Page 55

2-41 elec – + diagnosis function (lcd type display unit) crank sen- sor 32 to rque sen s o r o r crank senso r failu re. Powe r assist will stop afte r determine the error. Error c o de will record. 1 1. Rep lace the torque sen s or . 2. Rep lace the cr an k sen s or . 3. Rep lace the enco rder lead...

Page 56

2-42 elec – + diagnosis function (lcd type display unit) motor or co ntrolle r 50 abno rma l vo ltage of th e sen- sor for u phase current while the motor is no t op erating . Powe r assi st will i m med iately sto p after determine the error. Error c o de will record. 1 r epl ace th e controlle r a...

Page 57

2-43 elec – + diagnosis function (lcd type display unit) motor or co ntrolle r 80 detected circui t boa rd temp er- ature is to o low. (–20°c) powe r assist will stop afte r determine the error. Error c o de will record. 2 r epl ace th e controlle r a s se mb ly. 81 detected circui t boa rd temp er-...

Page 58

2-44 elec – + diagnosis function (lcd type display unit) *restoration max le vel: assist m o de lamps 1 are d ispla yed with a slow fla s hes. Func tion displays 2 are displayed with “--- -”. Sp eed sen - sor – th e vehicl e sp eed ha s n o t go ne out th ough the motor is rotating. Powe r assi st b...

Page 59

2-45 elec – + speed sensor set speed sensor set speed sensor inspection 1. Pickup • check that the pickup is installed at the specified location on the bike. • check that the pickup is not damaged. 2. Magnet sensor a. Check that the magnet sensor is not dam- aged. B. Check that no metallic foreign m...

Page 60: Drive Unit

3-1 drive unit drive unit drive axle, motor (drive axle with square-type end) fwd fw d 1 11 12 13 31 32 10 30 29 25 22 19 21 20 26 27 28 18 17 16 23 24 33 7 6 5 2 3 4 8 9 14 15 ls new new 4.5 nm (0.45 kgf • m) t.R . 40 nm (4.0 kgf • m) t.R. 1.3 nm (0.13 kgf • m) t.R. 0.75 nm (0.075 kgf • m) t.R . 4....

Page 61

3-2 drive unit drive axle, motor (drive axle with square-type end) fwd fw d 1 11 12 13 31 32 10 30 29 25 22 19 21 20 26 27 28 18 17 16 23 24 33 7 6 5 2 3 4 8 9 14 15 ls new new 4.5 nm (0.45 kgf • m) t.R . 40 nm (4.0 kgf • m) t.R. 1.3 nm (0.13 kgf • m) t.R. 0.75 nm (0.075 kgf • m) t.R . 4.5 nm (0.45 ...

Page 62

3-3 drive unit drive axle, motor (drive axle with square-type end) fwd fw d 1 11 12 13 31 32 10 30 29 25 22 19 21 20 26 27 28 18 17 16 23 24 33 7 6 5 2 3 4 8 9 14 15 ls new new 4.5 nm (0.45 kgf • m) t.R . 40 nm (4.0 kgf • m) t.R. 1.3 nm (0.13 kgf • m) t.R. 0.75 nm (0.075 kgf • m) t.R . 4.5 nm (0.45 ...

Page 63

3-4 drive unit drive axle, motor (drive axle with square-type end) fwd fw d 1 11 12 13 31 32 10 30 29 25 22 19 21 20 26 27 28 18 17 16 23 24 33 7 6 5 2 3 4 8 9 14 15 ls new new 4.5 nm (0.45 kgf • m) t.R . 40 nm (4.0 kgf • m) t.R. 1.3 nm (0.13 kgf • m) t.R. 0.75 nm (0.075 kgf • m) t.R . 4.5 nm (0.45 ...

Page 64

3-5 drive unit drive axle, motor (drive axle with spline-type end [isis]) drive axle, motor (drive axle with spline-type end [isis]) fwd fw d 3 2 2 1 1 11 12 13 31 32 10 30 29 25 22 19 21 20 26 27 28 18 17 16 23 24 33 4 8 9 14 15 new new ls 7 6 5 4.5 nm (0.45 kgf • m) t.R . 40 nm (4.0 kgf • m) t.R ....

Page 65

3-6 drive unit drive axle, motor (drive axle with spline-type end [isis]) fwd fw d 3 2 2 1 1 12 13 14 32 33 11 31 30 26 23 20 22 21 27 28 29 19 18 17 24 25 34 8 7 6 5 4 9 10 15 16 ls new new new 4.5 nm (0.45 kgf • m) t.R . 40 nm (4.0 kgf • m) t.R . 1.7 nm (0.17 kgf • m) t.R. 0.75 nm (0.075 kgf • m) ...

Page 66

3-7 drive unit drive axle, motor (drive axle with spline-type end [isis]) fwd fw d 3 2 2 1 1 12 13 14 32 33 11 31 30 26 23 20 22 21 27 28 29 19 18 17 24 25 34 8 7 6 5 4 9 10 15 16 ls new new new 4.5 nm (0.45 kgf • m) t.R . 40 nm (4.0 kgf • m) t.R . 1.7 nm (0.17 kgf • m) t.R. 0.75 nm (0.075 kgf • m) ...

Page 67

3-8 drive unit drive axle, motor (drive axle with spline-type end [isis]) fwd fw d 3 2 2 1 1 12 13 14 32 33 11 31 30 26 23 20 22 21 27 28 29 19 18 17 24 25 34 8 7 6 5 4 9 10 15 16 ls new new new 4.5 nm (0.45 kgf • m) t.R . 40 nm (4.0 kgf • m) t.R . 1.7 nm (0.17 kgf • m) t.R. 0.75 nm (0.075 kgf • m) ...

Page 68

3-9 drive unit drive axle, motor removal of the parts from the drive axle (drive axle with square-type end) 1. Remove the following parts: • locknut (left-hand screw) • drive sprocket or spider • spacer (for sprocket only) • flanged bolt removal of the parts from the drive axle (drive axle with spli...

Page 69

3-10 drive unit drive axle, motor 2. Remove the following parts: • plate washer 1 • clutch boss assembly 2 1 2 3. Remove the following parts: • one-way outer boss 1 • driven gear assembly 2 • gear cover 3 1 3 2 4. Remove the following parts: • heat-dissipating sheet 1 • tapping screw 2 2 1 5. Discon...

Page 70

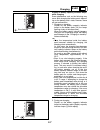

3-11 drive unit drive axle, motor removal of the torque sensor assembly and drive axle. 1. Remove the following parts: • tapping screw 1 • holder 2 • torque sensor assembly 3 • drive axle 4 notice do not disassemble the torque sensor assembly because it cannot be readjusted. Installation of the driv...

Page 71

3-12 drive unit drive axle, motor 2. Install the following part: • heat-dissipating sheet 1 notice precautions thermal protection may be compromised by an ill-fitting heat-dissipating sheet, so be sure to replace the heat-dissipating sheet with a new one when the assembly is disassembled. Tip tip • ...

Page 72

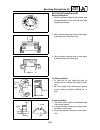

3-13 drive unit drive axle, motor installation of the bearing housing 1. Apply three bond 1215 ® to the following parts: • housing complete 1 apply a continuous 2 to 3 mm thick coating as shown in the drawing (area indicated by dark line). Tip tip • before applying the sealant, thoroughly clean all ...

Page 73

3-14 drive unit drive axle, motor installation of the stator cover 1. Apply three bond 1215 ® to the following parts: • motor complete 1 apply a continuous 2 to 3 mm thick coating as shown in the drawing (area indicated by dark line). Tip tip • before applying the sealant, thoroughly clean all the m...

Page 74: Service Data

4-1 service data service data tightening torque unit: nm kgf·m (in) other, general tightening torques the tightening torques of bolts and nuts other than those with tightening force for specified locations is determined by the screw diameter (width between two surfaces) and the pitch. Lubricants, ar...

Page 75

4-2 service data cable, wire, and pipe routing diagram cable, wire, and pipe routing diagram 1 wire lead 2 2 torque sensor plate 3 wire lead 3 (yellow) 4 wire lead 4 (blue) 5 wire lead 5 (white) 6 controller assembly 7 heat-dissipating sheet 8 wire lead 1 9 wire lead 1 couplers 1 0 wire lead 1 coupl...

Page 76

4-3 service data troubleshooting troubleshooting symptom check point/method possible cause/check part replacement/action the pedal feels heavy. Is the air pressure in the tires normal? Check for appropriate air pressure. Check for punctures. Repair puncture, replace tube. Is the gear-shifting workin...

Page 77

4-4 service data troubleshooting the 3 assist mode lamps, the “%” lamp, the “km” lamp, and the “km/h” lamp are flashing alternately, and “er” is dis- playing on the led type dis- play unit. Check the error log according to the display on the display unit when the error occurred. (see chapter 2 “how ...

Page 78

4-5 service data troubleshooting although the power to the display unit is turned on, all of the led display of the led type display unit turn on for 4 seconds, and then the power turns off automatically. Battery pack signal lead wires (see chapter 2 “when the battery pack signal lead wire becomes d...

Page 79

4-6 service data troubleshooting when pressing the battery capacity indicator button on the battery pack, lamps [1]/[3] and [2]/[4] or [1]/[2] and [3]/[4] turn on alternately. Hold down the battery capac- ity indicator button on the bat- tery pack for 10 seconds. (see chapter 2 “error diag- nosis mo...

Page 81

Yamaha x94 series service manual 7th edition published october 2014 unauthorized reproduction prohibited published by: yamaha motor co., ltd..

Page 82: Service Manual

Service manual e-bike systems x94 series.