- DL manuals

- Zamil

- Air Conditioner

- CNX150

- Installation, operation & maintenance manual

Zamil CNX150 Installation, operation & maintenance manual

Summary of CNX150

Page 1

Pl-om-cnx-07-1m-e installation, operation & maintenance manual air cooled condensing units 'cnx' series.

Page 2: Index

Contents page model decoding ....................................................................................................................................... 2 physical data ..........................................................................................................................

Page 3: Model Decoding

2 1, 2 & 3 basic 4, 5 & 6 nominal cooling capacity* (mbh) 8 special options 7 electrical supply ( v-ph-hz ) 10 generation code cnx condensing unit 150 220 240 300 360 420 480 540 600 720 840 **m00 **m10 **m20 **m40 **m60 ***2m00 ***2m40 z :special options f : 460-3-60 00 01 02 03 9 manufacturing yea...

Page 4: Physical Data

Model number cnx150 cnx220 cnx240 cnx300 cnx360 cnx420 cnx480 cnx540 cnx600 nominal capacity , tons * 13 19 22 28 31 36 41 47 53 number of refrigeration circuit dual dual dual dual dual dual dual dual dual compressor type scroll semi-hermetic reciprocating oil per system (liters) 4.1 4.1 4.1 4.7 4.6...

Page 5: Physical Data

Model number cnx720 cnx840 cnxm00 cnxm10 cnxm20 cnxm40 cnxm60 cnx2m00 cnx2m40 nominal capacity , tons * 63 64 75 92 105 121 139 154 281 number of refrigeration circuit dual dual dual dual quadruple quadruple quadruple quadruple quadruple compressor type semi-hermetic reciprocating screw oil per syst...

Page 6: Electrical Data

Lra (each) rla (each) 460-3-60 460-3-60 460-3-60 460-3-60 460-3-60 460-3-60 460-3-60 460-3-60 460-3-60 460-3-60 460-3-60 460-3-60 460-3-60 460-3-60 460-3-60 460-3-60 460-3-60 460-3-60 cnx 150 cnx 220 cnx 240 cnx 300 cnx 360 cnx 420 cnx 480 cnx 540 cnx 600 cnx 720 cnx 840 cnx m00 cnx m10 cnx m20 cnx ...

Page 7: Dimensions

2121 [86.50] [83.50] 2197 20 3 [8 .0] 155 0 [ 61.0] 943 943 73 [2.875] [37.125] [80.0] [37.125] 2032 "a" "b" "c" 1 2 3 5 4 6 7 5 7 6 4 5 3 2 1 dimensions notes: 1. All dimensions are in mm, (dimensions in brackets are in inches). 2. Allow 48" (1219 mm) clearance on all sides for proper airflow. Cnx ...

Page 8: Dimensions

255.0 [10 .00 ] ty p 357.5 [14 .07 ] ty p 335 .4 [13. 20] 375.6 [14.8 0 ] 2121 [86.50] 2197 [83.50] 1550 [61.0] 203 [8.0] dimensions cnx 480 - cnx 600 cnx 720 - cnx 840 notes: 1. All dimensions are in mm, (dimensions in brackets are in inches). 2. Allow 48" (1219 mm) clearance on all sides for prope...

Page 9: Dimensions

Dimensions cnx m00 - cnx m10 notes: 1. All dimensions are in mm, (dimensions in brackets are in inches). 2. Allow 48" (1219 mm) clearance on all sides for proper airflow. 8.

Page 10: Dimensions

Dimensions cnx m20 notes: 1. All dimensions are in mm, (dimensions in brackets are in inches). 2. Allow 48" (1219 mm) clearance on all sides for proper airflow. 9.

Page 11: Dimensions

Elec t r ic pow e r i n let 285.0 [1 1.220] 91 7. 0 [ 3 6 .10 2 ] t y p 7 86.0 [ 30.9 44] t y p 670 .5 [26 .397 ] t y p 487 .0 [19 .173 ] t y p dimensions cnx m40 notes: 1. All dimensions are in mm, (dimensions in brackets are in inches). 2. Allow 48" (1219 mm) clearance on all sides for proper airf...

Page 12: Dimensions

285.0 [11.2 20] 917.0 [36. 102] t y p 786.0 [30.94 4] t y p 670.5 [ 2 6.397] t y p 4 8 7.0 [19.173] t y p ele c t r ic pow e r in le t dimensions cnx m60 notes: 1. All dimensions are in mm, (dimensions in brackets are in inches). 2. Allow 48" (1219 mm) clearance on all sides for proper airflow. 11.

Page 13: Dimensions

Dimensions cnx 2m00 notes: 1. All dimensions are in mm, (dimensions in brackets are in inches). 2. Allow 48" (1219 mm) clearance on all sides for proper airflow. 12.

Page 14: Dimensions

Dimensions cnx 2m40 notes: 1. All dimensions are in mm, (dimensions in brackets are in inches). 2. Allow 48" (1219 mm) clearance on all sides for proper airflow. 13 2185 [8 6.02 3] 275 [10 .826] 2200 [8 6.614] 91 7. 0 [ 3 6. 102 ] t y p 78 6. 0 [ 3 0 .944] t y p 67 0. 5 [ 2 6 .3 9 7 ] t y p 4 8 7 .0...

Page 15

14 microprocessor control system each condensing unit are provided with microprocessor based control board that monitors analog and digital inputs to achieve precise control and safety functions during unit’s operation. Input signals for cooling control can be digital signals coming from a thermosta...

Page 16: User Sequence of Operation

15 user sequence of operation machine starting: - if off, the machine is started by pushing the on/off button. - the on led (green) will lit. - on the main screen is showed the status “starting”. - after 15 seconds of delay the system will be running. Machine shut-down: - the machine is halted pushi...

Page 17: Schematic Wiring Diagram

Olr2 cc1 cc2 olr1 olr2 cc2 cb6 cb7 cb6 cb6 uvm-1 cc1 olr1 cc3 olr3 cb7 fmc1 cb6 cb8 fmc5 fmc4 fmc2 cb7 fmc6 fmc2 fmc1 fmc2 fmc1 fmc3 fmc1 ops1-1 ops2-1 fmc4 fmc2 cc2a-1b cc1a-1b dip switch settings - mb board ju11 - closed (1,2) off td2 - closed s1 on 1 2 off 3 off 4 olr2 cc2 olr4 cc4 olr3 cc3 olr1 ...

Page 18: Schematic Wiring Diagram

17 schematic wiring diagram power supply : 460-3-60 (dual compressor units) applicable on models: cnx150 - cnxm10 notes 1. Any wire replacement should be of the 90 0 c or its equivalent. 2. Use copper conductor wires only. 3. Compressors are provided with internal line break or ssps for thermal prot...

Page 19: Schematic Wiring Diagram

Note: 1. Refer to next page for legend, notes & wiring diagram for optional items. 2. Refer to unit control box (inside panel) for exact wiring diagram. 18 schematic wiring diagram power supply : 460-3-60 (four compressor units) applicable on models: cnxm20 - cnxm60 to hvtb/busbar l2 l1 l3 comp3 com...

Page 20: Schematic Wiring Diagram

Note: 1. Refer to next page for legend, notes & wiring diagram for optional items. 2. Refer to unit control box (inside panel) for exact wiring diagram. 19 schematic wiring diagram power supply : 460-3-60 (four compressor units) applicable on models: cnxm20 - cnxm60 jp7 ahu motor on/off control (230...

Page 21: Schematic Wiring Diagram

20 notes 1. Any wire replacement should be of the 90 0 c or its equivalent. 2. Use copper conductor wires only. 3. Compressors are provided with internal line break or ssps for thermal protection. 4. Fused disconnect switch or circuit breaker to be provided by end user with rating as recommended by ...

Page 22: Schematic Wiring Diagram

21 note: 1. Refer to next page for legend, notes & wiring diagram for optional items. 2. Refer to unit control box (inside panel) for exact wiring diagram. Schematic wiring diagram power supply : 460-3-60 (four compressor units) applicable on models: cnx2m00 - cnx2m40 power supply t.K. 10 no 12c 9 n...

Page 23: Schematic Wiring Diagram

+ suction pressure transducer (a5-sp1) + 3 4 2 1 menu * tout=15°c tin=28°c set cooling 75% esc * com1 gnd leaving air temp. Sensor (ptc : -10 ~ +50 c) user interface board * on/off (a8-sp2) 29b s1 serial cable on sh - o2 (a10-op2) dip + - d2 (a9-dp2) tin + + sh 31b 30b sh (a1-st1) t.Out 25 sh sh 24 ...

Page 24: Schematic Wiring Diagram

23 schematic wiring diagram power supply : 460-3-60 (four compressor units) applicable on models: cnx2m00 - cnx2m40 notes 1. Any wire replacement should be of the 90 0 c or its equivalent. 2. Use copper conductor wires only. 3. Compressors are provided with internal line break or ssps for thermal pr...

Page 25

Typical high and low voltage field wiring connections 24 (remove jp7) 52 20 1 2 1 67 17 (remove jp6) (remove jp7).

Page 26: Rigging Instructions

Attention to riggers hook rigging sling thru holes in base rail, as shown below. Holes in base rail are centered around the unit center of gravity. Center of gravity is not unit center line. Ensure center of gravity aligns with the main lifting point before lifting. Use spreader bar when rigging, to...

Page 27

Load distribution, kg. (aluminum condenser coil) model no. R1 r2 r3 r4 r5 r6 r7 r8 r9 r10 cnx150 200 200 200 200 - - - - - - cnx220 231 231 231 231 - - - - - - cnx240 245 245 245 245 - - - - - - cnx300 265 265 265 265 - - cnx360 228 228 232 232 204 204 - - - - cnx420 240 240 244 244 216 216 - - - - ...

Page 28: Installation Instructions

General the complete shipment should be inspected for damage. Any damage visible at the time of delivery should be noted on the shipment invoice. These units are shipped completely assembled and wired. Units require interconnecting piping (ahu), external power, thermostat wiring, condensate drain pi...

Page 29

2. It is important to first determine the amount of refrigerant required for the system, the unit nameplate normally identify the weight of the refrigerant required. 3. The refrigerant should be added in small amounts allowing sufficient time for the unit pressure to equalize each time. Wiring all w...

Page 30

• duct leakage inside/outside building • volume dampers • volume damper access doors • fire dampers • fire damper access doors • transfer grilles/door grilles • duct insulation/liner • diffusers/grilles • duct humidistat • filter flag check-out & operational start-up procedure after the completion o...

Page 31: Electrical

Electric power supply all wiring should be in accordance with national electric code and local standards. Before making an installation, check the electric power supply. The power supply must be of the same characteristics as that on the nameplate. Normally the wire size used establishes the circuit...

Page 32

Motor contactor the motor controller (contactor) is a load current carrying device which makes and breaks to start and stop the compres- sor motor. The magnetic coil of the controller is energized to make and break the contactor contacts. Frequently, motor contactors are subjected to quick cycling d...

Page 33: Refrigeration

Refrigeration compressor scroll compressors are used as standard for models cnx150 - cnx300 and semi-hermetic reciprocating compressors are standard for models cnx360 - cnx2m00 except for model cnx2m40 available with semi-hermetic compact screw compressors. All compressors are conforming to ari 540....

Page 34

Start the compressor, allowing it to operate long enough to pump down to approximately 1 psig. Shut the compressor off and observe the compound gauge. The gauge pressure may build rapidly. Repeat the pump down process several times observing the gauge pressure each time after the compressor stops. I...

Page 35

34 should the control open, it will remain open until the pressure in the system is lowered to 300 psig. Tripping of the high pressure control is normally due to: 1. Restricted condenser coil. 2. Overcharge of refrigerant. 3. Defective fan motor or fan capacitor. 4. Incorrect fan blade. 5. Fan motor...

Page 36: Trouble Shooting Chart

35 1. Close start or disconnect switch. 2. Refer to electrical section. 3. Repair or replace control. 4. Relocate control. 5. Check wiring against diagram. 6. Replace or relocate. 7. Trace control circuit with wiring dia- gram and repair. 8. Replace the compressor with all pre- cautions. 1. Line dis...

Page 37: Trouble Shooting Chart

Trouble shooting chart symptom causes check & corrective measure units runs ok, but short cycles on. 1. Check the cause. 2. Differential set too close - widen. 3. (a) check airflow to the condenser correct. (b) reduce refrigerant charge. (c) purge. 4. (a) fix leak, add refrigerant. (b) replace devic...

Page 38: Trouble Shooting Chart

Trouble shooting chart symptom causes check & corrective measure loss of oil pressure. 1. Loss of oil from compressor due to: (a) oil trapping in system. (b) compressor short cycling. (c) insufficient oil in system. (d) operation at excessively low suction pressure. 2. Excessive liquid refrigerant r...

Page 39: Parts List

Parts list model number cnx150f cnx220f cnx240f cnx300f cnx360f cnx420f cnx480f cnx540f cnx600f compressor 80061402 80061408 80061411 80061414 80069717 80069720 80069723 80069726 80069729 compressor contactor 80009857 80009861 80009861 80009863 80009863 80009865 80009865 80009865 80009867 capacity u...

Page 40: Recommended Spare Parts

Percentage of spare parts one year supply two year supply 100 units 1000 units 100 units 1000 units compressor 2% 1% 3% 2% condenser fan motor 2 1 3 2 contactor compressor 2 1 3 2 contactor fan motors 2 1 3 2 hps/sensor/transducer 2 1 3 2 expansion valve 1 0.5 2 1 filter drier 2 1 3 2 transformer (2...

Page 41

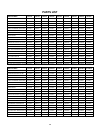

1 x x x x x x x 3 x x x x x x x 6 x x 12 x x x x preventive maintenance schedule frequency of maintenance, months i t e m clean air filters & replace if required. Clean evaporator coil, drain pan & drain line. Clean condenser coil. Check blower belt/tension/wear/crack and replace it, if required. Lu...

Page 42

Safety data refrigerant r134a toxicity nil in contact with skin liquid splashes or spray may cause freeze burns. Unlikely to be hazardous by skin absorp- tion. Thaw affected areas with water. Remove contaminated clothing carefully - may adhere to skin in case of freeze burns. Wash affected areas wit...

Page 43

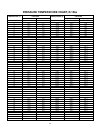

42 pressure temperature chart, r-134a temperature ( 0 f) pressure temperature ( 0 c) pressure psia psig kpa (absolute) kpa (gauge) 0 21.2 6.5 -17.78 146.2 44.9 2 22.2 7.5 -16.67 153.2 51.8 4 23.3 8.6 -15.56 160.4 59.1 6 24.3 9.6 -14.44 167.9 66.6 8 25.5 10.8 -13.33 175.7 74.3 10 26.6 11.9 -12.22 183...

Page 44

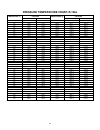

43 pressure temperature chart, r-134a temperature ( 0 f) pressure temperature ( 0 c) pressure psia psig kpa (absolute) kpa (gauge) 96 130.4 115.7 35.56 899.2 797.9 98 134.4 119.7 36.67 927.1 825.8 100 138.6 123.9 37.78 955.7 854.3 102 142.8 128.1 38.89 984.9 883.6 104 147.1 132.4 40.00 1014.8 913.4 ...