- DL manuals

- Zanotti

- Refrigerator

- DFZ

- Use And Maintenance Handbook

Zanotti DFZ Use And Maintenance Handbook

DFZ

DFZ

MANUALE USO E MANUTENZIONE

MANUALE USO E MANUTENZIONE

USE

USE

AND MAINTENANCE INSTRUCTIONS

AND MAINTENANCE INSTRUCTIONS

INSTRUCTIONS D'UTILISA

INSTRUCTIONS D'UTILISA

TION ET D'ENTRETIEN

TION ET D'ENTRETIEN

BEDIENUNGS- UND W

BEDIENUNGS- UND W

ARTUNGSANLEITUNG

ARTUNGSANLEITUNG

MANUAL

MANUAL

DE USO

DE USO

Y

Y

MANTENIMIENT

MANTENIMIENT

O

O

Summary of DFZ

Page 1

Dfz dfz manuale uso e manutenzione manuale uso e manutenzione use use and maintenance instructions and maintenance instructions instructions d'utilisa instructions d'utilisa tion et d'entretien tion et d'entretien bedienungs- und w bedienungs- und w artungsanleitung artungsanleitung manual manual de...

Page 3

To carry out the instructions more easily, open the cover flap containing the key for the various functions.

Page 4

English gb gb.

Page 5: Preliminary Information

Table of contents pag. Preliminary information 48 important safety warnings 48 warranty 50 how to order spare parts 51 disposing of the packing 51 disposing of the machine 51 1. Description of the machine 52 1.1 available models 52 1.2 main technical specifications 52 2. Rating plate 57 3. Descripti...

Page 6: 5. Goods Loading Procedure

47 4.8 time and display contrast programming 65 4.8.1 continuous operation 66 4.8.2 disabling diesel operation 66 4.8.3 keyboard block 67 4.8.4 print or record data 68 4.9 alarms 70 5. Goods loading procedure 74 5.1 storage and stacking 74 5.2 mobile partitions 75 5.3 tips on the temperatures of car...

Page 7: Preliminary Information

48 preliminary information thank you for choosing one of the models of dfz zanotti refrigeration units. This manual is addressed to the operators of dfz zanotti refrigeration units. Inside you will find the necessary information to use and service the products correctly, safety tips, warranty terms ...

Page 8

49 safety tips by drilling the walls of the unit or the isothermal cold room, you could damage the electric wires or the refrigeration piping. Should such action be strictly nec- essary, great care should be taken to avoid any damage. Touching turning fans and moving belts can cause irreparable dama...

Page 9: Warranty

50 engine the perkins engines fitted on all dfz zanotti refrigeration units are designed to keep pollution caused by exhaust gas at a minimum level. However, we strongly recommend to avoid starting the engine in a confined area, as the exhaust gas is toxic. The symptoms caused by carbon monoxide pro...

Page 10: Disposing of The Packing

51 when ordering spare parts, always include the serial number shown on the machine's rating plate. Disposing of the packing dispose of all wooden, plastic and polystyrene packing in compliance with the laws in force in the country where the equipment is used. Disposing of the machine should the mac...

Page 11

52 the dfz refrigeration units are made up of the following main components: 1. A condensing unit installed outside the isothermal box; 2. An evaporating unit installed inside the isothermal box; 3. An electronic central control unit located in the driver's cab of the vehicle. All models are suitabl...

Page 12

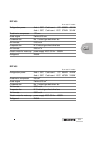

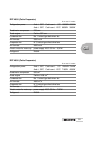

53 dfz 430 p. On road p. Rmains refrigeration power amb. T. 30°c cold room t. 0°c 6098w 4951w amb. T. 30°c cold room t. -20°c 3724w 3014w road/mains compressor 170 cm 3 road engine perkins 676 cm 3 condenser fan no. 1 helical-type belt-driven fan air flow rate 2100 m 3 /h evaporator fan n° 2 helical...

Page 13

Dfz 465 p. On road p. Rmains refrigeration power amb. T. 30°c cold room t. 0°c 9500w 7848w amb. T. 30°c cold room t. -20°c 5400w 3555w road/mains compressor 230 cm 3 road engine perkins 954 cm 3 condenser fan no. 1 helical-type belt-driven fan air flow rate 3500 m 3 /h evaporator fan n° 3 helical-ty...

Page 14

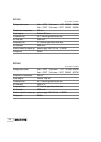

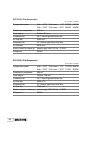

55 dfz 465u (cubic evaporator) p. On road p. Rmains refrigeration power amb. T. 30°c cold room t. 0°c 10908w 6090w amb. T. 30°c cold room t. -20°c 6636w 3868w road/mains compressor 235 cm 3 road engine perkins 957 cm 3 condenser fan no. 1 helical-type belt-driven fan air flow rate 3500 m 3 /h evapor...

Page 15

Dfz 465u (flat evaporator) p. On road p. Rmains refrigeration power amb. T. 30°c cold room t. 0°c 9739w 5561w amb. T. 30°c cold room t. -20°c 5630w 3098w road/mains compressor 235 cm 3 road engine perkins 954 cm 3 condenser fan no. 1 helical-type belt-driven fan air flow rate 3500 m 3 /h evaporator ...

Page 16: 2. Rating Plate

57 the dfz zanotti units are identified by plates located on the right side of the condensing circuit. They contain all the information to be communicated to the technicians in case of servicing, i.E.: – model – serial number – voltage – electrical input – refrigerant – weight of the unit 2. Rating ...

Page 17

58 the dfz zanotti refrigeration units are equipped with a microprocessor-based electronic controller (driver's cabin control) which manages operation in a fully automatic way. In particular, the electronic controller supervises the operations for turning the diesel engine and electric motor on and ...

Page 18: 4. Operation

59 4.1 before operating the unit 1. Check the belts. In fact, their tension must be perfect in order to prevent them from slipping if they are too slack (as this would generate heat and would therefore shorten the life of the belts) or the bearings from wearing out too fast if the belts are too tigh...

Page 19

60 4.2 setting the unit at work press push-button 1 to turn on the driver's cabin control. The mask shown in fig. 2 will appear after a few seconds. This mask shows: • ta1: cold room temperature • sp1: operating set point • current date and time, • type of diesel operation, either slow (low) or fast...

Page 20

61 if two cold rooms are present, the mask will appear: to program the set point of the second cold room sp2, proceed as follows: - press key : the cursor will start blinking under the present sp1 set point value. - press the key until the value relating to sp2 is highlighted. - press the up/down ke...

Page 21

62 warning if the plug is connected before the diesel engine is stopped using the button (fig. 2) , the diesel engine will turn off and the electric motor will come on after approximately 5 minutes. Similarly, if power is interrupted during electric standby, automatic startup of the diesel engine wi...

Page 22

63 in this mask, you can see for how many hours the oil and oil filter have been used, as well as the total working hours of the diesel engine and electric motor. When the oil or oil filter have been used for over a limit number of hours, the sym- bol will be displayed on the main mask; then, access...

Page 23

64 user's handbook update the cabin command has a slightly different graphic display and several new functions. The main window is as shown in the figure below: in this window three indications can be seen at the top left: which indicates the automatic function (start/stop); the snow-flake which ind...

Page 24

65 4.8 time and display contrast programming starting from the main mask and pressing key first and then key , you will access the mask below. By pressing key you can access the clock programming mask: press key to highlight the day, press the key to go from one term to another, press the up/down ke...

Page 25

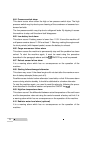

66 4.8.1 continuous operation this function allows the start/stop function of the diesel motor to be cut-out and kept in motion in a continuous way; to activate this function starting from the main window press the key , the following window appears: then press the key , instead of , will appear on ...

Page 26

67 4.8.3 keyboard block to prevent unwanted interventions the keyboard blocking function has been introduced; activate it starting from the main window, press the key and then the key , in this way the following window is accessed: now press the key , to go to the following window where entering the...

Page 27

68 to unblock the keyboard press the menu key and re-enter the password in the following window 4.8.4 print or record data in the following window, reached by pressing and the key starting from the main window is the key which when pressed accesses the window where the following con be entered: from...

Page 28

69 example: from: 10/04/01 to: 12/04/01 evp: 1 res: 10 min sta: 12:00 (noon) sto. 14:00 (2 p.M.) prn: printer with the data thus entered press the key to print all the data from 10/04/01 to 12/04/01 recorded from 12 noon to 2 p.M. Every 10 minutes. Whenever using download on pc, the hyperterminal pr...

Page 29

70 4.9 alarms every time an alarm occurs, the icon starts blinking and the buzzer goes off. To silence the buzzer, just press any key. To see the alarm mask, press key ; in this way, you will access the mask below where you will see the different alarm codes. Each alarm code has a relevant descripti...

Page 30

71 alarm code description type a01 water temperature alarm automatic reset a02 oil pressure alarm manual reset a03 thermal relay alarm manual reset a04 pressure switch alarm automatic reset a05 low battery level alarm automatic reset a06 damaged room sensor alarm manual reset a07 damaged defrost sen...

Page 31

72 a04 pressure switch alarm this alarm occurs when either the high or low pressure switch trips. The high pressure switch may trip due to poor cleaning of the condenser or loosened con- denser fan belts. The low pressure switch may trip due to refrigerant leaks. By tripping it causes the machine to...

Page 32

73 a11 oil level alarm (optional) it is a warning alarm which has no consequences on the operation of the machine. A12 air filter alarm this alarm occurs if the air filter cartridge is clogged. Replace the cartridge. It is a warning alarm which has no consequences on the operation of the machine. A1...

Page 33: 5. Goods Loading Procedure

74 5.1 storage and stacking one of the main concerns to take into account when storing goods, is how to ensure proper air circulation in the isothermal cold room. If the air cannot circu- late freely throughout the cargo, ice or warm areas will almost certainly develop, which could irreparably damag...

Page 34

75 5.3 tips on temperature of carried goods product - reference temperature bananas - 15°c (55/60°f) fresh fruit and vegetables - 4/6°c (39/43°f) fresh meati and seafood - 2°c (36°f) milk and dairy products - 2/6°c (36/43°f) ice-cream -20/-25°c (-15/-20°f) deep frozen fruit and vegetables -18°c (0°f...

Page 35: 6. Using The Unit Safely

76 the dfz zanotti units are built to keep the operators safe. The use of protec- tion gloves is, in any case, fundamentally important during controls, repairs, and maintenance for every action which the operator must carry out inside the unit, whether when handling the evaporator or the condenser w...

Page 36: 7. Routine Maintenance

77 maintenance intervals 50 hours 1000 hours action or 15 days or 10 months check the concentration of coolant • check the trapezoidal belts for tension and wear • check and adjust the engine rpm • check that all screws and nuts are well tightened • check that the injectorsare working properly • cle...

Page 37

78 important • carry out the following maintenance operations after one year: - renovating refrigerant, - checking and adjusting valve clearances, - checking that the cylinder heads are well tightened, - checking that the injectors are in good working condition. Belts properly tensioned belts allow ...

Page 38: 8. Troubleshooting Guide

79 should you find any other faults, check the alarm pages on the keyboard locat- ed on the vehicle's dashboard. In case of further problems, contact the nearest zanotti dealer. 8. Troubleshooting guide trouble on turning on, the engine does not start the unit won't start the unit jams the unit does...

Page 39

80 authorization for vehicles used to carry perishable foodstuffs. Prior to the begin- ning of its operation, the refrigerated vehicle must be authorized by the departmental veterinary service. Characteristics of vehicles used to carry perishable food- stuffs refrigerated vehicle. A refrigerated veh...

Page 40

81 gb gb symbols, items and identification plates to be affixed on refrigerated vehicles. Refrigeration plate: this wording must be followed by the identification items according to the following list: • class a standard refrigerated vehicle fna • class a reinforced refrigerated vehicle fra • class ...

Page 41

82 alt alternator ba room sensor bh radiator sensor e1 glow plugs es heaters on condensate drain pipes fm1 automatic switch f1e electronic control unit f8-9-10 evaporators fans fuses f1 fuse for auxiliary evaporator fan f3 cooling-cycle solenoid fuse for auxiliary evaporator f4 heating-cycle solenoi...

Page 42

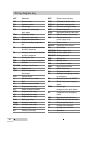

Data ore funzionamento n. Documento 50 ore o 15 giorni dalla messa in servizio 50 hours or 15 days from start-up date - 50 heures ou 15 jours à partir de la mise en service stunden oder 15 tage ab inbetriebsetzung - 50 horas o 15 días a partir de la puesta en marcha date - date - datum - fecha hours...

Page 43

Data ore funzionamento n. Documento 1000 ore o 10 mesi dall’ultimo tagliando 1000 hours or 10 months from the last service - 1000 heures ou 10 mois à partir du dernier coupon de révision 1000 stunden oder 10 monate ab der letzten wartung - 1000 horas o 10 meses a partir de la última revisión date - ...

Page 44

Zanotti s.P.A. - 46020 pegognaga (mantova) - italy via martin l. King, n o 30 - tel. (0376) 5551- telefax (0376) 536554 e-mail: info@zanotti.Com - internet: http://www.Zanotti.Com 0man129a del 10/2002.