Summary of YFM 400 FWA P

Page 1

Yfm400fwa ( p ) 5gh3-ae2 supplementary service manual 2002.

Page 3: Foreword

Foreword this supplementary service manual has been prepared to introduce new service and new data for the yfm400fwa(p) 2002. For complete information on service procedures, it is necessary to use this supplementary service manual together with the following manual. Yfm400fwa(m) 2000 service manual:...

Page 4: Notice

Eb001000 notice this manual was produced by the yamaha motor company primarily for use by yamaha dealers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manual, so it is assumed that anyone who uses this book to perform maintenance and repairs on y...

Page 5: How to Use This Manual

Eb002000 how to use this manual manual organization this manual consists of chapters for the main categories of subjects. (see “illustrated symbols”) 1st title 1: this is the title of the chapter with its symbol in the upper right corner of each page. 2nd title 2: this title indicates the section of...

Page 6: Illustrated Symbols

Eb003000 illustrated symbols illustrated symbols 1 to 9 are printed on the top right of each page and indicate the subject of each chapter. 1 general information 2 specifications 3 periodic checks and adjustments 4 engine 5 carburetion 6 drive train 7 chassis 8 electrical 9 troubleshooting illustrat...

Page 7: Contents

Contents specifications ............................................................................................1 general specifications ..................................................................1 maintenance specifications .........................................................2 engin...

Page 9: Spec

– 1 – spec general specifications specifications general specifications item standard model code: 5ghl: (cdn) 5ghm: (europe) 5ghn: (oceania) engine: engine type liquid-cooled 4-stroke, sohc cylinder arrangement forward-inclined single cylinder displacement 401 cm³ bore × stroke 84.5 × 71.5 mm (3.33 ...

Page 10: Spec

– 2 – spec maintenance specifications maintenance specifications engine item standard limit cylinder: bore size 84.500 ~ 84.510 mm (3.3268 ~ 3.3272 in) 84.600 mm (3.3307 in) taper limit ---- 0.05 mm (0.0016 in) out of round limit ---- 0.01 mm (0.0004 in) measuring point 40 mm (1.57 in) ---- cam chai...

Page 11: Spec

– 3 – spec maintenance specifications automatic centrifugal clutch: clutch shoe thickness 1.5 mm (0.06 in) 1.0 mm (0.04 in) clutch-in revolution 1,960 ~ 2,240 r/min ---- clutch-stall revolution 3,300 ~ 3,900 r/min ---- carburetor: i.D.Mark 5gh9 11 ---- main jet (m.J) #130 ---- main air jet (m.A.J) #...

Page 12: Spec

– 4 – spec maintenance specifications electrical item standard limit c.D.I.: magneto model/manufacturer f4t46471/mitsubishi ---- pickup coil resistance/color 459 ~ 561 Ω at 20 °c (68 °f)/ /white/red-white/green ---- rotor rotation direction sensing coil resis- tance/color 0.104 ~ 0.127 Ω at 20 °c (6...

Page 13: Spec

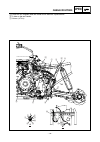

– 5 – spec cable routing 1 rear brake switch 2 rear brake cable 3 front brake hose 4 on command four-wheel drive switch 5 throttle cable 6 horn switch 1 2 3 4 5 6 cable routing.

Page 14: Spec

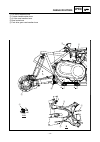

– 6 – spec 1 on command four-wheel drive switch lead 2 front brake hose 3 throttle cable 4 rear brake cable 5 rear brake switch lead 6 handlebar switch 7 starter cable 8 coolant reservoir breather hose 9 sub-wire harness 1 (to fan motor coupler) 0 sub-wire harness 1 (to gear motor and four- wheel dr...

Page 15: Spec

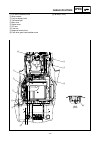

– 7 – spec 1 headlight coupler 2 circuit breaker 3 terminal 4 terminal coupler 5 engine temperature warning light 6 four-wheel drive indicator light 7 neutral indicator light 8 reverse indicator light 9 parking indicator light 0 coolant reservoir breather hose a differential gear case breather hose ...

Page 16: Spec

– 8 – spec 1 thermo switch 2 fuel tank breather hose 3 carburetor drain hose 4 speedometer cable 5 coolant reservoir breather hose 6 coolant reservoir hose 7 sub-wire harness 1 È to hole on the front fender. É insert the fuel tank into the hole in the handlebar cover. Ê 10 mm (0.4 in) e e e e d d d ...

Page 17: Spec

– 9 – spec 1 neutral switch lead 2 starter motor lead 3 negative battery lead 4 water pump breather hose 5 speed sensor 6 carburetor drain hose 7 wire harness 8 sub-wire harness 2 9 ground lead 0 ac magneto lead a final drive gear case breather hose b speed sensor c rectifier/regulator a a b 7 b a 0...

Page 18: Spec

– 10 – spec È fasten the ac magneto lead and starter motor lead with a plastic band. É to hole on the rear fender. Ê 120 mm (4.72 in) a a b 7 b a 0 9 8 a c 6 5 4 3 2 1 È É Ê a b cable routing.

Page 19: Spec

– 11 – spec 1 spark plug lead 2 rear brake cable 3 select lever control cable 4 rear brake reservoir hose 5 rear brake light switch lead È fasten the radiator inlet hose and fan motor breather hose with a plastic band. É pass the rear brake cable through the cable guide. Ê pass the rear brake reserv...

Page 20: Spec

– 12 – spec 1 fan motor breather hose 2 cylinder head breather hose 3 air filter case breather hose 4 rear brake hose 5 final drive gear case breather hose a-a 3 5 4 4 3 1 2 b b a a a a 4 cable routing.

Page 21: Spec

– 13 – spec 1 fan motor breather hose 2 wire harness 3 positive battery lead 4 tail/brake light 5 main fuse 6 starter relay 7 cdi unit 8 fuse box 9 negative battery lead 0 final drive gear case breather hose È 30 mm(1.18 in) a a 1 2 3 4 4 5 6 7 8 9 0 a-a È cable routing.

Page 22: Spec

– 14 – spec 1 fan motor breather hose 2 front brake hose 3 wire harness 4 cylinder head breather hose 5 throttle cable 6 final drive gear case breather hose 7 air vent hose 8 starter cable 9 rear brake cable È 70 mm (2.76 in) a-a a a a a 3 1 1 2 3 5 4 1 6 7 4 8 9 È cable routing.

Page 23: Chk

– 15 – chk adj introduction/periodic maintenance/ lubrication intervals eb300000 periodic checks and adjustments introduction this chapter includes all information necessary to perform recommended inspections and adjust- ments. These preventive maintenance procedures, if followed, will ensure more r...

Page 24: Chk

– 16 – chk adj periodic maintenance/lubrication intervals note: ● recommended brake fluid: dot 4 ● brake fluid replacement: 1. When disassembling the master cylinder or caliper, replace the brake fluid. Normally check the brake fluid level and add fluid as required. 2. On the inner parts of the mast...

Page 25: Chk

– 17 – chk adj adjusting the rear brake light switch chassis adjusting the rear brake light switch note: the rear brake light switch is operated by movement of the brake pedal. The rear brake light switch is properly adjusted when the brake light comes on just before the braking effect starts. 1.Che...

Page 26: Eng

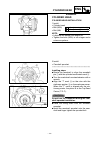

– 18 – eng cylinder head engine cylinder head cylinder head installation 1.Install: ● cylinder head ● bolt (m10) ● bolt (m6) note: ● lubricate the washer with engine oil. ● tighten the bolts (m10) in two stages and a crisscross pattern. T r . . 40 nm (4.0 m • kg, 29 ft • lb) t r . . 10 nm (1.0 m • k...

Page 27: Eng

– 19 – eng cylinder head note: be sure the “i” mark 5 on the camshaft sprocket is aligned with the match mark 2 on the cylinder head. ● force the camshaft clockwise and counter- clockwise to remove timing chain slack. ● insert a screwdriver into the timing chain ten- sioner hole and push the timing ...

Page 28: Eng

– 20 – eng cylinder head 4.Tighten: ● camshaft sprocket bolt 1 note: use the rotor holder 2 to hold the starter pul- ley. 5.Check: ● camshaft sprocket punch mark ● rotor “t” mark out of alignment → adjust. Rotor holder: p/n. Yu-01235, 90890-01235 t r . . 60 nm (6.0 m • kg, 43 ft • lb).

Page 29: Eng

– 21 – eng recoil starter and cdi magneto recoil starter and cdi magneto order job name/part name q’ty remarks cdi magneto removal remove the parts in the order below. Engine oil drain. Refer to “engine oil replacement” in chapter 3. Seat and side panels refer to “seat and side panels” in chapter 3....

Page 30: Eng

– 22 – eng recoil starter and cdi magneto order job name/part name q’ty remarks 7 pickup coil 1 8 stator assembly 1 9 cdi rotor 1 refer to “cdi magneto removal/ installation”. 10 starter wheel gear 1 11 woodruff key 1 12 bush/washer 1/1 13 starter idle gear shaft 1 14 washer/bearing 1/1 15 starter i...

Page 31: Eng

– 23 – eng transmission transmission order job name/part name q’ty remarks transmission removal remove the parts in the order below. Crankcase separation refer to “crankcase”. 1 driven sprocket 1 2 chain 1 3 clutch dog 2 1 4 shift fork “l” 1 5 spring 1 6 low wheel gear 1 7 secondary shaft 1 8 middle...

Page 32: Eng

– 24 – eng transmission order job name/part name q’ty remarks 11 shift fork “r” 1 12 spring 1 13 shift cam 1 14 stopper wheel 1 15 clutch dog 1 1 16 high wheel gear 1 17 stopper lever 1 18 spacer/o-ring 1/1 for installation, reverse the removal procedure..

Page 33: Elec

– 25 – – + elec electric starting system electrical eb803000 electric starting system circuit diagram b p b br /l r /y t l /b w /l w /l l /b r r w /g w /lw /r w /g r w /rw /g w ww w ww 1 w /g w /r w /g r w w w w w w 2 b r br br /l r rb r/ l br on off br /l br /l br r br br b br 3 z u (bla ck) br ww ...

Page 34: Elec

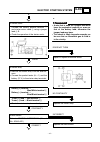

– 26 – – + elec electric starting system eb803020 troubleshooting procedure check: 1.Fuse (main, ignition) 2.Battery 3.Starter motor 4.Starter relay 5.Main switch 6.Engine stop switch if the starter motor fails to operate: 7.Neutral switch 8.Rear brake switch 9.Park switch 10.Start switch 11.Wiring ...

Page 35: Elec

– 27 – – + elec electric starting system c0ntinuity turns 3.Starter motor ● connect the battery positive terminal 1 and starter motor cable 2 using a jumper lead 3 . ● check the operation of the starter motor. * * warning ● a wire that is used as a jumper lead must have the equivalent capacity or mo...

Page 36: Elec

– 28 – – + elec electric starting system c0ntinuity correct 6.Engine stop switch refer to “switch inspection”. (manual no.: 5gh3-ae1) * incorrect replace the handlebar switch (right). Correct 7.Neutral switch refer to “switch inspection”. (manual no.: 5gh3-ae1) incorrect replace the neutral switch. ...

Page 37: Elec

– 29 – – + elec signal system eb806000 signal system circuit diagram b p b br /l r /y t l /b w /l w /l l /b r r w /g w /lw /r w /g r w /rw /g w ww w ww 1 w /g w /r w /g r w w w w w w 2 b r br br /l r rb r/ l br on off br /l br /l br r br br b br 3 z u (bla ck) br ww w r l /wl /b b b g /w g /w g /w b...

Page 38: Elec

– 30 – – + elec signal system 3 main switch 4 battery 5 main fuse 9 cdi unit c reverse switch d neutral switch h four-wheel drive indicator light i coolant temperature indicator light j park switch k thermo switch l four-wheel drive fuse o four-wheel drive switch r diode s ignition fuse w engine sto...

Page 39: Elec

– 31 – – + elec signal system checking the signal system 1.If the tail/brake light fails to come on: continuity 1.Bulb and bulb socket ● check the bulb and bulb socket for continu- ity. No continuity replace the bulb and/or bulb socket. Continuity 2.Brake light switches refer to “switch inspection”....

Page 40: Elec

– 32 – – + elec signal system 2.If the reverse indicator light fails to come on: continuity 1.Bulb and bulb socket ● check the bulb and bulb socket for continu- ity. No continuity replace the bulb and/or bulb socket. Continuity 2.Reverse switch refer to “switch inspection”. (manual no.: 5gh3-ae1) no...

Page 41

Yfm400fwa(p) 2002 wiring diagram b p b br/l r/y t l/b w/l w/l l/b r r w/g w/l w/r w/g r w/r w/g w w w w w w 1 w/g w/r w/g r w w w w w w 2 b r br br/l r r br/l br on off br/l br/l br r br br b br 3 z u (black) b r w w w r l/w l/b b b g/w g/w g/w b b r r r r r b b l/w 7 d È 5 4 6 o r w b o o o b/y b a...