- DL manuals

- Z Corporation

- 3D Printers

- Z810

- System User Manual

Z Corporation Z810 System User Manual

Summary of Z810

Page 1

Z810 system user manual january 2004 copyright © 2002-2004 z corporation rev. F, part number 09505 z ® 810 color 3d printer user manual.

Page 2

Z corporation z810 system user manual www.Zcorp-users.Com 2 table of contents 1 introduction.......................................................................................................................7 1.1 o verview ............................................................................

Page 3

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 3 5.2.1 part containing an opening or hollow area............................................................ 41 5.2.2 part containing overhangs ..................................................................

Page 4

Z corporation z810 system user manual www.Zcorp-users.Com 4 11.1.6 material ordering........................................................................................... 97 11.1.7 recycling ...........................................................................................................

Page 5

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 5 table of figures f igure 1: t he p rinting p rocess .................................................................................................... 8 f igure 2: t he s helling and i nfrastructure f eat...

Page 6

Z corporation z810 system user manual www.Zcorp-users.Com 6 use of equipment the equipment was manufactured under patents licensed to z corp. To be used for the fabrication of appearance models and prototypes. Other uses may be restricted; contact z corporation for further information. The equipment...

Page 7

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 7 1 introduction 1.1 overview this z810 color 3d printer manual will speed you along the path towards quickly and inexpensively building parts. The manual contains the following sections: 1. Introduction. Thi...

Page 8

Z corporation z810 system user manual www.Zcorp-users.Com 8 1.2 how it works the z corp. Printer systems are based on the massachusetts institute of technology’s patented 3dp ™ (3d printing) technology. The zprint software first converts three-dimensional data from cad, or other sources into cross- ...

Page 9

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 9 the z corp. Printer system employ several techniques to quickly build parts. First, binder solution is applied in a higher concentration around the edges of the part, creating a strong “shell” around the ex...

Page 10

Z corporation z810 system user manual www.Zcorp-users.Com 10 figure 3: illustration of z corp. System print orientations accuracy. The accuracy of the printer depends on the materials you choose and the offset and scaling factors used. You can employ the anisotropic scaling feature in the software t...

Page 11

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 11 2 system components 2.1 z810 printer components the z810 system consists of the following hardware components: 2.1.1 z810 3d printer site requirements: power: 100-240 vac, 50-60 hz compressed air: clean, d...

Page 12

Z corporation z810 system user manual www.Zcorp-users.Com 12 top cover zc3 wash fluid container overflow vacuum receptacle overflow chute electronics enclosure pump enclosure waste container clear binder container color binder container (cyan, magenta, yellow) control panel top cover handle zf8 powd...

Page 13

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 13 carriage print heads removable build pallet spread roller overflow chute service station print head spit area top deck gantry - moves along the slow axis printer assembly - rests on the gantry figure 5: z8...

Page 14

Z corporation z810 system user manual www.Zcorp-users.Com 14 2.1.1.1 z810 carriage assembly carriage cover carriage cover latch note: one is located in the back of the carriage (not shown) print heads (numbered from 0-5 from front to back) 0 1 2 3 4 5 figure 6: z810 3d printer carriage assembly.

Page 15

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 15 2.1.1.2 z810 service station print head spit area wash fluid spray nozzle squeegees print head parking cap figure 7: z810 3d printer service station.

Page 16

Z corporation z810 system user manual www.Zcorp-users.Com 16 2.1.1.3 z810 rear connector panel power input - connector provided powder feeder serial cable - connector provided diagnostic video connector - no connector provided serial input connection - connector provided network connection - connect...

Page 17

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 17 2.1.1.4 z810 printer control panel l c d p a n e l . Displays the current status o f t h e z 8 1 0 3d printer. O n l i n e b u t t o n . Enables and disables printer communication. Spread button. This butt...

Page 18

Z corporation z810 system user manual www.Zcorp-users.Com 18 2.1.2 zf8 powder feeder site requirements: power: voltage : 100vac, 50/60hz, 20a 115vac, 50/60hz, 17a 230vac, 50/60hz, 10a compressed air: clean, dry air (dew point 40 o f/4 o c or below) air fitting: ¼ “industrial” quick disconnect or oth...

Page 19

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 19 2.1.2.1 zf8 rear connector panel air connector - connecting hose provided power input - connector provided power switch powder feeder serial cable - connector provided figure 11: zf8 powder feeder rear con...

Page 20

Z corporation z810 system user manual www.Zcorp-users.Com 20 2.2 zd8 depowdering unit site requirements: power: voltage: receptacle for plug type : 190-200 vac, 50hz, 10.5a iec 60309-2: red-6h-32a-3p+n+e 208-230 vac, 60hz, 15a iec nema l15-30 plug 380-400 vac, 50hz, 5.3a iec 60309-2 plug, red-6h-16a...

Page 21

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 21 s e l e c t o r l e v e l . Adjusts the amount o f a i r u s e d f o r a i r curtain across the z d 8 w i n d o w a n d opening. Zd8 window. Creates a shield to reduce airbourne powder particles. Tracks. A...

Page 22

Z corporation z810 system user manual www.Zcorp-users.Com 22 2.2.1 air curtain a fraction of the clean air exhausting from the blower is focused into a curtain and directed downward across the zd8 window and front opening. This air curtain helps powder from being ejected from the part during depowde...

Page 23

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 23 2.2.2 zd8 control panel main control switch light push button warning lamp figure 14: zd8 control panel please note: if the warning lamp is illuminated (indicating that the filter cleaning cycle has been i...

Page 24

Z corporation z810 system user manual www.Zcorp-users.Com 24 2.2.3 powder collection drawer p o w d e r collection drawer handle figure 15: zd8 powder collection drawer all of the discarded powder from the depowdering process is deposited in the powder collection drawer at the base of the zd8 depowd...

Page 25

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 25 2.3 despatch lbb forced convection oven (option) key features • 42 inches (1.07 meters) deep x 45 inches (1.14 meters) wide x 84 inches (2.13 meters) tall. Height includes oven stand. Oven alone is 51 inch...

Page 26

Z corporation z810 system user manual www.Zcorp-users.Com 26 3 quick start guide here is a quick guide to printing a part in the z810 3d printer. 3.1 printer preparation 1. Clean the top deck. 2. Clean service station..

Page 27

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 27 3. Spread powder over the build area. 4. Empty powder overflow chute. 5. Check fluid levels of binder, and wash fluid. Fill or replace if needed. Empty waste container..

Page 28

Z corporation z810 system user manual www.Zcorp-users.Com 28 3.2 setting up the build 1. Set up the build on the zprint software. 2. Check 3d print setup for build settings and edit as needed. 3. Press 3d print to begin printing process..

Page 29

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 29 3.3 transferring the part to the depowdering unit 1. Gross depowder the part in the printer, leaving the powder underneath to support the model. 2. Transfer build pallet to cart using track system. 3. Tran...

Page 30

Z corporation z810 system user manual www.Zcorp-users.Com 30 3.4 depowdering the part 1. Turn air gun on and adjust air pressure. 2. Depowder part. Leave supporting powder underneath plaster parts. Depowder starch parts completely. 3. Remove part from depowdering unit. 4. Clean depowdering unit..

Page 31

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 31 3.5 transfer to oven transfer part to oven for additional drying. 3.6 finish part depowder or infiltrate as needed. Infiltrate part with z corp. Recommended wax or resins. More information on infiltrants c...

Page 32

Z corporation z810 system user manual www.Zcorp-users.Com 32 3.7.1.2 gross and fine depowdering • become familiar with where the parts are placed and how they are oriented in the build box so you do not accidentally bump or brush against a fragile part during the depowdering process. • when performi...

Page 33

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 33 4 preparing the z810 3d printer 4.1 replacing the build pallet put the printer offline. If there is no pallet in the printer, replace the pallet by pressing ‘load/unload’ on the control panel to move the b...

Page 34

Z corporation z810 system user manual www.Zcorp-users.Com 34 3. Wipe the cover plate and deck off when finished. 4. Vacuum up or wipe up any powder between the overflow chute and the service station. 4.3 greasing the fast axis the carriage bearings have been replaced with bearings with grease fittin...

Page 35

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 35 4.4 oil slow axis 4.4.1 snowplows. The snowplows are located near the back and front of the gantry at the outer edges of the spead roller. There are two wicks found on each snowplow. Place a few drops of o...

Page 36

Z corporation z810 system user manual www.Zcorp-users.Com 36 4.5 fill bed 1. Press the ‘fill bed’ button on the control panel. This will prompt the powder feeder and gantry to deposit and spread powder over the build pallet. It will continue spreading until the build pallet is covered. 2. To cancel ...

Page 37

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 37 4.7 checking powder levels if you do not have enough powder to complete your build, you will need to fill the powder feeder. To view how much powder is left in the feeder, choose ‘get piston levels’ under ...

Page 38

Z corporation z810 system user manual www.Zcorp-users.Com 38 4.8 check fluid levels 4.8.1 binder containers check the fluid levels on the binder and waste containers. It is good practice to fill the binder bottles when they are half empty. The color binder containers can hold half a gallon (2 liters...

Page 39

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 39 4.8.2 check waste container the waste bottle should be emptied before each build. To empty the waste container: 1. Unscrew cap. 2. Place paper towel around the float sensor located at the bottom of the bin...

Page 40

Z corporation z810 system user manual www.Zcorp-users.Com 40 4.8.3 zc3 wash fluid container over time, zc3 wash fluid will evaporate or become contaminated with powder and will need to be replaced. If the fluid level has reached 1/2 of the container, it will need to be replaced. For more information...

Page 41

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 41 5 using zprint software this chapter will briefly explain how to set up the build, check the settings, and print. For more information about features in the zprint software, please refer to the zprint soft...

Page 42

Z corporation z810 system user manual www.Zcorp-users.Com 42 5.2.2 part containing overhangs unsupported overhangs should be placed on the left hand-side and as close to the build plate as possible. The plaster powder, being extremely fine, is more fluid in the build. Placing a small solid piece u...

Page 43

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 43 it is also strongly recommended that slice viewing and collision detection (if more than one part is being printed) be used before beginning the build. These features are found under the view menu of the s...

Page 44

Z corporation z810 system user manual www.Zcorp-users.Com 44 5.3.1.2 saturation values the saturation values determine how much binder is placed on the powder to print the part. The part is made up of two areas, the shell and the core, as described in section 1.2, how it works. Thus, there are two s...

Page 45

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 45 5.4 printing the build it is strongly recommended that the build settings be confirmed before printing. To check build settings, choose ‘3d print setup’ under the file menu or click on the icon located on ...

Page 46

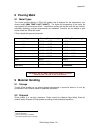

Z corporation z810 system user manual www.Zcorp-users.Com 46 6 removing the part 6.1 set times once the build has completed, let the part sit in the printer to set. This will allow the part to dry while being supported by surrounding powder. Recommended set times material system set time plaster mat...

Page 47

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 47 6.2 gross depowdering gross depowdering is the initial removal of excess powder from the build. 1. Put printer ‘offline’. 2. Turn on the vacuum. 3. Insert the vacuum hose into a vacuum receptacle in the po...

Page 48

Z corporation z810 system user manual www.Zcorp-users.Com 48 6. Vacuum powder around the edges of the build area and part. 7. Carefully vacuum around the part from the top to the bottom and from the outside edges of the build area to the inside. 8. Raise the build piston as needed for easier access ...

Page 49

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 49 9. Leave powder underneath the part to support any overhanging surfaces. 10. Carefully vacuum around the part to remove as much powder as possible. 6.3 transfering the parts to the depowdering station 1. P...

Page 50

Z corporation z810 system user manual www.Zcorp-users.Com 50 2. Vacuum off any surrounding powder. 3. Place the tracks on each side of build pallet. Tracks 4. Secure the tracks to the top deck by interlocking the “j-shaped” slots with the track pegs. Peg for cart track peg for side track vacuum nozz...

Page 51

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 51 5. Place zd8 cart in front of printer and attach tracks from cart to top deck. Cart tracks build pallet 6. Press ‘online’ on the control panel to lower build pallet. 7. Push or pull pallet onto cart. Remov...

Page 52

Z corporation z810 system user manual www.Zcorp-users.Com 52 8. Lift zd8 window. 9. Move cart in front of zd8 depowdering station. 10. Orient the zd8 turntable so that the track pegs are towards the front of the depowdering unit. 11. Attach the tracks. 12. Push build pallet into depowdering unit. 13...

Page 53

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 53 6.4 post processing tools there are six tools included in the accessories kit that are used to assist the user with gross depowdering and cleaning of the part. 1 3 2 4 5 6 1. Wide blade utility scraper: th...

Page 54

Z corporation z810 system user manual www.Zcorp-users.Com 54 3. Soft horsehair brush: this brush has very soft bristles and assists the user with the gross depowdering process. Brushing powder away from the part is a useful technique prior to the vacuuming step. 4. Stiff detailing brush: this brush ...

Page 55

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 55 7 depowdering the part 7.1 changing air nozzles you may choose to use different air nozzles for different stages of depowdering. For rough depowdering, use the large nozzle. Use the fine point nozzle for d...

Page 56

Z corporation z810 system user manual www.Zcorp-users.Com 56 5. Depowder the part beginning from the top surface area and working downwards. Rotate turntable as needed. Remove as much powder from part as possible. For plaster parts do not remove the supporting powder. For starch parts remove support...

Page 57

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 57 out certain sections of your part using your respective cad software package to decrease volume. For more information, refer to the zcast design guide located in the appendix of this manual or found on the...

Page 58

Z corporation z810 system user manual www.Zcorp-users.Com 58 8 infiltrants infiltrant material system application z-max tm epoxy starch and plaster system spray or brush z-bond tm cyanoacrylate starch and plaster system spray, brush, drizzle z-snap epoxy zp250 material system spray, brush, drizzle w...

Page 59

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 59 general application notes • material can be brushed or sprayed. • material will penetrate between 0.079-0.28 inches (2 – 7 mm). • material will pool off the part during curing, if it is over-applied. • bet...

Page 60

Z corporation z810 system user manual www.Zcorp-users.Com 60 8.2 using z-bond tm cyanoacrylate z-bond cyanoacrylate is an extremely fast setting, low viscosity, general-purpose infiltration resin. This resin is designed to rapidly strengthen parts. Z-bond is a one part, user friendly, no-odor, non-b...

Page 61

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 61 for more information on the uses of z-bond resin, please refer to the technical data sheet that can be found on the user group website at www.Zcorp-users.Com . 8.3 using z-snap tm epoxy z-snap epoxy is a f...

Page 62

Z corporation z810 system user manual www.Zcorp-users.Com 62 8.4 using paraplast x-tra wax paraplast x-tra is a low viscosity, general purpose, infiltration wax formulated to melt at very low temperatures (122 °f or 50°c) and strengthen both starch and plaster powder parts. This material cures rapid...

Page 63

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 63 9 applications.

Page 64

Z corporation z810 system user manual www.Zcorp-users.Com 64 in this section, you will learn various ways to maximize the versatility of your z corporation 3d printer through the implementation of advanced part processing techniques. Please visit the user group website at www.Zcorp-users.Com for mor...

Page 65

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 65 9.2 painting parts this procedure reduces the amount of sanding needed to produce a nice, smooth surface on z corporation parts. 1. Depowder and dry the part. 2. Hand sand the part with 230 grit sand paper...

Page 66

Z corporation z810 system user manual www.Zcorp-users.Com 66 9.3 polyester resin many types of transportation equipment require the use of geometrically complex ducting for heating, ventilation and air conditioning (hvac) of the interior space. Prototype ducting produced on the z corporation 3d prin...

Page 67

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 67 9.4 electroplating parts printed on the 3d printer on either starch or plaster can be easily prepared and electroplated for the look and feel of a metal part. Preparation preparation is the most important ...

Page 68

Z corporation z810 system user manual www.Zcorp-users.Com 68 9.5 water transfer printing water transfer printing is a process that enables 2d printed patterns to be applied to three-dimensional objects. The process is suitable for production as well as prototyping. Currently, the most prevalent use ...

Page 69

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 69 priming: z corp. Parts should be primed and painted in a base color (e.G. Brown for parts which are to be printed in a wood grain decor). Spreading film: the film is spread out on the water surface of the ...

Page 70

Z corporation z810 system user manual www.Zcorp-users.Com 70 top coating: the parts are clear coated or varnished to protect the printed surface. A varying degree of gloss can be achieved by using different top coats. Polishing completes the process. Presenting: the finished parts can now be used. T...

Page 71

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 71 master approach sdn. Bhd. – located in malaysia. They offer dip printing as a service. Website: www.Maproach.Com . Dorchase industrial, ltd. – located in hong kong. They provide dip printing as a service. ...

Page 72

Z corporation z810 system user manual www.Zcorp-users.Com 72 preparation 1. Starch-based powder parts should be used. Oven-drying the part at 104 o f (40 o c) after removal has been included in the process at some locations, especially where humidity may be an issue with ‘green’ part characteristics...

Page 73

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 73 9.7 flexible parts material • por-a-mold 2030 preparation • read and understand the material safety data sheet, as well as any directions. • zp15e parts should be used. • be sure the parts are completely d...

Page 74

Z corporation z810 system user manual www.Zcorp-users.Com 74 9.8 thermoforming this process consists of heating a thermoplastic sheet to a formable plastic state and then applying air pressure and/or mechanical assists to shape it to the contours of a mold. In this process, the air pressure may rang...

Page 75

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 75 the instructions below are specific to molds produced on z corporation printers. It is assumed that the user currently owns a thermoforming system and is familiar with using molds created from other techni...

Page 76

Z corporation z810 system user manual www.Zcorp-users.Com 76 9.9 rtv molding room temperature vulcanization (rtv) molding, also known as silicone rubber molding (srm), is an inexpensive soft molding solution for creating dozens of prototypes accurately. The benefit of rtv molding is that anyone can ...

Page 77

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 77 process overview printed part Î mold box setup Î pour silicone Î make parting line Î mold with cavity Î pour urethane Î cast part master pattern production preparation of the master is the key to successfu...

Page 78

Z corporation z810 system user manual www.Zcorp-users.Com 78 4. Sand the filler with 220-grit sand paper. The finish at this point should be completely smooth with no surface defects. 5. Prime the part with a sprayable / sandable primer. Z corporation recommends plasti-kote ® sandable primer for par...

Page 79

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 79 choosing a silicone there are several aspects to consider for the novice mold maker when choosing a mold material. The foremost aspect should be whether to use a silicone with a tin or platinum-based catal...

Page 80

Z corporation z810 system user manual www.Zcorp-users.Com 80 preparing and pouring the silicone mold preparing the silicone is relatively easy but must be performed properly to ensure a good mold. Pay close attention to the mix ratio of the two components of the silicones. Be sure to prepare a large...

Page 81

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 81 mold preparation and casting spray mold release onto all areas that will be exposed to the casting material and place the mold halves together. Use tape, rubber bands, or clamped boards to hold the mold to...

Page 82

Z corporation z810 system user manual www.Zcorp-users.Com 82 10 changing and aligning the print heads 10.1 changing the print heads warning: do not touch or contaminate the gold contacts on either the print heads or the carriage with your fingers. Avoid spilling binder on the contacts. If you do get...

Page 83

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 83 8. Unlock the head clamp latch by pushing the top cover down and unlatch. Open the carriage cover. 9. To remove the print head, lift the blue handle on top of each print head and pull up gently. Repeat for...

Page 84

Z corporation z810 system user manual www.Zcorp-users.Com 84 13. Replace the carriage cover and tighten the clamps in the front and back of the carriage. Press the ‘online’ button once to complete the process or click ‘done’ in the software. The print heads will now need to be aligned..

Page 85

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 85 10.2 aligning the print heads 1. Place a piece of adhesive paper onto alignment plate by removing one piece of backing, placing the edge of the paper to the edge of the plate. Remove the remainder of the b...

Page 86

Z corporation z810 system user manual www.Zcorp-users.Com 86 3. Close the top cover and put the printer online. 4. Select the ‘alignment’ option under the 810service menu. 5. Click on ‘print test pattern’ in the alignment dialog box. It will take a minute to initialize the printer, send the pattern,...

Page 87

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 87 f1, s1 corresponds to the entries in the dialog box. These additional targets will be most even when the alignment is correct. Bull's eye targets, one for each print head. When it looks centered, the print...

Page 88

Z corporation z810 system user manual www.Zcorp-users.Com 88 see the examples below for properly and improperly aligned reticules. Normal reticule patterns: fast axis to the left good fast axis reticule the three short lines are interleaved with the long lines. Fast axis to the right slow axis too l...

Page 89

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 89 7. Look up the numbers that are next to the best-aligned pattern as described above. 8. Choose ‘edit alignment’ in the alignment dialog box. 9. Enter numbers for the best aligned pattern in each row into t...

Page 90

Z corporation z810 system user manual www.Zcorp-users.Com 90 10. Click ‘ok’. The software will ask you to update the alignment. Click ‘ok’ to update the printer’s configurations. 11. Remove the paper off the plate carefully. If you would like to save the sheet, remove the top edge of the paper, adhe...

Page 91

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 91 15. Unpark the gantry to expose the service station. 16. Clean the service station of any hp ink residue as described in section 4.2 cleaning the service station. Clean the deck and fast axis rails. Oil th...

Page 92

Z corporation z810 system user manual www.Zcorp-users.Com 92 11 changing material systems if using zcast powder, you will need new metal snowplows (part number 04357 & 04358), and a zf8 zcast powder feeder. These items are needed to prevent damage to the printer. Please ensure that these hardware ch...

Page 93

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 93 3. Change binder supply if necessary. If you are using starch powder, use zb tm 51 binder. If using plaster, zp250 powder, or zcast powder, use zb56 binder. 4. Change binder supply mode if necessary using ...

Page 94

Z corporation z810 system user manual www.Zcorp-users.Com 94 8. Change zf8 powder feeders with the desired powder system. 9. Fill zf8 feeder with desired powder if necessary. 10. Use the ‘fill bed’ option under the 810service menu to spread powder. 11. Set up build in zprint software and print..

Page 95

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 95 11.1 using zcast 500 powder 11.1.1 general information zcast 500 powder is a plaster-ceramic composition that allows you to print sand casting-like molds and/or cores with your z corporation 3d printer. On...

Page 96

Z corporation z810 system user manual www.Zcorp-users.Com 96 11.1.3 loading zcast into the z810 3d printer 1. Disconnect the electronic cable, power cable, and air line to the zf8 feeder. 2. Pull the release lever on the back side of the printer and simultaneously remove the zf8 starch or plaster fe...

Page 97

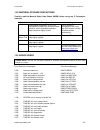

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 97 11.1.6 material ordering you can order zcast consumables either directly from z corp. Or through your local reseller. The item list for zcast is as follows: part # description denomination 06091 zcast 500 ...

Page 98

Z corporation z810 system user manual www.Zcorp-users.Com 98 11.2 using zp250 powder zp250 powder is the newest powder system formulated for z corporation 3d printers utilizing the hewlett packard print head technology - the zprinter™ 310, z ® 406, and z810 3d printers. Specifically formulated to ha...

Page 99

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 99 • to change the default values in the “make fixture” window, select “preferences” from the zprint edit menu and select the “fixtures” tab. Enter the new values, and click ‘ok’. • to create a fixture that c...

Page 100

Z corporation z810 system user manual www.Zcorp-users.Com 100 11.2.3 part removal and post processing 1. Remove the part and depowder. Dry the parts in in an oven at 150 °f (66°c) for at least 2 hours or longer depending on the mass/volume of the part. A. If a fixture was used during the printing pr...

Page 101

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 101 4. Apply a silicone mold release (such as ims paintable neutral oil mold release – www.Imscompany.Com or hapco grease-it fdg - www.Hapcoweb.Com ) liberally onto the top surface of the fixture where the pa...

Page 102

Z corporation z810 system user manual www.Zcorp-users.Com 102 7. Let the part sit for 30 minutes at room temperature to allow excess z-snap epoxy to drain or wick into the fixture. Z-max parts should sit at ambient for 1 hour prior to the oven cure. 8. If using z-snap epoxy place the part with fixtu...

Page 103

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 103 12 maintenance maintenance action frequency z810 3d printer 1. Change zc3 wash fluid once every two weeks or as needed 2. Flush binder with distilled water when not in use for two or more weeks 3. Clean u...

Page 104

Z corporation z810 system user manual www.Zcorp-users.Com 104 4. Place paper towel around the filter to absorb any fluid when unscrewing the filter. Unscrew the filter. 5. Remove screen and clean under running water. 6. Fill container with fresh wash fluid. 7. Replace screen and filter cap and repla...

Page 105

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 105 9. Reconnect fluid connectors and close cabinet door. 12.2 flush system with distilled water if the printer will not be in use for more than two weeks, it is strongly recommended that it be flushed with d...

Page 106

Z corporation z810 system user manual www.Zcorp-users.Com 106 6. Remove clear binder container through the quick disconnect. Fluid disconnect float sensor disconnect 7. Pull out clear binder container. 8. Unscrew binder cap with connections. 9. Place binder cap into distilled water. Please note: whe...

Page 107

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 107 10. Place distilled water into printer and reconnect sensor and fluid connections. 11. Choose the ‘flush binder’ option under the service menu. 12. Click ‘start’ to begin flush process. Flush distilled wa...

Page 108

Z corporation z810 system user manual www.Zcorp-users.Com 108 12.3 clean under gantry it is necessary to clean under the gantry when powder and binder have adhered to the bottom causing layers to be dragged when printing. It is also good practice to clean under the gantry to prevent powder and binde...

Page 109

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 109 5. Repark the gantry by clicking ‘ok’ on the dialog box. 6. Raise build piston to original position and vacuum up any powder or debris that has fallen into the build area. 12.4 oil slow axis rail the slow...

Page 110

Z corporation z810 system user manual www.Zcorp-users.Com 110 12.6 clean spreader roller the spreader roller may become dirty with powder and binder debris after printing. Cleaning the spreader roller will prevent uneven spreading of powder over the build pallet. 1. Choose the ‘toggle roller on/off’...

Page 111

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 111 12.7 cleaning the squeegee squirters periodically, the wash fluid flowing out of the squeegee squirters may converge. This can be caused by a clog in the holes and contamination of the wash fluid. To clea...

Page 112

Z corporation z810 system user manual www.Zcorp-users.Com 112 12.8 bleeding air from the fluid system air may get into the fluid system through leaks or have run low on binder. If you need to remove air from your system, follow the procedure below: 1. Fill the binder jug with binder solution. 2. Sel...

Page 113

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 113 12.9 clean powder screen on the zf8 powder feeder the powder screen in the zf8 powder feeder prevents any large pieces of debris from entering the feeder. Periodically, the screen needs to be cleaned in o...

Page 114

Z corporation z810 system user manual www.Zcorp-users.Com 114 2. Slide the powder drawer out. There are two handles available. One handle option extends out to allow you tow, push, and maneuver the powder drawer to and from an emptying location. The other handle option allows you to pull and push th...

Page 115

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 115 13 z810 system details 13.1 symbols used the following symbols are used on the z810 3d printer: this is the international symbol for ‘standby power’. It is used on the z810 3d printer power switch. The z8...

Page 116

Z corporation z810 system user manual www.Zcorp-users.Com 116 13.3 material storage precautions carefully read the material safety data sheets (msds) before using any z corporation materials. Material storage usage powder store powder on pallets in a cool, dry, ventilated area away from sources of h...

Page 117

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 117 1300, queue: out of memory 1301, queue: can't create event 1302, queue: received null pointer 1400, keyboard: can't add callback 1401, keyboard: can't create pipe 1402, keyboard: error writing pipe 1403, ...

Page 118

Z corporation z810 system user manual www.Zcorp-users.Com 118 2001, stripes: bad saturation 2002, stripes: too many lines per stripe 2003, stripes: line is too long 2004, stripes: bad print mode %d 2005, stripes: bad line offset 2100, unrle: bad layer number 2101, unrle: bad print mode %d 2200, bmoc...

Page 119

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 119 3008, sequencer: overrun while waiting for hf 3009, sequencer: stalled while waiting for hf 3010, sequencer: sequence didn't finish, flags = %x 3011, sequencer: error in dpc, flags = %x 3012, sequencer: s...

Page 120

Z corporation z810 system user manual www.Zcorp-users.Com 120 4006, tcp: error %d listening on socket 4007, tcp: error %d accepting socket 4008, tcp: error %d selecting socket 4009, tcp: error %d getting received byte count 4010, tcp: error %d receiving from socket 4011, tcp: error %d looking up hos...

Page 121

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 121 50103, powder: overflow full, overflow full 50200, service: failed head check, bad heads %02x 50300, pistons: build piston is tilted).

Page 122

Z corporation z810 system user manual www.Zcorp-users.Com 122 14 index 3 3d print, 45 a air gun, 55 aligning the print heads. See alignment alignment, 85 edit alignment, 89 alignment plate, 85 anisotropic scaling values, 43 plaster, 43 starch, 43 zcast powder, 43 apollo 5005, 58 applications, 63 ele...

Page 123

Z810 system user manual z corporation z corporation service (781) 852-5050 / (887) 88-zcorp 123 z-snap epoxy, 61 investment casting, 71 l load/unload replacing build pallet, 33 m maintenance, 103 bleed air, 112 change zc3 wash fluid, 103 clean gantry, 108 clean spreader roller, 110 emptying powder d...

Page 124

Z corporation z810 system user manual www.Zcorp-users.Com 124 z z810 3d printer, 11 carriage assembly, 14 components, 11 control panel, 17 error codes, 116 flush binder, 105 gantry, 108 power entry module, 16 service station, 15 site requirements, 11 spreader roller, 110 z810 printer changing print ...

Page 125: Zcast

Appendix i 09521 zcast ® design guide rev b zcast ® direct metal casting design guide february 2004.

Page 126

Appendix i zcast design guide - 2 table of contents 1 introduction ................................................................................. 4 2 cautions & warnings .................................................................. 5 2.1 caution .................................................

Page 127

Appendix i zcast design guide - 3 pour............................................................................................................................................ 21 8 pouring metal............................................................................ 22 8.1 metal types...........

Page 128: 1 Introduction

Appendix i zcast design guide - 4 1 introduction the zcast process was created to allow for the rapid fabrication of metal parts. It allows cast metal parts to be verified without the time and expense typically associated with production tooling. While the range of uses is broad, the zcast process m...

Page 129: 2 Cautions & Warnings

Appendix i zcast design guide - 5 2 cautions & warnings 2.1 caution mold must baked dry prior to pouring do not infiltrate this material with resin or wax!! Zcast parts in its untreated (raw) state contains about 10% moisture per unit weight. Casting molten metal against untreated material relea...

Page 130: 3 Zcast

Appendix i zcast design guide - 6 3 zcast advantages today, metal casting molds are commonly created by first producing a machined pattern (or pattern set) that is then used to create the molds. Instead of utilizing this costly and often time consuming process, the zcast process utilizes 3d printing...

Page 131: 4 Locating A Foundry

Appendix i zcast design guide - 7 4 locating a foundry whether you are an experienced mold designer with a foundry in house, or a design engineer who has never designed a mold, the first step in the zcast process is to run a trial with your foundry. Typically, any foundry will find their end of the ...

Page 132

Appendix i zcast design guide - 8 5 designing with zcast – mold design zcast offers flexibility and simplicity in mold design. Because of its simplicity, the engineer or designer can spend more time focusing on the design of the part rather than on the design of the mold. This simplicity does away w...

Page 133

Appendix i zcast design guide - 9 5.2.1 direct pour a mold designed by this method incorporates the cavity of the casting and the entire gating system, including risers and vents. This keeps the mold setup simple by minimizing parts. It is most handy for small molds: up to 5 lbs in aluminum or 15 lb...

Page 134

Appendix i zcast design guide - 10 5.2.3 combination method combining zcast with the traditional sand casting techniques can keep the cost per prototype down to a minimum. Mold sections (cores in particular) are made in zcast while the rest of the mold is made conventionally. In the combination meth...

Page 135

Appendix i zcast design guide - 11 5.3.1 direct pour before addressing the mold design specifics, we will consider the basic steps of designing a mold using a standard cad package. Most middle to high-end cad packages such as pro/e, solidworks, catia, unigraphics, and autodesk inventor, etc. As well...

Page 136

Appendix i zcast design guide - 12 5.3.3 combination method the combination method is slightly more process oriented and is not represented in the context of this document. Users familiar with the conventional sand casting process that incorporates the use of a pattern will find this technique to be...

Page 137

Appendix i zcast design guide - 13 6 design techniques with zcast 6.1 direct gating conventional methods of runner design are based on having a flat pattern that must be drawn out of a sand mold. This forces the runners and gates out sideways resulting in a mold that covers a larger area. Such a des...

Page 138

Appendix i zcast design guide - 14 arching is a phenomenon that occurs on the first few layers printed. It diminishes as the part continues to build. To minimize arching, print the non-critical faces of your mold facing downwards. 6.5 venting perhaps the most important concept in zcast mold design i...

Page 139

Appendix i zcast design guide - 15 6.5.1 venting cores follow these guidelines to obtain best results when designing vents for your cores: • the cores should be shelled in by approximately .250” (7mm) wall thickness where possible. • any single wall of the core should be no thicker than 0.500” (14mm...

Page 140

Appendix i zcast design guide - 16 figure 10: attach a flexible plastic hose like the one shown above to reach ‘blind spots’ 6.6 parting lines the process for creating a mold in cad software typically involves taking an object (the casting) and subtracting it from a larger, encompassing object (the ...

Page 141

Appendix i zcast design guide - 17 6.8 mating surfaces the mating surfaces of the mold should be offset to accommodate for surface imperfections. A total gap of 0.020” (0.5mm) should be created, in the model, at all mating surfaces. The offset can be created on either side of the parting surface or ...

Page 142

Appendix i zcast design guide - 18 6.10 wall thickness guidelines as indicated in the section 6.3 ‘shelling your mold’, thinner sections bake quicker and more efficiently. Maintain the following guidelines for modeling your mold with thin walls: • any mold wall that is in contact with metal should b...

Page 143

Appendix i zcast design guide - 19 • using “bleed compensation” is recommended. This will improve the accuracy so parts will fit together better 3 . • orient parts so that the most critical faces are facing up in the build. For example, when possible, put the outside of the mold components (non-mold...

Page 144

Appendix i zcast design guide - 20 figure 13: a,b,c: horizontal filter orientation – metal rises up through filters (maximum are achieved with horizontal placement. D,e,f: vertical filter orientation a b c f e d.

Page 145: 7 Mold

Appendix i zcast design guide - 21 7 mold preparation after the mold is designed and printed in a z corporation 3d printer, there are only a few necessary steps before you are ready to pour metal: mold wash – mold wash is used in traditional sand casting to improve the surface finish of the castings...

Page 146: 8 Pouring

Appendix i zcast design guide - 22 8 pouring metal 8.1 metal types the current product offering is zcast 500 powder and is designed for low temperature, non- ferrous metals [max temp 1100 ° c (2000 ° f)]. The higher the temperature of the metal, the more gassing on contact there will be. It becomes ...

Page 147: 10 Finishing

Appendix i zcast design guide - 23 9.3 powder recycling unprinted zcast material can be recycled. Z corp. Recommends that you add approximately 30% new powder with recycled powder. 10 finishing 10.1 de-molding removing a casting from a zcast mold is virtually identical in process to the removal of a...

Page 148: 11 Foundry Consumables

Appendix i zcast design guide - 24 11 foundry consumables you can purchase foundry consumables through a wide offering of vendors. This includes items such as core wash, pouring sleeves, filters, core paste, etc. Prominent foundry consumables that are commonly used are: ceramic filters – these dispo...

Page 149

Appendix i zcast design guide - 25 11.1 sand casting glossary 11.1.1 cope and drag molds are typically made up of two halves encapsulating the outer surfaces of the casting. The two parts are called the cope and drag; the cope being the “top” section and the drag being the “bottom.” these components...

Page 150

Appendix i zcast design guide - 26 11.1.4 pouring cup the pouring cup, as the name implies, is where the molten metal is poured into the mold. The pouring cup can take many different forms, each to better optimize the feeding of metal into the mold and minimize the amount of turbulence produced in t...

Page 151

Appendix i zcast design guide - 27 11.1.8 ingates the metal enters the mold cavity through the ingates. Ingates typically feed thicker sections of the casting, which subsequently, feed thinner sections. Thick sections, where the metal will be slowest to cool, should be allowed to feed thin sections ...

Page 152: 12 Conclusion

Appendix i zcast design guide - 28 12 conclusion with the information in this document, the design and pouring of your prototype metal parts is only a step away. If you or your foundry has questions about any of the information contained herein, or need additional information, please contact us the ...