- DL manuals

- Yamaha

- Motorcycle

- YFM400FWA 2000 5GH3-AE1

- Service Manual

Yamaha YFM400FWA 2000 5GH3-AE1 Service Manual

Summary of YFM400FWA 2000 5GH3-AE1

Page 1

Service manual yfm400fwa ( m ) 5gh3-ae1 2000

Page 2

Yfm400fwa(m) 2000 service manual 1999 by yamaha motor co., ltd. First edition, july 1999 all rights reserved. Any reproduction or unauthorized use without the written permission of yamaha motor co., ltd. Is expressly prohibited..

Page 3: Notice

Eb001000 notice this manual was produced by the yamaha motor company primarily for use by yamaha dealers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manual, so it is assumed that anyone who uses this book to perform mainte- nance and repairs on...

Page 4: How to Use This Manual

Eb002000 how to use this manual manual organization this manual consists of chapters for the main categories of subjects. (see “illustrated sym- bols”) 1st title 1 : this is the title of the chapter with its symbol in the upper right corner of each page. 2nd title 2 : this title indicates the sectio...

Page 5: Gen

Eb003000 illustrated symbols illustrated symbols 1 to 0 are printed on the top right of each page and indicate the subject of each chapter. 1 general information 2 specifications 3 periodic inspections and adjustments 4 engine 5 cooling system 6 carburetion 7 drive train 8 chassis 9 electrical 0 tro...

Page 6: Table of Contents

Table of contents general information 1 specifications spec 2 periodic inspection and adjustments 3 engine eng 4 cooling system cool 5 carburetion carb 6 drive train driv 7 chassis chas 8 electrical elec 9 troubleshooting 10 gen info insp adj – + trbl shtg.

Page 7: Gen

Gen info 1.

Page 8: Gen

Gen info chapter 1. General information machine identification .........................................................................1-1 vehicle identification number ..................................................1-1 model label ...................................................................

Page 9: Gen

Gen info.

Page 10: Gen

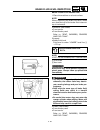

1 - 1 gen info machine identification general information machine identification vehicle identification number the vehicle identification number 1 is stamped into the left side of the frame. Model label the model label 1 is affixed to the frame. This information will be needed to order spare parts..

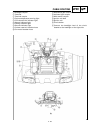

Page 11: Gen

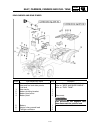

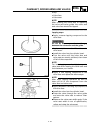

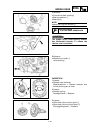

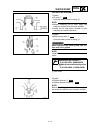

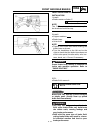

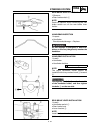

1 - 2 gen info features liquid cooling engine compact liquid cooled 45˚ inclined engine. A liquid cooling system has been incorpo- rated for stable power and engine endur- ance. 1 radiator 2 thermo switch 3 fan motor park position when the drive select lever is shifted into the park position, a stop...

Page 12: Gen

1 - 3 gen info eb101000 important information preparation for removal procedures 1.Remove all dirt, mud, dust and foreign material before removal and disassembly. 2.Use proper tools and cleaning equipment. Refer to the “special tools” section. 3.When disassembling the machine, always keep mated part...

Page 13: Gen

Gen info 1 - 4 eb101030 lock washers/plates and cotter pins 1.Replace all lock washers/plates 1 and cot- ter pins after removal. Bend lock tabs along the bolt or nut flats after the bolt or nut has been tightened to specification. Eb101040 bearings and oil seals 1.Install bearings and oil seals so t...

Page 14: Gen

1 - 5 gen info checking of connections eb801000 checking of connections check the connectors for stains, rust, mois- ture, etc. 1.Disconnect: ● connector 2.Check: ● connector moisture → dry each terminal with an air blower. Stains/rust → connect and disconnect the terminals several times. 3.Check: ●...

Page 15: Gen

Gen info 1 - 6 special tools eb102001 special tools the following special tools are necessary for complete and accurate tune-up and assembly. Use only the appropriate special tools; this will help prevent damage caused by the use of inappropriate tools or improvised techniques. Special tools may dif...

Page 16: Gen

Gen info 1 - 7 special tools kit 90890-04088 bolt 90890-01275 buffer boss installer set crankshaft installer bolt these tools are used to install the crankshaft. Yu-90050 crankshaft installer set these tools are used to install the crankshaft. Adapter ym-33279 spacer 90890-04060 ym-90070-a adapter (...

Page 17: Gen

Gen info 1 - 8 special tools 90890-04134 ym-04134 sheave spring compressor this tool is needed when removing or installing the secondary sheave spring. 90890-04135 ym-04135 sheave fixed block this tool is needed when removing or installing the secondary sheave spring. 90890-01404 ym-01404 flywheel p...

Page 18: Gen

Gen info 1 - 9 special tools 90890-03112 yu-03112 pocket tester this instrument is needed for checking the electrical system. 90890-03113 engine tachometer this tool is needed for observing engine rpm. Yu-8036-a inductive tachometer this tool is needed for observing engine rpm. 90890-03141 ym-33277-...

Page 19: Gen

Gen info 1 - 10 special tools 90890-04128 ym-04128 bearing retainer wrench this tool is needed when removing or installing the middle driven pinion gear bearing retainer. 90890-04129 ym-04129 pinion gear fix clamp this tool is used to hold the shift cam. 90890-06754 ignition checker this instrument ...

Page 20: Spec

Spec 2.

Page 21: Spec

Spec chapter 2. Specifications general specifications .........................................................................2-1 maintenance specifications ...............................................................2-5 engine .......................................................................

Page 22: Spec

Spec.

Page 23: Spec

2 - 1 spec specifications general specifications item standard model code: 5gh3 : (for cdn) 5gh4 : (for gb, f, ch) 5gh5 : (for oceania) dimensions: overall length 1,965 mm (77.36 in) overall width 1,070 mm (42.13 in) overall height 1,120 mm (44.09 in) seat height 820 mm (32.28 in) wheelbase 1,225 mm...

Page 24: Spec

2 - 2 spec differential gear case oil periodic oil change 0.35 l (0.31 lmp qt, 0.37 us qt) total amount 0.40 l (0.35 lmp qt, 0.42 us qt) radiator capacity (including all routes) 1.1 l (0.97 lmp qt, 1.16 us qt) air filter: wet type element fuel: type regular unleaded gasoline (for cdn, gb, f, ch) unl...

Page 25: Spec

2 - 3 spec manufacturer front dunlop (for cdn, gb, f, ch) cheng shin (for oceania) rear dunlop (for cdn, gb, f, ch) cheng shin (for oceania) type front kt123 (for cdn, gb, f, ch) c828 (for oceania) rear kt127 (for cdn, gb, f, ch) c828 (for oceania) item standard general specifications.

Page 26: Spec

2 - 4 spec tire pressure (cold tire): maximum load* 210 kg (463 lb) off-road riding front 22 ~ 28 kpa (0.22 ~ 0.28 kg/cm 2 , 3.2 ~ 4.0 psi) rear 22 ~ 28 kpa (0.22 ~ 0.28 kg/cm 2 , 3.2 ~ 4.0 psi) *load in total weight of rider accessories brake: front brake type dual disc brake operation right hand o...

Page 27: Spec

2 - 5 spec maintenance specifications engine item standard limit cylinder head: warp limit ---- 0.03 mm (0.0012 in) cylinder: bore size 84.500 ~ 84.510 mm (3.3268 ~ 3.3272 in) 84.600 mm (3.3307 in) taper limit ---- 0.05 mm (0.0016 in) out of round limit ---- 0.01 mm (0.0004 in) camshaft: drive metho...

Page 28: Spec

2 - 6 spec cam chain: cam chain type/no. Of links 92rh2015/116 ---- cam chain adjustment method automatic ---- rocker arm/rocker arm shaft: shaft outside diameter 11.981 ~ 11.991 mm (0.4717 ~ 0.4721 in) 11.951 mm (0.4705 in) arm-to-shaft clearance 0.009 ~ 0.037 mm (0.0004 ~ 0.0015 in) 0.08 mm (0.003...

Page 29: Spec

2 - 7 spec stem runout limit ---- 0.01 mm (0.0004 in) valve seat width in 1.2 ~ 1.4 mm (0.0472 ~ 0.0551 in) ---- ex 1.2 ~ 1.4 mm (0.0472 ~ 0.0551 in) ---- valve spring: inner spring free length in 39.9 mm (1.57 in) 37.9 mm (1.49 in) ex 39.9 mm (1.57 in) 37.9 mm (1.49 in) set length (valve closed) in...

Page 30: Spec

2 - 8 spec compressed pressure (installed) in 235.4 ~ 251.1 n (24.00 ~ 25.60 kg, 52.92 ~ 56.45 lb) ---- ex 235.4 ~ 251.1 n (24.00 ~ 25.60 kg, 52.92 ~ 56.45 lb) ---- tilt limit in 2.5˚/1.6 mm (2.5˚/0.06 in) ex 2.5˚/1.6 mm (2.5˚/0.06 in) direction of winding (top view) in clockwise ---- ex clockwise -...

Page 31: Spec

2 - 9 spec 2nd ring type taper ---- dimensions (b × t) 1.2 × 3.6 mm (0.0472 × 0.1417 in) ---- end gap (installed) 0.4 ~ 0.6 mm (0.0157 ~ 0.0236 in) 0.95 mm (0.0374 in) side clearance 0.03 ~ 0.07 mm (0.0012 ~ 0.0028 in) 0.13 mm (0.0051 in) oil ring dimensions (b × t) 2.8 × 2.8 mm (0.1102 × 0.1102 in)...

Page 32: Spec

2 - 10 spec transmission: main axle deflection limit ---- 0.06 mm (0.0024 in) drive axle deflection limit ---- 0.06 mm (0.0024 in) shifter: shifter type cam drum and guide bar ---- air filter oil grade: engine oil ---- carburetor: i. D. Mark 5gh1 00 (for cdn) 5gh4 20 (for gb, f, ch, oceania) ---- ma...

Page 33: Spec

2 - 11 spec radiator cap opening pressure 93.3 ~ 122.7 kpa (0.933 ~ 1.227 kg/cm 2 , 13.53 ~ 17.79 psi) ---- radiator capacity 0.55 l (0.48 imp qt, 0.58 us qt) ---- coolant reservoir capacity 0.25 l (0.22 imp qt, 0.26 us qt) ---- from low to full level 0.15 l (0.13 imp qt, 0.16 us qt) ---- water pump...

Page 34: Spec

2 - 12 spec cylinder head tightening sequence: item standard limit maintenance specifications.

Page 35: Spec

2 - 13 spec tightening torques part to be tightened part name thread size q’ty tightening torque remarks nm m·kg ft·lb cylinder head oil passage union bolt m6 1 7 0.7 5.1 cylinder head (exhaust pipe) stud bolt m8 2 15 1.5 11 cylinder head bolt m10 4 40 4.0 29 bolt m6 2 10 1.0 7.2 camshaft sprocket c...

Page 36: Spec

2 - 14 spec crankcase cover (left) bolt m6 6 10 1.0 7.2 lt recoil starter bolt m6 4 10 1.0 7.2 lt starter one-way clutch bolt m8 6 30 3.0 22 lt clutch carrier assembly nut m22 1 140 14 100 stake middle drive shaft bearing retainer torx screw m8 4 25 2.5 18 lt middle driven shaft drive pinion gear nu...

Page 37: Spec

2 - 15 spec chassis item standard limit steering system: steering bearing type bushings (top) ---- ball bearing (bottom) front suspension: shock absorber travel 106 mm (4.17 in) ---- fork spring free length 317.5 mm (12.50 in) ---- spring fitting length 256.5 mm (10.09 in) ---- spring rate (k1) 14 n...

Page 38: Spec

2 - 16 spec front disc brake: type dual ---- disc outside diameter × thickness 180.0 × 3.5 mm (7.09 ~ 0.14 in) ---- pad thickness inner 4.5 mm (0.18 in) 1 mm (0.04 in) pad thickness outer 4.5 mm (0.18 in) 1 mm (0.04 in) master cylinder inside diameter 14 mm (0.55 in) ---- caliper cylinder inside dia...

Page 39: Spec

2 - 17 spec tightening torques part to be tightened thread size tightening torque remarks nm m·kg ft·lb engine bracket (front-upper) and frame m8 33 3.3 24 engine bracket (front-lower) and frame m8 33 3.3 24 engine bracket (front-upper) and engine m10 42 4.2 30 engine bracket (front-lower) and engin...

Page 40: Spec

2 - 18 spec front bumper and frame m8 33 3.3 24 front carrier and frame m8 33 3.3 24 front carrier and front bumper m8 33 3.3 24 rear carrier and frame m8 33 3.3 24 differential gear case filler bolt m14 23 2.3 16 differential gear case drain bolt m10 10 1.0 7 ring gear m8 39 3.9 28 lt differential ...

Page 41: Spec

2 - 19 spec electrical item standard limit voltage: 12 v ---- ignition system: ignition timing (b.T.D.C.) 10˚/ 1,000 r/min ---- advanced timing (b.T.D.C.) 33˚/ 5,000 r/min ---- advancer type digital type ---- c.D.I.: magneto model/manufacturer f4t46471/mitsubishi ---- pickup coil resistance/color 45...

Page 42: Spec

2 - 20 spec starter relay model/manufacturer ms5f-561/jideco ---- amperage rating 180 a ---- coil winding resistance 4.18 ~ 4.62 Ω at 20 ˚c (68 ˚f) ---- horn: type plane type ---- quantity 1 ---- model/manufacturer mf-12/nikko ---- maximum amperage 1.5 a ---- performance 100 ~ 108 db/2 m ---- coil w...

Page 43: Spec

2 - 21 spec eb201000 how to use the conversion table all specification data in this manual are listed in si and metric units. Use this table to convert metric unit data to imperial unit data. Ex. Conversion table eb202001 general torque specifications this chart specifies torque for standard fas- te...

Page 44: Spec

2 - 22 spec lubrication points and lubricant types engine lubrication points lubricant type oil seal lips (all) ls o-ring (all) ls bearings (all) e crank pin e connecting rod (bearing) e camshaft sprocket m crankshaft e piston surface/piston rings e piston pin e baffer boss e valve stem/valve stem e...

Page 45: Spec

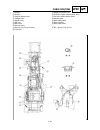

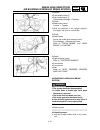

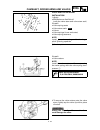

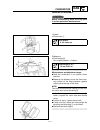

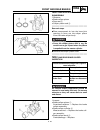

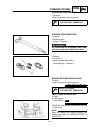

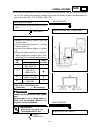

2 - 23 spec coolant flow diagrams coolant flow diagrams 1 radiator 2 thermo switch 3 fan motor.

Page 46: Spec

2 - 24 spec coolant flow diagrams 1 radiator 2 thermostat.

Page 47: Spec

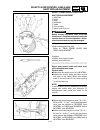

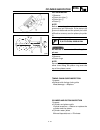

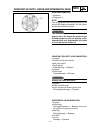

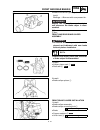

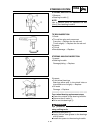

2 - 25 spec oil flow diagrams oil flow diagrams 1 camshaft 2 crankshaft 3 drive axle.

Page 48: Spec

2 - 26 spec oil flow diagrams 1 oil filter.

Page 49: Spec

2 - 27 spec oil flow diagrams 1 oil pump 2 oil strainer.

Page 50: Spec

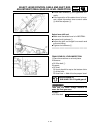

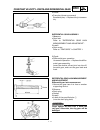

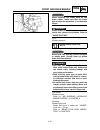

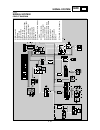

2 - 28 spec cable routing cable routing 1 rear brake switch 2 rear brake cable 3 front brake hose 4 on command four-wheel drive switch 5 throttle cable 6 on command four-wheel drive switch lead 7 front brake switch lead 8 handlebar switch 9 starter cable 0 coolant reservoir breather hose a sub-wire ...

Page 51: Spec

2 - 29 spec cable routing 1 headlight coupler 2 terminal 3 terminal coupler 4 engine temperature warning light 5 four-wheel drive indicator light 6 neutral indicator light 7 parking indicator light 8 reverse indicator light 9 coolant reservoir breather hose 0 fan motor breather hose a differential g...

Page 52: Spec

2 - 30 spec cable routing 1 thermo switch 2 fuel tank breather hose 3 starter motor lead 4 negative battery lead 5 speed sensor 6 carburetor drain hose 7 wire harness 8 sub-wire harness 2 9 ground lead 0 speed sensor a cdi magneto lead b final drive gear case breather hose c rectifier/regulator d su...

Page 53: Spec

2 - 31 spec cable routing Å to hole on the front fender. ı insert the fuel tank into the hole in the handlebar cover. Ç fasten the cdi magneto lead and starter motor lead with a plastic band. Î to hole on the rear fender. ‰ pass the speedometer cable through the guide on the air duct..

Page 54: Spec

2 - 32 spec cable routing 1 cylinder head breather hose 2 spark plug lead 3 rear brake cable 4 select lever control cable 5 rear brake reservoir hose 6 rear brake hose.

Page 55: Spec

2 - 33 spec cable routing 1 diode 1 2 diode 2 3 positive battery lead 4 taillight lead 5 starter relay 6 cdi unit 7 main fuse 8 reverse relay 9 starting circuit cut-off relay 0 fuse box a negative battery lead b final drive gear case breather hose c cylinder head breather hose d starter cable e rear...

Page 56: Spec

2 - 34 spec.

Page 57: Insp

Insp adj 3.

Page 58: Insp

Insp adj chapter 3. Periodic inspections and adjustments introduction ...........................................................................................3-1 periodic maintenance/lubrication intervals ...........................3-1 seat, carriers, fenders and fuel tank ..........................

Page 59: Insp

Insp adj differential gear oil replacement .......................................3-45 constant velocity joint dust boot inspection ..............3-46 steering system inspection ....................................................3-46 toe-in adjustment ..................................................

Page 60: Insp

3 - 1 insp adj introduction/periodic maintenance/ lubrication intervals eb300000 periodic inspections and adjustments introduction this chapter includes all information necessary to perform recommended inspections and adjustments. These preventive maintenance procedures, if followed, will ensure mor...

Page 61: Insp

3 - 2 insp adj periodic maintenance/lubrication intervals note: ● recommended brake fluid: dot 4 ● brake fluid replacement: 1.When disassembling the master cylinder or caliper cylinder, replace the brake fluid. Nor- mally check the brake fluid level and add fluid as required. 2.On the inner parts of...

Page 62: Insp

3 - 3 insp adj seat, carriers, fenders and fuel tank seat, carriers, fenders and fuel tank seat and side panels order job name/part name q’ty remarks seat and side panels removal remove the parts in the order below. 1 seat 1 2 fuel tank side panel (left) 1 3 fuel tank side panel (right) 1 4 engine s...

Page 63: Insp

3 - 4 insp adj seat, carriers, fenders and fuel tank front carrier, front bumper and front fender order job name/part name q’ty remarks front carrier, front bumper and front fender removal remove the parts in the order below. Seat and fuel tank side panels refer to “seat and side panels”. 1 front ca...

Page 64: Insp

3 - 5 insp adj seat, carriers, fenders and fuel tank order job name/part name q’ty remarks 9 indicator light coupler 2 disconnect. 10 sub-wire harness 1 coupler 1 disconnect. 11 main switch coupler 1 disconnect. 12 auxiliary dc jack coupler 1 disconnect. 13 speedometer light coupler 1 disconnect. 14...

Page 65: Insp

3 - 6 insp adj seat, carriers, fenders and fuel tank rear carrier and rear fender p order job name/part name q’ty remarks rear carrier and rear fender removal remove the parts in the order below. Seat and fuel tank side panels refer to “seat and side panels”. Fuel tank refer to “fuel tank”. 1 rear c...

Page 66: Insp

3 - 7 insp adj seat, carriers, fenders and fuel tank order job name/part name q’ty remarks 8 final drive gear case breather hose 1 9 cylinder head breather hose 1 10 clamp screw 1 loosen. 11 air filter case 1 12 plastic band 1 13 rear fender 1 for installation, reverse the removal procedure..

Page 67: Insp

3 - 8 insp adj seat, carriers, fenders and fuel tank fuel tank order job name/part name q’ty remarks fuel tank removal remove the parts in the order below. Seat and side panels refer to “seat and side panels”. Fuel tank cover refer to “front carrier, front bumper and front fender”. 1 fuel hose 1 2 f...

Page 68: Insp

3 - 9 insp adj footrest boards footrest boards order job name/part name q’ty remarks footrest boards removal remove the parts in the order below. Fuel tank side panels refer to “seat and side panels”. 1 footrest 2 2 left footrest board 1 3 right footrest board 1 4 left footrest bracket 1 5 right foo...

Page 69: Insp

3 - 10 insp adj valve clearance adjustment engine valve clearance adjustment note: ● the valve clearance must be adjusted when the engine is cool to the touch. ● adjust the valve clearance when the pis- ton is at the top dead center (t.D.C.) on the compression stroke. 1.Remove: ● seat ● front carrie...

Page 70: Insp

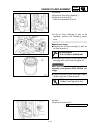

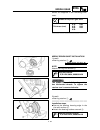

3 - 11 insp adj valve clearance adjustment 6.Remove: ● timing plug 1 7.Check: ● valve clearance out of specification → adjust. Valve clearance (cold): intake: 0.06 ~ 0.10 mm (0.0024 ~ 0.0039 in) exhaust: 0.16 ~ 0.20 mm (0.0063 ~ 0.0079 in) ********************************* checking steps: ● turn the...

Page 71: Insp

3 - 12 insp adj valve clearance adjustment 8.Adjust: ● valve clearance ********************************* adjustment steps: ● loosen the locknut 1. ● insert a feeler gauge 2 between the adjuster end and the valve end. ● turn the adjuster 3 clockwise or counter- clockwise with the valve adjusting tool...

Page 72: Insp

3 - 13 insp adj valve clearance adjustment/timing chain adjustment/idling speed adjustment 11.Install: ● fuel tank ● front fender ● front carrier ● seat refer to “seat, carriers, fenders and fuel tank”. Timing chain adjustment adjustment free. Idling speed adjustment 1.Start the engine and let it wa...

Page 73: Insp

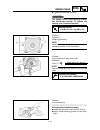

3 - 14 insp adj idling speed adjustment/ throttle lever free play adjustment 5.Adjust: ● engine idling speed ********************************* adjustment steps: ● turn the throttle stop screw 1 in or out until the specified idling speed is obtained. ********************************* 6.Detach: ● indu...

Page 74: Insp

3 - 15 insp adj throttle lever free play adjustment 1.Check: ● throttle lever free play a out of specification → adjust. Throttle lever free play: 3 ~ 5 mm (0.12 ~ 0.20 in) 2.Remove: ● seat ● fuel tank side panel (right) refer to “seat, carriers, fenders and fuel tank”. 3.Adjust: ● throttle lever fr...

Page 75: Insp

3 - 16 insp adj throttle lever free play adjustment/ speed limiter adjustment ● tighten the locknut 5. ● push in the adjuster cover 4. Warning after adjusting the free play, turn the handle- bar to the right and left to make sure that the engine idling speed does not increase. **********************...

Page 76: Insp

3 - 17 insp adj speed limiter adjustment/ starter lever free play adjustment ● tighten the locknut. Warning ● particularly for a beginner rider, the speed limiter should be screwed in completely. Screw it out little by little as their riding technique improves. Never remove the speed limiter for a b...

Page 77: Insp

3 - 18 insp adj ● tighten the locknut 2. ● push in the adjuster cover 1. Warning after adjusting the free play, turn the han- dlebar to right and left, and make sure that the engine idling speed does not increase. ********************************* 4.Install: ● fuel tank side panel (left) ● seat refe...

Page 78: Insp

3 - 19 insp adj spark plug inspection/ ignition timing check 6.Measure: ● plug gap a use a wire gauge or feeler gauge. Out of specification → regap. 7.Tighten: ● spark plug note: before installing a spark plug, clean the gasket surface and plug surface. 8.Install: ● fuel tank side panel (right) ● se...

Page 79: Insp

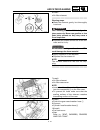

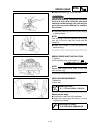

3 - 20 insp adj ignition timing check/ compression pressure measurement 3.Check: ● ignition timing ********************************* checking steps: ● warm up the engine and keep it at the specified speed. ● remove the recoil starter 1. ● remove the timing plug 2. ● visually check the stationary poi...

Page 80: Insp

3 - 21 insp adj compression pressure measurement 1.Check: ● valve clearance out of specification → adjust. Refer to “valve clearance adjust- ment”. 2.Start the engine and let it warm up for several minutes. 3.Stop the engine. 4.Remove: ● seat ● fuel tank side panel (right) refer to “seat, carriers, ...

Page 81: Insp

3 - 22 insp adj compression pressure measurement/ engine oil level inspection compression pressure (at sea level): standard: 1,400 kpa (14 kg/cm 2 , 203 psi) minimum: 1,218 kpa (12.2 kg/cm 2 , 177 psi) maximum: 1,568 kpa (15.7 kg/cm 2 , 227 psi) ********************************* measurement steps: ●...

Page 82: Insp

3 - 23 insp adj engine oil level inspection/ engine oil replacement note: recommended oil classification: api service “se”, “sf” type or equivalent (e.G. “sf–se–cc”, “sf–se–sd” etc.) caution: do not allow foreign material to enter the crankcase. 4.Start the engine and let it warm up for several minu...

Page 83: Insp

3 - 24 insp adj engine oil replacement 4.Remove: ● engine oil filler plug (dipstick) 1 ● engine oil drain bolt 2 drain the crankcase of its oil. 5.If the oil filter cartridge is also to be replaced, perform the following proce- dure. ********************************* replacement steps: ● remove the ...

Page 84: Insp

3 - 25 insp adj engine oil replacement 7.Fill: ● crankcase refer to “engine oil level inspec- tion”. 8.Install: ● engine oil filler plug 9.Warm up the engine for a few minutes, then stop the engine. 10.Inspect: ● engine (for engine oil leaks) ● oil level refer to “engine oil level inspec- tion”. 11....

Page 85: Insp

3 - 26 insp adj air filter cleaning air filter cleaning note: there is a check hose 1 at the bottom of the air filter case. If dust and/or water col- lects in this hose, clean the air filter element and air filter case. 1.Remove: ● seat ● fuel tank cover refer to “seat, carriers, fenders and fuel ta...

Page 86: Insp

3 - 27 insp adj air filter cleaning 6.Clean: ● air filter element ********************************* cleaning steps: ● wash the element gently, but thoroughly in solvent. Warning use a cleaning solvent which is designed to clean parts only. Never use gasoline or low flash point solvents as they may c...

Page 87: Insp

3 - 28 insp adj coolant level inspection coolant level inspection 1.Place the machine on a level surface. 2.Remove: ● seat ● fuel tank side panel (left) 3.Inspect: ● coolant level the coolant level should be between the minimum level mark a and maximum level mark b. Below the minimum level mark → ad...

Page 88: Insp

3 - 29 insp adj coolant replacement coolant replacement 1.Remove: ● seat ● fuel tank side panel (left) ● engine side cover ● front carrier ● front fender refer to “seat, carpiers, fenders and fuel tank”. ● left footrest board refer to “footrest boards”. 2.Remove: ● engine skid plate (rear) 1 3.Remov...

Page 89: Insp

3 - 30 insp adj coolant replacement 8.Remove: ● radiator cap 1 warning a hot radiator is under pressure. Therefore, do not remove the radiator cap when the engine is hot. Scalding hot fluid and steam may be blown out, which could cause seri- ous injury. When the engine has cooled, open the radiator ...

Page 90: Insp

3 - 31 insp adj coolant replacement 13.Fill: ● cooling system (with the specified amount of the recom- mended coolant) handling notes for coolant coolant is potentially harmful and should be handled with special care. Warning ● if coolant splashes in your eyes, thor- oughly wash them with water and ...

Page 91: Insp

3 - 32 insp adj coolant replacement 15.Fill: ● coolant reservoir (with the recommended coolant to the maximum level mark a ) 16.Install: ● coolant reservoir cap 17.Start the engine, warm it up for several minutes, and then turn it off. 18.Inspect: ● coolant level refer to “checking the coolant level...

Page 92: Insp

3 - 33 insp adj coolant temperature indicator light check/ v-belt inspection coolant temperature indicator light check 1 coolant temperature indicator light v-belt inspection 1.Remove: ● right footrest board ● crankcase cover (right) refer to “primary and secondary sheaves” in chapter 4. 2.Inspect: ...

Page 93: Insp

3 - 34 insp adj v-belt inspection 4.Replace: ● v-belt ********************************* replacing steps: ● install the bolts 1 (90101-06016) into the secondary fixed sheave hold. Note: tightening the bolts 1 will push the sec- ondary sliding sheave away, causing the gap between the secondary fixed a...

Page 94: Insp

3 - 35 insp adj front brake adjustment/ rear brake adjustment chassis front brake adjustment 1.Check: ● brake lever free play a out of specification → bleed the front brake system. Refer to “air bleeding (hydraulic brake system)”. Free play: 0 mm (0 in) (at brake lever end) rear brake adjustment war...

Page 95: Insp

3 - 36 insp adj rear brake adjustment 3.Check: ● rear brake pedal height a out of specification → adjust. 4.Adjust: ● rear brake lever free play ● rear brake pedal height ********************************* adjustment steps: ● loosen the locknut (handlebar) 1 and fully screw in the brake lever cable a...

Page 96: Insp

3 - 37 insp adj rear brake adjustment ● loosen the locknut 6. ● pull up the brake outer cable and turn the brake cable adjusting (nut) 7 until the clearance c is within the specified limits. Note: make sure the pin 8 is all the way to the right of the link plate hole. ● hold the adjusting nut 7 and ...

Page 97: Insp

3 - 38 insp adj brake fluid level inspection brake fluid level inspection 1.Place the machine on a level surface. Note: when inspecting the brake fluid level, make sure that the top of the brake fluid reservoir top is horizontal. 2.Remove: (rear brake) ● front carrier ● front fender panel refer to “...

Page 98: Insp

3 - 39 insp adj front brake pad inspection/rear brake pad inspection/brake hose inspection front brake pad inspection 1.Remove: ● front wheels 2.Inspect: ● brake pad wear indicators 1 almost touch the brake disc → replace the brake pads as a set. Refer to “front and rear brakes” in chapter 8. 3.Oper...

Page 99: Insp

3 - 40 insp adj brake hose inspection/ air bleeding (hydraulic brake system) 2.Inspect: ● front brake hoses 1 ● rear brake hoses 2 cracks/wear/damage → replace. 3.Check: ● brake hose clamp loosen → tighten. 4.Hold the machine in an upright position and apply the front or rear brake. 5.Check: ● brake...

Page 100: Insp

3 - 41 insp adj air bleeding (hydraulic brake system) b. Install the diaphragm. Be careful not to spill any fluid or allow the reservoir to overflow. C. Connect the clear plastic hose 1 tightly to the caliper bleed screw 2. Å front ı rear d. Place the other end of the hose into a container. E. Slowl...

Page 101: Insp

3 - 42 insp adj select lever control cable and shift rod adjustment select lever control cable and shift rod adjustment 1 neutral 2 high 3 low 4 reverse 5 park 6 control cable 7 select lever shift rod warning before moving the select lever, bring the machine to a complete stop and return the throttl...

Page 102: Insp

3 - 43 insp adj select lever control cable and shift rod adjustment/final gear oil level inspection ● check that locknuts 2 are tightened cor- rectly. ● if the operation of the select lever is incor- rect, adjust the select lever control cable 3 with the adjuster 4. Select lever shift rod: ● make su...

Page 103: Insp

3 - 44 insp adj final gear replacement 1.Place the machine on a level surface. 2.Remove: ● final gear case protector 1 3.Place a receptacle under the final gear case. 4.Remove: ● oil filler bolt ● drain plug 1 5.Drain: ● final gear oil 6.Install: ● drain plug note: check the gasket (drain plug). If ...

Page 104: Insp

3 - 45 insp adj differential gear oil inspection 1.Place the machine on a level surface. 2.Remove: ● oil filter bolt ● oil drain plug 1 3.Drain: ● differential gear oil 4.Install: ● oil drain plug t r . . 10 nm (1.0 m • kg, 7 ft • lb) 5.Fill: ● differential gear oil caution: take care not allow fore...

Page 105: Insp

3 - 46 insp adj differential gear oil replacement/ constant velocity joint dust boot inspection/ steering system inspection 4.Drain: ● differential gear oil 5.Install: ● drain plug note: check the gasket (drain plug). If it is dam- aged, replace it with new one. 6.Fill: ● differential gear case note...

Page 106: Insp

3 - 47 insp adj steering system inspection/ toe-in adjustment 3.Check: ● tie-rod ends turn the handlebar to the left and/or right until it stops completely, then move the handlebar from the left to the right slightly. Tie-rod end has any vertical play → replace the tie-rod end(s). 4.Raise the front ...

Page 107: Insp

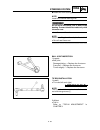

3 - 48 insp adj toe-in adjustment ● face the handlebar straight ahead. ● measure the width Å between the marks. ● rotate the front tires 180˚ until the marks are exactly opposite one another. ● measure the width ı between the marks. ● calculate the toe-in using the formula given below. ● if the toe-...

Page 108: Insp

3 - 49 insp adj front shock absorber adjustment/rear shock absorber adjustment/tire inspection front shock absorber adjustment warning always adjust both front shock absorber spring preload to the same setting. Uneven adjustment can cause poor handling and loss of stability. 1.Adjust: ● spring prelo...

Page 109: Insp

3 - 50 insp adj tire inspection 1)tire characteristics influence the handling of atv’s. The tires listed below have been approved by yamaha motor co., ltd. For this model. If other tire combina- tions are used, they can adversely affect your machine’s handling characteristics and are therefore not r...

Page 110: Insp

3 - 51 insp adj tire inspection pulling load (total weight of trailer and cargo): 500 kg (1,102 lb) tongue weight (vertical weight on trailer hitch point): 15 kg (33 lb) be extra careful of the machine balance and stability when towing a trailer. 1.Measure: ● tire pressure (cold tire pressure) out o...

Page 111: Insp

3 - 52 insp adj wheel inspection/ cable inspection and lubrication wheel inspection 1.Inspect: ● wheels 1 damage/bends → replace. Note: always balance the wheel when a tire or wheel has been changed or replaced. Warning ● never attempt even small repairs to the wheel. ● ride conservatively after ins...

Page 112: Insp

3 - 53 insp adj levers, pedal, etc. Lubrication 1.Lubricate the pivoting parts. Recommended lubricant: yamaha chain and cable lube or engine oil levers, pedal, etc. Lubrication.

Page 113: Insp

3 - 54 insp adj battery inspection eb305000 electrical battery inspection note: since the mf battery is a sealed type bat- tery, it is not possible to measure the spe- cific gravity of the electrolyte in order to check the charge state of the battery. There- fore the charge of the battery has to be ...

Page 114: Insp

3 - 55 insp adj battery inspection batteries generate explosive hydrogen gas. Always follow these preventive measures: ● charge batteries in a well-ventilated area. ● keep batteries away from fire, sparks or open flames (e.G., welding equipment, lighted cigarettes, etc.). ● do not smoke when chargin...

Page 115: Insp

3 - 56 insp adj battery inspection ● check the condition of the battery using the following charts. Example: ● open-circuit voltage = 12.0 v ● charging time = 6.5 hours ● charge condition of the battery = 20 ~ 30% ● charging method for mf batteries caution: ● if it is impossible to set the standard ...

Page 116: Insp

3 - 57 insp adj battery inspection charging method using a variable voltage charger.

Page 117: Insp

3 - 58 insp adj battery inspection charging method using a constant voltage charger.

Page 118: Insp

3 - 59 insp adj battery inspection/fuse inspection 5.Inspect: ● battery terminals dirty → clean with a wire brush. Poor connection → correct. Note: after cleaning the terminals, apply a light coat of grease. 6.Install: ● battery 7.Connect: ● battery leads caution: first, connect the positive lead 1,...

Page 119: Insp

3 - 60 insp adj fuse inspection note: set the tester to the “ Ω × 1” position. ● if the tester indicates o, replace the fuse. ********************************* 3.Replace: ● blown fuse ********************************* replacement steps: ● turn off the ignition. ● install a new fuse of the proper amp...

Page 120: Insp

3 - 61 insp adj headlight beam adjustment/ headlight bulb replacement headlight beam adjustment 1.Adjust: ● headlight beam (vertically) turn the adjuster 1 in or out. Turning in headlight beam raised. Turning out headlight beam lowered. Headlight bulb replacement 1.Remove: ● front carrier ● front fe...

Page 121: Insp

3 - 62 insp adj headlight bulb replacement 5.Install: ● bulb secure the new bulb with the headlight unit. Caution: avoid touching the glass part of the bulb. Keep it free from oil; otherwise, the trans- parency of the glass, life of the bulb, and luminous flux will be adversely affected. If oil gets...

Page 122: Eng

Eng 4.

Page 123: Eng

Eng chapter 4. Engine engine removal ......................................................................................4-1 air ducts, muffler and exhaust pipe .....................................4-1 select lever unit and coolant reservoir ...........................4-2 hoses and leads ............

Page 124: Eng

Eng primary and secondary sheaves ..................................................4-42 primary sheave .............................................................................4-44 secondary sheave .......................................................................4-45 primary and secondary...

Page 125: Eng

Eng middle gear ............................................................................................4-75 middle drive shaft .......................................................................4-75 middle driven shaft ....................................................................4-76...

Page 126: Eng

Eng.

Page 127: Eng

4 - 1 eng engine removal engine engine removal air ducts, muffler and exhaust pipe order job name/part name q’ty remarks air ducts, muffler and exhaust pipe removal remove the parts in the order below. Engine oil refer to “engine oil replacement” in chapter 3. Front and rear fender/footrest boards r...

Page 128: Eng

4 - 2 eng engine removal select lever unit and coolant reservoir order job name/part name q’ty remarks select lever unit and coolant reservoir removal remove the parts in the order below. 1 shift arm 1 2 select lever shift rod 1 3 select lever unit 1 4 coolant reservoir breather hose 1 5 coolant res...

Page 129: Eng

4 - 3 eng engine removal hoses and leads order job name/part name q’ty remarks hoses and leads removal remove the parts in the order below. Water pump inlet hose refer to “water pump” in chapter 5. 1 cylinder head breather hose 1 2 spark plug lead 1 3 thermo switch lead 1 4 starter motor lead 1 5 cd...

Page 130: Eng

4 - 4 eng engine removal engine mounting bolts order job name/part name q’ty remarks engine mounting bolt removal remove the parts in the order below. Rear wheels refer to “front and rear wheels” in chapter 8. Swingarm refer to “rear shock absorber and swingarm” in chapter 8. 1 engine mounting bolt ...

Page 131: Eng

4 - 5 eng engine removal order job name/part name q’ty remarks 9 engine assembly 1 for installation, reverse the removal procedure. Note: remove the engine assembly from the left side of the machine..

Page 132: Eng

4 - 6 eng engine installation 1.Install: ● engine bracket (front upper) 1 ● engine mount bolt (front upper)/nut 2 ● engine bracket bolt (front upper) 3 ● engine bracket (front lower) 4 ● engine mount bolt (front lower) 5 ● engine bracket bolt (front lower) 6 ● engine mount bolt (rear upper)/nut 7 ● ...

Page 133: Eng

4 - 7 eng cylinder head cylinder head order job name/part name q’ty remarks cylinder head removal remove the parts in the order below. Fuel tank/rubber cover refer to “seat, carriers, fenders and fuel tank” in chapter 3. Front fender/air filter case air duct assembly 1 refer to “engine removal”. Exh...

Page 134: Eng

4 - 8 eng cylinder head order job name/part name q’ty remarks 5 cylinder head breather hose 1 6 camshaft sprocket cover/o-ring 1/1 7 tappet cover/o-ring 2/2 8 thermo switch lead 1 disconnect. 9 timing chain tensioner cap bolt 1 refer to “cylinder head removal/ installation”. 10 timing chain tensione...

Page 135: Eng

4 - 9 eng cylinder head cylinder head removal 1.Align: ● “t” mark (with stationary pointer) ********************************* checking steps: ● turn the crankshaft counterclockwise with a wrench. ● align the “t” mark 1 on the rotor with the stationary pointer 2 on the crankcase cover. When the “t” m...

Page 136: Eng

4 - 10 eng cylinder head note: ● fasten a safety wire to the timing chain to prevent it from falling into the crankcase. ● when removing the camshaft sprocket, it is not necessary to separate the timing chain. 5.Remove: ● cylinder head note: ● loosen the 6 mm bolts first. ● working in a crisscross p...

Page 137: Eng

4 - 11 eng cylinder head cylinder head inspection 1.Eliminate: ● carbon deposits (from the combustion chambers) use a rounded scraper. Note: do not use a sharp instrument to avoid damaging or scratching: ● spark plug threads ● valve seats 2.Inspect: ● cylinder head scratches/damage → replace. ● cyli...

Page 138: Eng

4 - 12 eng cylinder head cylinder head installation 1.Install: ● cylinder head ● bolt (m10) ● bolt (m6) note: ● lubricate the washer with engine oil. ● tighten the bolts (m10) in two stages and a crisscross pattern. T r . . 40 nm (4.0 m • kg, 29 ft • lb) t r . . 10 nm (1.0 m • kg, 7.2 ft • lb) 2.Ins...

Page 139: Eng

4 - 13 eng cylinder head note: be sure the punch mark 5 on the camshaft sprocket is aligned with the match mark 2 on the cylinder head. ● force the camshaft clockwise and coun- terclockwise to remove timing chain slack. ● insert a screwdriver into the timing chain tensioner hole and push the timing ...

Page 140: Eng

4 - 14 eng cylinder head 4.Tighten: ● camshaft sprocket bolt 1 note: use the rotor holder 2 to hold the starter pulley. 5.Check: ● camshaft sprocket punch mark ● rotor “t” mark out of alignment → adjust. Rotor holder: p/n. Yu-01235, 90890-01235 t r . . 60 nm (6.0 m • kg, 43 ft • lb).

Page 141: Eng

4 - 15 eng camshaft, rocker arms and valves camshaft, rocker arms and valves order job name/part name q’ty remarks camshaft, rocker arms and valves removal remove the parts in the order below. 1 intake manifold/o-ring 1/1 2 thermo switch 1 3 oil check bolt 1 4 lock washer/bearing retainer 1/1 5 cams...

Page 142: Eng

4 - 16 eng camshaft, rocker arms and valves order job name/part name q’ty remarks 12 valve spring (inner) 2 refer to “valve and valve spring removal/installation”. 13 valve (intake) 1 14 valve (exhaust) 1 15 valve stem seal 2 16 valve spring seat 2 for installation, reverse the removal procedure..

Page 143: Eng

4 - 17 eng camshaft, rocker arms and valves camshaft and rocker arm removal 1.Remove: ● camshaft 1 note: screw in a m10 bolt 2 into the thread hole on the camshaft, and pull out the camshaft. 2.Remove: ● rocker arm shafts (intake and exhaust) 1 ● rocker arms 2 note: use a slide hammer 3 to remove th...

Page 144: Eng

4 - 18 eng camshaft, rocker arms and valves 2.Remove: ● valve cotters note: attach a valve spring compressor 1 between the valve spring retainer and the cylinder head to remove the valve cotters. Camshaft inspection 1.Inspect: ● cam lobes pitting/scratches/blue discoloration → replace. 2.Measure: ● ...

Page 145: Eng

4 - 19 eng camshaft, rocker arms and valves ● inspect the surface of the rocker arm shafts. Blue discoloration/pitting/scratches → replace/check lubrication. ● measure the inside diameter a of the rocker arm holes. Out of specification → replace. ● measure the outside diameter b of the rocker arm sh...

Page 146: Eng

4 - 20 eng camshaft, rocker arms and valves 2.Replace: ● valve guide ********************************* replacement steps: note: to ease guide removal, installation and to maintain correct fit, heat the cylinder head to 100 ˚c (212 ˚f) in an oven. ● remove the valve guide using a valve guide remover ...

Page 147: Eng

4 - 21 eng camshaft, rocker arms and valves 5.Measure: ● runout (valve stem) out of specification → replace. Note: ● when installing a new valve always replace the guide. ● if the valve is removed or replaced always replace the oil seal. 6.Eliminate: ● carbon deposits (from the valve face and valve ...

Page 148: Eng

4 - 22 eng camshaft, rocker arms and valves 9.Lap: ● valve face ● valve seat note: after refacing the valve seat or replacing the valve and valve guide, the valve seat and valve face should be lapped. ********************************* lapping steps: ● apply a coarse lapping compound to the valve fac...

Page 149: Eng

4 - 23 eng camshaft, rocker arms and valves 10.Measure: ● valve spring free length a out of specification → replace. 11.Measure: ● compressed spring force a out of specification → replace. B installed length free length (valve spring): inner: 39.9 mm (1.57 in) : 37.9 mm (1.49 in) outer: 43.27 mm (1....

Page 150: Eng

4 - 24 eng camshaft, rocker arms and valves valve and valve spring installation 1.Apply: ● molybdenum disulfide oil (onto the valve stem and valve stem seal) 2.Install: ● valve spring seats ● valve stem seals ● valves ● valve springs (inner and outer) ● valve spring retainers note: install the valve...

Page 151: Eng

4 - 25 eng camshaft, rocker arms and valves camshaft and rocker arm installation 1.Apply: ● engine oil (onto the rocker arm shafts) 2.Install: ● rocker arms 1 ● rocker arm shafts (intake and exhaust) 2 note: use a slide hammer bolt 3 to install the rocker arm shaft. 3.Install: ● camshaft 1 note: ins...

Page 152: Eng

4 - 26 eng cylinder and piston cylinder and piston order job name/part name q’ty remarks cylinder and piston removal remove the parts in the order below. Cylinder head refer to “cylinder head”. Water pump outlet hose/pipe refer to “water pump” in chapter 5. 1 cooling water inlet joint 1 2 timing cha...

Page 153: Eng

4 - 27 eng cylinder and piston piston removal 1.Remove: ● piston pin clips 1 ● piston pin 2 ● piston 3 note: before removing piston pin, deburr the clip groove and pin hole area. If the piston pin groove is deburred and the piston pin is still difficult to remove, use the piston pin puller 4 . Cauti...

Page 154: Eng

4 - 28 eng cylinder and piston 2.Measure: ● piston-to-cylinder clearance ********************************* measurement steps: 1st step: ● measure the cylinder bore “c” with the cylinder bore gauge. Note: measure cylinder bore “c” by taking side- to-side and front-to-back measurements of the cylinder...

Page 155: Eng

4 - 29 eng cylinder and piston 3rd step: ● find the piston-to-cylinder clearance with the following formula. ● if out of specification, rebore or replace the cylinder, and replace the piston and piston rings as a set. ********************************* piston-to-cylinder clearance = cylinder bore “c”...

Page 156: Eng

4 - 30 eng cylinder and piston 3.Measure: ● ring end gap out of specification → replace. Note: you cannot measure the end gap on the expander spacer of the oil control ring. If the oil control ring rails show excessive gap, replace all three rings. End gap standard limit top ring 0.2 ~ 0.4 mm (0.008...

Page 157: Eng

4 - 31 eng cylinder and piston ● if out of specification, replace the piston. ********************************* piston pin-to-piston clearance: 0.004 ~ 0.022 mm (0.00016 ~ 0.00087 in) : 0.07 mm (0.003 in) piston installation 1.Install: ● piston rings (onto the piston) note: ● be sure to install the ...

Page 158: Eng

4 - 32 eng cylinder and piston 4.Lubricate: ● piston ● piston rings ● cylinder note: apply a liberal coating of engine oil. Cylinder installation 1.Install: ● cylinder note: install the cylinder with one hand while compressing the piston rings with the other hand. Caution: ● be careful not to damage...

Page 159: Eng

4 - 33 eng recoil starter and cdi magneto recoil starter and cdi magneto order job name/part name q’ty remarks cdi magneto removal remove the parts in the order below. Engine oil drain. Refer to “engine oil replacement” in chapter 3. Seat and side panels refer to “seat and side panels” in chapter 3....

Page 160: Eng

4 - 34 eng recoil starter and cdi magneto order job name/part name q’ty remarks 7 pickup coil 1 8 stator assembly 1 9 cdi rotor 1 refer to “cdi magneto removal/ installation”. 10 starter wheel gear 1 11 woodruff key 1 12 bearing/washer 1/1 13 starter idle gear shaft 1 14 washer/bearing 1/1 15 starte...

Page 161: Eng

4 - 35 eng recoil starter and cdi magneto order job name/part name q’ty remarks recoil starter disassembly disassemble the parts in the order below. 1 cap 1 refer to “recoil starter disas- sembly/assembly”. 2 starter handle 1 3 friction plate 1 4 pawl spring 1 5 drive pawl 1 6 spring 1 7 sheave drum...

Page 162: Eng

4 - 36 eng recoil starter and cdi magneto cdi magneto removal 1.Remove: ● starter pulley 1 note: use the rotor holder 2 to hold the starter pulley. Rotor holder: p/n. Yu-01235, 90890-01235 2.Remove: ● crankcase cover (left) ● gasket ● dowel pins note: working in a crisscross pattern, loosen each bol...

Page 163: Eng

4 - 37 eng recoil starter and cdi magneto starter clutch inspection 1.Inspect: ● starter one-way clutch 1 cracks/damage → replace. ● bolts 2 (starter clutch) loose → replace with a new one, and clinch the end of the bolt. Note: the arrow mark on the starter clutch must face inward, away from the cdi...

Page 164: Eng

4 - 38 eng recoil starter and cdi magneto starter pulley inspection 1.Inspect: ● starter pulley cracks/pitting → deburr or replace. Recoil starter inspection 1.Inspect: ● rope 1 ● sheave drum 2 ● drive pawl 3 wear/damage → replace. ● coil spring 4 ● pawl spring 5 ● spring 6 fatigue → replace. Recoil...

Page 165: Eng

4 - 39 eng recoil starter and cdi magneto 2.Install: ● starter spring 1 ● sheave drum assembly 2 note: ● mesh the spring hook 3 with the case slit, then wind the spring clockwise into the case from the larger to smaller diameter. ● mesh the sheave drum hook 4 with the spring hook 5. 3.Install: ● spr...

Page 166: Eng

4 - 40 eng recoil starter and cdi magneto 2.Install: ● woodruff key ● cdi rotor note: ● before installing the rotor, clean the out- side of the crankshaft and the inside of the rotor. ● after installing the rotor, check that the rotor rotates smoothly. If not, reinstall the key and rotor. 3.Install:...

Page 167: Eng

4 - 41 eng recoil starter and cdi magneto 5.Install: ● select lever unit ● select lever shift rod note: before installing the select lever shift rod, make sure that the select lever and shift cam is in the neutral position. 6.Adjust: ● select lever shift rod refer to “select lever control cable and ...

Page 168: Eng

4 - 42 eng primary and secondary sheaves primary and secondary sheaves order job name/part name q’ty remarks primary and secondary sheave removal remove the parts in the order below. Front fender refer to “seat, carriers, fenders and fuel tank” in chapter 3. Rear fender right footrest boards 1 exhau...

Page 169: Eng

4 - 43 eng primary and secondary sheaves order job name/part name q’ty remarks 9 primary fixed sheave 1 refer to “primary and secondary sheaves removal/installation”. 10 secondary sheave assembly 1 for installation, reverse the removal procedure..

Page 170: Eng

4 - 44 eng primary and secondary sheaves primary sheave order job name/part name q’ty remarks primary sheave disassembly disassemble the parts in the order below. 1 primary pulley sheave cap 1 refer to “primary sheave assem- bly”. 2 primary pulley slider 4 3 spacer 4 4 primary pulley cam 1 5 primary...

Page 171: Eng

4 - 45 eng primary and secondary sheaves secondary sheave order job name/part name q’ty remarks secondary sheave disassembly disassemble the parts in the order below. 1 nut 1 refer to “secondary sheave dis- assembly/assembly”. 2 spring seat 1 3 compression spring 1 4 spring seat 1 5 guide pin 4 6 se...

Page 172: Eng

4 - 46 eng primary and secondary sheaves primary and secondary sheaves removal 1.Loosen: ● nut (secondary sheave) 1 ● nut (primary sheave) 2 note: ● use the sheave holder 3 to hold the pri- mary sheave. ● first, loosen the nut (secondary sheave) 2, then loosen the nut (primary sheave) 1. Sheave hold...

Page 173: Eng

4 - 47 eng primary and secondary sheaves primary sheave inspection 1.Inspect: ● weight outside diameter a out of specification → replace the weight. Weight outside diameter: 30 mm (1.18 in) : 29.5 mm (1.16 in) 2.Inspect: ● primary puller slider ● primary sliding sheave splines wear/cracks/damage → r...

Page 174: Eng

4 - 48 eng primary and secondary sheaves primary sheave assembly 1.Clean: ● primary sliding sheave face 1 ● primary fixed sheave face 2 ● collar 3 ● weight 4 ● primary sliding sheave cam face 2.Install: ● weight 1 note: ● apply shell ssg-2656-2 grease (120 g) to the whole outer surface of the weight...

Page 175: Eng

4 - 49 eng primary and secondary sheaves 3.Apply: ● bel-ray assembly lube ® (to the guide pin sliding groove 1, and o- ring 2 ) new 4.Install: ● spring seat ● compression spring ● spring seat ● nut ********************************* installing steps: ● attach the sheave fixed block, locknut wrench an...

Page 176: Eng

4 - 50 eng primary and secondary sheaves primary and secondary sheaves installation 1.Install: ● secondary sheave assembly ● v-belt ● primary sheave assembly note: ● tightening the bolts 1 will push the sec- ondary sliding sheave away, causing the gap between the secondary fixed and slid- ing sheave...

Page 177: Eng

4 - 51 eng clutch clutch order job name/part name q’ty remarks clutch removal remove the parts in the order below. Primary and secondary sheaves refer to “primary and secondary sheaves”. 1 cover 1 2 clutch housing assembly 1 refer to “clutch removal/instal- lation”. 3 gasket/dowel pin 1/2 4 one-way ...

Page 178: Eng

4 - 52 eng clutch order job name/part name q’ty remarks clutch housing disassembly disassemble the parts in the order below. 1 oil seal 1 2 circlip 1 3 bearing housing 1 4 circlip 1 5 bearing 1 6 circlip 1 7 bearing 1 8 clutch housing 1 for assembly, reverse the disassembly procedure..

Page 179: Eng

4 - 53 eng clutch clutch removal 1.Remove: ● clutch housing assembly ● gasket ● dowel pins note: working in crisscross pattern, loosen each bolt 1/4 of a turn. Remove them after all of them are loosened. 2.Straighten: ● punched portion of the nut 1 . 3.Remove: ● nut 1 note: use a clutch holding tool...

Page 180: Eng

4 - 54 eng clutch 2.Inspect: ● clutch shoe heat damage → replace. 3.Measure: ● clutch shoe thickness out of specification → replace. Clutch shoe thickness: 1.5 mm (0.06 in) clutch shoe wear limit a : 1.0 mm (0.04 in) clutch installation 1.Install: ● collar ● clutch carrier assembly ● nut 1 note: use...

Page 181: Eng

4 - 55 eng clutch 4.Install: ● dowel pins ● gasket ● clutch housing assembly note: ● tighten the bolts in stages, using a criss- cross pattern. ● after tightening the bolts, check that the clutch housing assembly to counterclock- wise rotates smoothly. New t r . . 10 nm (1.0 m • kg, 7.2 ft • lb).

Page 182: Eng

4 - 56 eng crankcase crankcase starter motor, timing chain and oil filter order job name/part name q’ty remarks starter motor, timing chain and oil filter removal remove the parts in the order below. Engine assembly refer to “engine removal”. Cylinder head refer to “cylinder head”. Cylinder and pist...

Page 183: Eng

4 - 57 eng crankcase order job name/part name q’ty remarks 6 oil filter 1 7 speed sensor 1 8 shift cam stopper 1 9 neutral switch 1 10 park switch 1 11 reverse switch 1 12 oil filler cap 1 13 bearing cover/gasket 1/1 14 oil delivery pipe 1 15 drain plug/o-ring 1/1 16 compression spring 1 17 oil stra...

Page 184: Eng

4 - 58 eng crankcase crankcase order job name/part name q’ty remarks crankcase separation remove the parts in the order below. 1 shift lever cover/gasket 1/1 refer to “shift lever installa- tion”. 2 shift lever 1/o-ring 1/1 3 shift lever 2 assembly 1 4 crankcase (left) 1 refer to “crankcase separati...

Page 185: Eng

4 - 59 eng crankcase crankcase bearing order job name/part name q’ty remarks crankcase bearing removal remove the parts in the order below. Crankshaft and oil pump refer to “crankshaft and oil pump”. Transmission refer to “transmission”. Middle drive/driven shaft refer to “middle gear”. 1 oil seal 2...

Page 186: Eng

4 - 60 eng crankcase oil pump drive gear removal 1.Straighten: ● lock washer tab 2.Remove: ● oil pump drive gear nut ********************************* removal steps: ● temporaly install the clutch carrier assembly 1. ● hold the clutch carrier assembly with a clutch holding tool 2 and loosen the oil ...

Page 187: Eng

4 - 61 eng crankcase ● remove the left crankcase. Caution: use a soft hammer to tap on one side of the crankcase. Tap only on reinforced por- tions of the crankcase. Do not tap on the crankcase mating surfaces. Work slowly and carefully. Make sure that the crankcase halves separate evenly. ● remove ...

Page 188: Eng

4 - 62 eng crankcase crankcase inspection 1.Thoroughly wash the case halves in a mild solvent. 2.Clean all the gasket mating surfaces and crankcase mating surfaces thoroughly. 3.Inspect: ● crankcase cracks/damage → replace. ● oil delivery passages clogged → blow out with compressed air. Bearings and...

Page 189: Eng

4 - 63 eng crankcase 4.Tighten: ● crankcase bolts (follow the proper tightening sequence) Å right crankcase ı left crankcase note: tighten the bolts in stages, using a criss- cross pattern. Å ı t r . . 10 nm (1.0 m • kg, 7.2 ft • lb) 5.Apply: ● 4-stroke engine oil (to the crank pin, bearing and oil ...

Page 190: Eng

4 - 64 eng crankcase oil pump drive gear installation 1.Install: ● straight key ● oil pump drive gear ● lock washer ● oil pump drive gear nut new 2.Tighten: ● oil pump drive gear nut ********************************* tightening steps: ● temporary install the clutch carrier assembly 1. ● hold the clu...

Page 191: Eng

4 - 65 eng crankshaft and oil pump crankshaft and oil pump order job name/part name q’ty remarks crankshaft and oil pump removal remove the parts in the order below. Crankcase separation refer to “crankcase”. 1 washer/circlip 1/1 2 oil pump assembly/gasket 1/1 3 balancer 1 refer to “crankshaft remov...

Page 192: Eng

4 - 66 eng crankshaft and oil pump oil pump order job name/part name q’ty remarks oil pump disassembly disassemble the parts in the order below. 1 rotor cover 1 2 pin 2 3 shaft 1 4 pin 1 5 inner rotor 1 6 outer rotor 1 7 oil pump housing 1 for assembly, reverse the disassembly procedure..

Page 193: Eng

4 - 67 eng crankshaft and oil pump crankshaft removal 1.Remove: ● crakshaft seal 1 note: mark a note of the pasition of each crank- shaft seal so that they can be installed in the correct place and in the correct direc- tion. 2.Remove: ● crankshaft use a crankcase separating tool 1. Crankcase separa...

Page 194: Eng

4 - 68 eng crankshaft and oil pump 3.Check: ● oil pump operation unsmooth → repeat steps #1 and #2 or replace the defective parts. Crankshaft inspection 1.Measure: ● crank width a out of specification → replace the crank- shaft. ● side clearance d out of specification → replace the crank- shaft. ● r...

Page 195: Eng

4 - 69 eng crankshaft and oil pump crankshaft and balancer installation 1.Install: ● crankshaft note: hold the connecting rod at the top dead center (t.D.C.) with one hand while turning the nut of the installing tool with the other. Operate the installing tool until the crank- shaft bottoms against ...

Page 196: Eng

4 - 70 eng transmission transmission order job name/part name q’ty remarks transmission removal remove the parts in the order below. Crankcase separation refer to “crankcase”. 1 driven sprocket 1 2 drive sprocket 1 3 chain 1 4 clutch dog 2 1 5 shift fork “l” 1 6 spring 1 7 low wheel gear 1 8 seconda...

Page 197: Eng

4 - 71 eng transmission order job name/part name q’ty remarks 12 shift fork “r” 1 13 spring 1 14 shift cam 1 15 stopper wheel 1 16 clutch dog 1 1 17 high wheel gear 1 18 stopper lever 1 19 spacer/o-ring 1/1 for installation, reverse the removal procedure..

Page 198: Eng

4 - 72 eng transmission shift fork inspection 1.Inspect: ● shift fork cam follower 1 ● shift fork pawl 2 scoring/bends/wear/damage → replace. 2.Inspect: ● guide bar roll the guide bar on a flat surface. Bends → replace. Warning do not attempt to straighten a bent guide bar. 3.Check: ● shift fork mov...

Page 199: Eng

4 - 73 eng transmission transmission inspection 1.Measure: ● axle runout use a centering device and a dial gauge. Out of specification → replace the bent axle. Runout limit (drive axle): 0.03 mm (0.001 in) 2.Inspect: ● gear teeth blue discoloration/pitting/wear → replace. ● mated dogs rounded edges/...

Page 200: Eng

4 - 74 eng transmission 2.Check: ● shift operation unsmooth operation → repair. Note: ● oil each gear and bearing thoroughly. ● before assembling the crankcase, be sure that the transmission is in neutral and that the gears turn freely..

Page 201: Eng

4 - 75 eng middle gear middle gear middle drive shaft order job name/part name q’ty remarks middle drive shaft removal remove the parts in the order below. Crankcase separation refer to “crankcase”. Transmission refer to “transmission”. 1 bearing housing assembly 1 2 nut 1 refer to “middle drive sha...

Page 202: Eng

4 - 76 eng middle gear middle driven shaft order job name/part name q’ty remarks middle driven shaft assembly remove the parts in the order below. Crankcase separation refer to “crankcase”. 1 circlip 2 refer to “middle driven shaft removal/installation”. 2 bearing 2 3 universal joint 1 4 universal j...

Page 203: Eng

4 - 77 eng middle gear order job name/part name q’ty remarks 12 front drive shaft coupling 1 13 bearing retainer 1 14 middle driven shaft 1 for installation, reverse the removal procedure..

Page 204: Eng

4 - 78 eng middle gear middle drive shaft removal 1.Straighten: ● punched portion of the nut (middle drive pinion gear) 2.Loosen: ● nut (middle drive pinion gear) 1 note: secure the middle drive shaft in the vise with a clean rag. 3.Remove: ● nut (middle drive pinion gear) ● middle drive pinion gear...

Page 205: Eng

4 - 79 eng middle gear 2.Remove: ● nut 1 ● washer ● universal joint yoke note: use the universal joint holder 2 to hold the universal joint yoke. 3.Remove: ● bearing housing assembly 1 ********************************* bearing housing removal steps: ● clean the outside of the middle driven shaft. ● ...

Page 206: Eng

4 - 80 eng middle gear 5.Remove: ● front drive shaft coupling ● bearing retainer 1 ● bearing 2 note: attach the ring nut wrench 3 . Caution: the middle driven shaft bearing retainer has left-handed threads. To loosen the retainer turn it clockwise. Ring nut wrench: p/n. Ym-38404, 90890-01430 6.Remov...

Page 207: Eng

4 - 81 eng middle gear 4.Inspect: ● o-ring damage → replace. ● bearings pitting/damage → replace. 5.Check: ● u-joint movement roughness → replace u-joint. Middle drive and driven gear shim selection when the drive and driven gear, bearing housing assembly and/or crankcase replaced, be sure to adjust...

Page 208: Eng

4 - 82 eng middle gear example: 1) if the bearing housing is marked “+04”, ..... A is 10.54, 2) b is 55 3) if the crankcase (right) is marked “66.03”, ..... C is 66.03. 4) therefore, the shim thickness is 0.47 mm. A = 66.03 – 10.54 – 55 = 0.49 5) round off hundredths digit and select appropriate shi...

Page 209: Eng

4 - 83 eng middle gear where: d = a numeral (usually a decimal num- ber) on the bearing housing is either added to or subtracted from “76”. E = a numeral (usually a decimal num- ber) on the middle driven pinion gear is either added to or subtracted from “59”. F = a numeral (usually a decimal num- be...

Page 210: Eng

4 - 84 eng middle gear shims are supplied in the following thick- ness. ********************************* middle drive pinion gear shim thickness (mm) 0.10 0.40 0.15 0.50 0.20 0.60 0.30 middle driven shaft installation 1.Install: ● bearing retainer 1 note: attach the ring nut wrench 2. Caution: the ...

Page 211: Eng

4 - 85 eng middle gear ● tighten the bearing retainer. Caution: the middle driven shaft bearing retainer has left-handed threads. To tighten the retainer turn it counterclockwise. ********************************* 3.Install: ● shims 1 ● bearing housing note: install the shims so that the tabs are po...

Page 212: Eng

4 - 86 eng middle gear ● install the bearing 1 onto the yoke. Caution: check each bearing. The needles can easily fall out of their races. Slide the yoke back and forth on the bearings; the yoke will not go all the way onto a bearing if a needle is out of place. ● press each bearing into the u-joint...

Page 213: Eng

4 - 87 eng middle gear ● attach the gear lash measurement tool 2 and dial gauge 3. A 46 mm (1.8 in) ● measure the gear lash while rotating the middle driven shaft back and forth. Note: measure the gear lash at 4 positions. Rotate the middle driven gear 90˚ each time. ● if the gear lash is incorrect,...

Page 214: Eng

4 - 88 eng.

Page 215: Cool

Cool 5.

Page 216: Cool

Cool chapter 5. Cooling system radiator .....................................................................................................5-1 radiator inspection ......................................................................5-3 radiator installation ..........................................

Page 217: Cool

Cool.

Page 218: Cool

5 - 1 cool radiator cooling system radiator order job name/part name q’ty remarks radiator removal remove the parts in the order below. Seat and side panels refer to “seat and side panels” in chapter 3. Front carrier, front bumper and front fender refer to “front carrier, front bumper and front fend...

Page 219: Cool

5 - 2 cool radiator order job name/part name q’ty remarks 5 radiator inlet hose 1 disconnect. 6 radiator outlet hose 1 disconnect. 7 radiator 1 8 radiator fan 1 9 thermo switch 1 for installation, reverse the removal procedure..

Page 220: Cool

5 - 3 cool radiator radiator inspection 1.Inspect: ● radiator fins obstruction → clean. Apply compressed air to the rear of the radiator. Damage → repair or replace. Note: straighten any flattened fins with a thin, flat-head screwdriver. 2.Inspect: ● radiator hoses cracks/damage → replace. 3.Measure...

Page 221: Cool

5 - 4 cool radiator radiator installation 1.Fill: ● cooling system (with the specified amount of the recom- mended coolant) refer to “coolant replacement” in chapter 3. 2.Check: ● cooling system leaks → repair or replace any faulty part..

Page 222: Cool

5 - 5 cool thermostat thermostat order job name/part name q’ty remarks thermostat removal remove the parts in the order below. Seat and fuel tank side panel (right) refer to “seat and side panels” in chapter 3. Coolant drain. Refer to “coolant replacement” in chapter 3. 1 radiator inlet hose 1 2 the...

Page 223: Cool

5 - 6 cool thermostat thermostat inspection 1.Check: ● thermostat 1 does not open at 63.5 ~ 65.5 ˚c (146.3 ~ 149.9 ˚f) → replace. ********************************* checking steps: ● suspend the thermostat in a container filled with water. ● slowly heat the water. ● place a thermometer in the water. ...

Page 224: Cool

5 - 7 cool water pump water pump order job name/part name q’ty remarks water pump removal remove the parts in the order below. Seat, fuel tank side panel (left) and engine side cover refer to “seat and side panels” in chapter 3. Left footrest board refer to “footrest boards” in chapter 3. 1 water pu...

Page 225: Cool

5 - 8 cool water pump order job name/part name q’ty remarks water pump disassembly remove the parts in the order below. 1 water pump housing cover 1 2 gasket 1 3 circlip 1 4 impeller 1 5 rubber damper holder 1 6 rubber damper 1 7 water pump seal 1 8 oil seal 1 9 bearing 1 0 water pump housing 1 for ...

Page 226: Cool

5 - 9 cool water pump water pump disassembly 1.Remove: ● rubber damper holder 1 ● rubber damper 2 (from the impeller, with a thin, flathead screwdriver) note: do not scratch the impeller shaft. 2.Remove: ● water pump seal 1 note: tap out the water pump seal from the inside of the water pump housing....

Page 227: Cool

5 - 10 cool water pump water pump assembly 1.Install: ● oil seal 1 (into the water pump housing 2) note: ● before installing the oil seal, apply tap water or coolant onto its outer surface. ● install the oil seal with a socket 3 that matches its outside diameter. New 2.Install: ● water pump seal 1 (...

Page 228: Cool

5 - 11 cool water pump 4.Measure: ● impeller shaft tilt out of specification → repeat steps (3) and (4). Caution: make sure that the rubber damper and rub- ber damper holder are flush with the impel- ler. 1 straightedge 2 impeller max. Impeller shaft tilt: 0.15 mm (0.006 in).

Page 229: Cool

5 - 12 cool.

Page 230: Carb

Carb 6.

Page 231: Carb

Carb chapter 6. Carburetion carburetor ...............................................................................................6-1 carburetor inspection ................................................................6-4 carburetor assembly .......................................................

Page 232: Carb

Carb.

Page 233: Carb

6 - 1 carb carburetor carburetion carburetor order job name/part name q’ty remarks carburetor removal remove the parts in the order below. Seat/fuel tank side panels/fuel tank/ rubber cover refer to “seat, carriers, fenders and fuel tank” in chapter 3. 1 drain hose 1 2 starter cable/starter plunger ...

Page 234: Carb

6 - 2 carb carburetor order job name/part name q’ty remarks carburetor disassembly disassemble the parts in the order below. 1 air vent hose 1 2 throttle stop screw 1 3 vacuum chamber cover 1 4 spring 1 5 jet needle holder 1 6 spring 1 7 jet needle set 1 8 piston valve 1 9 coasting enricher 1 0 floa...

Page 235: Carb

6 - 3 carb carburetor order job name/part name q’ty remarks d pilot jet 1 e pilot screw set 1 refer to “carburetor assembly”. F main jet 1 g needle jet 1 refer to “carburetor disassem- bly/assembly”. H starter jet 1 i pilot air jet 1 for assembly, reverse the disassembly procedure..

Page 236: Carb

6 - 4 carb carburetor carburetor inspection 1.Inspect: ● carburetor body ● float chamber cracks/damage → replace. ● fuel passage contamination → clean as indicated. ● fuel chamber body contamination → clean. ********************************* cleaning steps: ● wash the carburetor in a petroleum based...

Page 237: Carb

6 - 5 carb carburetor 5.Inspect: ● vacuum chamber cover 1 ● spring 2 cracks/damage → replace. 6.Inspect: ● diaphragm (coasting enricher) 1 ● spring 2 ● cover 3 tears (diaphragm)/damage → replace. 7.Inspect: ● jet needle 1 ● main jet 2 ● needle jet 3 ● pilot air jet 4 ● pilot jet 5 ● pilot screw 6 ● ...

Page 238: Carb

6 - 6 carb carburetor carburetor assembly caution: before reassembling, wash all of the parts in a clean petroleum based solvent. 1.Install: ● pilot screw 1 pilot screw: 2-1/2 turns out 2.Measure: ● float height a out of specification → adjust. ********************************* measurement and adjus...

Page 239: Carb

6 - 7 carb carburetor fuel level adjustment 1.Measure: ● fuel level a out of specification → adjust. ********************************* fuel level measurement and adjustment steps: ● place the machine on a level surface. ● connect the fuel level gauge 1 to the drain pipe 2. ● loosen the drain screw 3...

Page 240: Carb

6 - 8 carb.

Page 241: Drive

Drive 7.

Page 242: Driv

Driv chapter 7. Drive train troubleshooting ...................................................................................7-1 constant velocity joints and differential gear ....................7-4 ring gear removal ........................................................................7-9 cons...

Page 243: Driv

Driv.

Page 244: Driv

7 - 1 driv troubleshooting drive train troubleshooting the following conditions may indicate damaged shaft drive components: note: areas a, b, and c above may be extremely difficult to diagnose. The symptoms are quite sub- tle and difficult to distinguish from normal machine operating noise. If ther...

Page 245: Driv

7 - 2 driv troubleshooting caution: too little gear lash is extremely destructive to the gear teeth. If a test ride following reas- sembly indicates this condition, stop riding immediately to minimize gear damage. C.A slight “thunk” evident at low speed operation. This noise must be distin- guished ...

Page 246: Driv

7 - 3 driv troubleshooting troubleshooting chart when basic condition “a” and “b” exist, check the following points: elevate and spin both wheels. Feel for wheel bearing damage. Yes replace the wheel bearing. (refer to “steering system” and “rear shock absorber and swingarm” in chapter 8.) no check ...

Page 247: Driv

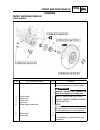

7 - 4 driv constant velocity joints and differential gear constant velocity joints and differential gear order job name/part name q’ty remarks constant velocity joint and differen- tial gear removal remove the parts in the order below. Engine skid plate (front) front fender refer to “seat, carriers,...

Page 248: Driv

7 - 5 driv constant velocity joints and differential gear order job name/part name q’ty remarks 4 differential gear 1 5 drive shaft 1 6 compression spring 1 7 coupling gear 1 for installation, reverse the removal procedure..

Page 249: Driv

7 - 6 driv constant velocity joints and differential gear order job name/part name q’ty remarks constant velocity joint disassembly disassemble the parts in the order below. 1 circlip 1 2 boot band 2 refer to “constant velocity joint assembly”. 3 boot band 2 4 dust boot 2 5 circlip 1 6 double off-se...

Page 250: Driv

7 - 7 driv constant velocity joints and differential gear order job name/part name q’ty remarks defferential gear disassembly disassembly the parts in the order below. 1 gear motor/o-ring 1/1 2 four-wheel drive switch 1 3 dust seal 1 4 circlip 1 5 coupling gear/bearing/circlip 1/1/1 6 stopper bolt/s...

Page 251: Driv

7 - 8 driv constant velocity joints and differential gear order job name/part name q’ty remarks c shim (right) 1 d circlip/bearing 1/1 e drive pinion gear 1 f differential gear case 1 for assembly, reverse the disassembly procedure..

Page 252: Driv

7 - 9 driv constant velocity joints and differential gear ring gear removal 1.Remove: ● ring gear 1 note: the ring gear and the differential gear cover should be fastened together. Do not disas- semble the differential gear. Caution: the differential gears are assembled into a proper unit at the fac...

Page 253: Driv

7 - 10 driv constant velocity joints and differential gear 2.Inspect: ● drive shaft splines ● universal joints ● front drive gear splines wear/damage → replace. ● spring fatigue → replace. Move the spring up and down. 3.Inspect: ● front drive shaft bends → replace. Warning do not attempt to straight...

Page 254: Driv

7 - 11 driv constant velocity joints and differential gear 3.Check: ● free play (thrust movement) excessive play → replace the joint assem- bly. Differential gear assembly 1.Measure: ● gear lash refer to “differential gear lash measurement and adjustment”. 2.Install: ● gear motor refer to “features”...

Page 255: Driv

7 - 12 driv constant velocity joints and differential gear 4.Attach: ● gear lash measurement tool 1 ● dial gauge 2 a measuring point is 30 mm (1.18 in) 5.Measure: ● gear lash gently rotate the gear coupling from engagement to engagement . Note: measure the gear lash at four positions. Rotate the sha...

Page 256: Driv

7 - 13 driv constant velocity joints and differential gear ring gear shim (left and right) thickness (mm) 0.1 1.0 0.2 1.5 0.3 2.0 0.4 2.5 0.5 differential gear operation check 1.Block the rear wheels, and elevate the front wheels by placing a suitable stand under the frame. 2.Remove the wheel cap an...

Page 257: Driv

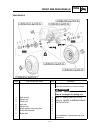

7 - 14 driv rear axle/final drive gear and drive shaft rear axle/final drive gear and drive shaft order job name/part name q’ty remarks rear axle, final drive gear assembly and drive shaft removal remove the parts in the order below. Final gear oil drain. Rear wheel hubs/brake disc refer to “front a...

Page 258: Driv

7 - 15 driv rear axle/final drive gear and drive shaft order job name/part name q’ty remarks final drive gear disassembly disassemble the parts in the order below. 1 bolt 2 2 bolt 6 3 bearing housing 1 4 oil seal/bearing 1/1 5 ring gear stopper 1 6 ring gear stopper shim 1 7 oil seal/bearing 1/1 8 r...

Page 259: Driv

7 - 16 driv rear axle/final drive gear and drive shaft order job name/part name q’ty remarks a bearing retainer/o-ring 1/1 refer to “final drive gear disas- sembly/assembly”. B oil seal 1 c final drive pinion gear 1 d collar 1 e bearing 1 f final drive pinion gear shim 1 g final drive gear case/o-ri...

Page 260: Driv

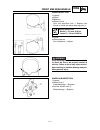

7 - 17 driv rear axle/final drive gear and drive shaft rear axle removal 1.Remove: ● rear axle 1 (with dust seal) ● o-ring caution: ● never directly tap the axle end with a hammer, since this will result in damage to the axle thread and spline. ● attach a suitable socket 2 on the axle end and tap it...

Page 261: Driv

7 - 18 driv rear axle/final drive gear and drive shaft final drive roller bearing removal and reassembly 1.Remove: ● roller bearing (ring gear) 1 use a suitable press tool 2 and an appro- priate support for the main housing. ● oil seal 3 2.Remove: ● roller bearing (final drive pinion gear) 1 *******...

Page 262: Driv

7 - 19 driv rear axle/final drive gear and drive shaft final drive pinion gear and ring gear positioning when the final drive pinion gear, ring gear, final gear case and/or ring gear bearing housing are replaced, be sure to adjust the positions of the final drive pinion gear and ring gear using the ...

Page 263: Driv

7 - 20 driv rear axle/final drive gear and drive shaft shims are supplied in the following thick- nesses. ********************************* final drive pinion gear shim thickness (mm) 0.15 0.30 0.40 0.45 0.50 0.60 ring gear shim selection 1.Select: ● ring gear shim(s) 1 *****************************...

Page 264: Driv

7 - 21 driv rear axle/final drive gear and drive shaft 5) therefore, shim thickness “b” is 0.63. “b”= 45.53 + 1.05 – (34.95 + 11.00) = 46.58 – 45.95 = 0.63 6) round off the hundredth digit and select the appropriate shim(s). In the example above, the calculated number is 0.63. The chart instructs yo...

Page 265: Driv

7 - 22 driv rear axle/final drive gear and drive shaft ● remove the ring gear assembly. ● measure the thrust clearance. Calculate the width of the flattened plastigauge ® 1. ● if out of specification, select the correct washer. Ring gear thrust clearance: 0.1 ~ 0.2 mm (0.004 ~ 0.008 in) thrust washe...

Page 266: Driv

7 - 23 driv rear axle/final drive gear and drive shaft ring gear stopper clearance adjustment 1.Remove: ● ring gear 1 ● ring gear stopper 2 ● shim(s) 3 4 bearing housing Å left-hand threads 2.Select: ● suitable shim(s) shim thickness (mm) 0.10 0.15 0.20 0.30 0.40 0.50 3.Install: ● shim(s) ● ring gea...

Page 267: Driv

7 - 24 driv rear axle/final drive gear and drive shaft drive shaft inspection 1.Inspect: ● drive shaft (splines) 1 ● coupling gear (splines) 2 wear/damage → replace. Final drive gear inspection 1.Inspect: ● final gear case 1 ● bearing housing (ring gear) 2 cracks/damage → replace. Note: when the fin...

Page 268: Driv